Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

668results about How to "Scratch resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light cured transfer printing film and preparation method and application thereof

InactiveCN101941339AHigh material strengthGood weather resistanceDecorative surface effectsOrnamental structuresLacquerPrinting ink

The invention belongs to the field of decorative materials, and particularly relates to an ultraviolet light cured transfer printing film and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly coating or printing a mold release agent on a base load film, and performing infrared curing; uniformly coating or printing an ultraviolet light cured printing ink with a patterning function on a mold release agent layer, and performing curing through ultraviolet irradiation; or uniformly coating or printing an ultraviolet cured protective layer coating with anti-scratching and wear-resistant functions on the mold release agent layer first, then uniformly coating or printing the ultraviolet light cured printing ink with the patterning function on the mold release agent layer after the curing through the ultraviolet irradiation, and performing the curing through the ultraviolet irradiation; and uniformly coating or printing an ultraviolet light cured bottom color coating on an ultraviolet light cured printing ink decorative pattern layer, and performing the curing through the ultraviolet irradiation to obtain the ultraviolet light cured transfer printing film which can be used for producing an ultraviolet light cured transfer printing film decorative board. The ultraviolet light cured transfer printing film has high material strength, and has the advantages of high weathering resistance, high environmental protection, rich colors and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning, noninflammability and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

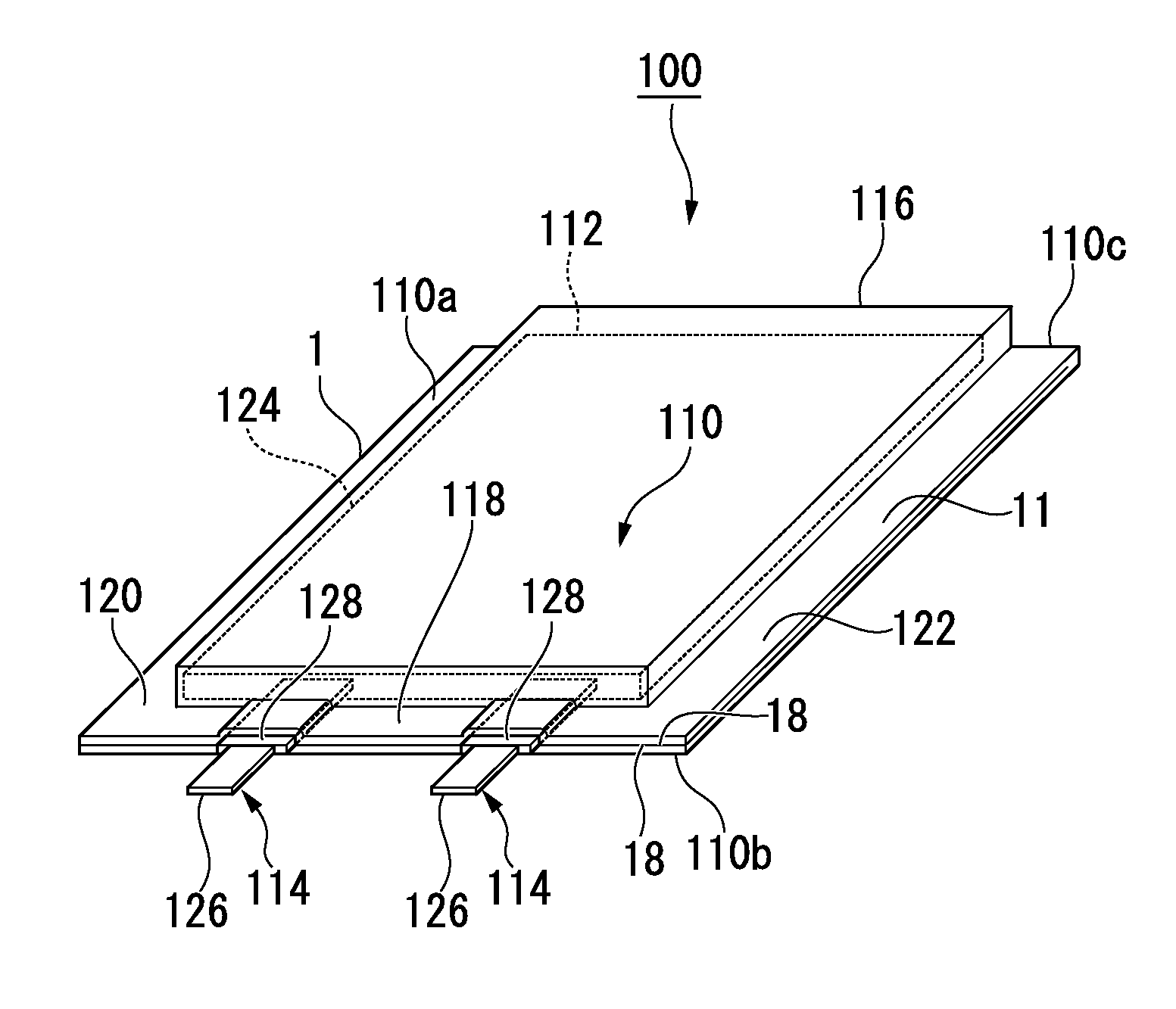

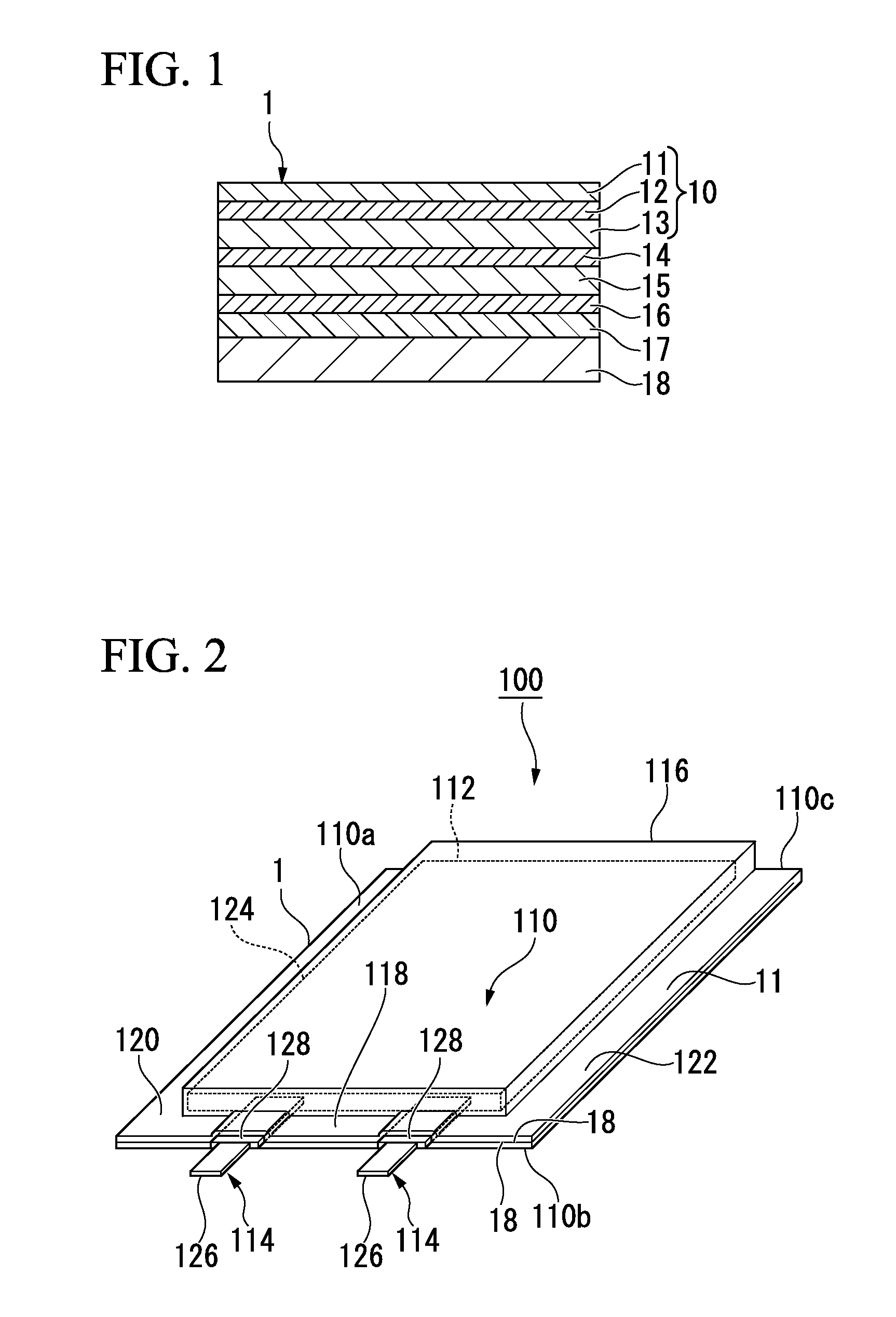

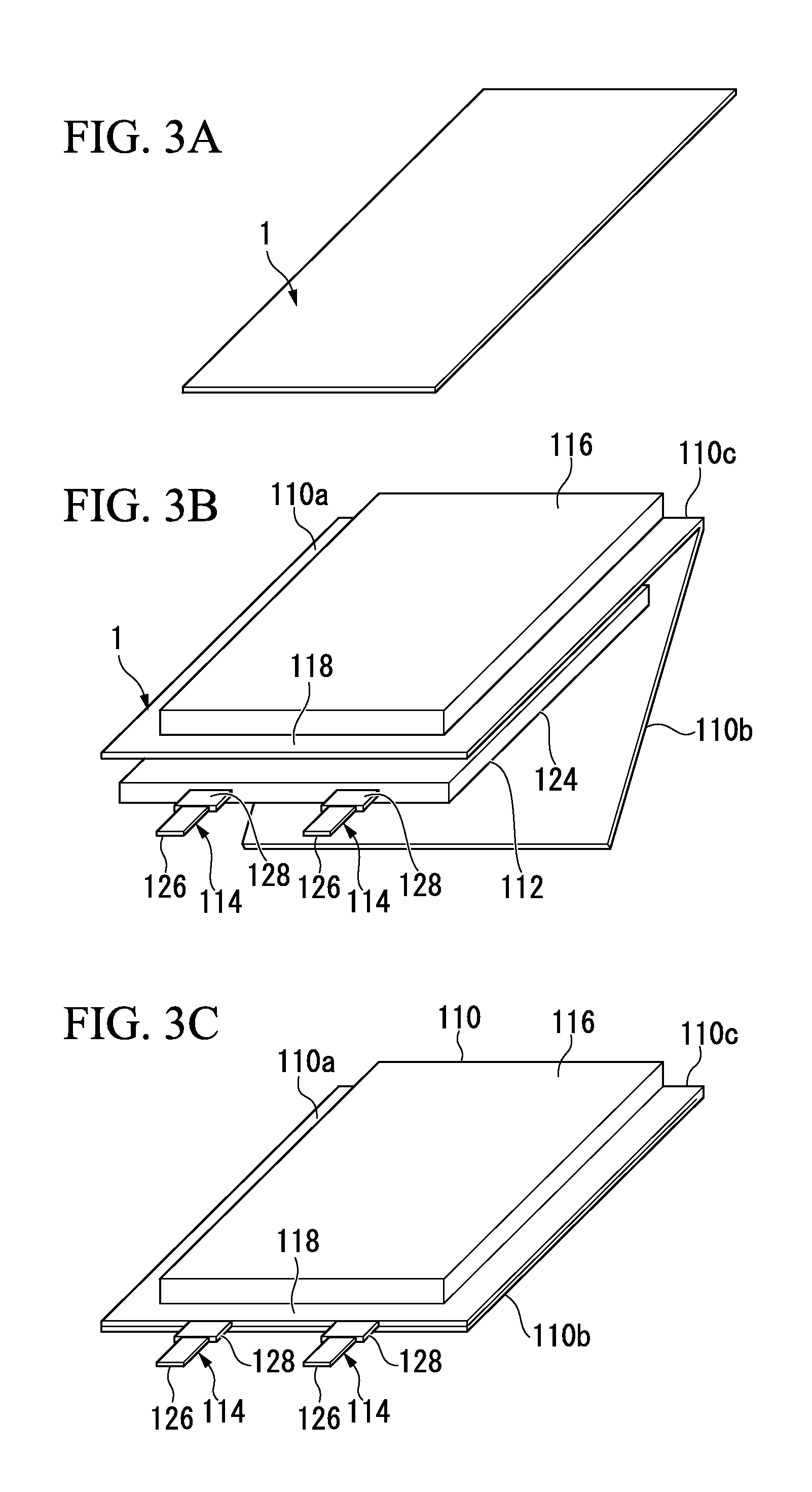

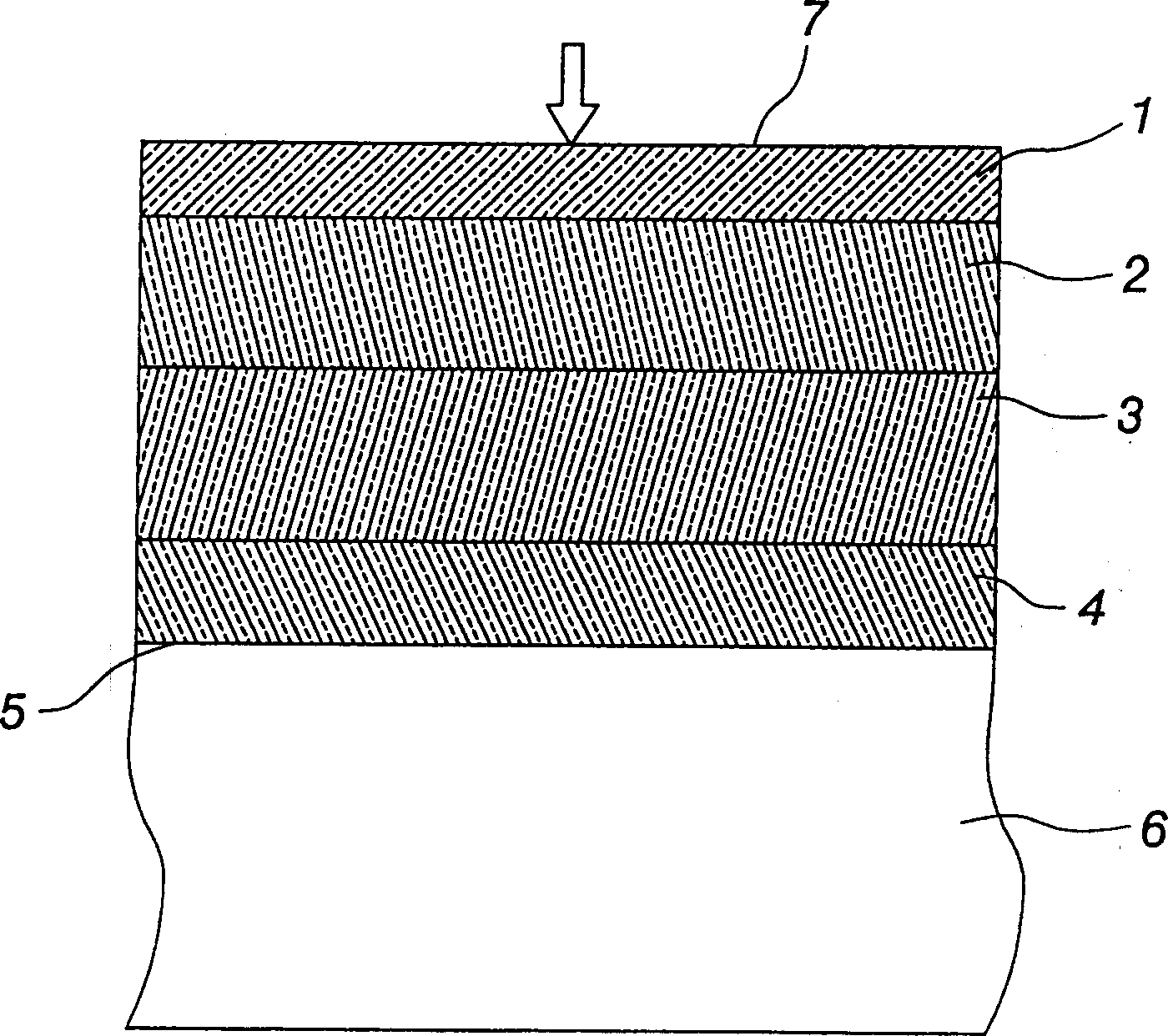

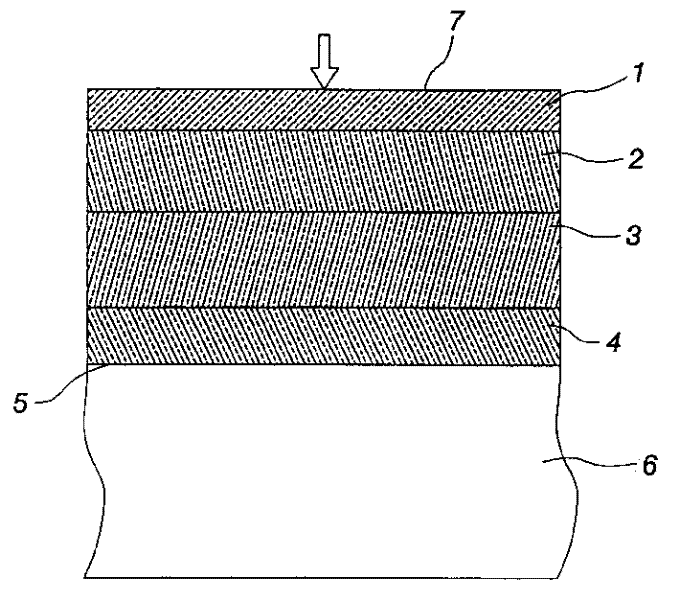

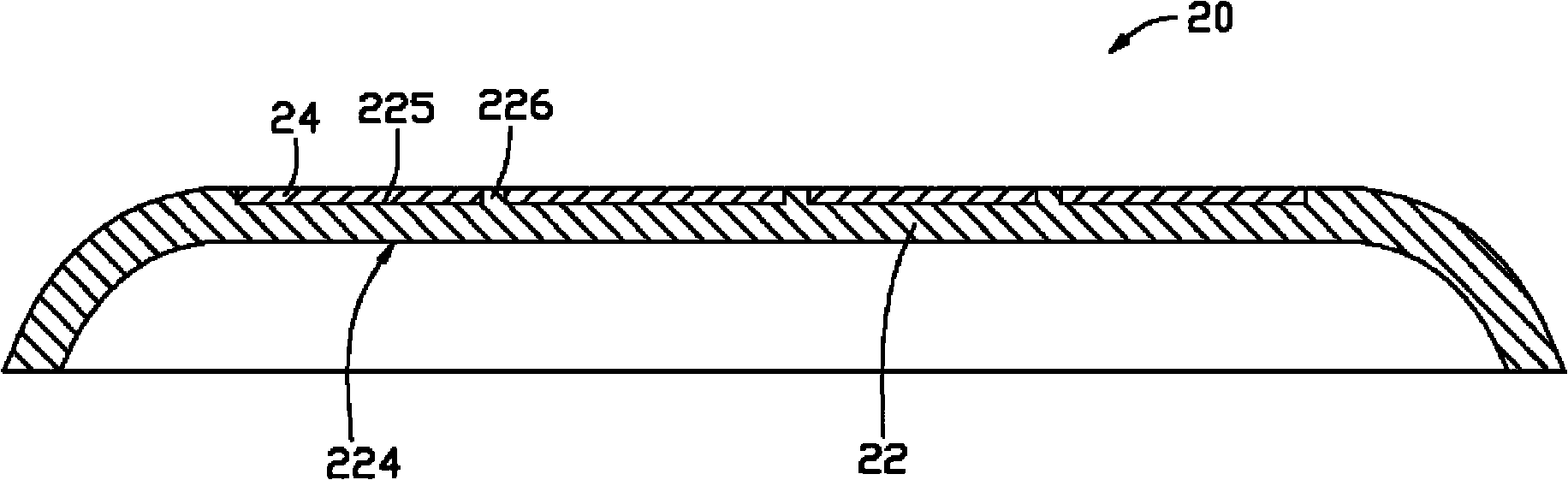

Packaging material for lithium ion battery, lithium ion battery, and method for manufacturing lithium ion battery

ActiveUS20140072864A1Good molding effectStay in shapeFinal product manufactureElectrode carriers/collectorsMetal foilPack material

A packaging material for a lithium ion battery includes: a base material layer that is formed from a film obtained by biaxially stretching a multi-layered coextruded film including a first thermoplastic resin layer having rigidity and chemical resistance and being disposed at an outer side thereof, a second thermoplastic resin layer having a capability of propagating stress and adhesiveness, and a third thermoplastic resin layer having toughness; a metal foil layer that is laminated on one surface of the base material layer; an anti-corrosion-treated layer that is laminated on the metal foil layer; an inner adhesive layer that is laminated on the anti-corrosion-treated layer; and a sealant layer that is laminated on the inner adhesive layer.

Owner:TOPPAN PRINTING CO LTD

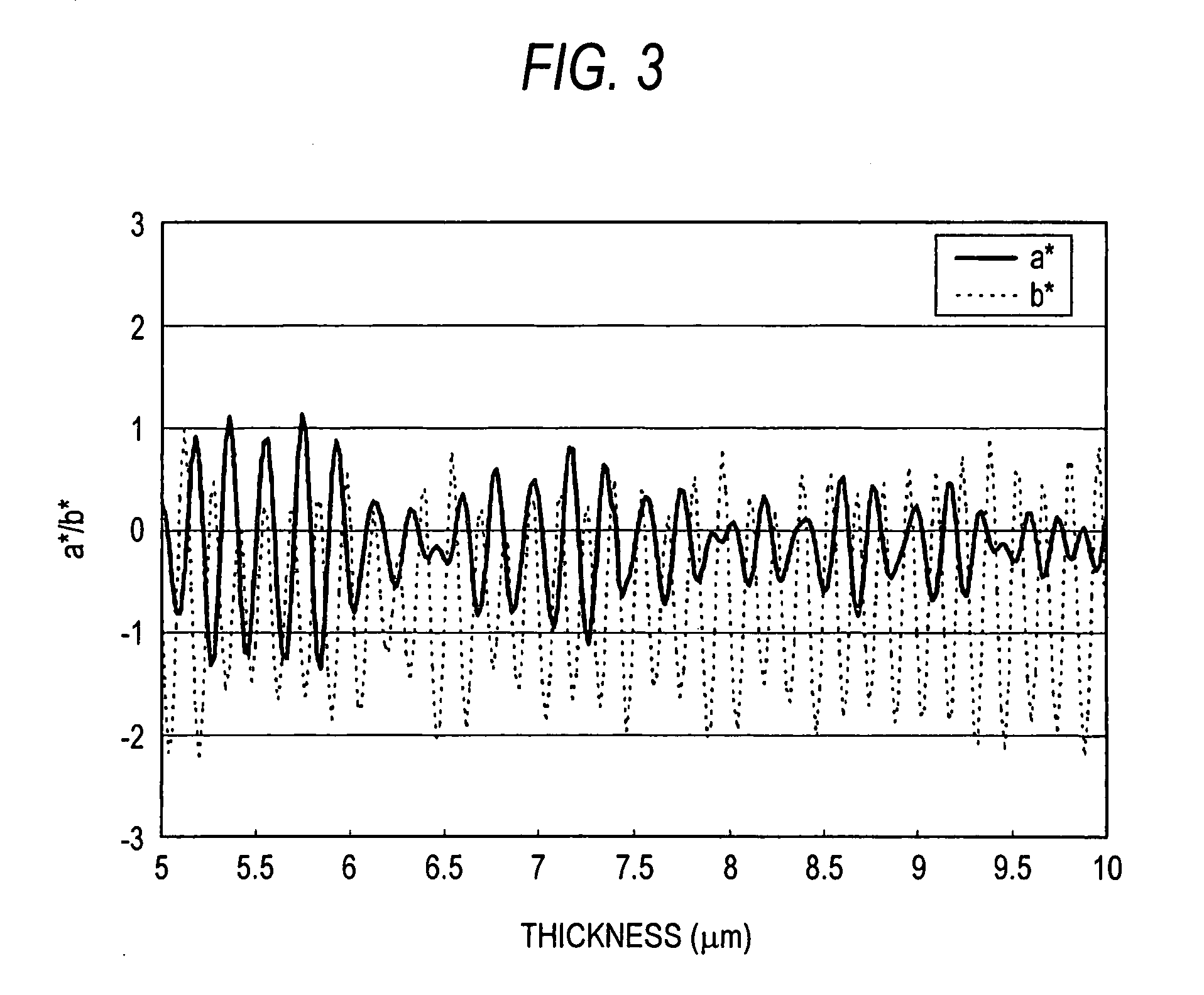

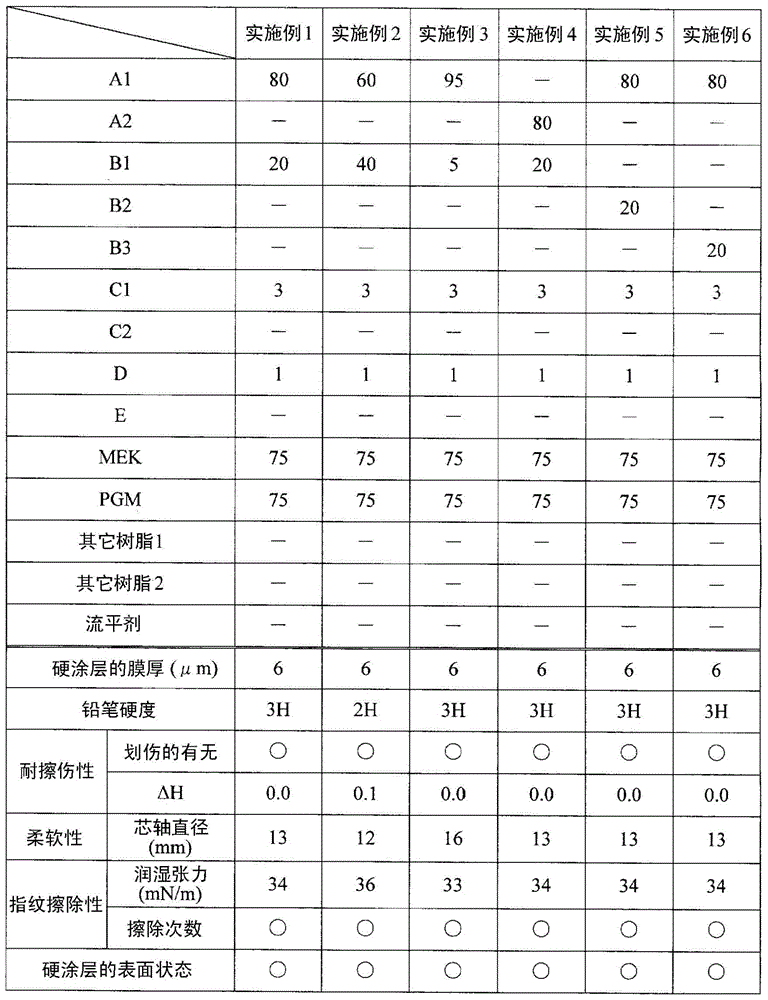

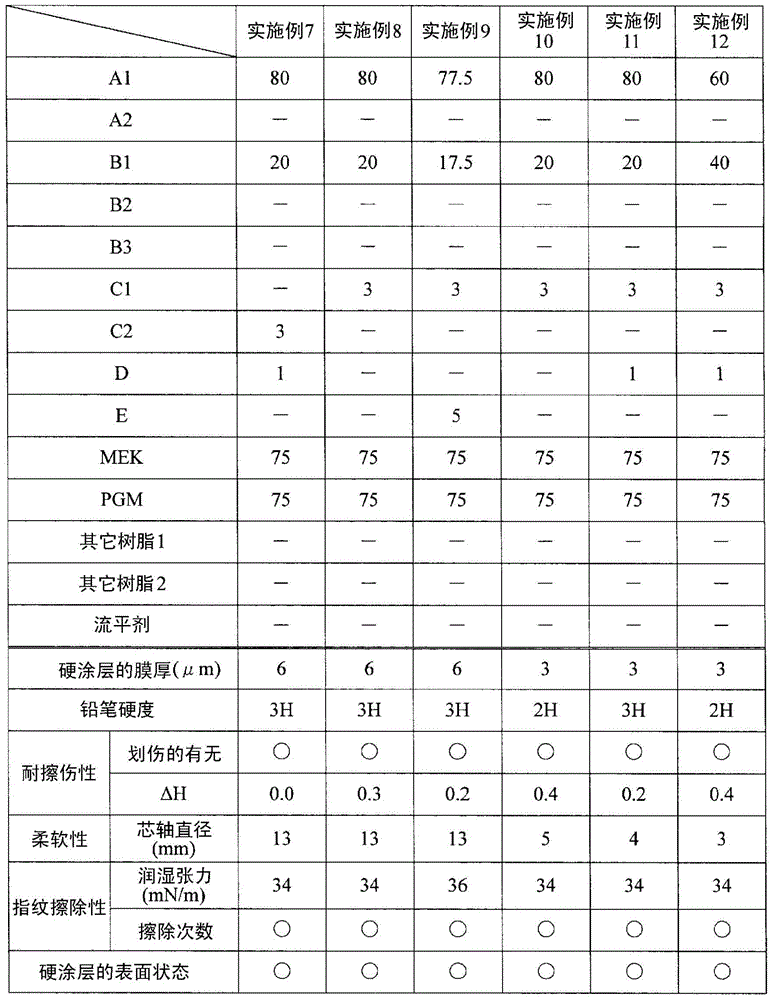

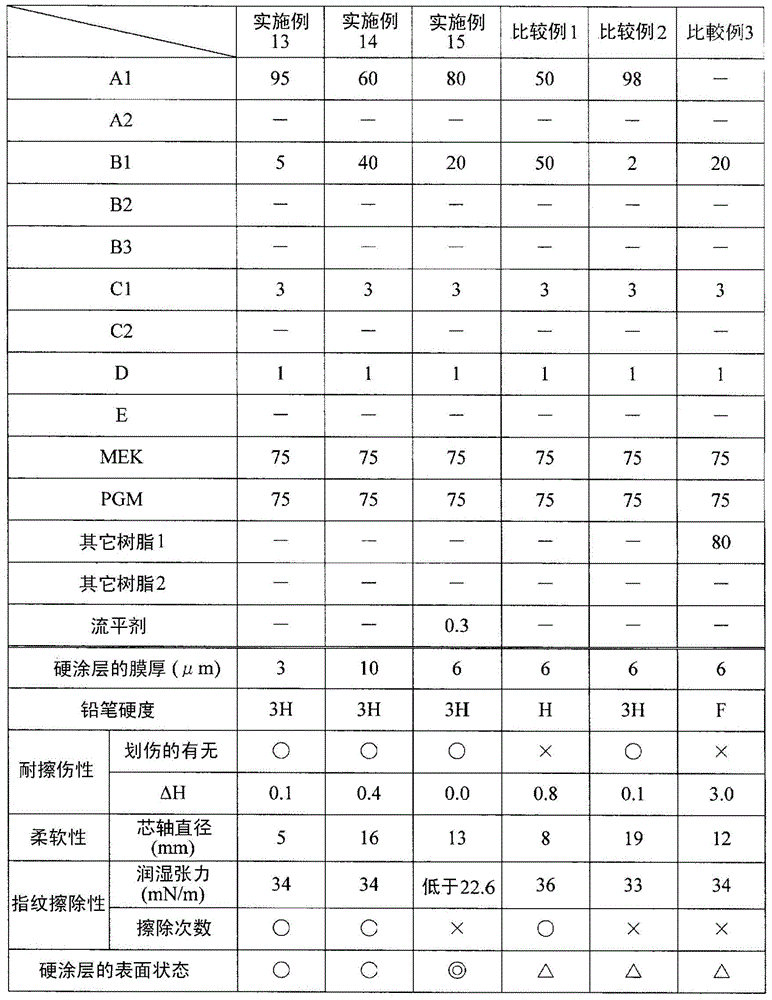

Anti-Reflection Film

InactiveUS20070285776A1Improve propertiesScratch resistantPolarising elementsCoatingsProduction rateRefractive index

An anti-reflection film having a hard coat layer attaining both improvement in resistance to unevenness in interference under an artificial light source and solution to handling problems such as curling and brittleness and sufficient anti-reflection properties, scratch resistance and productivity is provided. The anti-reflection film includes a transparent support, a hard coat layer, and a low refractive index layer having in this order. The dry thickness of the hard coat layer is from 6 to 15 μm. The color difference of light from an artificial light source reflected by the hard coat layer between at an arbitrary point and another arbitrary point disposed 5 mm apart therefrom in the film longitudinal or crosswise direction is 2.0 or less as calculated in terms of ΔEab* value of CIE.

Owner:FUJIFILM CORP

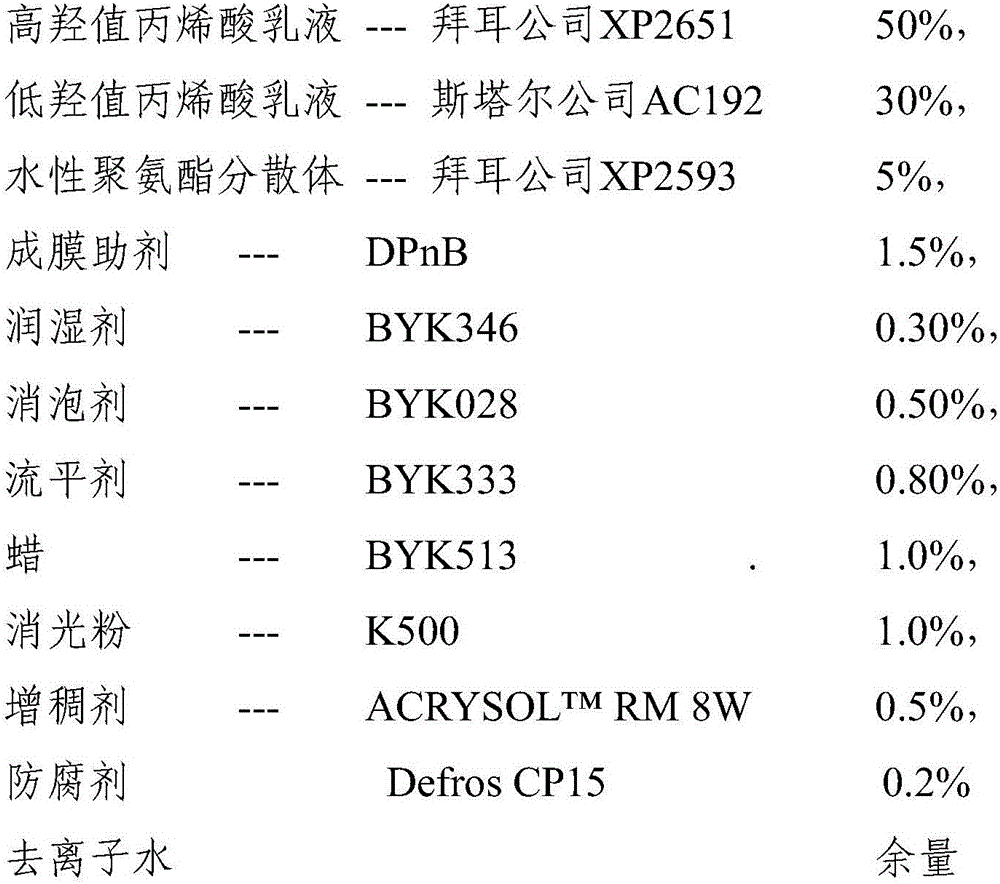

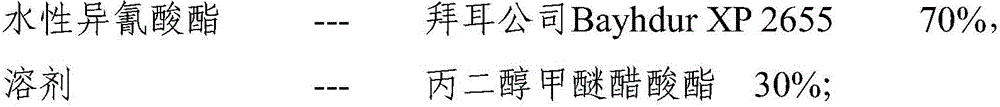

Waterborne two-component woodware coating and preparation method thereof

The invention discloses a waterborne two-component woodware coating and a preparation method thereof. The waterborne two-component woodware coating is prepared from main agent A and curing agent B. The main agent A comprises high-hydroxyl-value acrylic emulsion, low-hydroxyl-value acrylic emulsion, an aqueous polyurethane dispersion, a film forming auxiliary, a moistening agent, a leveling agent, an antifoaming agent, wax, extinction powder, a thickening agent, a preservative and deionized water, and the curing agent B comprises waterborne isocyanate and a solvent. The waterborne two-component woodware coating uses hydroxyl acrylic and the aqueous polyurethane dispersion as main film forming matters, the waterborne isocyanate serves as a cross-linking agent, the extinction powder and a wax auxiliary are added, curing reaction is performed at the normal temperature, and the coating has the advantages of high hardness, excellent chemical resistance, good scratch resistance, better transparence and simple, economical and reasonable production process, and can be widely applied to products such as wooden furniture and doors and windows.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

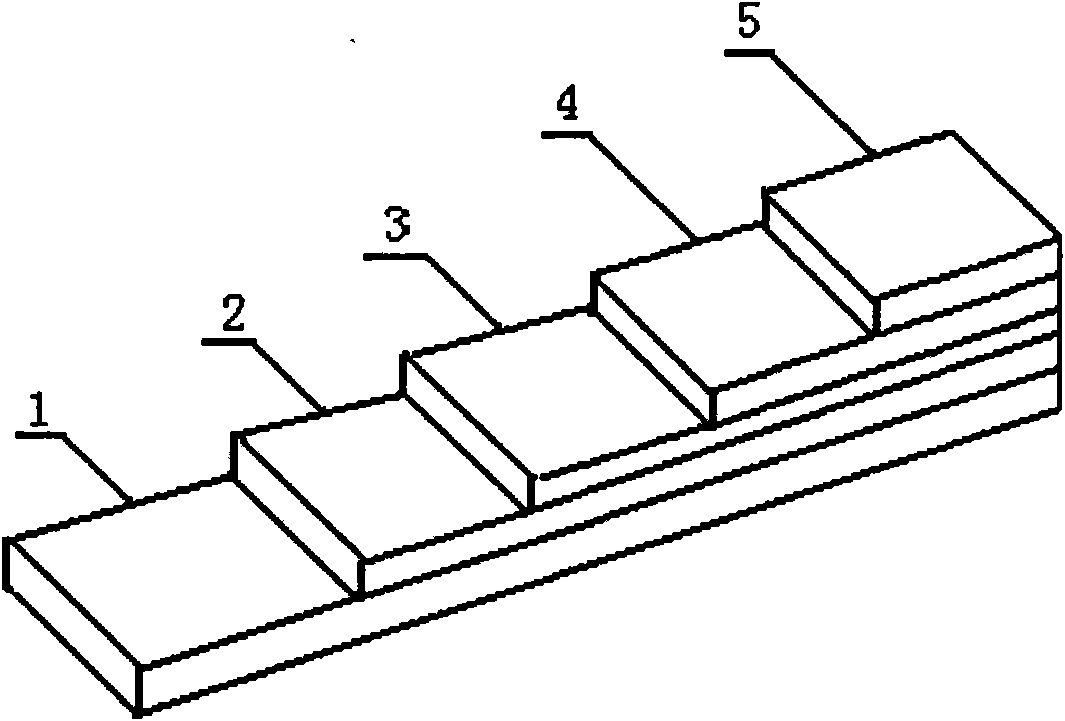

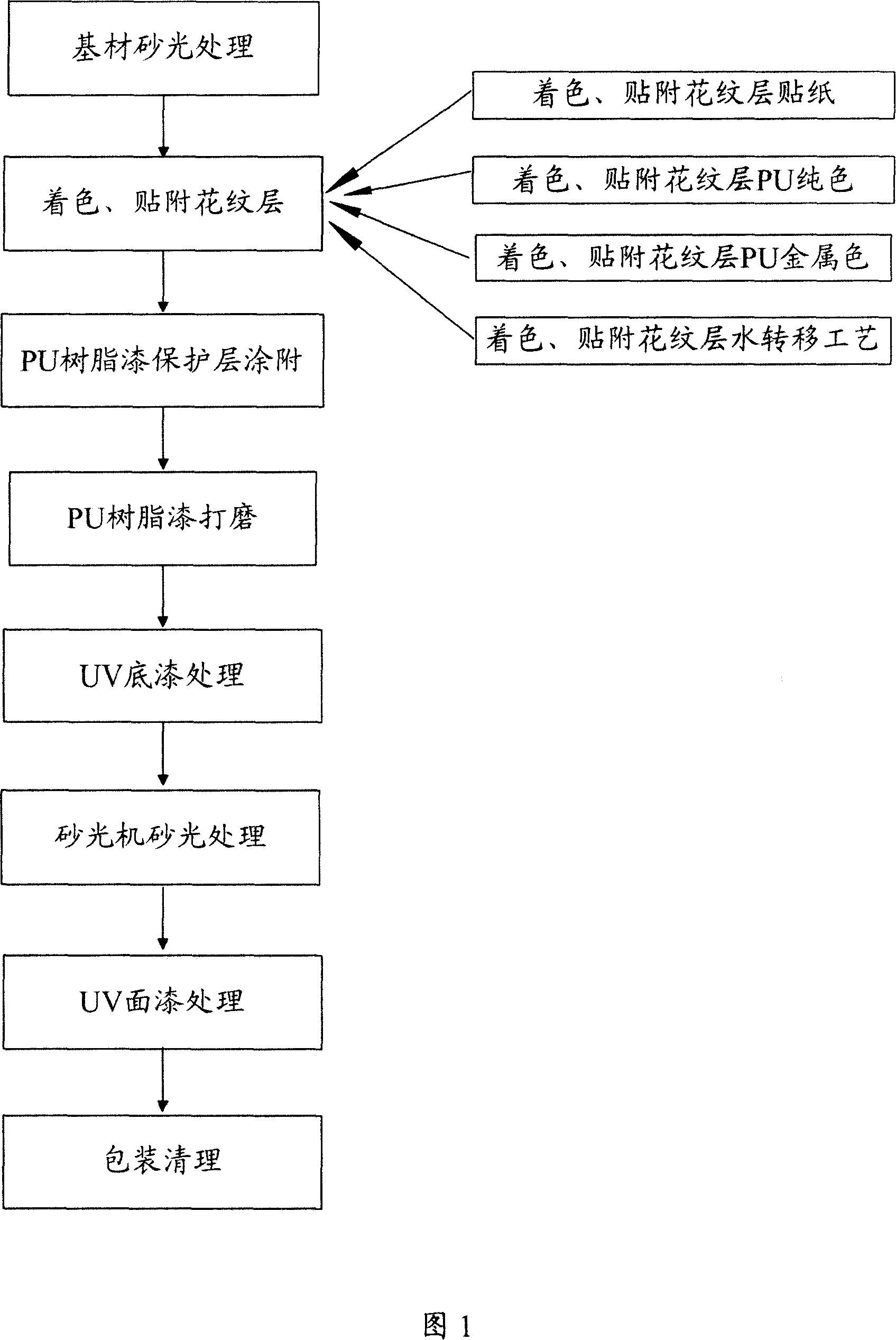

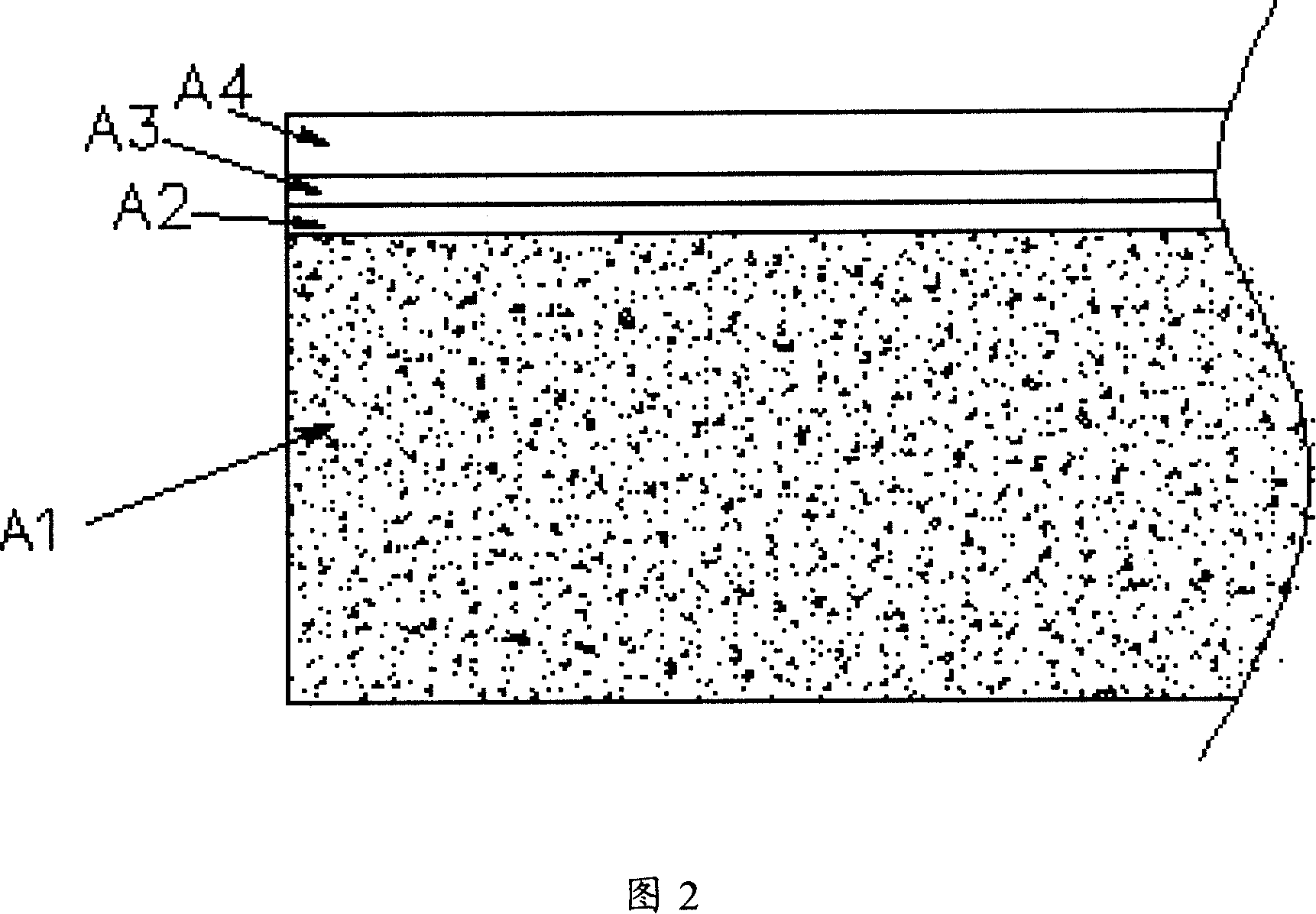

Decorative board processing method

ActiveCN101116987AFlexible color changeRich and gorgeous appearanceWood working apparatusLacquerMedium density fiberboard

The invention relates to a processing method of decoration boards. The decoration boards are processed by the substrate material surface and substrate material coloring and UV rays fixes the base lacquer and the surface lacquer by the forward drench-roll technology and the drench-spread technology. The substrate materials are particle board adhered with melamine fumiture surface paper on single or double faces or medium density fiberboard. The steps comprise 1) substrate material surface is processed; 2) substrate material surface is colored; 3) the base lacquer is fixed by UV rays; 4) the surface lacquer is fixed by UV rays. Prior to step 4), a step of polishing can also be comprised, i.e. large-scale polishing machine polishes the whole base lacquer after the fixing machine of UV rays fix completely. After the step 4), a step of cleaning package can also be added, that is, micro flaws can be removed that decoration boards with small bubbles or unapparent impurities are polished by dropping sand and package is checked. The decoration boards produced by the method has the advantages of wear resistance, environmental protection, rich and bright colors.

Owner:TIANJIN DAYIN BUILDING MATERIAL CO LTD

Cyan ink and ink set

A cyan ink applicable to an ink set has plurality of aqueous inks each containing at least: water; a water-insoluble coloring material; and plurality of water-soluble organic solvents including a good medium or good mediums for the water-insoluble coloring material and a poor medium or poor mediums for the water-insoluble coloring material. A ratio of a poor medium to a good medium in the cyan ink is in a specific range. A water-soluble organic solvent showing the maximum Ka value out of respective Ka values of the plurality of water-soluble organic solvents is the poor medium. A ratio of a poor medium to a good medium in an arbitrary aqueous ink in the ink set except the cyan ink and the ratio of the poor medium to the good medium in the cyan ink satisfy a specific relationship.

Owner:CANON KK

Water-based environment-friendly finishing paint and preparation method thereof

InactiveCN101712833AGood anti-corrosion decoration effectHigh hardnessEpoxy resin coatingsWater basedEpoxy

The invention discloses a water-based environment-friendly finishing paint, which is prepared from the following compositions in part by weight: 20 to 70 parts of water borne acrylic resin solution of which the solid content is 30 to 80 percent and / or 20 to 70 parts of water borne epoxy resin solution of which the solid content is 30 to 80 percent, 4 to 10 parts of water borne amino resin solution of which the solid content is 60 to 98 percent; 1 to 5 parts of organic amine, 0.2 to 2 parts of wetting and leveling agent, 0.2 to 2 parts of thickener, 0.1 to 0.8 part of defoaming agent, 1 to 5 parts of adhesion promoter, 0.2 to 5 parts of catalyst, 10 to 30 parts of alcohol diluting solvent and / or 1 to 5 parts of nontoxic ether diluting solvent, and 20 to 50 parts of deionized water, wherein the catalyst is one or more of ammonias, alcohols and benzenesulfonic acids. The water-based environment-friendly finishing paint has the advantages of wide applicable range, high hardness, good flexibility, strong adhesion, good scratchproof performance, and environmental protection. Simultaneously, the invention also discloses a method for preparing the water-based environment-friendly finishing paint.

Owner:重庆亢石新材料科技有限公司

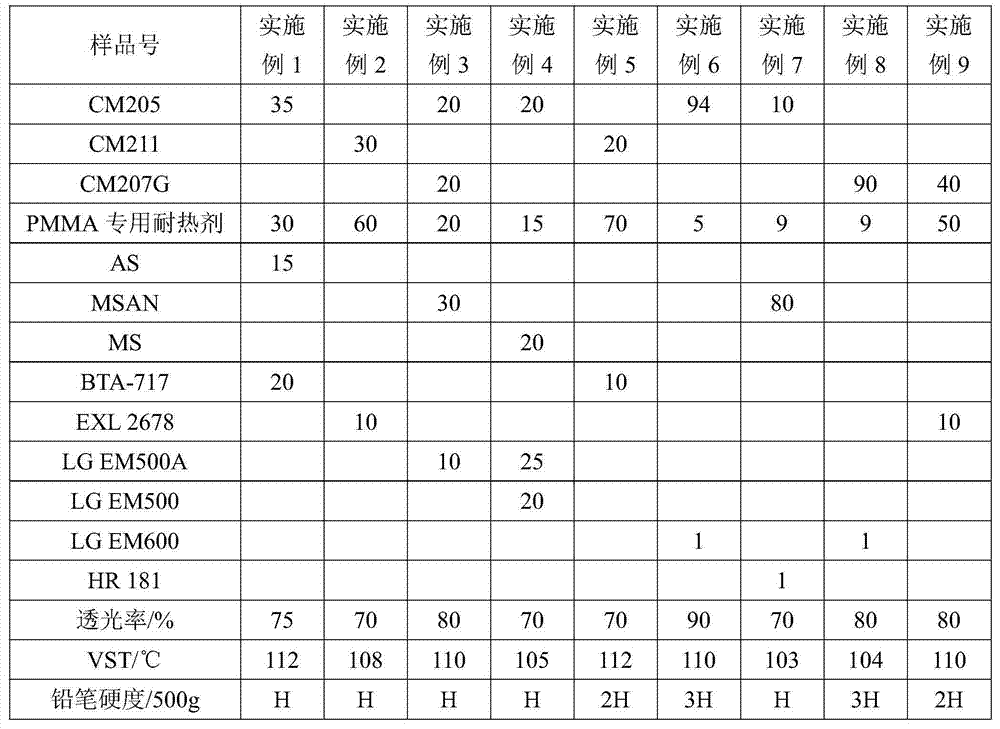

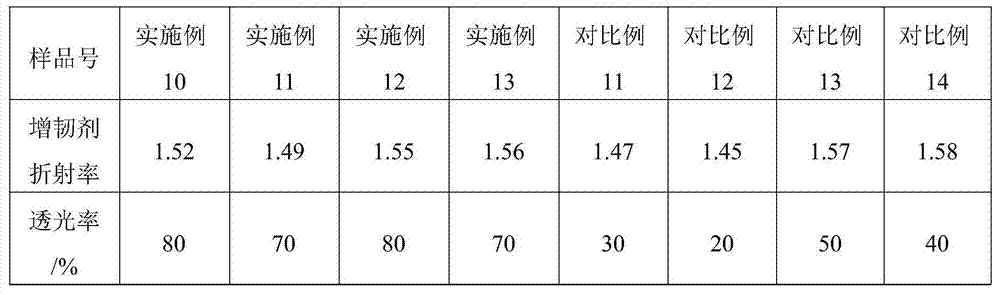

Heat-resistant scratch-resistant high-transmittance PMMA alloy resin composition and preparation method thereof

The invention relates to a heat-resistant scratch-resistant high-transmittance PMMA alloy resin composition. The composition is prepared from the following raw materials in parts by weight: 10-94 parts of polymethyl methacrylate, 5-70 parts of special heat-retardant agent for PMMA, 1-45 parts of a flexibilizer, 0-80 parts of a fluidity regulator, 0.1-1 part of an antioxidant, 0.1-2 parts of a lubricating agent and 0.001-1.0 part of an additive, wherein the special heat-retardant agent for PMMA refers to a maleic anhydride-styrene-methyl acrylate terpolymer MAH-St-MMA. The maleic anhydride-styrene-methyl acrylate terpolymer, polymethyl methacrylate and fluidity regulator used in the invention have good compatibility, and high transparency is achieved after blending; and moreover, the flexibilizer with refractive index consistent with that of a blended matrix resin is selected, and by virtue of the conventional double screw molding, the prepared alloy resin has the advantages of high transmittance, scratch resistance and heat resistance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Aqueous environment-friendly packaging steel drum paint and preparation method thereof

InactiveCN101735703AGood anti-corrosion decoration effectHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to an aqueous environment-friendly packaging steel drum paint, which is prepared by mixing the following compositions in part by weight: 20 to 70 parts of aqueous solution of acrylic resin with a solid content of 30 to 80 percent and / or aqueous solution of epoxy resin with the solid content of 30 to 80 percent, 4 to 10 parts of aqueous solution of amino resin with the solid content of 60 to 98 percent, 1 to 5 parts of organic amine, 1 to 50 parts of filling materials with the granularity of more than 2,000 meshes, 0.5 to 10 parts of color paste, 0.2 to 2 parts of wetting levelling agent, 0.2 to 2 parts of thickening agent, 0.1 to 0.8 part of antifoaming agent, 1 to 5 parts of adhesive force accelerant, 0.2 to 5 parts of catalyst, 0 to 30 parts of alcohol diluting solvent and / or 0 to 5 parts of non-toxic ether diluting solvent, and 20 to 50 parts of deionized water. The aqueous environment-friendly packaging steel drum paint has the advantages of wide application range, high rigidity, good flexibility, strong adhesive force and good anti-scraping and anti-collision properties and environmental protection; and meanwhile, the invention discloses a preparation method for the aqueous environment-friendly packaging steel drum paint.

Owner:重庆亢石新材料科技有限公司

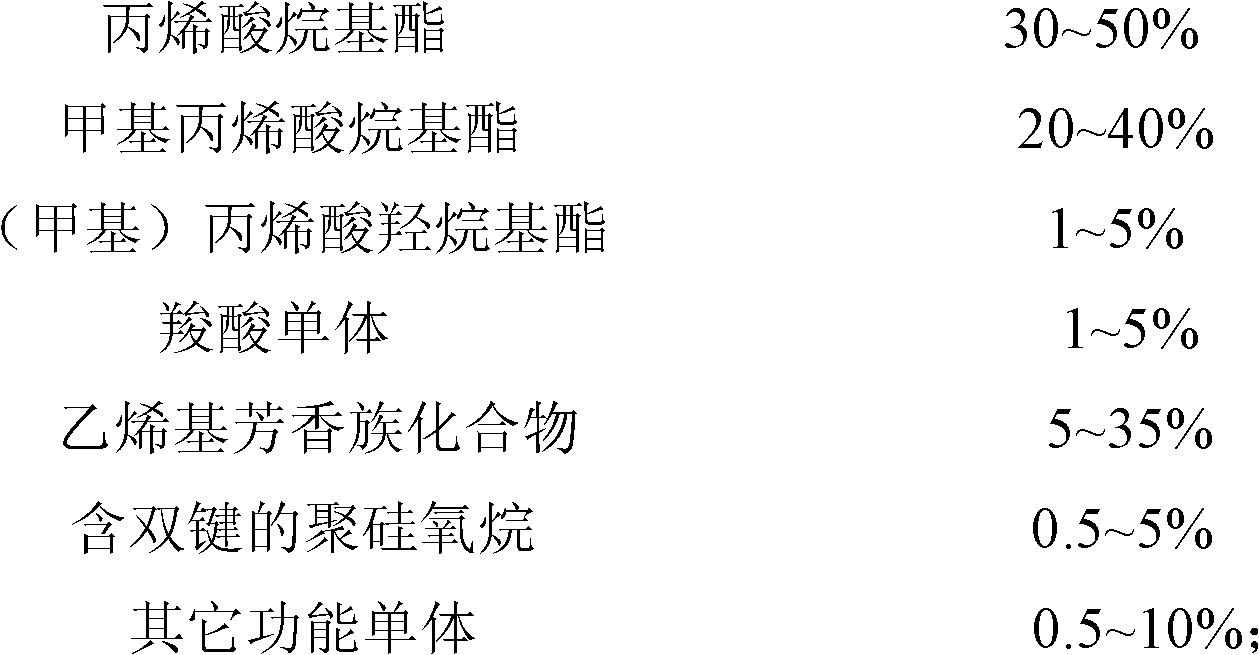

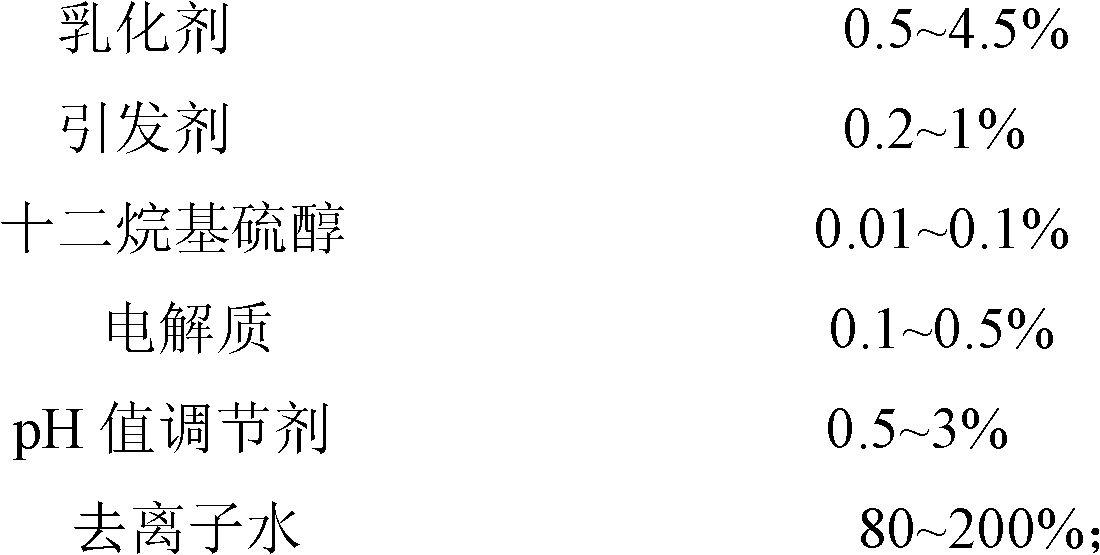

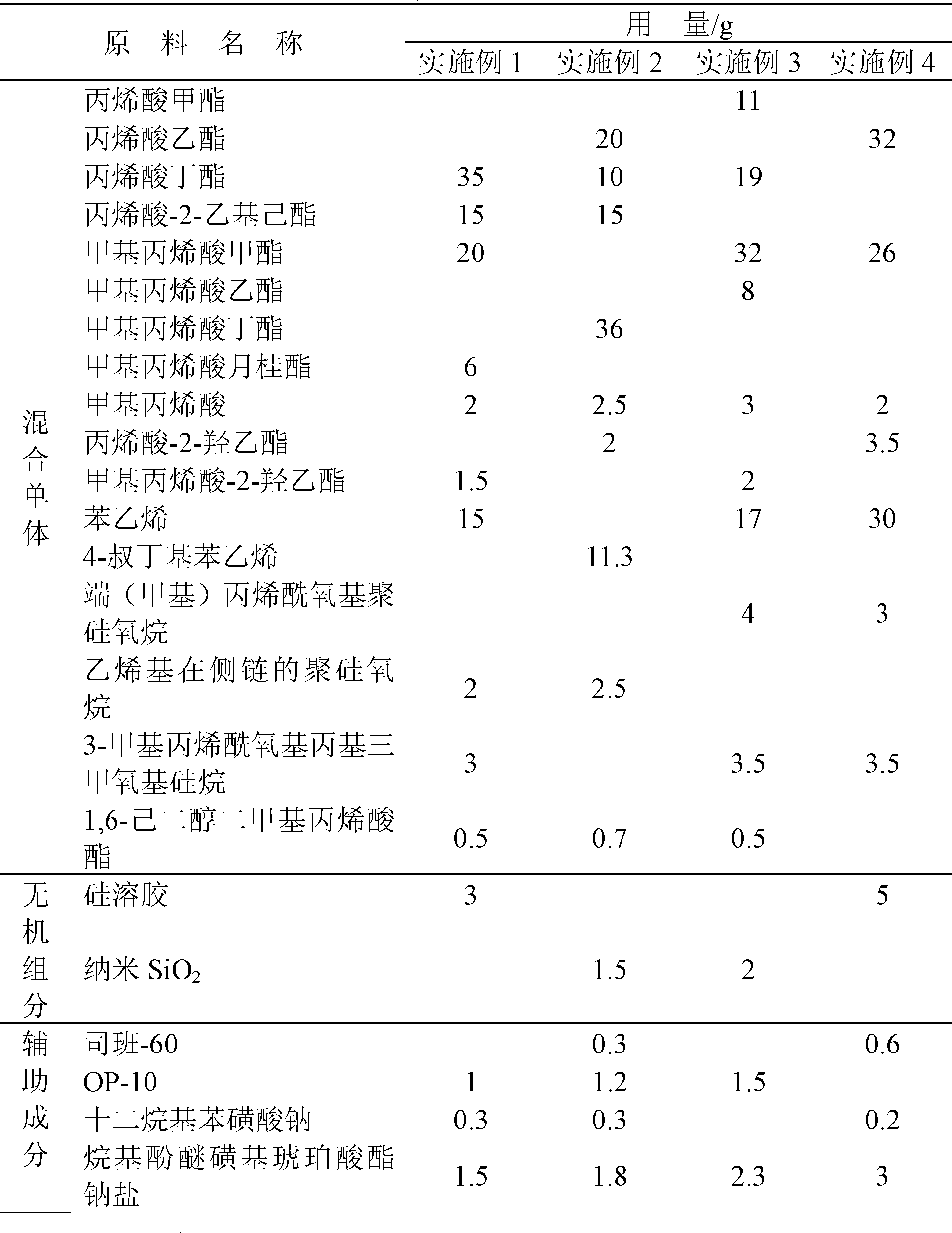

Self-layering organic-inorganic nano composite emulsion and method for preparing same

The invention relates to self-layering organic-inorganic nano composite emulsion and a method for preparing the same. The emulsion is made of mixed monomers, inorganic components and auxiliary components. The self-layering organic-inorganic nano composite emulsion is obtained by generating (or precipitating) organic nano particles inside (or on the surface) of latex particles in situ while introducing double-bond polysiloxane, and the emulsion is high in solid content, low in viscosity and high in storage stability. Due to differences of surface energy and compatibility (solubility parameters) between polysiloxane and other components in filming of emulsion, the polysiloxane molecules migrate to be enriched to a coating surface to form a self-layering structure.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Multifunctional green environmental protection type nanometer paint

The multifunctional green nano paint consists of mainly: quaternary methacrylic acid-butyl acrylate-styrene-methyl methacrylate copolymer emulsion 20-65 wt%; nano titania 0.3-5 wt%; nano zinc oxide 0.2-3 wt%; silica 0.3-3 wt%; nano calcium carbonate 0.5-5 wt%; deionized water 3-12 wt%; superfine talcum powder 1-3 wt%; superfine calcium carbonate 3-15 wt%; titanium white3-25 wt%; and assistants including dispersant, wetter, rheologic agent, thickener, color paste, defoaming agent, etc. 2-12 wt%. The paint of the present invention features no toxicity, no pollution, wash resistance, scratching resistance, ultraviolet resistance, ageing resistance, waterproofing and mould proofing as well as self-cleaning function, so that the paint may be used wide in the decoration of inner and outer walls and the anticorrosive treatment of metal material surface.

Owner:王崇高

Manufacturing method of hot bent 3D (Three Dimensional) glass white sheet

InactiveCN106746525AEliminate internal stressFlat surfaceEdge grinding machinesPolishing machinesNumerical controlHeating time

The invention relates to a manufacturing method of a hot bent 3D (Three Dimensional) glass white sheet. The manufacturing method comprises the following steps: (1) cutting a material: cutting a glass white sheet material into a plurality of small glass white sheets with proper sizes; (2) finely engraving: putting the small glass white sheets into a CNC (Computer Numerical Control) fine engraving machine, and punching and grinding edges; (3) cleaning: carrying out cleaning treatment on the glass white sheet by utilizing a glass cleaning machine; (4) carrying out ultrasonic treatment: washing surface residual waste dreg on the surface of the glass white sheet by utilizing an ultrasonic washing machine; (5) hot bending: putting the glass white sheet into a hot bending mold and hotly bending, machining and molding the glass white sheet into a 3D curve surface; (6) tempering: putting the hotly bent glass white sheet into a tempering frame; conveying the tempering frame into a tempering furnace and raising the temperature to 380 DEG C-420 DEG C, wherein the heating time is 4h-8h and the hardness reaches 7H; (7) carrying out plasma spraying: putting the glass white sheet into a fingerprint oil spraying machine and spraying fingerprint oil on a surface through plasmas; baking at a temperature of 140 DEG C-160 DEG C for 25-30 minutes until the fingerprint oil is dried; (8) fitting: fitting release films on upper and lower surfaces of the glass white sheet; and (9) packaging.

Owner:DONGGUAN YUANMEI PRECISION ELECTRONICS CO LTD

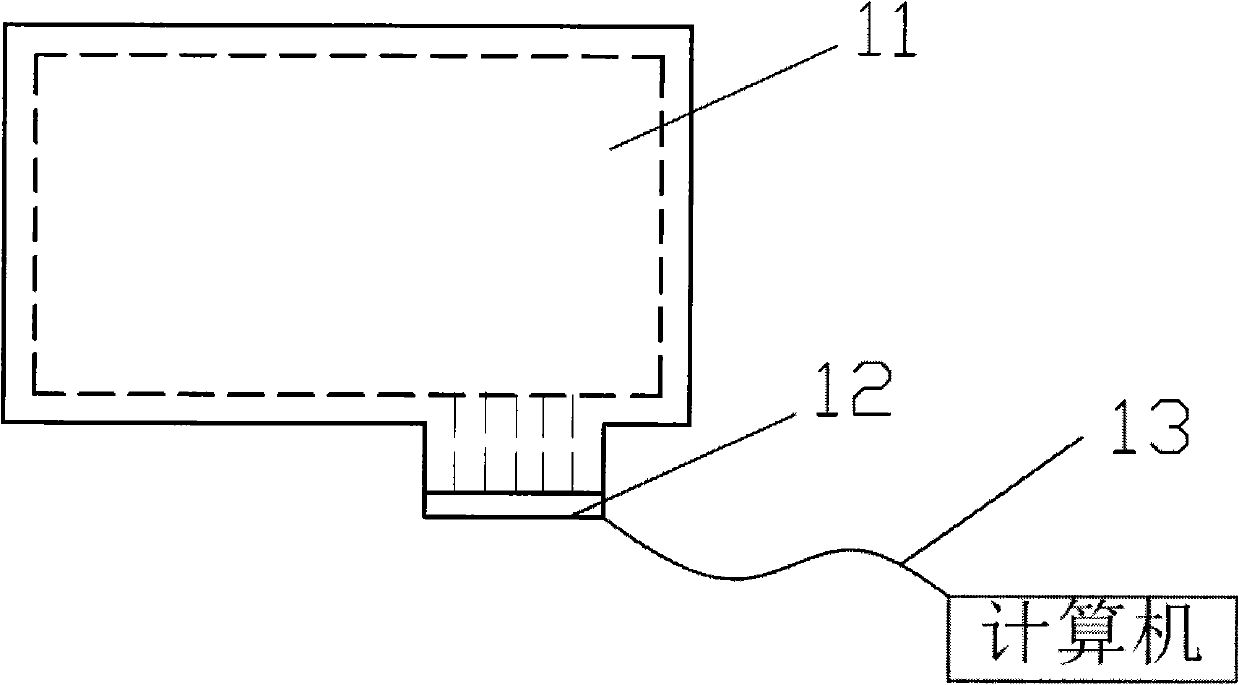

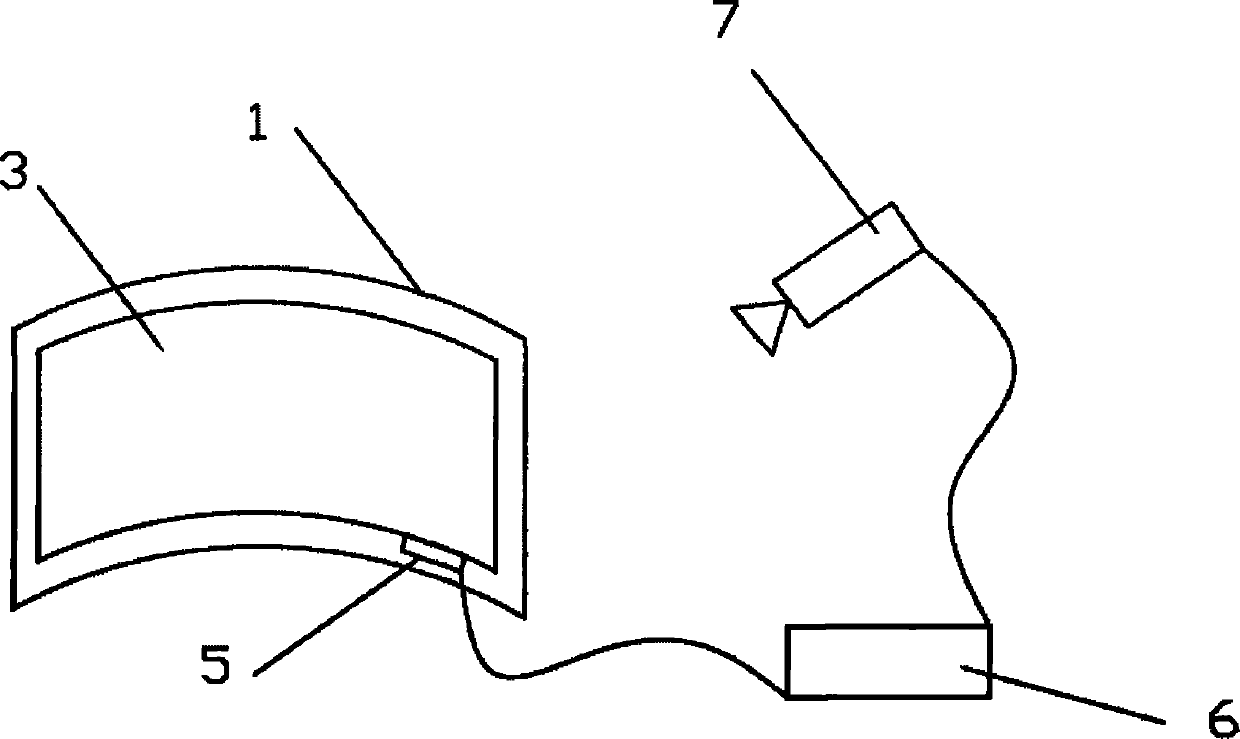

Curve screen based on nanometer touch-control membrane technique and manufacturing method thereof

ActiveCN102169388AImprove mechanical propertiesMalleableInput/output processes for data processingSystem integrationCarbon product

The invention discloses a curve screen based on nanometer touch-control membrane technique and a manufacturing method thereof. The curve screen comprises a curve substrate, wherein the curve substrate is an arc-shaped imaging device; the radian of the curve substrate is 0-180 degrees; the curve substrate is adhered to a nanometer touch-control membrane having flexibility; a sensing signal acquisition control integrated circuit is arranged on the nanometer touch-control membrane and is connected to a computer control unit through an interface; and the computer control unit is connected to the curve substrate in a wired or wireless communication manner. In the invention, the touch control technique is realized on the curved surface. The curve screen provided by the invention is suitable fordisplay devices in different sizes. The unit cost is low, the system integration is simple, and the operation is easy, thereby ensuring that the curve screen provided by the invention is a low energy-consumption and low-carbon product.

Owner:UC NANO TECH CO LTD

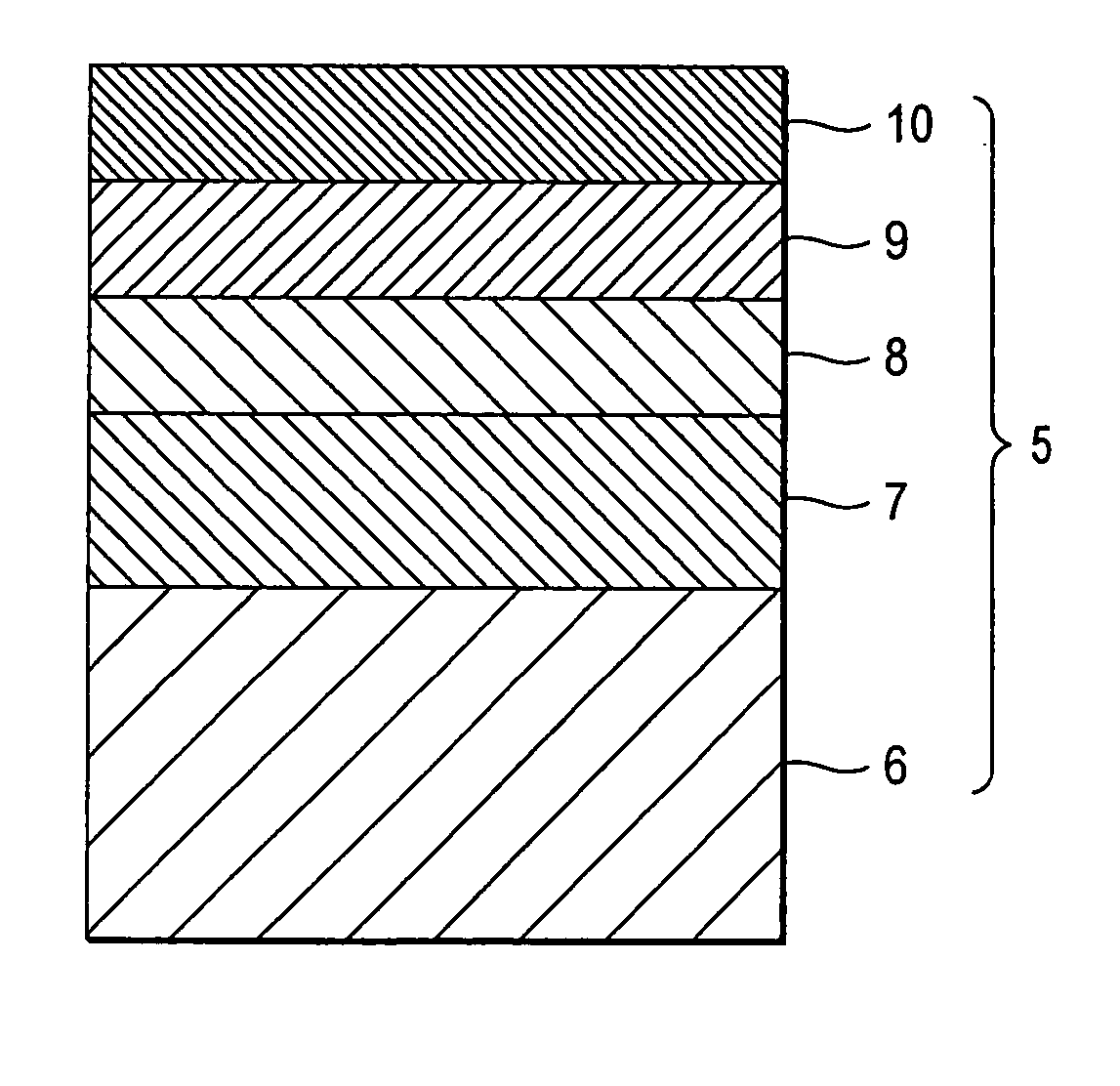

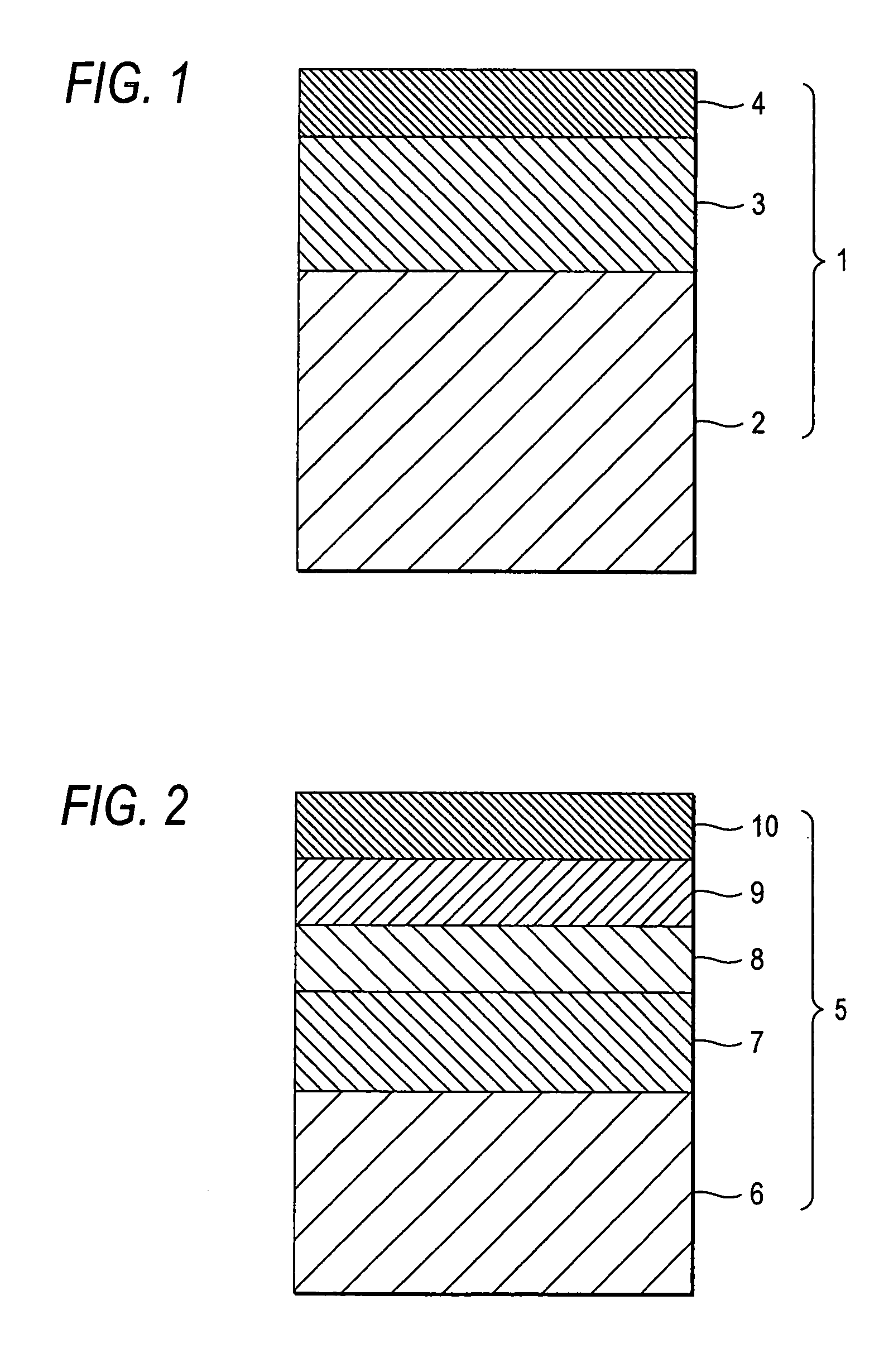

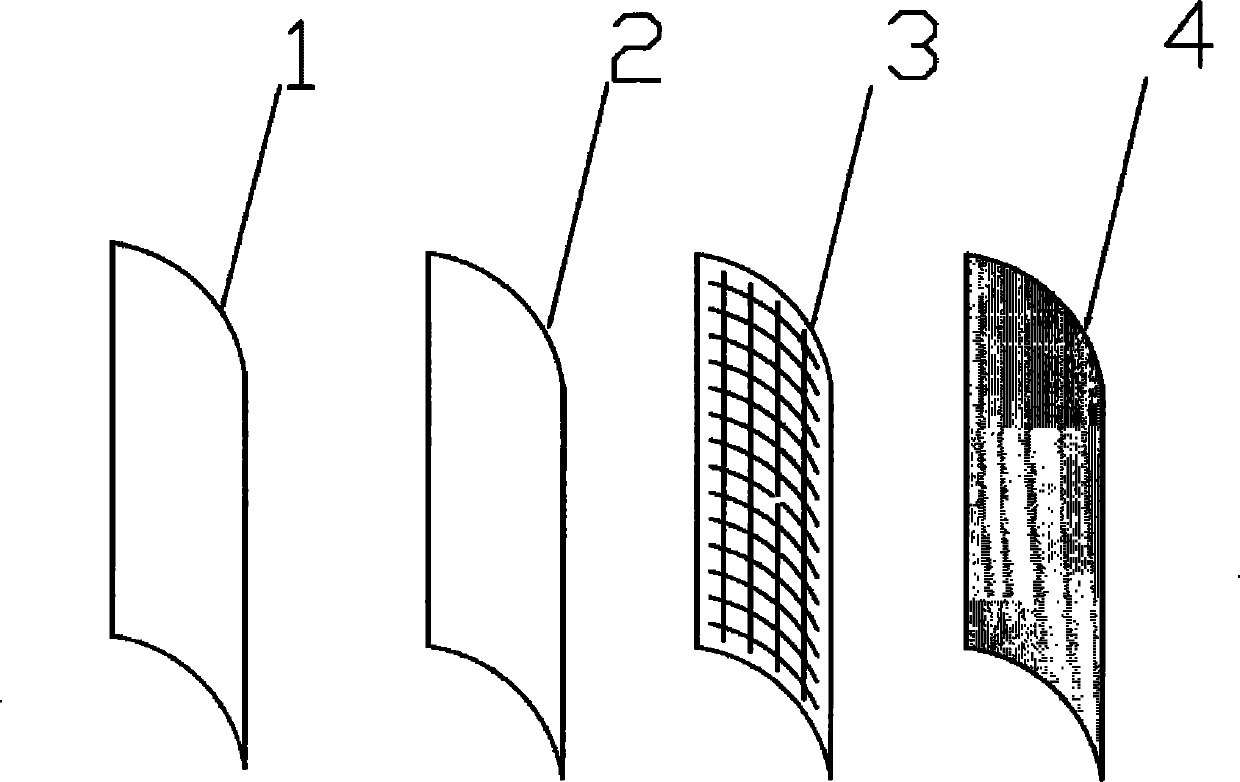

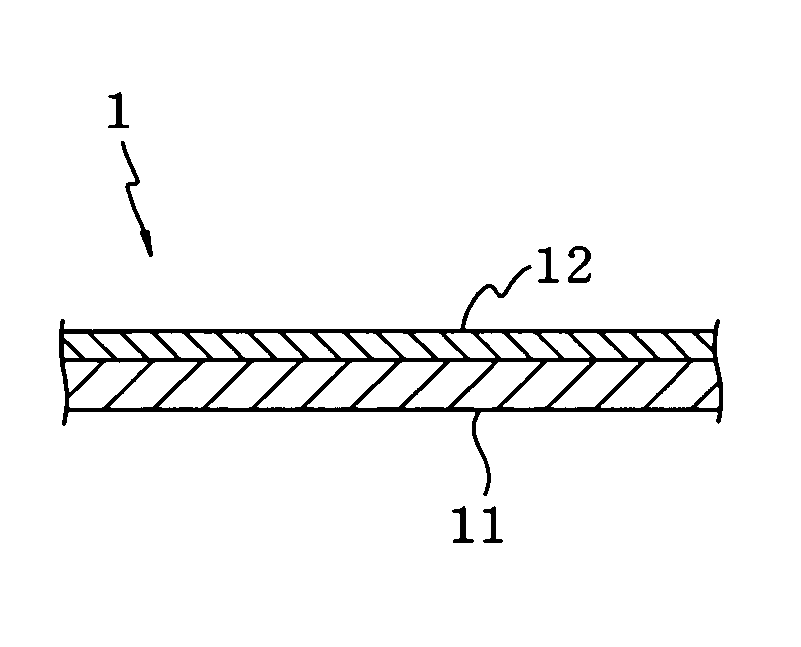

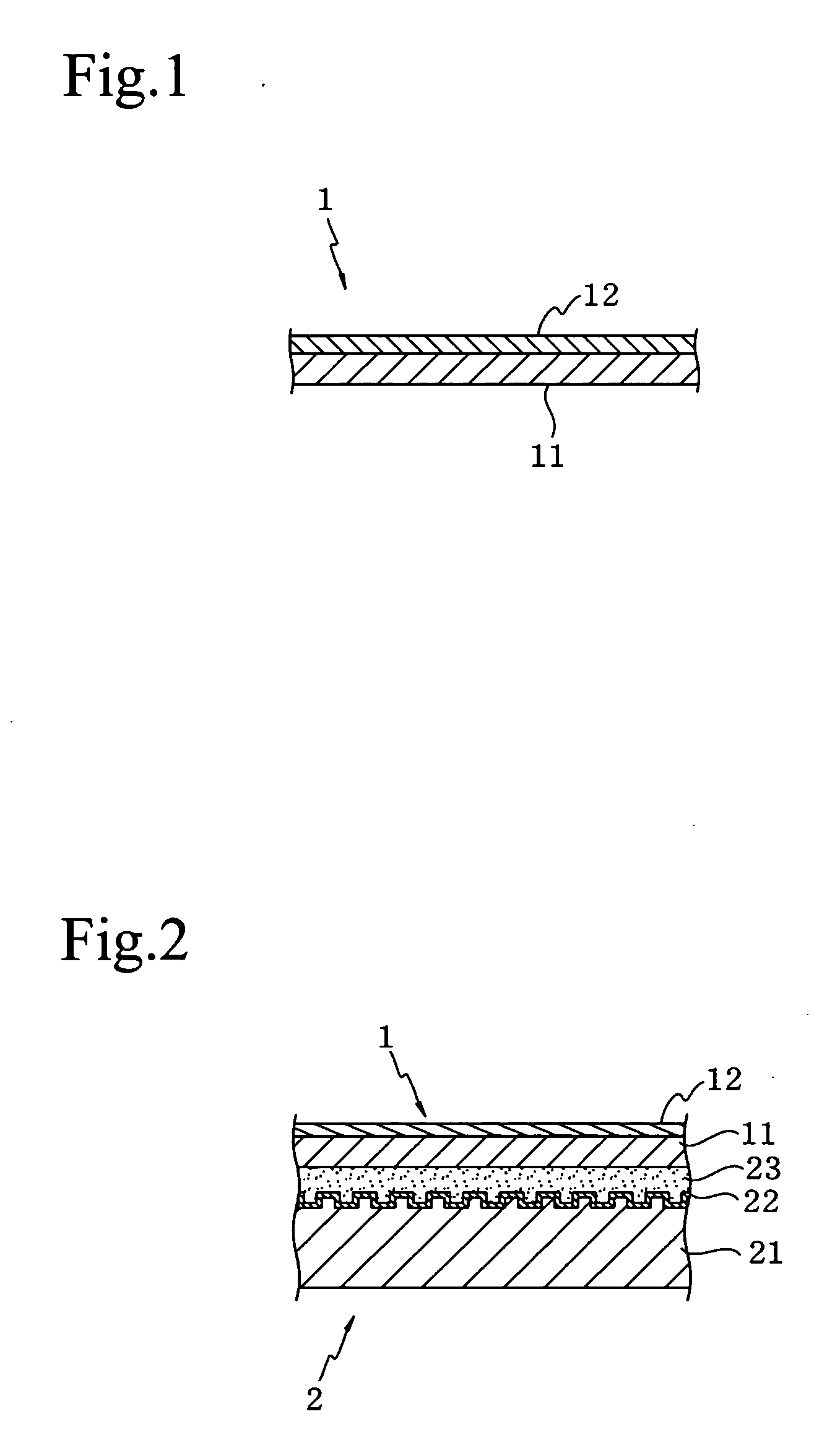

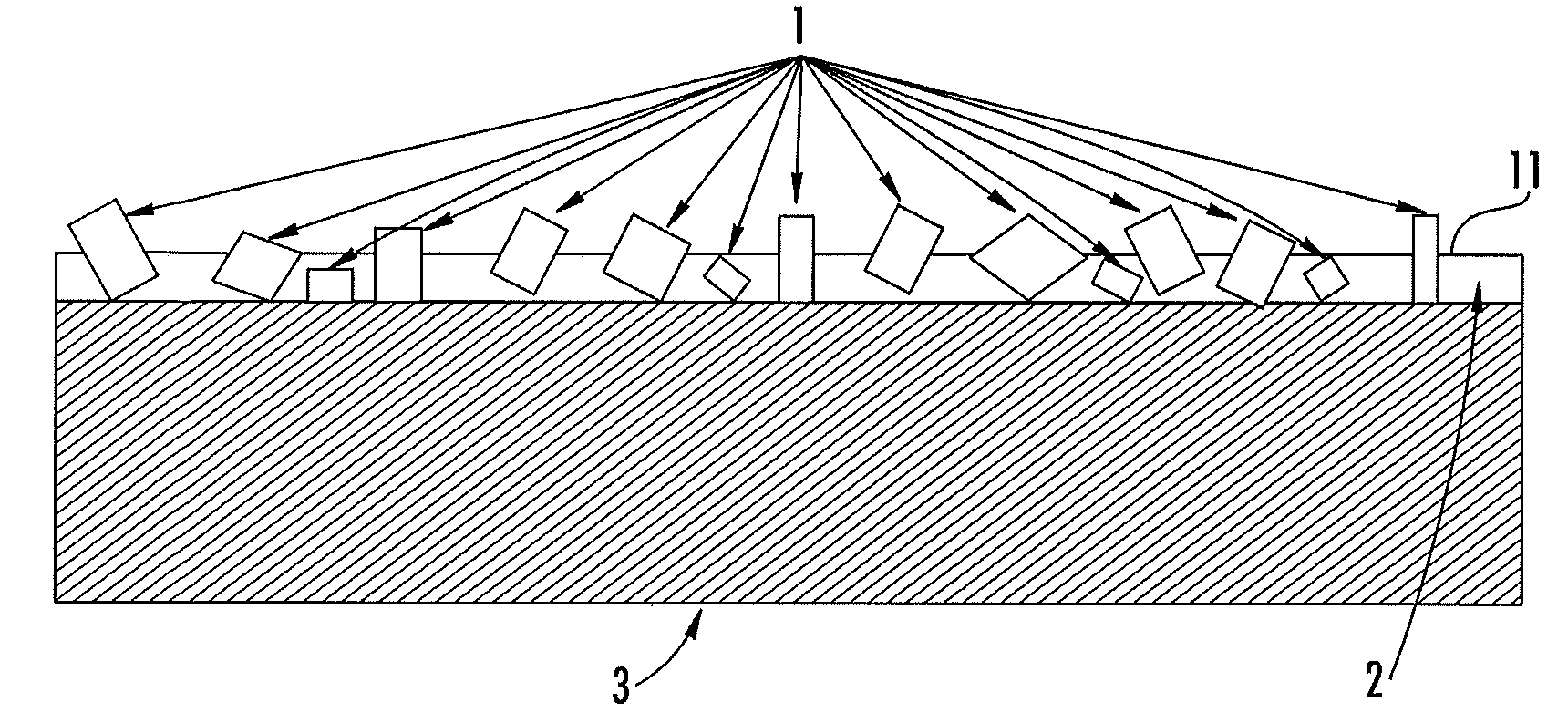

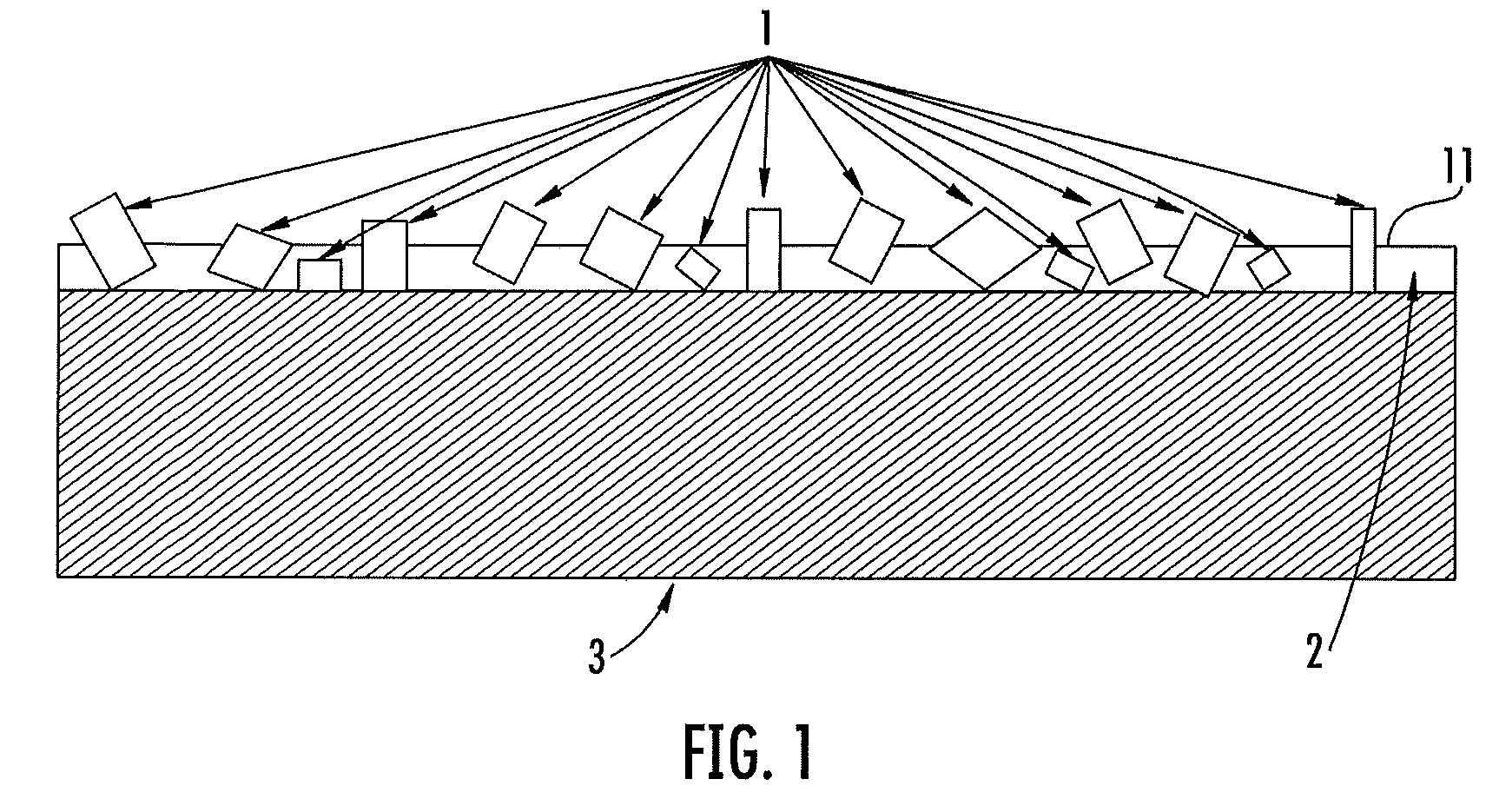

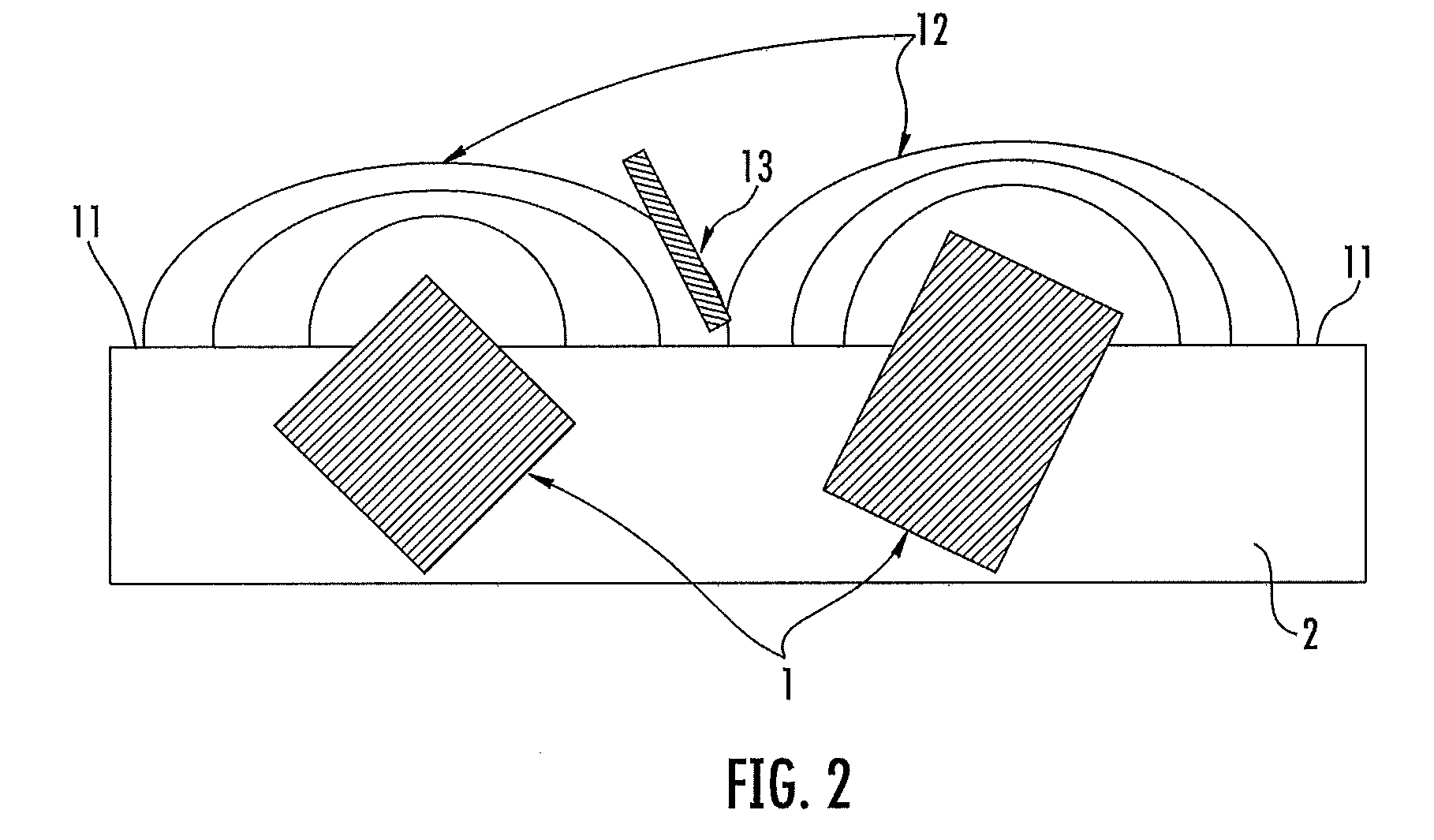

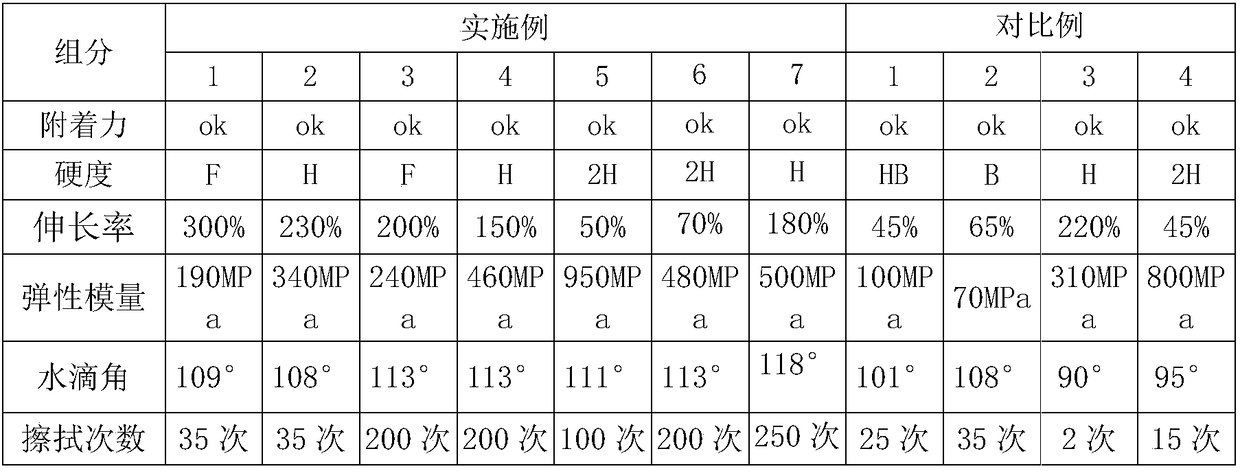

Coating composition, hard coat film, and optical disk

ActiveUS20050147809A1Maintaining surface hardnessSufficient surface hardnessPhotomechanical apparatusRecord information storageSimple Organic CompoundsOligomer

One side of a substrate film 11 is coated with a coating composition containing (A) a reactive particle produced by chemically bonding an organic compound having at least one polymerizable unsaturated group in its molecule to an inorganic oxide particle, (B) a monomer or oligomer of an organic compound having at least two polymerizable unsaturated groups in its molecule, (C) an organic compound with a weight average molecular weight of at least 1500 and having at least one polymerizable unsaturated group in its molecule, and, if desired, (D) a siloxane compound having a dimethylsiloxane skeleton, and the coating composition is cured by irradiation with ionizing radiation to form a hard coat layer 12 with a thickness of 2 to 20 μm. This provides a hard coat film having adequate surface hardness and suppressed warpage.

Owner:LINTEC CORP

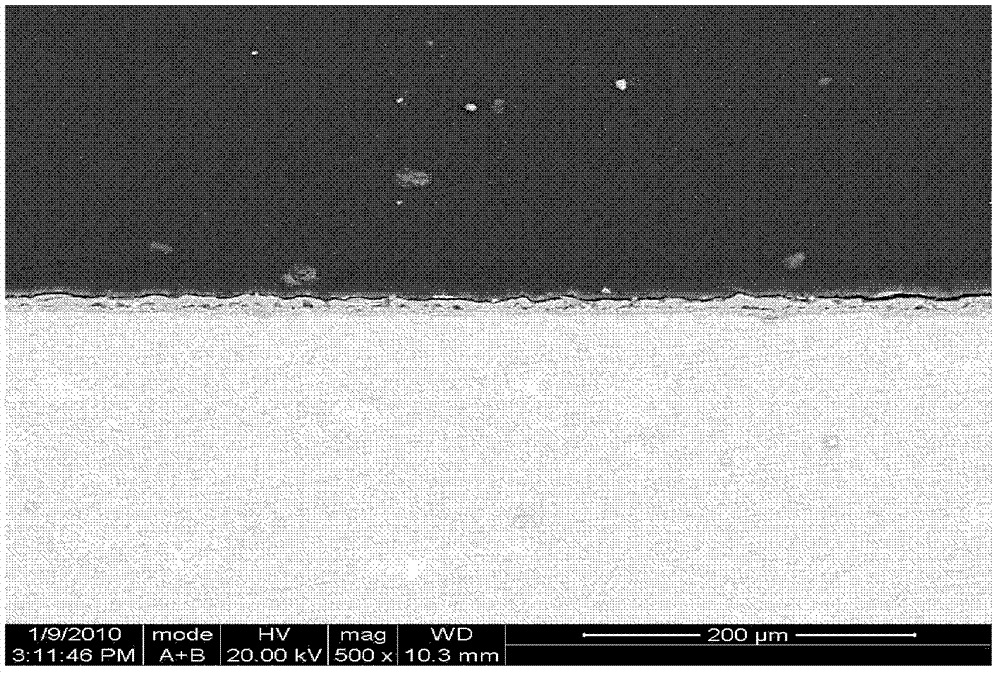

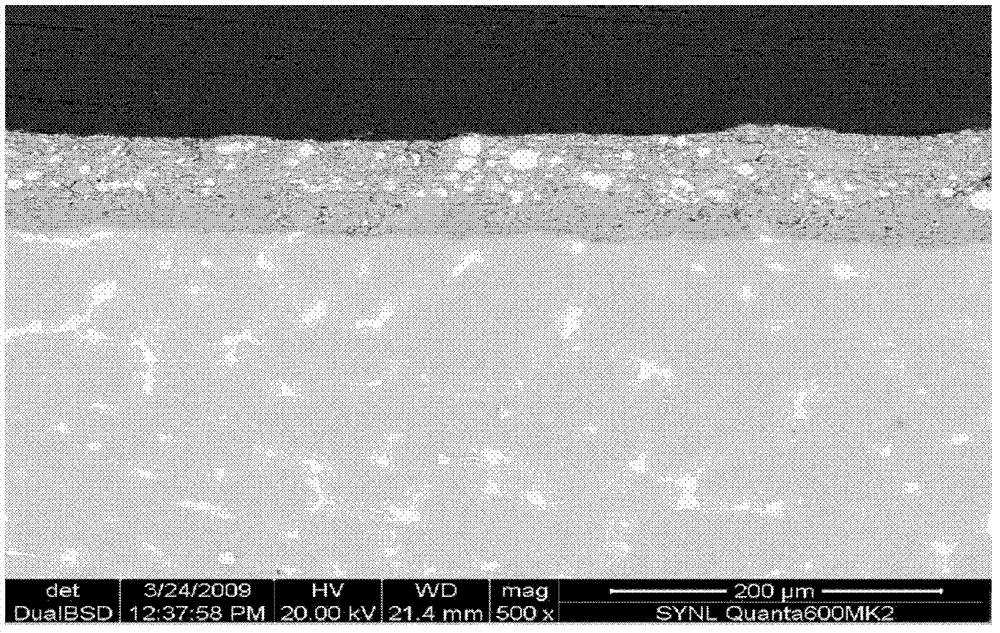

Magnesium alloy surface micro-arc oxidation nanometer self-assembly metal ceramic coating and preparation method thereof

InactiveCN103085379AAchieving densification and sealingReduce defectsAnodisationCeramic layered productsCross-linkMicro arc oxidation

The present invention discloses a magnesium alloy surface micro-arc oxidation nanometer self-assembly metal ceramic coating and a preparation method thereof. The coating comprises a micro-arc oxidation ceramic layer, a self-assembly nanometer film and an inorganic metal ceramic coating, wherein the micro-arc oxidation ceramic layer, the self-assembly nanometer film and the inorganic metal ceramic coating are sequentially attached on the magnesium alloy surface. The preparation method comprises: carrying out plasma electrolysis oxidation on the surface of a magnesium alloy substrate to form a micro-arc oxidation ceramic coating, then carrying out dipping or high pressure spraying of a self-assembly nanometer film as a connection layer on the surface of the ceramic layer, and adopting a low temperature sintering method to prepare an inorganic metal ceramic coating on the surface of the self-assembly nanometer film. According to the present invention, the head group of the self-assembly nanometer film and the micro-arc oxidation bottom layer ceramic layer form chemical bonding, and a sealing treatment is performed on micro-pores of the micro-arc oxidation film; a high density cross-linking effect on active function groups in the inorganic metal ceramic coating by the self-assembly nanometer film is achieved through the end group; and the magnesium alloy surface composite protection coating prepared by using the method has characteristics of good bonding strength, corrosion resistance, scratching resistance and high hardness.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

3D mobile phone back cover and molding process thereof

The invention discloses a 3D mobile phone back cover which comprises a body. The body comprises a glass back cover and a PET film. The glass back cover is integrally formed by a glass bending machine through hot bending. The PET film is punched and cut. The PET film is arranged in the glass back cover. The inner flat plate part coincides with a flat plate part. A side bending part coincides with an inner side bending part. The PET film is vacuum laminated with the glass back cover through a transparent optical adhesive layer. An ink pattern layer is arranged on one side, which fits the glass back cover, of the PET film. According to the 3D mobile phone back cover provided by the invention, the glass back cover and the PET film are free of signal interference, so that the signal of a mobile phone is strong; wireless charging is realized; the 3D mobile phone back cover is suitable for the application of a 5G network; the glass has the advantages of light weight, being thin, scratch resistance and heat dissipation, so that the mobile phone back cover has the corresponding effects of light weight, being thin, scratch resistance and heat dissipation; and the mobile phone is prevented from heating. The invention further discloses a molding process of the 3D mobile phone back cover.

Owner:FUJIAN SHISHI TONGDA ELECTRICAL APPLIANCE

Endogenous frosting-effect glass ink and method for producing frosting-effect product by utilizing same

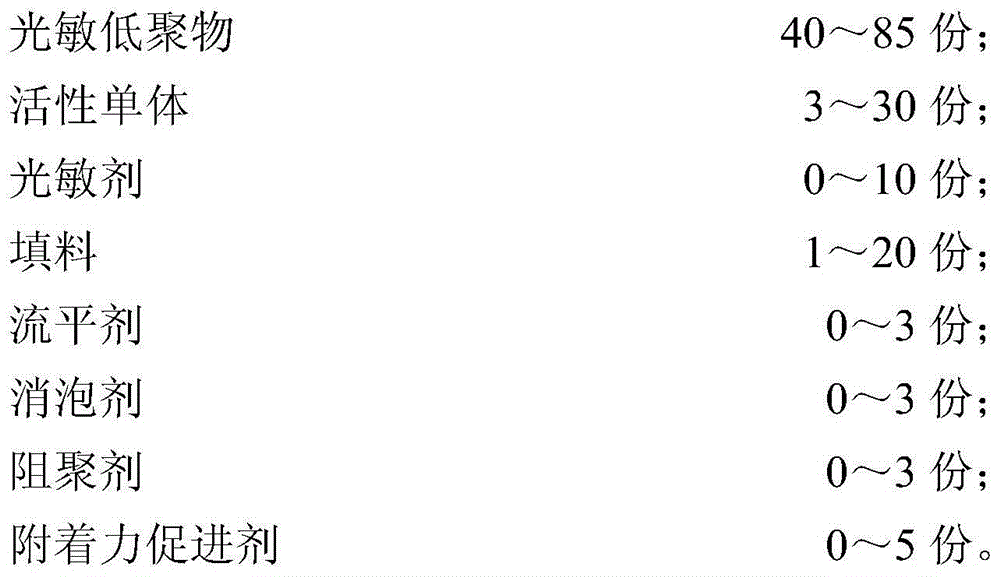

The invention discloses endogenous frosting-effect ink and a method for producing a frosting-effect product in a two-stage UV curing method. The ink consists of the following components in parts by weight: 40 to 85 parts of photosensitive oligomer, 3 to 30 parts of active monomer, 0 to 10 parts of photosensitive agent, 1 to 20 parts of stuffing, 0 to 3 parts of flatting agent, 0 to 3 parts of defoaming agent, 0 to 3 parts of polymerization inhibitor and 0 to 5 parts of adhesion promoter. The two-stage UV curing process comprises a low-energy UV light curing step and a high-energy UV light curing step. The ink is good in mobility, excellent in printing property, high in production efficiency and true in UV curing layer frosting effect, and no waste water and no waste gas are produced; and the endogenous frosting-effect glass ink has the characteristics of high hardness, scratch resistance, excellent adhesion force, excellent water resistance, excellent acid-alkali resistance and the like.

Owner:HANGZHOU KEWANG SPECIAL INK CO LTD

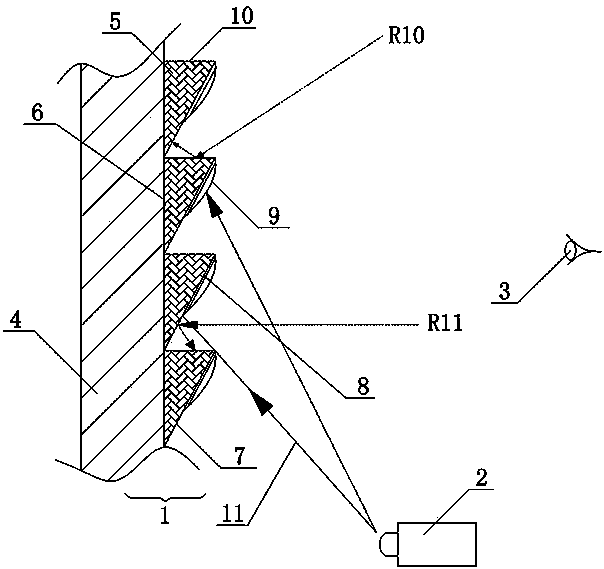

Projection system with forward projection optical screen

The invention relates to a projection system with a forward projection optical screen. The projection system is composed of a forward projection screen (1) and a projection machine (2), the forward projection screen (1) comprises a substrate layer (4), a microprism array structure layer (5), a metal medium mirror surface reflective film (8) and a light diffuse reflection layer (9), the microprism array structure layer (5) is arranged on the side, facing the projection machine (2), of the substrate layer (4), and the microprism array structure layer (5) is composed of a bottom face (6), a projection machine incident ray shadow area (7) and an environment ray absorption layer (10). The projection system has the advantages that under the bright environment, the high gain and high contrast ratio are achieved, meanwhile, no surface glare exists, and the high-color reduction is achieved; a protection layer can be selectively attached to the outer side of the microprism array structure layer, and the protection layer has the advantages of being resistant to scratch, dust and aging.

Owner:CHENGDU FSCREEN SCI TECH

Method for processing wood flooring

ActiveCN1827324AScratch resistantWith gloss retention effectWood working apparatusSolid woodEngineering

The invention discloses a method for processing solid wood floor, which comprises following steps: 1, drying and maintaining blank; 2, processing blank; 3, painting; 4, radio laser roller coating. The invention uses new bottom paint and surface paint plating method, to realize abrasion resistance and flexibility of product; uses flexible, abrasion resistant integrated surface paint, to realize the effect of flexible and abrasion resistant while the last roller wheel uses laser wheel, to realize better coating effect, better surface flatness and 30-40% reduced paint without generating foam.

Owner:JIUSHENG WOOD

Antireflective Laminate

InactiveUS20080138606A1Improve water resistanceGood alkali resistanceLayered productsCoatingsHigh-refractive-index polymerMaterials science

Disclosed is an antireflective laminate that has significantly improved water resistance, alkaline resistance, and wetting resistance, and has improved visibility and scratch resistance. The antireflective laminate comprises a light-transparent base material and a low-refractive index layer provided on the light-transparent base material, wherein the low-refractive index layer is provided directly on a surface of the light-transparent base material or is provided on the outermost surface of one or two or more optional layers provided on the surface of the light-transparent base material, and the low-refractive index layer comprises hydrophobitized fine particles having an average particle diameter of not less than 5 nm and not more than 300 nm, and a binder.

Owner:DAI NIPPON PRINTING CO LTD

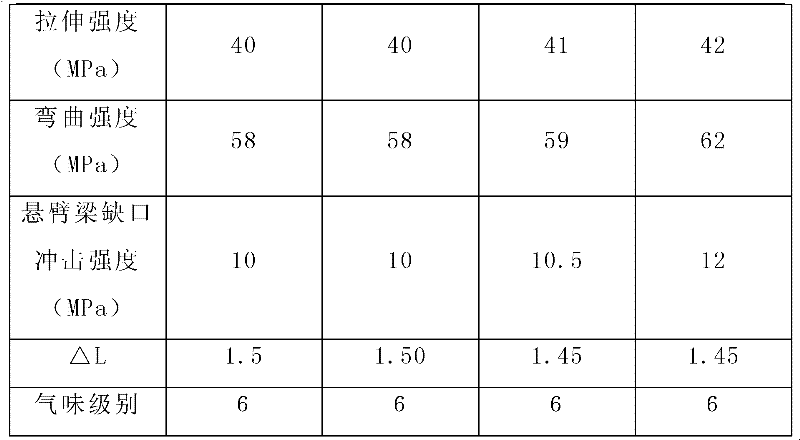

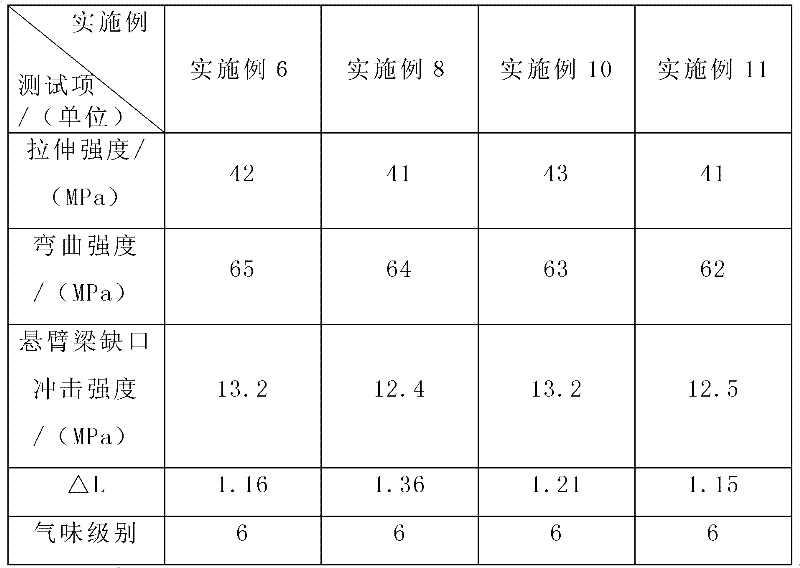

Low-odor scraping-resistant polypropylene material and preparation method thereof

The invention relates to a low-odor scraping-resistant polypropylene material and a preparation method of the low-odor scraping-resistant polypropylene material and belongs to the technical field of polypropylene materials. In order to solve the technical problems that the odor of the polypropylene material in the prior art is difficult to eliminate, the odor can be eliminated only through aiming at a certain single ingredient, the scraping resistance is poor, and the production cost is high when fluorine-containing polymers are adopted for production. The invention provides the low-odor scraping-resistant polypropylene material and also provides the preparation method of the polypropylene material, wherein the polypropylene material comprises acrylic resin, nanometer silicon dioxide, ultra-fine talcum powder, odor eliminating agents, disperse lubricating agents, antioxidants and hindered amine light stabilizers, the method comprises material mixing and squeezing granulation steps, and the low-odor scraping-resistant polypropylene material is obtained. The polypropylene material provided by the invention has the advantages of low odor and scraping resistance. The product obtained from the material has the advantage that the performance such as tensile strength, bending strength, cantilever beam notch impact strength and delta L is high. The method has the advantages that the process is simple, the operation is easy, raw materials are easy to obtain, and the industrial production is favorably realized.

Owner:浙江明江新材料科技股份有限公司

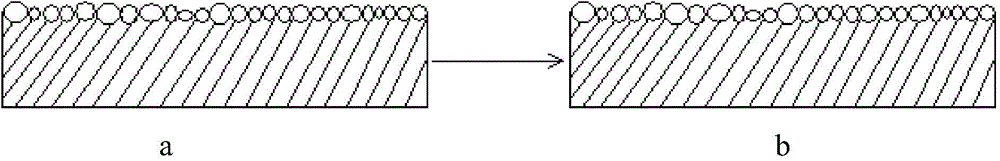

Method of manufacturing antimicrobial coating

InactiveUS20100034900A1Easy to controlLimited amountBiocideInorganic active ingredientsCoated surfaceMaterials science

A method of coating a substrate with the biocide particles dispersed into a coating permitting the antimicrobial particles to be positioned on the substrate such that they are in contact with the environment is provided. In the method, one or more biocides agents are dispersed into a coating. The coating with the biocide agent is applied to a substrate at a thickness such that at least some of the individual biocide particles extend beyond the surface of the coating.

Owner:MADICO INC

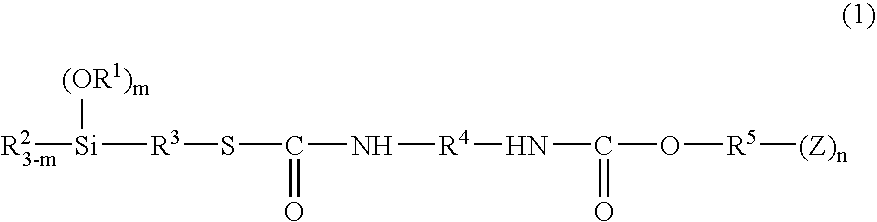

Energy ray-curable resin composition, cured product and laminate

ActiveCN104379621AScratch resistantGood flexibilitySynthetic resin layered productsPolyurea/polyurethane coatingsOligomerEthylene oxide

Provided are: an energy ray-curable resin composition which provides a coating film that has excellent scratch resistance and sufficient flexibility when cured; a cured product; and a laminate. An energy ray-curable resin composition of the present invention contains (A) a polyfunctional urethane (meth)acrylate oligomer that has 10-20 energy ray-curable functional groups, (B) at least one substance that is selected from among (meth)acrylate monomers having a cyclo ring structure and 2-6 energy ray-curable functional groups, (meth)acrylate monomers having 3-15 ethylene oxide chains and (meth)acrylate oligomers having a dendritic structure, and (C) a photopolymerization initiator. The blending ratio by mass of the component (A) to the component (B) is within the range from 60:40 to 95:5.

Owner:SOMAR CORP

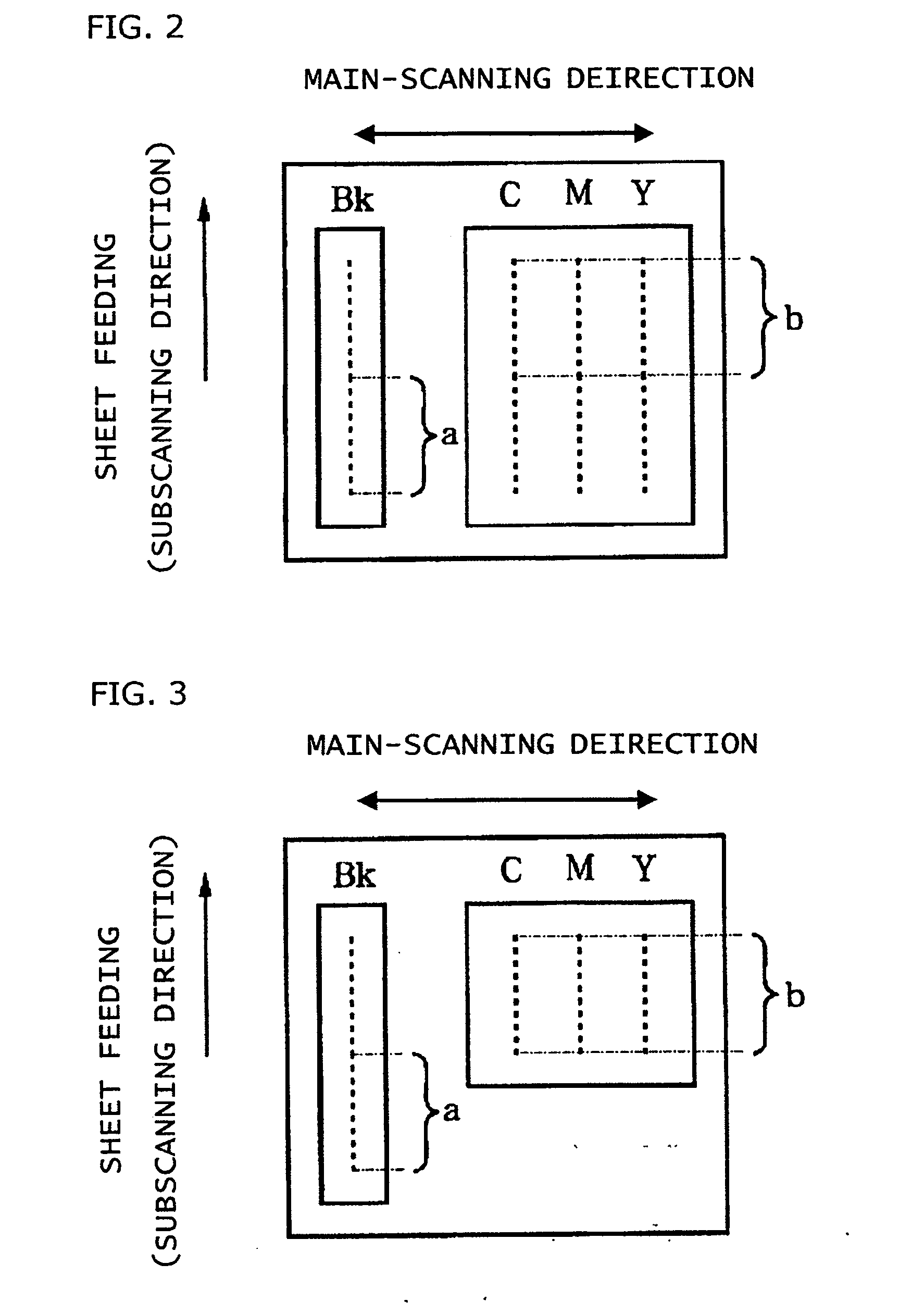

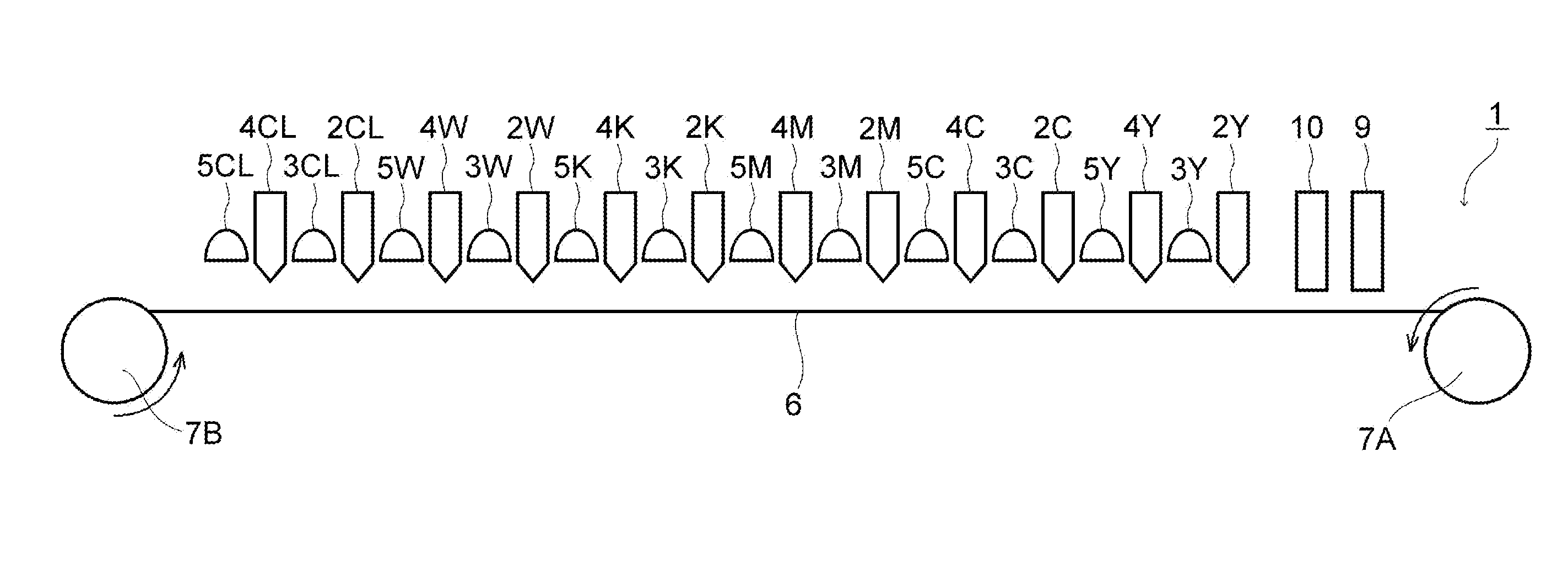

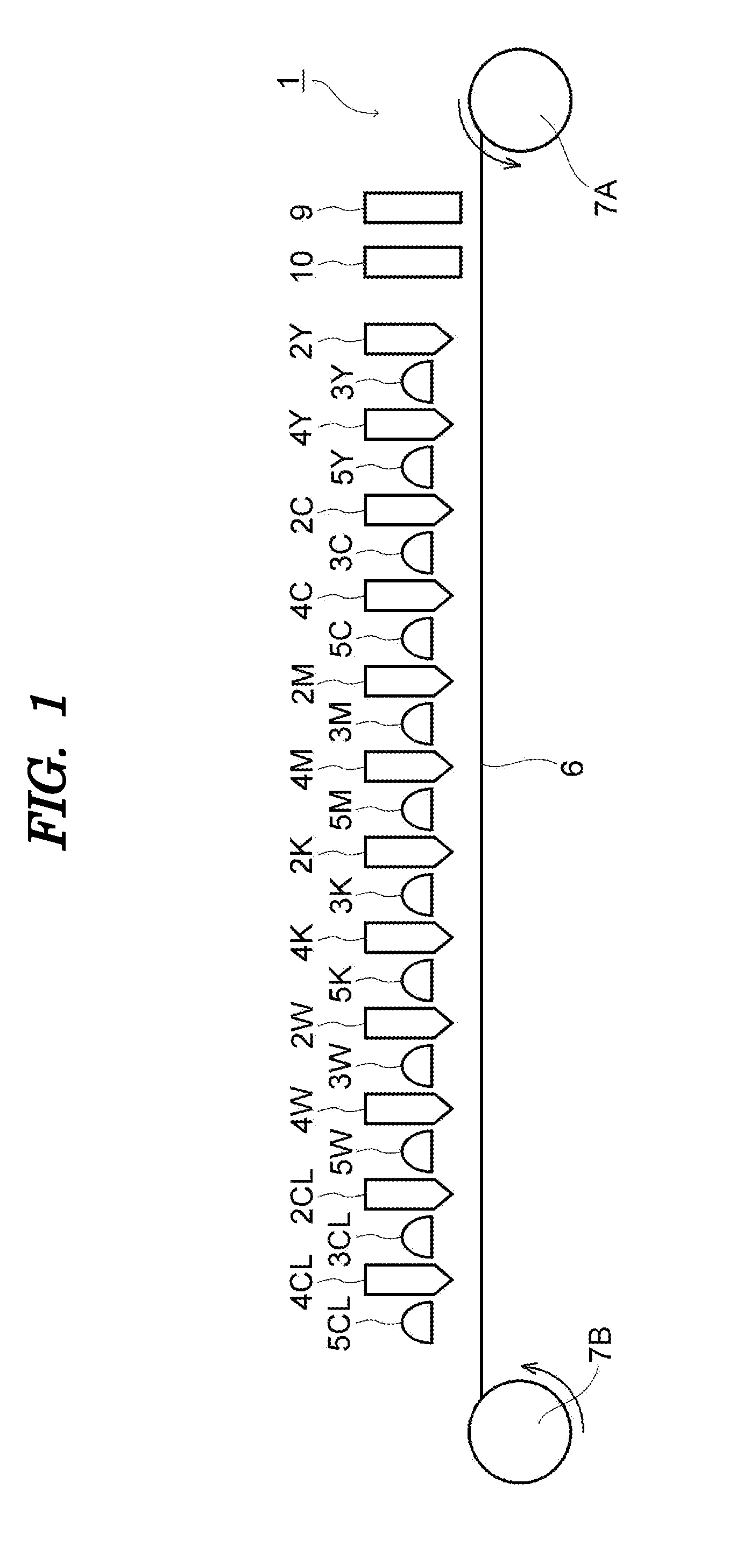

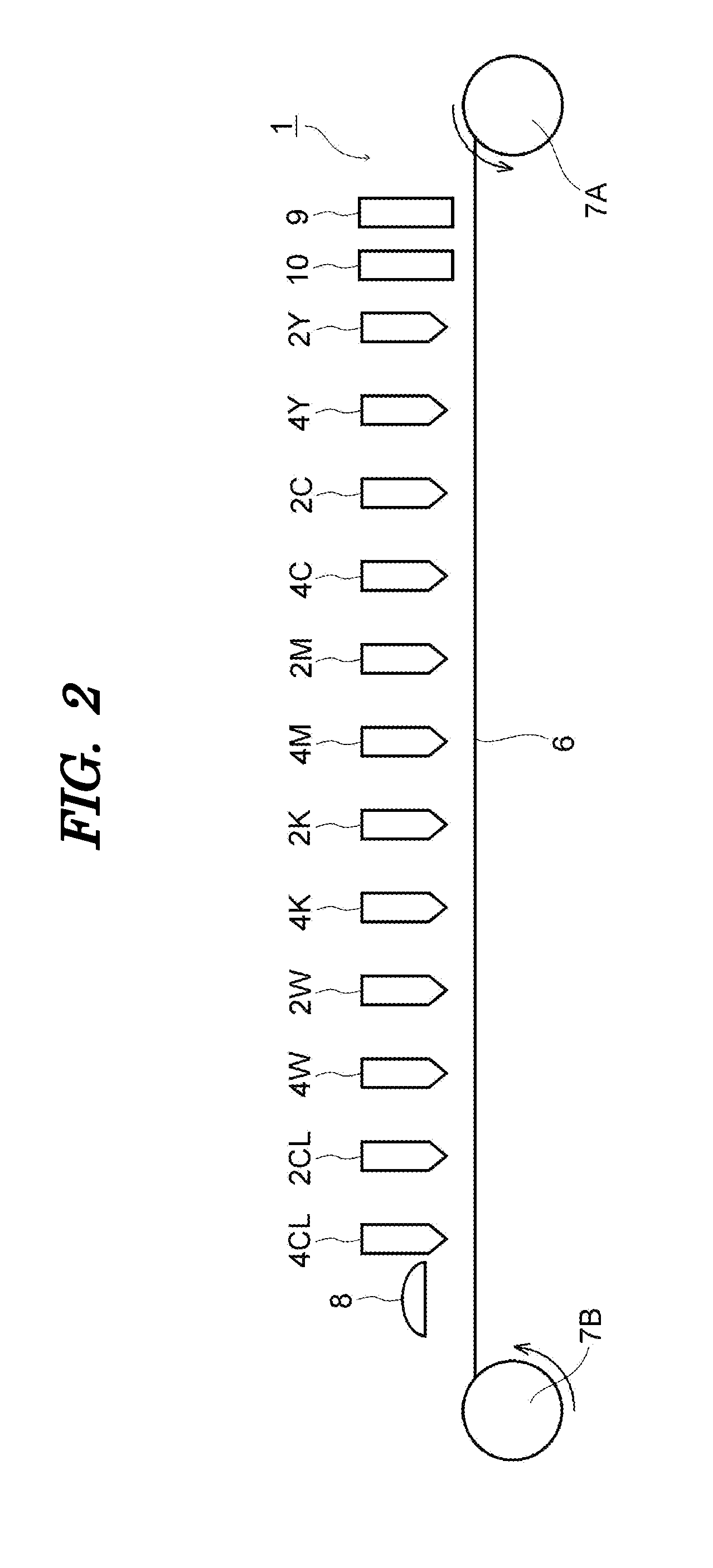

Inkjet recording method and inkjet recording system

InactiveUS20090244116A1Excellent scratch resistance and flexibilityScratch resistanceDuplicating/marking methodsInksPolymer chemistryRecording system

An inkjet recording method is provided that includes a preparatory step of preparing an ink set comprising at least ink composition A comprising (a-1) a polymerization initiator and (b-1) a polymerizable compound, at least 65 wt % of the total weight of the polymerizable compound (b-1) being a monofunctional polymerizable compound, and ink composition B comprising (a-2) a polymerization initiator and (b-2) a polymerizable compound, at least 50 wt % of the total weight of the polymerizable compound (b-2) being a polyfunctional polymerizable compound; and a selection step of selecting, as an ink composition used, ink composition A, ink composition B, or the proportions of ink composition A and ink composition B used according to the characteristics and / or the composition of a support used. There is also provided an inkjet recording system that includes the ink set and selection means for selecting, as an ink composition used, ink composition A, ink composition B, or the proportions of ink composition A and ink composition B used according to the characteristics and / or the composition of a support used.

Owner:FUJIFILM CORP

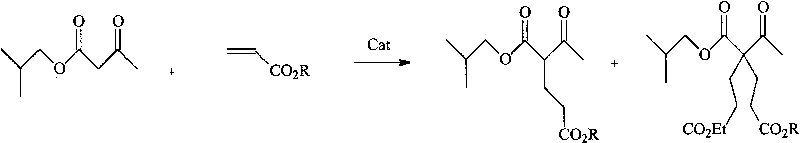

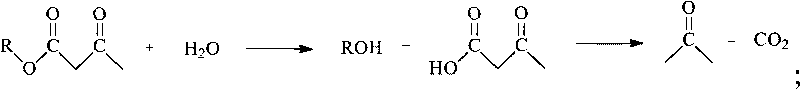

Method for preparing room-temperature self-crosslinking water-based polyurethane emulsion

ActiveCN101709108AImprove water resistanceImprove acid and alkali corrosion resistancePolyurea/polyurethane coatingsWater basedMechanical property

The invention discloses a method for preparing water-based polyurethane emulsion with a room-temperature self-crosslinking characteristic. The emulsion is prepared from the following raw materials in part by mass: 1) 100 parts of low-polymer diol, 2) 50 to 150 parts of polyisocyanate, 3) 8 to 28 parts of hydrophilic compound, 4) 5 to 50 parts of acetoacetyl compound, 5) 1 to 20 parts of micro-molecule dolichol compound, 6) 0.5 to 10 parts of polyamine compound, 7) 1 to 21 parts of ammonia or organic amine, selectively, 8) 0.01 to 0.1 parts of polyurethane reaction catalyst, and selectively, 9) 20 to 310 parts of organic solvent. After being formed into a film, the emulsion prepared by the method has excellent water resistance, acid and alkali resistance and chemical resistance, and also has the excellent physical and mechanical properties of high hardness, high elasticity, scratch resistance and the like.

Owner:WANHUA CHEM BEIJING +3

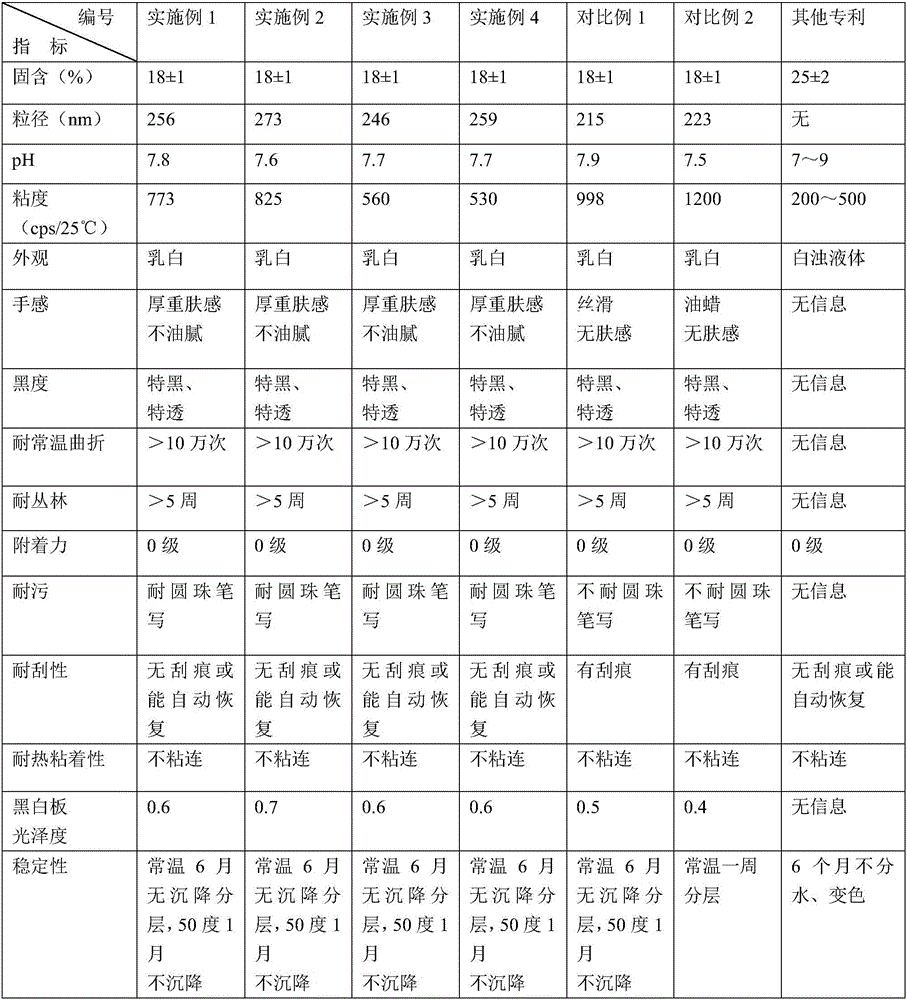

Aqueous matt surface finishing agent for PVC (Polyvinyl Chloride) leather and preparation method thereof

ActiveCN106349914AImprove performanceNo adverse phenomena such as whiteningAntifouling/underwater paintsPaints with biocidesWaxSurface finish

The invention relates to an aqueous matt surface finishing agent for PVC (Polyvinyl Chloride) leather and a preparation method thereof. The aqueous matt surface finishing agent is prepared from the following components: aqueous polyurethane resin, water, silicon dioxide matting powder, polysiloxane water dispersoid, aqueous wax emulsion, an aqueous wetting agent, an aqueous de-foaming agent and a thickening agent. The invention further relates to a preparation method of the aqueous matt surface finishing agent for the PVC leather. The aqueous matt surface finishing agent for the PVC leather, disclosed by the invention, has an excellent matt surface effect, a good heavy and skin feeling and a pollution-resisting performance and is aqueous and environment-friendly; meanwhile, the aqueous matt surface finishing agent has the advantages of good adhesive force, scratching resistance, bending resistance and forest resistance, and can meet the higher and higher requirements on skin feeling and pollution resistance of home decorations, electric appliances, furniture, automobile interiors and the like.

Owner:WANHUA CHEM GRP CO LTD +1

Ceramic microwave absorbing material and preparation method and application thereof

InactiveCN101665350AHigh surface hardnessScratch resistantScreening apparatusCooking vesselsMicrowaveUtilization rate

The invention discloses a ceramic microwave absorbing material and a preparation method and an application thereof. The ceramic microwave absorbing material comprises ceramic material powder and microwave absorbing powder, and the weight percentage of the components is as follows: 40 to 80 percent of ceramic material powder and 20 to 60 percent of microwave absorbing powder. The preparation methodof the ceramic microwave absorbing material comprises the following steps: 1) respectively weighing the ceramic material powder and the microwave absorbing powder according to weight percentage; 2) evenly mixing the ceramic material powder with the microwave absorbing powder to obtain compound wave-absorbing powder; 3) evenly mixing the compound wave-absorbing powder with methylcellulose and water to obtain the pulp of the ceramic microwave absorbing material; 4) forming the pulp to obtain a green body; and 5) drying the green body, and then sintering at high temperature to obtain the ceramicmicrowave absorbing material. The ceramic microwave absorbing material can be used for manufacturing ceramic microwave absorbing cooking equipment. The cooking equipment has high microwave utilization rate and heating efficiency; and food is not easy to be coked and is heated more uniformly. The preparation method of the ceramic microwave absorbing material has simple technique and low cost of raw material and processing.

Owner:MIDEA GRP CO LTD

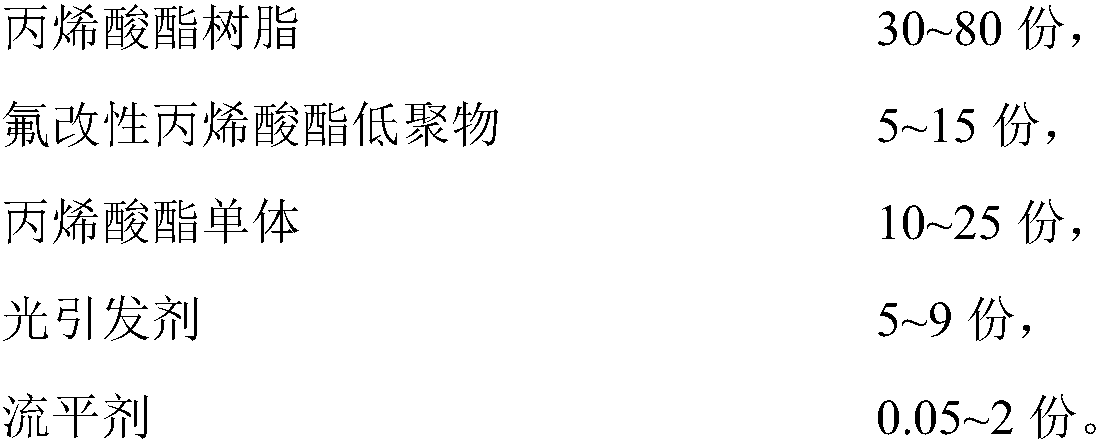

Flexible and stain-resistant ultraviolet curable coating composition and preparation method thereof

InactiveCN108264838AHas hardnessWith highlightsAntifouling/underwater paintsPaints with biocidesOligomerHardness

The invention provides a flexible and stain-resistant ultraviolet curable coating composition. The composition comprises, by weight, 30-80 parts of acrylate resin, 5-15 parts of a fluorine-modified acrylate oligomer, 10-25 parts of an acrylate monomer, 5-9 parts of a photoinitiator and 0.05-2 parts of a leveling agent. Compared with coatings in the prior art, the coating composition in the invention has a higher flexibility, and has the advantages of certain hardness, wear resistance, stain resistance, suitableness for bendable and crimped substrates, excellent comprehensive performances and wide applicability .

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Anti-reflection coating layer with transparent electric surface layer

InactiveCN1447133AScratch resistantHigh refractive indexVacuum evaporation coatingSputtering coatingSurface layerDisplay device

This invention relates to antireflection coating with transparent conductive surface layer with four layers, the first is the farest from the baseplate the second, third and fourth layers, in which, the first is the transparent conductive layer with good conductivity and antiscuffing and the antireflection coating of the transparent conductive surface has low reflection rate to be the panel of display or contacted screen.

Owner:APPLIED VACUUM COATING TECH

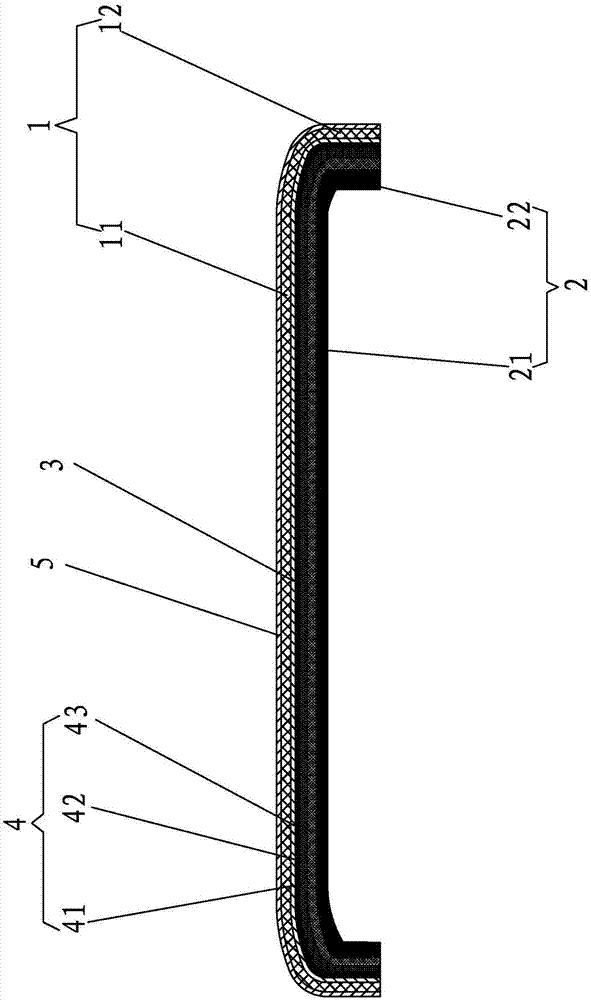

Housing of electronic device and manufacturing method thereof

InactiveCN102137554AImprove wear resistanceScratch resistantMolten spray coatingMetal casingsRough surfaceThermal spraying

The invention provides a housing of an electronic device, which comprises a metal matrix and a ceramic coating, wherein the thickness of the metal matrix is 0.4-0.6mm, the ceramic coating is directly formed on the surface of the metal matrix by hot spraying, and the surface of the metal matrix, which is in contact with the ceramic coating, is the rough surface after roughening treatment. The invention further provides a manufacturing method of the housing of the electronic device.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com