Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1102 results about "Zno nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanoparticle zinc oxide, ZnO, is a form of zinc oxide where the compound is formed into individual particles as small as 20 nanometers in diameter. The transparent particles, which effectively filter out ultraviolet-a (UVA) and ultraviolet-b (UVB) light, are then coated with inert silicon or aluminum oxide...

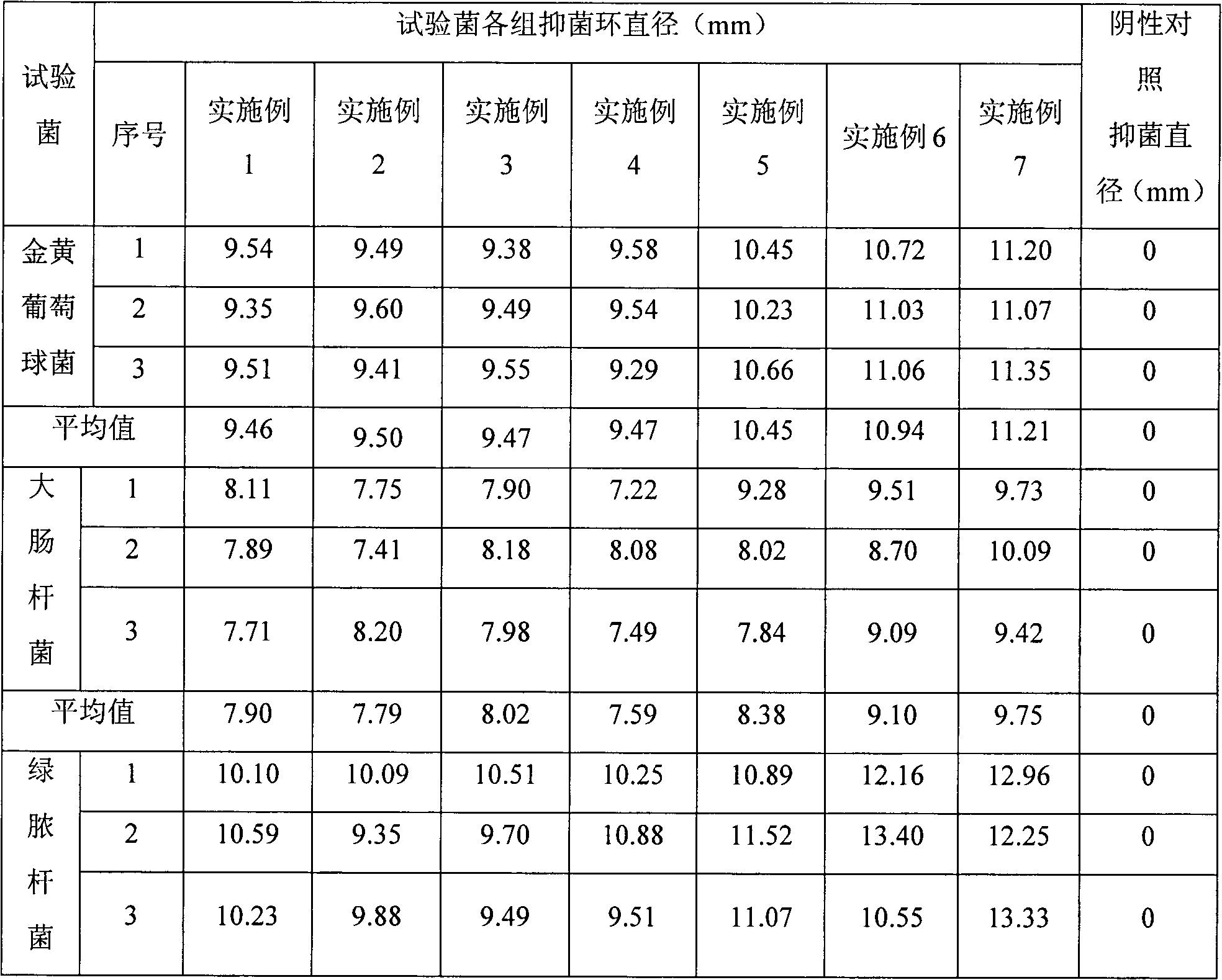

Nanometer doped zinc oxide and its prepn and application in photocatalysis to degrade organic matter and kill bacteria

InactiveCN1772375AImprove photocatalytic activityImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFiberRare earth

The present invention relates to Ag and RE doped nanometer zinc oxide and its preparation process and application in photocatalysis to degrade organic matter and killing bacteria. Ag, RE metals La, Ce, Pr, Nd, Sm, etc. are doped into nanometer zinc oxide to raise its photocatalytic activity in degrading harmful chemical matter and resisting bacteria. Under lighting, the doped nanometer zinc oxide has higher photocatalytic activity and higher antibacterial capacity; and in case of no lighting, it has relatively high antibacterial effect owing to the antibacterial effect one Ag, Zn, RE and other antibacterial ions. The preparation process may be an organic matter complexing process or a sprying pyrolysis process. The doped nanometer zinc oxide may be used through mixing with other material, or used as additive added into plastic, ceramic, fiber, timber, rubber, glass, cement, metal and other material to form various kinds of photocatalytic antibacterial material and product.

Owner:NANJING UNIV

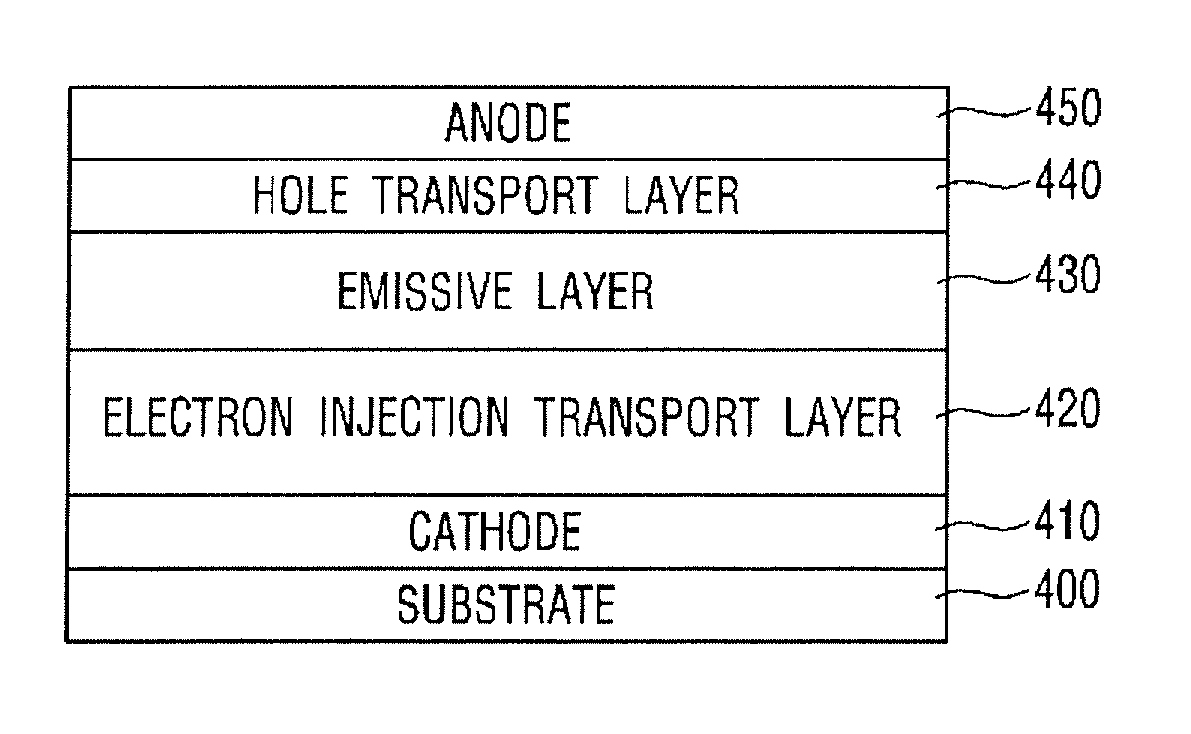

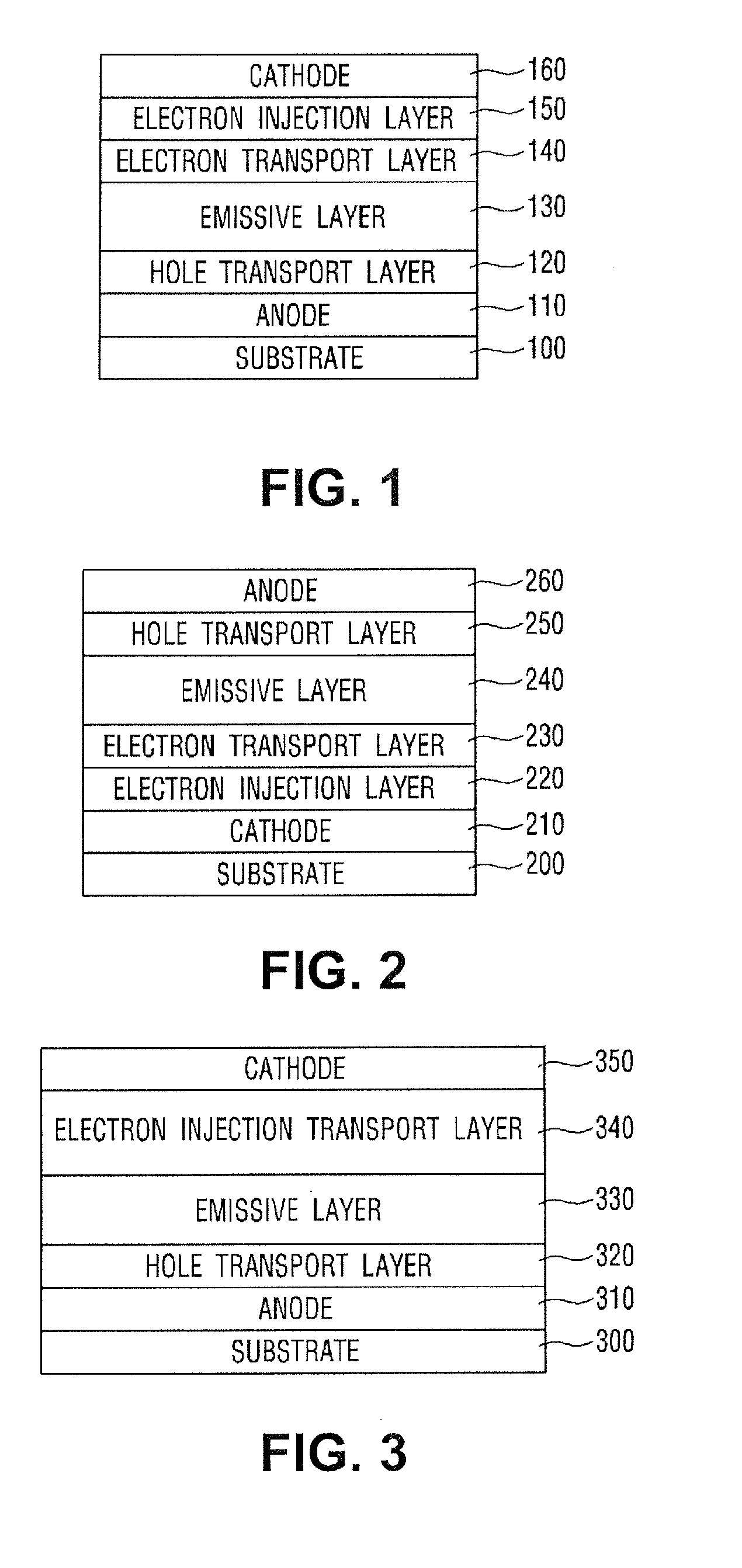

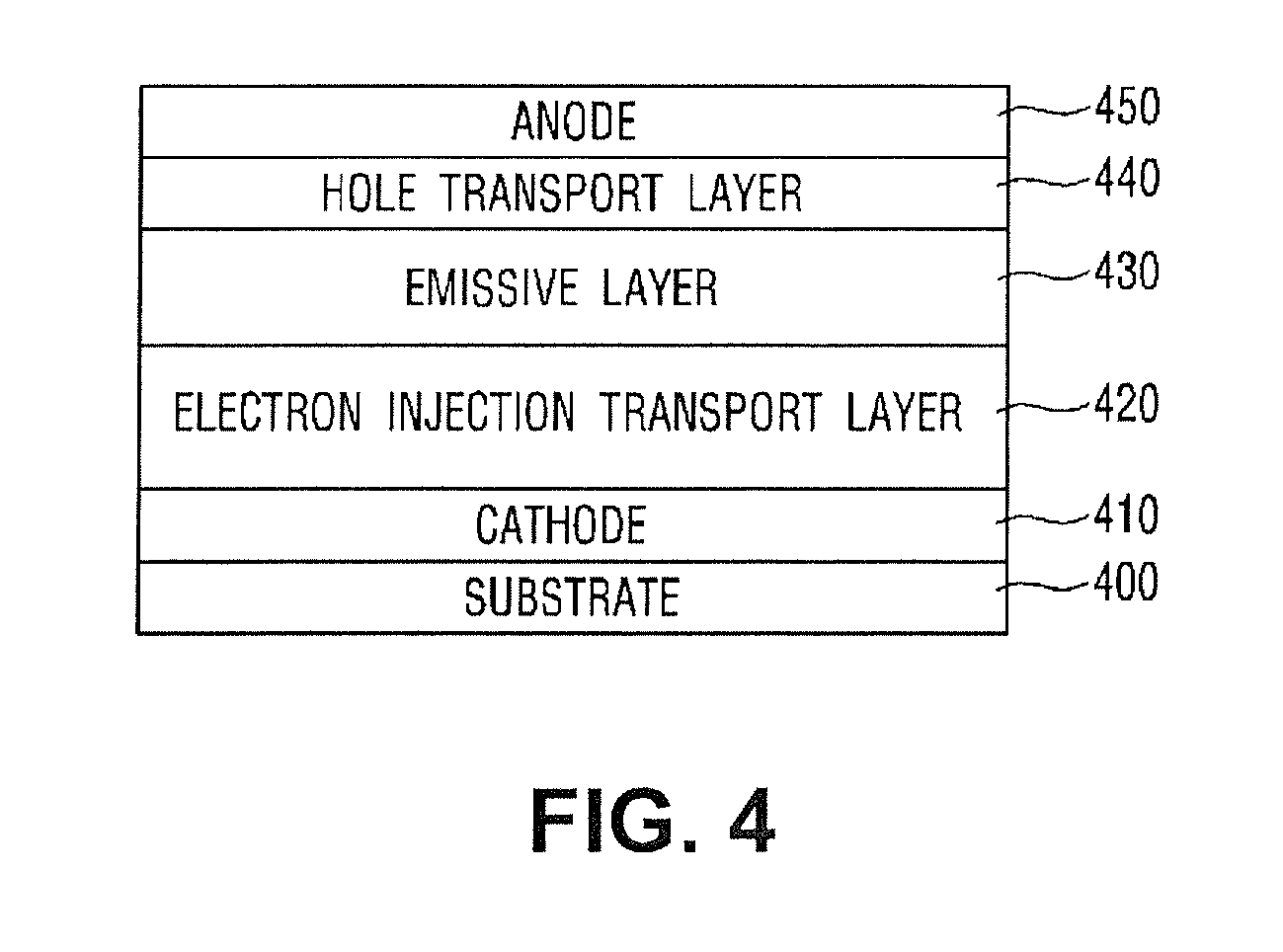

Organic light-emitting diodes

ActiveUS20110284825A1Improve luminous efficiencyReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingPlastic materialsZno nanoparticles

Owner:KOREA ADVANCED INST OF SCI & TECH

Nano-zinc oxide coated sericite powder composite material and preparation method thereof

InactiveCN104017393AImproves UV resistanceImprove antibacterial propertiesCosmetic preparationsInorganic pigment treatmentCalcium hydroxideOrganic solvent

The invention discloses a sericite / nano-zinc oxide composite material and a preparation method thereof. The composite material is characterized in that the surface of sericite powder is coated with nano-zinc oxide. The preparation method comprises the following step: adding calcium hydroxide or calcium oxide into a mixed system of the sericite powder and zinc sulfate solution so as to directly obtain the nano-zinc oxide coated sericite powder composite material. According to the method, the sericite which is taken as a base material is a natural mineral, so that the raw material is easily available, free of pollution and low in cost; the preparation process is simple, safe, reliable and easy to control; the obtained composite material is stable in quality, and has the good dispersibility in an organic solvent and also has the excellent ultraviolet resistance and the excellent antibacterial and deodorant performance. Thus, the composite material can be applied to the field of coatings, cosmetics and the like. The method has a good potential application value in the field of synthesis of the composite material or other related sciences.

Owner:ANHUI HENGHAO SCI & TECH

Cosmetic formulations comprising ZnO nanoparticles

The present invention relates to the formation of surface treated zinc oxide and titania particles, and in particular zinc oxide and titania nanoparticles, with a siloxane star-graft copolymer coating, comprising a looped and / or linear polymeric structure on a star-graft copolymer coating, on a particle surface to control the interfacial surface interactions between the particle and the oil phase of the cosmetic skin formulation.

Owner:BASF AG

Preparation method of nanometer zinc oxide

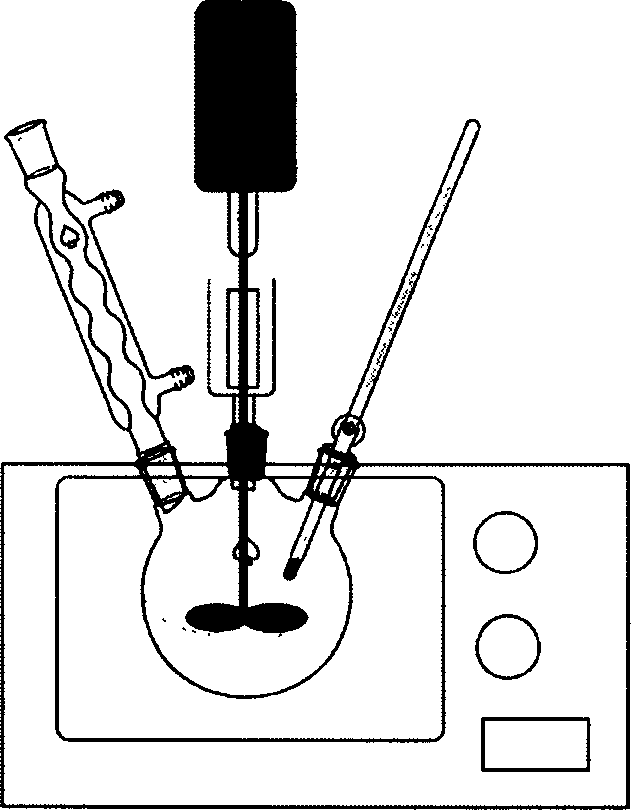

A process for preparing nano-zinc oxide includes such steps as dissolving soluble Zn salt and urea in water, microwave radiating while reacting by homogenizing-depositing method to obtain the deposit of alkaline zinc carbonate, vacuum drying, ball grinding, calcining to obtain the crystal grains of nano-zinc oxide, mixing with surface modifier, organic solvent and disperser, ball grinding, and microwave radiating which surface modifying.

Owner:SUZHOU UNIV

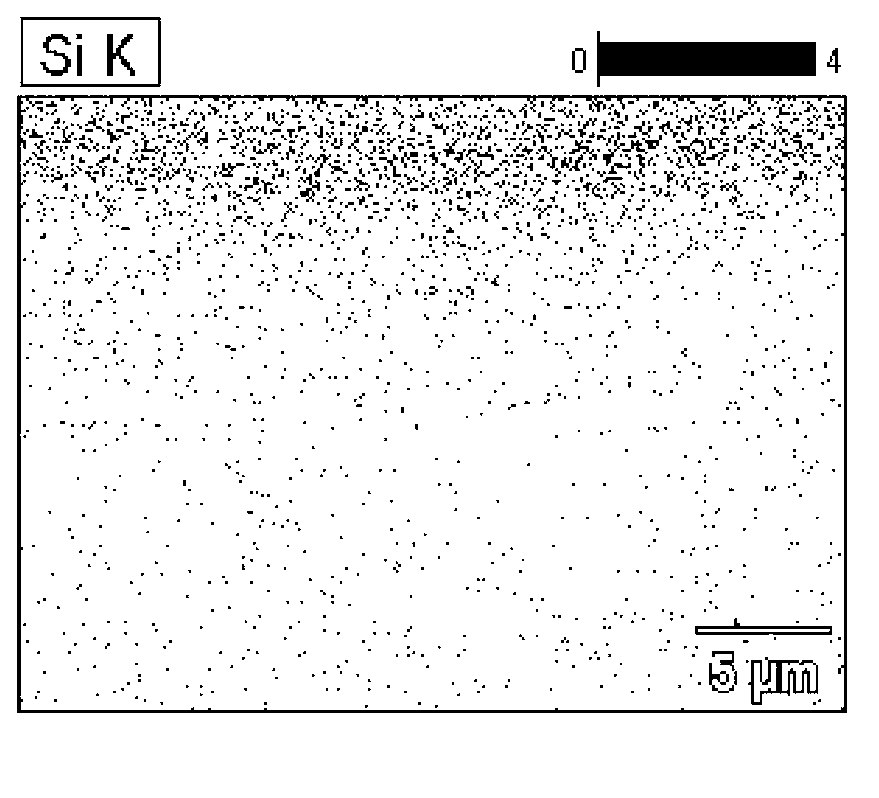

Surface modified nano zinc oxide water dispersion and its preparing method and use

InactiveCN1511889AAvoid reunionEasy to operateInorganic pigment treatmentFibre treatmentZno nanoparticlesWater soluble

The present invention belongs to the field of inorganic material, and is especially surface modified nano zinc oxide water dispersion and its preparation process and use. The water dispersion consists of: nano zinc oxide 0.1-10 wt%; hydrated SiO2 0.06-10 wt%, hydrated Al2O3 0.12-20 wt% or hydrated Fe2O3 0.05-10 wt%; silane coupling agent 0.1-10 wt%; and water soluble polymer 0.2-9 wt% other than water. The water dispersion is prepared through depositing hydrated SiO2, hydrated Al2O3 or hydrated Fe2O3 onto the surface of zinc oxide, and subsequent homogeneous mixing with silane coupling agent, water soluble polymer and water. The zinc oxide inside the water dispersion is dispersed homogeneously and stably without aggregation, and the water dispersion of the present invention may be used in preparing uvioresistant fabric.

Owner:BEIJING INST OF CLOTHING TECH

Cosmetic formulations comprising ZnO nanoparticles

The present invention relates to the formation of surface treated zinc oxide and titania particles, and in particular zinc oxide and titania nanoparticles, with a siloxane star-graft copolymer coating, comprising a looped and / or linear polymeric structure on a star-graft copolymer coating, on a particle surface to control the interfacial surface interactions between the particle and the oil phase of the cosmetic skin formulation.

Owner:BASF AG

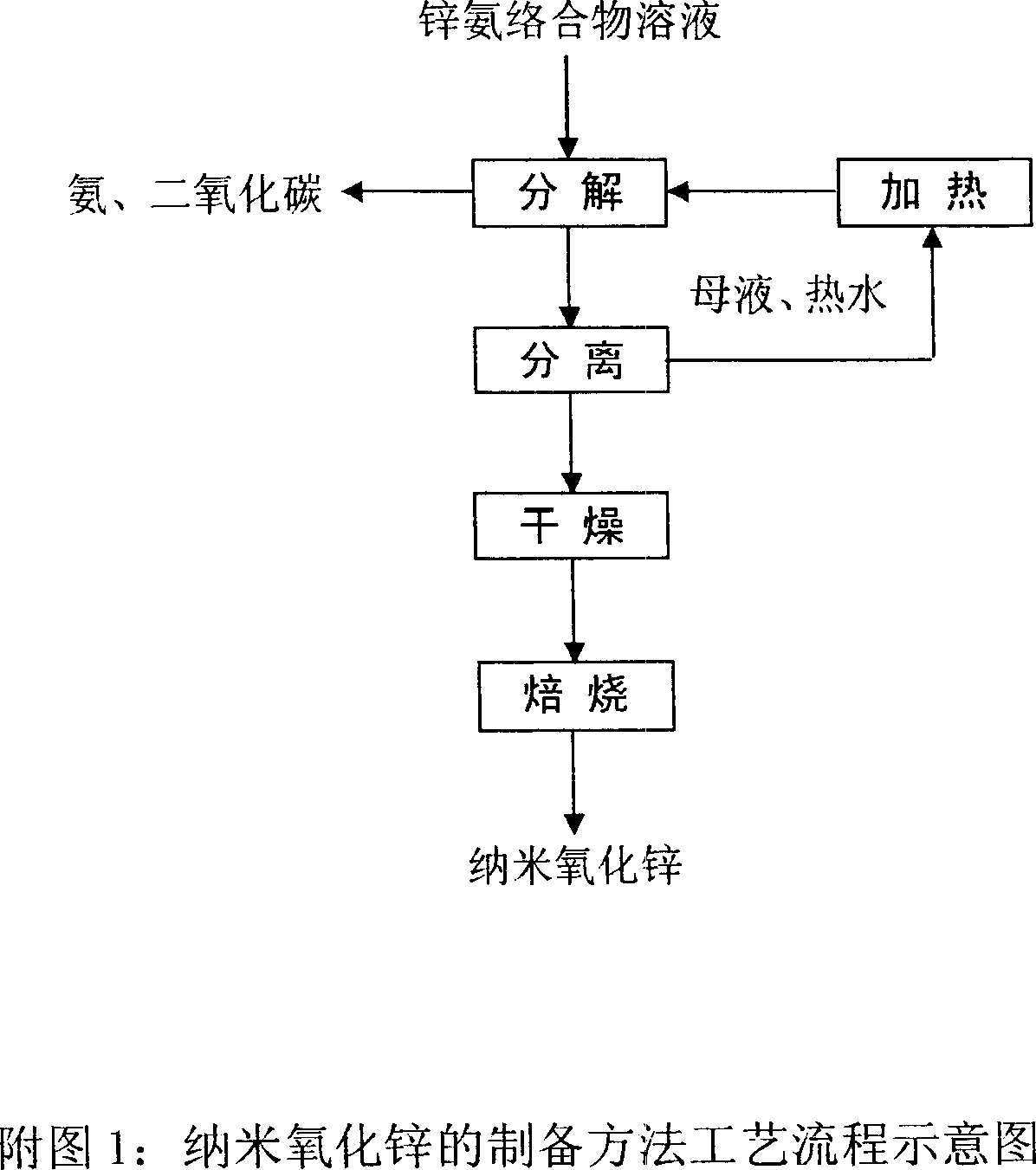

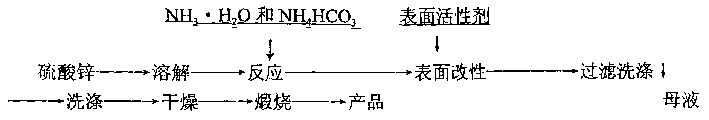

Preparing process of nano zinc oxide

InactiveCN1986421AUniform particle sizeUniform sizeNanostructure manufactureZinc oxides/hydroxidesDecompositionManganese

The process of preparing nanometer zinc oxide with low grade zinc oxide containing material includes the following steps: leaching the material with the mixed solution of ammonium bicarbonate and ammonia, separating to eliminate insoluble impurity, redox to eliminate Fe, Mn, Pb and other metal impurity to obtain zinc-ammonia complex solution; heating the zinc-ammonia complex solution to 90-100 deg.c through continuous mixing with hot circular mother liquid or hot water for fast continuous decomposition of zinc-ammonia complex; controlling the flow rate ratio between the circular mother liquid and the zinc-ammonia complex solution in 2-20, separating the basic zinc carbonate crystal continuously from the decomposed solution; drying and roasting at 400-600 deg.c for 1-4 hr to obtain the nanometer zinc oxide product of homogeneous size 10-50 nm.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method of anti-bacterial hydrogel dressing

InactiveCN101664563AGood biocompatibilityStrong hydration abilityAbsorbent padsBandagesPolyethylene glycolZno nanoparticles

The invention discloses a preparation method of anti-bacterial hydrogel dressing. The method comprises the following steps: 1) dissolving dihydroxy-terminated polyethylene glycol in tetrahydrofuran, adding acryloyl chloride to react at room temperature under the protection of nitrogen, treating the obtained reaction product through filtrating, evaporating, washing and concentrating to obtain polyethyleneglycol diacrylate crosslinking agent; 2) using ZnO nanoparticles containing Ag<+> to prepare 15-30wt% of nanometer water solution, then dissolving natural high molecular material in the nanometer water solution to obtain natural high molecular water solution containing nano-Ag; 3) mixing acrylamide, polyethyleneglycol and natural high molecular water solution containing nano-Ag, placing themixture at room temperature under the irradiation of <60>Co source for crosslinking and obtaining the anti-bacterial hydrogel dressing, the molar ratio of Ag to Zn is 1:4. The anti-bacterial hydrogeldressing prepared by the method is a kind of porous reticular dressing with antibacterial property and hydrating capacity.

Owner:绍兴锐创生物科技有限公司

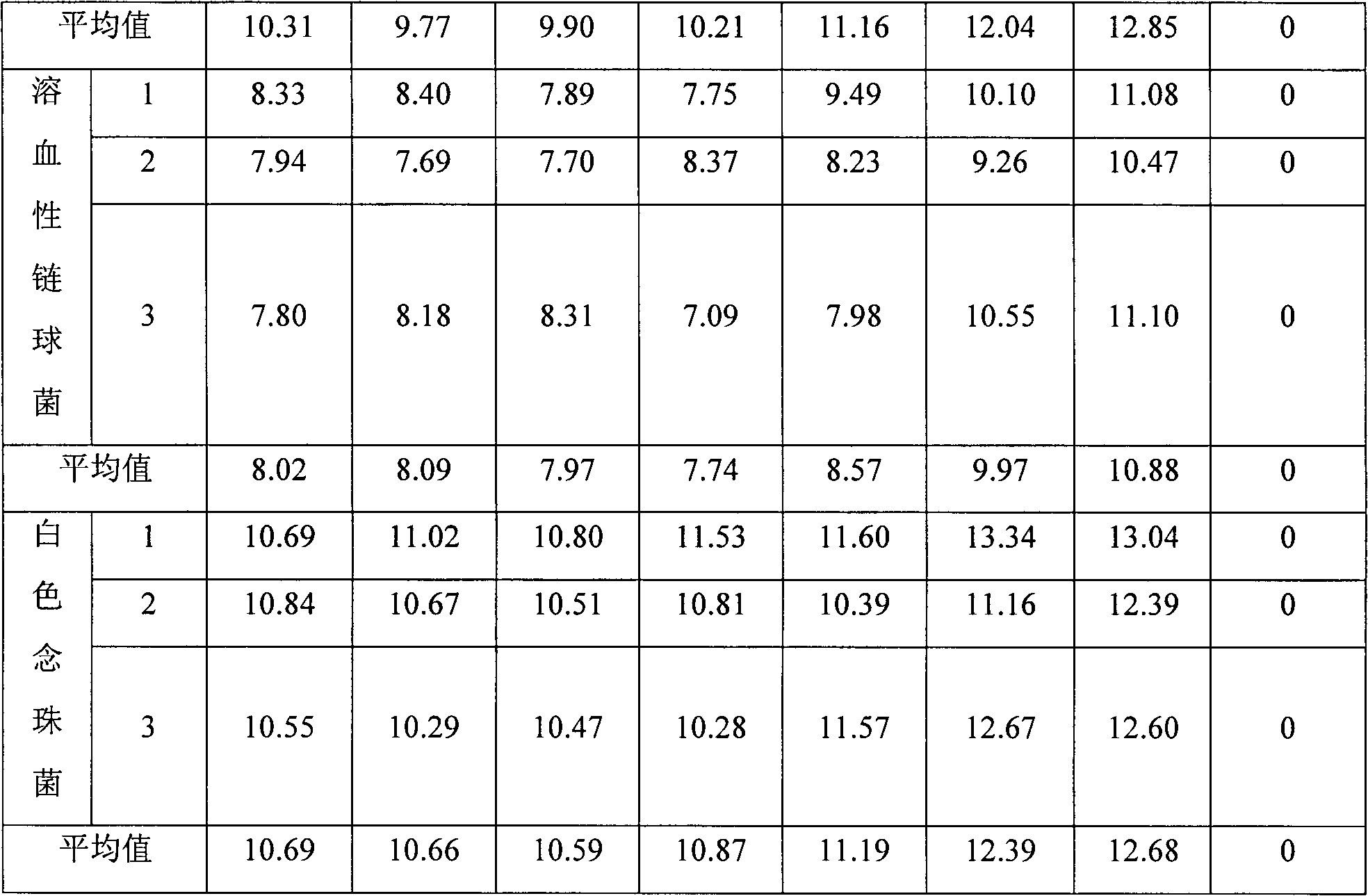

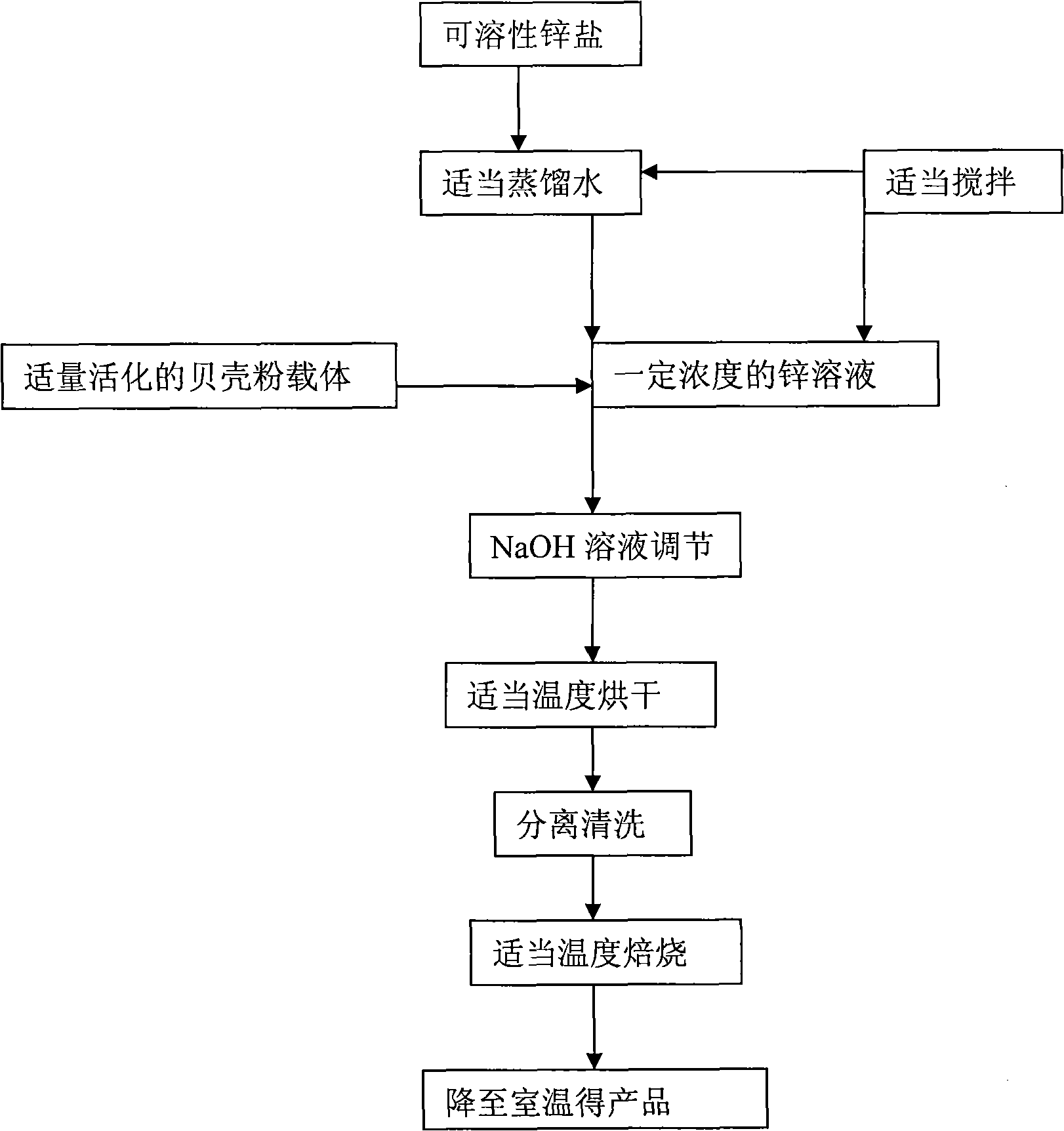

Method for preparing nano zinc oxide using shell powder as carrier

InactiveCN101352676ASolve associativitySolve for uniformityCatalyst carriersCatalyst activation/preparationFiberZno nanoparticles

The invention discloses a preparation method of nanometer zinc oxide which takes shell powder as a carrier, and in particular relates to a reproducible porous nanometer zinc oxide powder which takes the shell powder as the carrier and the preparation method thereof. In the preparation method, zinc oxide is loaded by impregnation on the shell powder carrier; firstly, zinc salt solution with appropriate concentration is prepared, and then an activated shell powder carrier is impregnated in the zinc salt solution by certain proportion, and then the obtained solution is stirred and stayed for a certain time, and treated by low temperature and abstersion pretreatment and finally roasted at high temperature, so the nanometer zinc oxide forms high-strength bond with the shell powder and promotes the catalytic activity of the nanometer zinc oxide at the same time. Impregnation can be conducted for a plurality of times to increase load. The nanometer ZnO is characterized by small particle size, good compatibility with materials, high catalytic efficiency, good stability, good regenerability, and the like, and can be applied to the fields of plastics, rubbers, fibers, coatings, home appliances, paints, ceramics, water and environment treatment, pharmaceutical and hygienic articles, etc. In terms of sources of raw materials and production technology, the preparation method not only reduces the production cost of nanometer ZnO catalyst but also is helpful for disposal of the increasingly serious environmental problems, thus bearing great environmental protection significance.

Owner:GUANGDONG OCEAN UNIVERSITY

Porous carbon adsorbing agent containing nano zinc oxide micropartical and its preparation process and application

InactiveCN1724138AImprove adsorption capacityAvoid breedingOther chemical processesSorbentPorous carbon

A porous charcoal adsorbent for cleaning environment is composed of porous charcoal as carrier and zinc oxide nano-particles as active component. Its preparing process includes such steps as reaction between zinc nitrate micro-emulsion and sodium hydroxide to obtain zinc oxide nano-particles, carrying them by porous charcoal and heat treating. Its advantages are high absorptive power and high photo-catalytic and antibacterial activities.

Owner:SUN YAT SEN UNIV

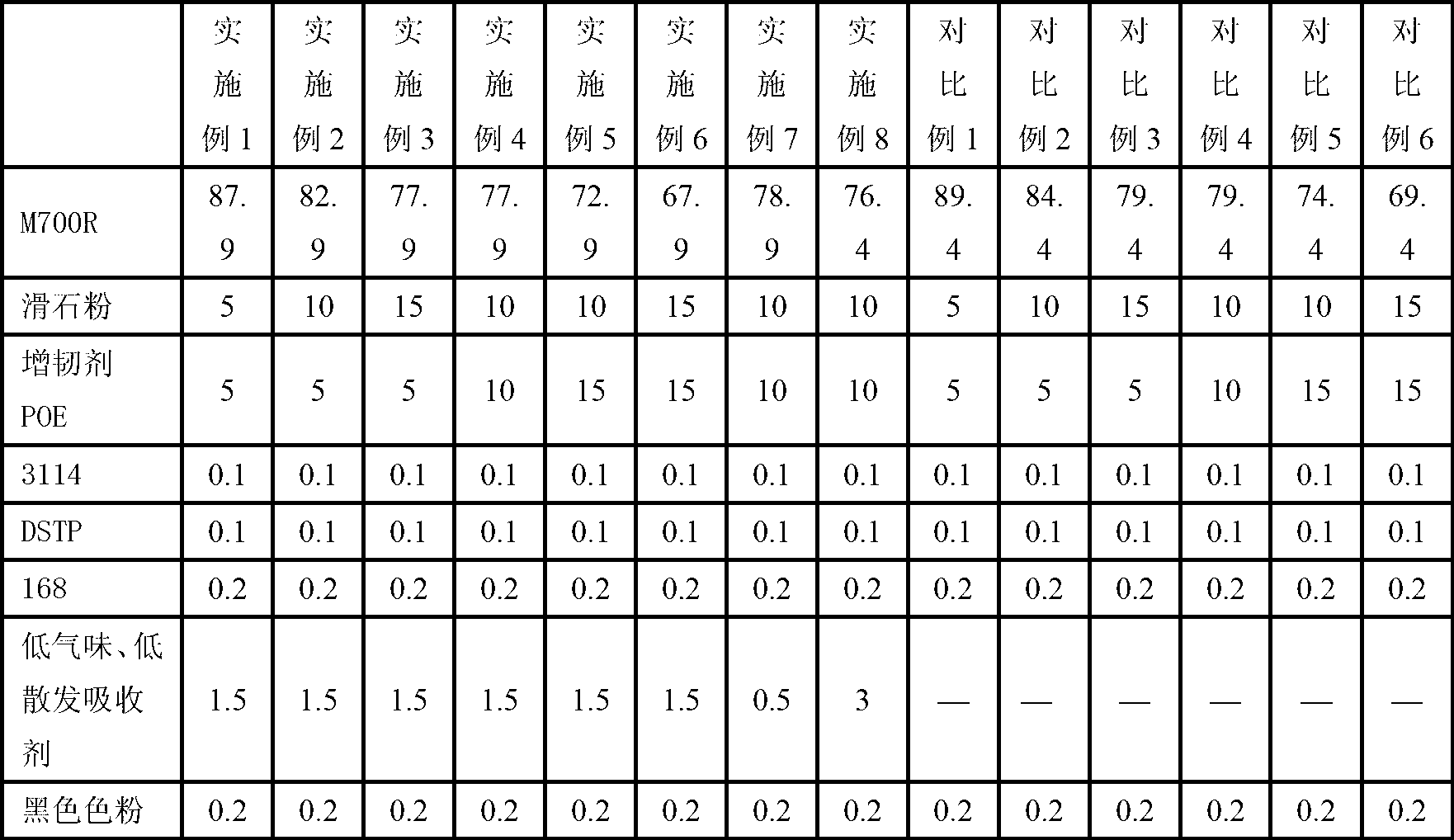

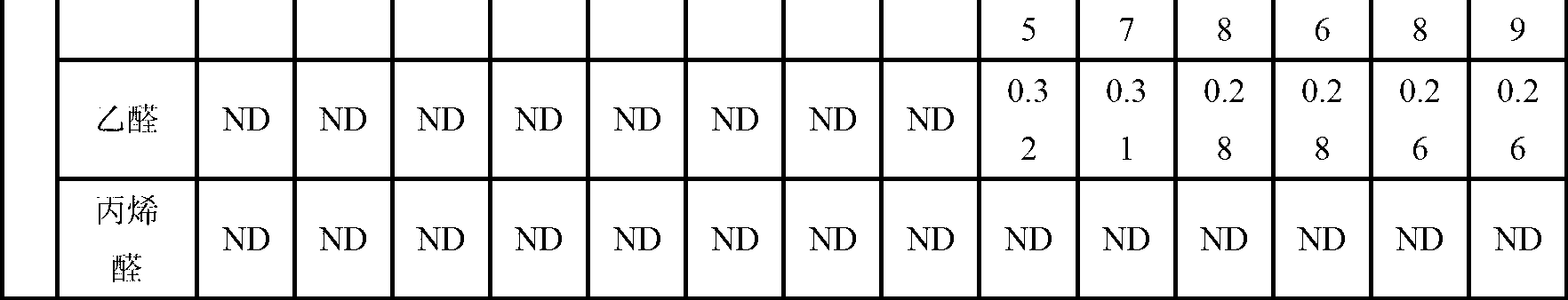

Low-odor low-volatilization modified polypropylene material and preparation method thereof

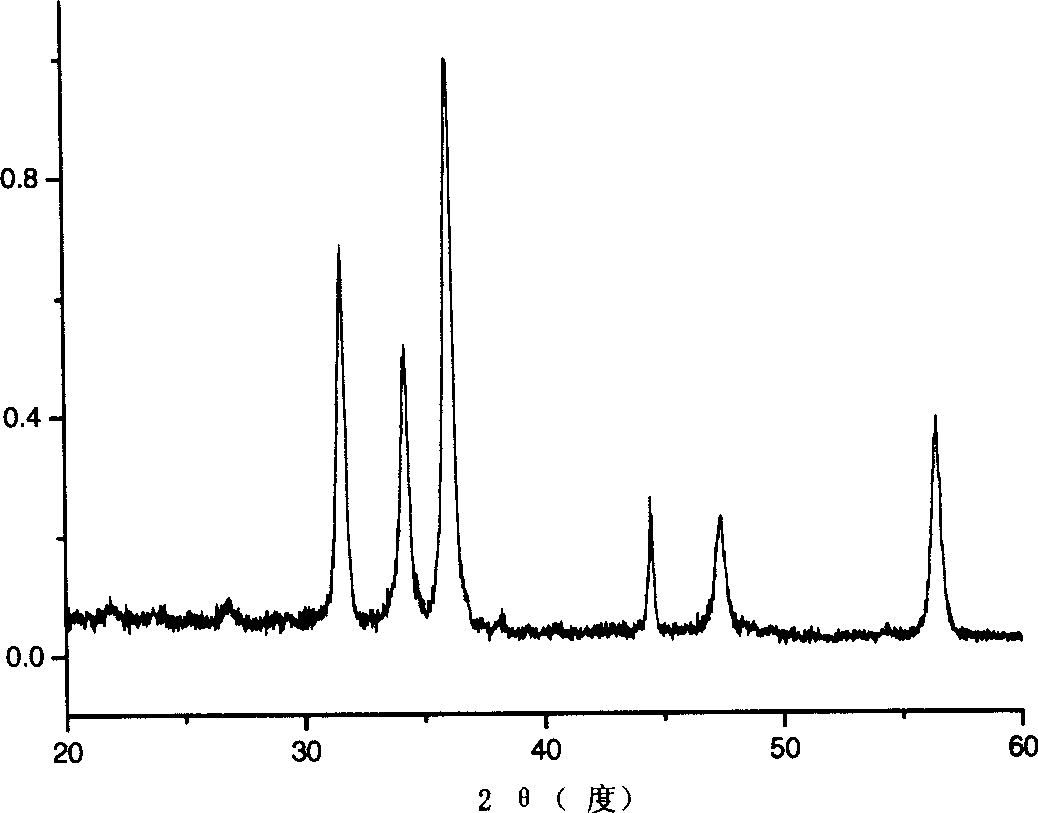

The invention discloses low-odor low-volatilization modified polypropylene material and a preparation method thereof. The low-odor low-volatilization modified polypropylene material is composed of the following raw materials by weight, polypropylene 65-89%, low-odor low-volatilization absorbent 0.5-3%, inorganic filler 5-15%, polyolefin elastomer (POE) flexibilizer 5-15% and antioxygen 0.1-2%. The low-odor low-volatilization modified polypropylene material has the advantages that nano-zinc oxide which is prepared by a microemulsion method is used for preparing nano-zinc oxide modified active carbon materials and loaded on the surface of multihole active carbon, residual monomers, decomposers and organic acid in base materials of polypropylene are effectively absorbed, obvious effect of absorbing odor is achieved, preparing process is simple, and production cost in low.

Owner:SHANGHAI PRET COMPOSITES

Preparation method of nanometer zinc oxide-bamboo charcoal composite particle with antibacterial and adsorption functions

ActiveCN103535376ANo pollution in the processSimple preparation processMaterial nanotechnologyBiocideFreeze-dryingZno nanoparticles

The invention relates to a preparation method of nanometer zinc oxide-bamboo charcoal composite particle with antibacterial and adsorption functions. The preparation method comprises the following steps: (1) adding a bamboo raw material into a mixed acid solution, reacting at 50-90 DEG C for 1-20 hours, adding alkali liquor to neutralize the solution after the reaction to obtain a carboxylated bamboo cellulose nanocrystals; (2) adding the carboxylated bamboo cellulose nanocrystals into a solution of 0.005-5 mol / L zinc ions, adding alkali liquor to neutralize, diluting the reaction product through deionized water, centrifuging and freeze drying or vacuum drying the reaction product, and then, vacuum calcining the reaction product at 200-600 DEG C for 1-8 hours to obtain the nanometer zinc oxide-bamboo charcoal composite particle. The process disclosed by the invention is simple, convenient, easy to operate and free of environmental pollution, and the preparation period of the composite particle is shortened; the prepared nanometer zinc oxide-bamboo charcoal composite particle is small in size, easy to regulate and control and large in specific surface area, the bamboo charcoal is very firmly combined with the nanometer zinc oxide, so that the antibacterial effect is durable, and the nanometer zinc oxide-bamboo charcoal composite particle has good adsorption capacity on toxic substance, thereby having a wide application prospect.

Owner:ZHEJIANG SCI-TECH UNIV +1

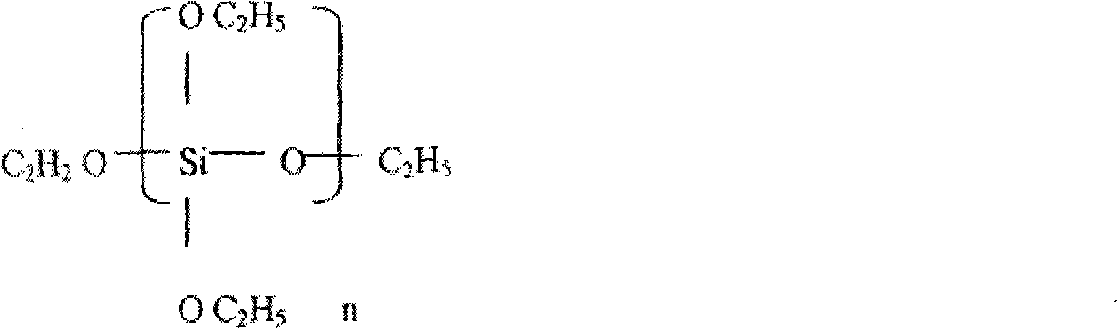

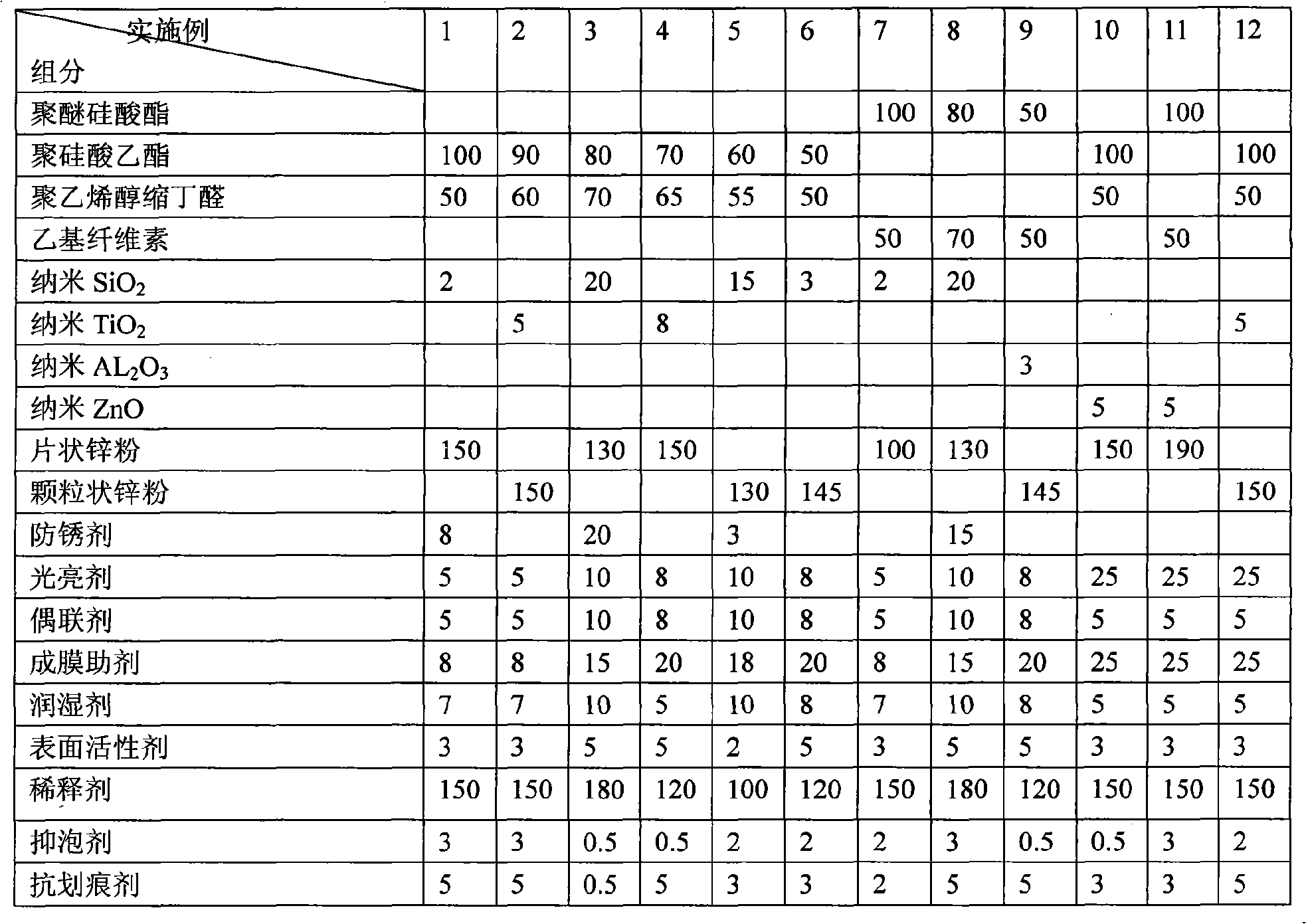

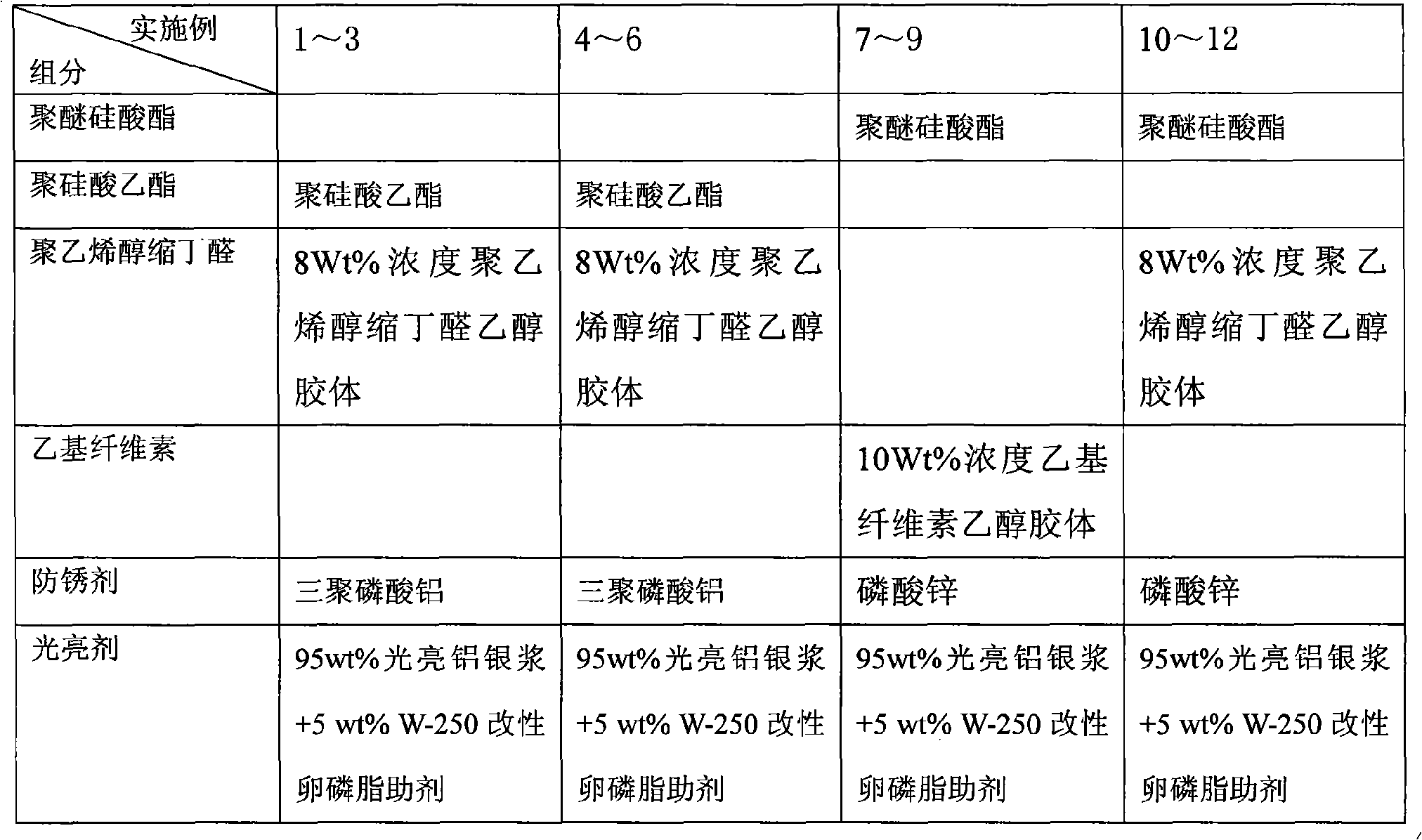

Zinc metallic coating

The invention discloses a zinc metal coating layer, the zinc metal coating is characterized in that when being calculated according to the parts by weight, the components of the the zinc metal coating are as follows: 50 parts to 100 parts of polyether silicate ester or polymerized silica acid ester, 50 parts to 100 parts of polyvinyl butyral or ethyl cellulose, 1 part to 20parts of one or a plurality of component (s) among nanometer silicon dioxide, nanometer titanium dioxide, nanometer molybdenum dioxide, or nanometer zinc oxide, 80 parts to 200 parts of zinc powder, 0 to 20 parts of rust preventing agent,, 5 parts to 100 parts of coupling agent, 5 parts to 25 parts of brightening agent, 8 parts to 250 parts of film forming auxiliary agent, 5 parts to 10 parts of wettinh agent, 1 part to 5 parts of surface activating agent, 100 parts to 200 parts of thinning agent, 0.5 part to 3 parts of anti-foaming agent and 0.5 part to 5 parts of anti-scratching agent. The bright metal zinc coating layer related by the invention can be taken as the anti-corrosive oxidation resistant zinc metal coating layer of metal product, particularly the black metal product, which can replace the commonly adopted galvanizing technology. The bright zinc metal coating layer of the invention can very conveniently and effectively paint a zinc metal coating layer the binding of which is firm on the metal product, particularly the black metal product.

Owner:胡仲寅

Anion easy-cleaning functional ceramic additive and preparation method thereof, ceramic prepared by using additive and preparation method thereof

The invention belongs to the technical field of ceramics, and particularly relates to an anion easy-cleaning functional ceramic additive and a preparation method thereof, a ceramic prepared by using the additive and a preparation method thereof. The additive is prepared from the following raw materials in percentage by mass: 10-16% of Chongguang stones with a particle size of 5-20 microns, 16-25% of tourmaline with a particle size of 5-15 microns, 5-15% of copper pectolite with a particle size of 5-20 microns, 8-12% of nano titanium dioxide, 6-8% of nano zinc oxide, 5-10% of lead-free frits, 7-20% of rare earth materials, 8-10% of superfine alumina, 8-15% of superfine quartz powder and 5-10% of sodium carbonate. The preparation method of the additive comprises the following steps of carrying out mixed ball-milling on the lead-free frits, the rare earth materials, the superfine alumina, the superfine quartz powder and the sodium carbonate firstly; and then, adding the Chongguang stones, the tourmaline, the copper pectolite, the nano titanium dioxide and the nano zinc oxide into the obtained product, and ball-milling the obtained mixture, so that the additive with a particle size of 1-10 microns is obtained. The additive disclosed by the invention has a self-polarizing performance, and has strong adsorption and decomposition functions, so that negative ions are produced; and after the additive is added into a ceramic, the ceramic is extremely easy to clean and not stained, and has no hidden dirt, therefore, the ceramic has a strong affinity to water.

Owner:ZIBO BAIKANG ECONOMIC & TRADE

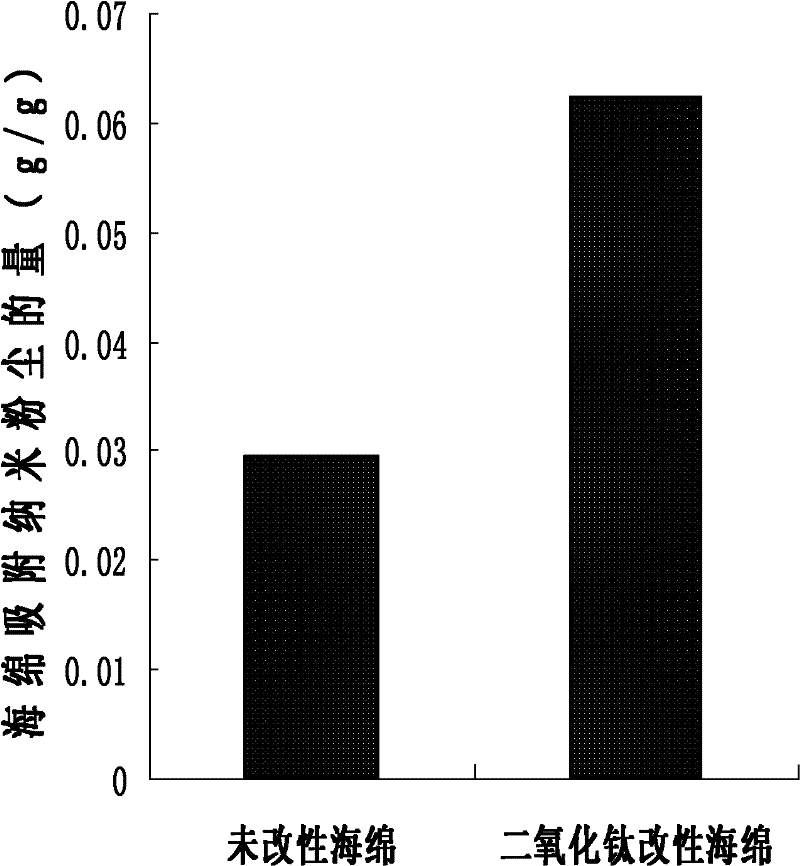

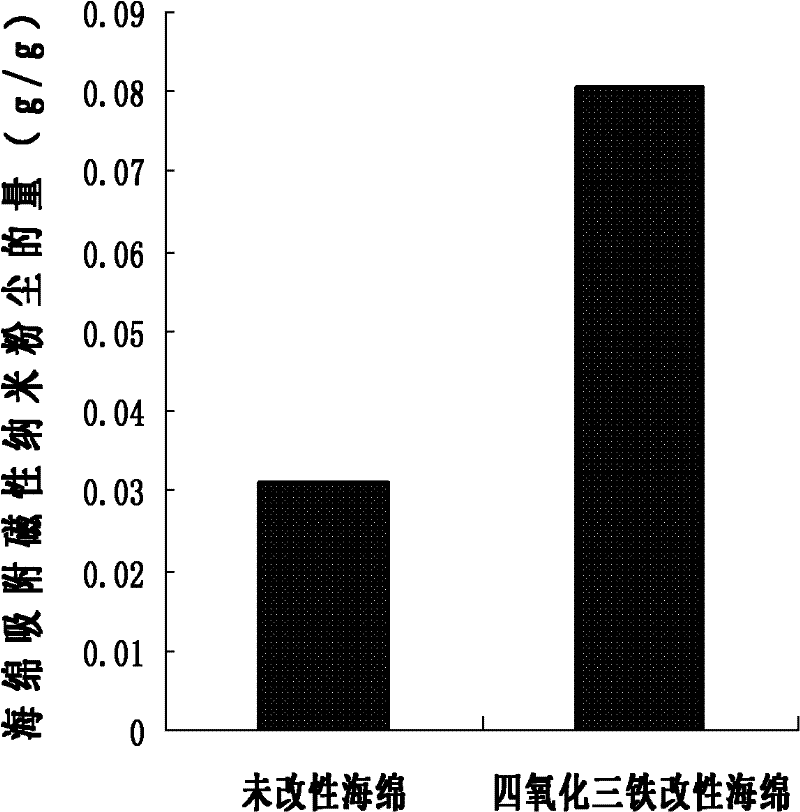

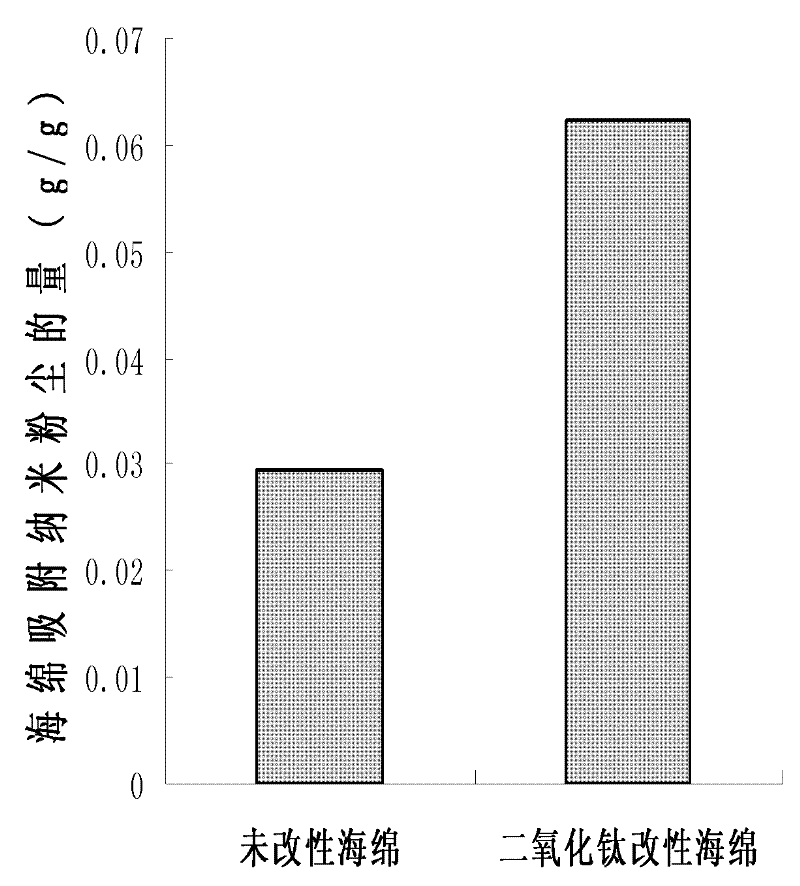

Inorganic nanoparticles-modified polyurethane sponge mask material, and preparation method and application thereof

InactiveCN102190882ARegular 3D network structureRegular three-dimensional network structure, poresProtective garmentFiberCarbon fibers

The invention provides an inorganic nanoparticles-modified polyurethane sponge mask material and a preparation method thereof, and also provides application of the inorganic nanoparticles-modified polyurethane sponge mask material in manufacturing a mask. In the invention, the inorganic nanoparticles used for modifying sponge comprise magnetic Fe3O4 nanoparticles, magnetic Fe2O3 nanoparticles, TiO2 nanoparticles, ZnO nanoparticles, mesoporous SiO2, carbon nanotubes and carbon fibers. The inorganic nanoparticles have the advantages of small particle size, large specific surface area, strong adsorption performance and like and contain charges on the surfaces, and a plurality of the nanoparticles have strong ultraviolet absorption capability, photocatalytic activity, and antibacterial and antiviral actions. The inorganic nanoparticles-modified polyurethane sponge mask material provided by the invention has high efficiency and capability in filtering out sub-micron dust, viruses and bacteria, has the function of adsorbing poisonous and harmful gases, has the characteristics of small gas absorption resistance, simple preparation method, low cost and broad application future, and can be recycled through water washing.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing high dispersity nano zinc oxide

The invention relates to a method to produce highly dispersed nano-zinc oxide. Zinc source and ammonium salt are mixed according to molar ratio 1:0.5-10 between zinc and ammonium; according to the molar ratio 1:0.5-10 between zinc and ammonia in ammonia water, concentration of which is 10-25 percent, ammonia water is added into the mixture, stirred for 1-10 hours, aged for 1-2 days and filtered; filtrate is steamed under 60 DEG C - 95 DEG C until white precipitate comes out and white precipitate is obtained after filtering; the white precipitate is washed by deionized water until pH value is 6-8, dried under 50 DEG C -110 DEG C, roasted for 1-8 hours under 200 DEG C-800 DEG C to get the nano-zinc oxide. The invention has the advantages of simple production process, mild reaction condition and getting nano-zinc oxide with large specific surface area, good dispersion, non-aggregation and comparatively good photo-catalytic activity.

Owner:CHINA RES INST OF DAILY CHEM IND

Process for preparing nano zinc oxide

InactiveCN1396117ASmall specific surface areaLarge specific surface areaZinc oxides/hydroxidesAmmonium salt fertilisersDispersitySulfate

A process for preparing nanometre zinc oxide includes such steps as proportionally dropping ammonia water to a zinc sulfate solution, adding ammonium hydrogen carbonate to obtain ZnCO3.Zn(OH)2 deposit, separation, washing with deionized water, vacuum drying to obtain a composite presoma, and then calcining at 150-600 deg.C for 1.5-2.5 hr to obtain the product. Its advantages are low cost and high dispersity of product in water.

Owner:SHANDONG XIAOYA GRP CO LTD

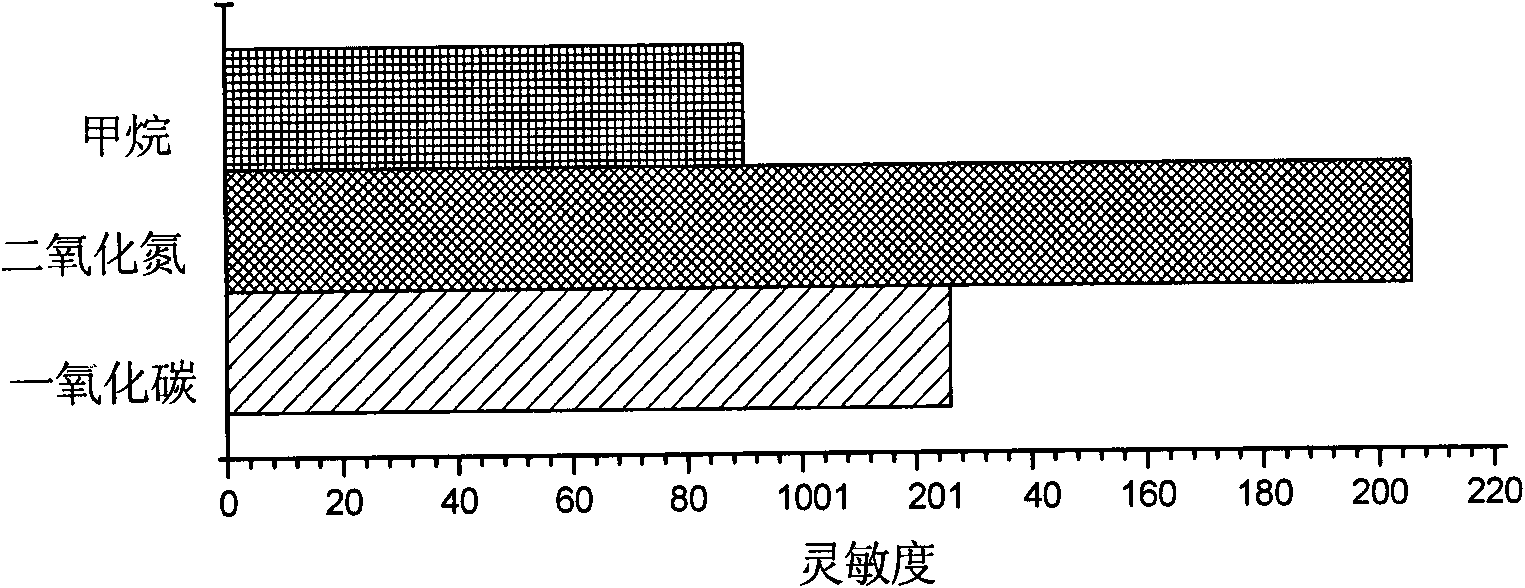

One-dimensional zinc oxide nanometer material and preparation method thereof

InactiveCN101591037AHigh crystallinitySimple stepsNanostructure manufactureZinc oxides/hydroxidesZno nanoparticlesCrystallinity

The invention provides a one-dimensional zinc oxide nanometer material and a preparation method thereof. The method comprises the steps of: performing a hydro-thermal reaction of a zinc salt solution and a sodium hydroxide solution; and successfully obtaining the one-dimensional zinc oxide nanometer material with high crystallinity by adding a surfactant and controlling reaction conditions. The diameter of one-dimensional nanometer zinc oxide is between 100 and 300nm, and the length is between 1 and 6mu m. Compared with the prior method for preparing the one-dimensional nanometer zinc oxide, the method has the advantages of low cost, simple operation, low energy consumption, high crystallinity of products and the like. The nanometer zinc oxide material has excellent gas sensitivity on gas such as methane, carbon monoxide, nitrogen dioxide and the like, and is a good gas-sensitive material.

Owner:BEIJING UNIV OF CHEM TECH

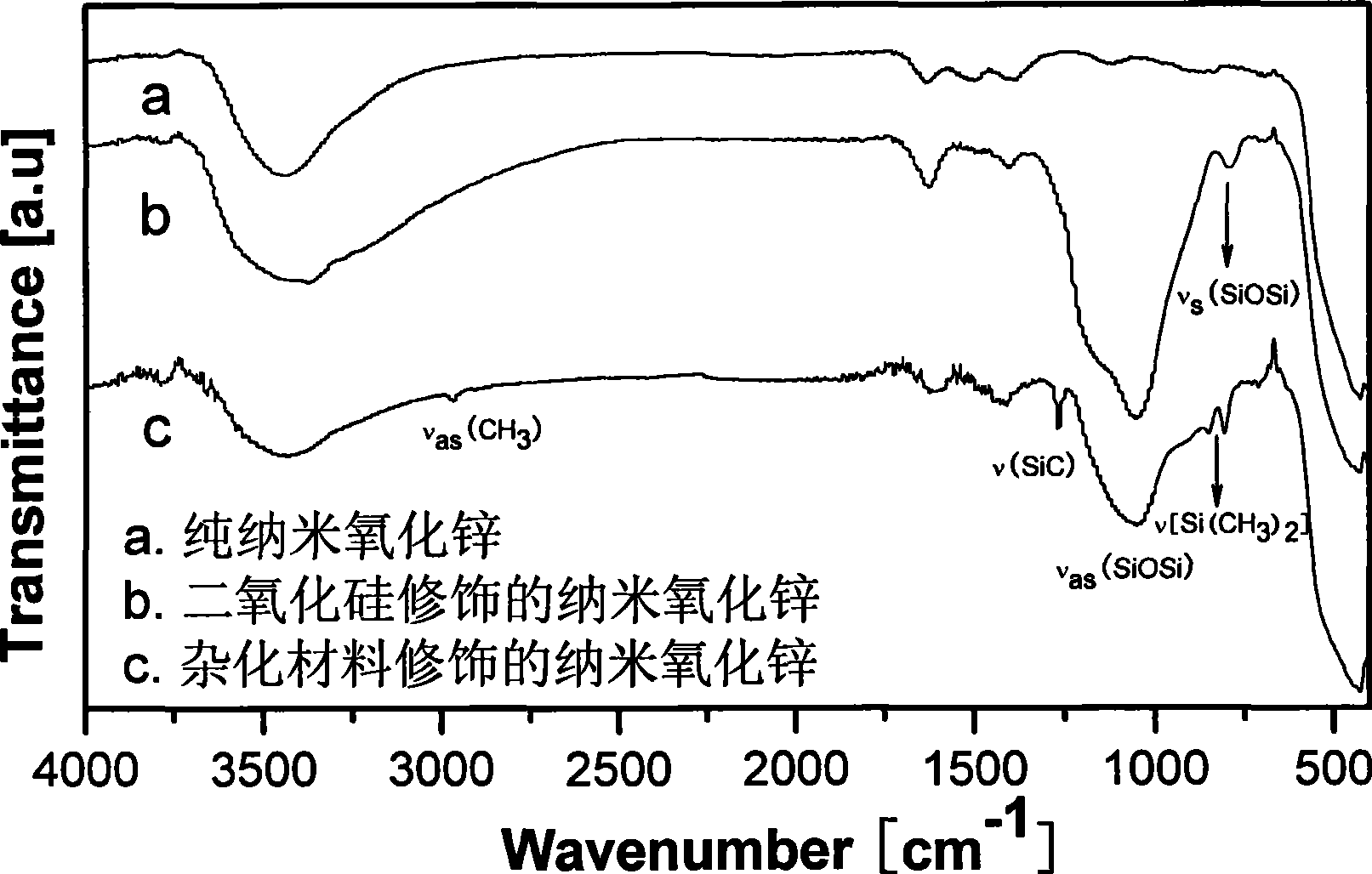

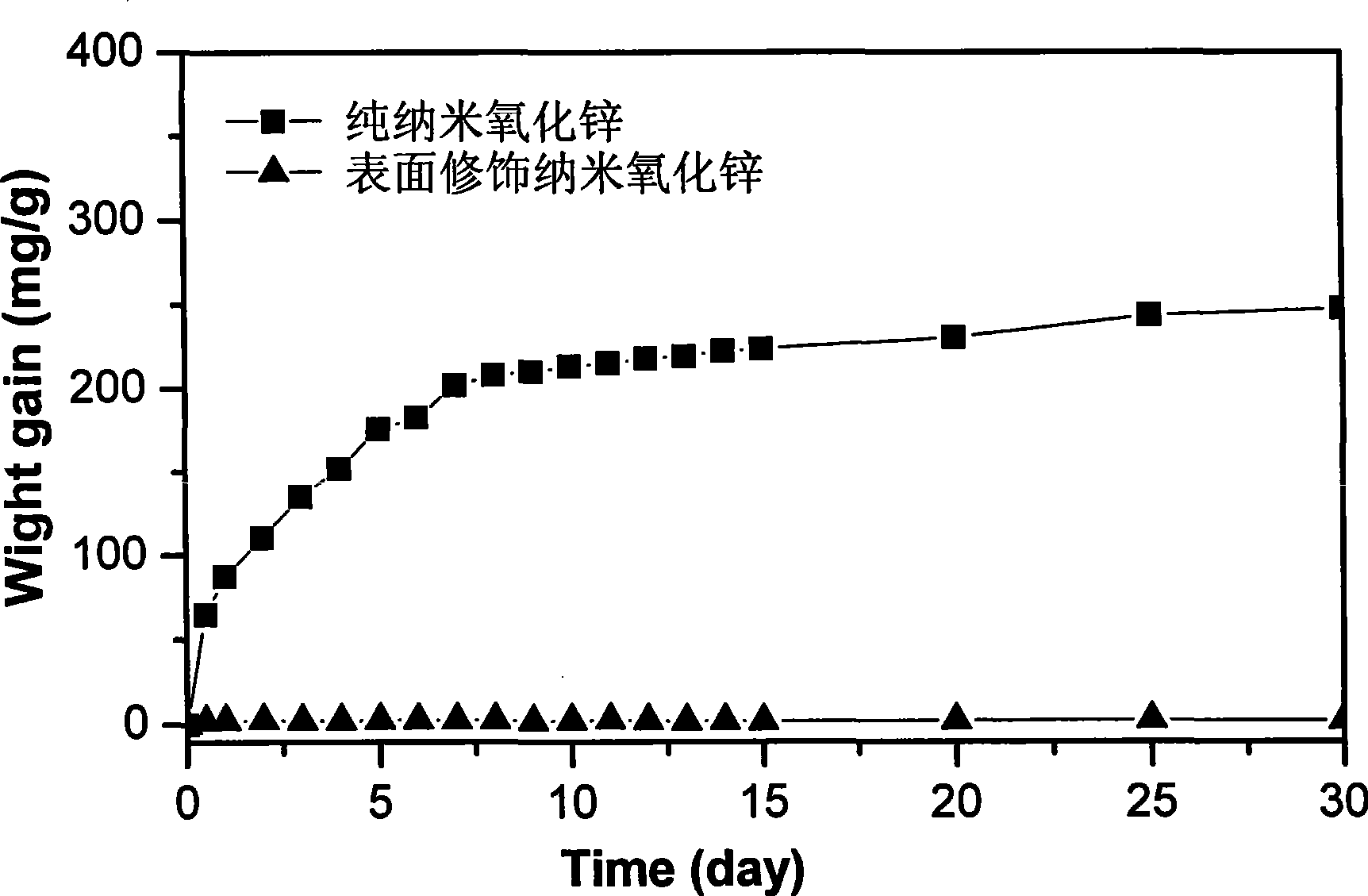

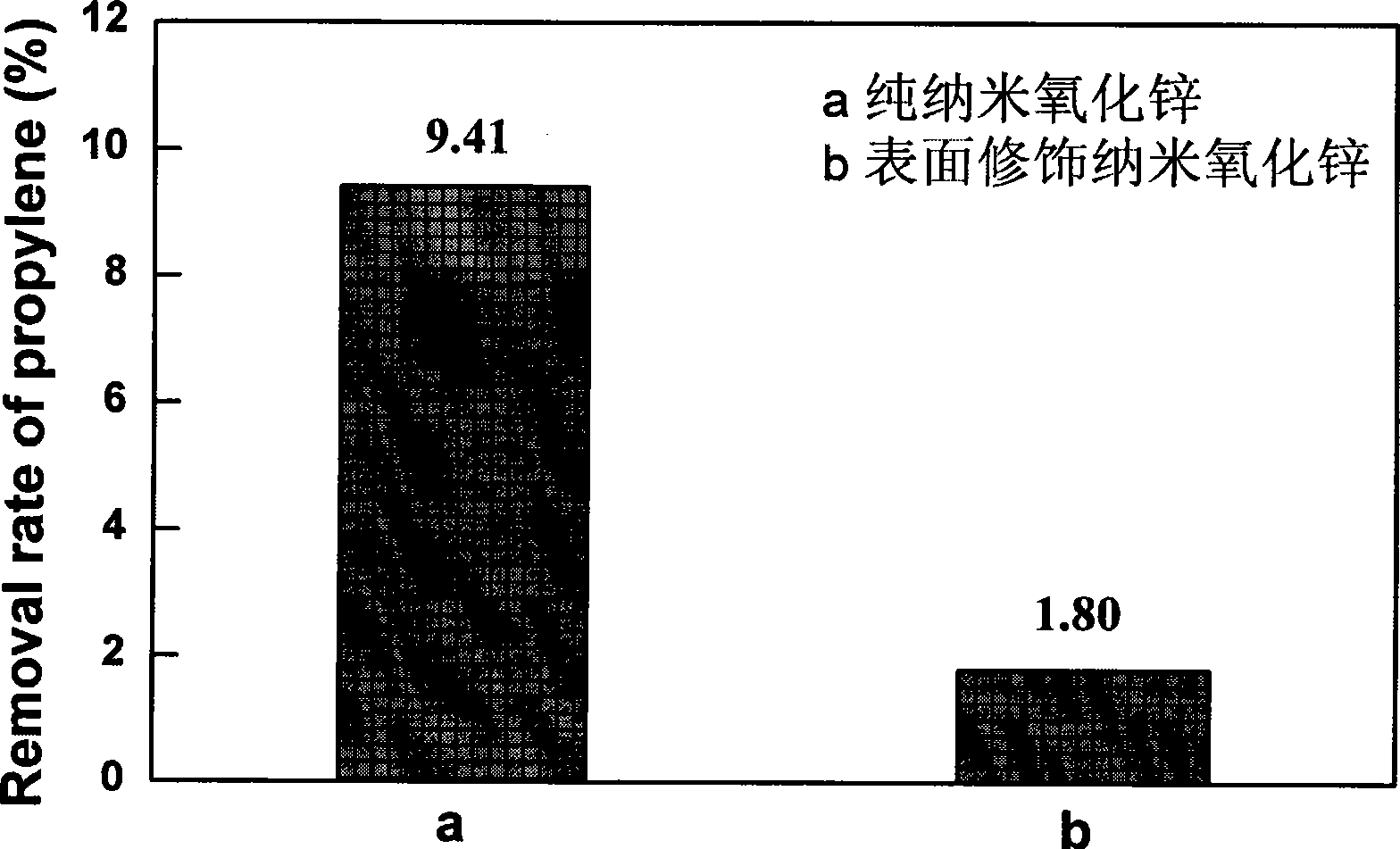

Nano zinc oxide surface modifying method

ActiveCN101543466ASimple processEasy to industrializeCosmetic preparationsToilet preparationsChemical reactionReaction temperature

The invention relates to a nano zinc oxide surface modifying method, which adopts the technical proposal comprising the following steps that: 1) nano zinc oxide powder is fully dispersed in mixed solution of deionized water and latent solvent to form slurry; and 2) a modifier consisting of tetraethyl orthosilicate and / or methyl silicate and organosilane is evenly mixed with the latent solvent, the mixture is added into the slurry in stirring, pH value is adjusted to be between 8 and 12 for reaction, the reaction temperature is about 90 DEG C and the reaction time is between 3 and 12 hours, wherein the organosilane is polydimethylsilane or / and silane coupling agent. The method adopts a common aqueous-phase chemical reaction method, uses common devices, can complete the surface modification on the nano zinc oxide powder of an organic-inorganic hybrid material through a one-step reaction, and has simple process and easy industrialization. Prepared products improve compatability with organic substrates, make the photocatalytic activity inhibited, and are particularly suitable to be used as a UV blocking agent in sun-screen cosmetics.

Owner:HENAN UNIVERSITY

Super-hydrophobic composite porous film and preparation method thereof

InactiveCN103191855AEasy to makeEasy to scalePretreated surfacesSpecial surfacesComposite filmAdhesive

The invention relates to a super-hydrophobic composite porous film and a preparation method thereof. Main composite materials on the surface of the super-hydrophobic flat composite porous film are nano-particles, and the composting method of super-hydrophobic surface materials is a spraying-precipitating method. The surface of the composite porous film is provided with a flat composite film with a nano-micro dual structure, contact angle of the surface and water reaches larger than 150 degrees, and rolling angle is smaller than 5 degrees; main ingredients of a super-hydrophobic coating are nano-particles which comprise but are not limited to one or multiple combinations of nano-silica, nano titanium dioxide or nano zinc oxide. The preparation method includes: uniformly mixing hydrophobic nano-particles, adhesives and diluents to form spraying liquid; utilizing the spraying-precipitating method to uniformly spray the spraying liquid on the surface of a substrate film; drying a modified film sprayed with the nano-particles at the temperature of 15-80 DEG C for 10-40 hours, and obtaining the super-hydrophobic flat composite film. The super-hydrophobic composite porous film is simple in preparation process, free of expensive equipment and easy for large-scale production.

Owner:TIANJIN UNIV

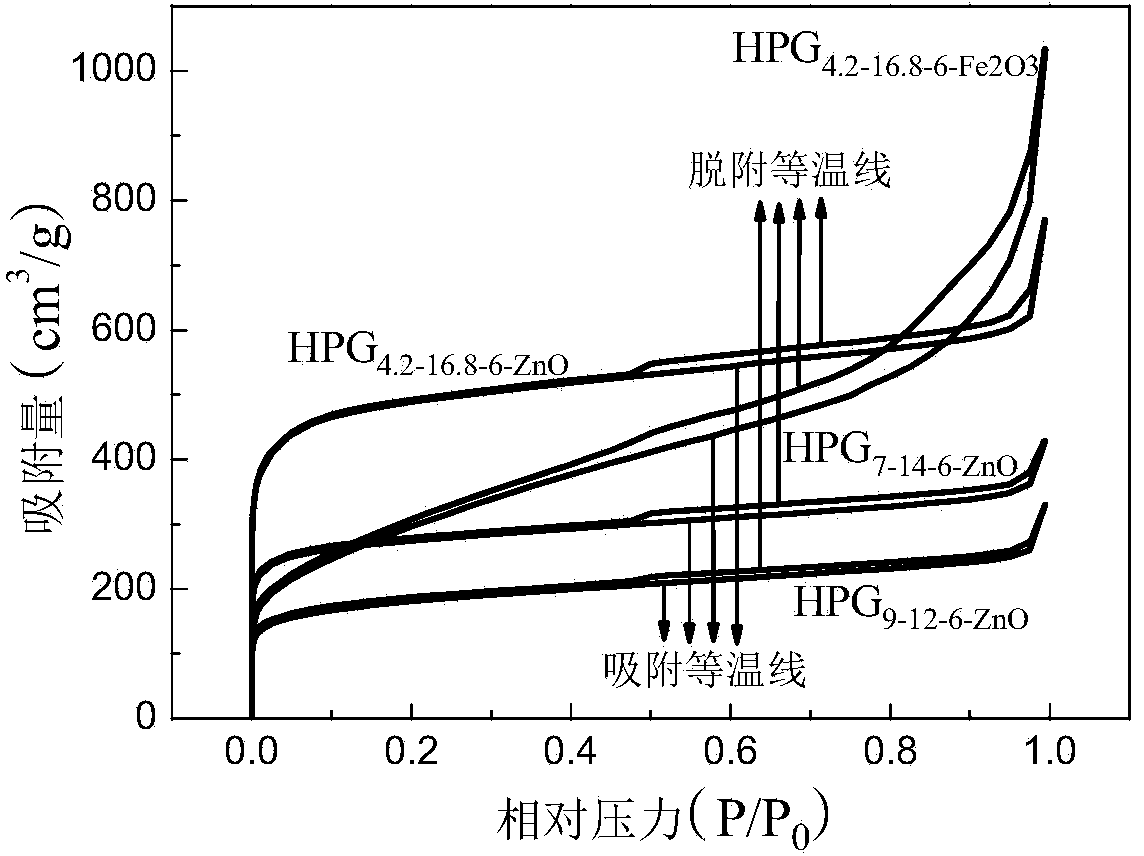

Preparation method of graded porous graphene material for super-capacitor

The invention discloses a preparation method of a graded porous graphene material for a super-capacitor, belonging to the technical field of preparation of carbon materials. The graded porous graphene material for the super-capacitor is prepared by taking coal asphalt as a carbon source, taking nano zinc oxide or nano iron sesquioxide formed by a transitional metal as a template, taking potassium hydroxide as an activator, transferring a grinded mixture of the three into a porcelain boat, placing the porcelain boat in a tubular furnace for heating under a negative-pressure condition through a one-step process. A specific surface area of the graded porous graphene material is between 664m<2> / g and 1862 m<2> / g, total pore volume is between 0.51 cm<3> / g and 1.60 cm<3> / g, average pore size is between 2.53 nm and 5.91 nm, and yield of the graded porous graphene is between 16.9% and 62.8%. According to the preparation method disclosed by the invention, the cheap coal asphalt is taken as the material, preparation process is greatly simplified and operation safety is increased. The preparation method disclosed by the invention has the advantages of being simple in process, low in cost, suitable for industrial production, and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

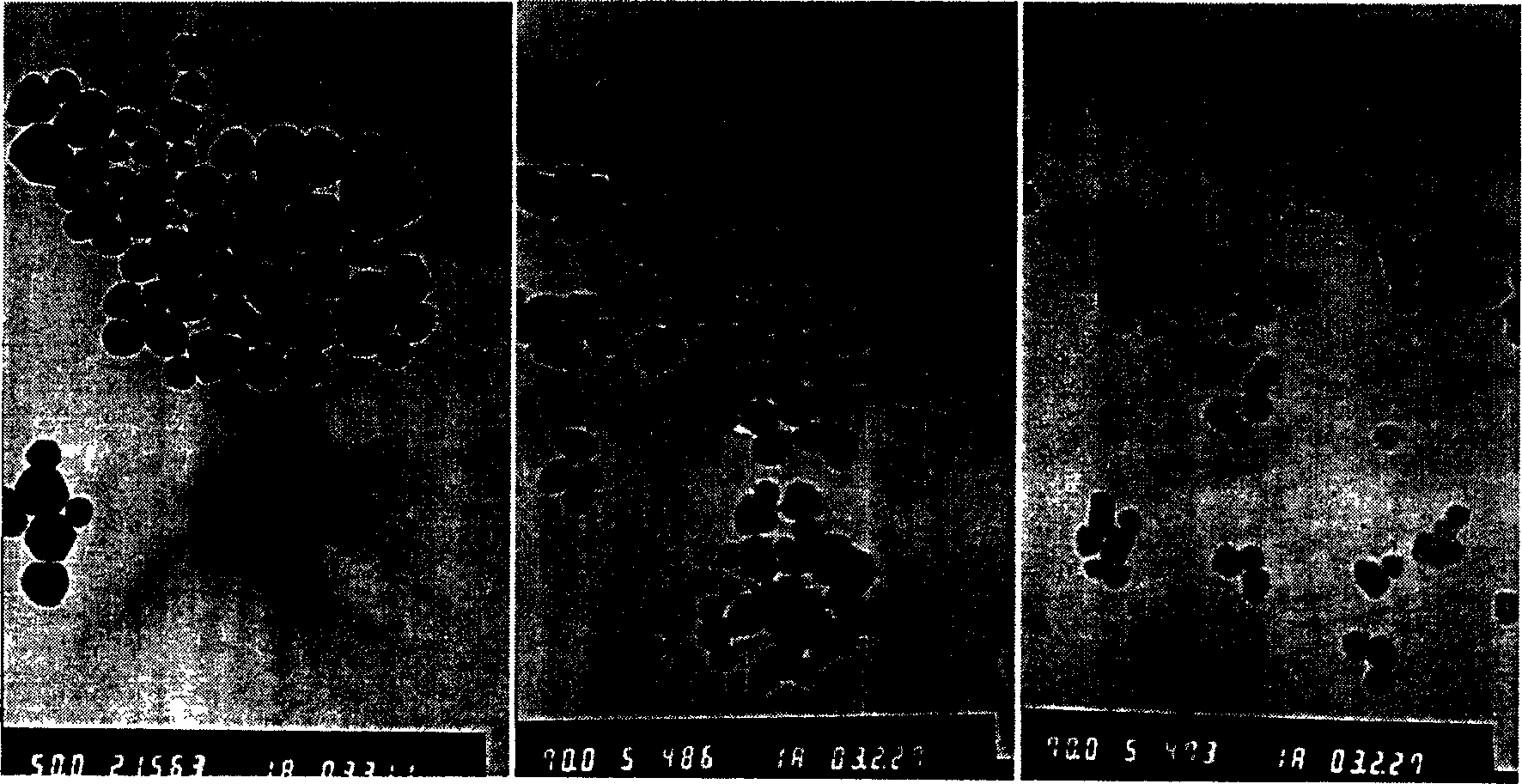

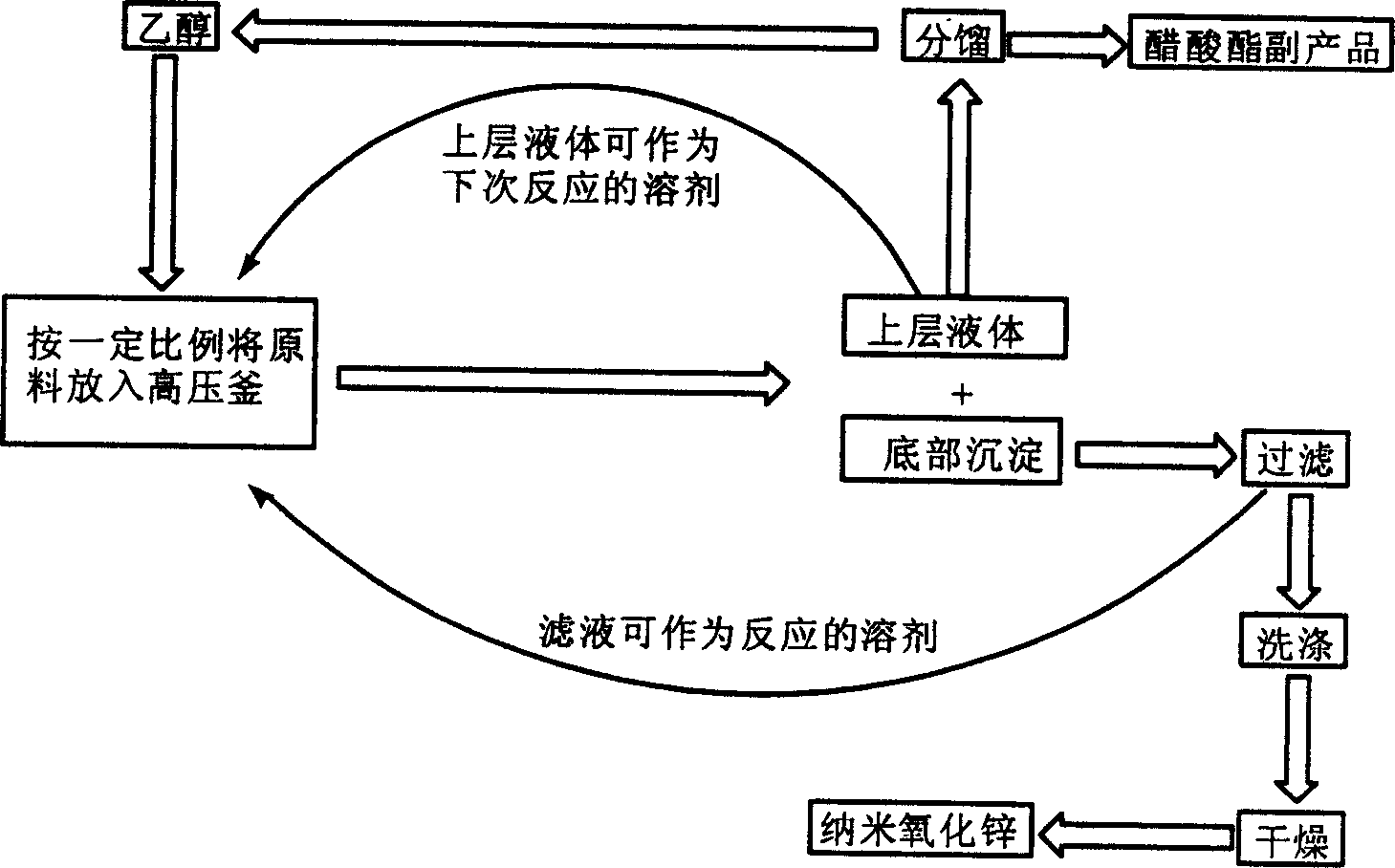

Process for preparing nano zinc oxide

The invention relates to a process for preparing nano zinc oxide wherein zinc acetate alcoholysis reaction is employed to couple the formation of zinc oxide and esterification reaction between acetates and ethanol, thus obtaining nana zinc oxide powder with double dispersibility.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

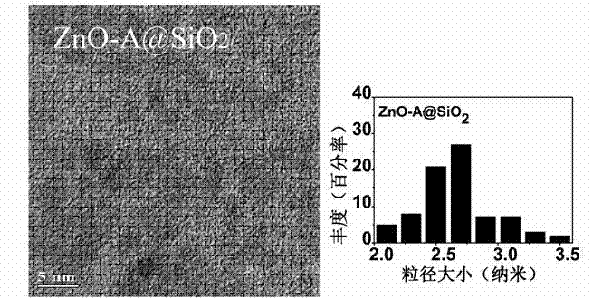

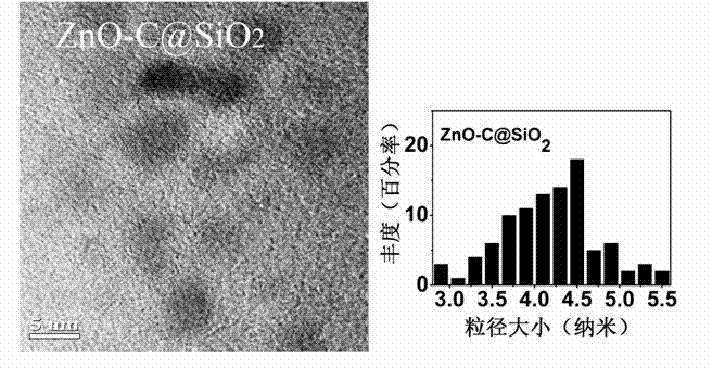

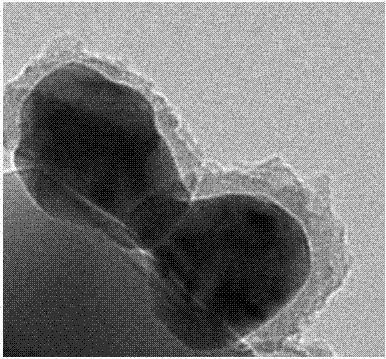

Core-shell zinc oxide-silica nanoparticle, and preparation method and application thereof

InactiveCN102732248ALuminous stabilityBright colorMicrobiological testing/measurementFluorescence/phosphorescenceMethacrylateLithium oxide

The invention specifically relates to a core-shell zinc oxide-silica nanoparticle, and a preparation method and application thereof, belonging to the technical field of nano-materials. The method comprises the following steps: subjecting lithium hydroxide and zinc methacrylate to hydrolysis at room temperature to produce luminous ZnO nanoparticles, adding siloxane monomers containing double bonds and azodiisobutyronitrile, carrying out heating to initiate polymerization so as to form a single organosilicon layer on the surface of the ZnO nanoparticles, then adding other siloxane and ammonia water, and carrying out hydrolysis at room temperature to form a silicon dioxide layer so as to prepare the core-shell zinc oxide-silica nanoparticles. The core of a core-shell zinc oxide-silica nanoparticle is a single zinc oxide luminous quantum dot and has a diameter of 2.7 to 4.6 nm; the shell of the nanoparticle is a thin silica layer; and the core-shell zinc oxide-silica nanoparticle is safe and nontoxic, has high quantum efficiency, stably emits light under continuous UV excitation in cells, can be used for preparing fluorescent labels for biological cells and is especially applicable to preparation of fluorescent labels for cervical carcinoma cells.

Owner:FUDAN UNIV

Carbon nano-pipe composite coating layer type wave absorption material and its preparation method

ActiveCN1651524AImprove conductivityAdjust the frequency rangeConjugated diene hydrocarbon coatingsRadiation-absorbing paintsThermal energyZno nanoparticles

A coated layer type composite wave absorbing material containing carbon nanotubes is composed of the basic substrate consisting of the polymer chosen from rubber, resin and plastics and carbon nanotubes, and the coated layer consisting of paint and nano-zinc oxide. Its advantages are high effect to absorb radar waves and adjustable frequency range of wave-absorbing peak.

Owner:TSINGHUA UNIV

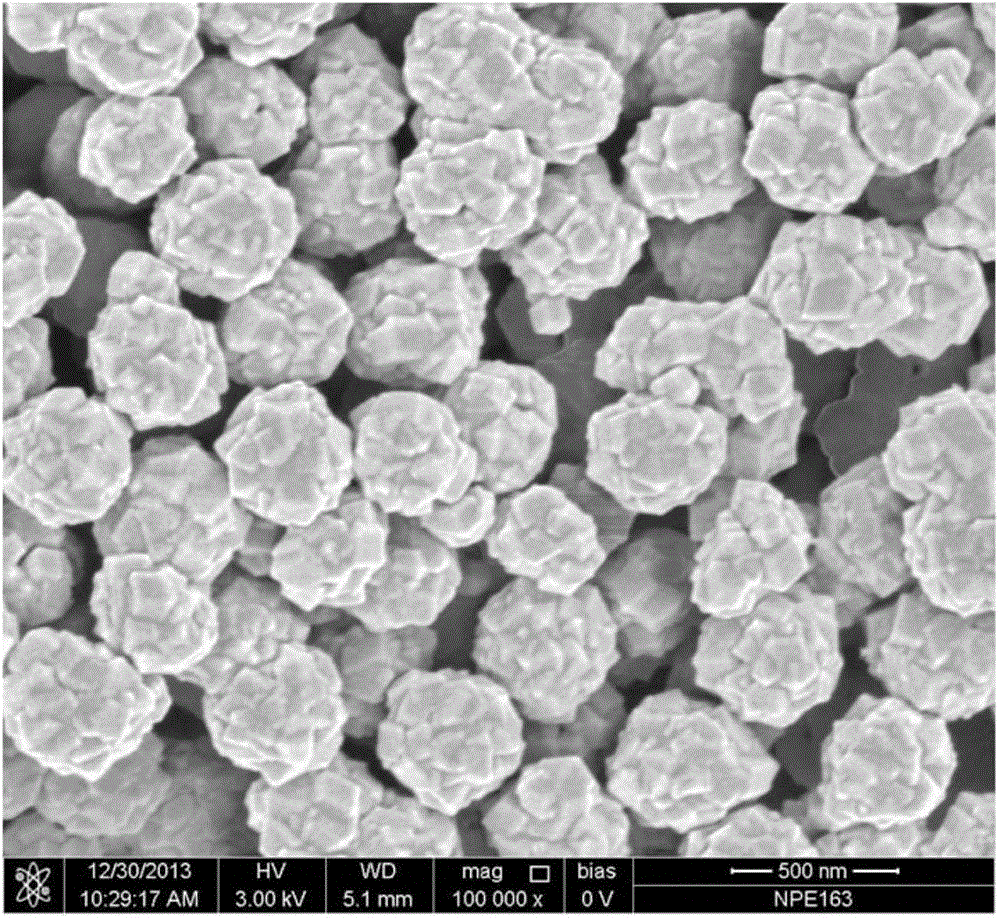

ZIF-8 film-coated Pd/ZnO core-shell catalyst and preparation method thereof

ActiveCN104084238ACatalyst protectionOrganic-compounds/hydrides/coordination-complexes catalystsZno nanoparticlesCore shell

The invention discloses a ZIF-8 film-coated Pd / ZnO core-shell catalyst, belonging to the field of novel materials. A Pd / ZnO core uses spherical ZnO as a supporter; the particle size of the spherical ZnO supporter is 300nm-500nm; the spherical ZnO supporter is formed by accumulation of ZnO nanoparticles with the particle size of 20nm-40nm. A stable Pd nanoparticle of PVP (Polyvinyl Pyrrolidone) is taken as an active center, and the thickness of a ZIF-8 film coating the Pd / ZnO core is 100nm-150nm. The spherical ZnO supporter and the stable Pd nanoparticle of PVP are mixed and a 2-methylimidazole solution is added to act with ZnO so as to obtain the ZIF-8 film layer on the outer surface of Pd / ZnO. According to the ZIF-8 film-coated Pd / ZnO core-shell catalyst, the ZIF-8 film with a molecular screening function endows the supported noble metal catalyst with high selectivity to reactants and products; meanwhile, the problem of activity reduction caused by the fact that the active ingredients of heterogeneous catalysts are likely to run away and be poisoned in reaction are solved.

Owner:DALIAN UNIV OF TECH

Rubber containing nano zinc oxide and its pugging process

A rubber product contains rubber matrix, vulcanizing agent and (10-80)-nm zinc oxide as vulcanizing activator. Its milling process includes feeding said rubber matrix and the nano zinc oxide treated by silane coupling agent into open mill to obtain mother rubber, sequentially adding the rubber matrix, said mother rubber, promoter, antiageing agent and sulfur, and milling. Its advantages are less consumption of nano zinc oxide (decreased by 60%), and high mechanical performance of product.

Owner:SHANGHAI UNIV OF ENG SCI

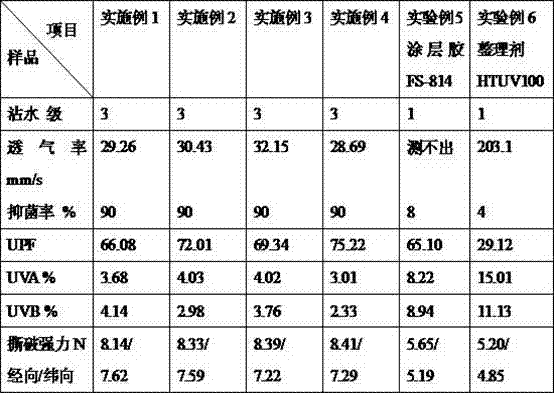

Waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive for textile and preparation method of waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive

ActiveCN104727151AGuaranteed waterproof performanceAntimicrobial GuaranteeFibre treatmentPolyesterWater based

The invention provides waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive for textile and a preparation method of the waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive. The adhesive is prepared by mixing the following raw materials in parts by weight: 65-68 parts of a water-based polyurethane waterproof permeable adhesive, 10-15 parts of polyethylene glycol having the average molecular weight of 600, 2-3.5 parts of a TDI tripolymer curing agent, 3-4 parts of anionic amino silicon oil emulsion, 5-7 parts of an anionic or non-ionic fluorine-containing waterproof agent, 5-7 parts of a phenylamide anionic antibacterial deodorant agent, 1.5-2.5 parts nano-zinc oxide powder and 1-2 parts of nano-titanium dioxide powder. The coating adhesive is simple and convenient to produce and convenient to use, has good waterproof color fastness, and is suitable for 10D-20D polyester, chinlon cloth fabric functional coatings.

Owner:DANDONG UNIK TEXTILE

Polypyrrole-clad nano spherical zinc oxide material and preparation method

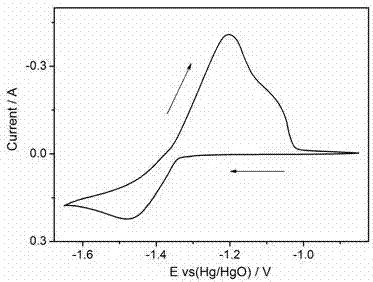

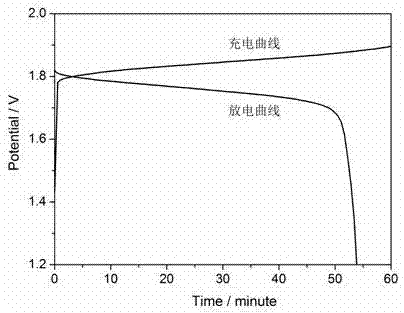

ActiveCN107275611ASuppress generationLong cycle lifeMaterial nanotechnologyCell electrodesPolypyrroleZno nanoparticles

The invention relates to a polypyrrole-clad nano spherical zinc oxide material with a core-shell structure and a preparation method. The polypyrrole-clad nano spherical zinc oxide material takes nano spherical zinc oxide as a core and polypyrrole as a shell cladding the surface of a zinc oxide particle. The preparation method comprises the steps of adding a precipitant such as hexamine to a zinc source, preparing a nano spherical zinc oxide particle by a hydrothermal reaction, adding nano zinc oxide to a solution containing a surfactant to form zinc oxide sol, adding a pyrrole monomer and an oxidant, performing in-situ oxidation polymerization, and forming a polypyrrole-clad layer on the surface of the zinc oxide particle. The prepared polypyrrole-clad nano zinc oxide material with the core-shell structure has a larger specific surface area; the activity of the nano zinc oxide material is improved; aggregation of the nano zinc oxide particle can be well avoided; existing of the polypyrrole-clad layer effectively alleviates pine-tree crystal forming of the zinc oxide particle in charging and discharging processes; and the cycle life of an electrode is significantly prolonged.

Owner:NANCHANG HANGKONG UNIVERSITY

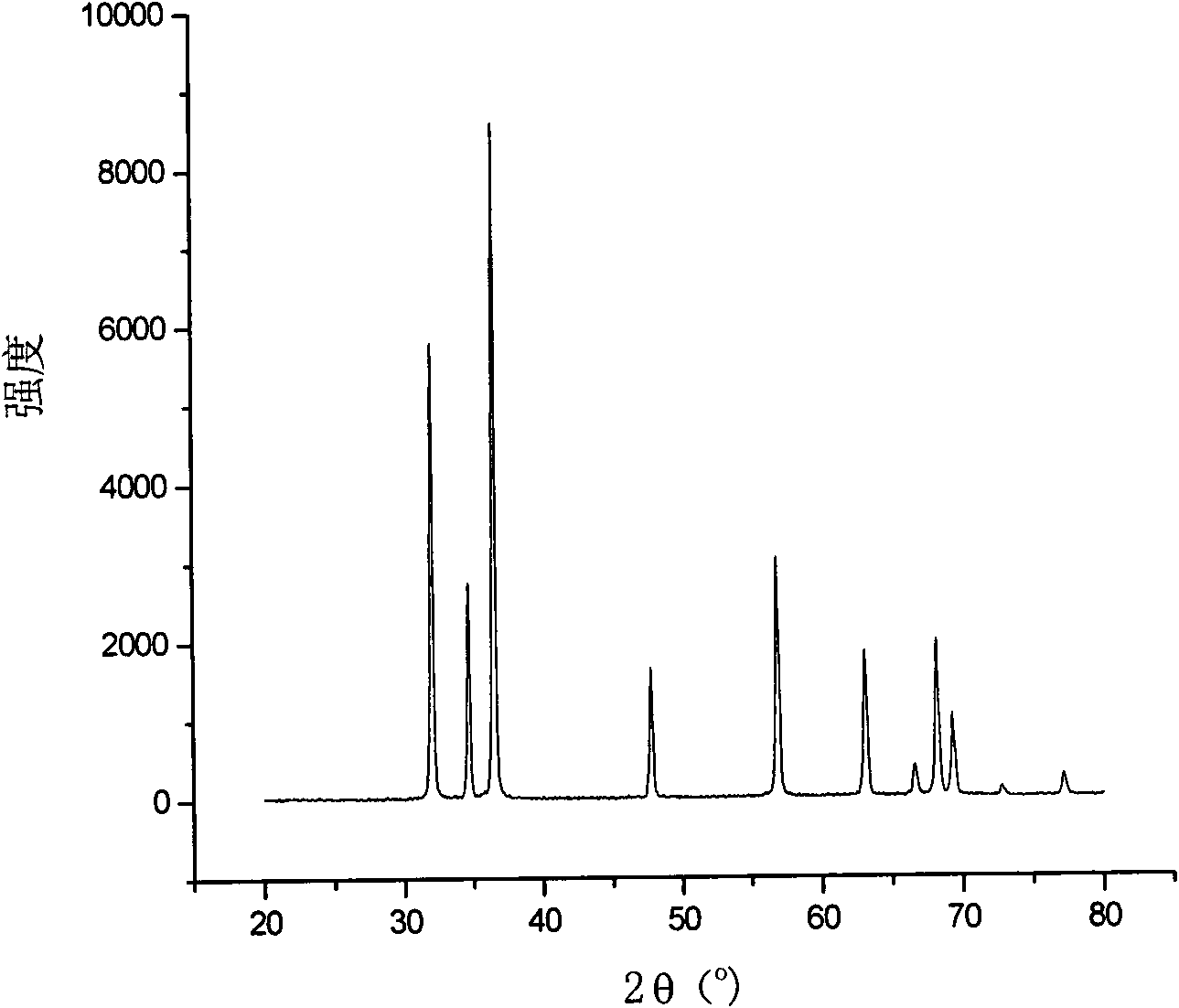

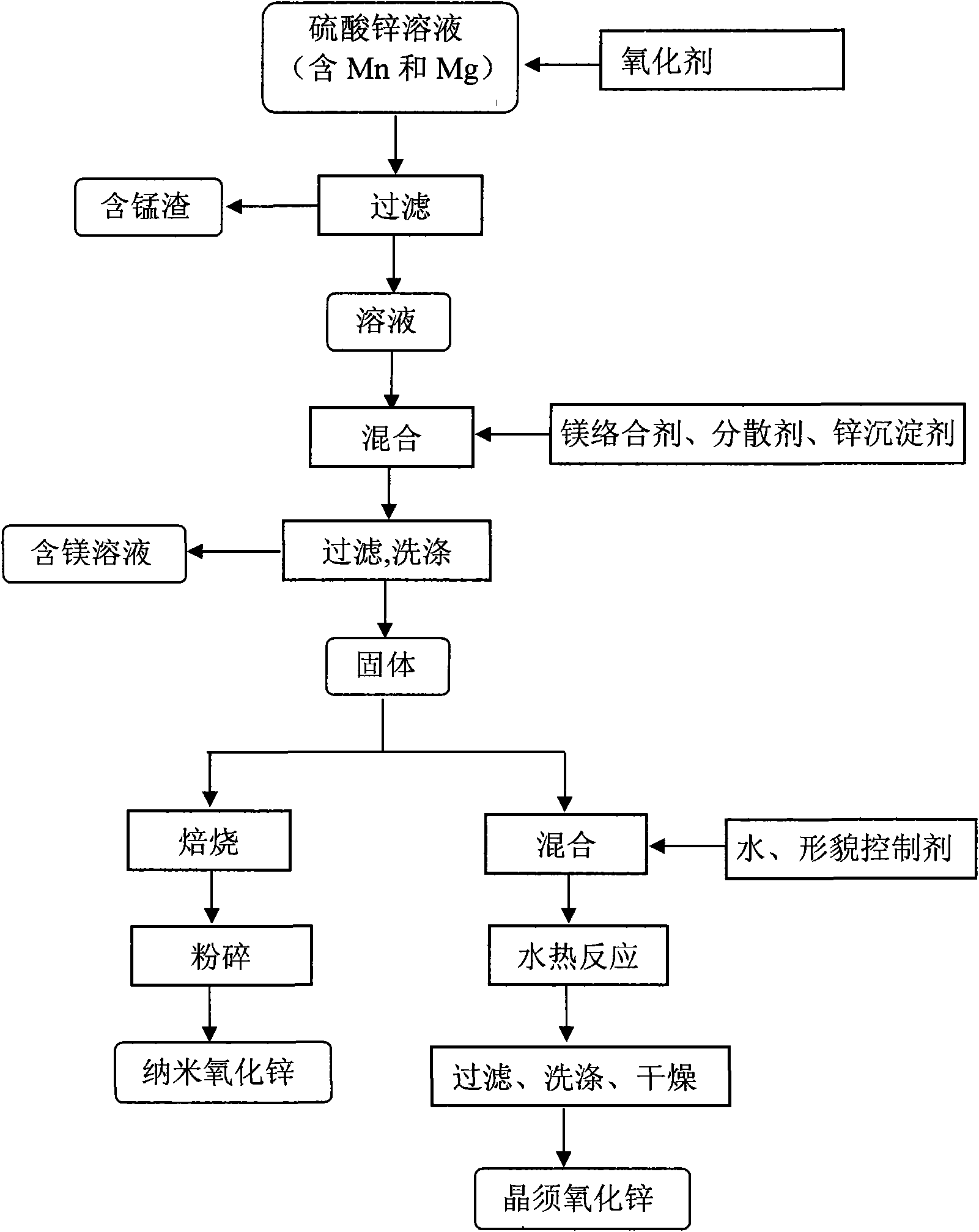

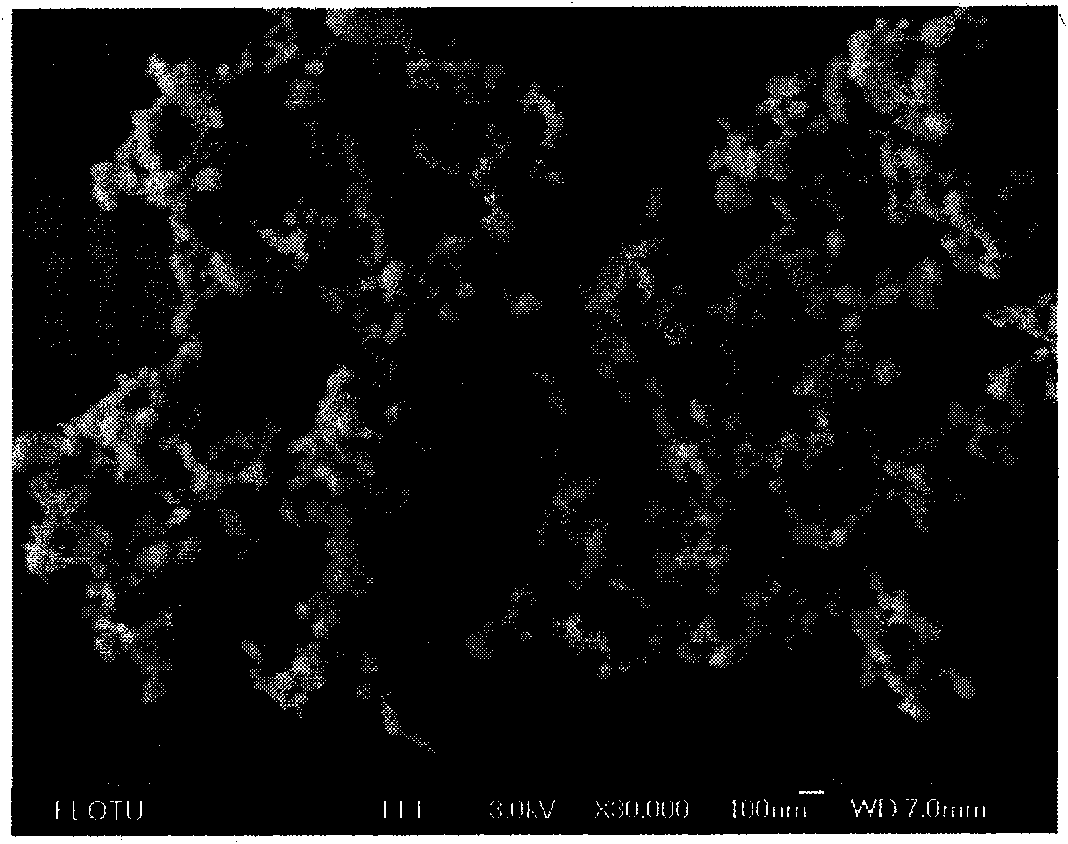

Method for preparing nano zinc oxide and crystal whisker zinc oxide by using industrial zinc sulfate as raw material

ActiveCN101559973APromote formationGood buttPolycrystalline material growthNanostructure manufactureManganeseZno nanoparticles

The invention relates to a method for preparing nano zinc oxide and crystal whisker zinc oxide by using industrial zinc sulfate as a raw material, which belongs to the technical field of preparation of inorganic chemical materials. The method uses a simulated industrial zinc sulfate solution containing impurities of manganese and magnesium as the raw material, and comprises the following steps: firstly, removing the manganese by adopting an oxidation method, and separating the magnesium and zinc by adopting a neutral complex magnesium-dissolving and zinc-depositing mode so as to prepare a precursor of a nano zinc salt; and secondly, preparing the crystal whisker zinc oxide with a regular shape by using a hydrothermal orientated growth method, or preparing high-purity nano zinc oxide by using a roasting method. The method well meets the prior zinc wet method metallurgical process, and has the advantages of clean and simple process, good impurity removing effect, high zinc total yield, low cost, excellent product performance, high added value and easy industrial popularization. The nano zinc oxide and the crystal whisker zinc oxide prepared by the method have regular shapes and uniform grain size, and can be used as functional packing materials or reinforcing materials applied to the fields of alloy, resin, rubber, ceramics, plastics, coatings, electronics and the like.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com