Antibacterial ceramic glaze, and preparation method and application thereof

A technology of antibacterial ceramics and ceramic glazes, applied in the field of architectural ceramics, can solve the problems that antibacterial agents cannot achieve the ideal antibacterial effect, antibacterial agents are easy to agglomerate, and infection, etc., to achieve stable and sustainable sterilization effects, high-efficiency sterilization and antibacterial effects, and guaranteed coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method of antibacterial ceramic glaze, the antibacterial agent is added to the ceramic glaze according to the weight percentage and mixed evenly, the suspending agent and the debonding agent are added into the ceramic glaze containing the antibacterial agent according to the weight percentage After mixing the raw materials evenly, add water and ball mill for 5-12 hours to obtain the antibacterial ceramic glaze, wherein the fineness of the ball-milling slurry is that a specific gravity cup passes through a 325-mesh sieve, the sieve residue is 0.5-0.8%, and the flow rate is 30 ~50 seconds.

[0042] After adding the antibacterial agent and the conventional ceramic glaze and mixing evenly, then adding the suspending agent and the debonding agent to improve the mixing uniformity of the slurry, so that the suspending agent and the degumming agent can better play the role of improving the dispersion uniformity of the antibacterial agent Effect, limit the fineness...

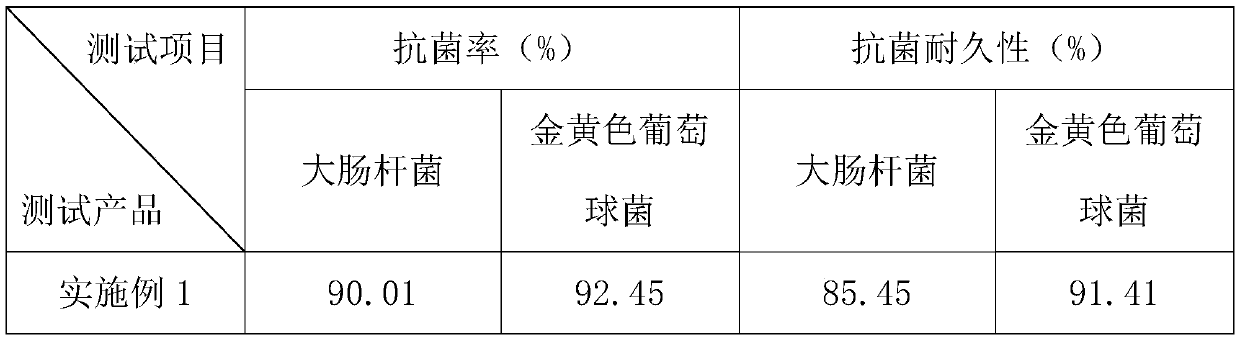

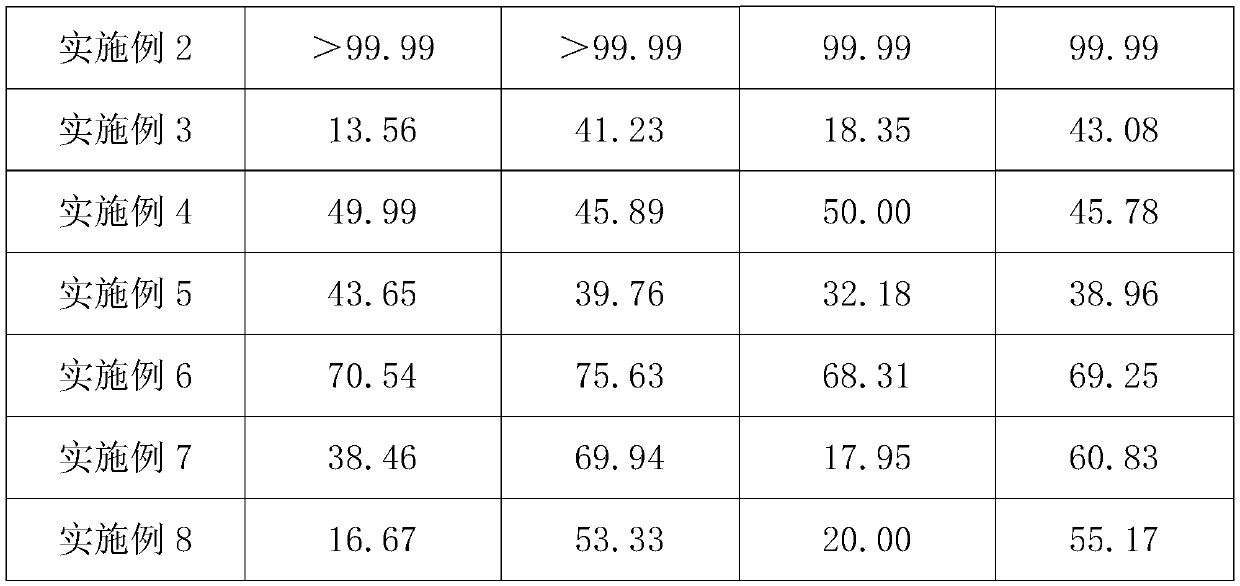

Embodiment 1

[0064] A ceramic tile using the above-mentioned antibacterial ceramic glaze, prepared according to the following steps:

[0065] (1) Calculated according to the weight percent of the dry weight of the ceramic glaze, add 2% nano-zirconium silicate silver-loaded and 0.1% nano-zinc oxide (the particle size of nano-zirconium silicate silver-loaded and nano-zinc oxide) 25nm ± 2nm, Fe in the mixture of nano-zirconium silicate loaded with silver and nano-zinc oxide 2 0 3 ≤0.01%, TiO 2 ≤0.02%), mixed evenly to prepare ceramic glazes containing antibacterial agents, calculated according to the dry weight percentage of ceramic glazes containing antibacterial agents, adding 0.1% medium-viscosity carboxymethyl fiber in the above ceramic glazes containing antibacterial agents Sodium plain (the degree of polymerization is 600), 0.01% low-viscosity sodium carboxymethylcellulose (the degree of polymerization is 150) and 0.5% sodium metasilicate are evenly mixed, then add water and ball mill...

Embodiment 2

[0072] A ceramic tile using the above-mentioned antibacterial ceramic glaze, prepared according to the following steps:

[0073] (1) Calculate according to the weight percentage of ceramic glaze dry weight, add 5% nano zirconium silicate loaded silver and 1% nano zinc oxide (the particle diameter of nano zirconium silicate loaded silver and nano zinc oxide) in conventional ceramic glaze 25nm ± 5nm, Fe in the mixture of nano-zirconium silicate loaded with silver and nano-zinc oxide 2 0 3 ≤0.01%, TiO 2 ≤0.03%), mixed evenly to prepare ceramic glazes containing antibacterial agents, calculated according to the dry weight percentage of ceramic glazes containing antibacterial agents, adding 0.12% medium viscose carboxymethyl fiber in the above ceramic glazes containing antibacterial agents Sodium plain (the degree of polymerization is 550), 0.02% low-viscosity sodium carboxymethylcellulose (the degree of polymerization is 200) and 0.3% sodium metasilicate are evenly mixed, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com