Foaming material for split solar thermal insulation board and preparation method thereof

A technology of solar energy and heat insulation panels, applied in the field of polyurethane foam plastics, can solve the problems of high product cost, high thermal conductivity, poor heat preservation, etc., achieve the effects of less bubbles, good fluidity, and reduced material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

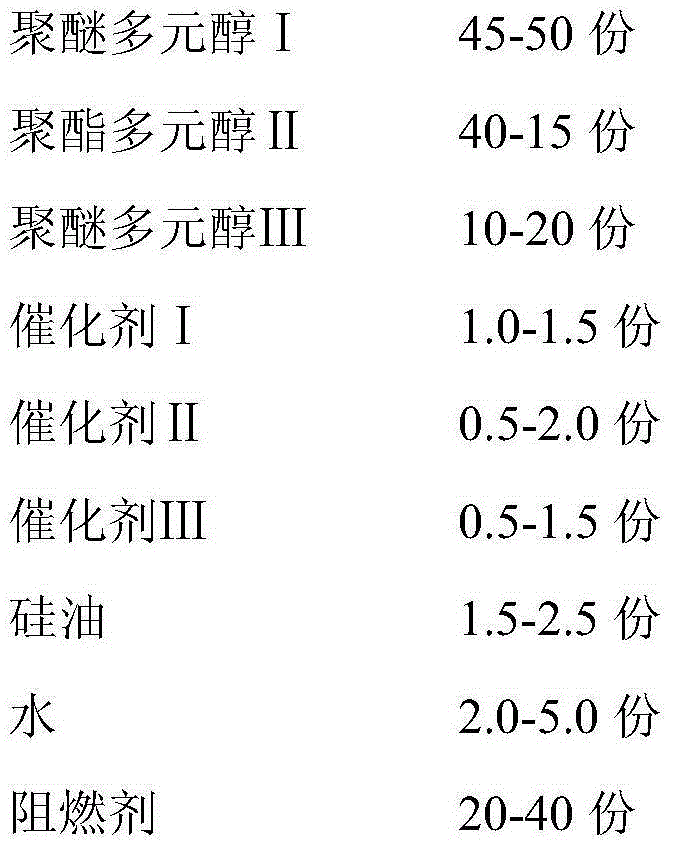

Method used

Image

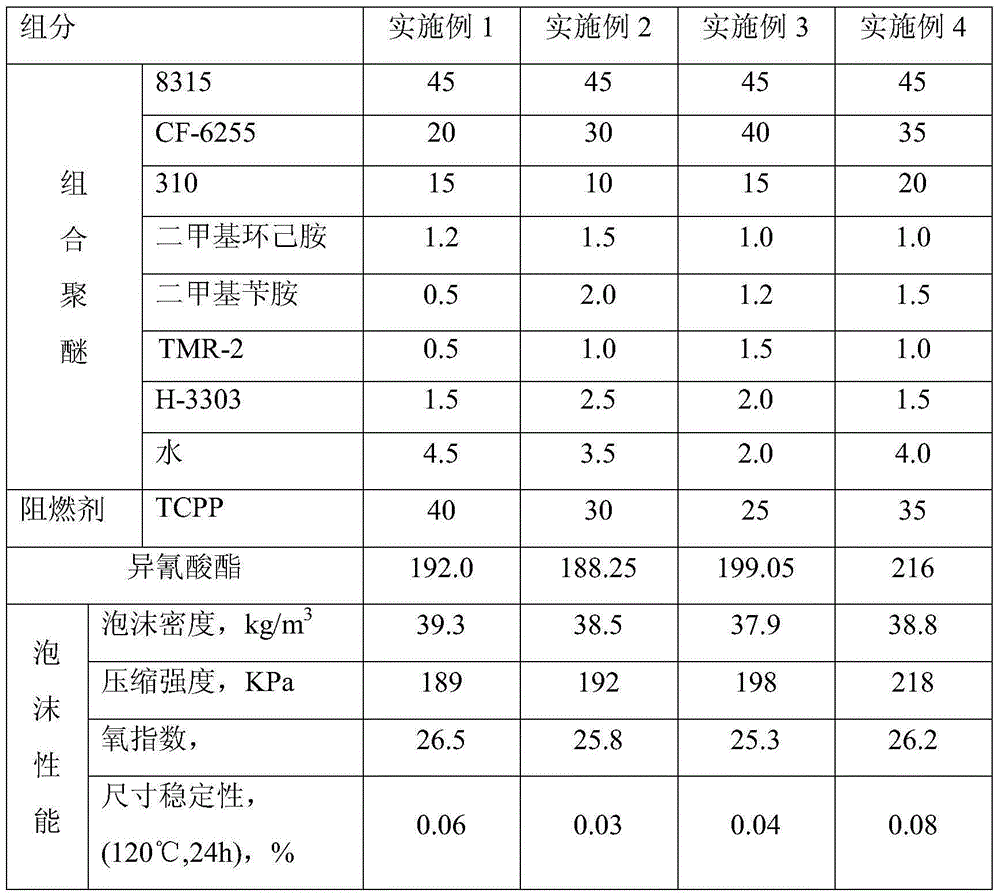

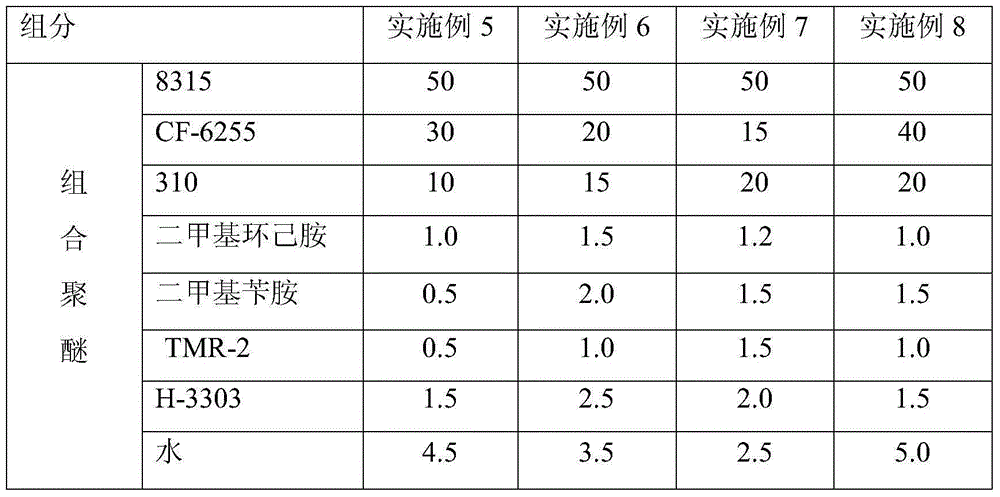

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with embodiment.

[0022] Polyether polyol Ⅰ is produced by Hebei Yadong Chemical Group Co., Ltd., the brand is 8315; polyester polyol Ⅱ is produced by Jiangsu Fusheng New Material Co., Ltd., the brand is CF-6255; polyether polyol Ⅲ is produced by Jurong Ningwu Chemical Production, the brand is 310; Catalyst Ⅲ is produced by American Air Chemical Products Co., Ltd., the brand is TMR-2; the silicone oil is H-3303, the manufacturer is Zhongshan Dongjun Chemical Co., Ltd.; the flame retardant is TCPP, the manufacturer is Jiangsu Fa Lectra Chemical Co., Ltd.

[0023] The examples are all prepared according to the following method: uniformly mix polyether polyol I, polyester polyol II, polyether polyol III, catalyst I, catalyst II, catalyst III, silicone oil and flame retardant. The prepared foaming material (component A) and isocyanate (component B) are mixed uniformly and reacted at a weight ratio of 1:1.5 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com