Heat-resistant scratch-resistant high-transmittance PMMA alloy resin composition and preparation method thereof

A high transmittance, alloy resin technology, applied in the field of polymer materials, can solve the problems of complex equipment, strict process requirements, unfavorable mass production, etc., and achieve the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

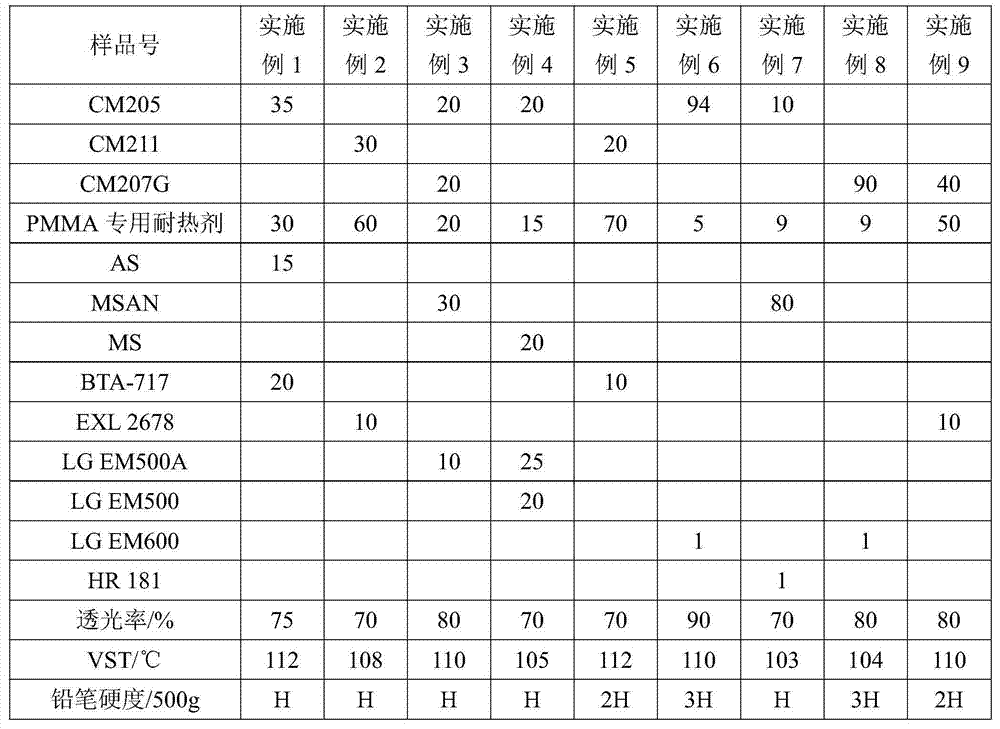

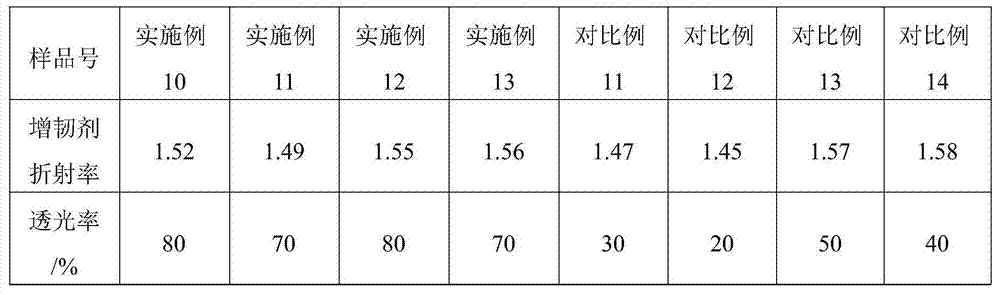

Examples

Embodiment 1

[0024] Embodiment 1 Preparation of heat-resistant, scratch-resistant, high-transmittance PMMA alloy resin of the present invention (1)

[0025] (1) Prepare materials according to the following components and parts by weight:

[0026] 35 parts of polymethyl methacrylate, 30 parts of special heat-resistant agent for PMMA, 20 parts of toughening agent, 15 parts of fluidity regulator, 0.3 parts of antioxidant, 1.5 parts of lubricant; 0.001 parts of coloring agent, 0.5 parts of UV absorber .

[0027] (2) Put the above-mentioned (1) raw materials into the high-speed mixer according to the formula and stir them, and then send them into the twin-screw extruder through the metering device after mixing evenly. Under the conveying, shearing and mixing of materials, the materials are melted and compounded, and then go through the steps of extrusion, drawing, cooling and pelletizing. Among them, the content of maleic anhydride MAH in the PMMA special heat-resistant agent is 20%; the poly...

Embodiment 2

[0028] Embodiment 2 Preparation of heat-resistant, scratch-resistant, high-transmittance PMMA alloy resin of the present invention (two)

[0029] (1) Prepare materials according to the following components and parts by weight:

[0030] 30 parts of polymethyl methacrylate, 60 parts of special heat-resistant agent for PMMA, 10 parts of toughening agent, 0.3 part of antioxidant, 1.5 parts of lubricant; 0.01 part of colorant, 0.5 part of UV absorber.

[0031] (2) Put the above-mentioned (1) raw materials into the high-speed mixer according to the formula and stir them, and then send them into the twin-screw extruder through the metering device after mixing evenly. Under the conveying, shearing and mixing of materials, the materials are melted and compounded, and then go through the steps of extrusion, drawing, cooling and pelletizing. Among them, the content of maleic anhydride MAH in the special heat-resistant agent for PMMA is 5%; the polymethyl methacrylate is Chimei's CM211; ...

Embodiment 3

[0032] Embodiment 3 Preparation of heat-resistant, scratch-resistant and high-transmittance PMMA alloy resin of the present invention (3)

[0033] (1) Prepare materials according to the following components and parts by weight:

[0034] 40 parts of polymethyl methacrylate, 20 parts of special heat-resistant agent for PMMA, 10 parts of toughening agent, 30 parts of fluidity regulator, 0.1 part of antioxidant, 2 parts of lubricant; 0.3 part of free radical scavenger; heat stabilizer 0.2 parts.

[0035] (2) Put the above-mentioned (1) raw materials into the high-speed mixer according to the formula and stir them, and then send them into the twin-screw extruder through the metering device after mixing evenly. Under the conveying, shearing and mixing of materials, the materials are melted and compounded, and then go through the steps of extrusion, drawing, cooling and pelletizing. Among them, the content of maleic anhydride MAH in PMMA special heat-resistant agent is 15%; polymet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com