Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Scratch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

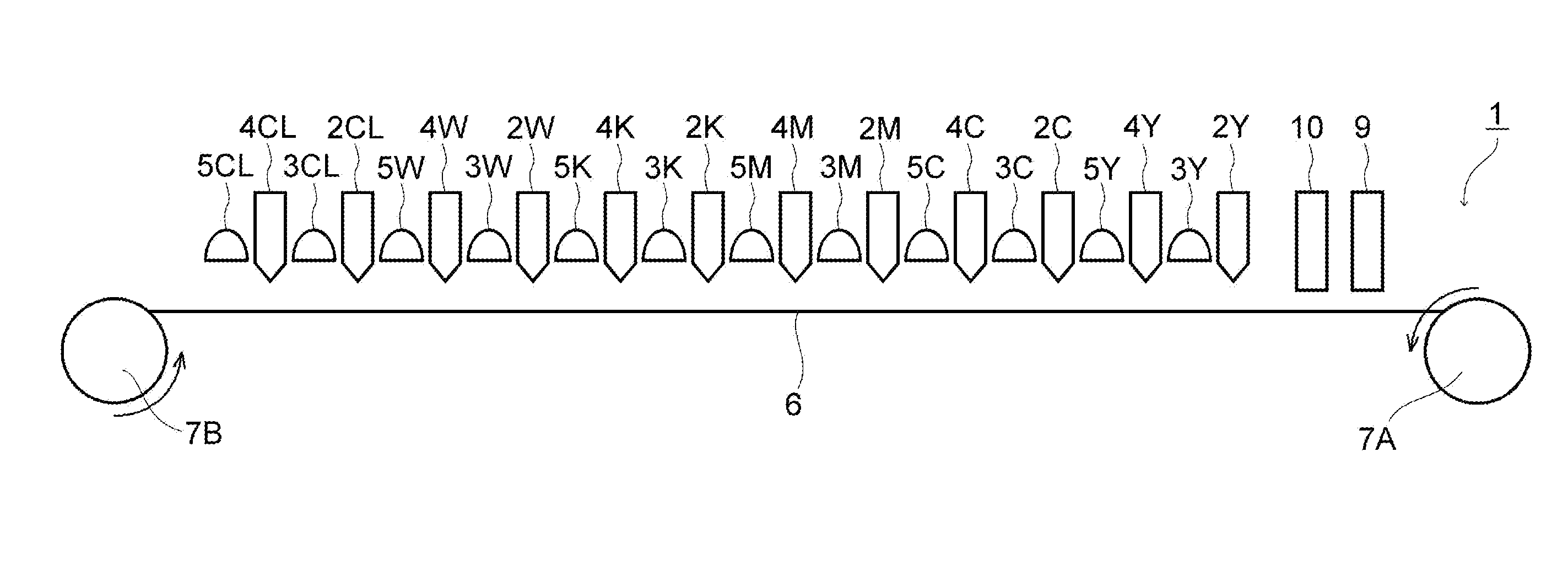

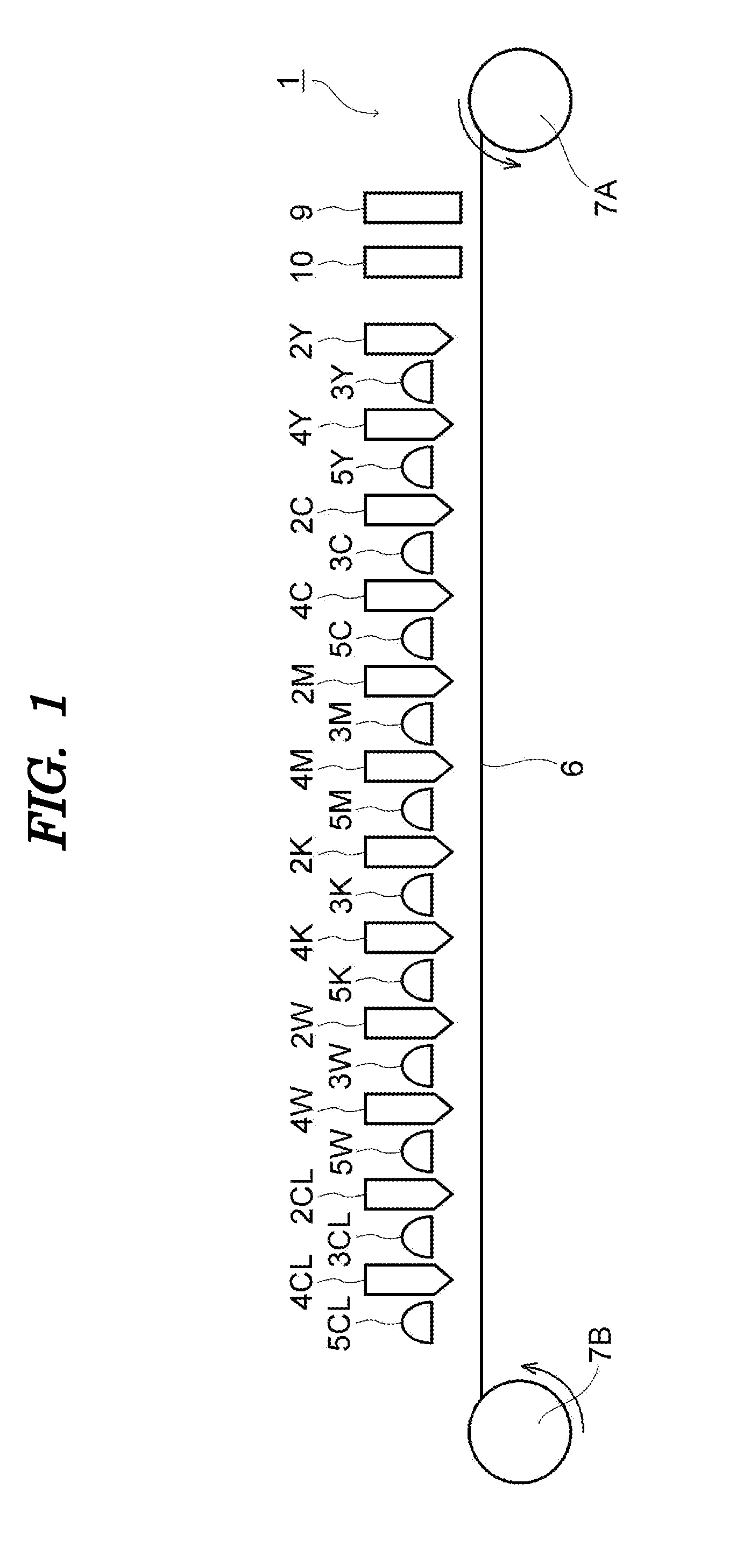

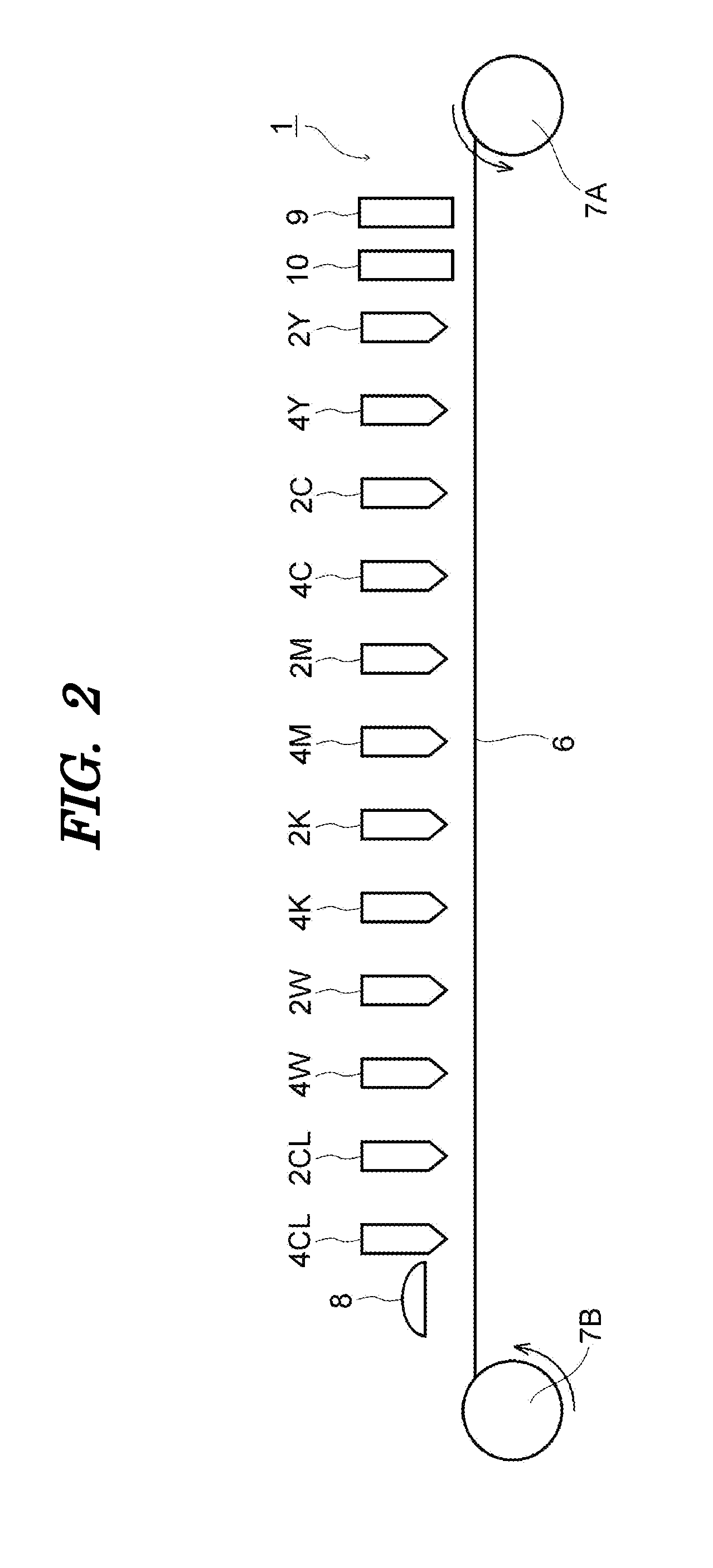

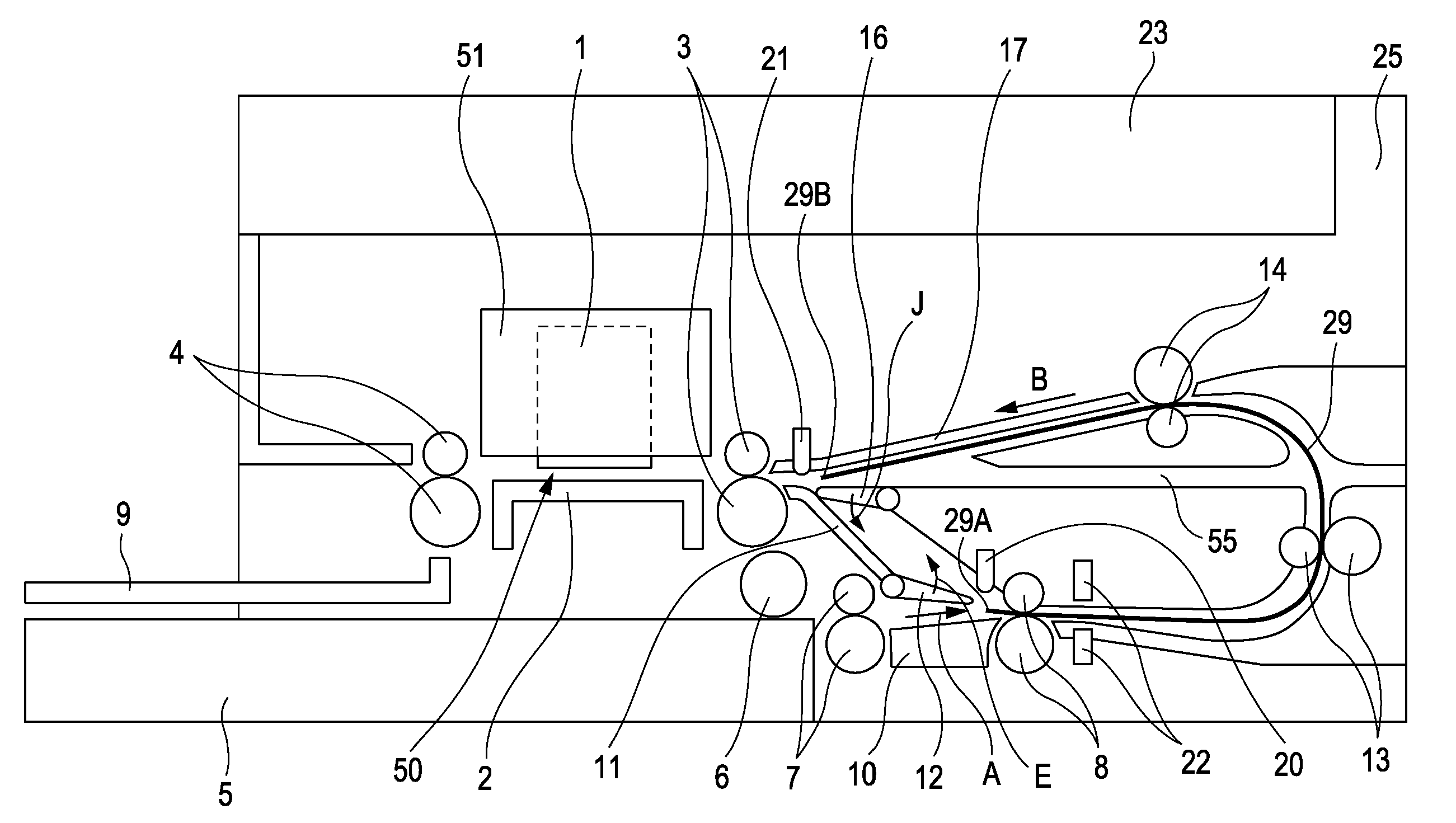

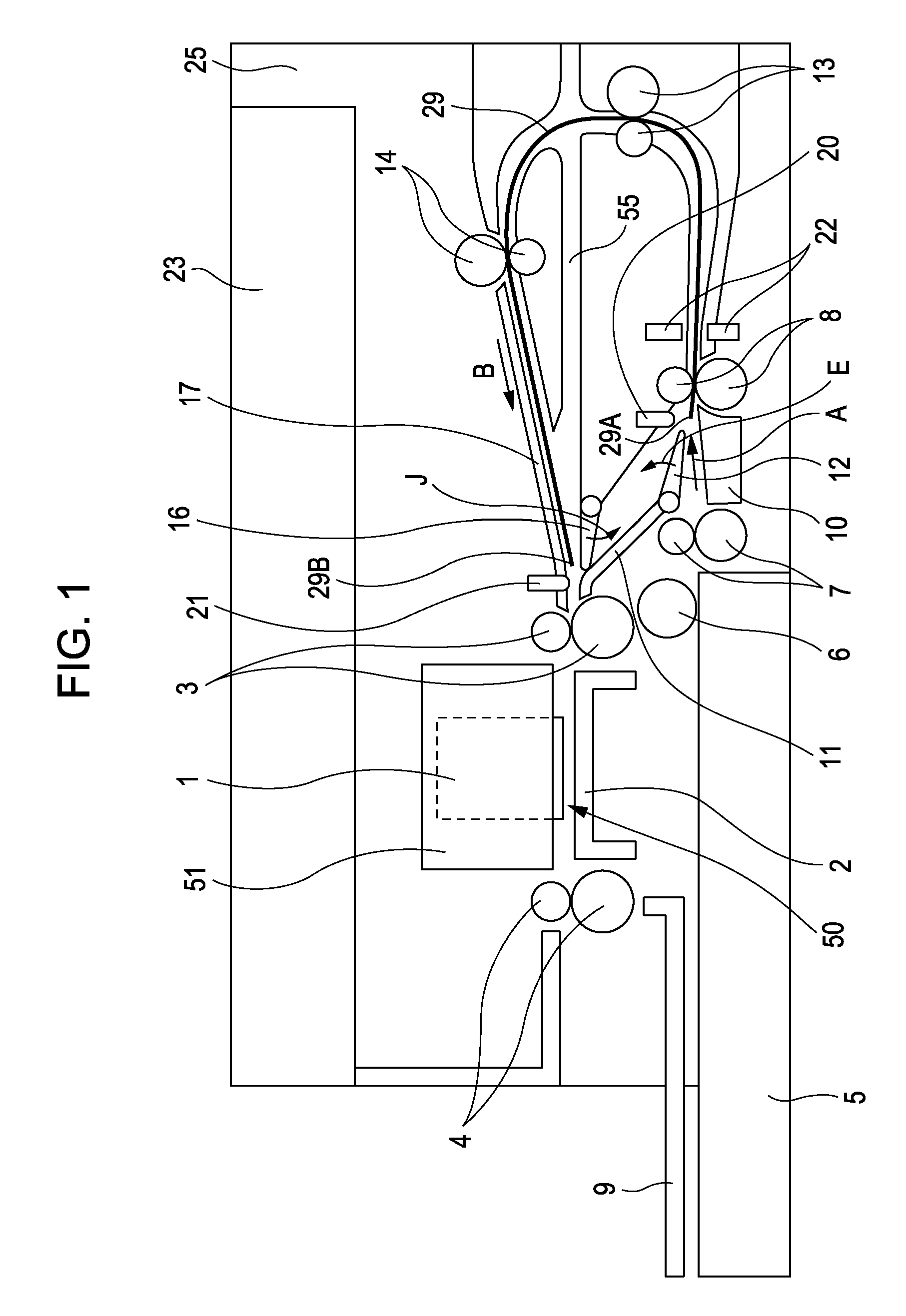

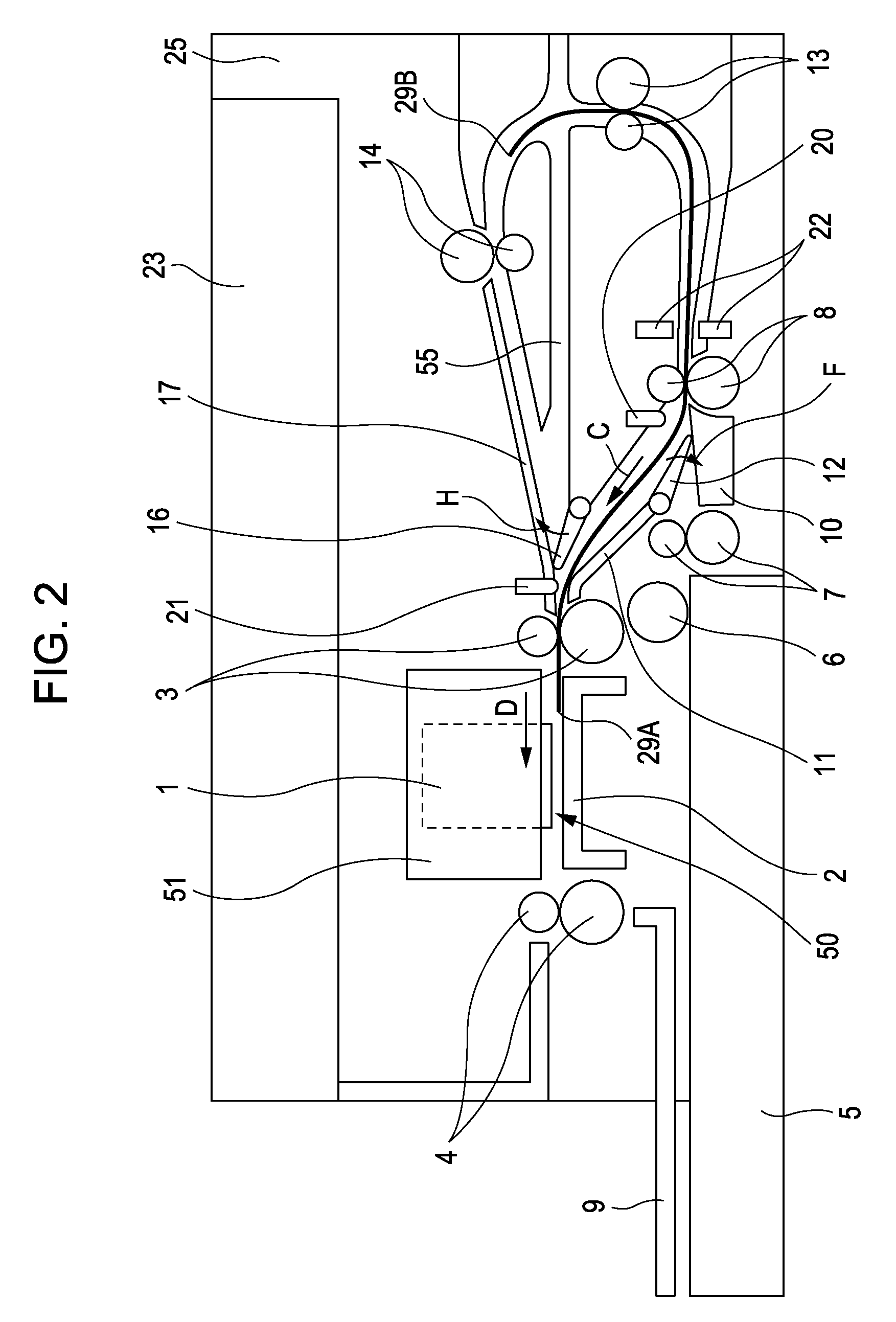

Inkjet recording method and inkjet recording system

InactiveUS20090244116A1Excellent scratch resistance and flexibilityScratch resistanceDuplicating/marking methodsInksPolymer chemistryRecording system

An inkjet recording method is provided that includes a preparatory step of preparing an ink set comprising at least ink composition A comprising (a-1) a polymerization initiator and (b-1) a polymerizable compound, at least 65 wt % of the total weight of the polymerizable compound (b-1) being a monofunctional polymerizable compound, and ink composition B comprising (a-2) a polymerization initiator and (b-2) a polymerizable compound, at least 50 wt % of the total weight of the polymerizable compound (b-2) being a polyfunctional polymerizable compound; and a selection step of selecting, as an ink composition used, ink composition A, ink composition B, or the proportions of ink composition A and ink composition B used according to the characteristics and / or the composition of a support used. There is also provided an inkjet recording system that includes the ink set and selection means for selecting, as an ink composition used, ink composition A, ink composition B, or the proportions of ink composition A and ink composition B used according to the characteristics and / or the composition of a support used.

Owner:FUJIFILM CORP

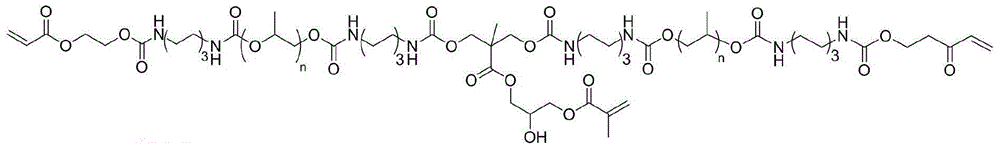

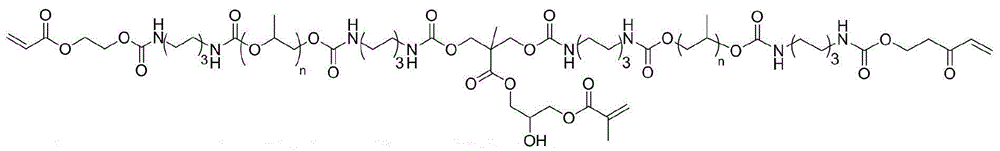

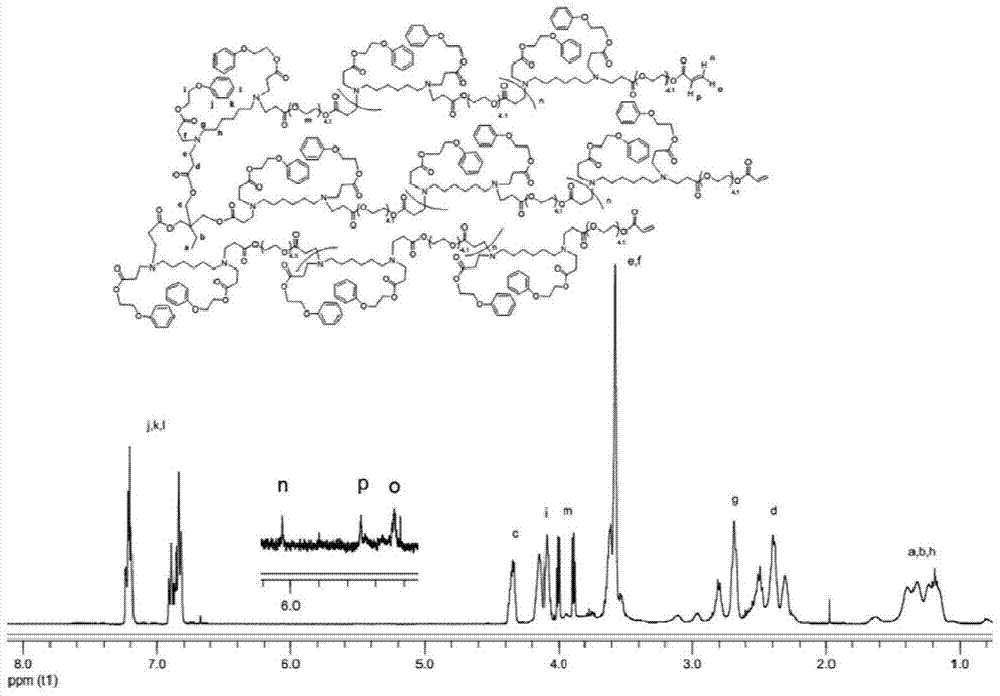

Ultraviolet light curing elastic self-healing coating composition

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Recording apparatus

InactiveUS20080278523A1Scratch resistanceMaintaining recording speedRecording apparatusTypewritersEngineeringMechanical engineering

Owner:CANON KK

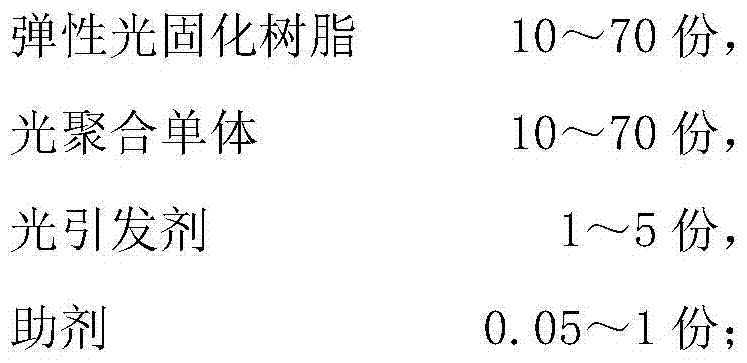

UV photo-curing elastic self-repairing brightening paint composition

InactiveCN104877544ASimple production processSimple preparation conditionsPolyurea/polyurethane coatingsUltraviolet lightsWear resistance

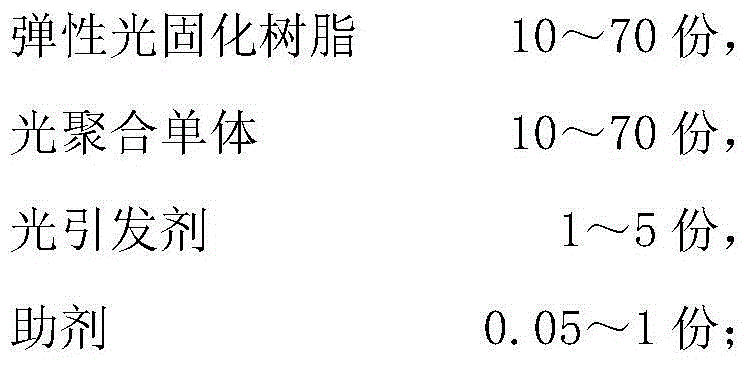

The invention provides a UV photo-curing elastic self-repairing brightening paint composition. The paint composition comprises the following ingredients in parts by weight: 10 to 70 parts of elastic photo-curing resin, 10 to 50 parts of photopolymerization monomer, 2 to 5 parts of photoinitiator and 0.05 to 1 part of additive. The UV photo-curing elastic self-repairing brightening paint composition can be smeared on an optical PET plastic base material; after being cured by ultraviolet light, a coating is excellent in elasticity and also good in attachment force, wear resistance and scratch resistance.

Owner:SHANGHAI WEIKAI CHEM +1

UV elastic self-repairing coating

InactiveCN105713508AScratch resistantWith wear resistancePolyurea/polyurethane coatingsUV curingSolvent

A UV elastic self-healing coating is composed of the following raw materials according to mass percentage: 50-70% of elastic photocurable resin, 2-10% of photopolymerizable monomer, 1-2% of photoinitiator, 22.2-25.2% of solvent, auxiliary 0.05‑15%, the prepared UV elastic self-healing coating can form a cross-linked network with both soft and hard segments after UV curing, and the elastic part is contributed by the elastic part of the elastic photocurable resin. The hard segment area is provided by the hard segment of the elastic photocurable resin, which ensures that the coating has good elastic self-healing properties and also has scratch resistance and wear resistance.

Owner:威堡涂料(天津)有限公司

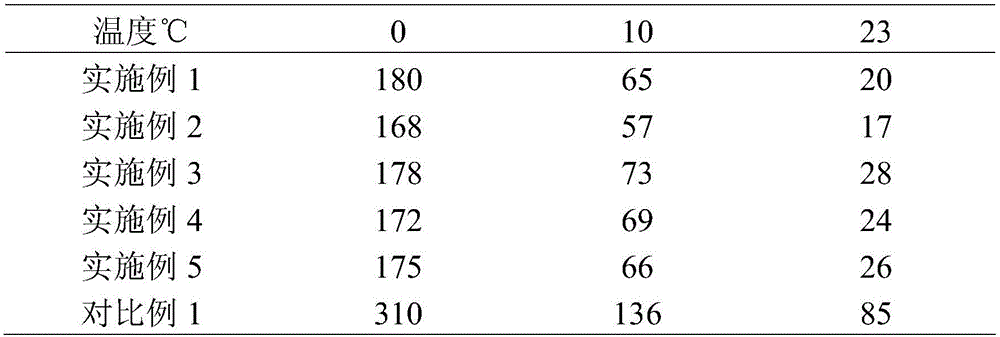

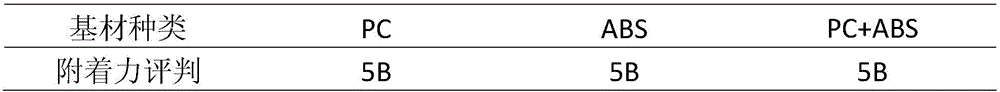

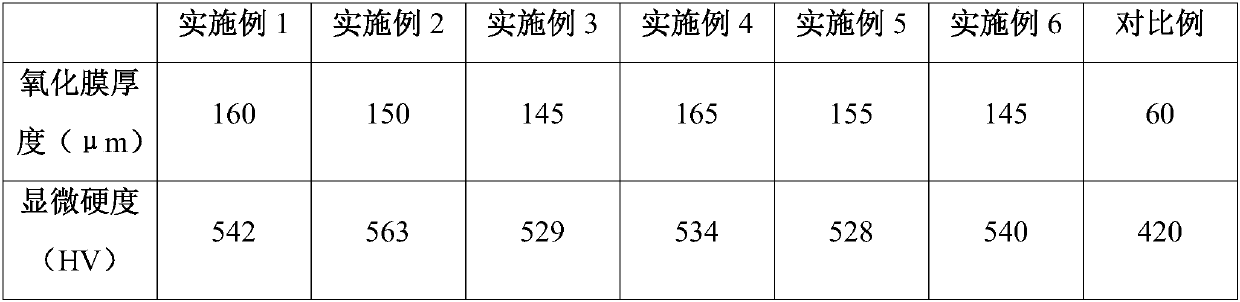

Aluminum alloy anode oxidation technology

The invention belongs to the technical field of metal surface treatment, and relates to an aluminum alloy anode oxidation technology. According to the technology, an aluminum alloy section is arrangedin an electrolytic bath loaded with oxidation electrolyte, so as to be electrolyzed; the electrolysis temperature is 10 to 30 DEG C; the aluminum alloy section is taken as an anode; a lead plate is taken as a cathode; an electrolysis mode is a direct current-alternating current overlapped method, so that an oxidation film is formed on the surface of the aluminum alloy section subjected to anode oxidation, the electrolysis speed is further improved through strict controlling of direct current-alternating current ratio, the deposition rate of the oxidation film is improved, an oxidation film with the thickness greater than 100 micrometers can be formed within 5min, the micro hardness of the obtained aluminum alloy section oxidation film is greatly improved, defects on the surface of the oxidation film are reduced, and the surface texture is denser.

Owner:CHINA ZHONGWANG

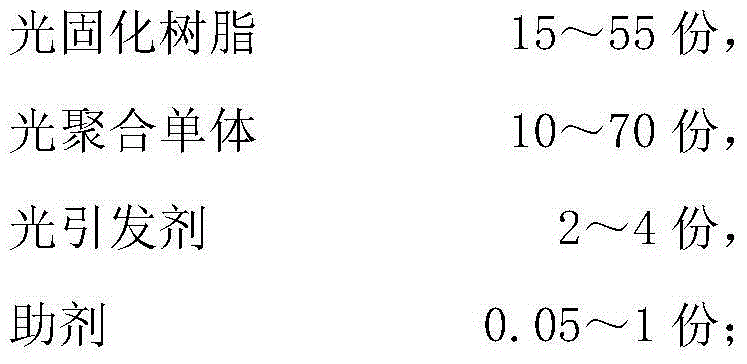

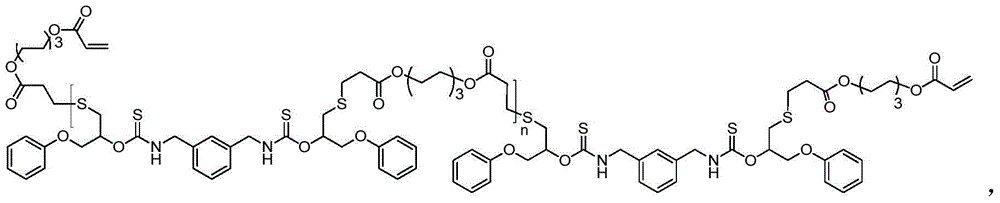

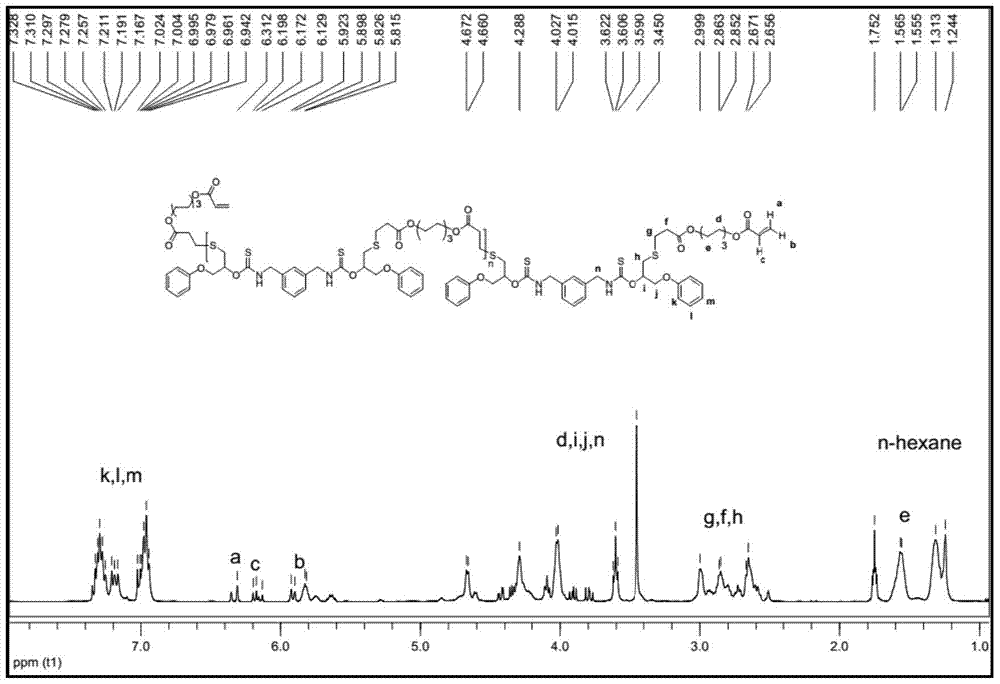

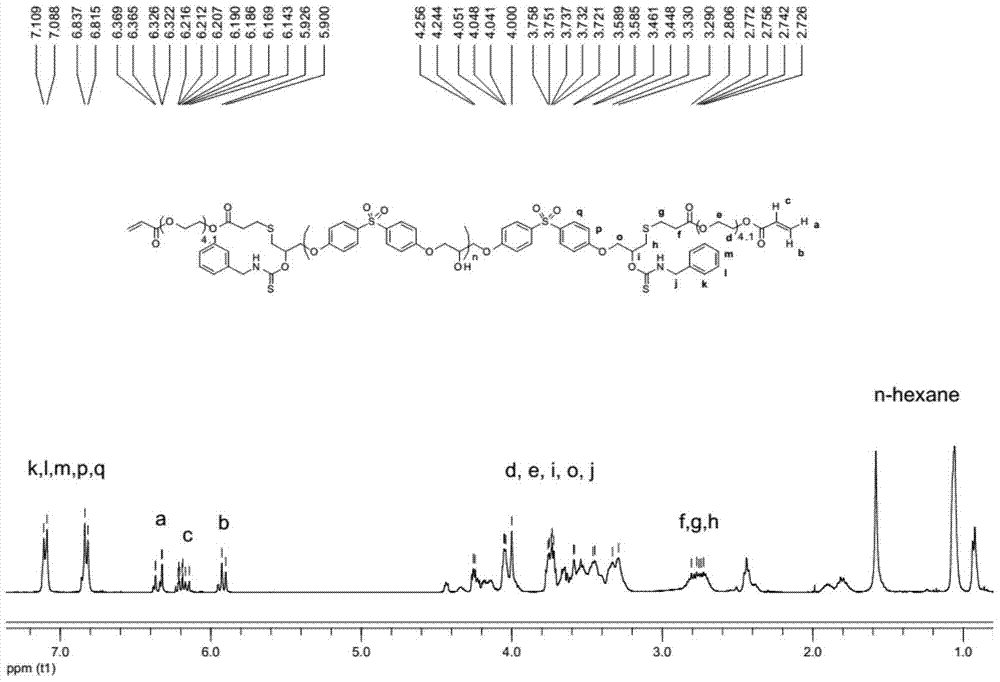

Self-repairing lustering coating composition with high refraction index

InactiveCN104877557AExcellent elasticity and wear and scratch resistanceSimple production processCoatingsPhotoinitiatorSelf repair

The invention relates to a self-repairing lustering coating composition with a high refraction index. The self-repairing lustering coating composition comprises the following components in parts by weight: 15-55 parts of a photo-curing resin, 10-70 parts of a photopolymerization monomer, 2-4 parts of a photoinitiator and 0.05-1 part of an auxiliary, wherein the photo-curing resin is a sulfur-containing bifunctional acrylate unsaturated polymer with high refraction index and a soft-hard segment structure. The self-repairing lustering coating composition with the high refraction index can coat an optical-grade PET plastic substrate; the coating subjected to ultraviolet photo-curing is high in refraction index, high in elasticity, and extremely high in adhesion force, abrasion resistance and scraping resistance performance.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Scratch-resistant art paint with fur-like effect and manufacturing method thereof

The invention discloses scratch-resistant art paint with a fur-like effect. The art paint comprises the following ingredients (by weight): 50-55% of water, 1.5-2% of glycol, 1-1.5% of a coalescing agent, 1-1.5% of glycerol, 0.2-0.25% of a preservative, 0.2-0.25% of an antifoaming agent, 0.2-0.3% of a mildew inhibitor, 0.1-0.15% of a pH regulator, 0.2-0.4% of a dispersant, 0.2-0.3% of a wetting agent, 0.2-0.3% of bentonite, 0.5-0.6% of a thickening agent, 25-30% of an emulsion and 10-15% of a toner. through the above ingredients, the art part has good abrasion resistance, can greatly resist conventional starch and scraping, is durable in use, has excellent hand feeling, can react with free formaldehyde in the air to permanently reduce the concentration of free formaldehyde in the air and reach the natural purification standard of being less than or equal to 0.08 mg / m<3>. Thereby, the indoor air is more environmentally-friendly and healthier.

Owner:广东金涂宝新材料股份有限公司

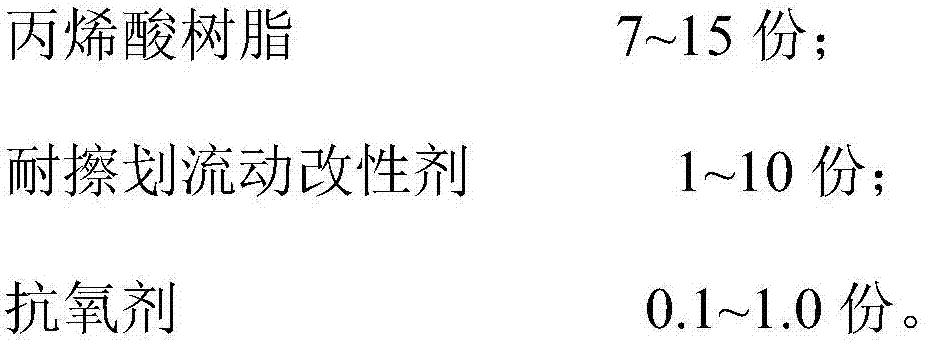

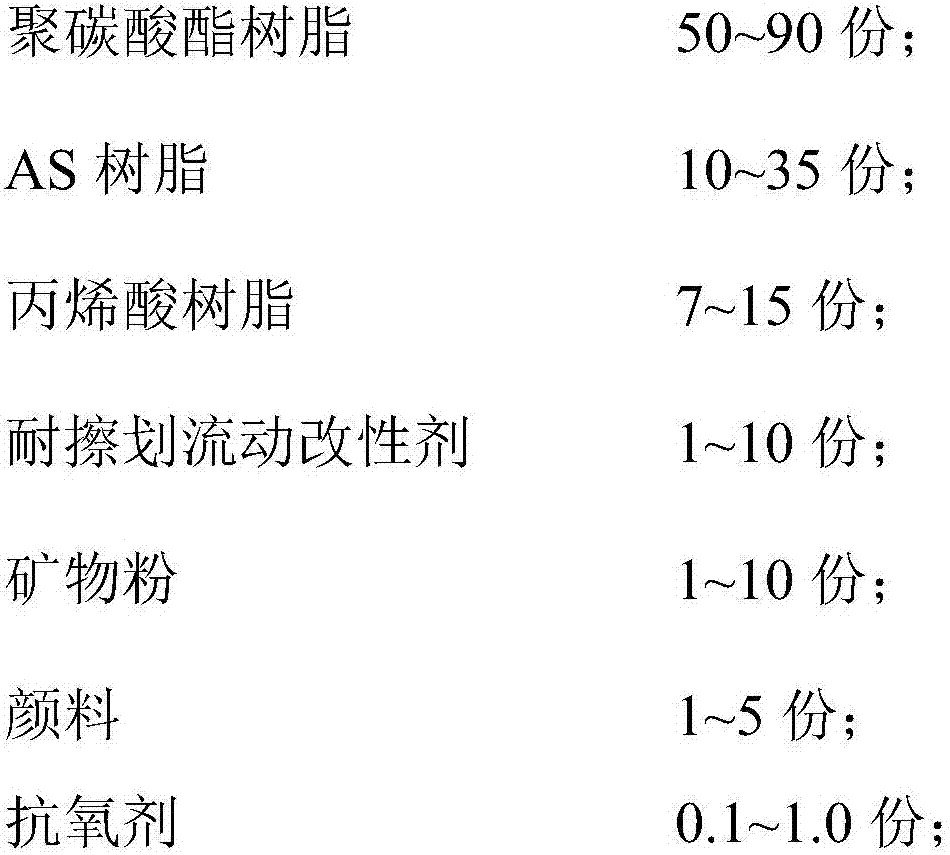

PC/AS/ acrylic resin alloy material and preparation method thereof

The invention relates to a PC / AS / acrylic resin alloy material, and belongs to the technical field of a high molecular material. The PC / AS / acrylic resin alloy material is prepared from, by weight, 50-90 parts of polycarbonate resin, 10-35 parts of AS resin, 7-15 parts of acrylic resin, 1-10 parts of anti-scraping flowing modifier, and 0.1-1.0 part of antioxidant. The PC / AS / acrylic resin alloy material has excellent scraping resistance weather resistance, workability, and coloring easiness.

Owner:四川长虹智能制造技术有限公司

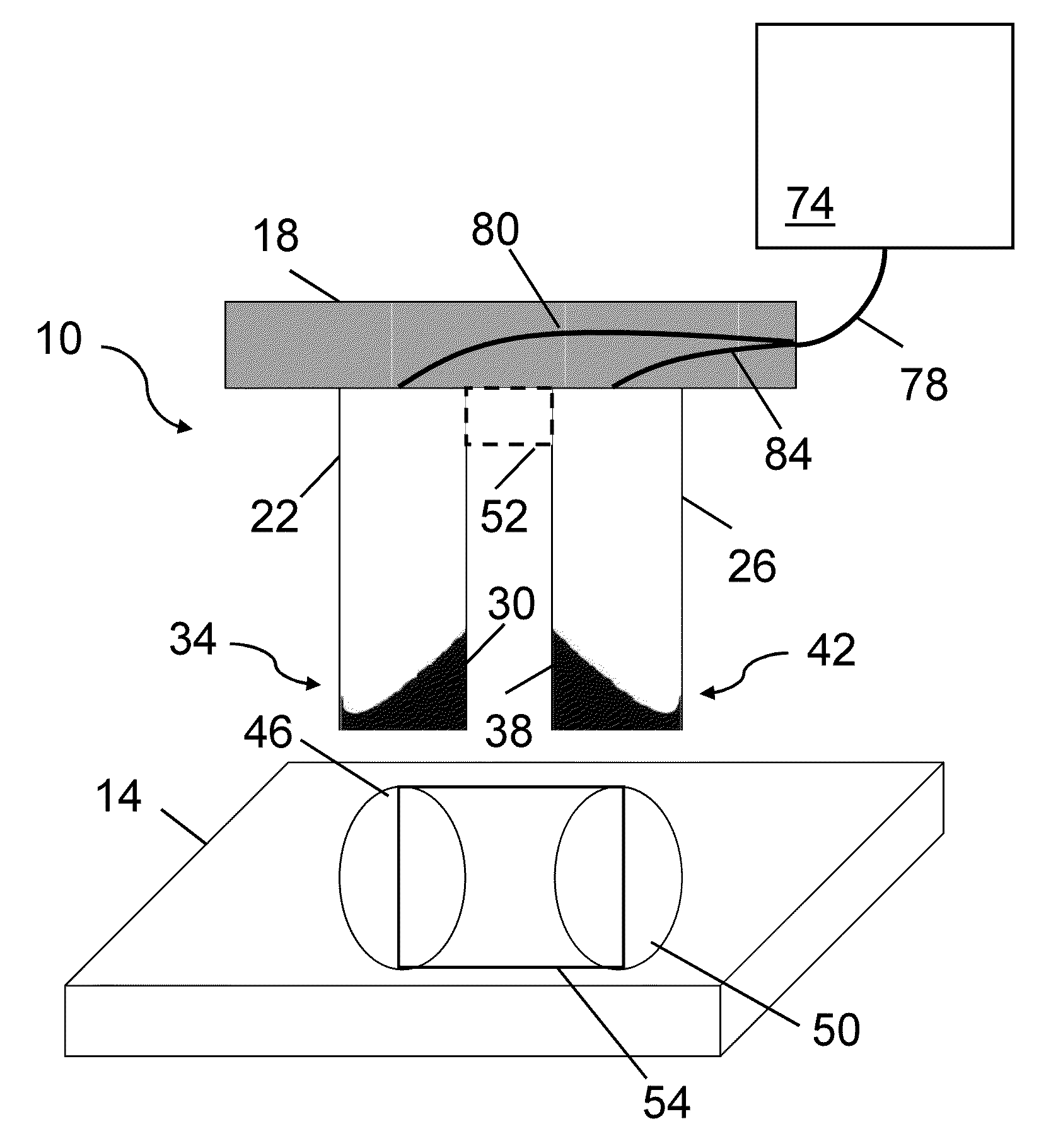

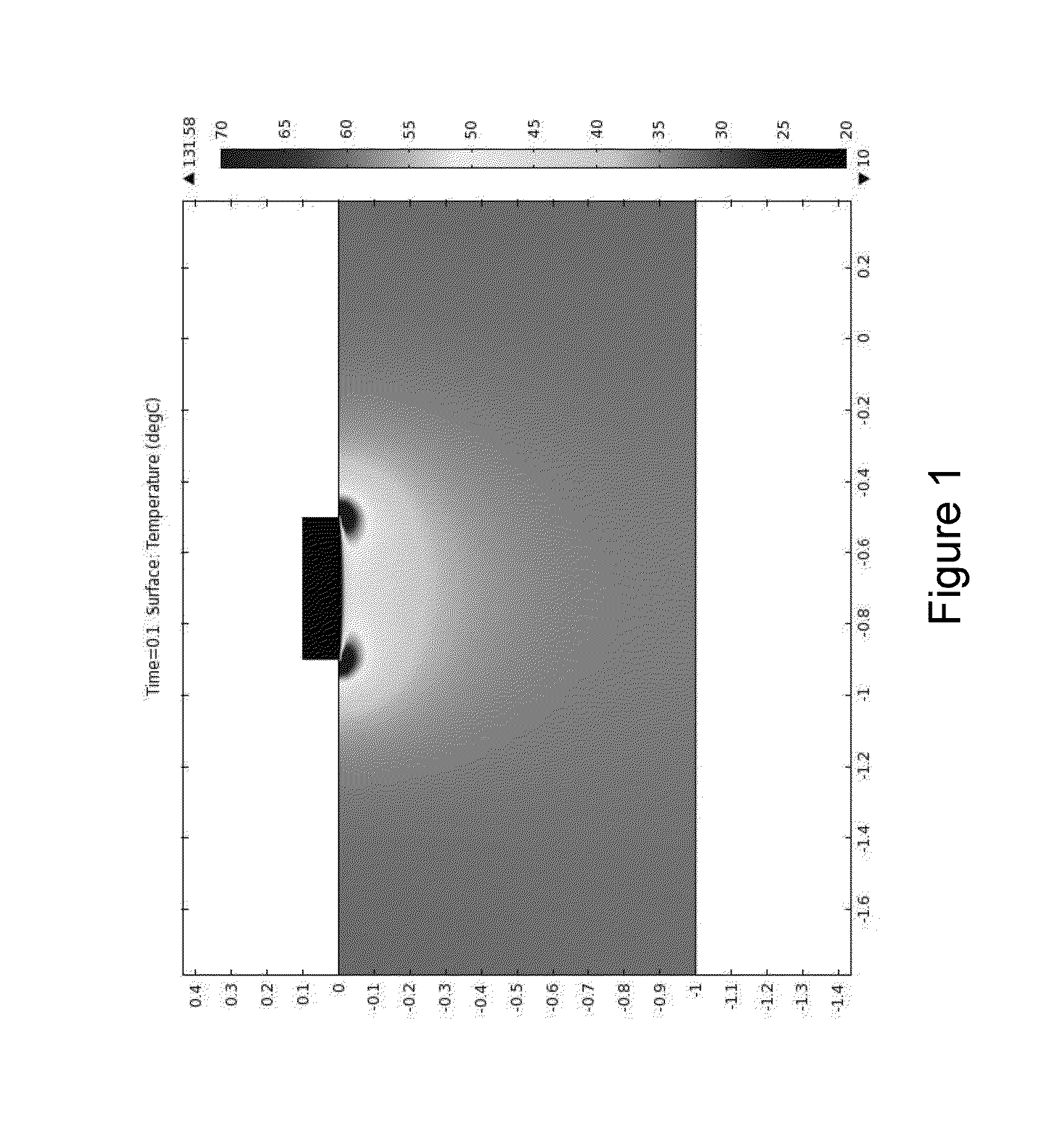

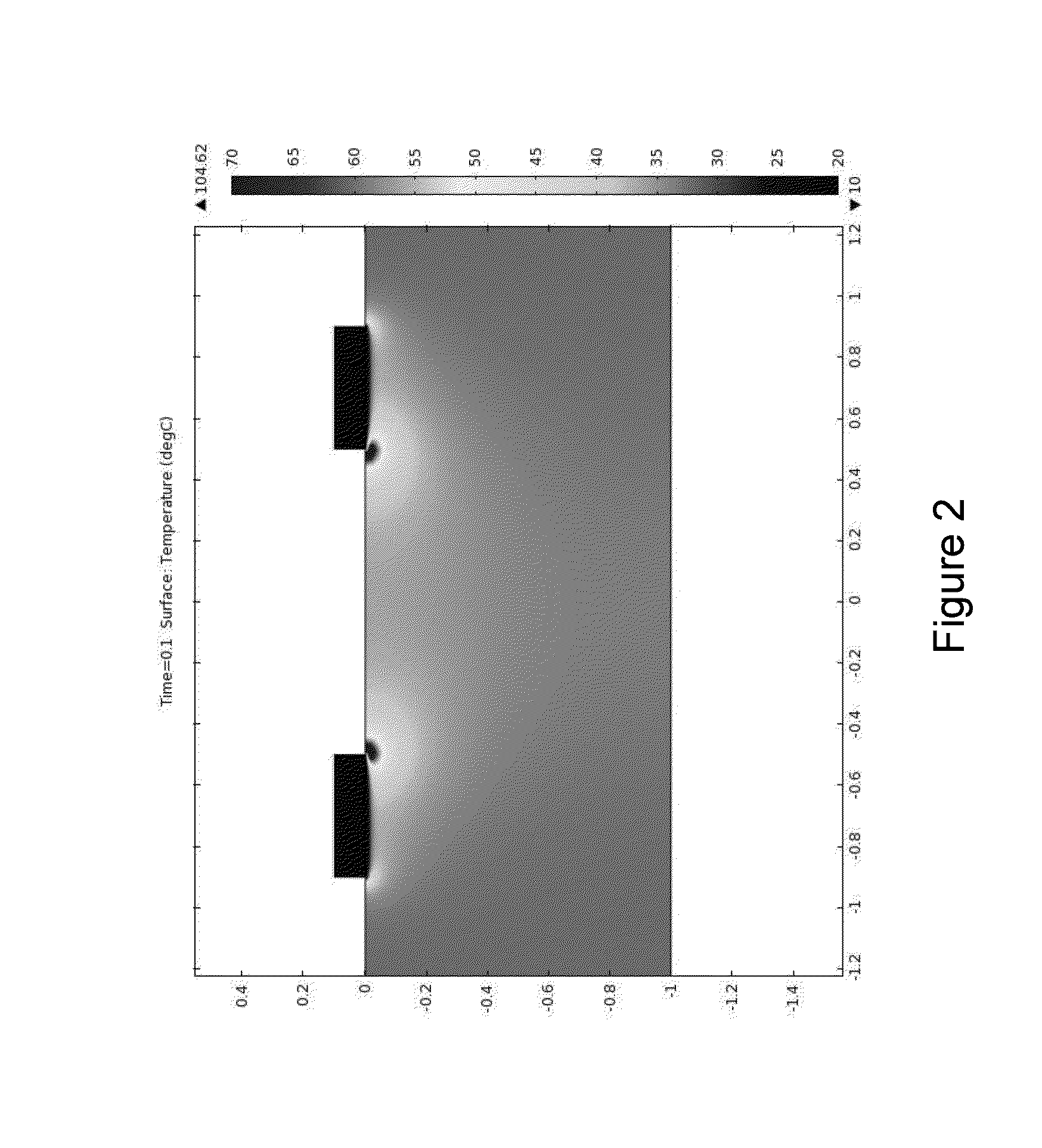

Reduction of RF Electrode Edge Effect

ActiveUS20130218243A1Low coefficient of thermal expansionScratch resistanceElectrotherapySurgical instruments for heatingEdge effectsBiomedical engineering

A skin surface is treated with RF energy (e.g., unipolar, monopolar, bipolar or multipolar RF delivery). A first semiconductive cap disposed on a first distal end of a first electrode and, optionally, a second semiconductive cap disposed on a second distal end of a second electrode are applied to the skin surface. RF energy is delivered from the first electrode and the second electrode through the first semiconductive cap and the second semiconductive cap, respectively, through the skin surface. The first semiconductive cap and / or the second semiconductive cap have an electrical conductivity matched or substantially matched to the skin's electrical conductivity (e.g., about 0.1 to about 2 times that of the skin).

Owner:CANDELA CORP +1

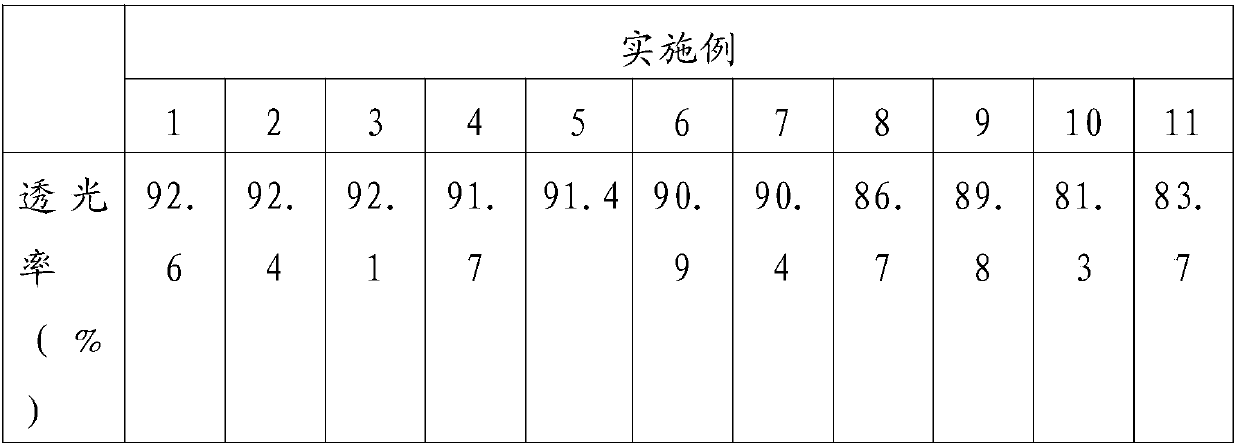

Preparation method of light guide plate used as liquid crystal display backlight

The invention provides a light guide plate as a liquid crystal display backlight and a preparation method thereof, comprising PMMA, PC, light diffusing agent, light stabilizer, heat stabilizer, silicone masterbatch, fused silica sand, the weight of each component The number of parts is: PMMA35‑60, PC25‑40, light diffusing agent 1‑8, light stabilizer 0.3‑3, heat stabilizer 0.1‑1, silicone masterbatch 2‑5, fused silica sand 10‑15. The above materials are melted and then injected into a mold to make a light guide plate. The light guide plate can exhibit higher hardness at normal temperature, and can effectively prevent scratches on the surface of the light guide plate.

Owner:GUANGDONG GMA OPTOELECTRONICS TECH

Scratching-resisting wearing-resisting sofa fabrics

InactiveCN103590170AImprove wear resistanceGood moisture absorption and air permeabilityWoven fabricsMetal fibersMoisture

The invention discloses scratching-resisting wearing-resisting sofa fabrics which comprise polynosic, bamboo fibers, metal fibers and Kevlar fibers. The scratching-resisting fibers are formed by weaving warp yarns and weft yarns, the warp yarns are formed by weaving the polynosic and the metal fibers in a mixing mode, the weft yarns are formed by weaving the bamboo fibers and the Kevlar fibers in a mixing mode, the weight percentage of the warp yarns in the scratching-resisting wearing-resisting fabrics is 47 %, and the weight percentage of the weft yarns in the scratching-resisting wearing-resisting fabrics is 53 %. In this way, the scratching-resisting wearing-resisting sofa fabrics are good in wear-resisting performance and good in moisture-absorbing air permeability, can resist to scratching of ordinary sharp objects, are longer in service life and are suitable for manufacturing surfaces of various kinds of sofas.

Owner:SUZHOU IND PARK YOUSHUN CLOTHING FACTORY

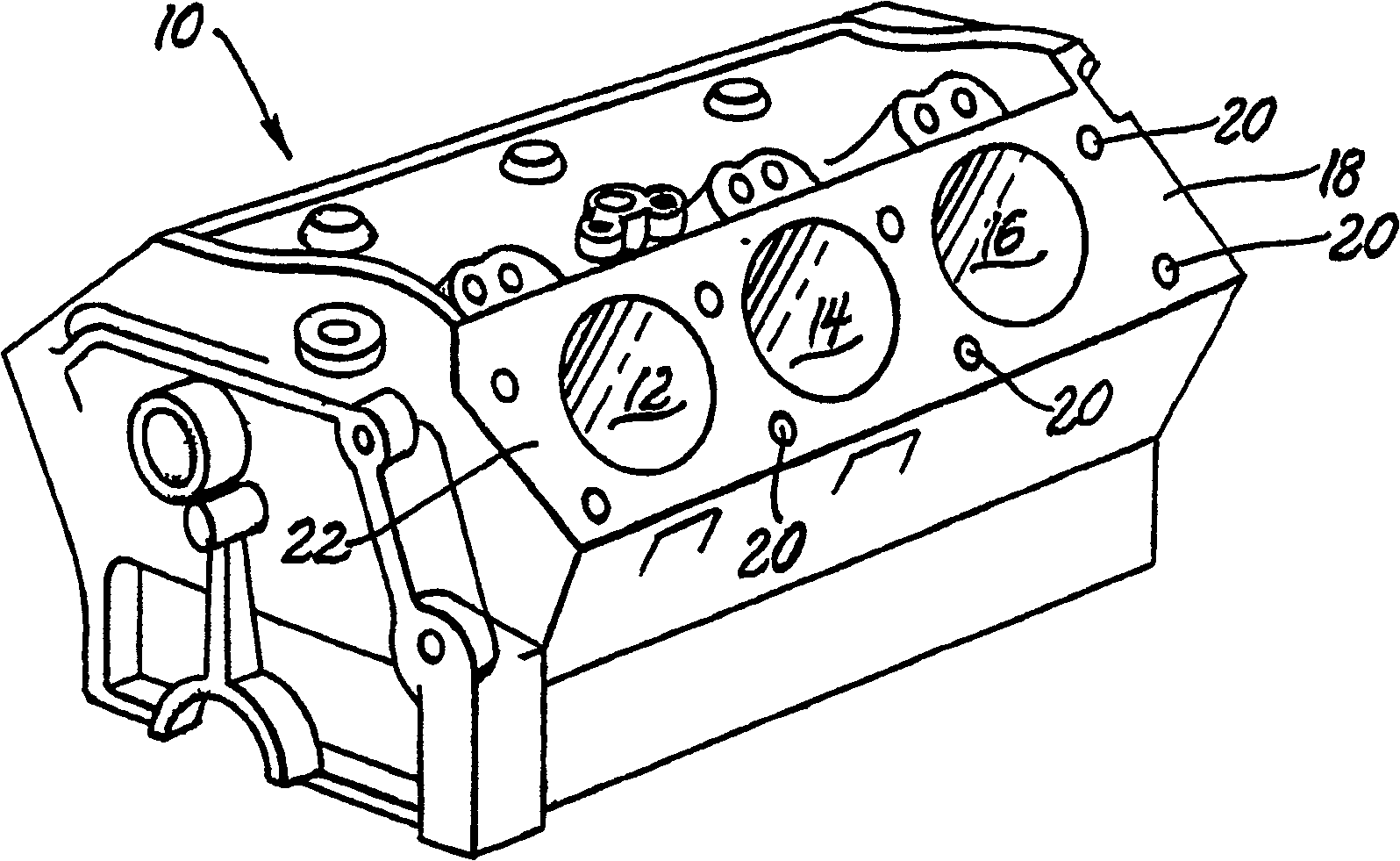

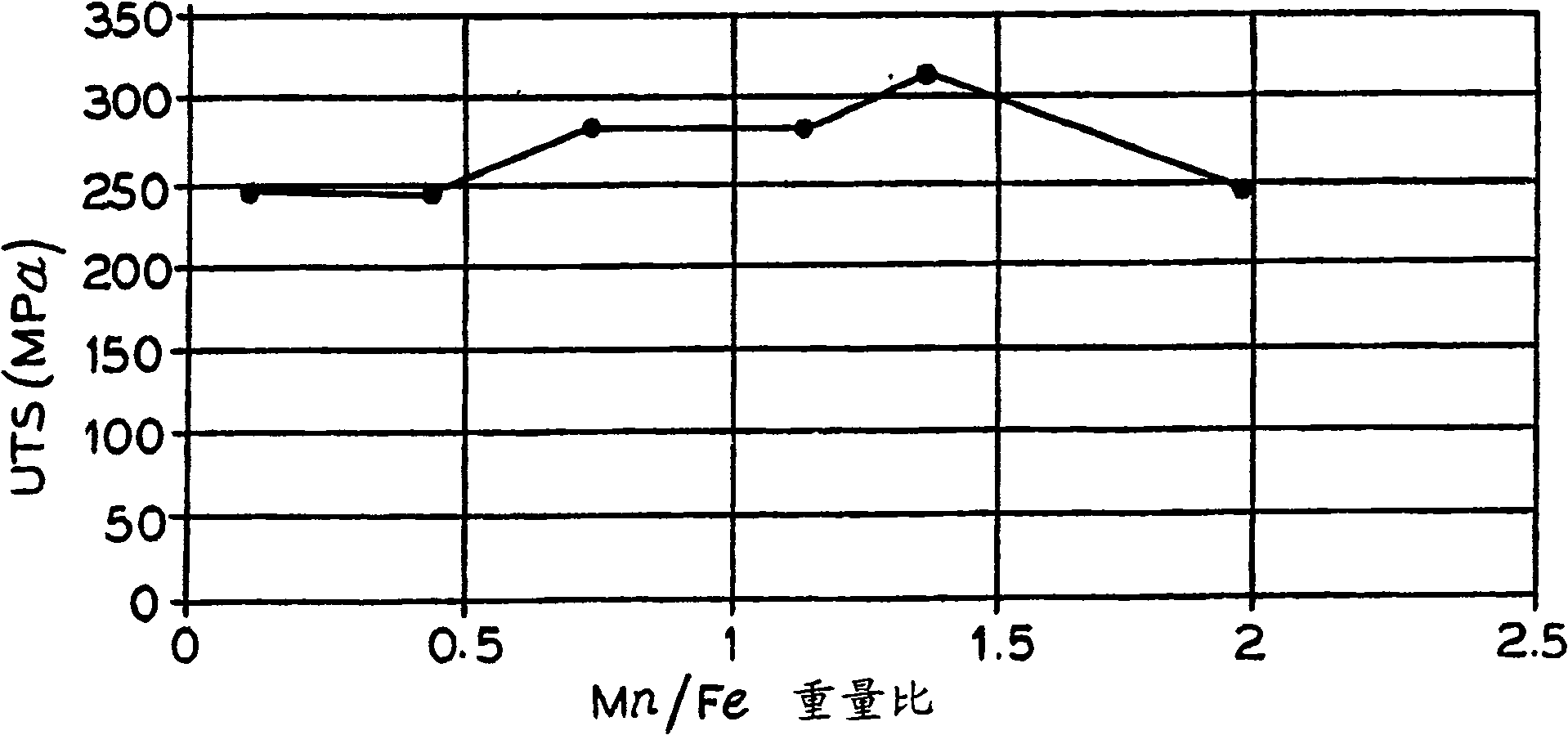

Aluminum alloy for engine blocks

An aluminum alloy is disclosed that is suitable for casting and machining cylinder blocks for engines, especially gasoline fuel engines for automotive vehicles. The casting has the strength and wear resistance to piston / seal scuffing for such engines. The alloy comprises, by weight, 9.5 to 12.5% silicon, 0.1 to 1.5% iron, 1.5 to 4.5% copper, 0.2 to 3% manganese, 0.1 to 0.6% magnesium, 2.0% max zinc, 0 to 1.5% nickel, 0.25% maximum titanium, up to 0.05% strontium and the balance aluminum, where the weight ratio of manganese to iron is 1.2 to 1.75 or higher when the iron content is equal to or greater than 0.4% and the weight ratio of manganese to iron is at least 0.6 to 1.2 when the iron content is less than 0.4% of the alloy.

Owner:GENERAL MOTORS CORP

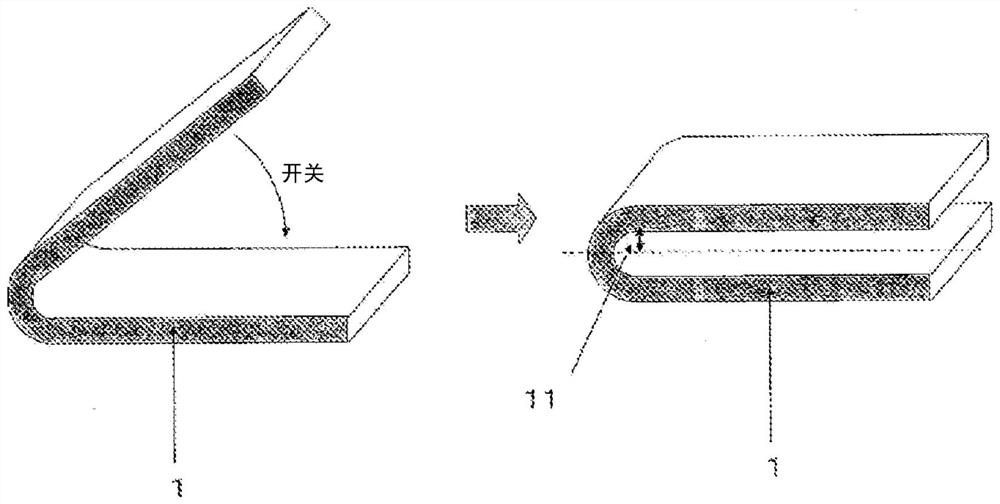

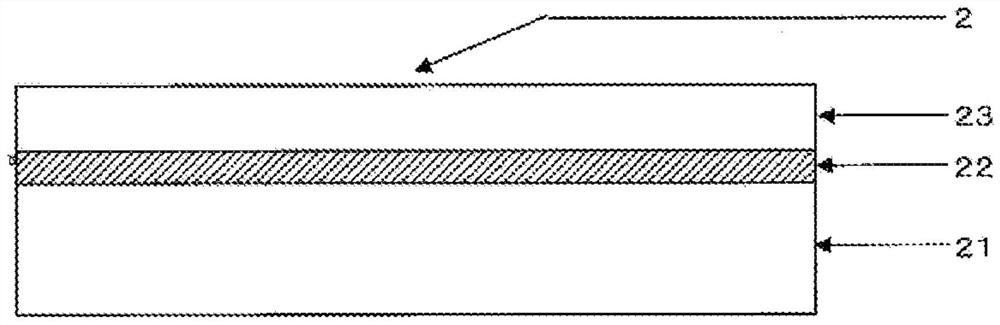

Folding-type display and portable terminal device

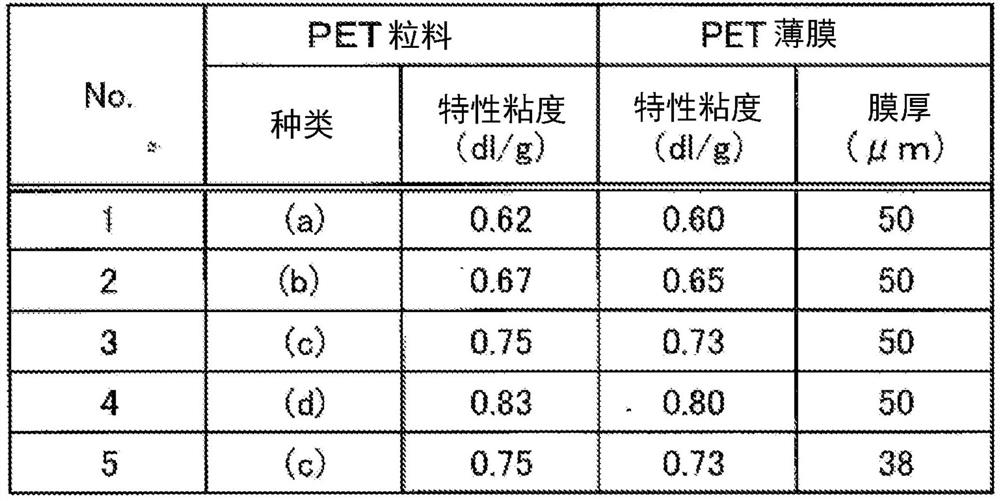

PendingCN112055874ANo distortionHigh hardnessDigital data processing detailsSynthetic resin layered productsPolyesterDisplay device

[Problem] To provide: a folding-type display which has excellent mass productivity and in which repeated folding does not result in disturbance of an image displayed on the folded part; and a portableterminal device on which this folding-type display is mounted. [Solution] This folding-type display is obtained by disposing a hard coat film on at least a part of the surface, wherein the hard coatfilm uses a polyester film having an intrinsic viscosity of 0.65-1.0 d1 / g as a base material film. A polyimide-based resin cured layer having a thickness of 0.5-3.0 microns and a hard coat layer are provided, in that order, on at least the surface side of the folding-type display in the base material film.

Owner:TOYOBO CO LTD

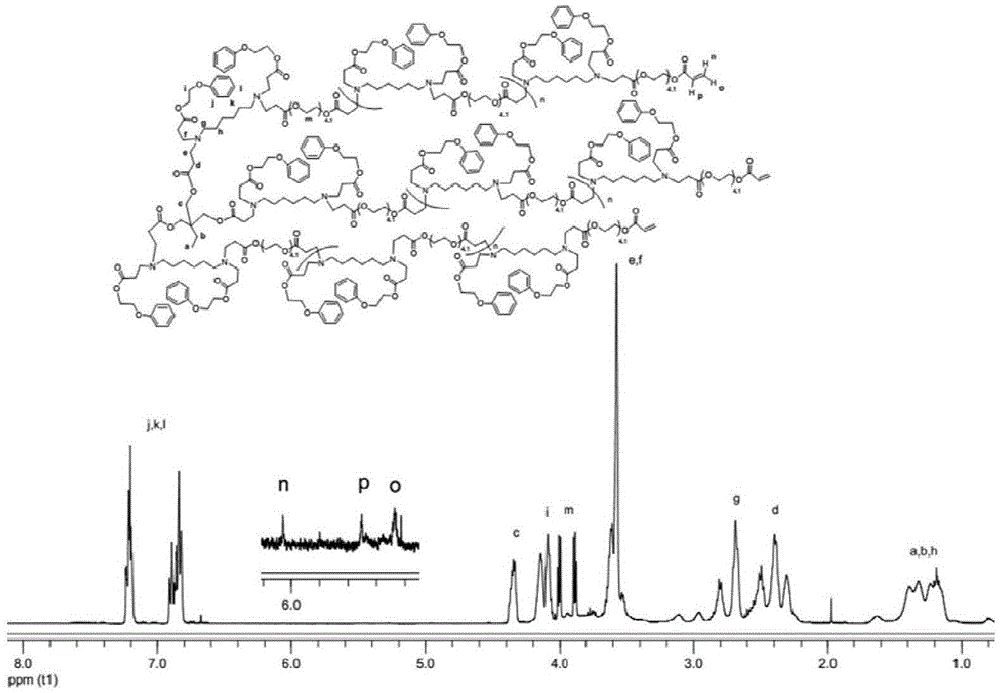

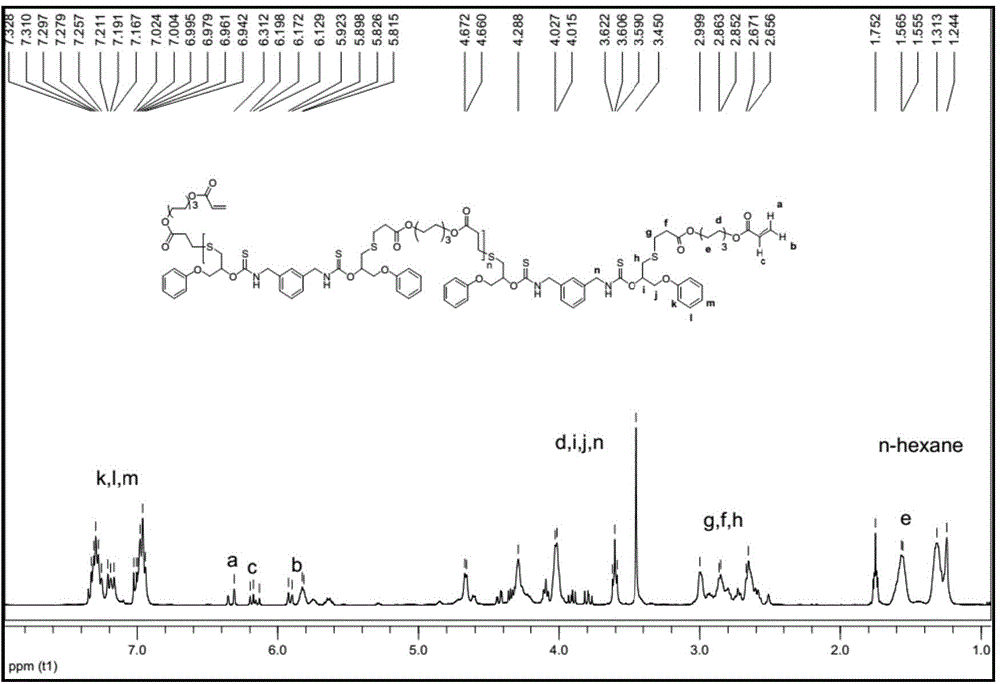

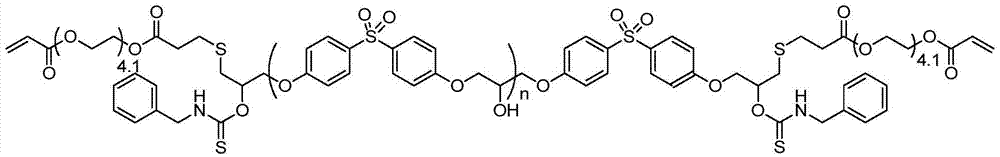

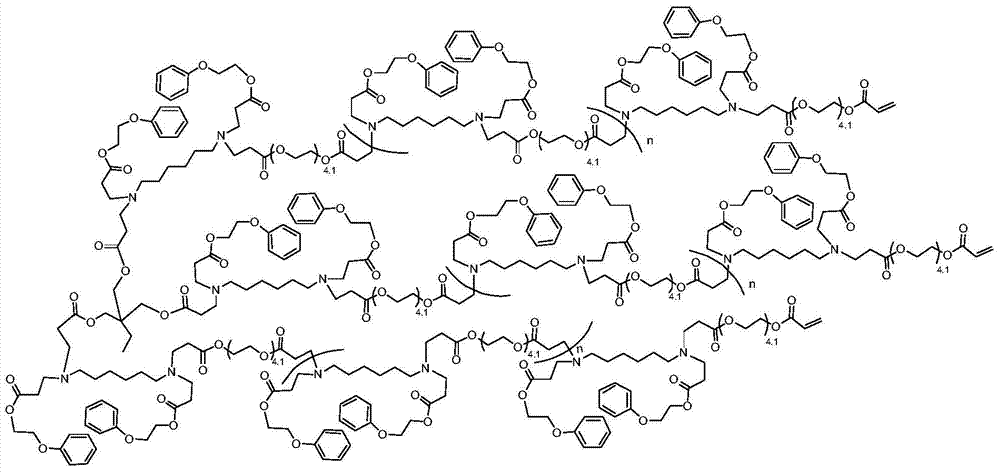

A kind of high anti-scratch self-repair brightening paint composition

InactiveCN105038566BSimple production processSimple preparation conditionsPolyurea/polyurethane coatingsUV curingPolyresin

The invention relates to a high-scrape-resistant self-repairing brightening coating composition which includes following components, by weight, 10-70 parts of photo-curable resin, 10-50 parts of a photo-polymerization monomer, 2-5 parts of a photo initiator and 0.05-1 part of an additive. The high-scrape-resistant self-repairing brightening coating composition can be used for coating an optical-grade PET plastic base material, and is excellent in scrape-resistant performance after UV curing. Meanwhile, the coating composition is excellent in rebounding performance and is excellent in adhesion on the base material.

Owner:SHANGHAI WEIKAI CHEM +2

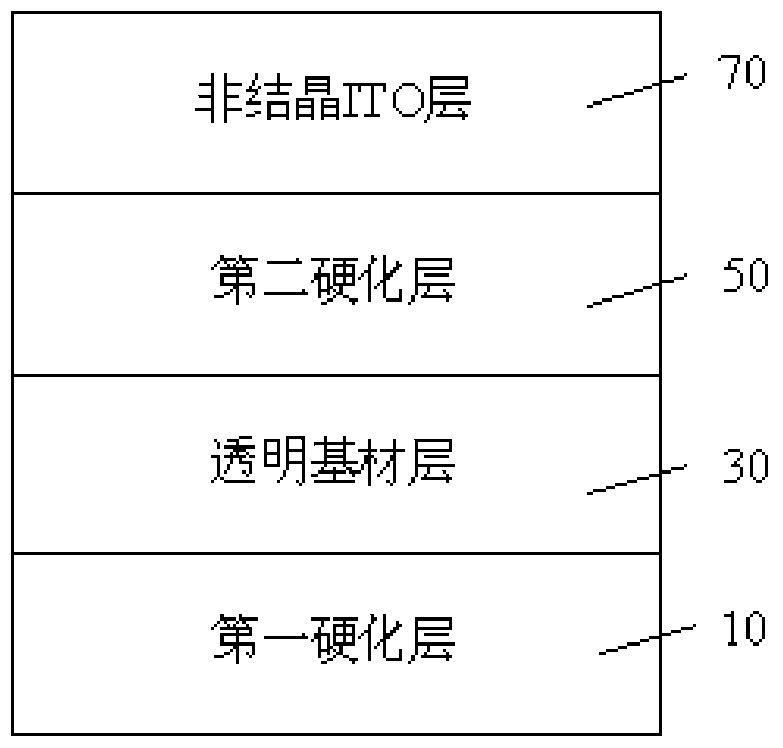

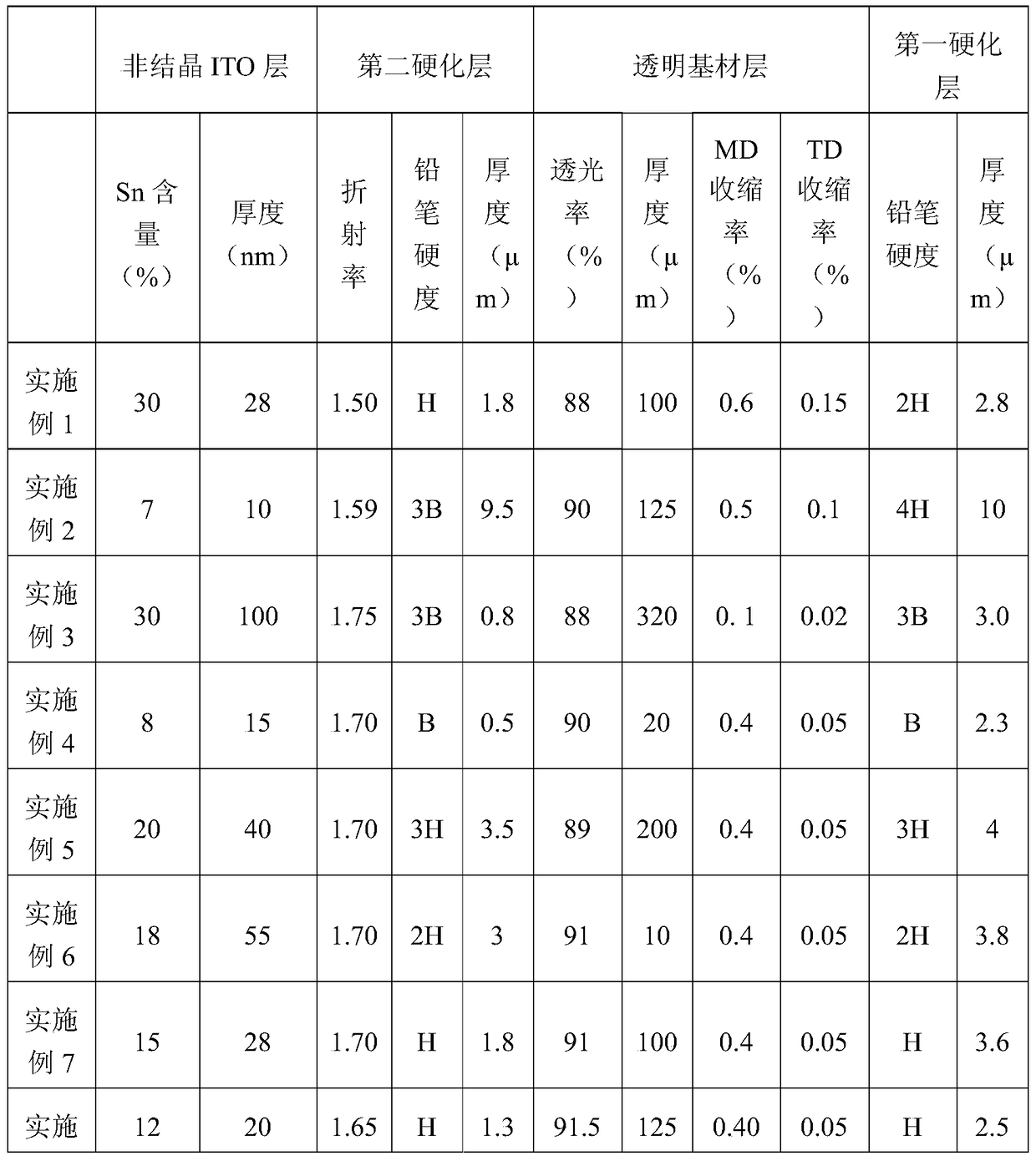

Transparent conductive film and capacitive touch screen containing the same

ActiveCN104951163BAlleviate the serious problem of three-dimensional linesLower impedanceInput/output processes for data processingIndium tin oxideTransparent conducting film

The invention provides a transparent conductive film and a capacitive touch screen comprising the same. The transparent conductive film comprises a first hardened layer, a transparent substrate layer, a second hardened layer and an amorphous ITO (indium tin oxide) layer, wherein the transparent substrate layer is arranged on the surface of the first hardened layer; the second hardened layer is arranged on the surface, far from the first hardened layer, of the transparent substrate layer, and the thickness of the first hardened layer is larger than that of the second hardened layer by 0.5-3 mu m; the amorphous ITO layer is arranged on the surface, far from the transparent substrate layer, of the second hardened layer. The transparent conductive film has the characteristics of low solid lines, low impedance, high-temperature resistance, scratch resistance, low cost, simple production process and the like.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

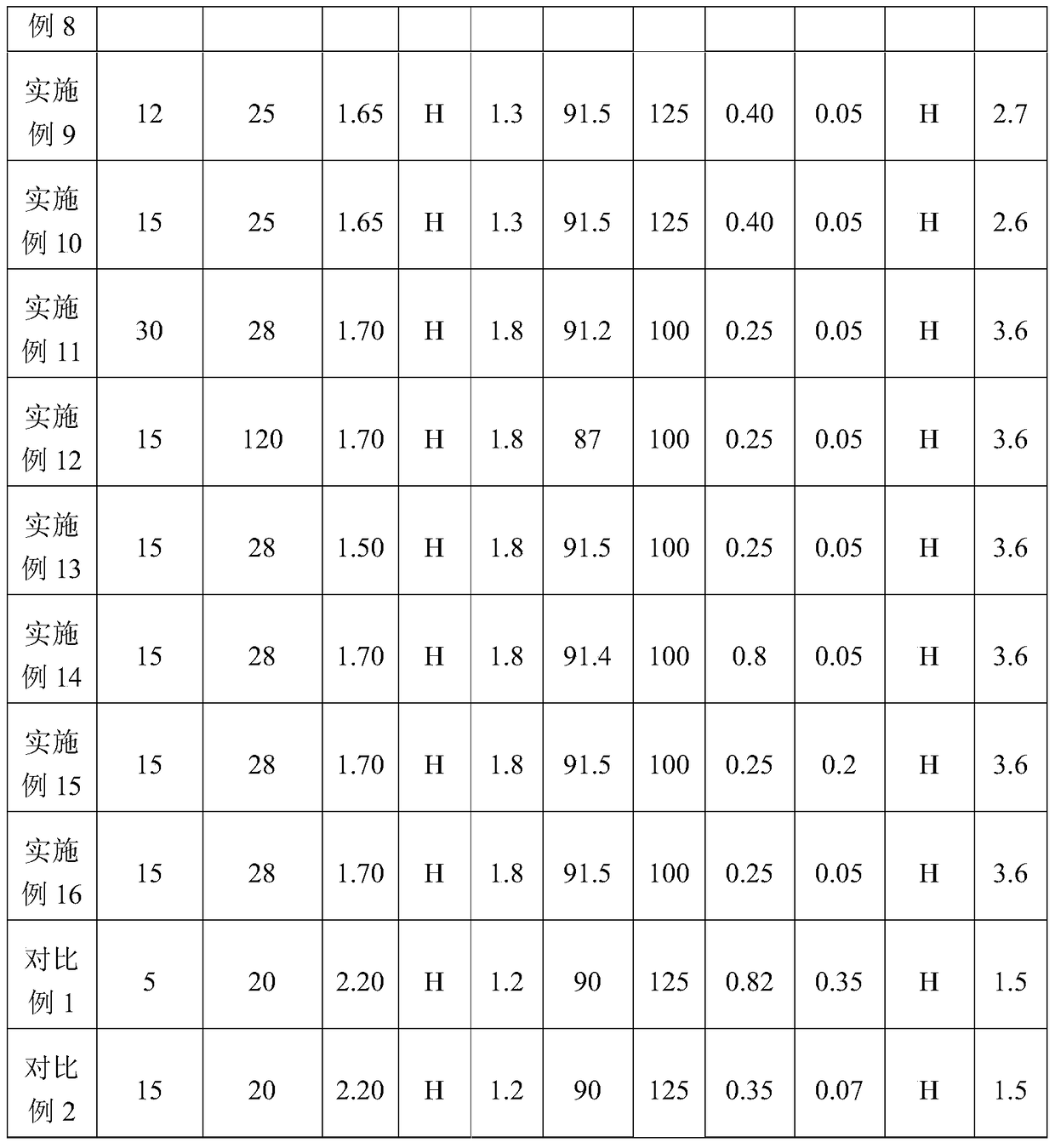

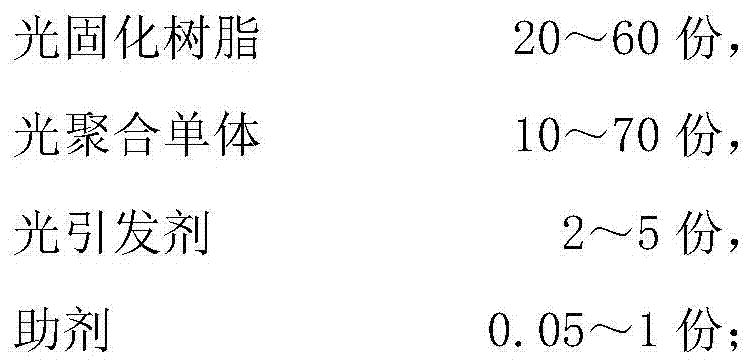

High refractive index self-healing brightening coating composition

InactiveCN104877557BSimple production processSimple preparation conditionsCoatingsPolymer scienceAdjuvant

The invention relates to a high refractive index self-repairing brightening coating composition. The coating composition comprises the following components and parts by weight: 15-55 parts of photocurable resin, 10-70 parts of photopolymerizable monomer, 2-4 parts of photoinitiator, 0.05-1 part of auxiliary agent; It is a sulfur-containing high refractive index difunctional acrylate unsaturated polymer with both soft and hard segment structures. The high refractive index self-healing and brightening coating composition of the present invention can be coated on the optical-grade PET plastic substrate; after ultraviolet light curing, the coating has a high refractive index, excellent elasticity, and has excellent adhesion, Wear and scratch resistance.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Method for manufacturing multilayer insulated electric wire insulated by biopolyester resin, and multilayer insulated electric wire insulated by biopolyester resin, manufactured according thereto

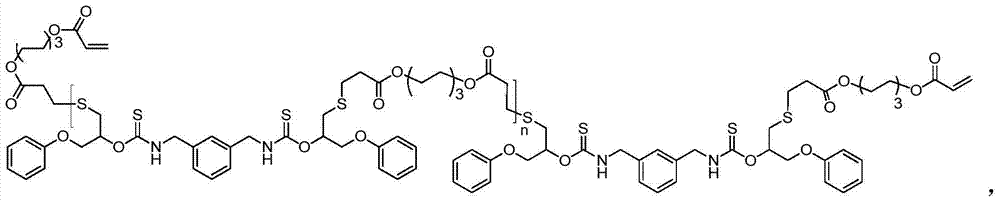

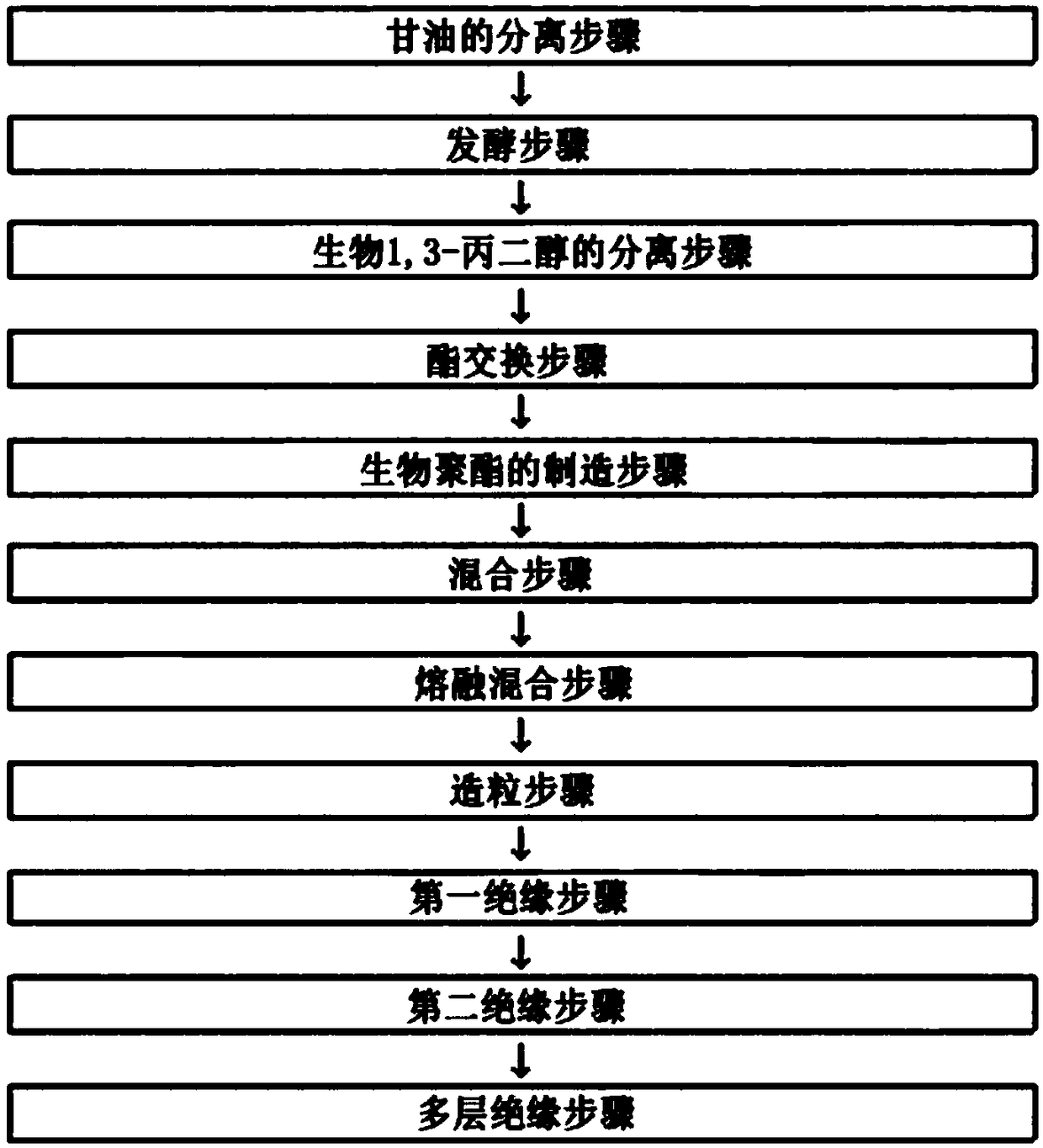

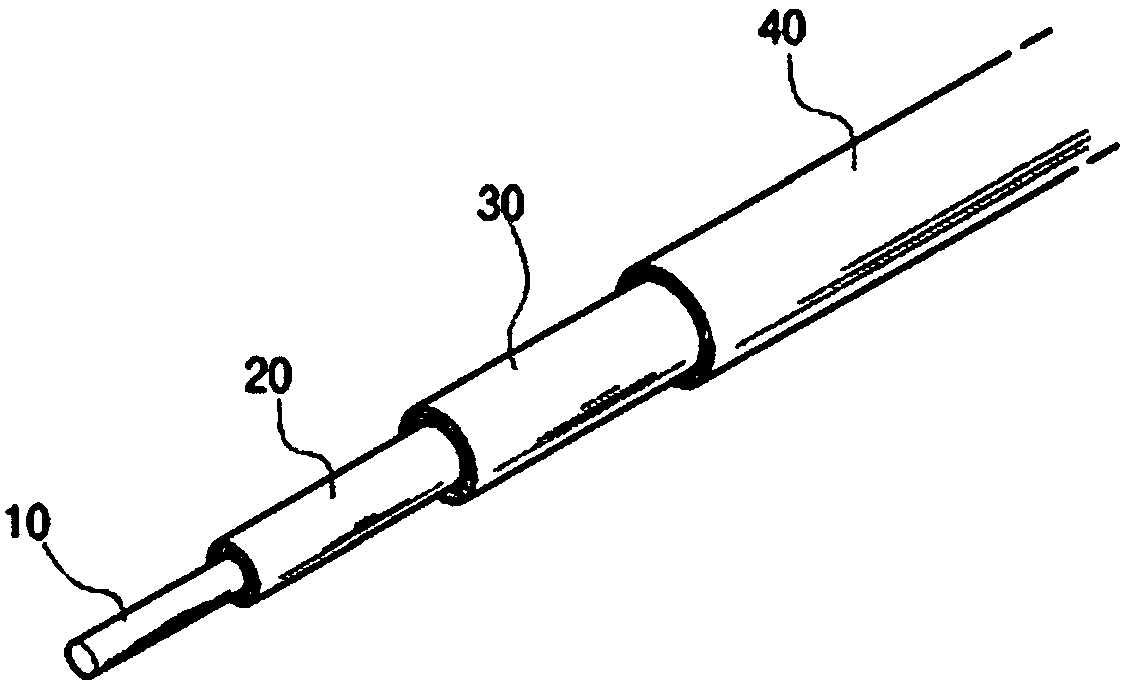

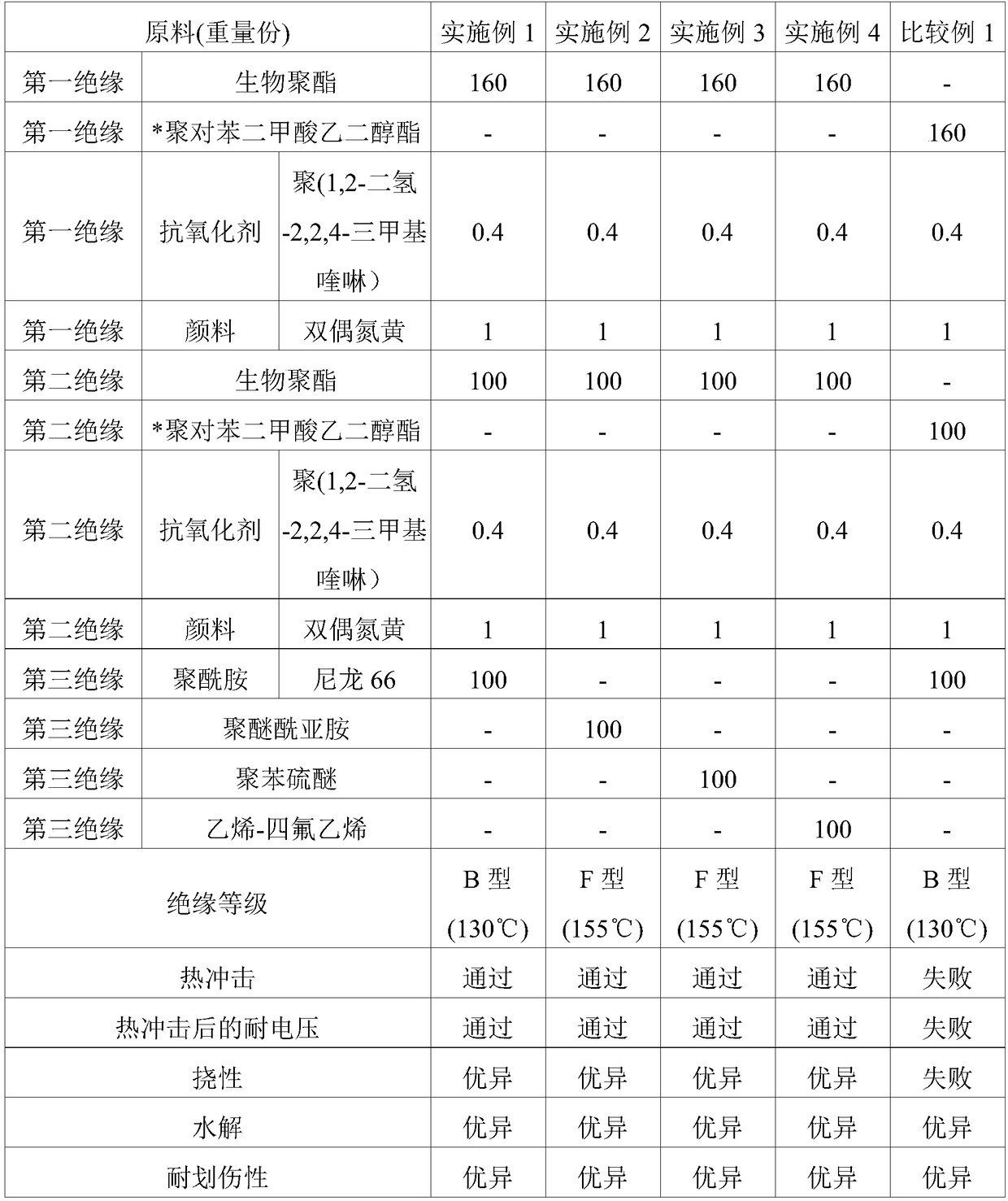

ActiveCN109196606AEasy to manufactureScratch resistancePlastic/resin/waxes insulatorsSubmarine cablesInsulation layerBiodiesel

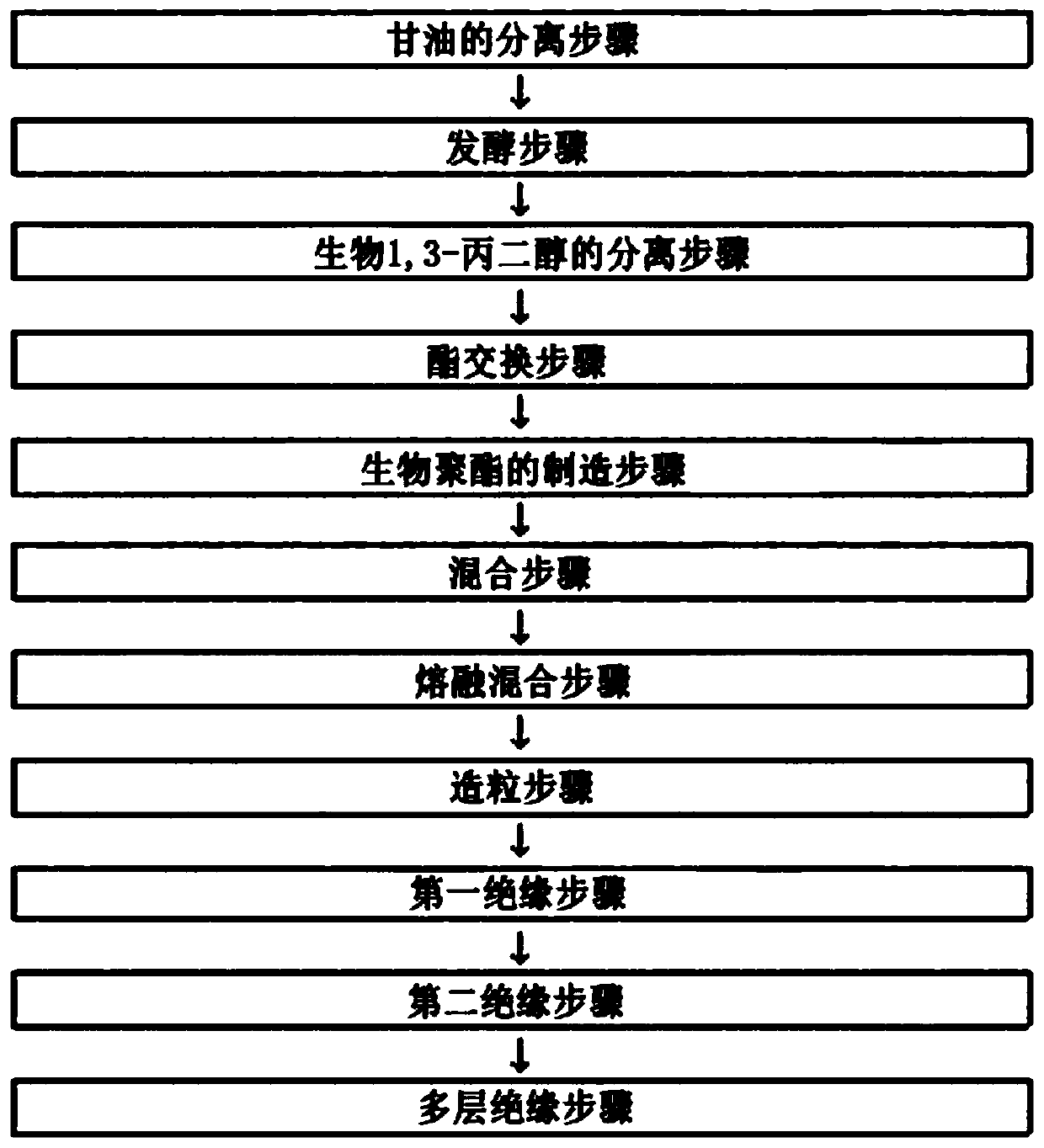

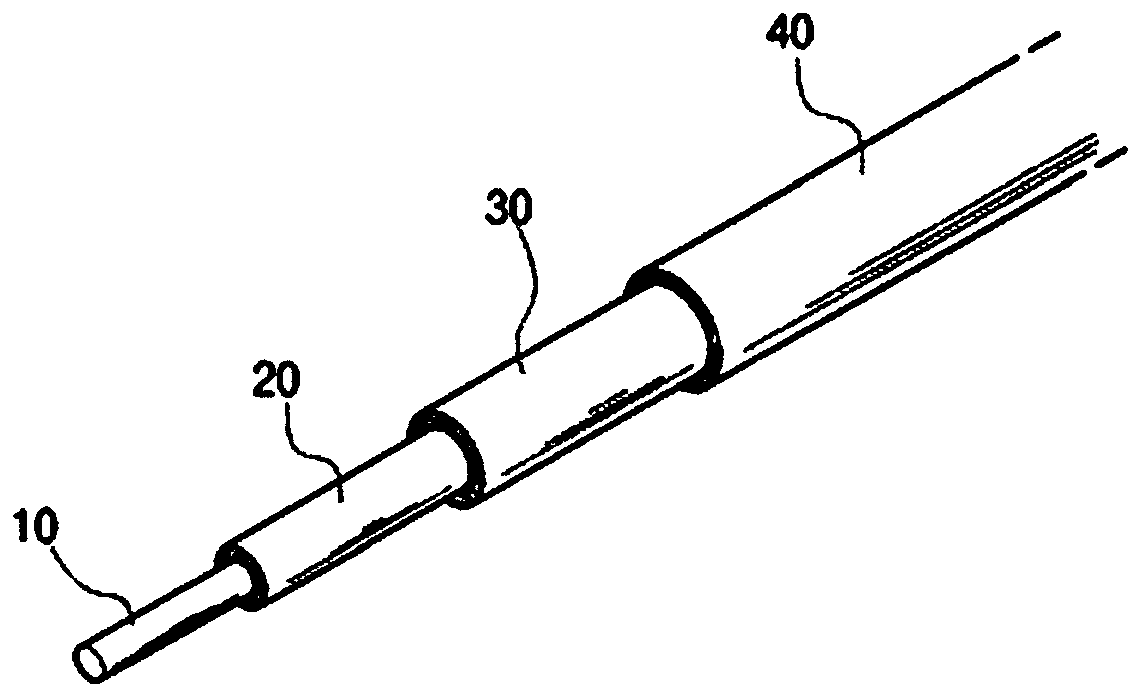

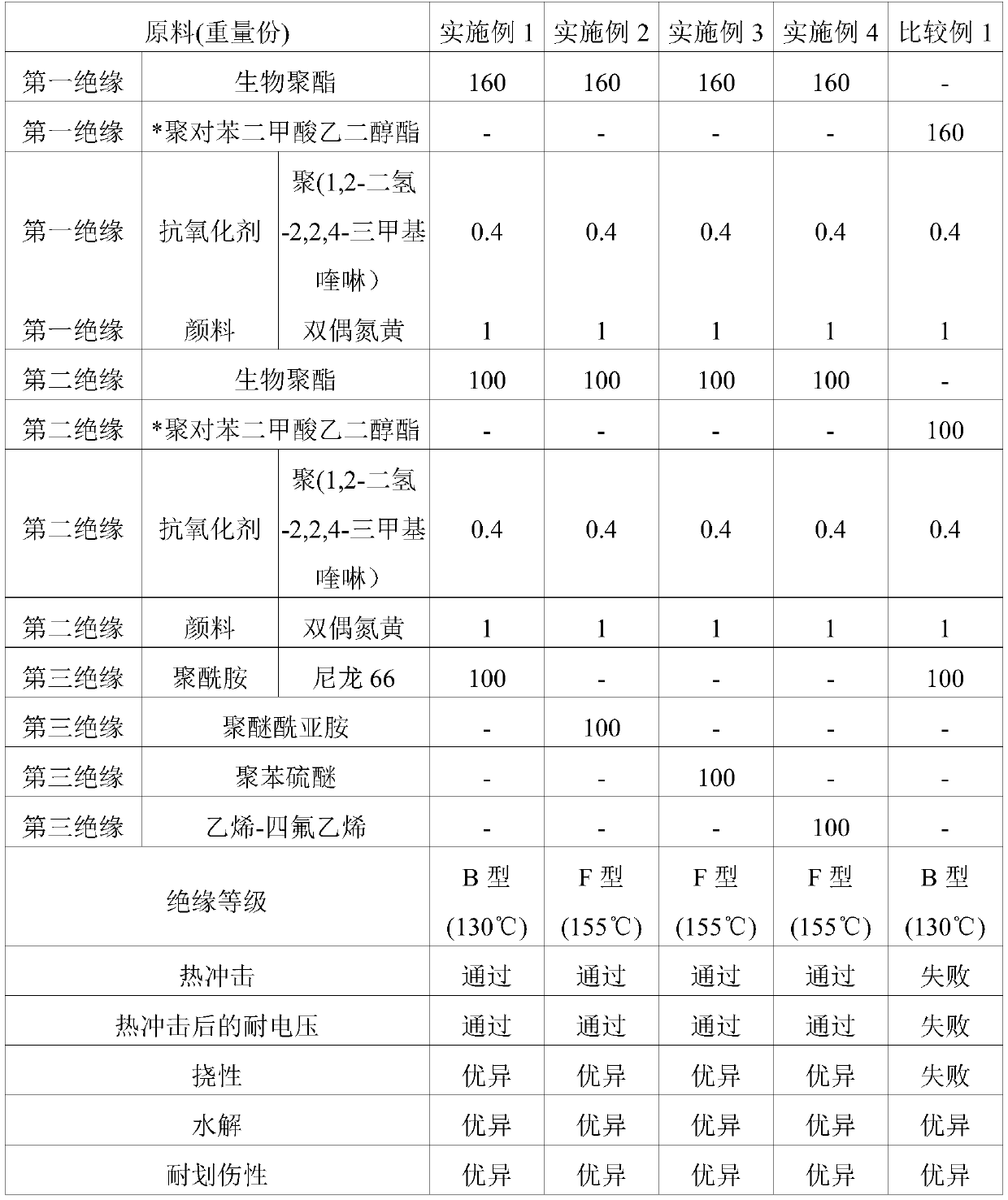

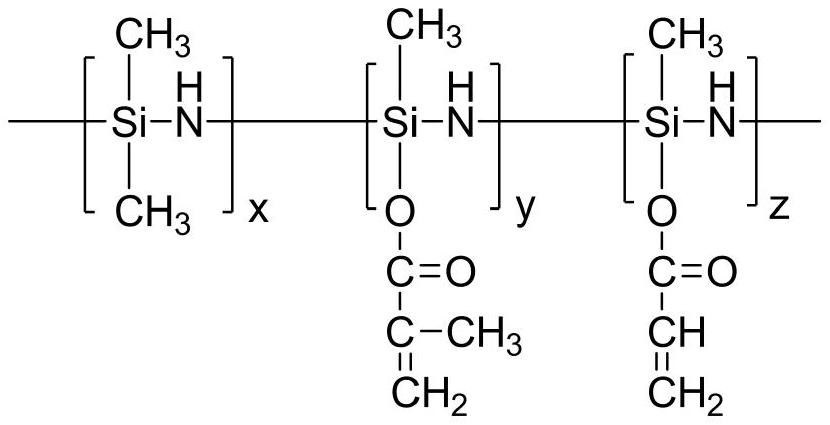

The present invention relates to: a method for manufacturing a multilayer insulated electric wire insulated by a biopolyester resin; and a multilayer insulated electric wire insulated by a biopolyester resin, manufactured according thereto, the method comprising the steps of: separating glycerol from biodiesel by-products; separating bio 1,3-propanediol by fermenting the glycerol; preparing a biopolyester resin by means of a transesterification reaction step, using the bio 1,3-propanediol, and a polycondensation reaction step; preparing biopolyester pellets by obtaining a mixture by mixing thebiopolyester resin with an antioxidant and a pigment, and then melt mixing the mixture; and forming two or more layers of insulation layers by extruding the biopolyester pellets on the outer circumference of a conductor, and then forming an outermost insulation layer by extruding polymer resin pellets on the insulation layers. According to the present invention, a multilayer insulated electric wire satisfying environmental protection requirements and simultaneously having the necessary characteristics such as heat resistance and impact resistance, flexibility before and after heating, and scratch resistance, which are required for a use as battery and electronic equipment wiring and coiling, can be readily manufactured.

Owner:KOREA INST OF IND TECH

Self-healing brightening coating composition

InactiveCN104877525BSimple production processReduce processing costsEpoxy resin coatingsPolymer scienceUltraviolet lights

The invention relates to a self-repairing brightening paint composition. The coating composition includes the following components and parts by weight: 20-60 parts of photocurable resin, 10-70 parts of photopolymerizable monomer, 2-5 parts of photoinitiator, and 0.05-1 part of auxiliary agent; It is a sulfur-containing high refractive index difunctional acrylate unsaturated polymer with a bisphenol S structure and a soft and hard segment structure. The self-healing and brightening coating composition with high refractive index of the present invention can be coated on optical-grade PET plastic substrates; after UV curing, the coating has a high refractive index, excellent elasticity, and excellent adhesion , Wear resistance and scratch resistance.

Owner:SHANGHAI CHENGYING NEW MATERIALS +2

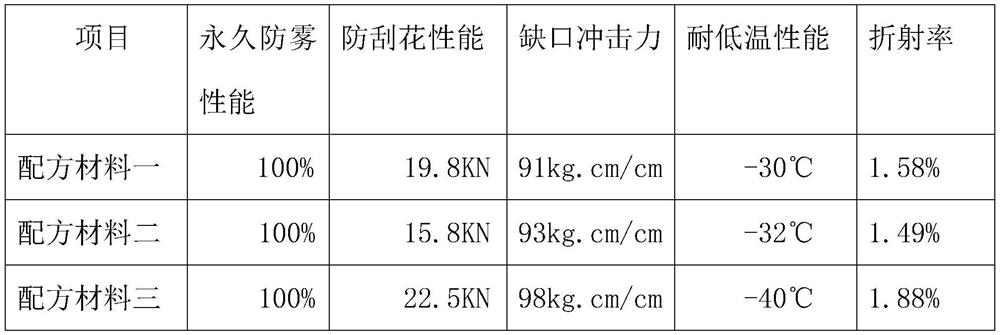

Formula and preparation process of PC material with permanent fog resistance, scratch resistant and high transparency

The invention discloses a formula and preparation process of a PC material with permanent fog resistance, scratch resistant and high transparency. PC resin, stearic acid monoglyceride, high-molecular polyester, butadiene, high polyglycidyl ester, alkyl silicone oil, a cross-linking agent and an antioxidant are proportioned according to certain parts by weight, the PC material is prepared by a stirrer, a reaction kettle, a double-screw or three-screw granulator, a granulator and a packaging machine, and the prepared product is tested, so that the product obtained by the invention has the best effects of permanent anti-fogging performance, scratch resistance, notch impact force, low temperature resistance, refractive index, glossiness and the like. The PC material can effectively achieve permanent anti-fogging and scratch-resistant effects, is widely applied to the fields of automobiles, optical lenses, protective masks, electronic appliances, high-end toys and the like, and has wide application prospects.

Owner:SHENZHEN ALL TECH LTD

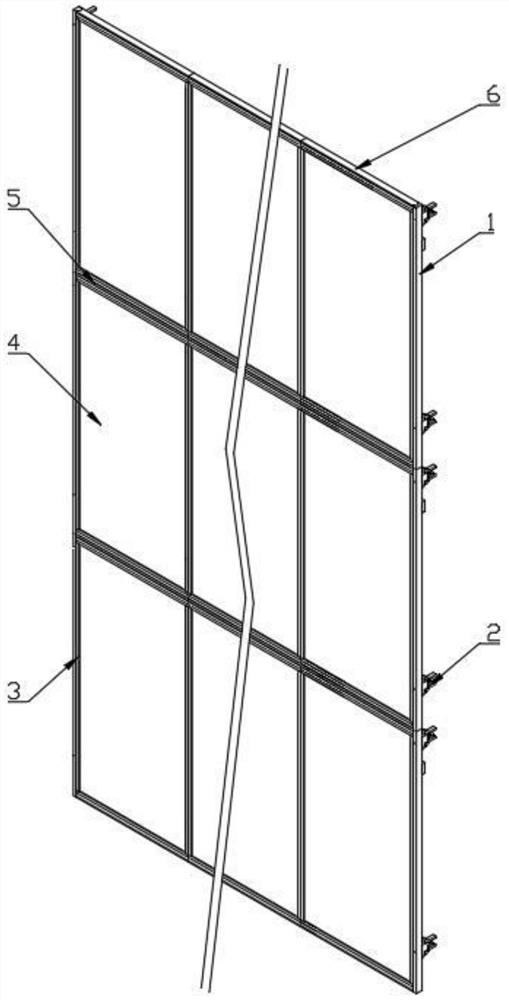

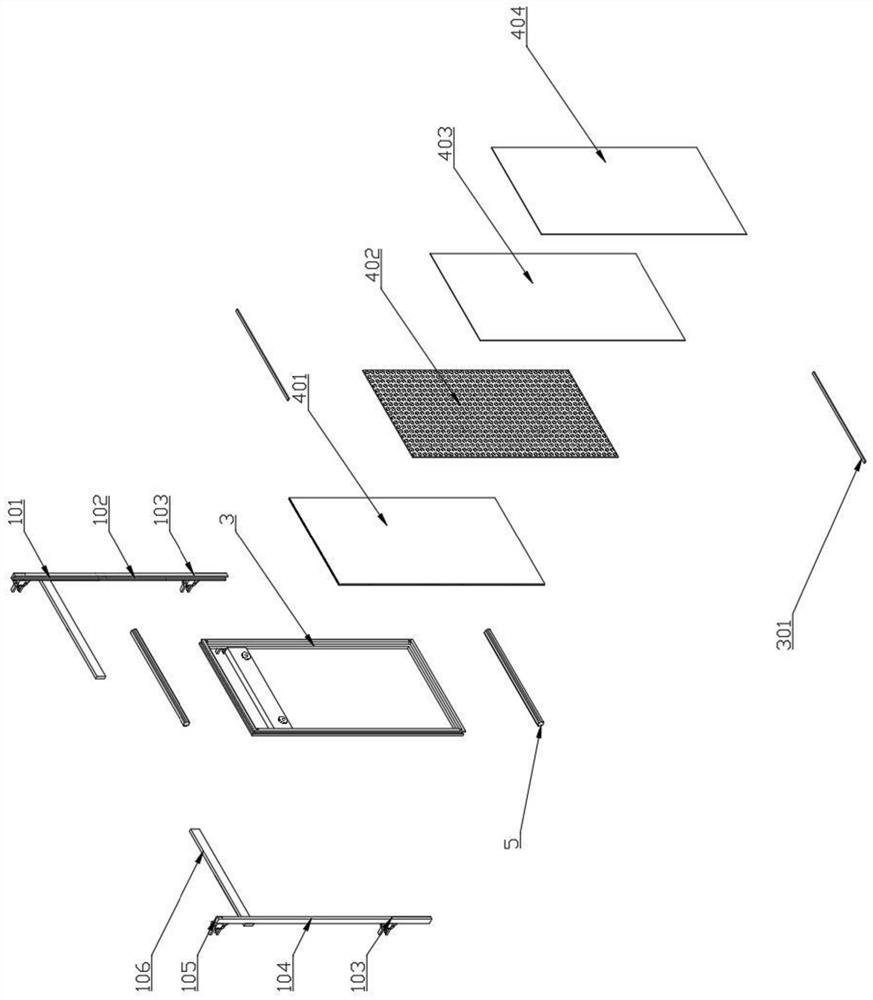

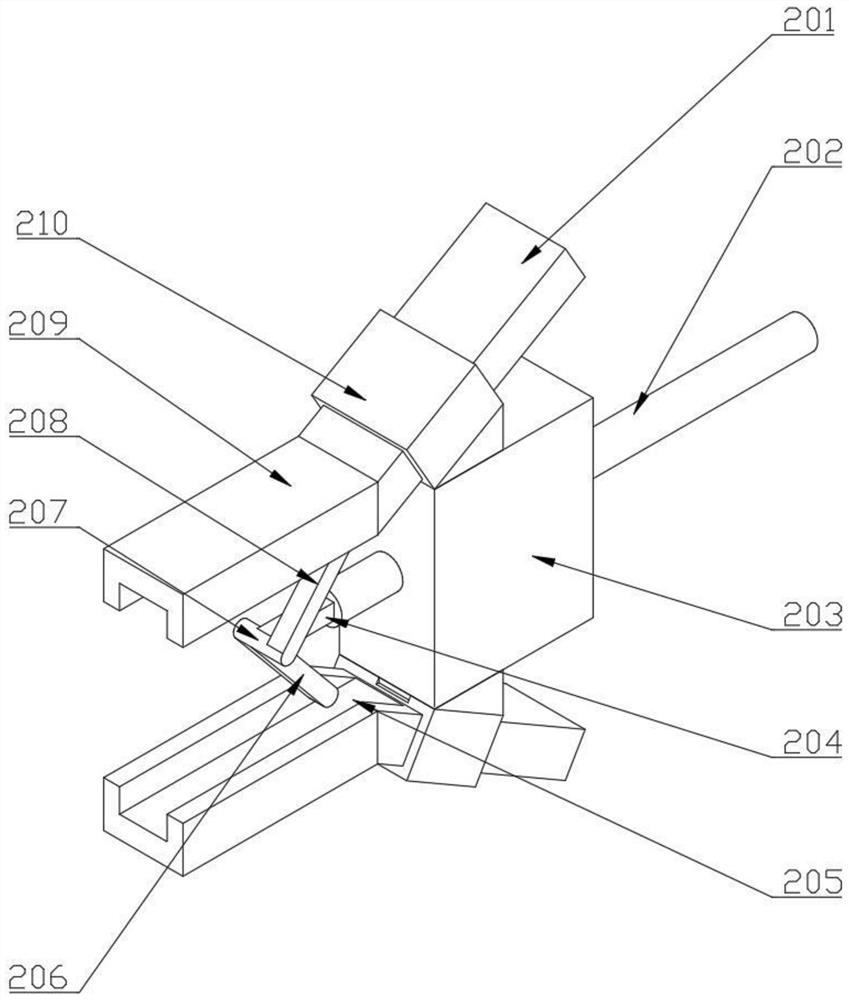

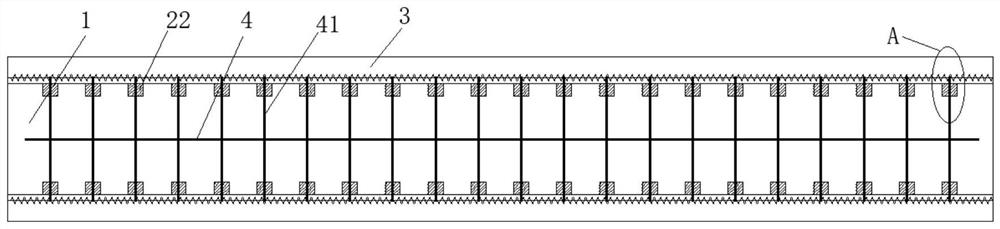

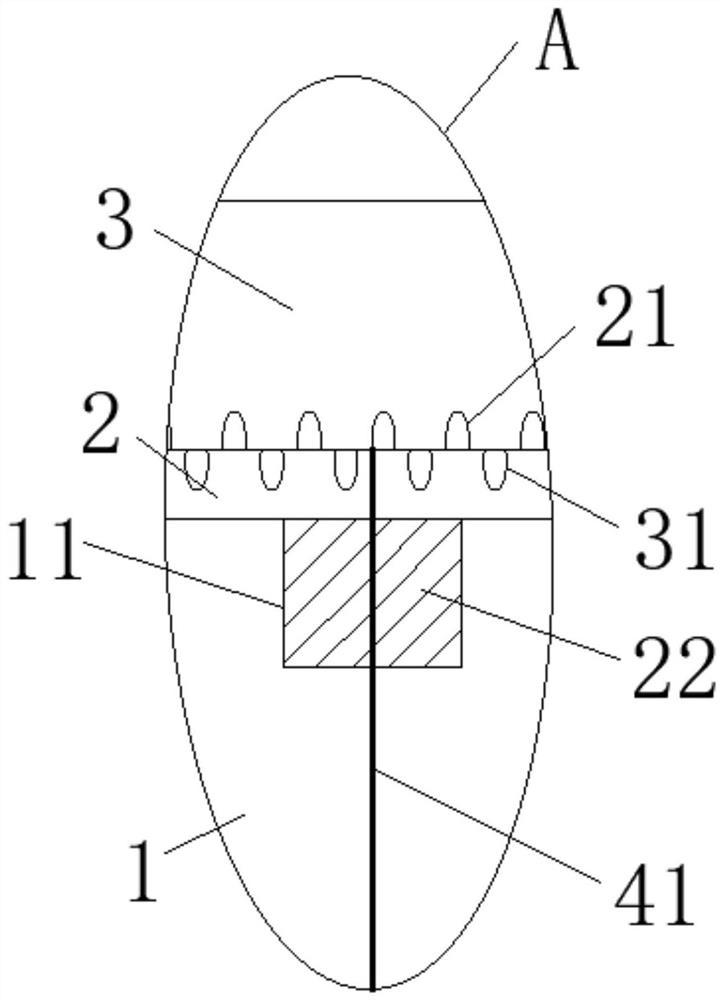

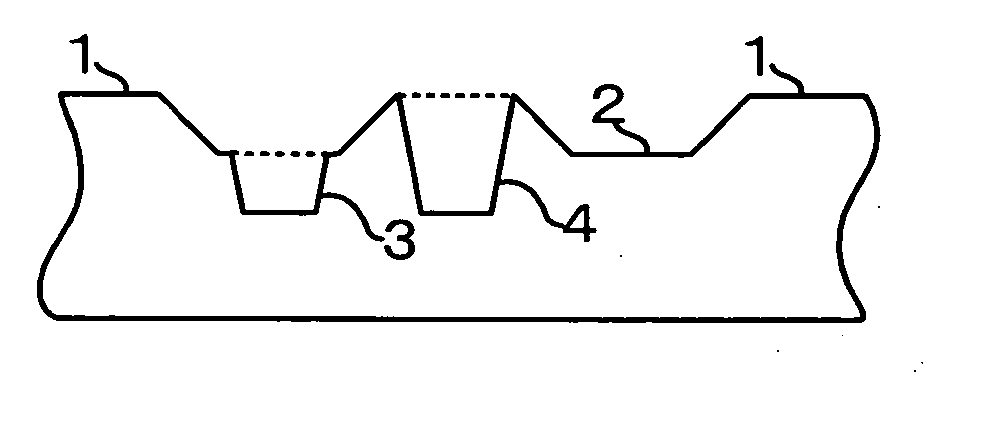

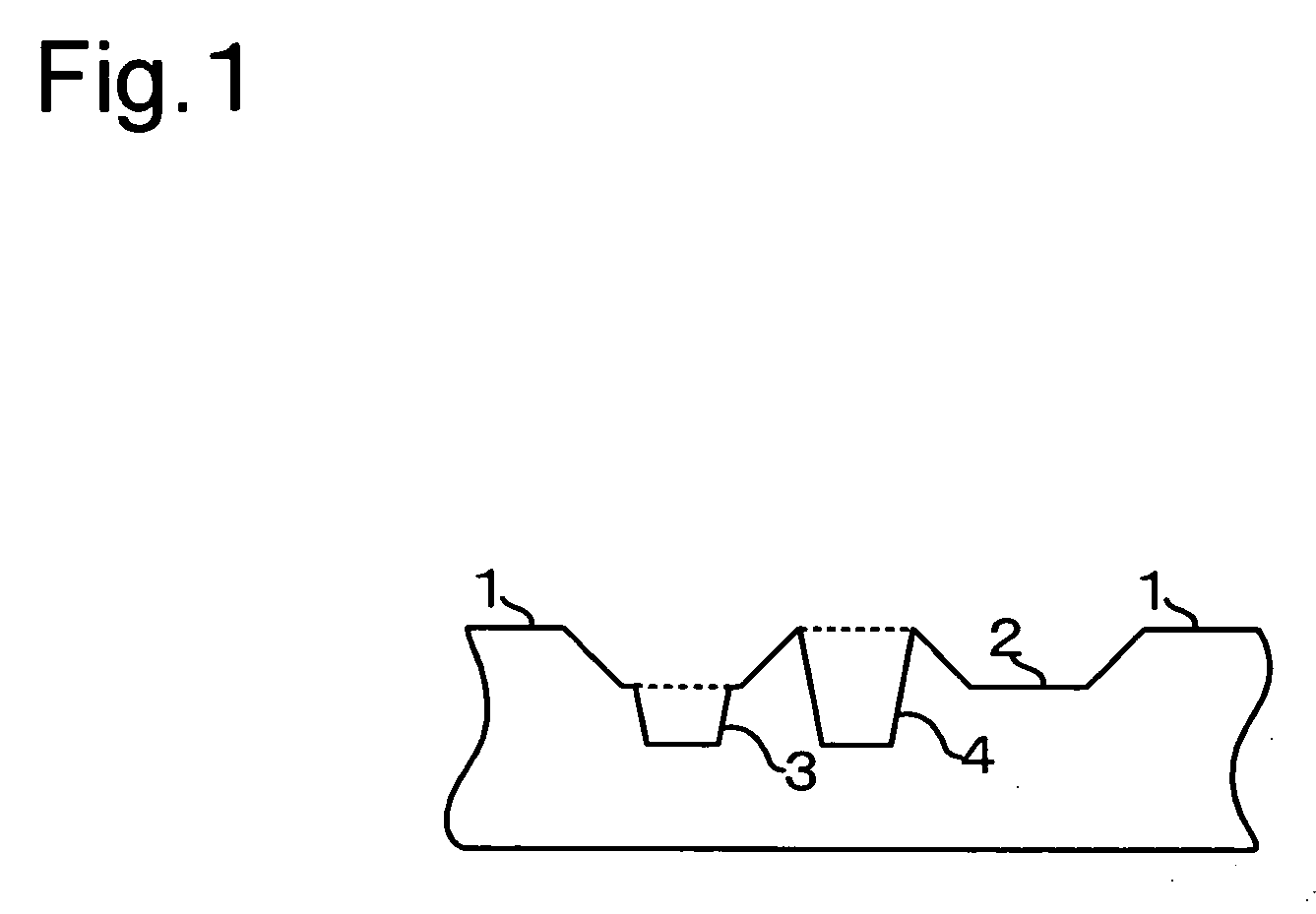

High-hardness scratch-resistant aluminum curtain wall

The invention provides a high-hardness scratch-resistant aluminum curtain wall, belongs to the technical field of building curtain walls, and aims to solve the problems that an existing aluminum curtain wall is easy to bend and deform and the surface of the existing aluminum curtain wall is easy to scratch. The curtain wall comprises a keel mechanism, the keel mechanism comprises a plurality of first keels and a plurality of second keels, a plurality of connecting mechanisms are arranged on the rear sides of the first keels and the second keels, fixing mechanisms are arranged between the first keels and the second keels at the corresponding positions, each fixing mechanism comprises a plurality of fixing frames, and splicing grooves are formed in one sides of the fixing frames. Splicing blocks are fixed to the other sides of the fixing frames, a placement groove and two fixing grooves are formed in the front side of each fixing frame, an anti-scratch curtain wall plate is placed in each placement groove, fixing plates are arranged on the two fixing grooves, U-shaped plates are fixed to the rear sides of the fixing frames, and bearing plates are arranged at the upper ends and the lower ends of the fixing frames. The fixing frames are connected with the fixing frames of the fixing mechanisms at the upper and lower ends through bearing plates. Bending deformation and surface scratches of the aluminum curtain wall can be avoided.

Owner:安徽鑫翊新材料有限公司

Preparation method of self-focusing glass device scratch repair material

ActiveCN103834301BSimple processPrevent sudden changes in refractive indexCoatingsOrganic acidRepair material

The invention discloses a preparation method of a repairing material for scratches on a self-focusing glass device. The preparation method comprises the steps: 1, dissolving tetrabutyl titanate in low alcohol to prepare a 1-20 percent solution; 2, dissolving organic acid in pure water to prepare a 0.1-10 percent solution B; 3, heating the solution A to 80 DEG C, gradually dropping the solution B in the solution A to obtain a solution C; 4, dissolving organosiloxane in the low alcohol to prepare a 0.5-5 percent solution D, once adding the solution D in the solution C, filling nitrogen with a pressure range of 0.1-1 MPa, reacting for 0.5-24 hours at the temperature of 80 DEG C and the pressure of 0.1-1 MPa; and 5, cooling to a room temperature, and ageing. The invention provides the preparation method of the repairing material for the scratches on the surface of a self-focusing lens, the surface of a self-focusing optical fiber and the surfaces of other glass devices with a self-focusing function.

Owner:XIAN JUNSHENG NEW MATERIAL TECH

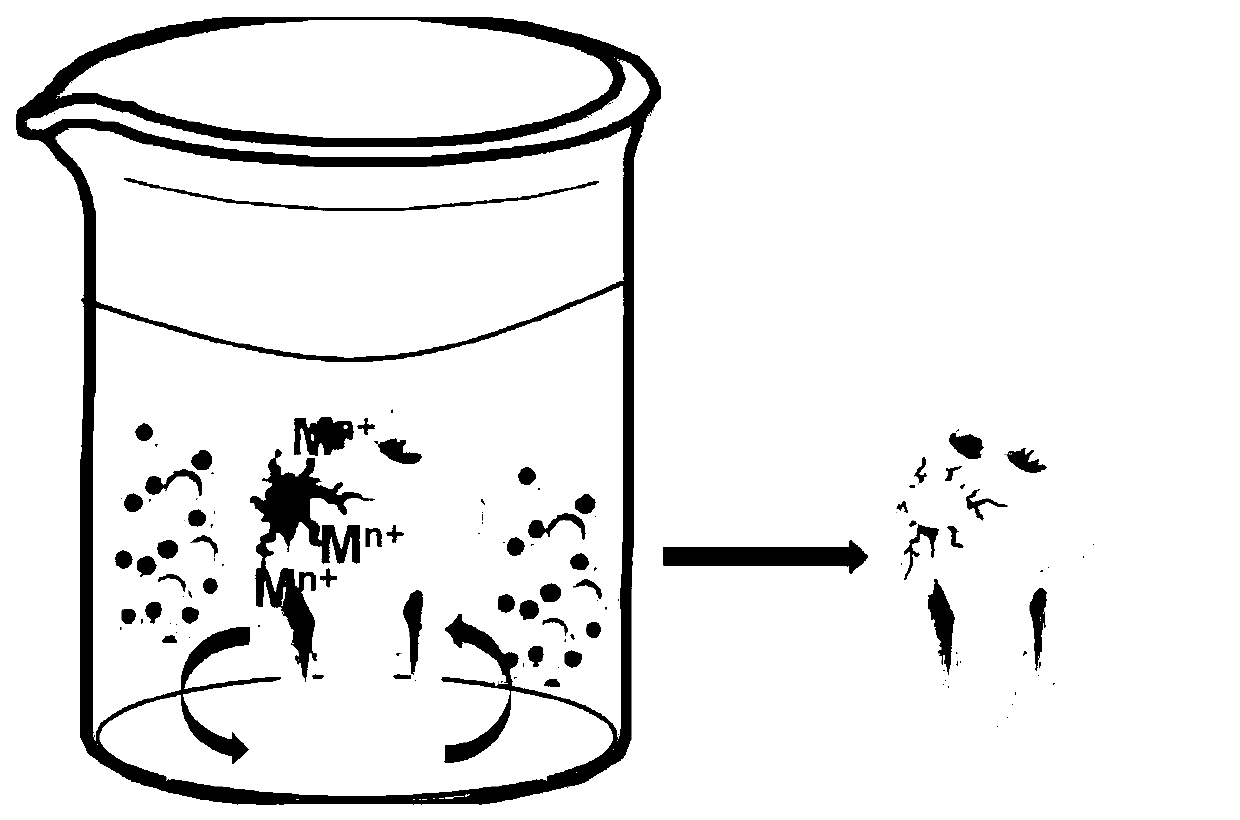

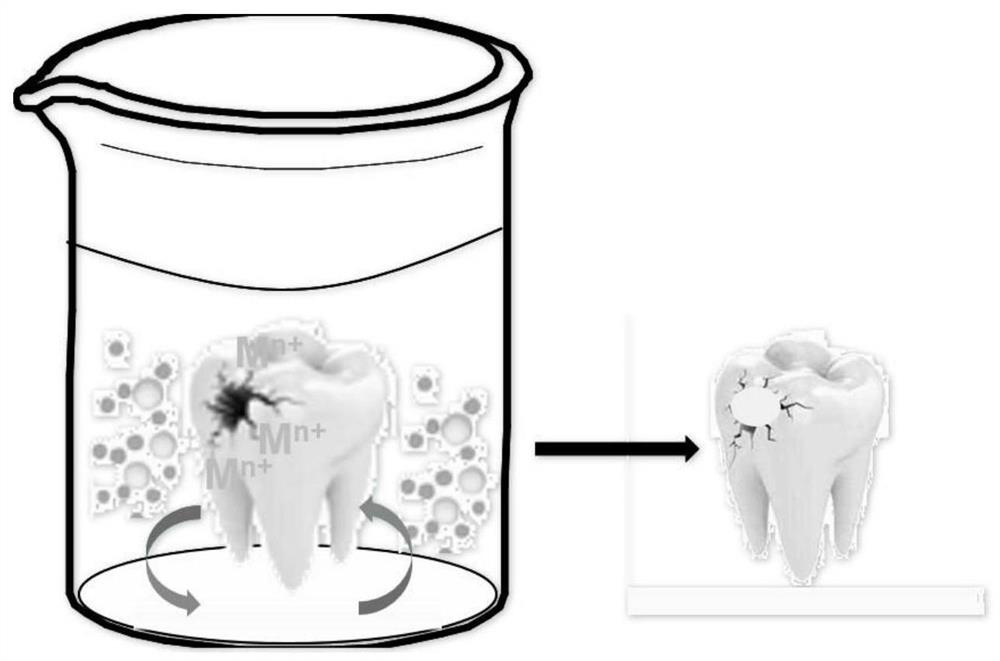

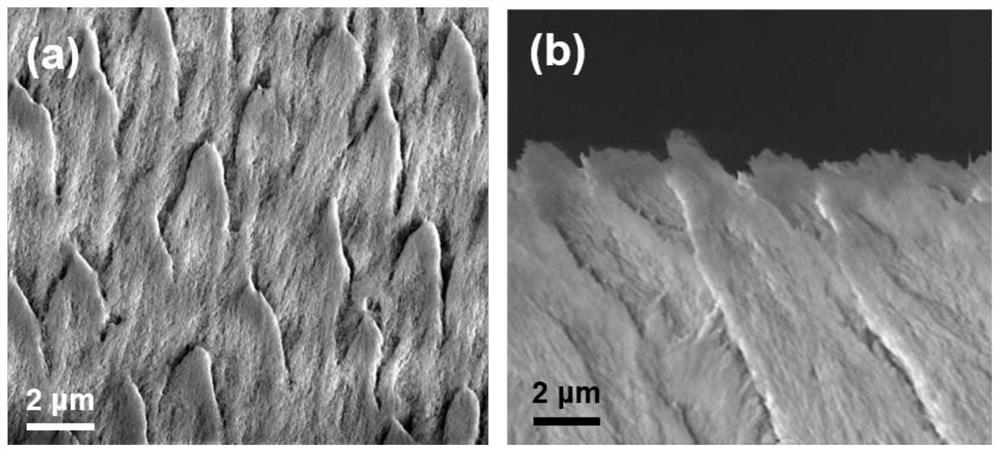

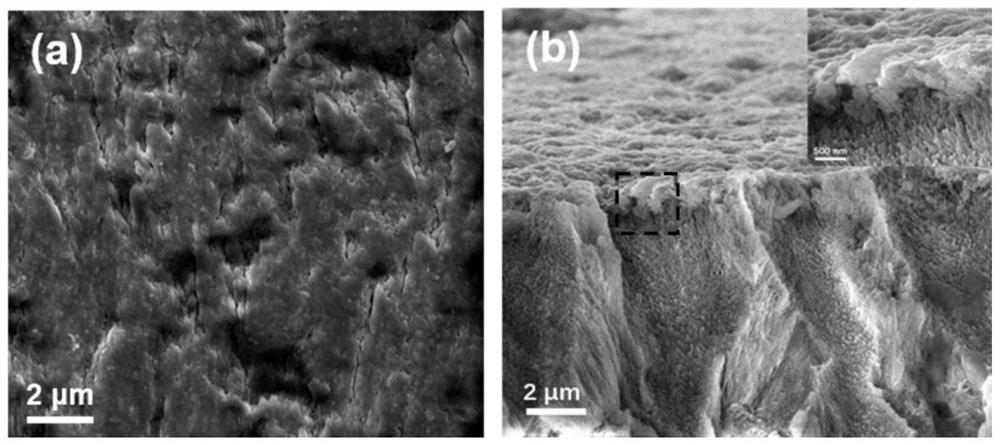

Method for repairing damaged dental enamel by metal oxide compact layer coating

ActiveCN110227033AEasy to operateRaw materials are easy to obtainImpression capsDentistry preparationsTooth enamelRoom temperature

The invention relates to the technical field of repairing damaged dental enamel by metal oxide coating, in particular to controllable preparation of a metal oxide repair layer closely connected with damaged dental enamel. Metal salt and a buffer solution which are easy to obtain are used as raw materials, growth of the metal oxide on the surface of the damaged dental enamel is promoted, the metaloxide repair layer closely connected with the damaged dental enamel is prepared, and repair of the damaged dental enamel is realized. The specific method comprises the steps as follows: (1) preparingthe buffer solution with target pH at the room temperature and adding a proper amount of metal salt; (2) then, adding the damaged dental enamel to the solution, and performing stirring for 3-5 h to coat the surface of the damaged dental enamel with a metal oxide precursor; and (3) placing the precursor in a reaction kettle, adding ethanol, conducting a reaction at 60-80 DEG C for 8-12 h to finallyobtain the uniform and compact metal oxide repair layer to realize repair of the damaged dental enamel.

Owner:BEIHANG UNIV

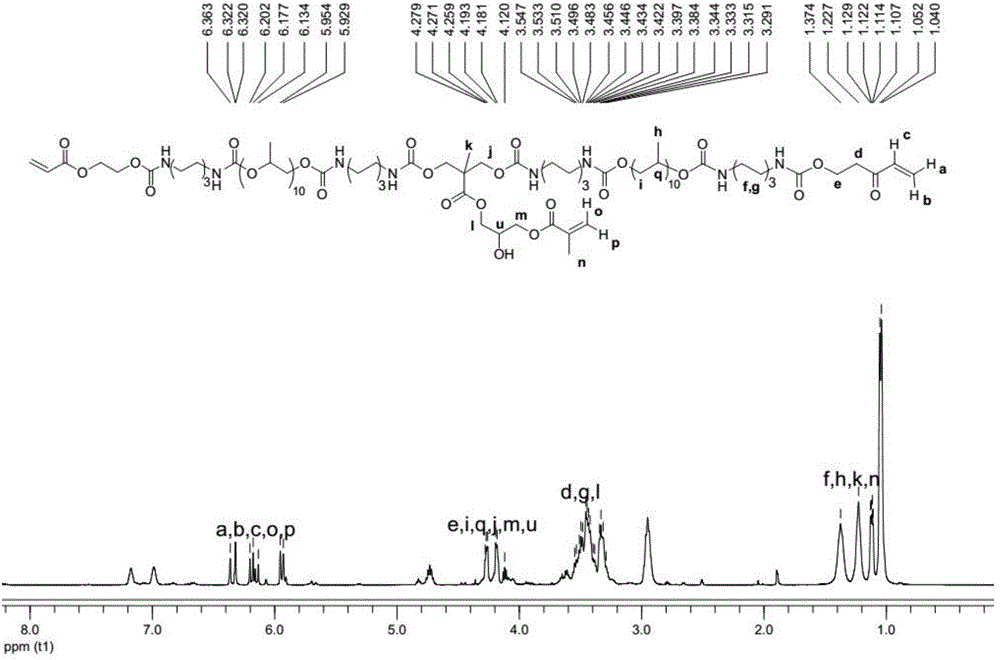

A kind of uv photocuring type elastic self-repair brightening coating composition

InactiveCN104877544BSimple production processSimple preparation conditionsPolyurea/polyurethane coatingsUltraviolet lightsPhotoinitiator

The invention provides a UV photo-curing elastic self-repairing brightening paint composition. The paint composition comprises the following ingredients in parts by weight: 10 to 70 parts of elastic photo-curing resin, 10 to 50 parts of photopolymerization monomer, 2 to 5 parts of photoinitiator and 0.05 to 1 part of additive. The UV photo-curing elastic self-repairing brightening paint composition can be smeared on an optical PET plastic base material; after being cured by ultraviolet light, a coating is excellent in elasticity and also good in attachment force, wear resistance and scratch resistance.

Owner:SHANGHAI WEIKAI CHEM +1

Scratch-proof frosted ecological plate and preparation method thereof

PendingCN113997362AMaintain aestheticsStrong hardnessSynthetic resin layered productsWood veneer joiningHardnessArtificial stone

The invention relates to a scratch-proof frosted ecological plate and a preparation method thereof. The scratch-proof frosted ecological plate comprises a base plate, the two sides of the base plate are both covered with thermoplastic resin layers, the sides, away from the base plate, of the thermoplastic resin layers are covered with artificial stone surface layers, artificial stone protruding blocks are embedded in the thermoplastic resin layers, and the artificial stone protruding blocks are fixedly connected with the artificial stone surface layers. According to the scratch-proof frosted ecological plate and the preparation method thereof provided by the technical schemes, the artificial stone surface layers serve as the surface layers, so that the surface layers have high hardness and can resist scratches, and the attractiveness of a plate can be kept.

Owner:湖南雪宝装饰材料有限公司

A method for repairing damaged tooth enamel by coating dense layers of metal oxides

ActiveCN110227033BEasy to operateRaw materials are easy to obtainImpression capsDentistry preparationsTooth enamelDentistry

The invention relates to a preparation method of a dense metal oxide thin layer coated on the surface of tooth enamel, in particular to a controllable preparation of a thin metal oxide layer closely connected with damaged tooth enamel. Using readily available metal salts and buffer solutions as raw materials, the growth of metal oxides on the surface of damaged enamel is promoted, and a thin layer of metal oxides that is closely connected with damaged enamel is prepared to realize the healing of damaged enamel. repair. The specific method is (1) prepare a buffer solution with a target pH at room temperature, and add an appropriate amount of metal salt; (2) then add the damaged enamel to the above solution, and stir for 3-5 hours to realize the metal oxide precursor in the damaged enamel. Surface coating; (3) Put the precursor into a reaction kettle, add ethanol, and react at 60-80°C for 8-12 hours, and finally obtain a uniform and dense metal oxide thin layer coated on the surface of the enamel.

Owner:BEIHANG UNIV

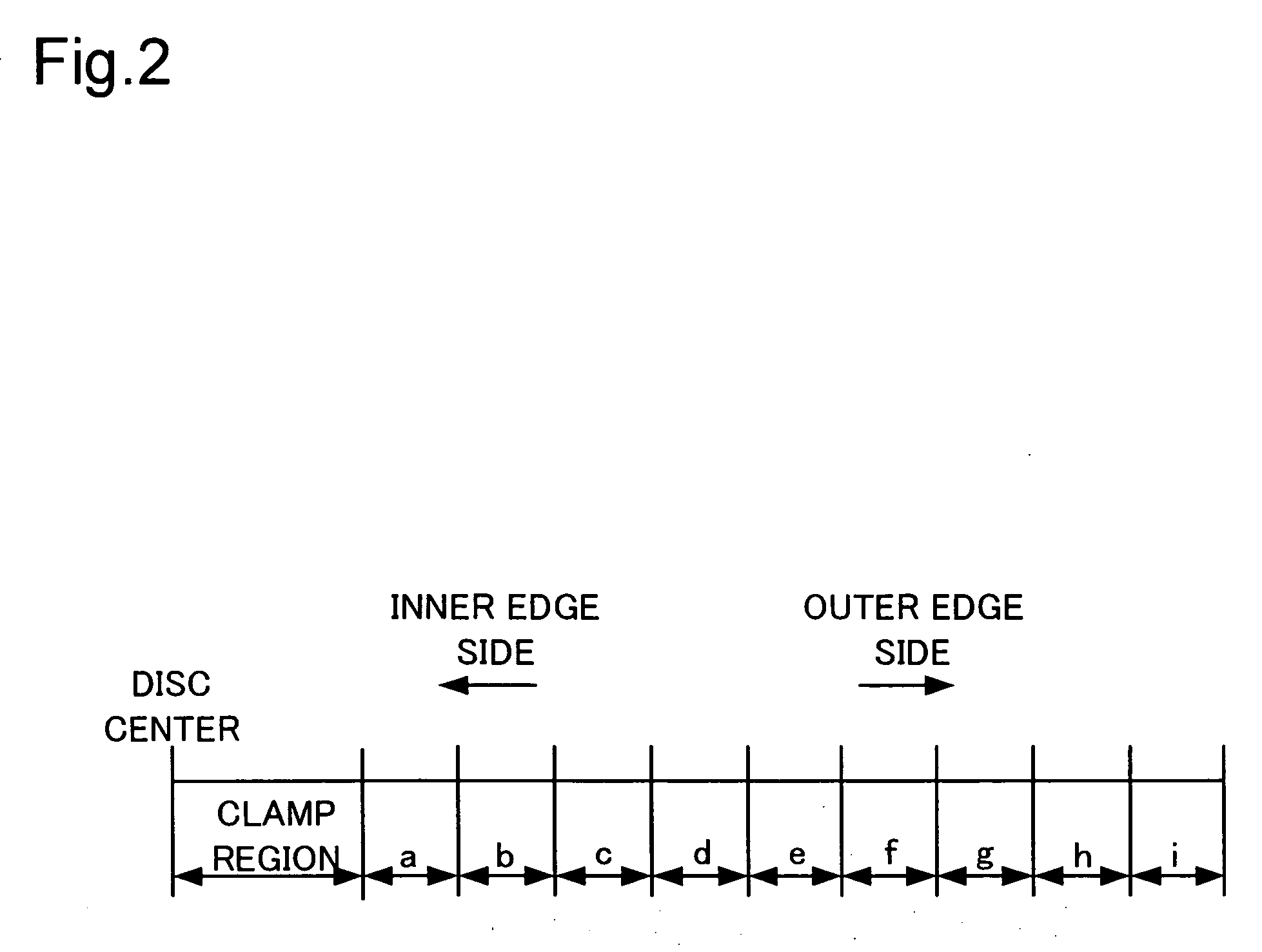

Test disk

InactiveUS20060171289A1Eliminate needScratch resistanceRecording verificationLighting and heating apparatusDVD-RWEngineering

With conventional test discs, changing them takes much time when a pickup is subjected to signal evaluation with respect to DVD- family discs (DVD-R and DVD-RW) and DVD+ family discs (DVD+R and DVD+RW), leading to low testing efficiency. A test disc of the invention has, formed on a single glass substrate, areas where there are provided regions where pits or no pits are formed and areas where there are provided regions where wobbles and land prepits are formed with varying parameters.

Owner:FUNAI ELECTRIC CO LTD

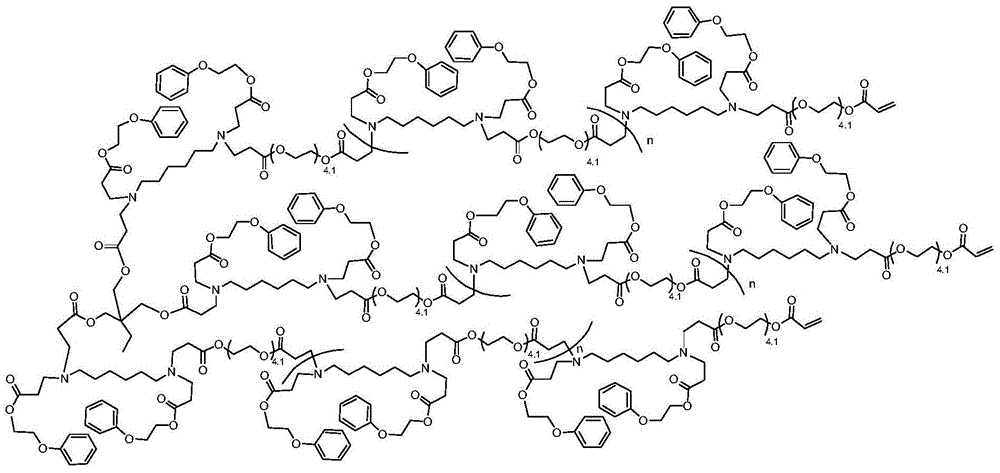

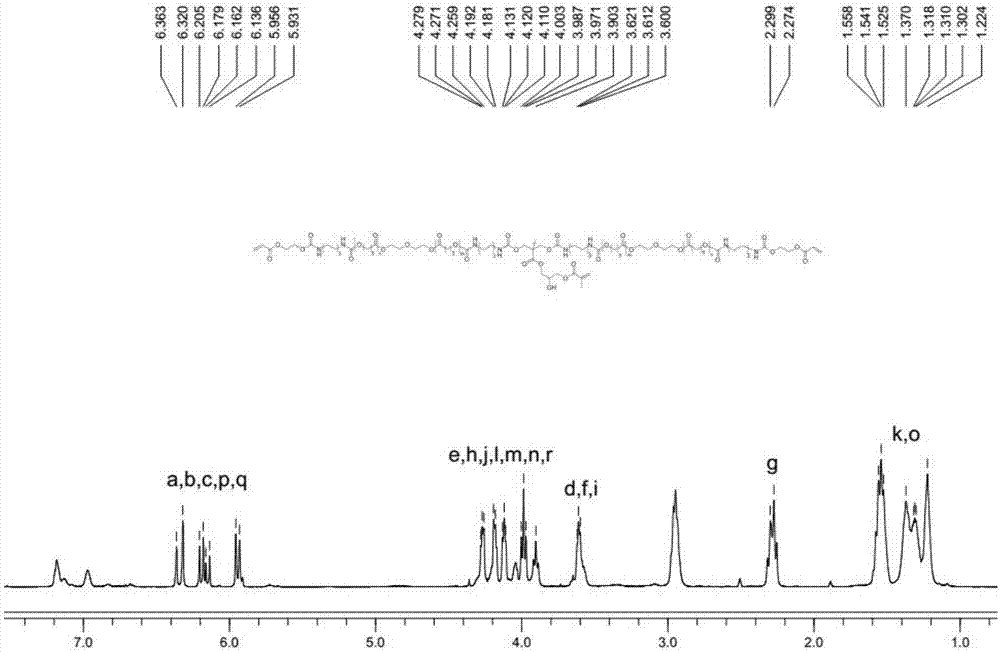

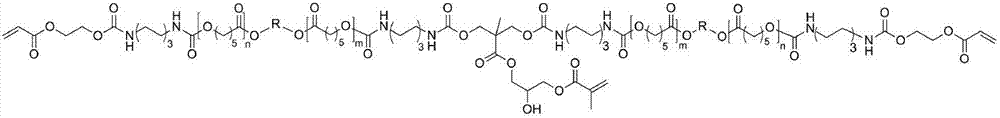

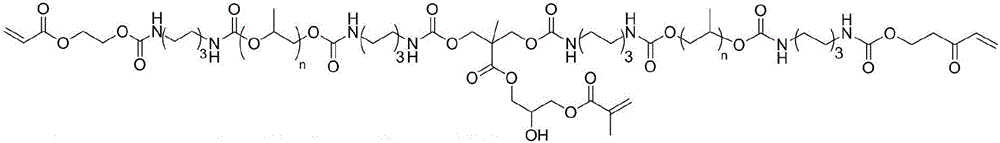

UV-curable elastic self-healing coating composition

InactiveCN104592884BSimple production processSimple preparation conditionsCoatingsSelf-healingAdhesion force

The invention relates to an ultraviolet light curing elastic self-healing coating composition. The composition comprises the following components in parts by weight: 10-70 parts of elastic light-cured resins, 10-70 parts of light curing monomers, 1-5 parts of light initiators and 0.05-1 part of auxiliary, wherein the elastic light-cured resins are tri-functional acrylate unsaturated polymers having a soft-hard segment structure and high elasticity performance. The ultraviolet light curing elastic self-healing coating composition can be coated on a PET substrate, and the coating subjected to ultraviolet curing is high in elastic self-healing performance, extremely high in adhesion force, abrasion resistance and scratching resistance.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Manufacturing method of biopolyester resin insulated multilayer insulated wire and produced biopolyester resin insulated multilayer insulated wire

ActiveCN109196606BEasy to manufactureScratch resistancePlastic/resin/waxes insulatorsSubmarine cablesPolymer scienceInsulation layer

The present invention relates to: a method for manufacturing a multilayer insulated electric wire insulated by a biopolyester resin; and a multilayer insulated electric wire insulated by a biopolyester resin, manufactured according thereto, the method comprising the steps of: separating glycerol from biodiesel by-products; separating bio 1,3-propanediol by fermenting the glycerol; preparing a biopolyester resin by means of a transesterification reaction step, using the bio 1,3-propanediol, and a polycondensation reaction step; preparing biopolyester pellets by obtaining a mixture by mixing the biopolyester resin with an antioxidant and a pigment, and then melt mixing the mixture; and forming two or more layers of insulation layers by extruding the biopolyester pellets on the outer circumference of a conductor, and then forming an outermost insulation layer by extruding polymer resin pellets on the insulation layers. According to the present invention, a multilayer insulated electric wire satisfying environmental protection requirements and simultaneously having the necessary characteristics such as heat resistance and impact resistance, flexibility before and after heating, and scratch resistance, which are required for a use as battery and electronic equipment wiring and coiling, can be readily manufactured.

Owner:KOREA INST OF IND TECH

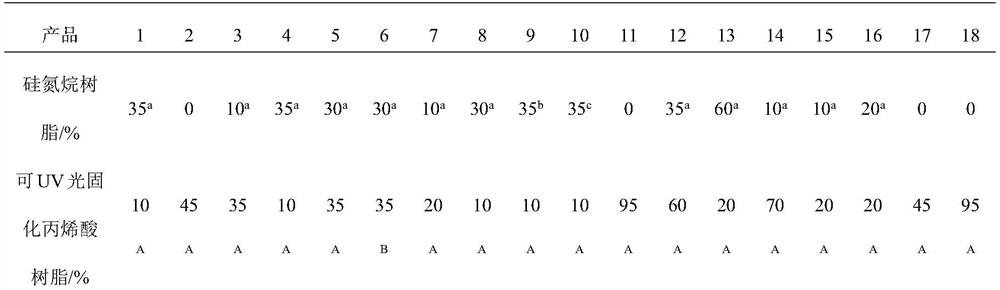

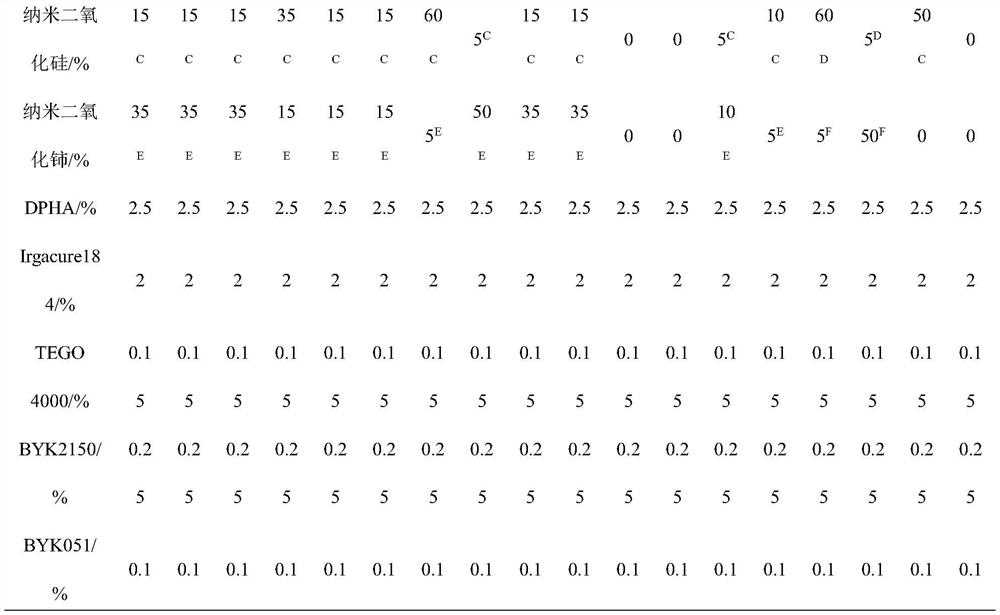

A kind of transparent PET optical hardening film based on radiation curing and preparation method thereof

The invention discloses a transparent PET optical hardened film based on radiation curing and a preparation method thereof. The PET optical hardened film is composed of a PET base film and a high-hardness transparent coating coated on the base film; the high-hardness transparent The coating comprises the following components by weight: 0-60% of photocurable organosilazane resin, 10-70% of UV-curable acrylic resin, 5-60% of nano-silica, 5-50% of flakes Nano ceria, 0-20% active diluent, 1-10% photoinitiator, 0-5% auxiliary agent; wherein, the auxiliary agent includes: any one or two of leveling agent, dispersant and defoamer more than one species. The PET optical hardening film of the present invention has the characteristics of high light transmittance, low haze, high hardness, scratch resistance, and low longitudinal shrinkage.

Owner:佛山市菲锐表面科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com