Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4991 results about "Nano zinc oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional composite absorbing material for purifying water and preparation method thereof

ActiveCN102350298AReduce wasteEfficient removalOther chemical processesWater/sewage treatment bu osmosis/dialysisAcrylic resinCerium

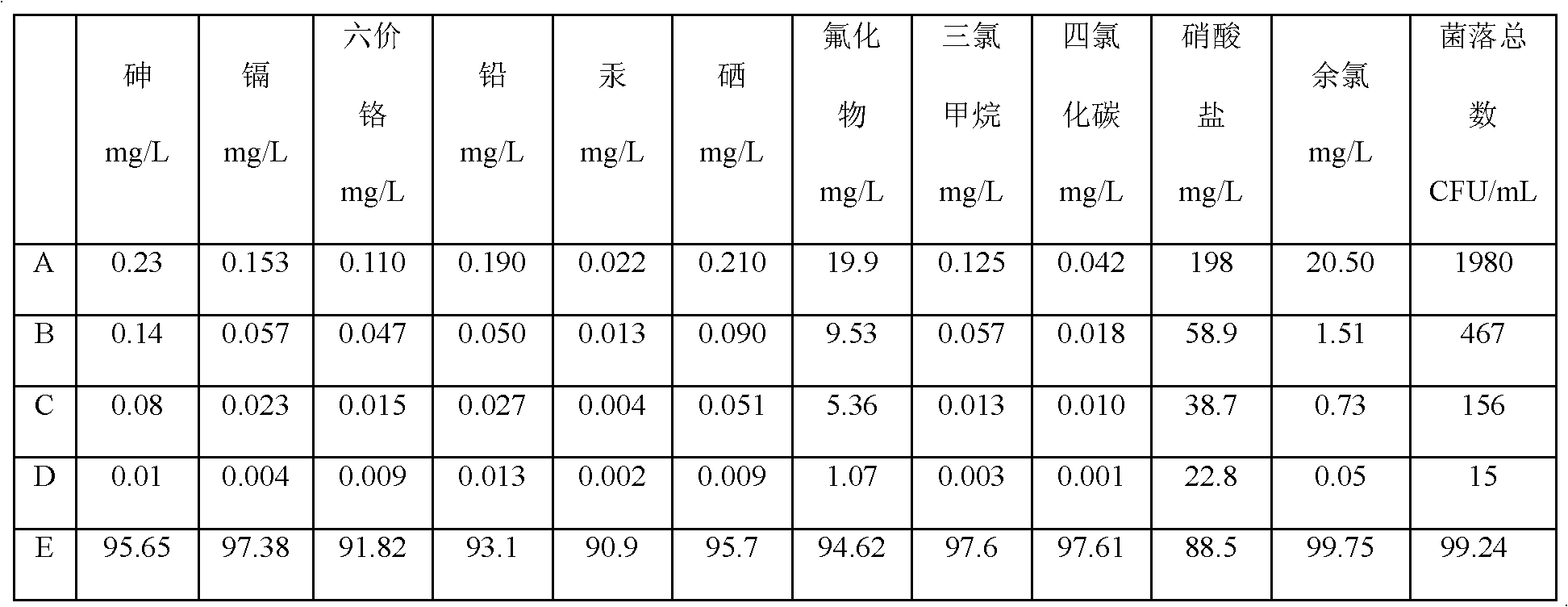

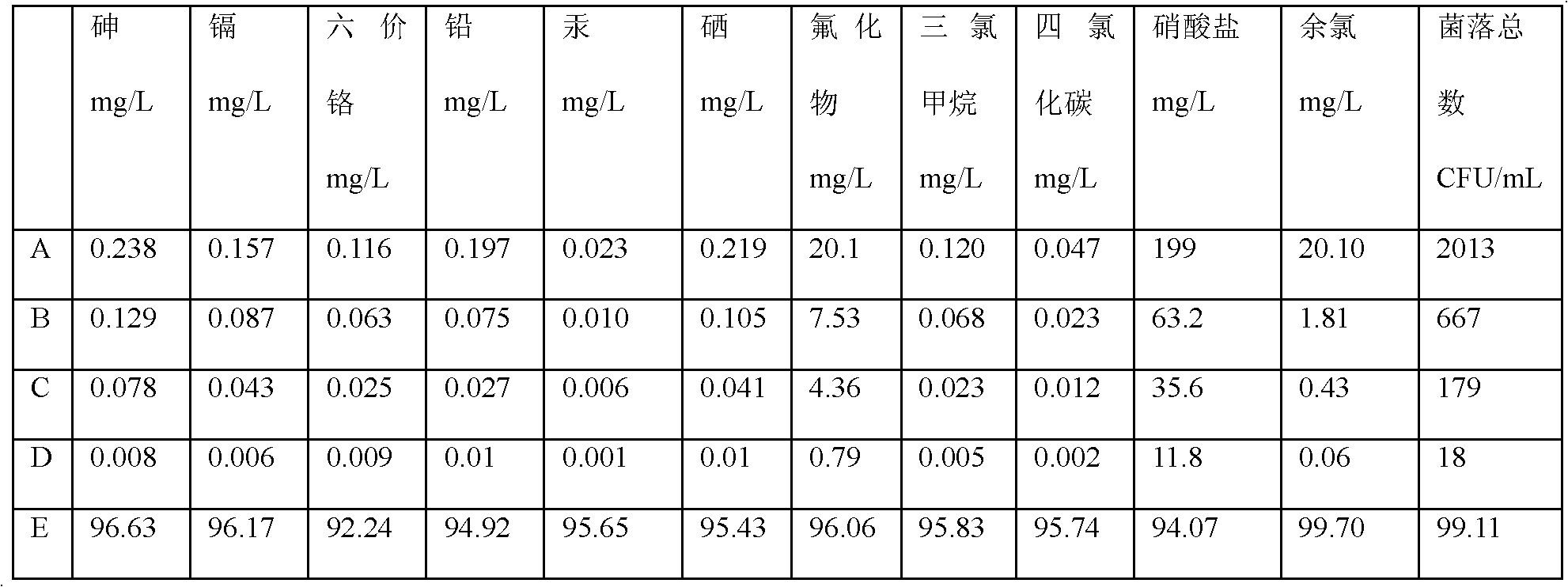

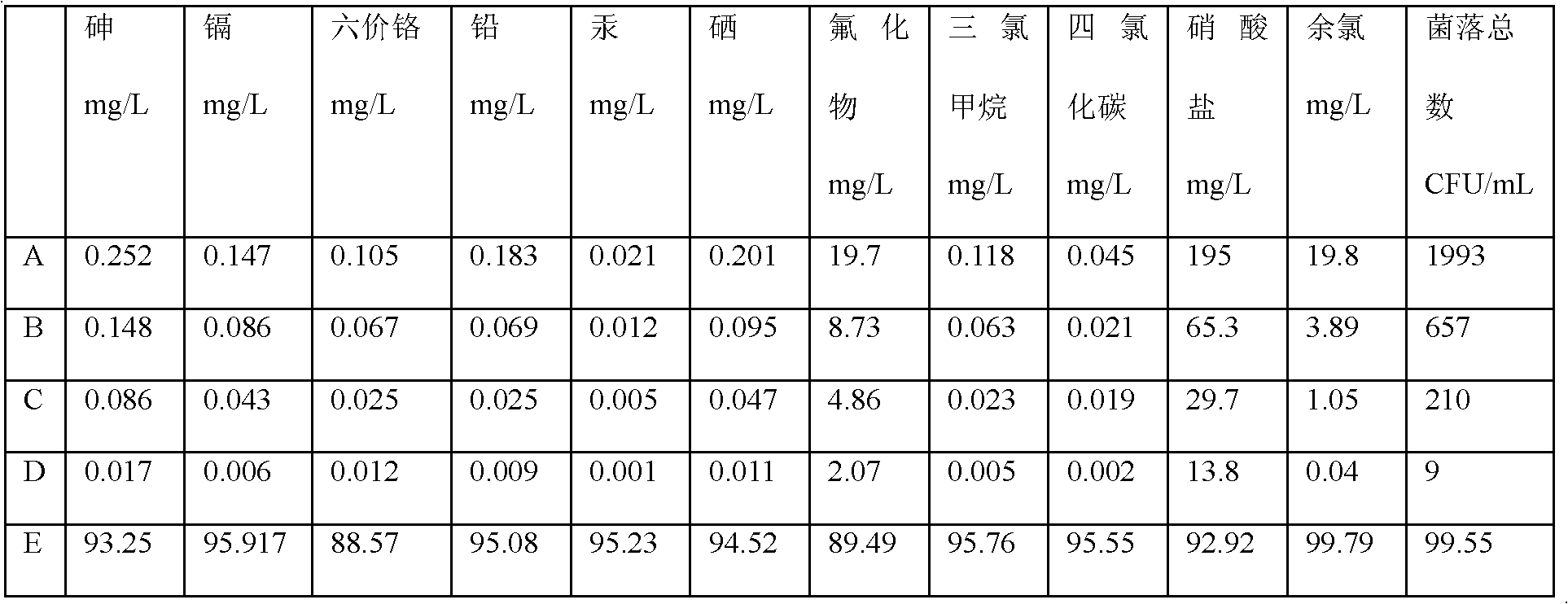

The invention provides a multifunctional composite absorbing material for purifying water and a preparation method thereof, relating to an absorbing material. The invention provides the multifunctional composite absorbing material for purifying water, which can be used for effectively removing a plurality of harmful substances in the water and has higher removal efficiency and lower production cost, and the preparation method thereof. The absorbing material is selected from at least one of absorbing materials A, B and C; the absorbing material A takes a mesoporous adsorption ceramic material as a carrier to load nano metals including nano silver, nano zinc, nano iron and nano cerium; the absorbing material B takes the mesoporous adsorption ceramic material as the carrier to load nano metal oxides including nano titanium dioxide, nano zinc oxide, nano ferric oxide and nano cerium dioxide; and the absorbing material C is prepared from the following raw materials according to the mass ratio: 100-200 parts of active carbon powder, 20-30 parts of polyethylene powder, 10-30 parts of calcium sulfite powder, 10-30 parts of natural zeolite powder, 20-40 parts of macroporous acrylic resin and 10-20 parts of attapulgite powder.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

Nanometer doped zinc oxide and its prepn and application in photocatalysis to degrade organic matter and kill bacteria

InactiveCN1772375AImprove photocatalytic activityImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFiberRare earth

The present invention relates to Ag and RE doped nanometer zinc oxide and its preparation process and application in photocatalysis to degrade organic matter and killing bacteria. Ag, RE metals La, Ce, Pr, Nd, Sm, etc. are doped into nanometer zinc oxide to raise its photocatalytic activity in degrading harmful chemical matter and resisting bacteria. Under lighting, the doped nanometer zinc oxide has higher photocatalytic activity and higher antibacterial capacity; and in case of no lighting, it has relatively high antibacterial effect owing to the antibacterial effect one Ag, Zn, RE and other antibacterial ions. The preparation process may be an organic matter complexing process or a sprying pyrolysis process. The doped nanometer zinc oxide may be used through mixing with other material, or used as additive added into plastic, ceramic, fiber, timber, rubber, glass, cement, metal and other material to form various kinds of photocatalytic antibacterial material and product.

Owner:NANJING UNIV

Special-purpose energy-saving environment-friendly type nano coating for aluminum alloy sections (door and window) and preparing method thereof

InactiveCN101012350AStrong UV resistanceImprove insulation efficiencyLiquid surface applicatorsEpoxy resin coatingsEpoxyPolyvinyl butyral

The invention discloses a specific nanometer paint of energy-saving environment-protective typed aluminium alloy section bar (door and window), which comprises the following parts: 90-100% filming agent, 0.1-10% hardener, 0.5-8% levelling agent, 0.5-10% nanometer material, 20-50% fill and 10% hollow microball, wherein the filming agent is one or more of epoxy resin, polyester resin, acrylic acid resin, amino resin, phenol resin or alkide resin; the hardener is one or more of dicyandiamide, imidazole, dihydrazide, polybasic carboxylic acid, beta-hydroxyalkyl amide or triglycidol isocyanuric ester hardener; the levelling agent is one or more of polyacrylic resin, siliceous acryl resin, polyvinyl butyral, benzoin, hydrocastor oil, cellulose acetate butyrate or epoxy soy oil; the nanometer material is nanometer zinc oxide; the hollow micro-ball is hollow ceramic microball.

Owner:苏州裕丰装饰门窗有限公司

Nano-zinc oxide coated sericite powder composite material and preparation method thereof

InactiveCN104017393AImproves UV resistanceImprove antibacterial propertiesCosmetic preparationsInorganic pigment treatmentCalcium hydroxideOrganic solvent

The invention discloses a sericite / nano-zinc oxide composite material and a preparation method thereof. The composite material is characterized in that the surface of sericite powder is coated with nano-zinc oxide. The preparation method comprises the following step: adding calcium hydroxide or calcium oxide into a mixed system of the sericite powder and zinc sulfate solution so as to directly obtain the nano-zinc oxide coated sericite powder composite material. According to the method, the sericite which is taken as a base material is a natural mineral, so that the raw material is easily available, free of pollution and low in cost; the preparation process is simple, safe, reliable and easy to control; the obtained composite material is stable in quality, and has the good dispersibility in an organic solvent and also has the excellent ultraviolet resistance and the excellent antibacterial and deodorant performance. Thus, the composite material can be applied to the field of coatings, cosmetics and the like. The method has a good potential application value in the field of synthesis of the composite material or other related sciences.

Owner:ANHUI HENGHAO SCI & TECH

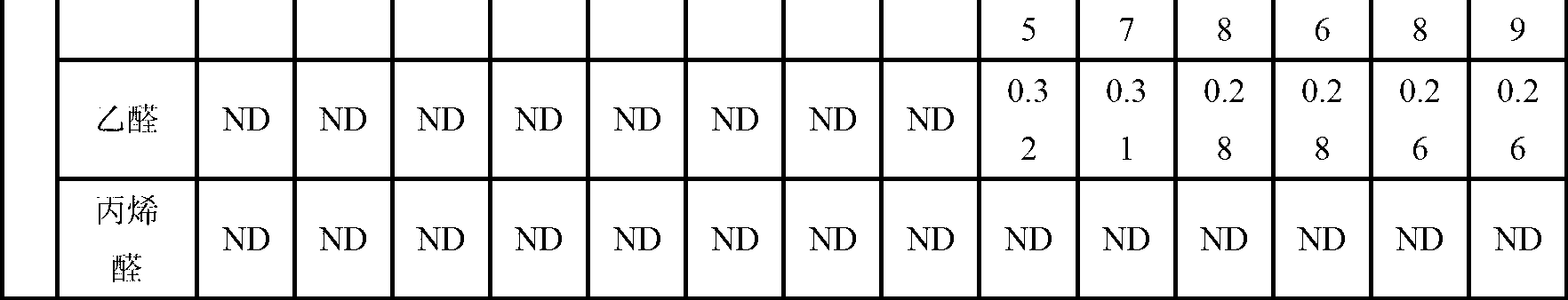

Low-odour polypropylene composite

The invention relates to a low-odour polypropylene compound, the compound comprises (by weight ratio) polypropylene 55-95, talcum powder 0-40, fatty acid ester compound 0.5-3, nano zinc oxide 0.5-3, nano titanium oxide 0.5-3, heat stabilizer DSTP 0.1-1.0, heat stabilizer 3114 0.1-1.0, heat stabilizer 618 0.1-0.5, wherein the fatty acid ester compound being C25-C45 long-chain fatty acid ester, the heat stabilizer DSTP being octadecyl thiodipropionate, the heat stabilizer 3114 being 3,obtaining 5-ditert-butyl-4-hydroxy benzylphosphonate diethylate, the heat stabilizer being dioctadecyl pentaerythritol diphosphite.

Owner:SHANGHAI PRET COMPOSITES +1

Negative-ion, far-infrared, antibacterial and anti-mite compound polyester fibers and manufacturing method thereof

InactiveCN107083579AWith far infrared heating performanceAntibacterial and anti-mite effectMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to negative-ion, far-infrared, antibacterial and anti-mite compound polyester fibers and a manufacturing method thereof. The compound polyester fibers are added with a negative-ion additive, a far-infrared additive and an antibacterial and anti-mite additive, wherein the negative-ion additive, the far-infrared additive and the antibacterial and anti-mite additive respectively account for 2%, 5% and 6% by mass in the compound polyester fibers; the negative-ion additive comprises an additive carrier and tourmaline negative-ion powder; the far-infrared additive comprises an additive carrier, Tai Chi stone powder, ZrO2 nano-powder, nano-silicon dioxide, nano-aluminum oxide, nano-manganese oxide and nano-calcium oxide; the antibacterial and anti-mite additive comprises an additive carrier, nano-Cu-ZnO compound particles, nano-titanium dioxide, nano-zinc oxide and nano-silicon dioxide; and the additive carrier is TiO2 hollow spheres.

Owner:GUANGZHOU ZHONGCHENG NEW MATERIALS TECH

Preparation method of nanometer zinc oxide

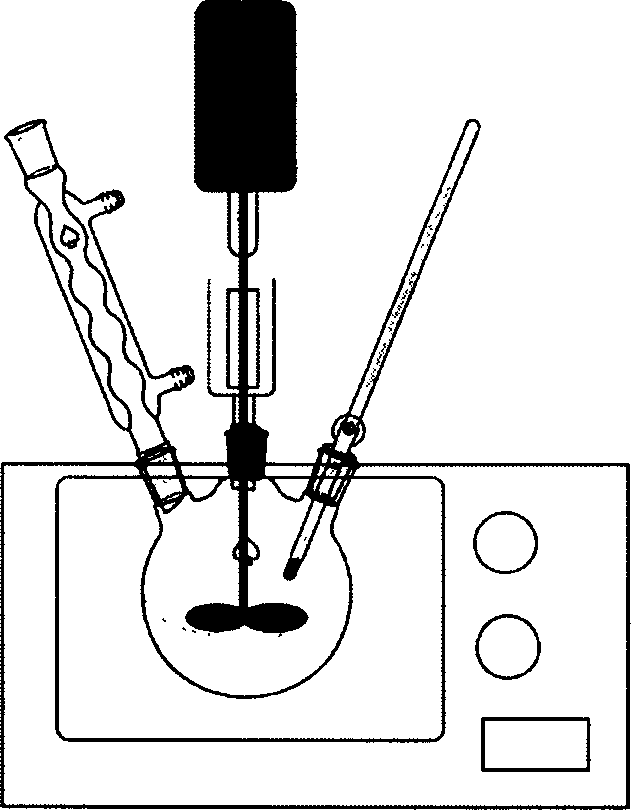

A process for preparing nano-zinc oxide includes such steps as dissolving soluble Zn salt and urea in water, microwave radiating while reacting by homogenizing-depositing method to obtain the deposit of alkaline zinc carbonate, vacuum drying, ball grinding, calcining to obtain the crystal grains of nano-zinc oxide, mixing with surface modifier, organic solvent and disperser, ball grinding, and microwave radiating which surface modifying.

Owner:SUZHOU UNIV

Surface modified nano zinc oxide water dispersion and its preparing method and use

InactiveCN1511889AAvoid reunionEasy to operateInorganic pigment treatmentFibre treatmentZno nanoparticlesWater soluble

The present invention belongs to the field of inorganic material, and is especially surface modified nano zinc oxide water dispersion and its preparation process and use. The water dispersion consists of: nano zinc oxide 0.1-10 wt%; hydrated SiO2 0.06-10 wt%, hydrated Al2O3 0.12-20 wt% or hydrated Fe2O3 0.05-10 wt%; silane coupling agent 0.1-10 wt%; and water soluble polymer 0.2-9 wt% other than water. The water dispersion is prepared through depositing hydrated SiO2, hydrated Al2O3 or hydrated Fe2O3 onto the surface of zinc oxide, and subsequent homogeneous mixing with silane coupling agent, water soluble polymer and water. The zinc oxide inside the water dispersion is dispersed homogeneously and stably without aggregation, and the water dispersion of the present invention may be used in preparing uvioresistant fabric.

Owner:BEIJING INST OF CLOTHING TECH

Anti-corrosion recombined composite bamboo material and manufacturing method thereof

ActiveCN103770168AImprove corrosion resistanceGood weather resistanceWood treatment detailsWood veneer joiningNano zinc oxideCorrosion prevention

The invention discloses an anti-corrosion recombined composite bamboo material and a manufacturing method thereof. The anti-corrosion recombined composite bamboo material is manufactured by utilizing bamboo as a main raw material, the density of the anti-corrosion recombined composite bamboo material is 0.9-1.50g / cm<3> and the water-absorbing thickness expansion ratio in the thickness direction and width direction of the anti-corrosion recombined composite bamboo material is respectively less than 1.5%; the anti-corrosion recombined composite bamboo material achieves a strong anti-corrosion level and has a bacterium damaged degree of zero level. The manufacturing method comprises the following steps: processing raw bamboo into bamboo strips, and then rolling the bamboo strips to obtain defibered bamboo bundles; digesting the defibered bamboo bundles by use of a dilute base solution and water sequentially, drying the bamboo bundles, and performing high-pressure transfusing on the bamboo bundles by use of a mixed aqueous solution of nano zinc oxide and bamboo mildew remover; then performing oxygen-exclusion drying treatment, high-temperature treatment and humidifying treatment; performing gumming, drying, curtain weaving, cold pressing and sizing, thermosetting and cooling equalization treatment, so as to obtain the anti-corrosion recombined composite bamboo material. The anti-corrosion recombined composite bamboo material has the advantages of corrosion resistance, weather resistance, insect prevention and good dimensional stability, and can be used for outdoor decoration.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

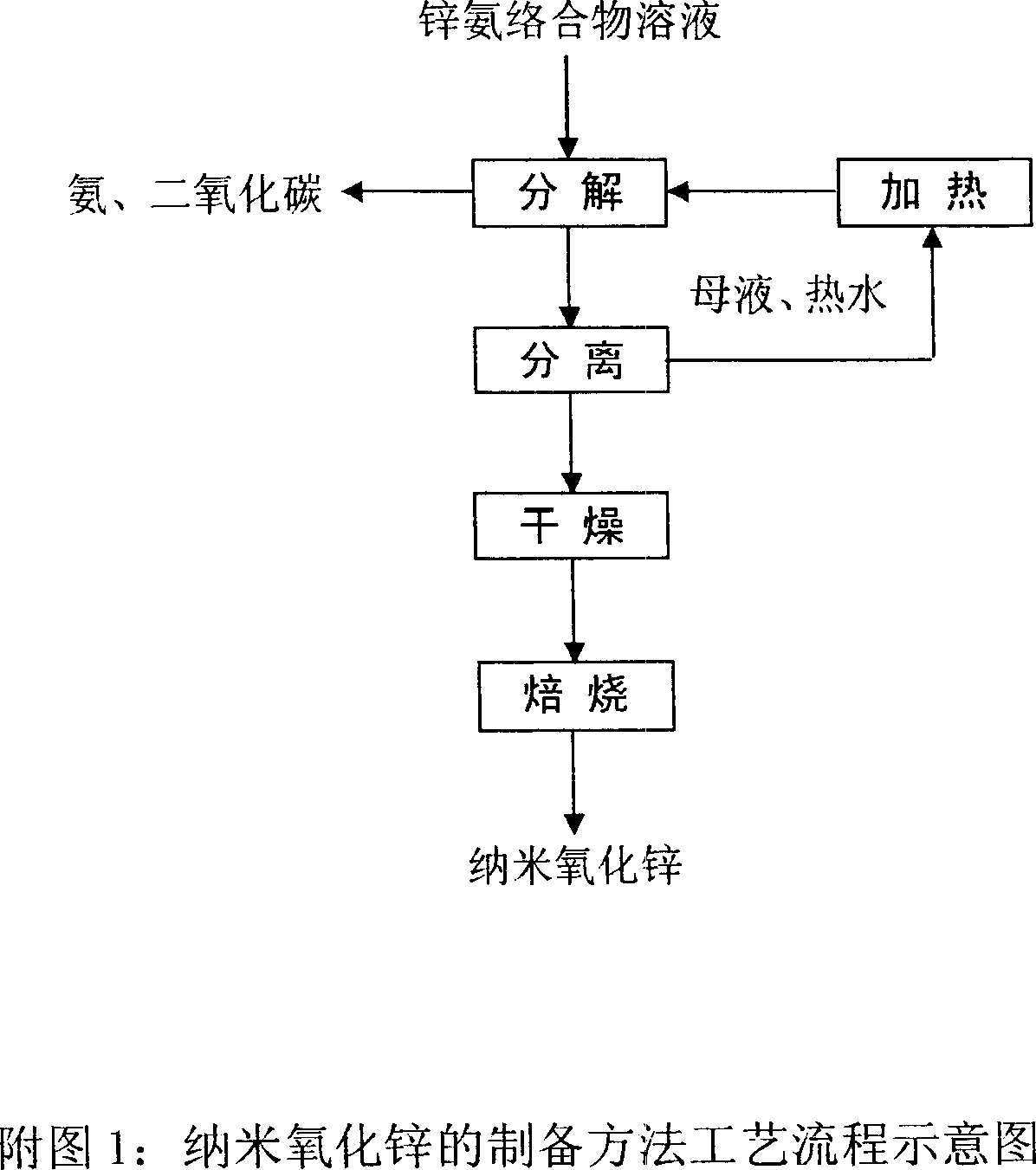

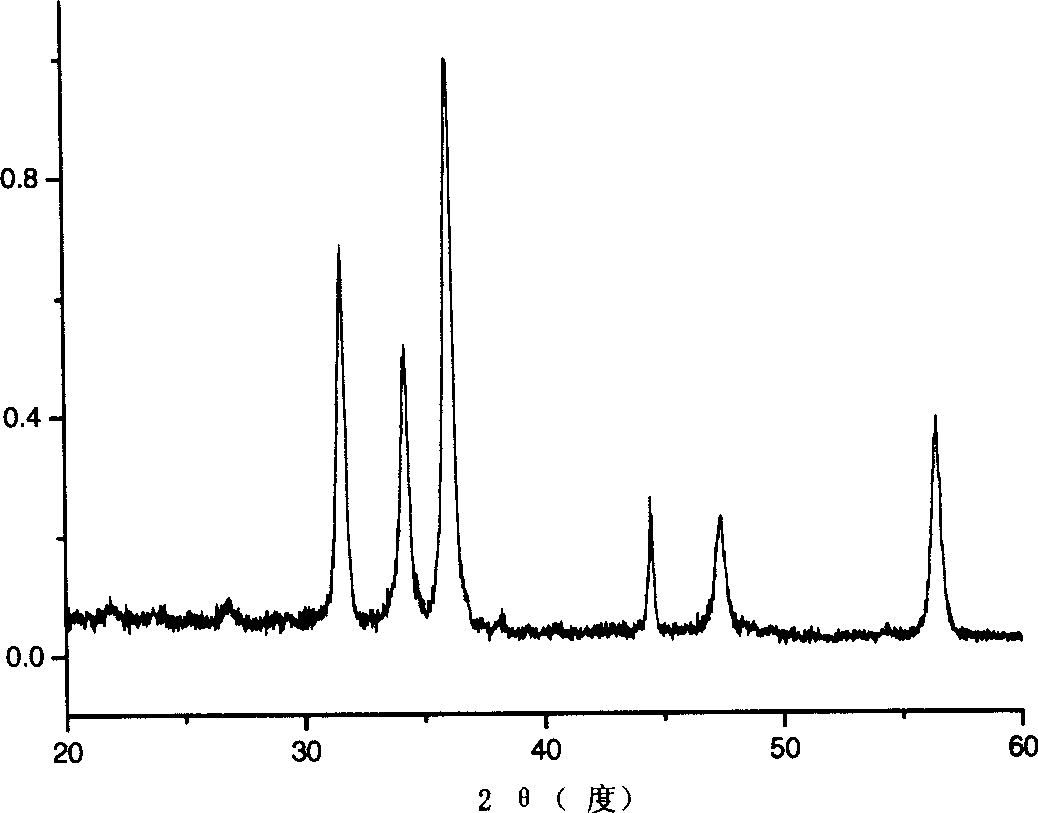

Preparing process of nano zinc oxide

InactiveCN1986421AUniform particle sizeUniform sizeNanostructure manufactureZinc oxides/hydroxidesDecompositionManganese

The process of preparing nanometer zinc oxide with low grade zinc oxide containing material includes the following steps: leaching the material with the mixed solution of ammonium bicarbonate and ammonia, separating to eliminate insoluble impurity, redox to eliminate Fe, Mn, Pb and other metal impurity to obtain zinc-ammonia complex solution; heating the zinc-ammonia complex solution to 90-100 deg.c through continuous mixing with hot circular mother liquid or hot water for fast continuous decomposition of zinc-ammonia complex; controlling the flow rate ratio between the circular mother liquid and the zinc-ammonia complex solution in 2-20, separating the basic zinc carbonate crystal continuously from the decomposed solution; drying and roasting at 400-600 deg.c for 1-4 hr to obtain the nanometer zinc oxide product of homogeneous size 10-50 nm.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Non-toxic anti-pollution paint for sea and method for preparing same

InactiveCN101333348AEasy to buyEasy to synthesizeAntifouling/underwater paintsPaints with biocidesHypochloriteElectrolysis

Nontoxic marine anti-fouling dope and a preparation method thereof are disclosed, belonging to technical fields of anti-fouling dope and underwater dope. The nontoxic marine anti-fouling dope contains film forming matter, nontoxic antifouling compound, dye, addition agent and water. The nontoxic antifouling compound is pre-dispersed slurry prepared by adding super-fine tourmaline powder and nano zinc oxide powder into 10 times amount of water, coating with sodium alkylbenzene sulfonate while heating and stirring. The nontoxic marine anti-fouling dope can be prepared through the steps of adding the nontoxic antifouling compound into ethanol aqueous solution, adjusting pH value to be 9-12, adding silicon ester ethanol solution to react for 2-4h, bathing in water and separating, and drying. The tourmaline of the nontoxic anti-fouling dope automatically develops an electric field on the surface of the dope in the seawater to enable the seawater to electrolyse to produce hypochlorite ions, which can prevent halobios to adhere or grow on the boat and the structure. The ion membrane is approximately 10 microns and causes no environment pollution. The nontoxic marine anti-fouling dope is mainly suitable for underwater fouling prevention.

Owner:DALIAN MARITIME UNIVERSITY +1

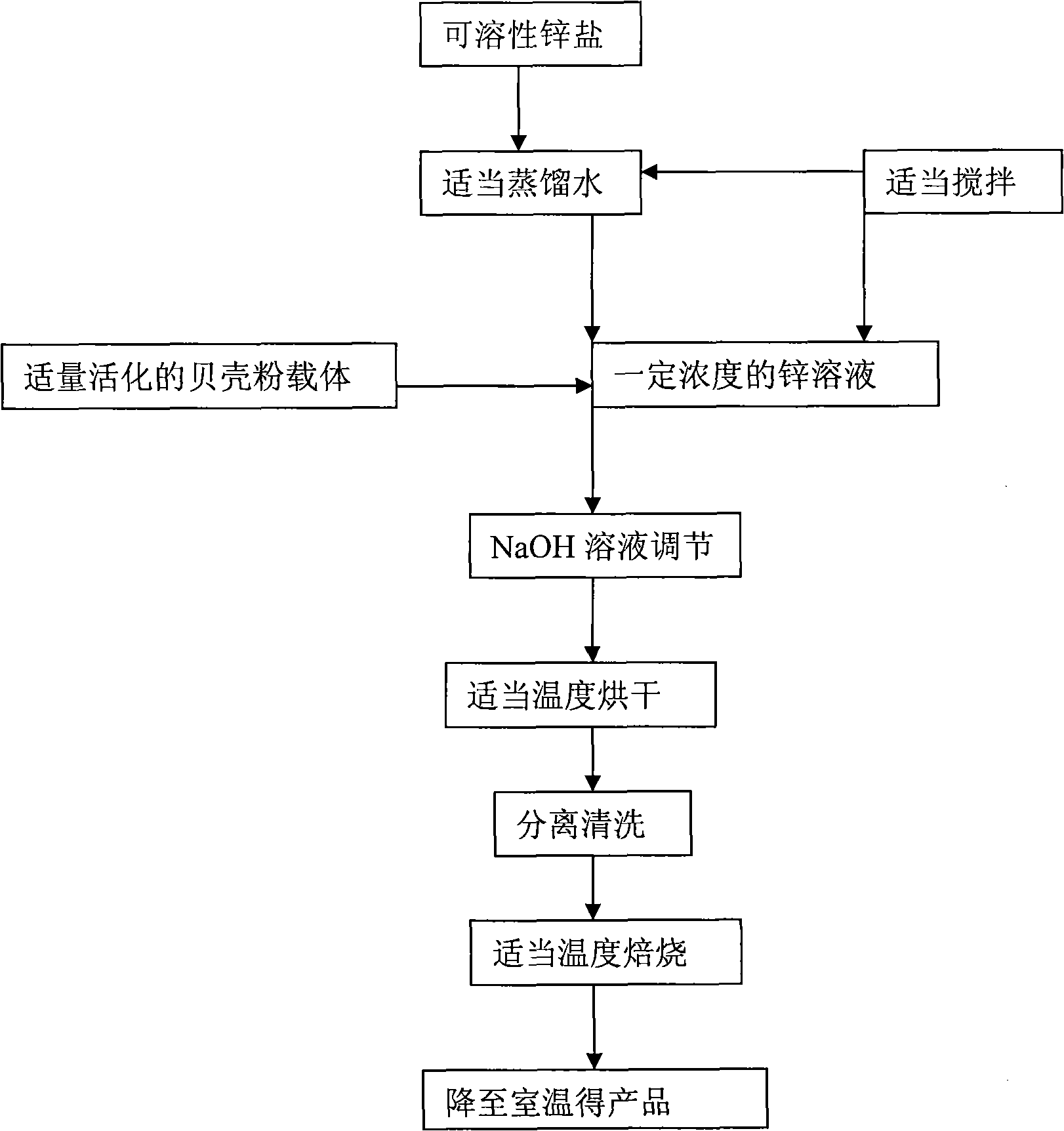

Method for preparing nano zinc oxide using shell powder as carrier

InactiveCN101352676ASolve associativitySolve for uniformityCatalyst carriersCatalyst activation/preparationFiberZno nanoparticles

The invention discloses a preparation method of nanometer zinc oxide which takes shell powder as a carrier, and in particular relates to a reproducible porous nanometer zinc oxide powder which takes the shell powder as the carrier and the preparation method thereof. In the preparation method, zinc oxide is loaded by impregnation on the shell powder carrier; firstly, zinc salt solution with appropriate concentration is prepared, and then an activated shell powder carrier is impregnated in the zinc salt solution by certain proportion, and then the obtained solution is stirred and stayed for a certain time, and treated by low temperature and abstersion pretreatment and finally roasted at high temperature, so the nanometer zinc oxide forms high-strength bond with the shell powder and promotes the catalytic activity of the nanometer zinc oxide at the same time. Impregnation can be conducted for a plurality of times to increase load. The nanometer ZnO is characterized by small particle size, good compatibility with materials, high catalytic efficiency, good stability, good regenerability, and the like, and can be applied to the fields of plastics, rubbers, fibers, coatings, home appliances, paints, ceramics, water and environment treatment, pharmaceutical and hygienic articles, etc. In terms of sources of raw materials and production technology, the preparation method not only reduces the production cost of nanometer ZnO catalyst but also is helpful for disposal of the increasingly serious environmental problems, thus bearing great environmental protection significance.

Owner:GUANGDONG OCEAN UNIVERSITY

Porous carbon adsorbing agent containing nano zinc oxide micropartical and its preparation process and application

InactiveCN1724138AImprove adsorption capacityAvoid breedingOther chemical processesSorbentPorous carbon

A porous charcoal adsorbent for cleaning environment is composed of porous charcoal as carrier and zinc oxide nano-particles as active component. Its preparing process includes such steps as reaction between zinc nitrate micro-emulsion and sodium hydroxide to obtain zinc oxide nano-particles, carrying them by porous charcoal and heat treating. Its advantages are high absorptive power and high photo-catalytic and antibacterial activities.

Owner:SUN YAT SEN UNIV

Efficient and environmentally-friendly antibacterial and mildewproof inorganic composite nano-powder slurry and its preparation method

Relateing to the field of antibacterial materials, the invention specifically provides an efficient and environmentally-friendly antibacterial and mildewproof inorganic composite nano-powder slurry obtained through compounding nano-magnesium oxide and other nano-inorganic materials and its preparation method. The nano-powder slurry takes nano-magnesium oxide as the main body, which is then compounded with one or more inorganic materials of nano-zinc oxide, nano-titanium oxide, nano-copper oxide, nano-cuprous oxide, nano-silver oxide, nano-zinc sulfide, nano-zirconium oxide, nano-yttrium oxide, nano-alumina, and nano-calcium oxide so as to form the nano-powder slurry, which comprises, by weight percent: 0.1-40% of nano-magnesium oxide, 0.01-40% of other inorganic materials, 0.5-12% of a polymeric dispersant, and the balance a solvent. In the method, a nano-inorganic material enters a solution composed of the polymeric dispersant and the solvent by means of high speed dispersion according to a predetermined proportion, and after ball milling, the composite nano-powder slurry can be obtained. The composite nano-powder slurry can be applied in antibacterial coatings, deodorants, textiles, paper products, plastics, rubbers, water treatment agents, ship protective agents, cosmetics and other aspects.

Owner:广东腐蚀科学与技术创新研究院

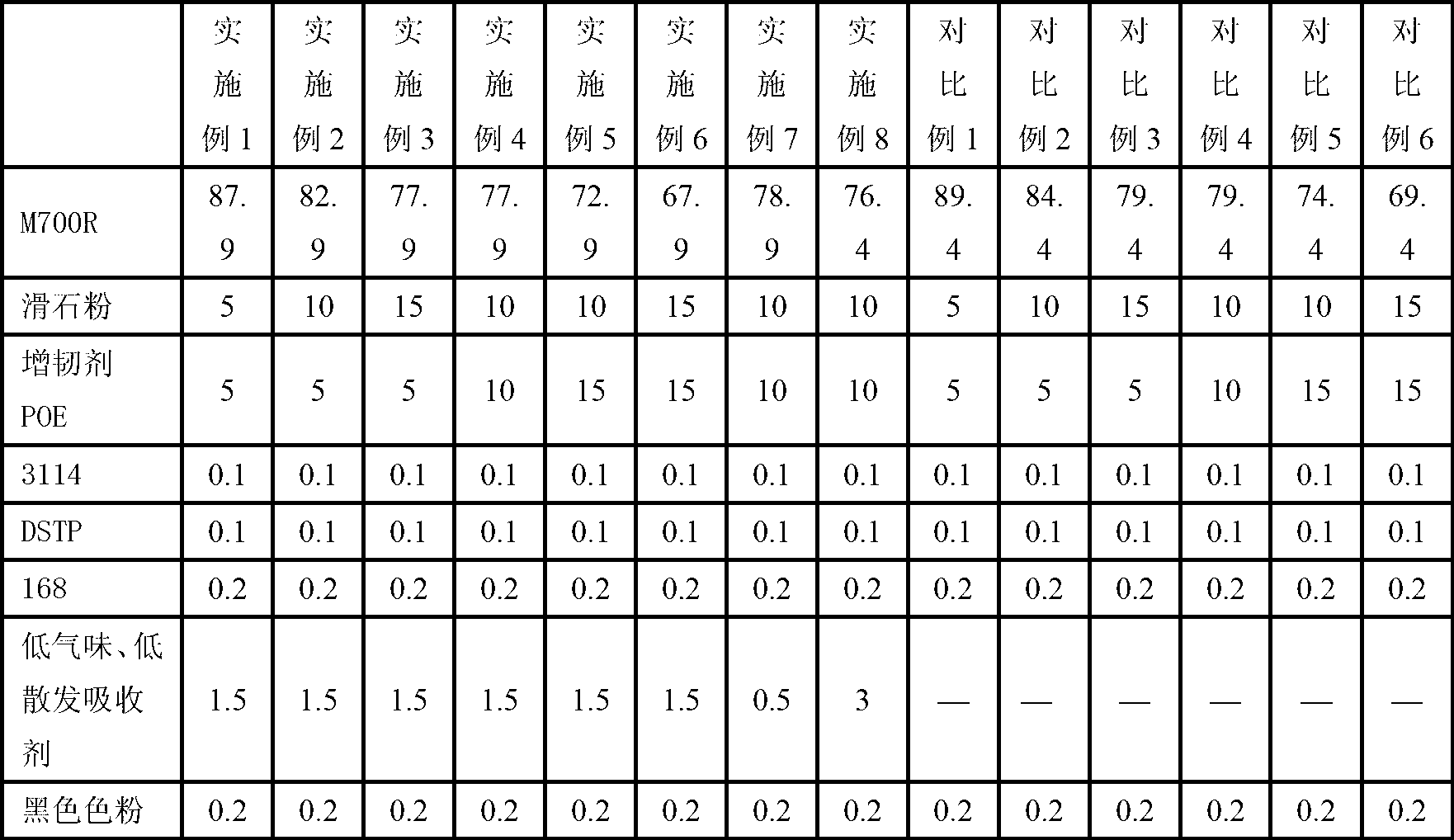

Low-odor low-volatilization modified polypropylene material and preparation method thereof

The invention discloses low-odor low-volatilization modified polypropylene material and a preparation method thereof. The low-odor low-volatilization modified polypropylene material is composed of the following raw materials by weight, polypropylene 65-89%, low-odor low-volatilization absorbent 0.5-3%, inorganic filler 5-15%, polyolefin elastomer (POE) flexibilizer 5-15% and antioxygen 0.1-2%. The low-odor low-volatilization modified polypropylene material has the advantages that nano-zinc oxide which is prepared by a microemulsion method is used for preparing nano-zinc oxide modified active carbon materials and loaded on the surface of multihole active carbon, residual monomers, decomposers and organic acid in base materials of polypropylene are effectively absorbed, obvious effect of absorbing odor is achieved, preparing process is simple, and production cost in low.

Owner:SHANGHAI PRET COMPOSITES

Thermostable white nano far-infrared ceramic powder and preparation method thereof

The invention discloses a thermostable white nano far-infrared ceramic powder and a preparation method thereof. The thermostable white nano far-infrared ceramic powder is prepared from the following components in percentage by weight: 20-30% of nano alumina, 3-8% of nano magnesia, 15-25% of nano monox, 10-20% of nano zirconia, 15-25% of nano zinc oxide, 7-10% of nano titanium oxide, 1-3% of nano rare earth oxide and 0.1-0.3% of nano precious metal oxide. In the invention, the nano rare earth oxide is one of yttrium oxide or lanthana or cerium oxide, and the nano precious metal oxide is one of platinum oxide or palladium oxide. The nano far-infrared ceramic powder can be subjected to subsequent processing at the high temperature of 1300-1450 DEG C, without reduction of radiance and radiation intensity, wherein the radiance can reach 0.90-0.94, and the nano far-infrared ceramic powder is white and can be widely applied to far-infrared household porcelain, wall and floor tiles, heating ceramic plates and high-temperature coating.

Owner:JINGDEZHEN BOZHI CERAMICS

Well Treatment Compositions and Methods Utilizing Nano-Particles

Disclosed embodiments relate to well treatment fluids and methods that utilize nano-particles. Exemplary nano-particles are selected from the group consisting of particulate nano-silica, nano-alumina, nano-zinc oxide, nano-boron, nano-iron oxide, and combinations thereof. Embodiments also relate to methods of cementing that include the use of nano-particles. An exemplary method of cementing comprises introducing a cement composition into a subterranean formation, wherein the cement composition comprises cement, water and a particulate nano-silica. Embodiments also relate to use of nano-particles in drilling fluids, completion fluids, stimulation fluids, and well clean-up fluids.

Owner:HALLIBURTON ENERGY SERVICES INC

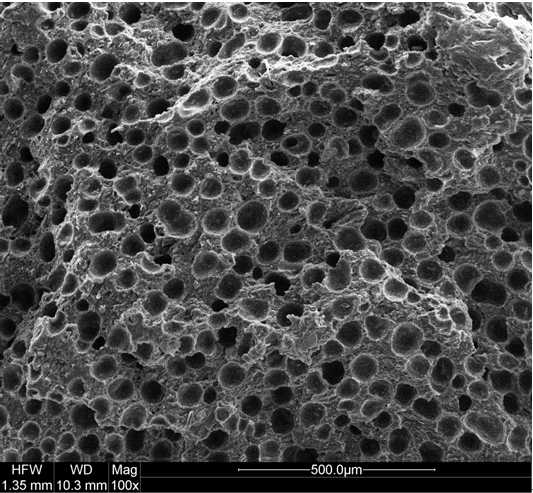

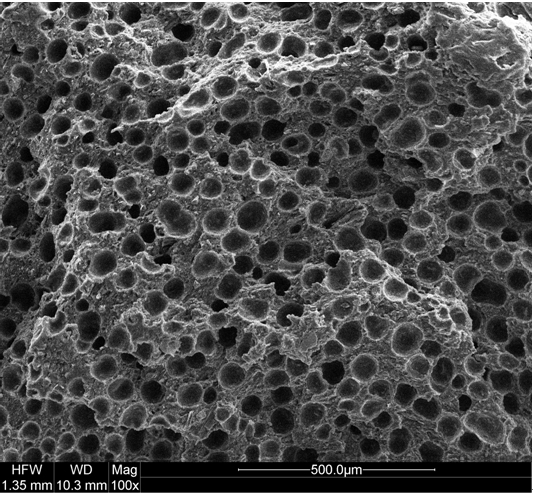

Micro-foaming wood plastic composite material plate for building template and preparation method thereof

The invention discloses a micro-foaming wood plastic composite material plate for a building template and a preparation method thereof. The wood plastic composite material consists of polrvinyl chloride, wood powder, lightweight active calcium carbonate, a foaming agent, a foaming stabilizer, polyethylene wax, a titanate coupling agent, chlorinated polyethylene, an adsorbent nano calcium oxide, an auxiliary foaming agent nano zinc oxide, a silicone processing adjuvant and reinforced fiber alkali-free glass fiber. The preparation method comprises the following steps of: mixing the wood powder and the nano calcium oxide powder at a high speed; adding the titanate coupling agent and then mixing at the high speed; adding the rest materials; mixing at the high speed and then mixing at a low speed to obtain a premix; extruding the premixing by using an extruder; and cooling very quickly to obtain the product. The micro-foaming wood plastic composite material plate has the characteristics ofhigh surface hardness, high flowability, high strength, high toughness, high dimensional stability, long service life and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Anion easy-cleaning functional ceramic additive and preparation method thereof, ceramic prepared by using additive and preparation method thereof

The invention belongs to the technical field of ceramics, and particularly relates to an anion easy-cleaning functional ceramic additive and a preparation method thereof, a ceramic prepared by using the additive and a preparation method thereof. The additive is prepared from the following raw materials in percentage by mass: 10-16% of Chongguang stones with a particle size of 5-20 microns, 16-25% of tourmaline with a particle size of 5-15 microns, 5-15% of copper pectolite with a particle size of 5-20 microns, 8-12% of nano titanium dioxide, 6-8% of nano zinc oxide, 5-10% of lead-free frits, 7-20% of rare earth materials, 8-10% of superfine alumina, 8-15% of superfine quartz powder and 5-10% of sodium carbonate. The preparation method of the additive comprises the following steps of carrying out mixed ball-milling on the lead-free frits, the rare earth materials, the superfine alumina, the superfine quartz powder and the sodium carbonate firstly; and then, adding the Chongguang stones, the tourmaline, the copper pectolite, the nano titanium dioxide and the nano zinc oxide into the obtained product, and ball-milling the obtained mixture, so that the additive with a particle size of 1-10 microns is obtained. The additive disclosed by the invention has a self-polarizing performance, and has strong adsorption and decomposition functions, so that negative ions are produced; and after the additive is added into a ceramic, the ceramic is extremely easy to clean and not stained, and has no hidden dirt, therefore, the ceramic has a strong affinity to water.

Owner:ZIBO BAIKANG ECONOMIC & TRADE

Process for preparing textile nano function finishing agent

The invention relates to a preparation method of a textile nano-functional finishing agent mainly containing inorganic nano-materials for producing antibacterial, deodorant, health-care and skin-care functional textiles. The inorganic nano-materials are dispersed in an aqueous solution of a surfactant under stirring conditions, Stir continuously to form a fluid colloid, then add auxiliary components, and continue to stir evenly to make a nano-functional finishing agent; the inorganic nano-material is nano-zinc oxide, nano-titanium dioxide or a mixture of the two, and its content is 0.01% by weight of the finishing agent-30 %, the rest are auxiliary ingredients, and the total weight percentage of the finished product is 100%; the nano-functional finishing agent is processed through dipping, rolling, baking, baking process steps or directly spraying the raw materials of textiles to make it antibacterial, deodorant , health care and skin care functions are used to prepare fabrics. The method has the advantages of simple production process, reasonable raw materials and formula, good product performance, and is an ideal fabric processing technology for disease prevention and health care.

Owner:QINGDAO UNIV

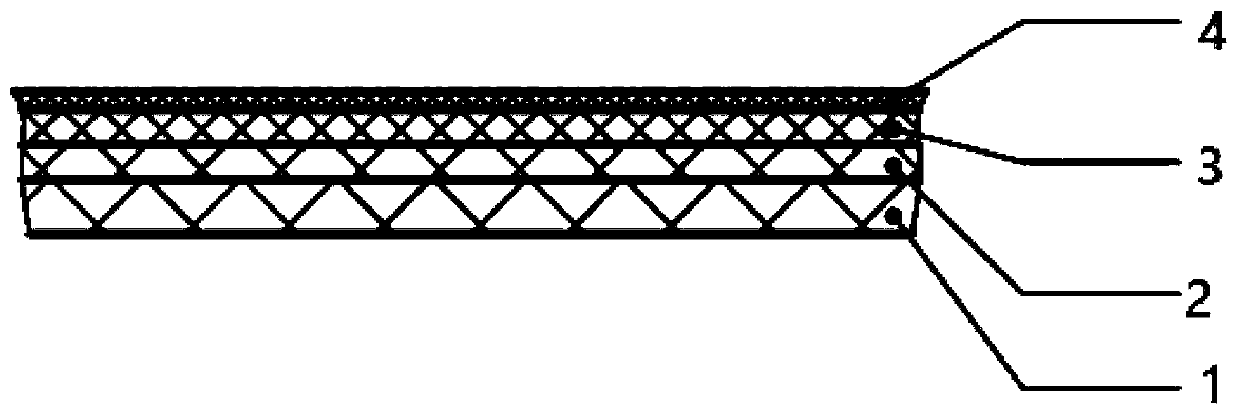

Antibacterial and antiviral non-woven fabric, preparation method of fabric and mask containing fabric

ActiveCN111172749AImprove antibacterial propertiesGood antiviral effectBiochemical fibre treatmentNon-woven fabricsNonwoven fabricAntibacterial agent

The present invention relates to an antibacterial and antiviral non-woven fabric, a preparation method of the fabric and a mask containing the fabric. The antibacterial and antiviral non-woven fabriccontains nano-silver, and also contains an inorganic antibacterial agent and / or an organic antibacterial agent; the inorganic antibacterial agent comprises any one or combination of at least two of nano titanium dioxide, nano zinc oxide, bismuth tungstate and nano silicon dioxide; and the organic antibacterial agent comprises chitosan and / or quaternary ammonium salt. The mask sequentially comprises a first fabric layer, the antibacterial and antiviral non-woven fabric and a second fabric layer from inside to outside. While the air permeability is not affected, the mask is endowed with the long-acting antibacterial, anti-haze and antiepidemic antiviral properties, has the catalytic degradation function for harmful gases such as formaldehyde and benzene in air, and can be repeatedly washed with water to be recycled, thereby greatly reducing the use cost of the protective mask.

Owner:同曦集团有限公司

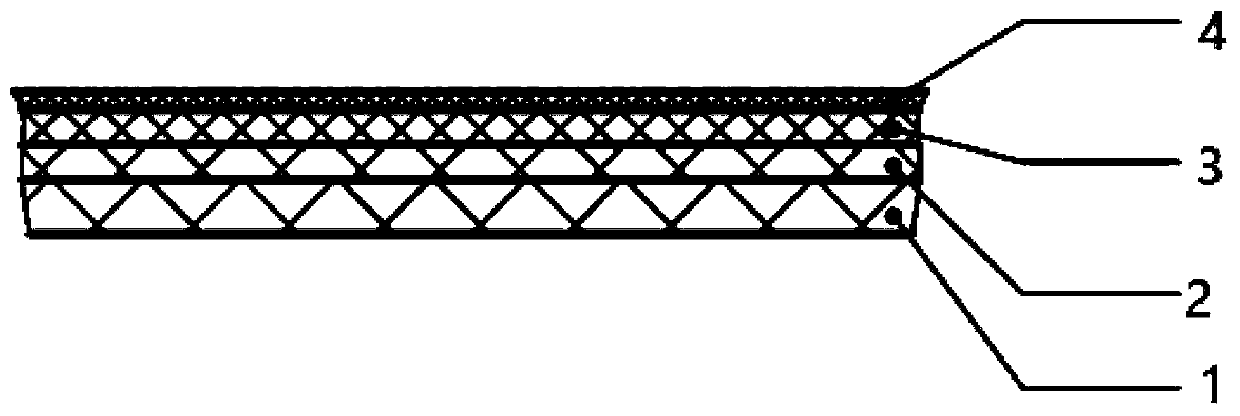

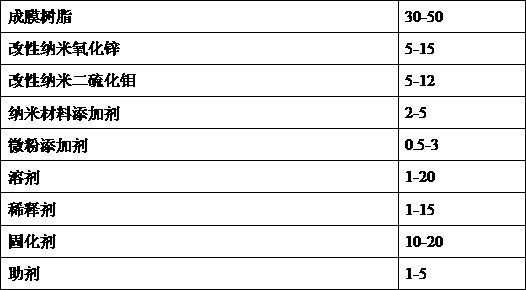

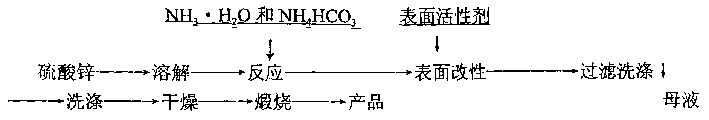

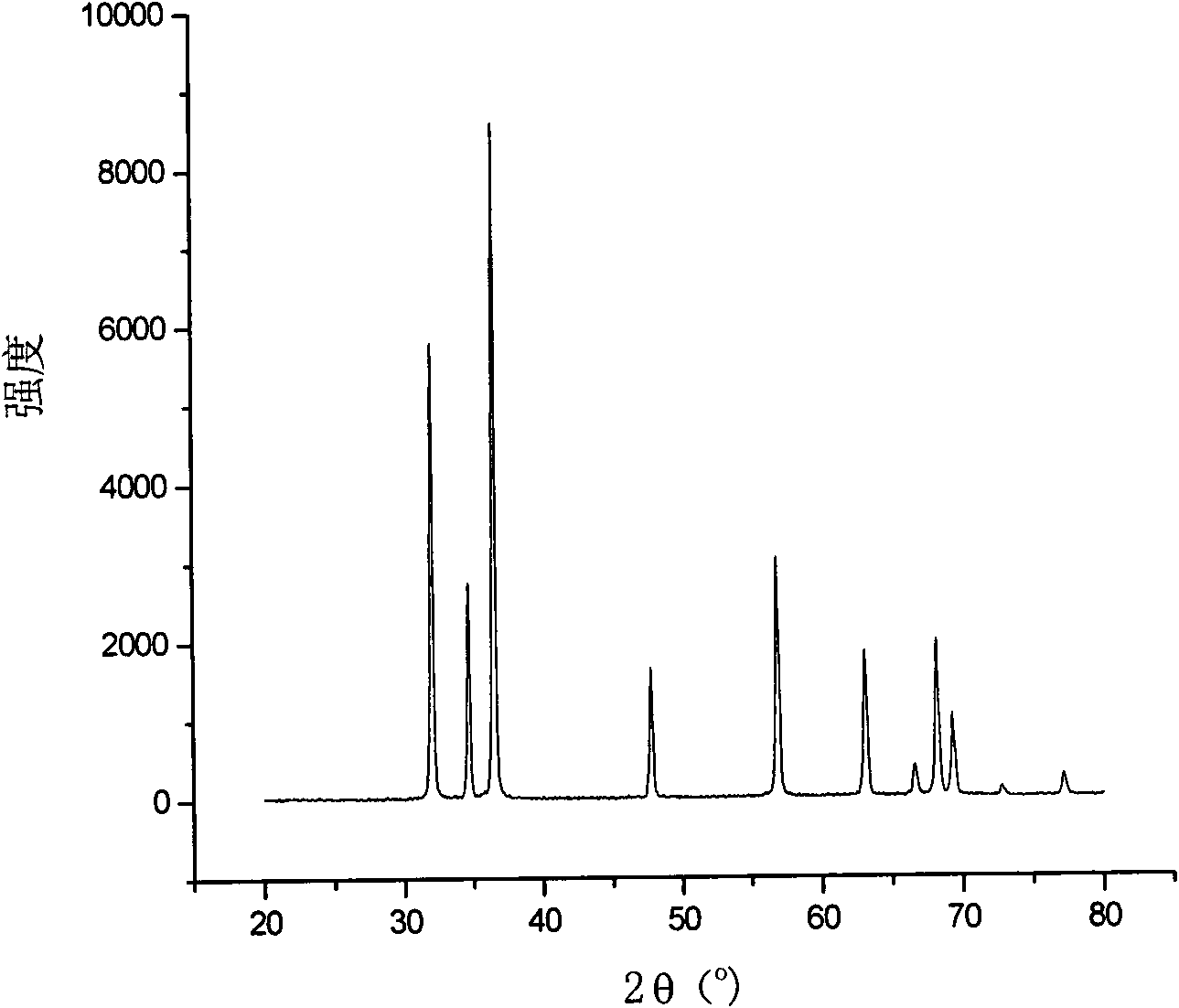

Temperature-resistant and wear-resistant nano composite functional coating

ActiveCN103232795AMeet needsGood synergyPolyurea/polyurethane coatingsEpoxy resin coatingsNano zinc oxideMolybdenum disulfide

The invention relates to a nano composite functional coating, a preparation method thereof and a use thereof. The coating comprises film-forming resins, modified nano zinc oxide, modified nano molybdenum disulfide, a nano material additive, a micro powder additive, a solvent, a diluent, a curing agent and auxiliaries in a certain mass ratio. The novel nano composite functional coating shows excellent high temperature resistance and abrasion resistance, and especially meets the environment requirement for high-temperature work; besides, the wear rate of the material is reduced and the service life of the material is prolonged; and therefore, the nano composite functional coating has wide industrial application prospect.

Owner:北京希柯节能环保科技有限公司

Method for preparing high dispersity nano zinc oxide

The invention relates to a method to produce highly dispersed nano-zinc oxide. Zinc source and ammonium salt are mixed according to molar ratio 1:0.5-10 between zinc and ammonium; according to the molar ratio 1:0.5-10 between zinc and ammonia in ammonia water, concentration of which is 10-25 percent, ammonia water is added into the mixture, stirred for 1-10 hours, aged for 1-2 days and filtered; filtrate is steamed under 60 DEG C - 95 DEG C until white precipitate comes out and white precipitate is obtained after filtering; the white precipitate is washed by deionized water until pH value is 6-8, dried under 50 DEG C -110 DEG C, roasted for 1-8 hours under 200 DEG C-800 DEG C to get the nano-zinc oxide. The invention has the advantages of simple production process, mild reaction condition and getting nano-zinc oxide with large specific surface area, good dispersion, non-aggregation and comparatively good photo-catalytic activity.

Owner:CHINA RES INST OF DAILY CHEM IND

Process for preparing nano zinc oxide

InactiveCN1396117ASmall specific surface areaLarge specific surface areaZinc oxides/hydroxidesAmmonium salt fertilisersDispersitySulfate

A process for preparing nanometre zinc oxide includes such steps as proportionally dropping ammonia water to a zinc sulfate solution, adding ammonium hydrogen carbonate to obtain ZnCO3.Zn(OH)2 deposit, separation, washing with deionized water, vacuum drying to obtain a composite presoma, and then calcining at 150-600 deg.C for 1.5-2.5 hr to obtain the product. Its advantages are low cost and high dispersity of product in water.

Owner:SHANDONG XIAOYA GRP CO LTD

Absorbing desulfurizing catalyst for catalytic cracking petroleum and preparing method thereof

InactiveCN1583962ASuitable for desulfurizationOctane has little effectHydrocarbon oils refiningNano zinc oxidePetroleum

A kind of catalyst for Fcc gasoline's adsorption desulfuration contains in weight percent: 10-85% nano zinc oxide, the atomic diameter of which is 100-500 mu m, 5-80% silica oxide, 5-30% alumina oxide, and 4-45% nickel oxide. The method of preparation is: (1) Mix evenly the nano zinc oxide, silica oxide, alumina oxide, and nickel oxide; dry the particle of step (b); roast the dry particle of step(c); deoxidize the particle of step(d) by proper reductant. The portions of this catalyst remain mixed, and the method adopts the technology of roasting. The catalyst has a good strength, high desulfuration activity, and effective regeneration. Because of the adoption of nano zinc oxide, it causes little to octane number and applies to desulfuration of FCC gasoline. Moreover, the method of preparation is simple and the operation is easy.

Owner:SINOPEC QILU CO

Multifunctional green environmental protection type nanometer paint

The multifunctional green nano paint consists of mainly: quaternary methacrylic acid-butyl acrylate-styrene-methyl methacrylate copolymer emulsion 20-65 wt%; nano titania 0.3-5 wt%; nano zinc oxide 0.2-3 wt%; silica 0.3-3 wt%; nano calcium carbonate 0.5-5 wt%; deionized water 3-12 wt%; superfine talcum powder 1-3 wt%; superfine calcium carbonate 3-15 wt%; titanium white3-25 wt%; and assistants including dispersant, wetter, rheologic agent, thickener, color paste, defoaming agent, etc. 2-12 wt%. The paint of the present invention features no toxicity, no pollution, wash resistance, scratching resistance, ultraviolet resistance, ageing resistance, waterproofing and mould proofing as well as self-cleaning function, so that the paint may be used wide in the decoration of inner and outer walls and the anticorrosive treatment of metal material surface.

Owner:王崇高

Preparation method of porous nano zinc oxide (ZnO)

InactiveCN102515246AZinc oxides/hydroxidesMetal/metal-oxides/metal-hydroxide catalystsZinc hydroxideDistillation

The invention discloses a preparation method of porous nano zinc oxide (ZnO). Zinc hydroxide gel is obtained through reaction and centrifugal separation with zinc salt, alkali and deionized water as raw materials according to the mass percent of zinc salt, alkali, sublimable compound template, amine chelant and deionized water of 0.001%-85%: 0.00001%-80%: 0.001%-65%: 0.001%-80%: 0.001%-95%. Wet zinc hydroxide products are obtained through processes of distilled water washing, ultrasonic dispersion, centrifugal separation and the like of zinc hydroxide gel, sublimable compound template, amine chelant and deionized water are added then, zinc hydroxide gel is dissolved to obtain solution through ultrasonic processing, and porous nano ZnO powder is obtained after processes of reduced pressure distillation of removal solvent and volatile constituent, drying, roasting, grinding and the like. The preparation method is simple and easy in process, small in investment and beneficial for popularization and application.

Owner:NANJING FORESTRY UNIV

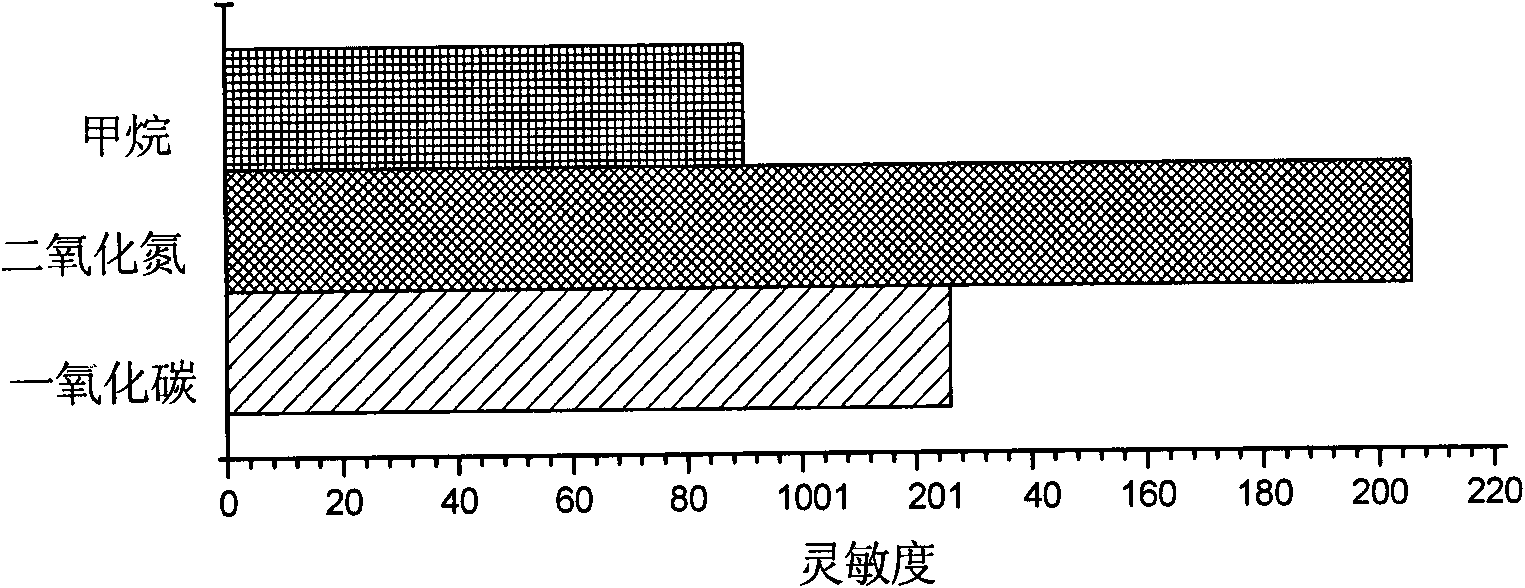

One-dimensional zinc oxide nanometer material and preparation method thereof

InactiveCN101591037AHigh crystallinitySimple stepsNanostructure manufactureZinc oxides/hydroxidesZno nanoparticlesCrystallinity

The invention provides a one-dimensional zinc oxide nanometer material and a preparation method thereof. The method comprises the steps of: performing a hydro-thermal reaction of a zinc salt solution and a sodium hydroxide solution; and successfully obtaining the one-dimensional zinc oxide nanometer material with high crystallinity by adding a surfactant and controlling reaction conditions. The diameter of one-dimensional nanometer zinc oxide is between 100 and 300nm, and the length is between 1 and 6mu m. Compared with the prior method for preparing the one-dimensional nanometer zinc oxide, the method has the advantages of low cost, simple operation, low energy consumption, high crystallinity of products and the like. The nanometer zinc oxide material has excellent gas sensitivity on gas such as methane, carbon monoxide, nitrogen dioxide and the like, and is a good gas-sensitive material.

Owner:BEIJING UNIV OF CHEM TECH

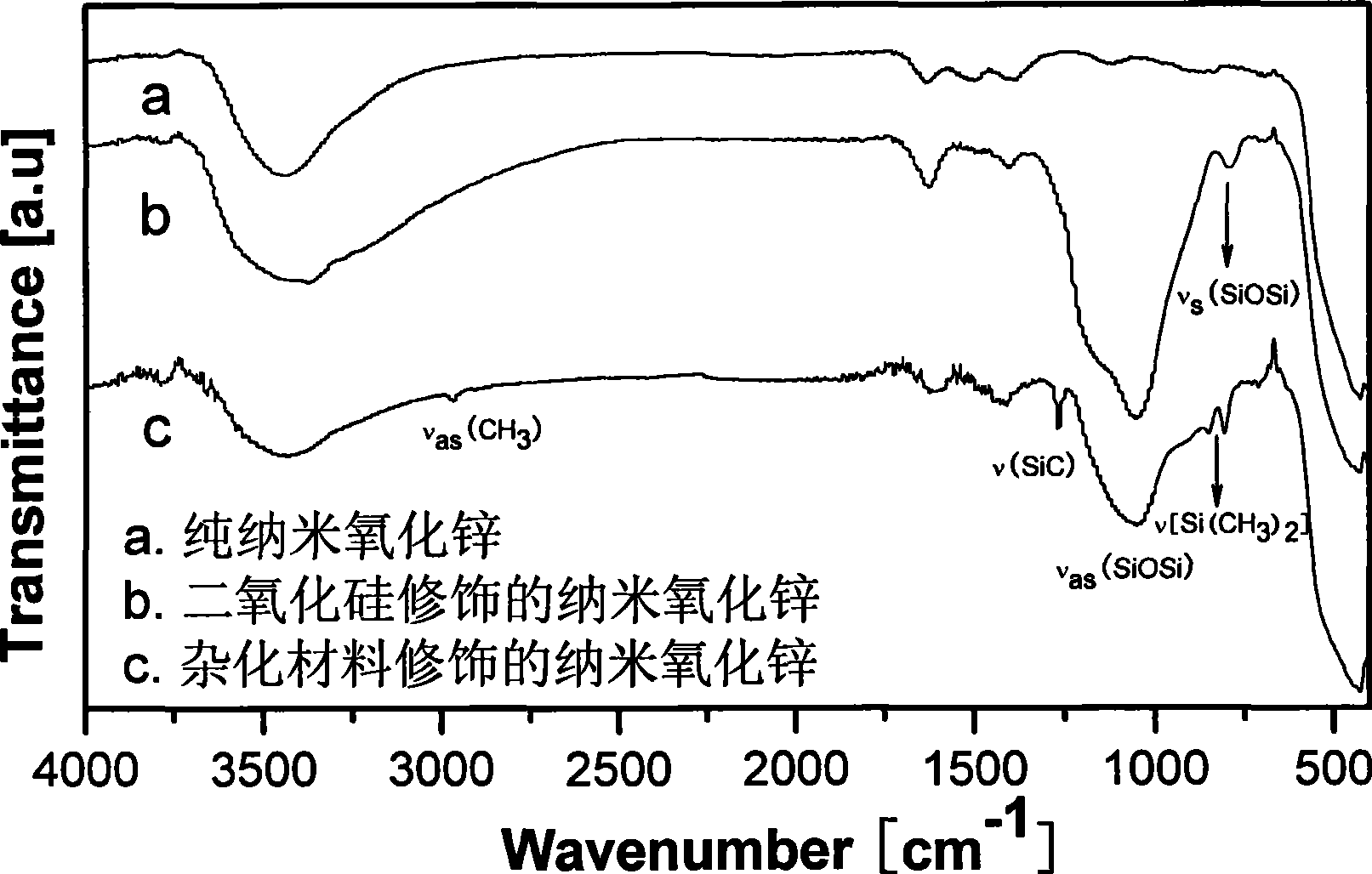

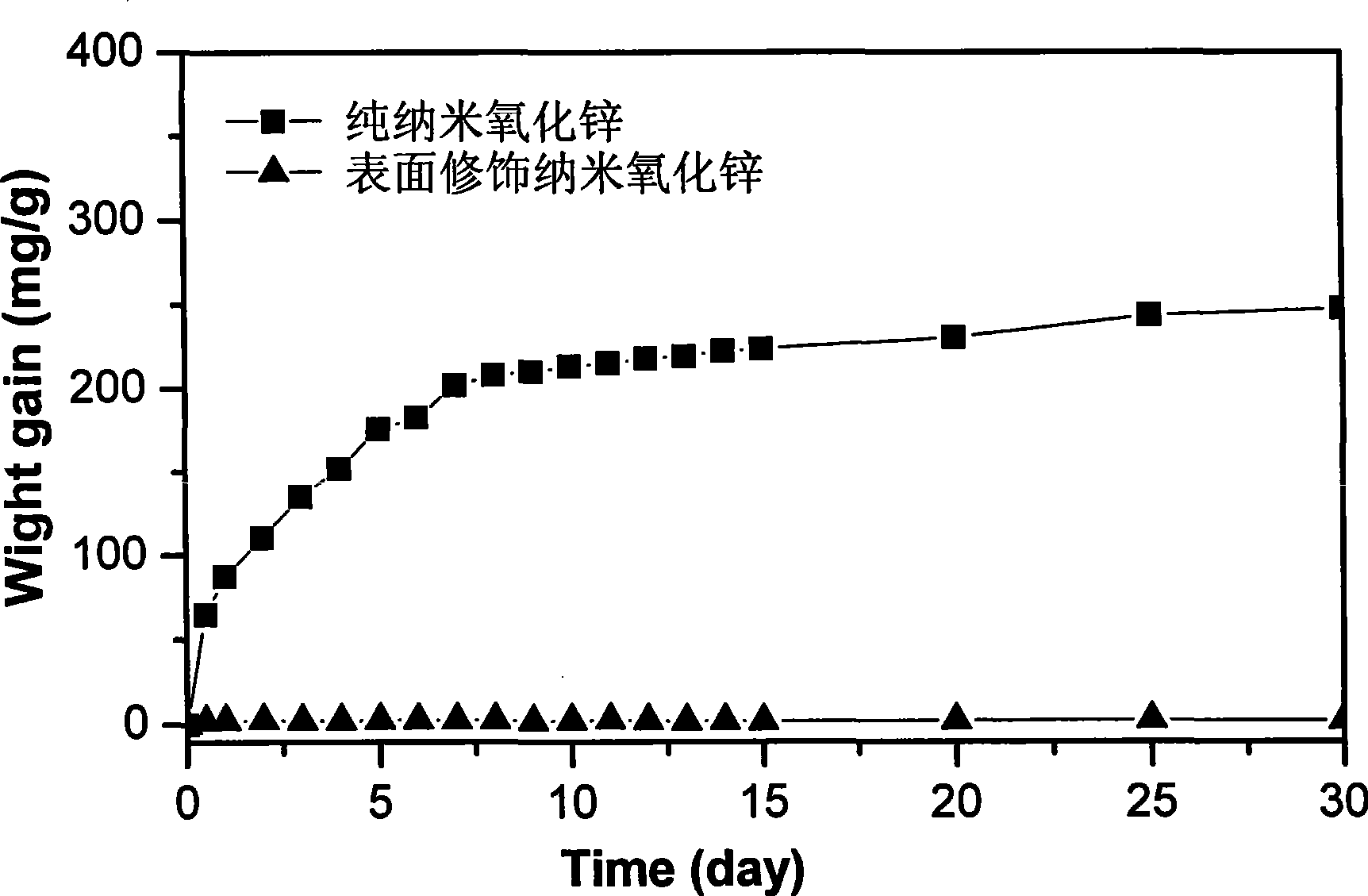

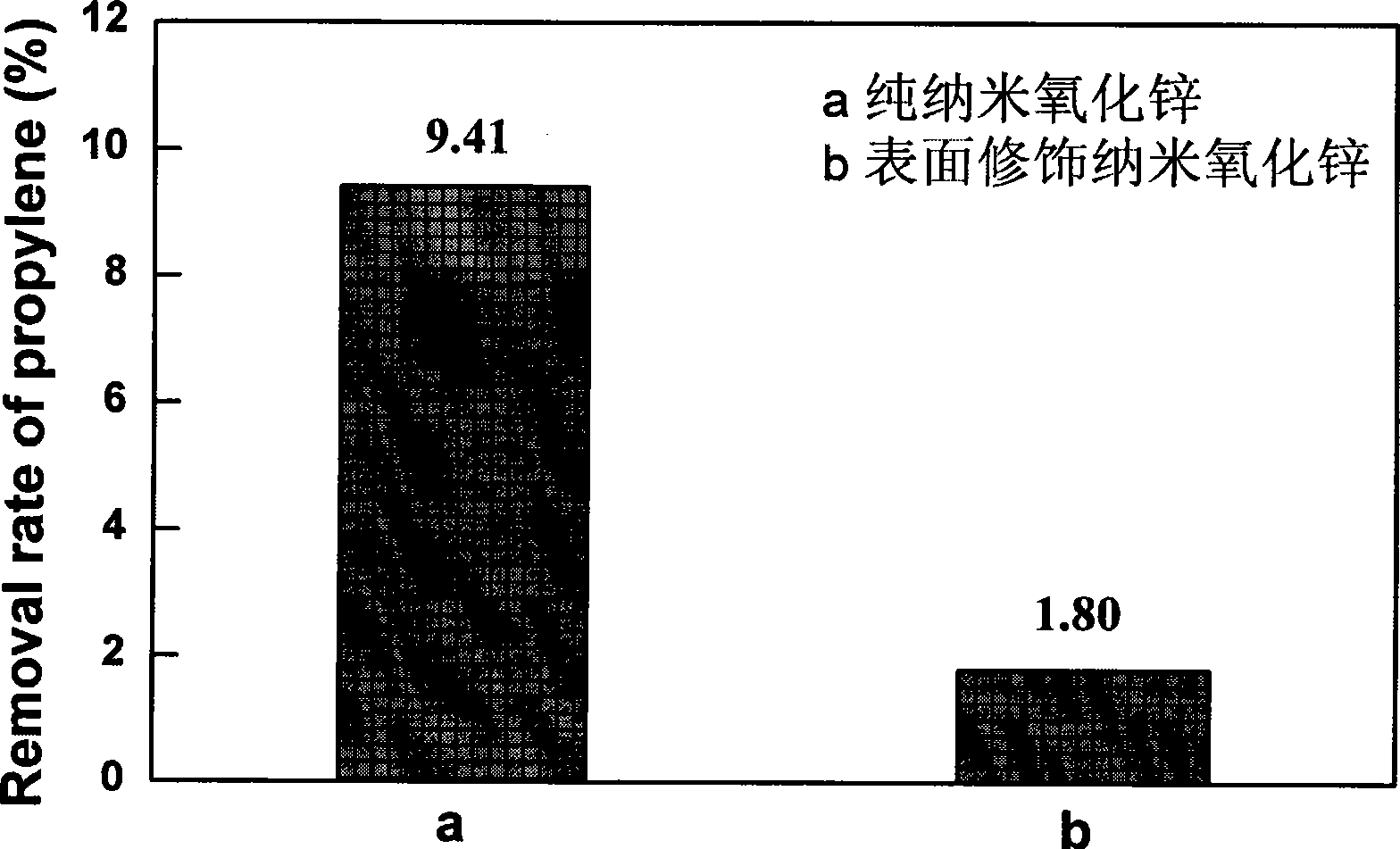

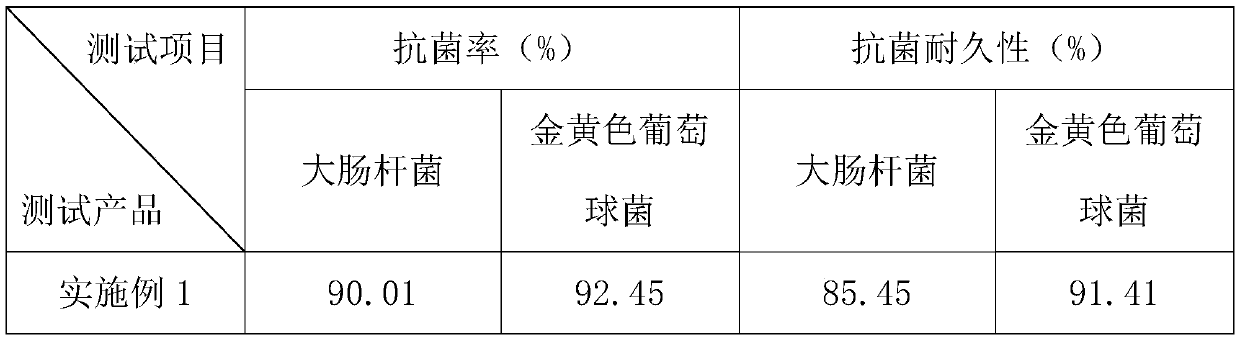

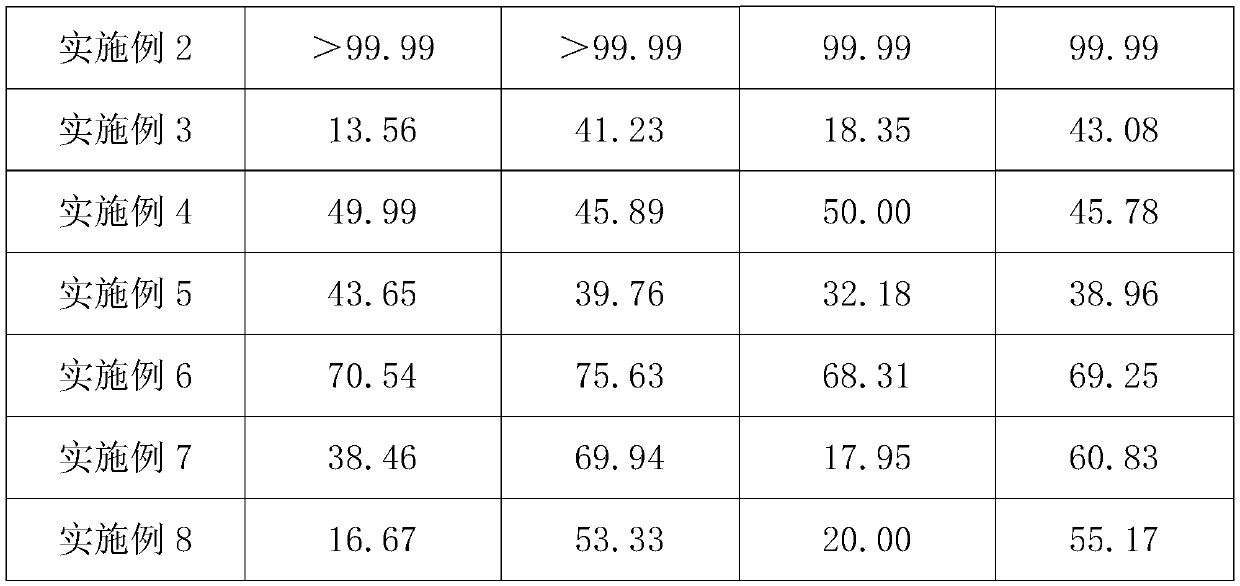

Nano zinc oxide surface modifying method

ActiveCN101543466ASimple processEasy to industrializeCosmetic preparationsToilet preparationsChemical reactionReaction temperature

The invention relates to a nano zinc oxide surface modifying method, which adopts the technical proposal comprising the following steps that: 1) nano zinc oxide powder is fully dispersed in mixed solution of deionized water and latent solvent to form slurry; and 2) a modifier consisting of tetraethyl orthosilicate and / or methyl silicate and organosilane is evenly mixed with the latent solvent, the mixture is added into the slurry in stirring, pH value is adjusted to be between 8 and 12 for reaction, the reaction temperature is about 90 DEG C and the reaction time is between 3 and 12 hours, wherein the organosilane is polydimethylsilane or / and silane coupling agent. The method adopts a common aqueous-phase chemical reaction method, uses common devices, can complete the surface modification on the nano zinc oxide powder of an organic-inorganic hybrid material through a one-step reaction, and has simple process and easy industrialization. Prepared products improve compatability with organic substrates, make the photocatalytic activity inhibited, and are particularly suitable to be used as a UV blocking agent in sun-screen cosmetics.

Owner:HENAN UNIVERSITY

Antibacterial ceramic glaze, and preparation method and application thereof

The invention relates to the technical field of architectural ceramics, and in particular, relates to antibacterial ceramic glaze, and a preparation method and an application thereof. The antibacterial ceramic glaze is composed of the following raw material components: a ceramic glaze material, an antibacterial agent, a suspending agent and a peptizing agent, wherein the antibacterial agent is a mixture of nano zirconium silicate loaded silver and nano zinc oxide, and the addition amount of the nano zirconium silicate loaded silver is 2-6% and the addition amount of the nano zinc oxide is 0.05-2% according to the weight percentage of the dry weight of the ceramic glaze material; the suspending agent is a mixture of low-viscosity sodium carboxymethyl cellulose and medium-viscosity sodium carboxymethyl cellulose; the peptizing agent is one of sodium tripolyphosphate or sodium metasilicate. The invention aims to provide the antibacterial ceramic glaze, and the preparation method and the application thereof; the prepared ceramic glaze can realize uniform dispersion of an antibacterial agent in the ceramic tile surface glaze, and has efficient sterilization and bacteriostasis effects and stable sustainable sterilization effect.

Owner:FOSHAN DONGPENG CERAMIC +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com