Nano zinc oxide surface modifying method

A technology of nano-zinc oxide and nano-zinc oxide powder, which is applied in cosmetics, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of time-consuming, many operation steps, and increased production costs, and achieve simple process, easy industrialization, and smooth The effect of catalytic activity inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) After mixing 150ml of deionized water and 50ml of ethanol in a beaker, take 6.5g of nano-zinc oxide powder and add it, ultrasonic treatment for 30min to fully disperse the nano-zinc oxide, then transfer to a 500ml three-neck bottle.

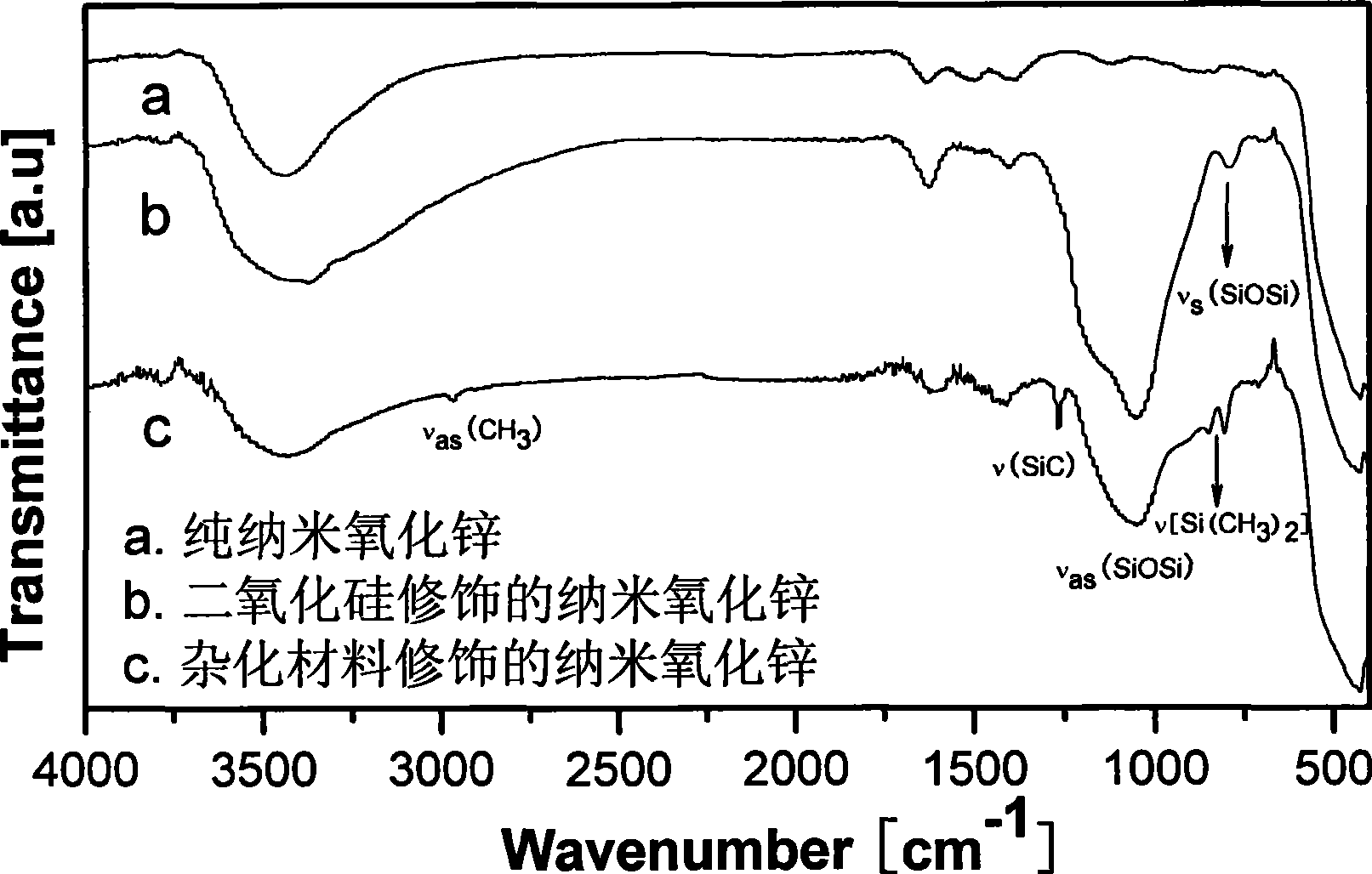

[0024] 2) Take 0.003mol tetraethyl orthosilicate, 0.027mol dimethyldiethoxysilane and 25ml ethanol and mix thoroughly, add into a three-necked bottle under vigorous stirring; adjust the pH of the solution to 9 with ammonia water (27%), and raise the temperature at the same time to 50°C and react for 10 hours.

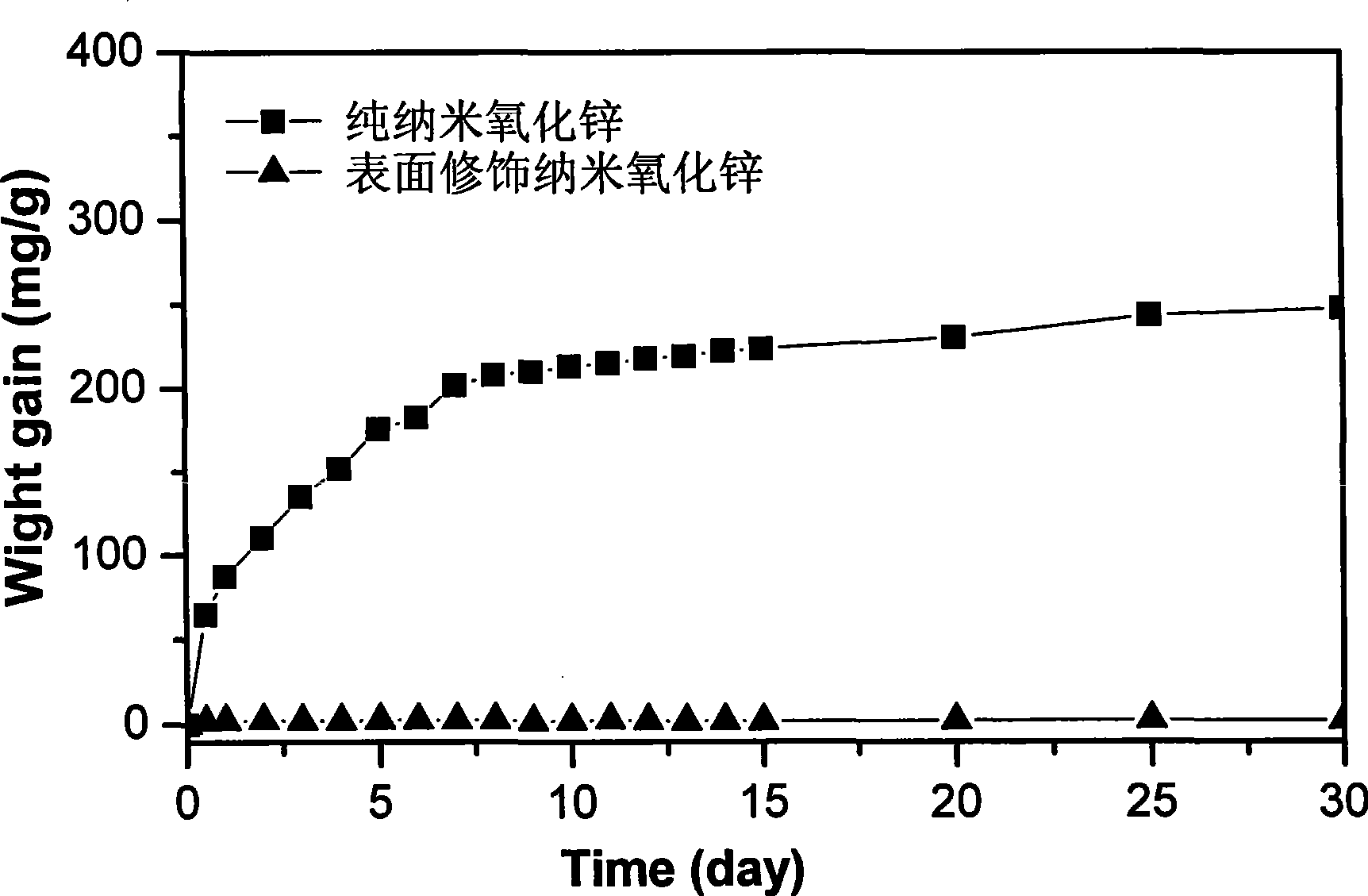

[0025] After the reaction is completed, filter, and the obtained filter cake is dried at 100°C for 24 hours, ground and pulverized to obtain surface-modified nano-zinc oxide powder.

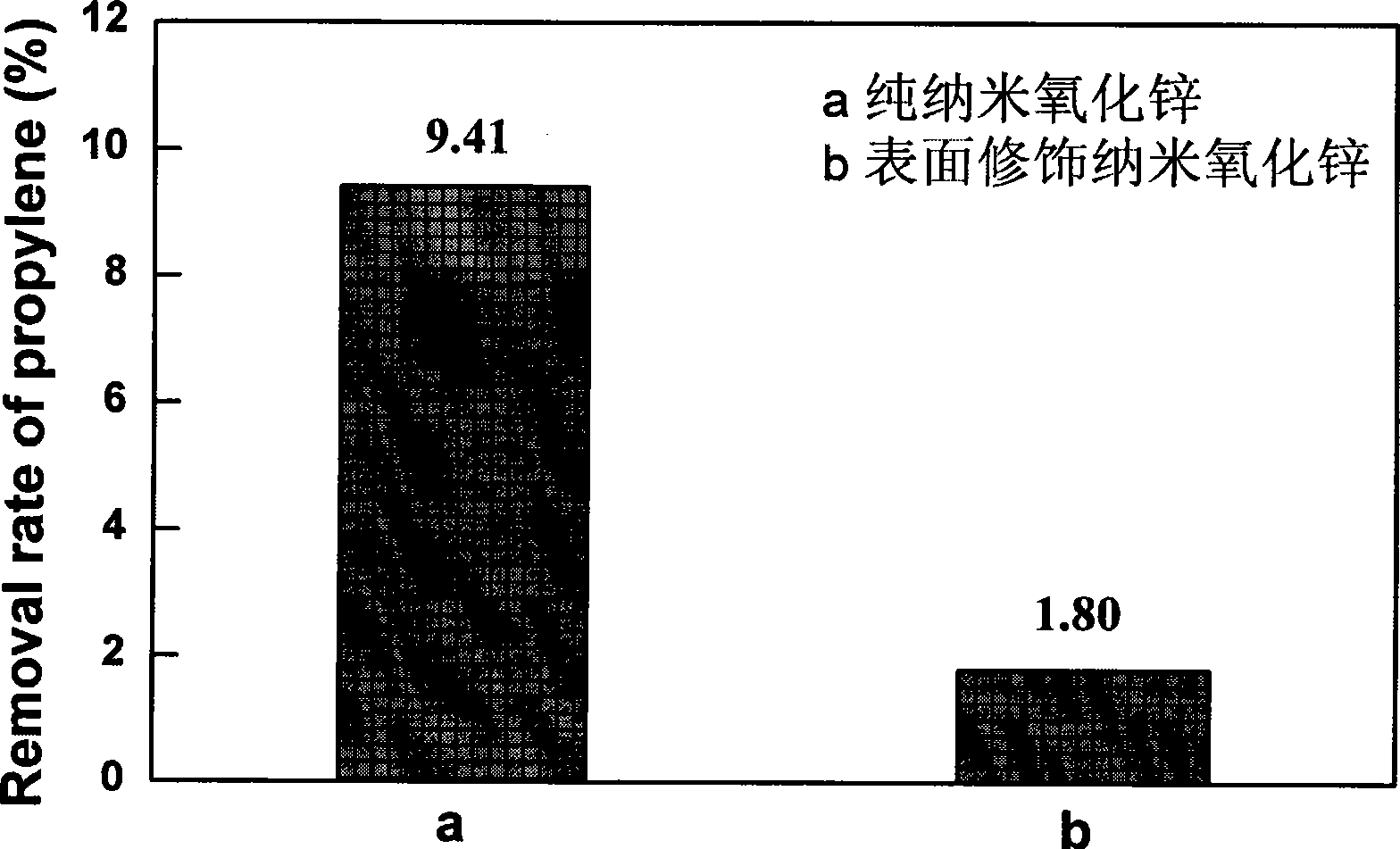

[0026] Comparative Example of Embodiment 1

[0027] 1) After mixing 150ml of deionized water and 50ml of ethanol in a beaker, take 6.5g of nano-zinc oxide powder and add it, ultrasonic treatment for 30min to fully disperse the nano-zinc oxide, then...

Embodiment 2

[0031] 1) After mixing 150ml of deionized water, 25ml of ethanol and 25ml of propanol in a beaker, take 6.5g of nano-zinc oxide powder and add it, ultrasonic treatment for 30min to fully disperse the nano-zinc oxide, then transfer it into a 500ml three-neck bottle.

[0032] 2) Take 0.015mol ethyl orthosilicate, 0.015mol monomethyltriethoxysilane and 25ml ethanol and mix thoroughly, add into a three-necked bottle under vigorous stirring; adjust the pH of the solution to 9 with ammonia water (27%), and raise the temperature at the same time to 70°C and react for 12 hours.

[0033] After the reaction, the product system was filtered, and the obtained filter cake was dried at 120°C for 12 hours, ground and pulverized to obtain surface-modified nano-zinc oxide powder.

Embodiment 3

[0035] 1) After mixing 100ml of deionized water, 25ml of methanol and 25ml of ethanol in a beaker, take 6.5g of nano-zinc oxide powder with a particle size of 10-100nm and add it, and use an emulsifier to high-speed shear (4000rmp, 10min) to make the nano Zinc oxide is fully dispersed and transferred to a 500ml three-neck bottle.

[0036] 2) Take 0.042mol of methyl orthosilicate, 0.018mol of diphenyldiethoxysilane and 25ml of methanol and mix them thoroughly, and add them into a three-necked flask under vigorous stirring; adjust the pH of the solution to 10 with sodium hydroxide solution, and simultaneously heat up to 80°C, react for 10 hours.

[0037] After the reaction is finished, the product system is directly spray-dried to obtain surface-modified nano-zinc oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com