Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

631results about "Submarine cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamic umbilicals with internal steel rods

InactiveUS6472614B1Power cables including communication wiresPower cables including electrical controlUltimate tensile strengthBallast

In an umbilical, one or more steel rods, which provide strength and ballast, are wound helically within the umbilical along with the steel tubes and / or elongated active umbilical elements. These steel rods replace some or all of the thermoplastic filler elements that would otherwise be included within the umbilical. An umbilical according to an embodiment of the invention may include a plurality of steel tubes helically wound around a core, and at least one substantially solid steel rod helically wound around the core, the steel rod being arranged in a void between the steel tubes. Thus, the invention avoids the need to apply additional armoring layers to the outside of the umbilical for strength and ballast.

Owner:TECH FRANCE SA

Submarine electric power transmission cable armour transition

ActiveUS20120024565A1Uniformity in mechanicalUniformity in handling characteristicPower cables with screens/conductive layersSubmarine cablesElectric power transmissionMetallic materials

An electric power transmission cable includes at least one first section provided with cable armour made of a first metallic material, and at least one second section provided with a cable armour made of a second metallic material, wherein the second metallic material has ferromagnetic properties substantially lower than those of the first metallic material.

Owner:PRYSMIAN SPA

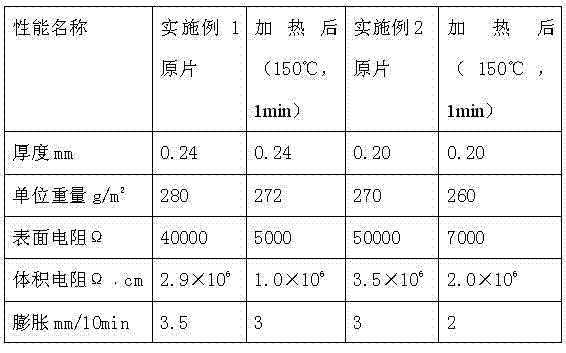

Preparation method of deep sea cable filling strip

ActiveCN102286162AExtended service lifeSimple production processSubmarine cablesInsulated conductorsElectrical conductorFilled cable

A preparation method of a deep sea cable filling strip relates to a preparation method of a conductor filling strip. The preparation method comprises the following process steps: mixing rubber, a vulcanizing agent, a vulcanization accelerator, an antiager, a plasticizer, a reinforcing filler and a tackifier in parts by weight; and then calendering, slitting and packaging to obtain the finished product. The method has a simple production technology, stable technical properties and high practicability; the product is used in the cable and the cable core of the optical cable, the product has high strength, uniform thickness and a good saturated water absorption effect and has the functions of shielding and buffering the electric field; and the product also has viscoelasticity, thus the filling cable core is stronger and the service life of the optical cable can be prolonged.

Owner:沈阳天荣电缆材料有限公司

Compact bidirectional repeaters for wireless communication systems

ActiveUS7009573B2Easy to implementSmall sizeAntenna arraysSubmarine cablesCommunications systemEngineering

Compact bidirectional repeaters are provided for wireless communication systems. Their compact size is realized with repeater structures that include different-polarization antennas, back lobe suppressing structures, circuit feedback paths, antenna-feedback detectors, and automatic gain control.

Owner:CALAMP CORP

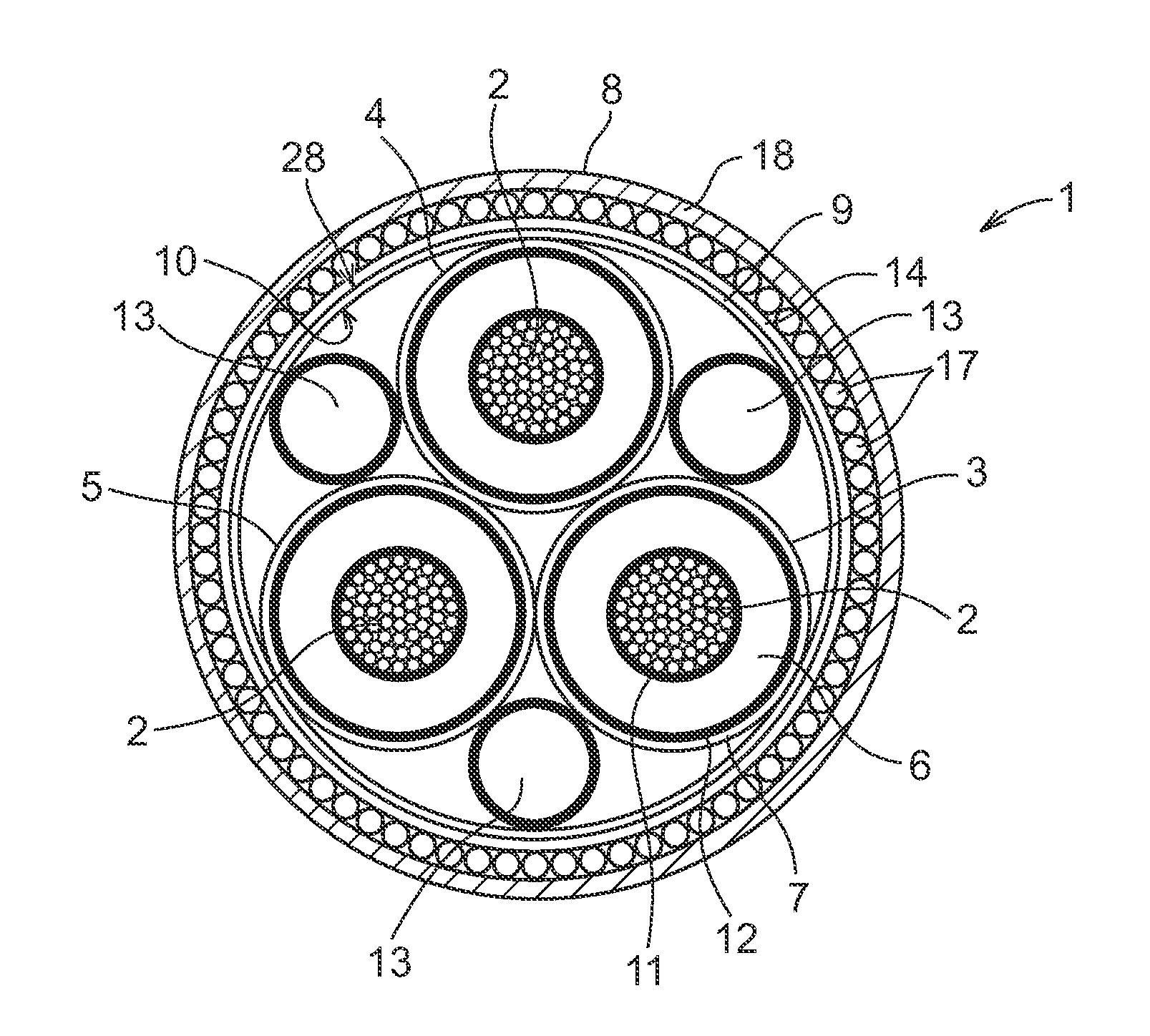

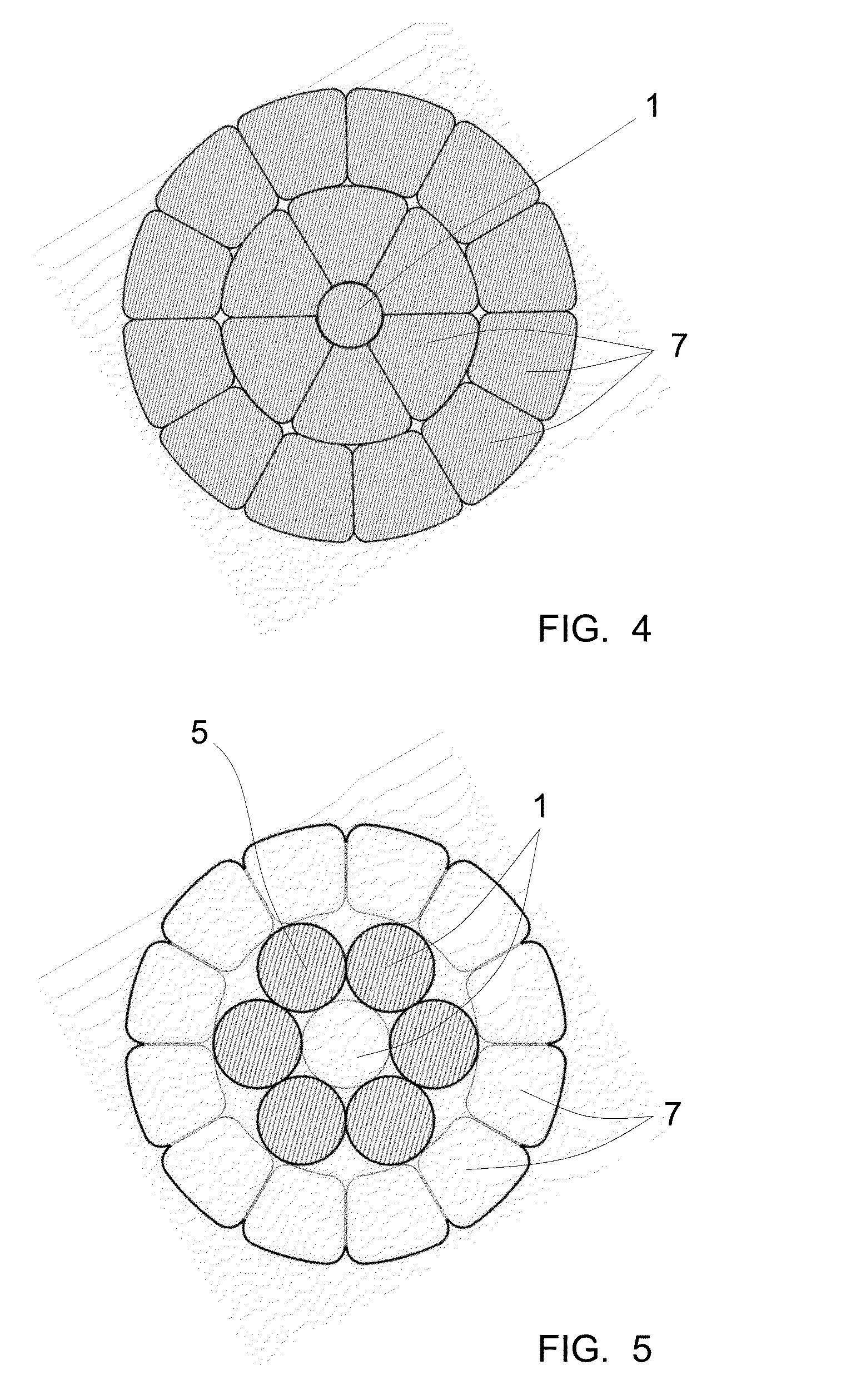

Flexible electrical elongated device suitable for service in a high mechanical load environment

InactiveUS6943300B2Reduce strainReliable load-transferring featureSubmarine cablesFlexible cablesElectrical conductorBiomedical engineering

A flexible electrical elongated device is provided, suitable for service in a high mechanical load environment. The device has a longitudinal axis, and at least one elongated electrical conductor element. The device further has an elongated load bearing component along the longitudinal axis and has an external surface including at least one groove disposed along the longitudinal axis. The groove is designed for holding the conductor element within it while allowing the conductor element to move substantially radially when the device is bent.

Owner:NEXANS

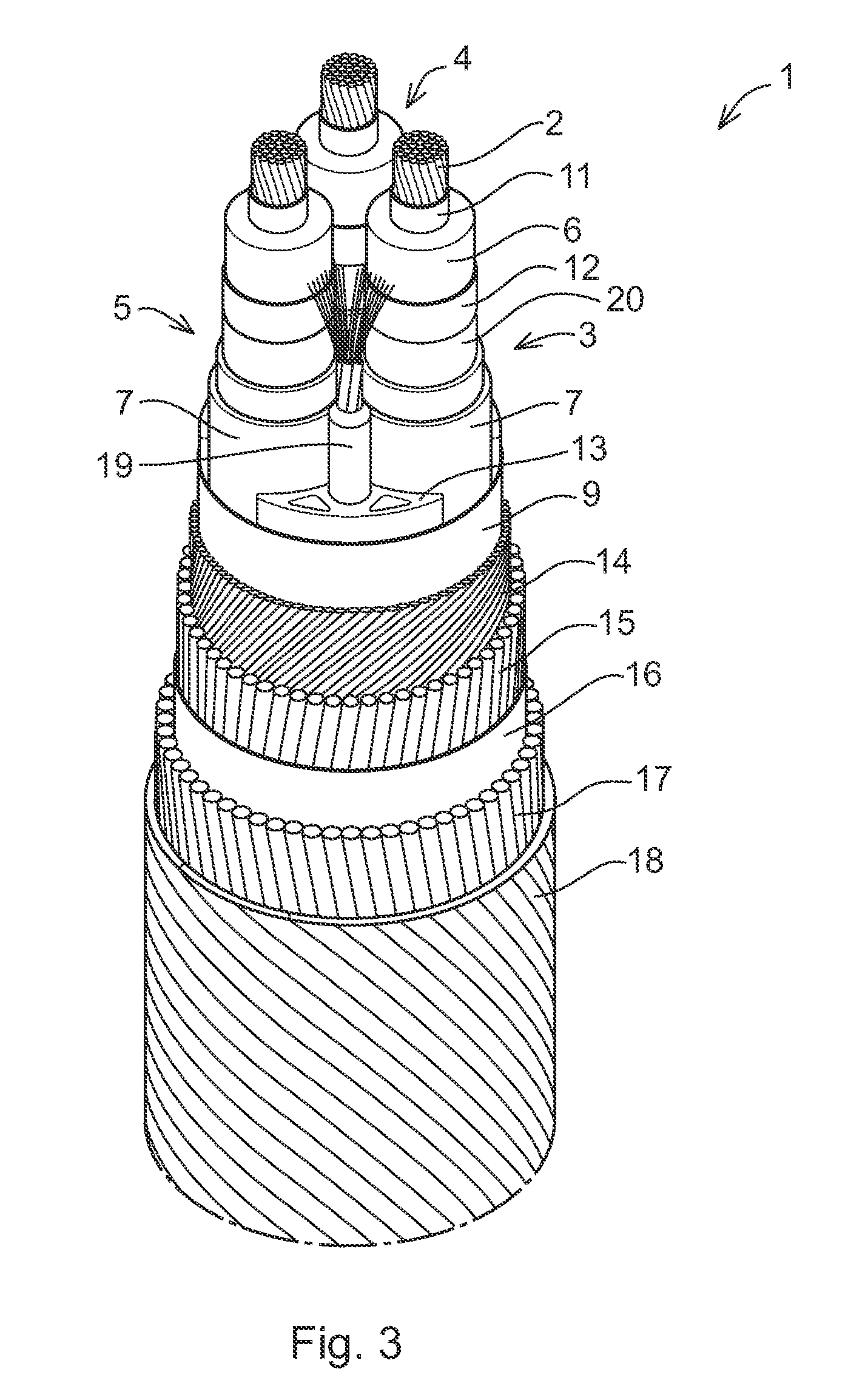

Umbilical

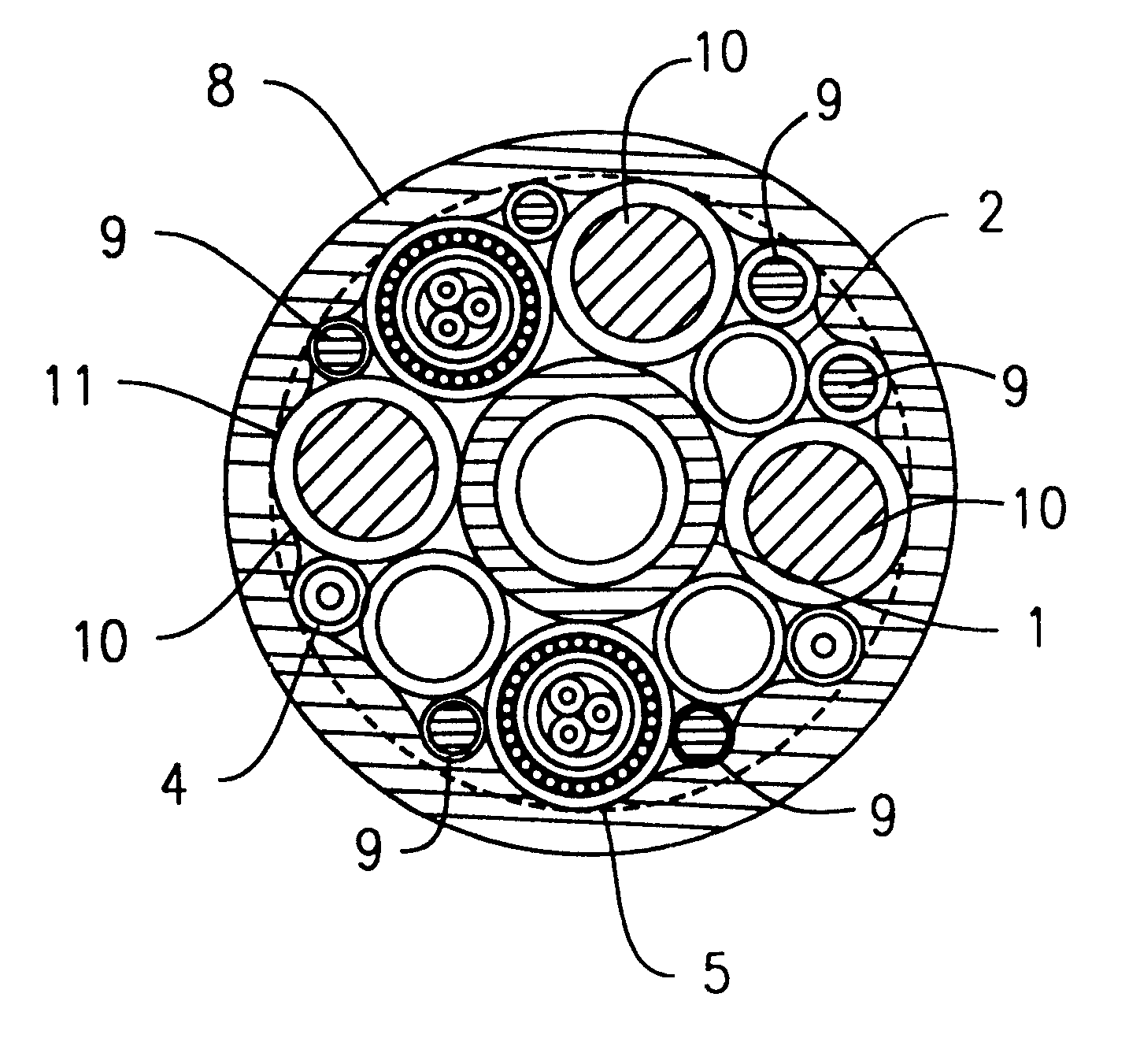

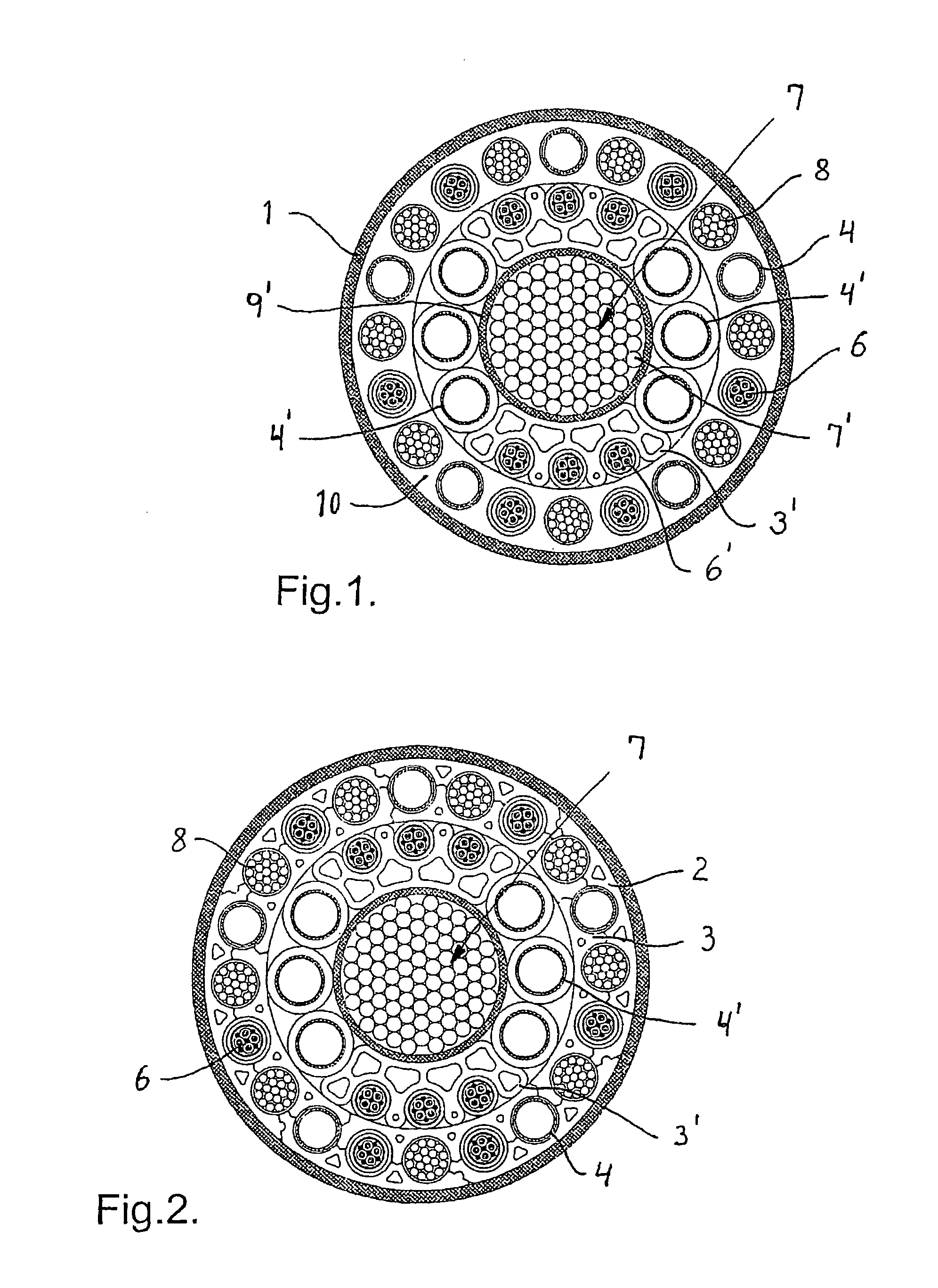

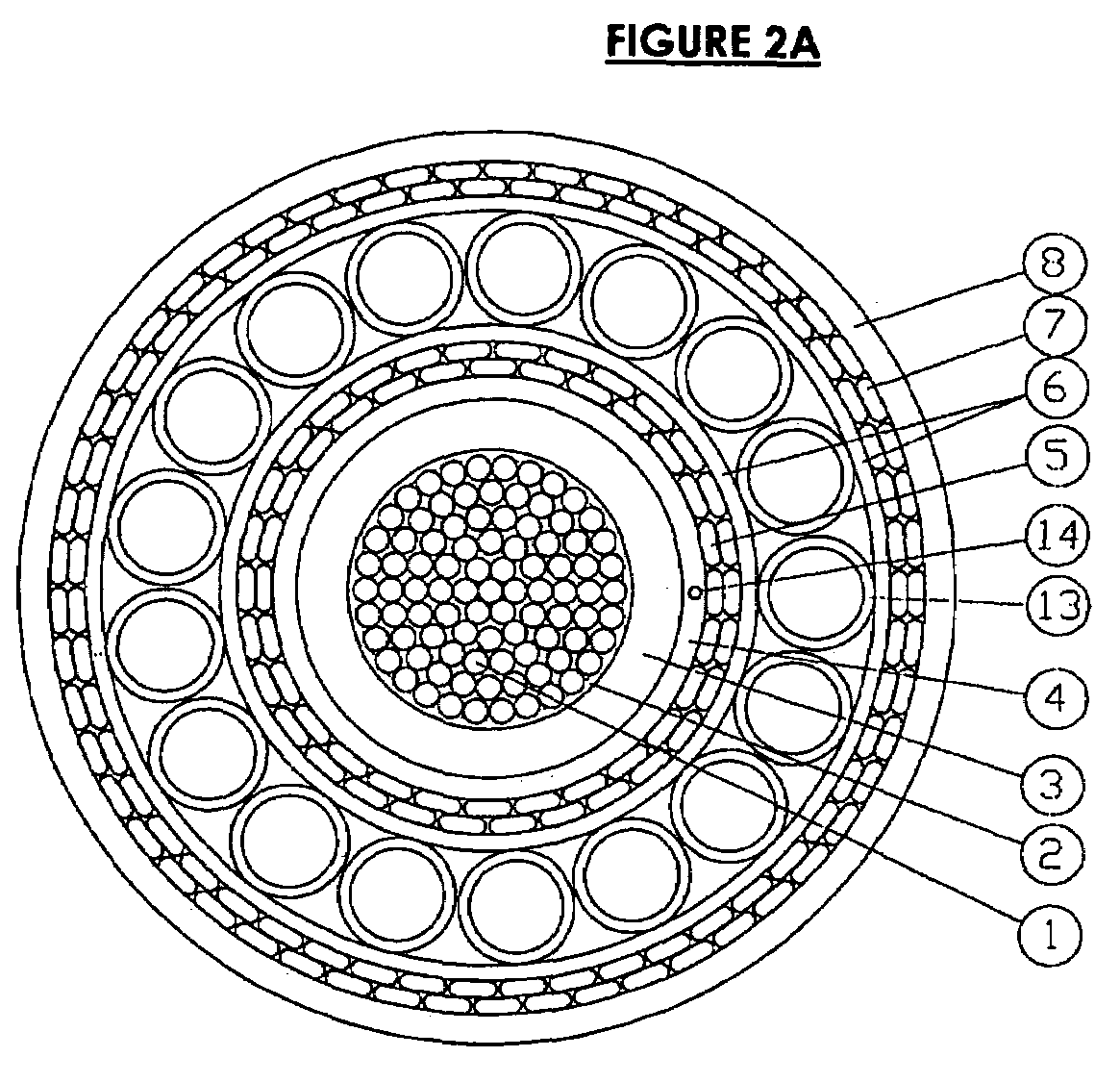

An umbilical for transfer of fluids and electric current / signals between the sea surface and equipment deployed on the sea bed, in particular in deep waters, is disclosed. The umbilical comprises a number of pipes (4, 4′) and electric conductors / wires (6, 6′) collected in a bundle, a filler material (10, 2, 3, 3′) lying at least partly around and between the pipes (4, 4′) and the conductors / wires (6, 6′), and a protective sheath (1) enclosing the pipes, conductors / wires and filler material. The load carrying elements (7) of the umbilical are light weighted rods (7′) of composite material that can either be collected in bundles or appear individually or in a combination thereof.

Owner:AKER SOLUTIONS AS

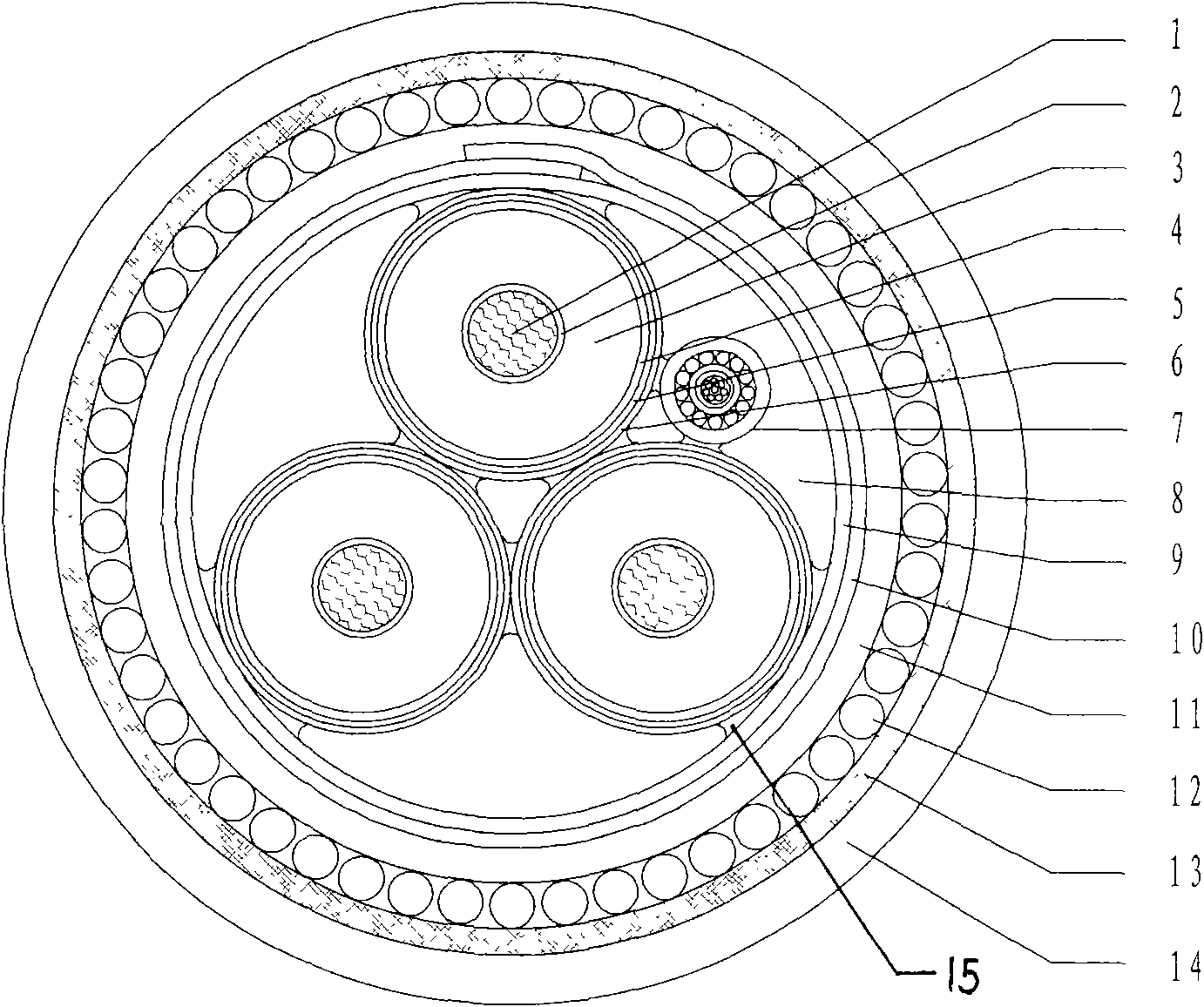

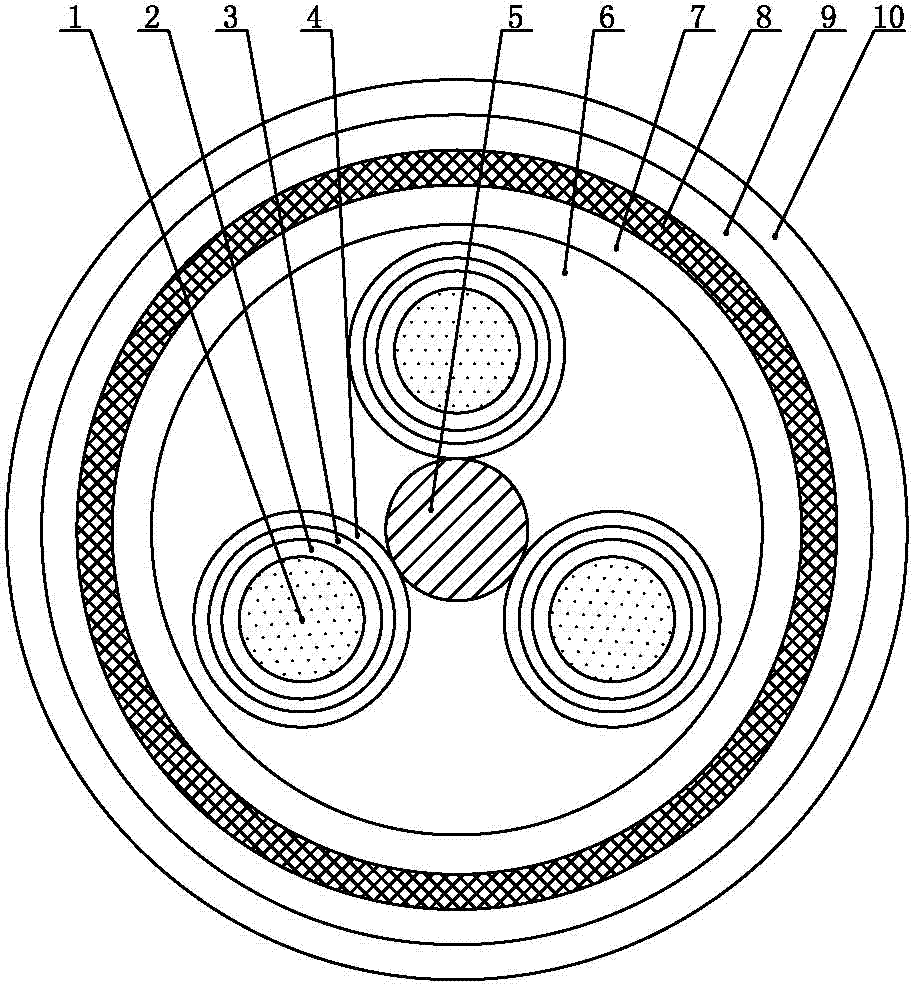

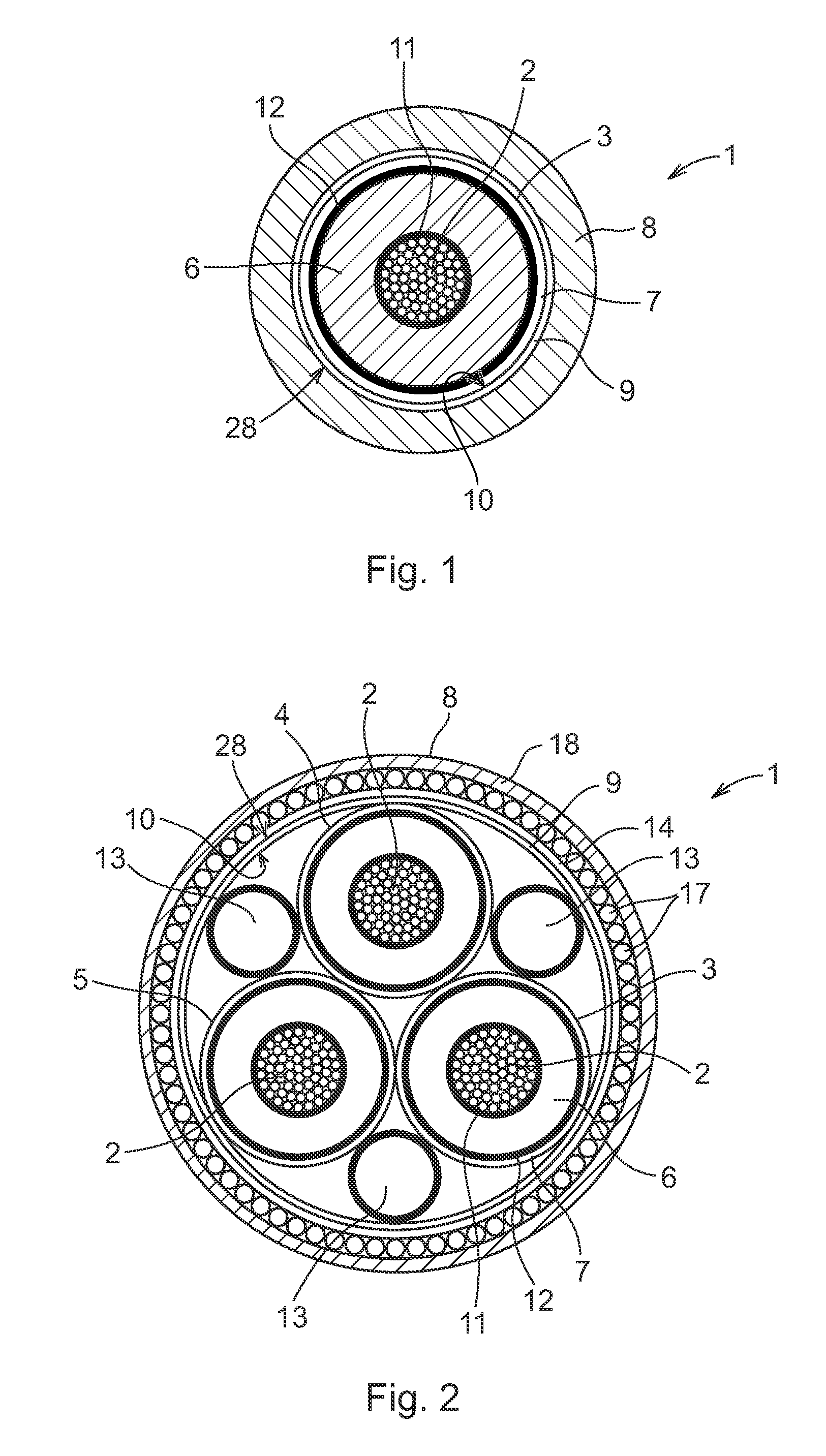

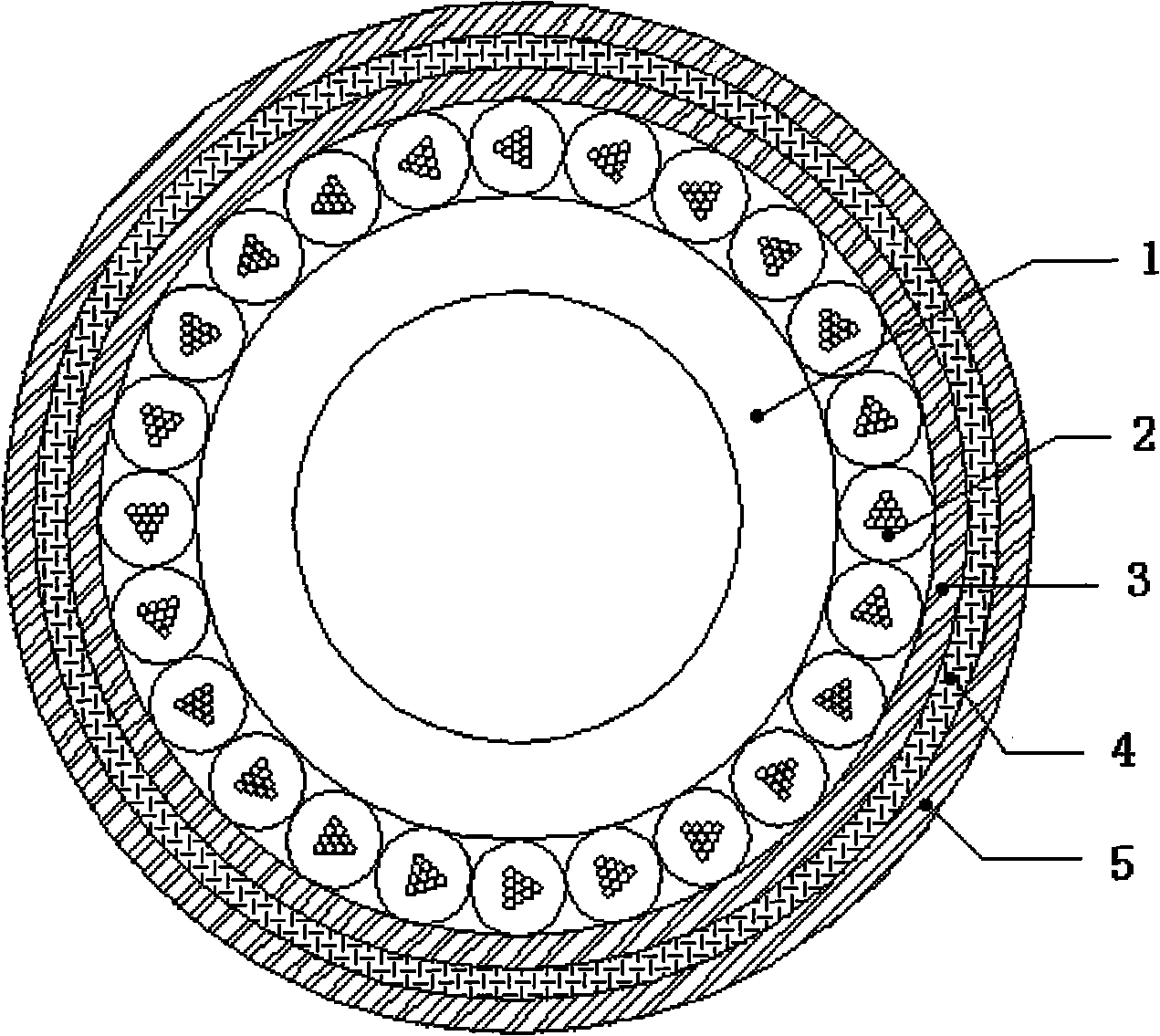

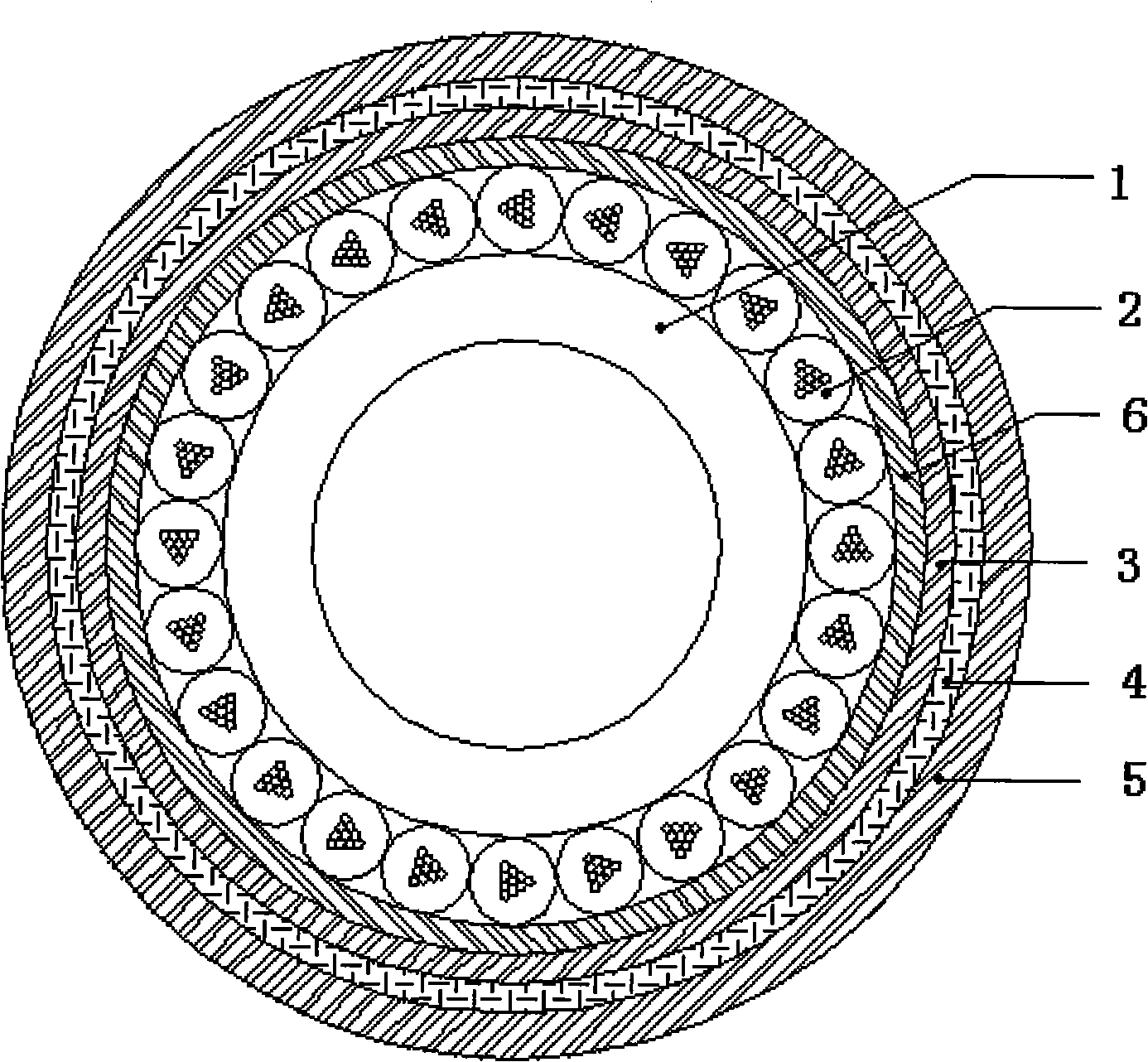

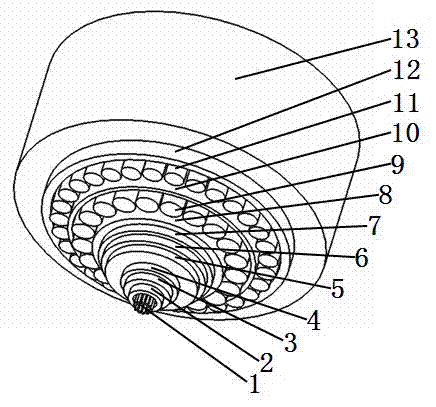

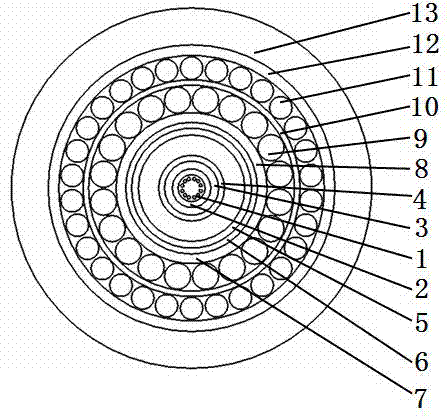

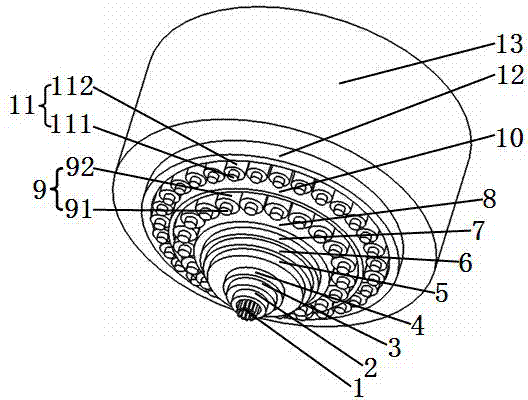

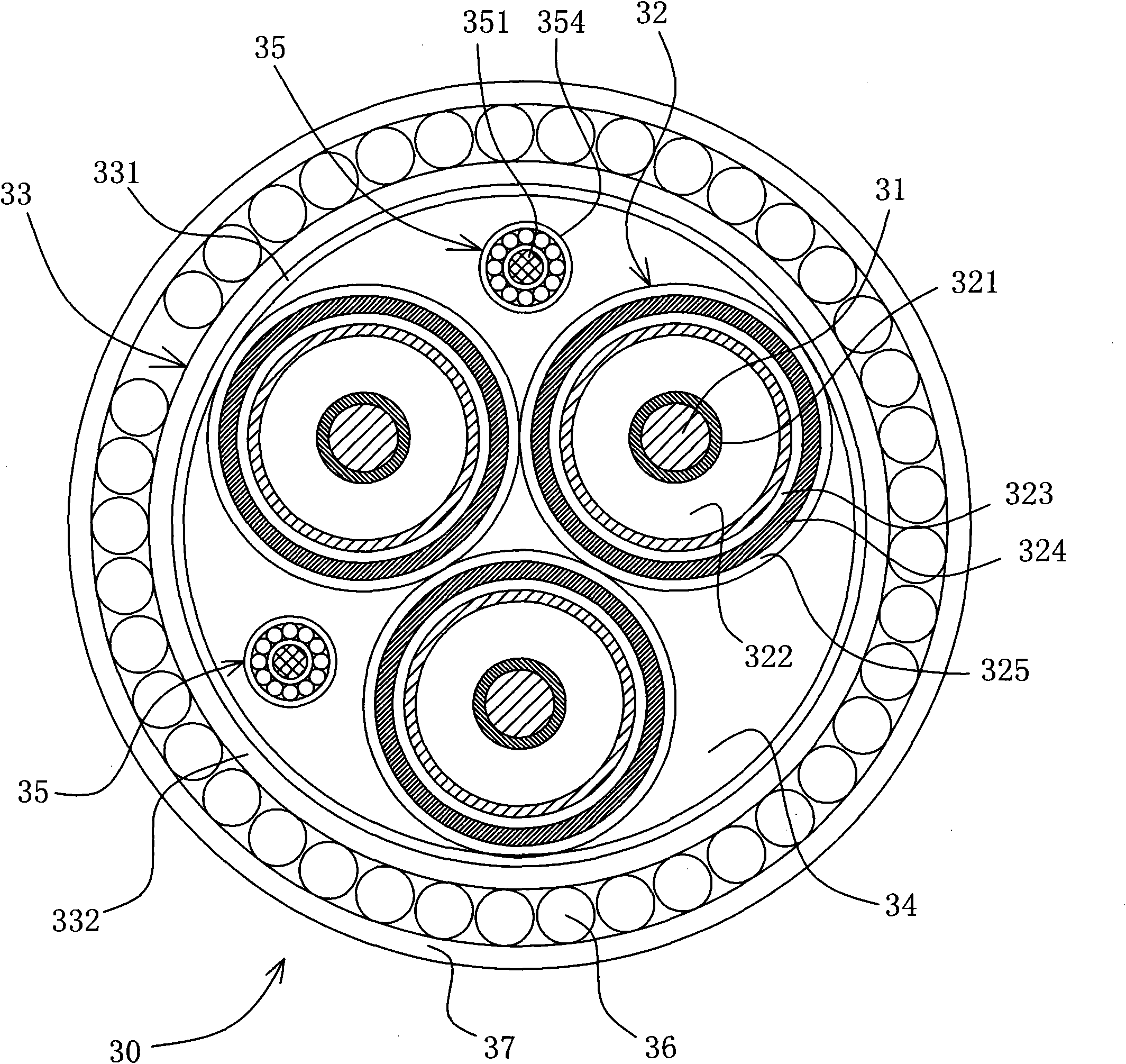

Rated voltage 220kv three-core photoelectric composite submarine cable

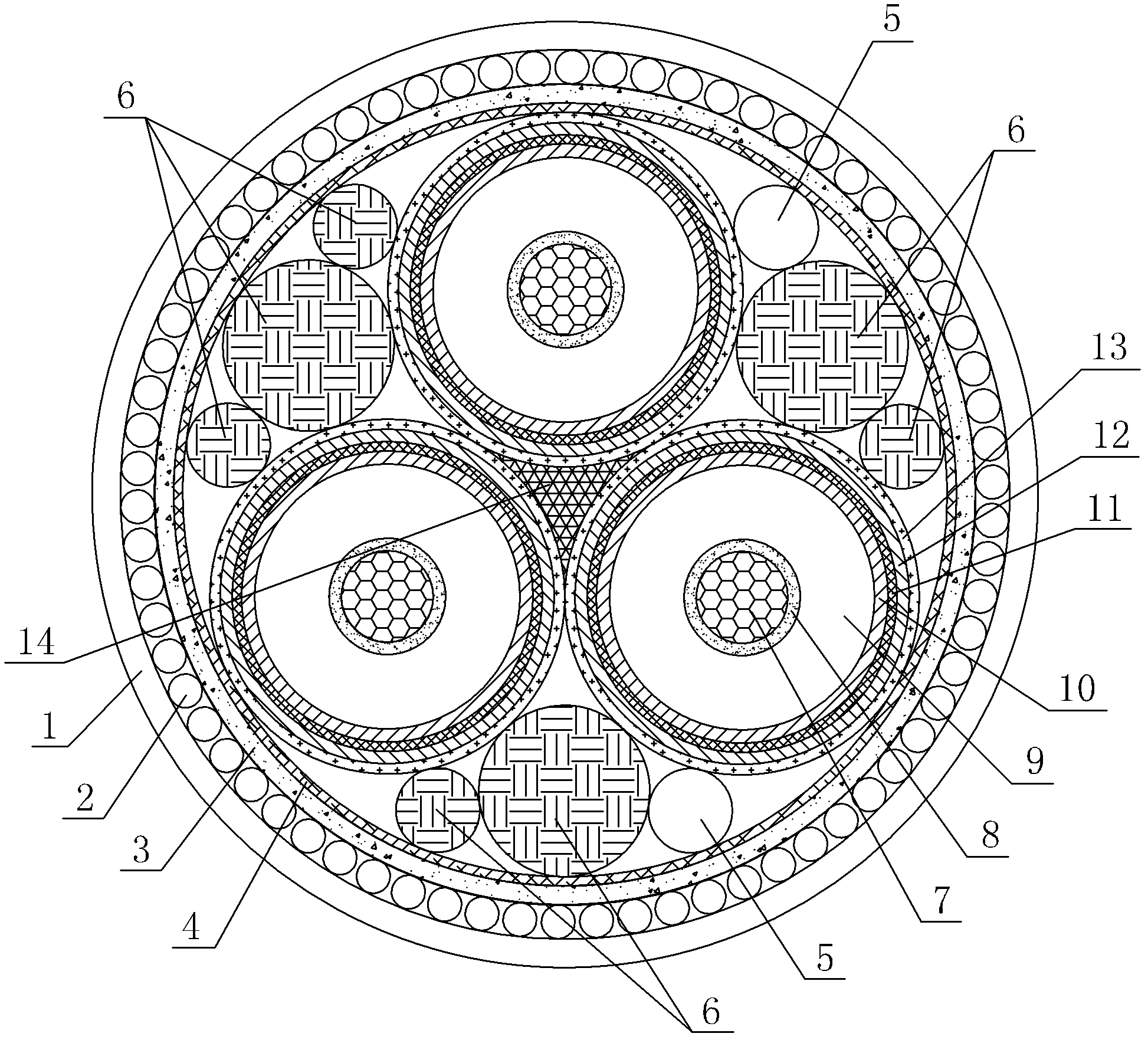

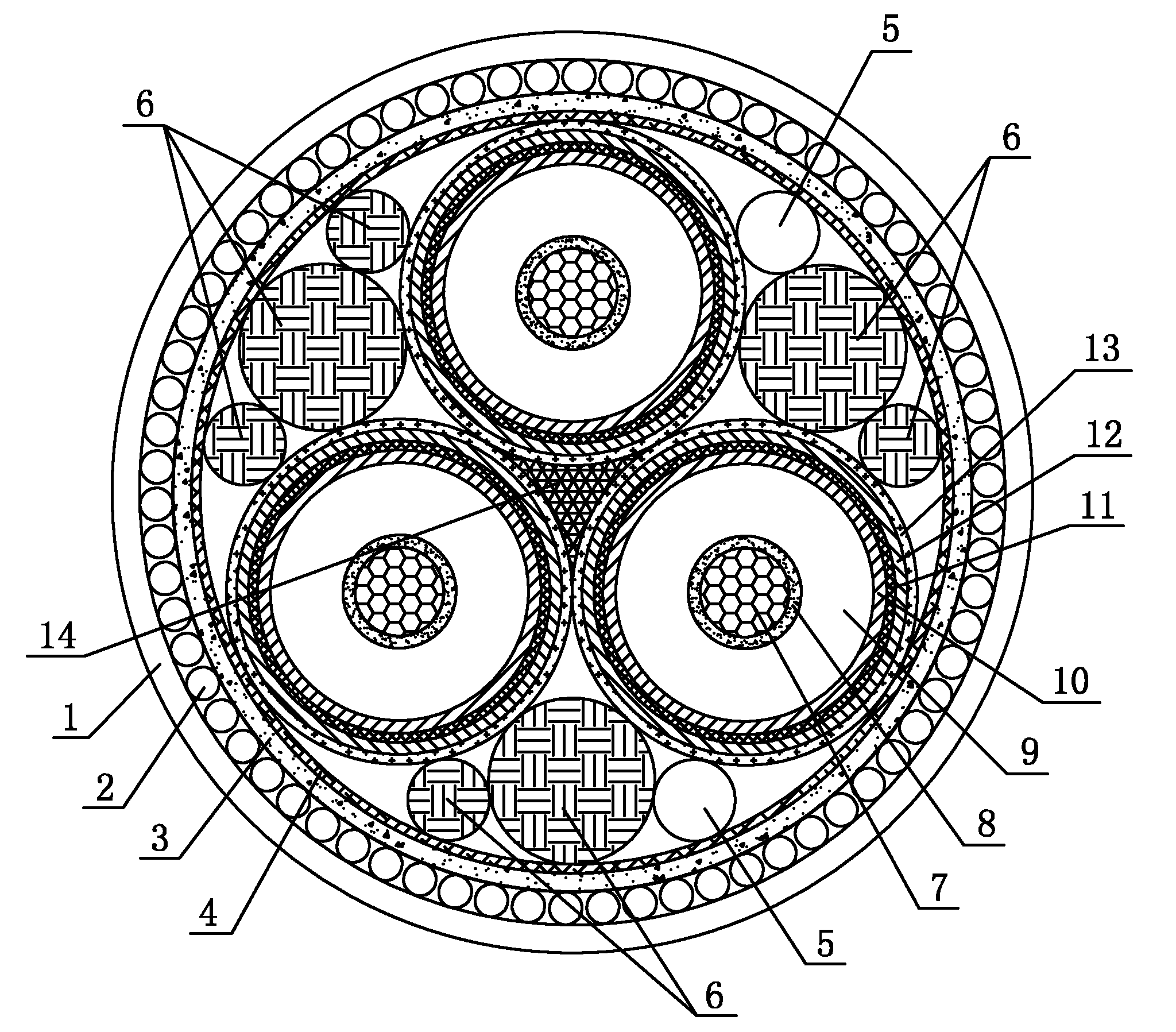

ActiveCN102290135ANo magnetic damageImprove effective utilizationPower cables with screens/conductive layersSubmarine cablesElectricityPhase balancing

The invention discloses a three-core photoelectric composite submarine cable with 220kV rated voltage. The cable is characterized by comprising an outer layer, an armor layer and a lining layer which are distributed from outside to inside in turn, wherein three electrical units in which every two units are externally tangential to each other are arranged in the lining layer; a plurality of filling units are filled in three gaps which are enclosed by the electrical units and the lining layer; the three electrical units and all the filling units are stranded into a submarine cable main core part; a gluing cloth tape is lapped outside the stranded submarine cable main core part; and at least one of all the filling units is an optical unit, and the rest filling units are filling ropes. The invention has the advantages that: the three-core photoelectric composite submarine cable with the 220kV rated voltage has a balanced phase during use, does not have requirements on armoring materials, can prevent the magnetic loss of the armor layer and improves the effective utilization rate of power; and the occupied sea area is greatly reduced compared with that of a single-core submarine cable with the same specification.

Owner:宁波东方电缆股份有限公司

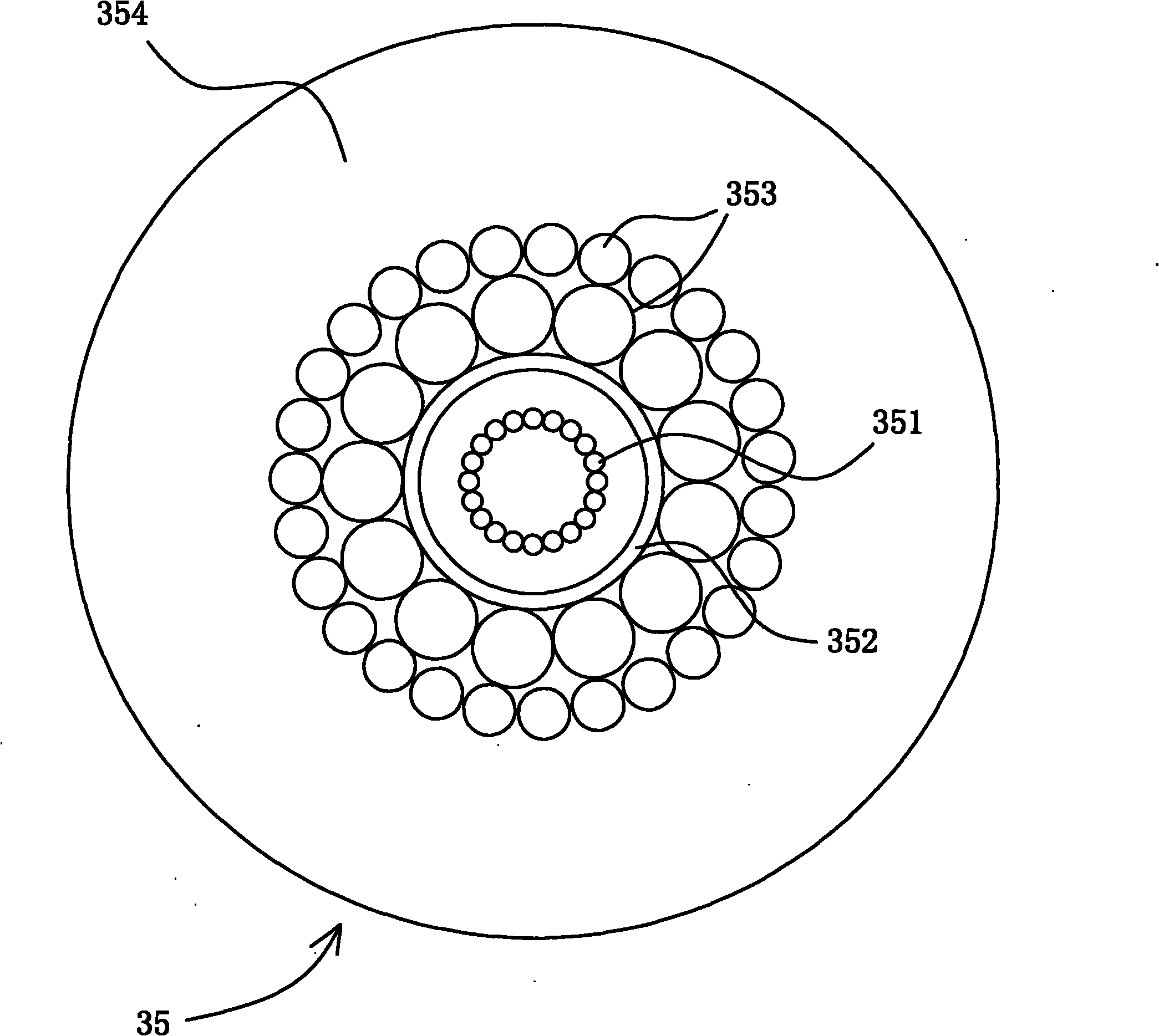

Micro-sensing optical unit and embedded application thereof

ActiveCN102012285AHigh sensitivityImprove thermal conductivityCommunication cablesThermometers using physical/chemical changesFiberEmbedded applications

The invention relates to a micro-sensing optical unit which is embedded inside or outside a cable, comprises a micro-sensing optical unit body and is characterized in that the micro-sensing optical unit body comprises an optical fiber for sensing, wherein a sealed stainless steel pipe is coated outside the optical fiber for sensing, and water-blocking fiber paste is filled in the stainless steel pipe; the number of the optical fiber for sensing can be 1 or two or plural, and the fiber excess length range in the stainless steel pipe is that the excess length is not less than 0 and less than 0.03%. The invention further relates to a cable, an optical cable, an aerial bare line and a submarine cable applying the structure in an embedded manner. The micro-sensing optical unit has high sensitivity to measured information of outside and can respond to temperature and strain in real time, the embedding process is simple and does not change the original performances of the optical cable, the temperature change can be reflected in a real-time manner, the smaller fiber excess length in the pipe can reduce the region of a stress and strain window of the optical fiber, the sensitivity to external stress (strain) reaction of the optical fiber can be improved, and the micro-sensing optical unit can not change the original structure and the performances of the optical cable and be embedded in the appropriate part of the optical cable and the cable.

Owner:江苏通光电子线缆股份有限公司

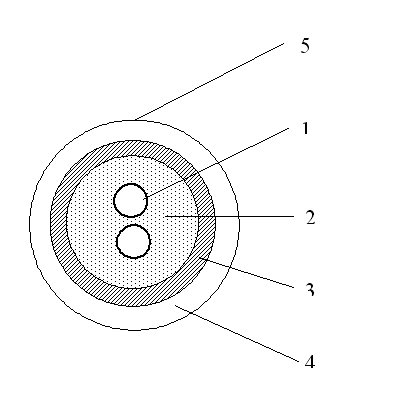

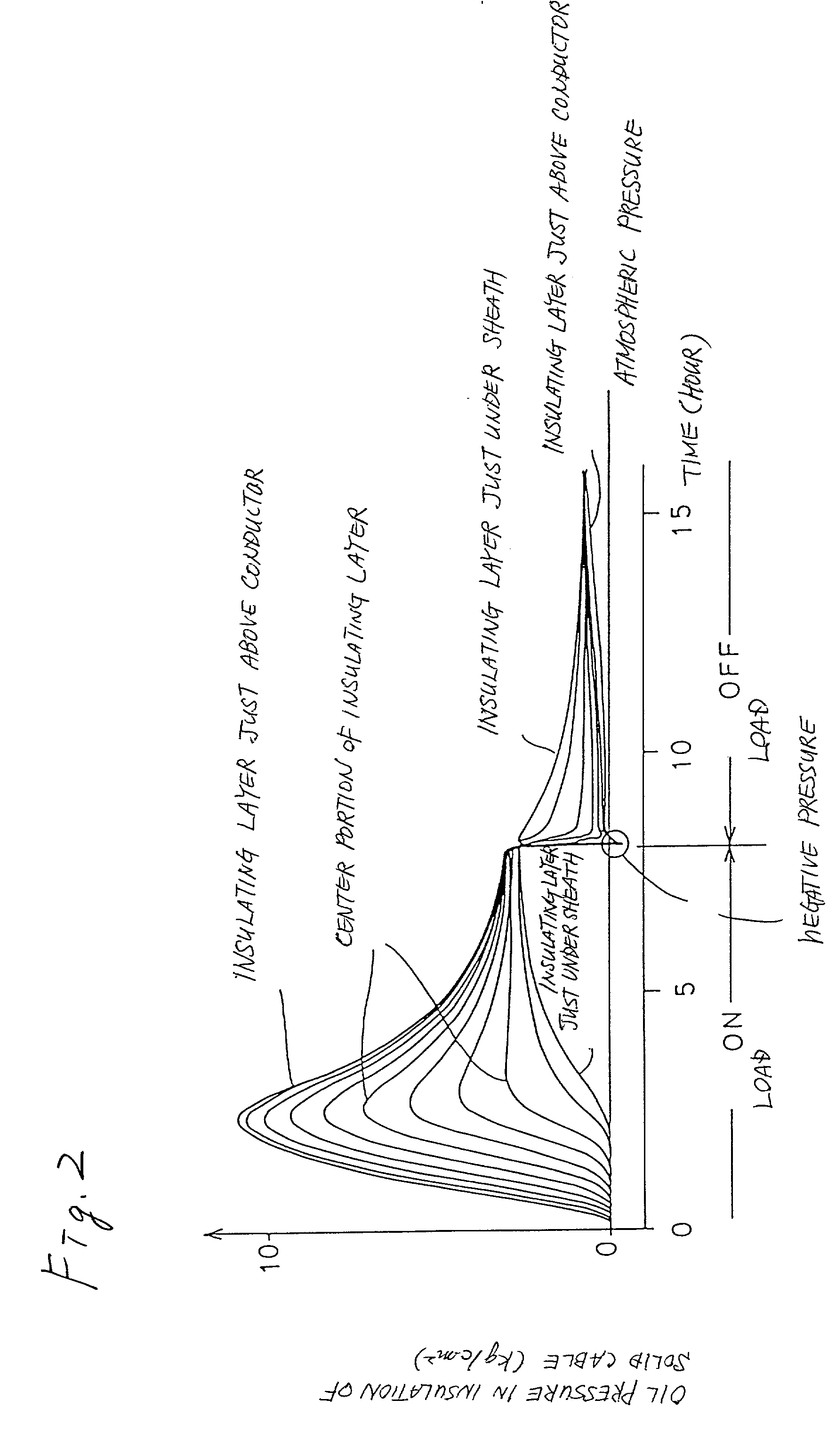

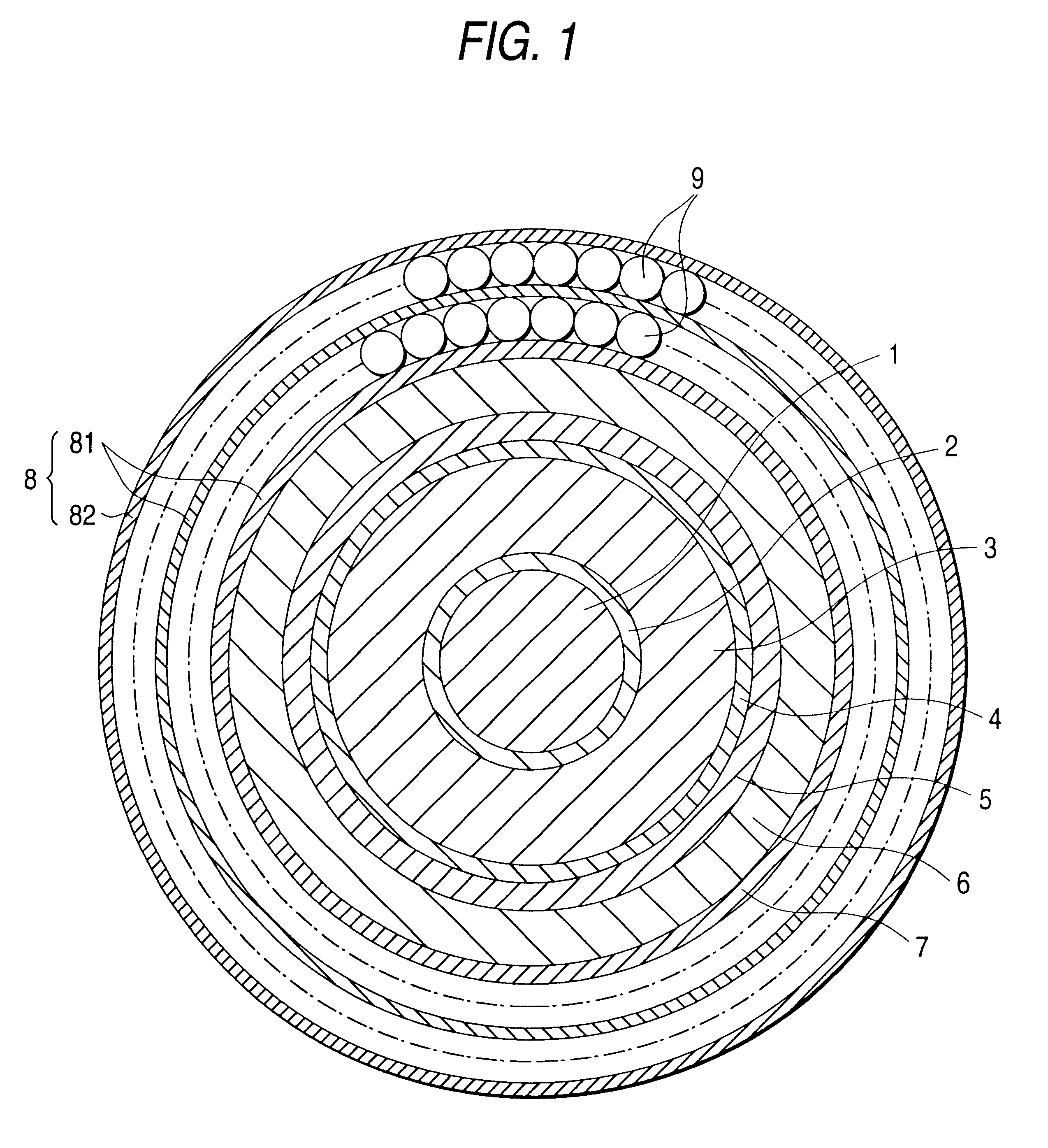

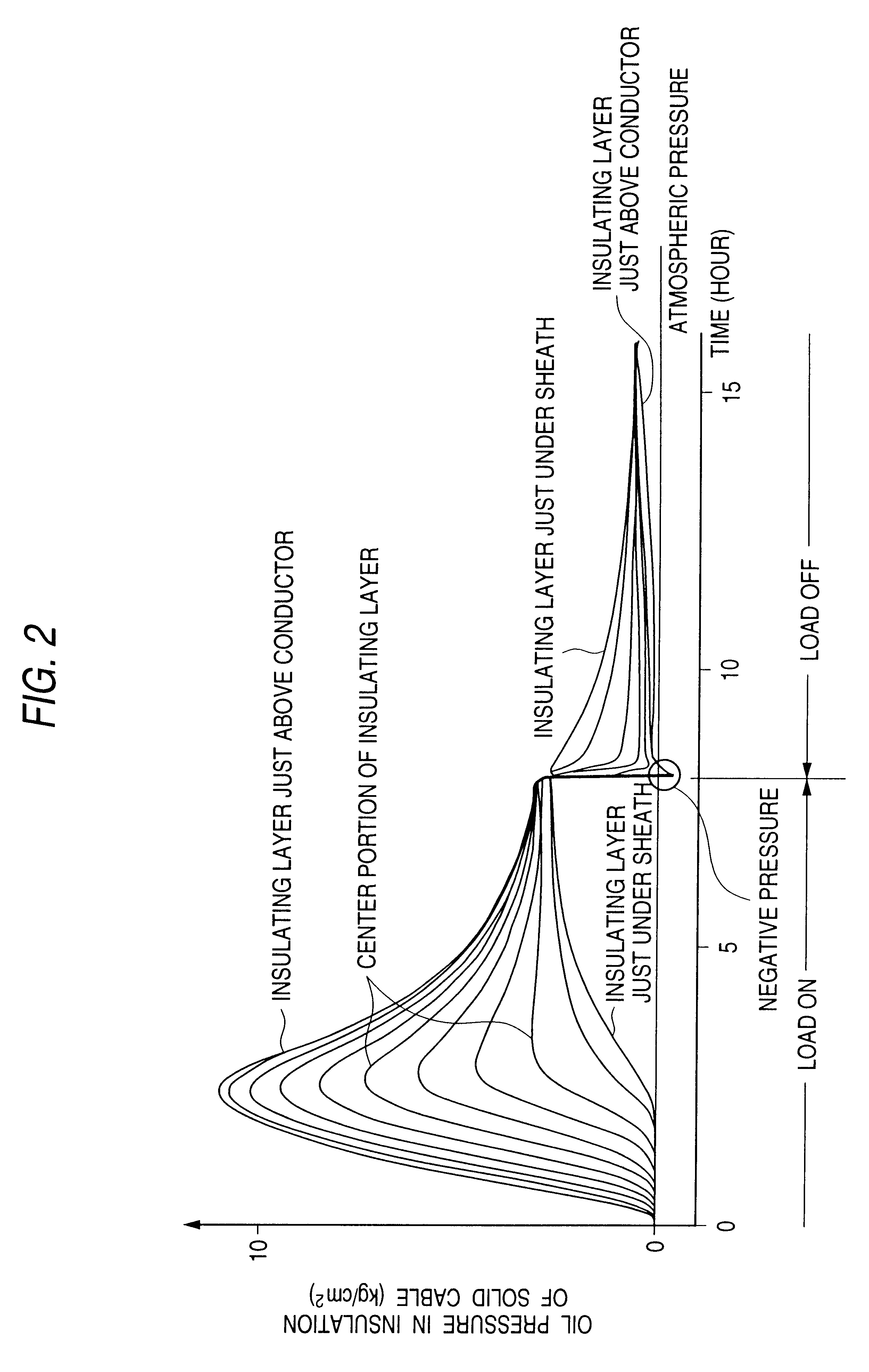

Solid cable, manufacturing method thereof, and transmission line therewith

InactiveUS20010042635A1High tensile strengthRubber insulatorsOil-pressure cablesInsulation layerElectrical conductor

A solid cable provided with an insulation layer on the outer circumference of a conductor, and impregnated with insulating oil in this insulation layer. Medium-viscosity insulating oil the viscosity of which is between not less than 10 cst and less than 500 cst at 60° C. is used as the insulating oil.

Owner:SUMITOMO ELECTRIC IND LTD

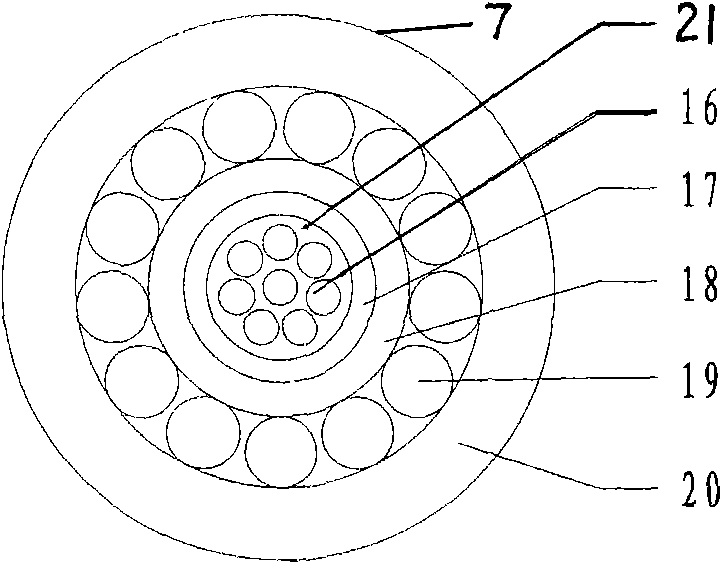

Rated voltage of 35kv or below shallow sea wind farm photoelectrical transmission composite cable

InactiveCN101562064ALow costEasy to layCommunication cablesSubmarine cablesFiberElectric power transmission

A rated voltage of 35kv or below shallow sea wind farm photoelectrical transmission composite cable comprises a cable core provided with a lead and a water-blocking filling piece, a water-blocking belting layer, a plastic-aluminum composite band layer, an internal sheath, a wire armoring layer and an external sheath, wherein the cable core are externally coated with the water-blocking belting layer, the plastic-aluminum composite band layer, the internal sheath, the wire armoring layer and the external sheath in turn, the cable core is internally provided with a fiber optic communication unit, a steel-tape armoring layer is arranged between the external sheath and the wire armoring layer. The structure of the fiber optic communication unit is as follows: a fiber loose tube is externally coated with an internal sheathing layer, an armoring layer and an external sheathing layer in turn. A conductor of the lead adopts two-tier structure: a central layer conductor is formed by twisting multiple stranded brass wires coated with water-blocking balm, and then coats a central layer semiconductive water-blocking band layer; an external layer conductor is coated outside the central layer semiconductive water-blocking band layer by multiple stranded brass wires coated with water-blocking balm, and then coats an external layer semiconductive water-blocking band layer. The invention has the complex function of optical communication and power transmission, one cable has two uses, thereby saving cost and facilitating laying; in addition, the cable has high strength, excellent wear resistance, corrosion resistance and waterproof function, and can adapt to the requirement for subsea use in long term.

Owner:JIANGSU HENGTONG POWER CABLE

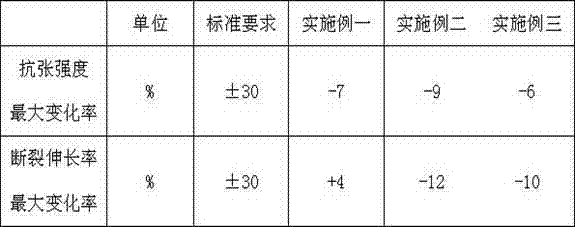

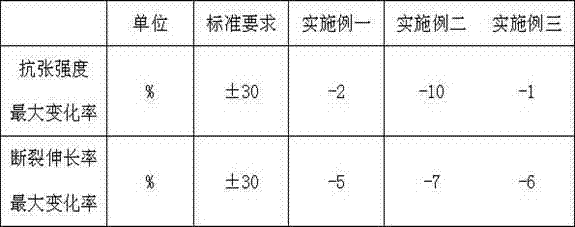

Reinforced tensile screening type vertical watertight degaussing cable for ship and manufacturing method thereof

InactiveCN102737760AEnsure watertight effectHigh tensile strengthNon-insulated conductorsSubmarine cablesCopper conductorVulcanization

The invention discloses a reinforced tensile screening type vertical watertight degaussing cable for a ship and a manufacturing method thereof. A twisted copper conductor is formed by soaking a plurality of tinned copper wires in a sealant and then twisting the tinned copper wires; a conductor sealant layer is soaked on the periphery of the twisted copper conductor; insulating rubber layers are extruded on the periphery of the conductor sealant layer; an aramid fiber reinforcing layer is weaved on the periphery of each insulating rubber layer so as to form an insulating core wire; chloroprene rubber filling strips are filled into gaps among the insulating core wires, and a cable core is integrally formed by twisting the insulating core wires; a cable core inner sealant layer is extruded on the periphery of the cable core; and an inner jacket rubber layer is extruded on the periphery of the cable core inner sealant layer. A plurality of seals are arranged on the periphery of a cable conductor, and the chloroprene rubber filling strips expand in a follow-up vulcanization process, thus entirely filling the gaps in the cable core; and one insulating core wire is not tangential to another insulating core wire. Therefore, when the cable core inner sealant layer is extruded, the sealant can permeate inside the cable core, so that the watertight effect can be ensured.

Owner:嘉兴君宏光学有限公司

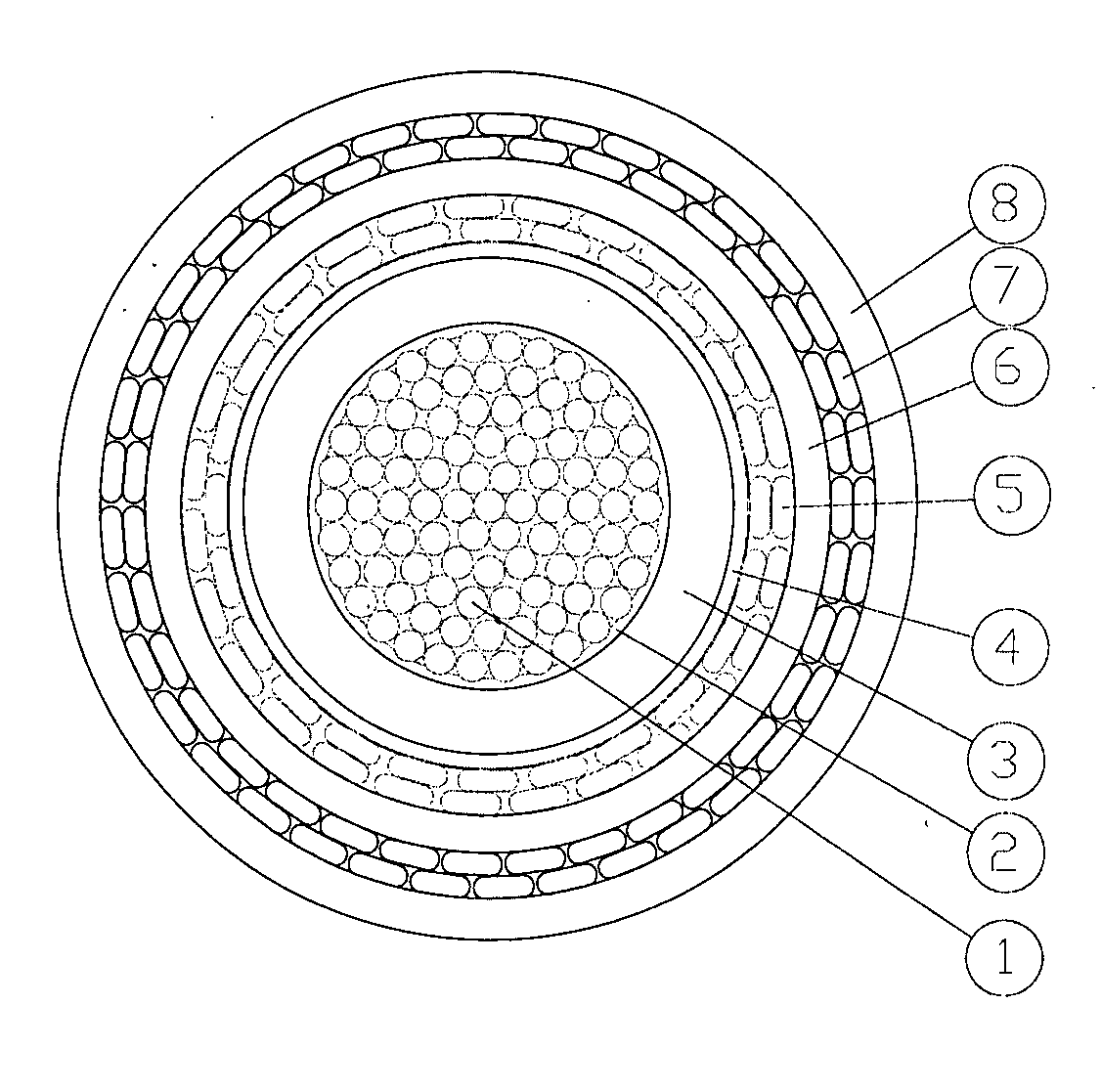

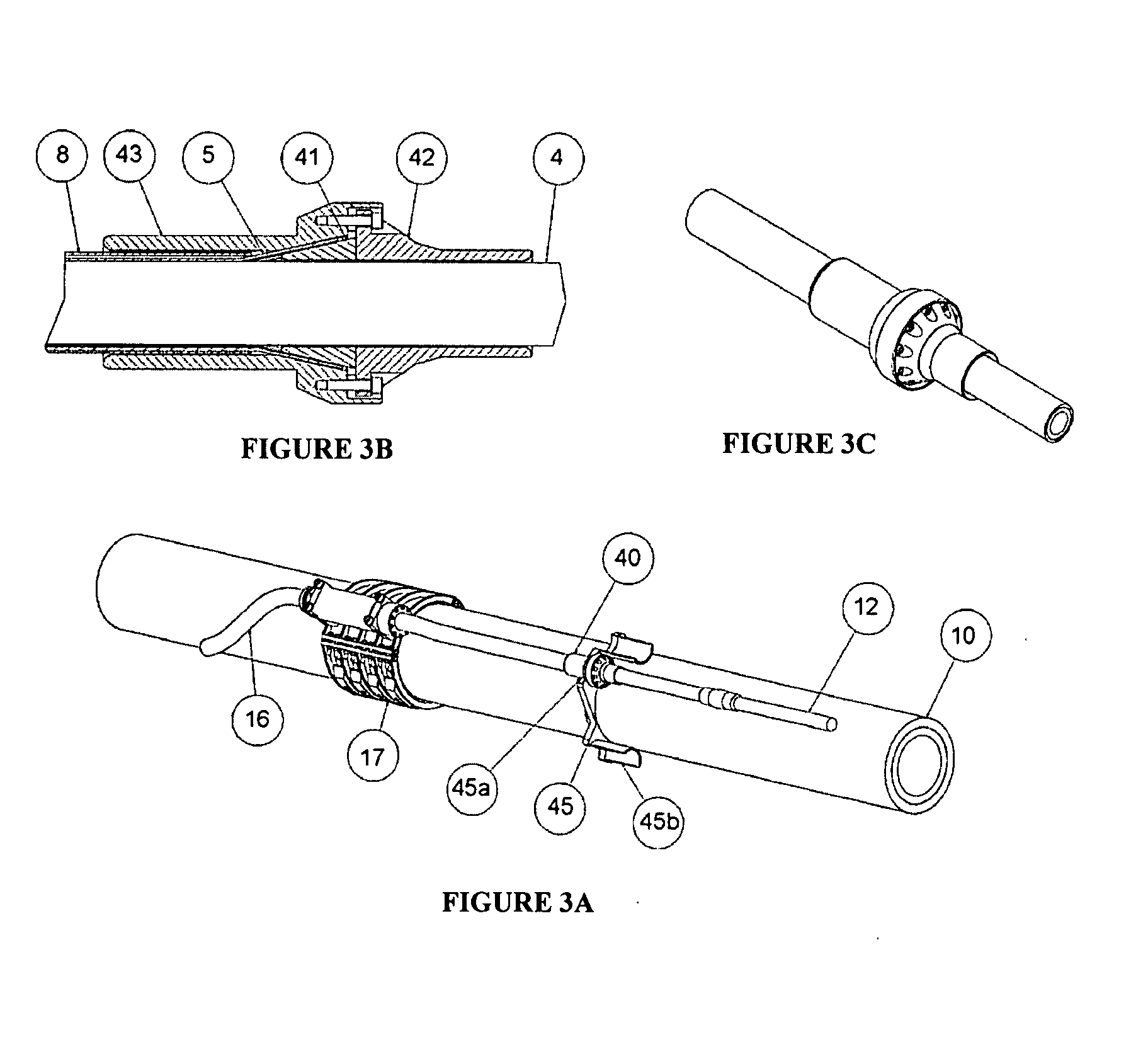

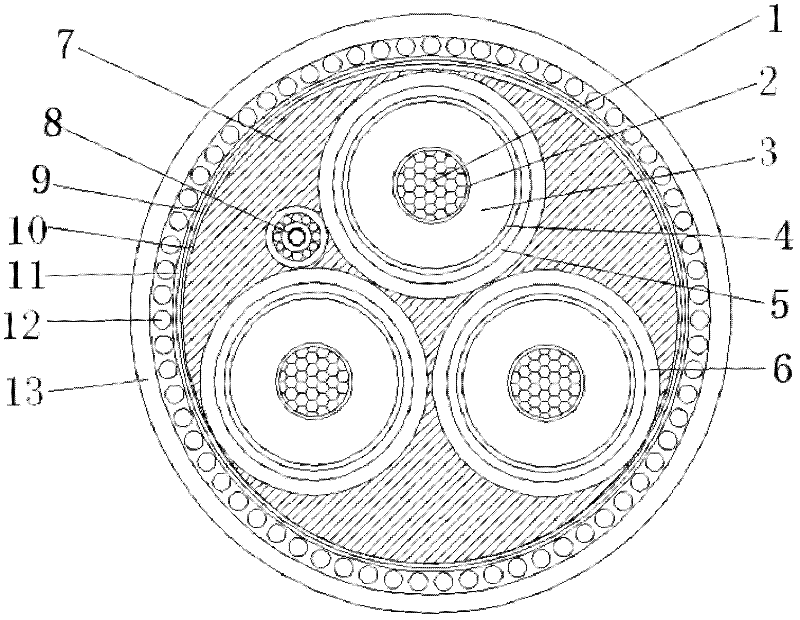

Sea electric power cable

ActiveCN101807450ASolve the problem of induced potentialSolve the circulation problemPlastic/resin/waxes insulatorsSubmarine cablesOcean bottomState of art

The invention relates to a sea electric power cable which comprises a conductor (1), semi-conduction layer (2), insulation layer (3), a buffer layer (4), a lead casing (5), an inner jacket layer (6), an armor layer (7) and an armored outer protective layer (8) which are arranged from inside to outside. The invention is characterized in that the inner jacket layer (6) is a mixed layer formed by the end-to-end connection of the semi-conduction layer and the insulation layer in series. Compared with the prior art, the armored inner jacket layer adopted by the invention is the mixed layer formed by the end-to-end connection of semi-conduction layer and insulation layer in series. Such design has the advantage that the underwater portion and the onshore portion of the sea electric power cable comprise different inner jacket layers, wherein the underwater portion is an anticorrosive semi-conduction layer, thereby effectively solving the problem of induced potential, and further solving the problem of circular current; and the onshore portion is an insulation layer which is the same structure as the common electric power cable, thereby realizing cross interconnection, and further achieving the purposes of reducing loss and raising current capacity.

Owner:浙江省电力公司舟山电力局

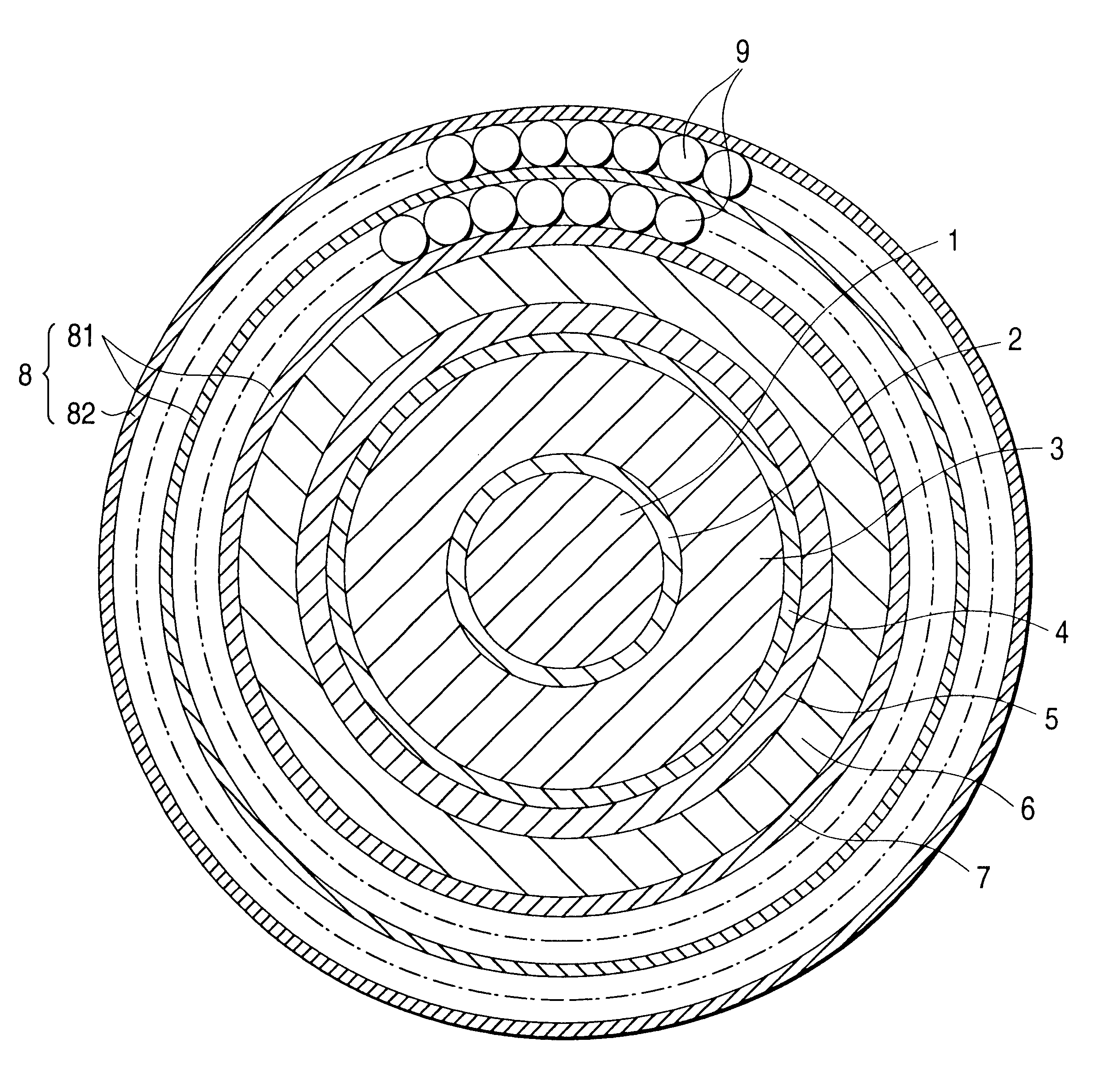

Electric power cable

ActiveUS20100186988A1Improve the immunityAvoid bending forcePower cables with screens/conductive layersSubmarine cablesElectrical conductorPower cable

An electric power sea cable including at least one cable core. The cable core includes an electric conductor, an electric insulation surrounding the conductor, and a protective sheath surrounding the electric insulation and acting as a water barrier. At least one outer layer surrounds the at least one cable core. The protective sheath is made of metal and the electrical power sea cable includes at least one friction reducing layer surrounding the at least one cable core and arranged inside of the at least one outer layer.

Owner:NKT HV CABLES AB

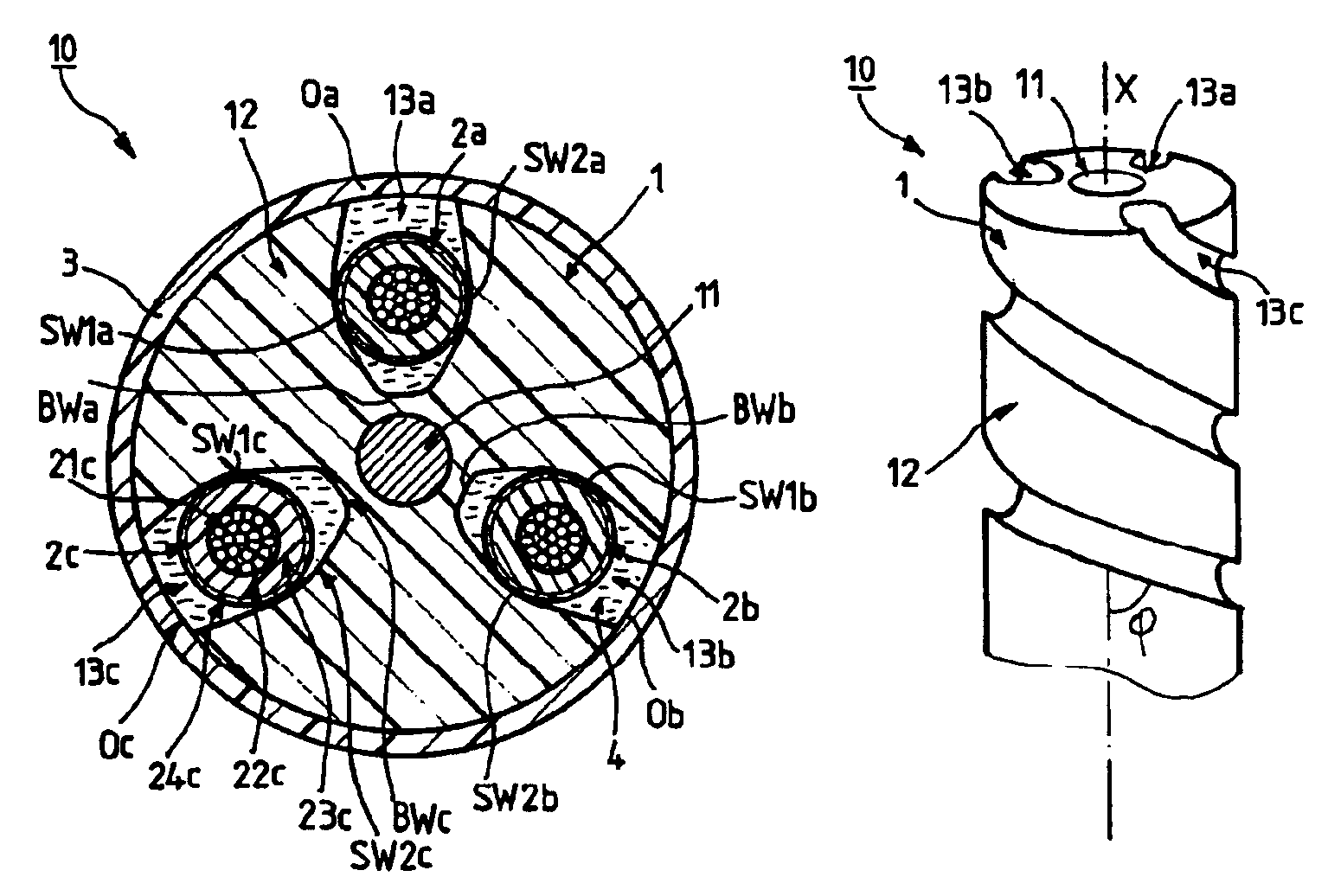

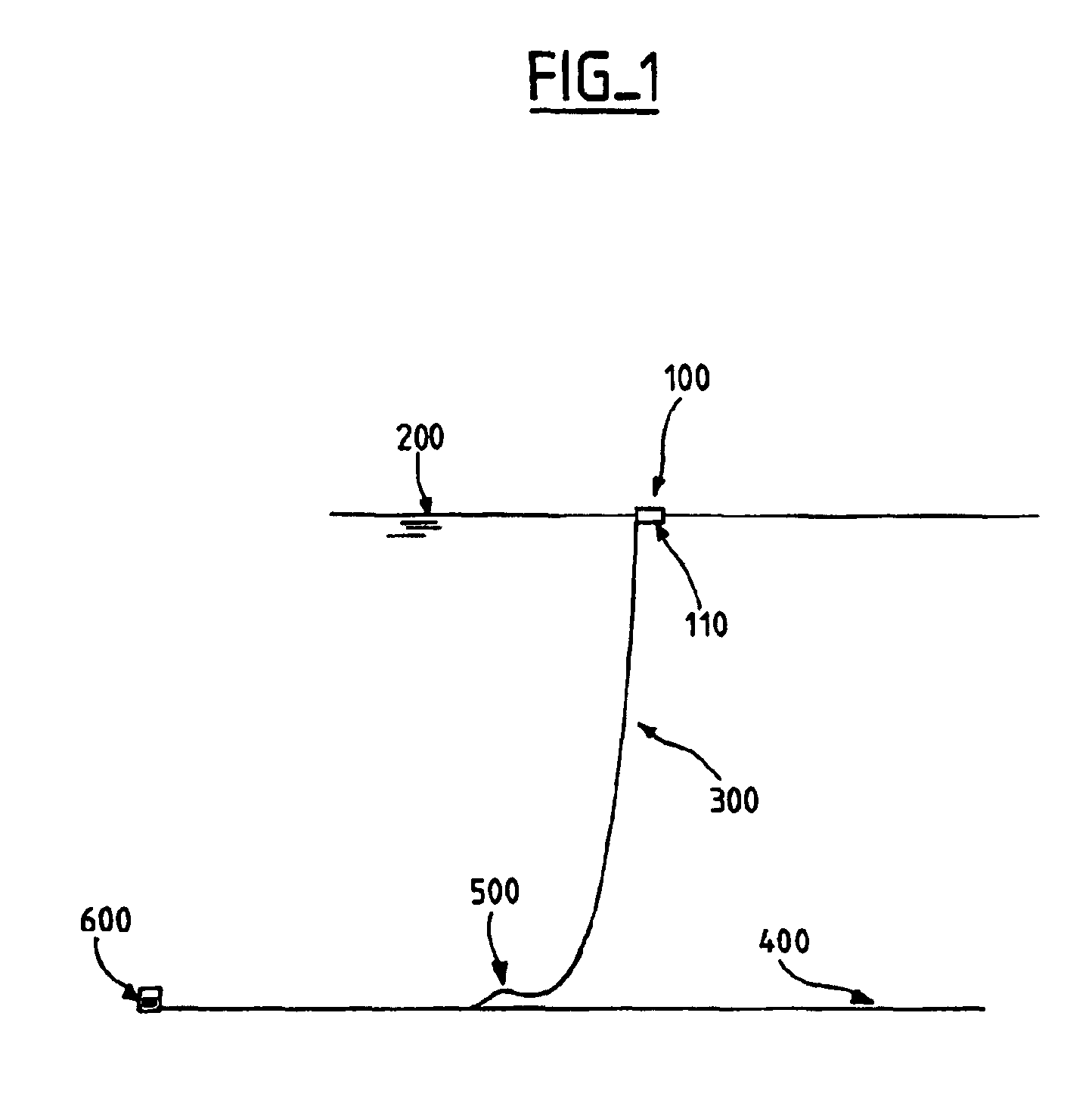

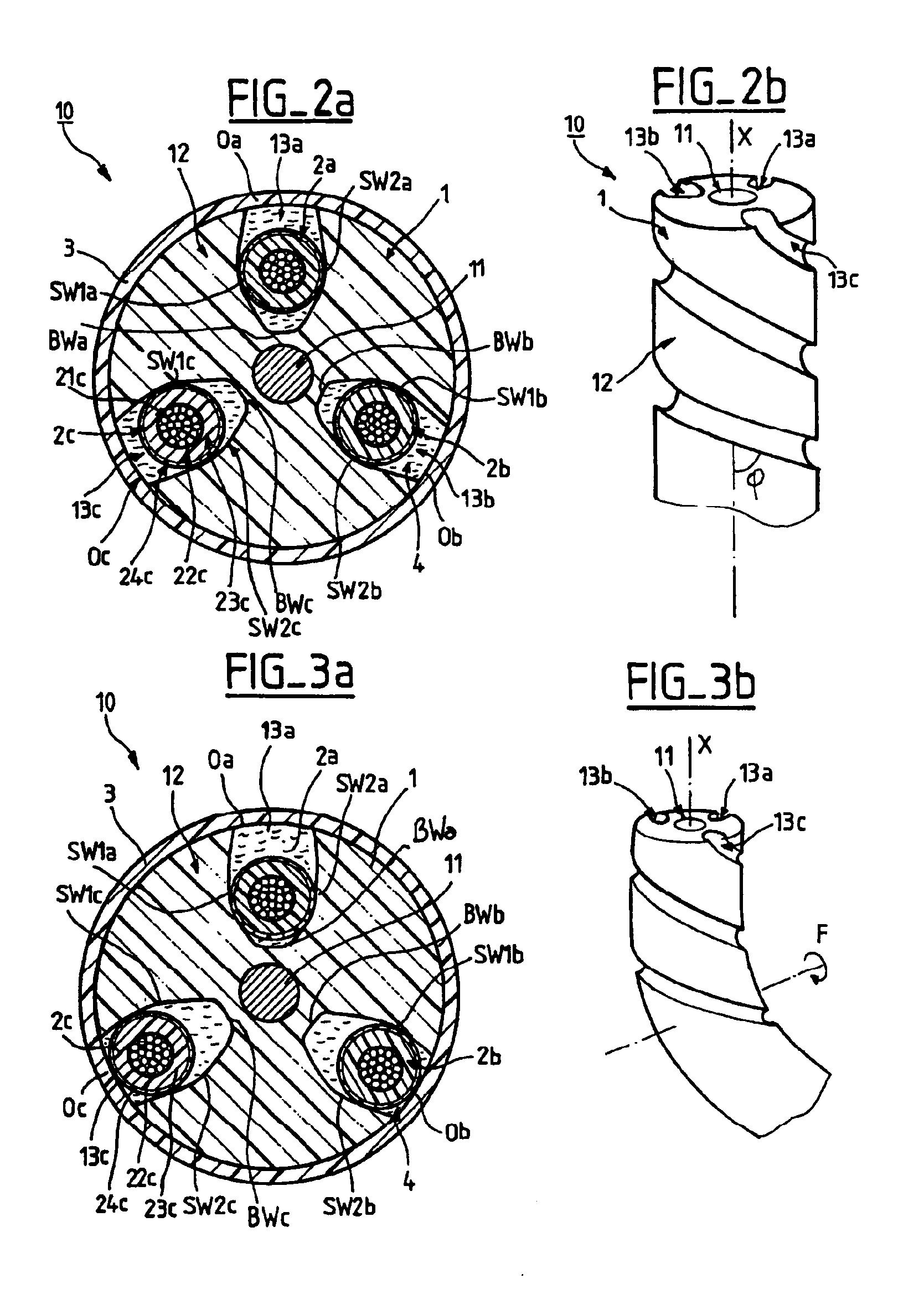

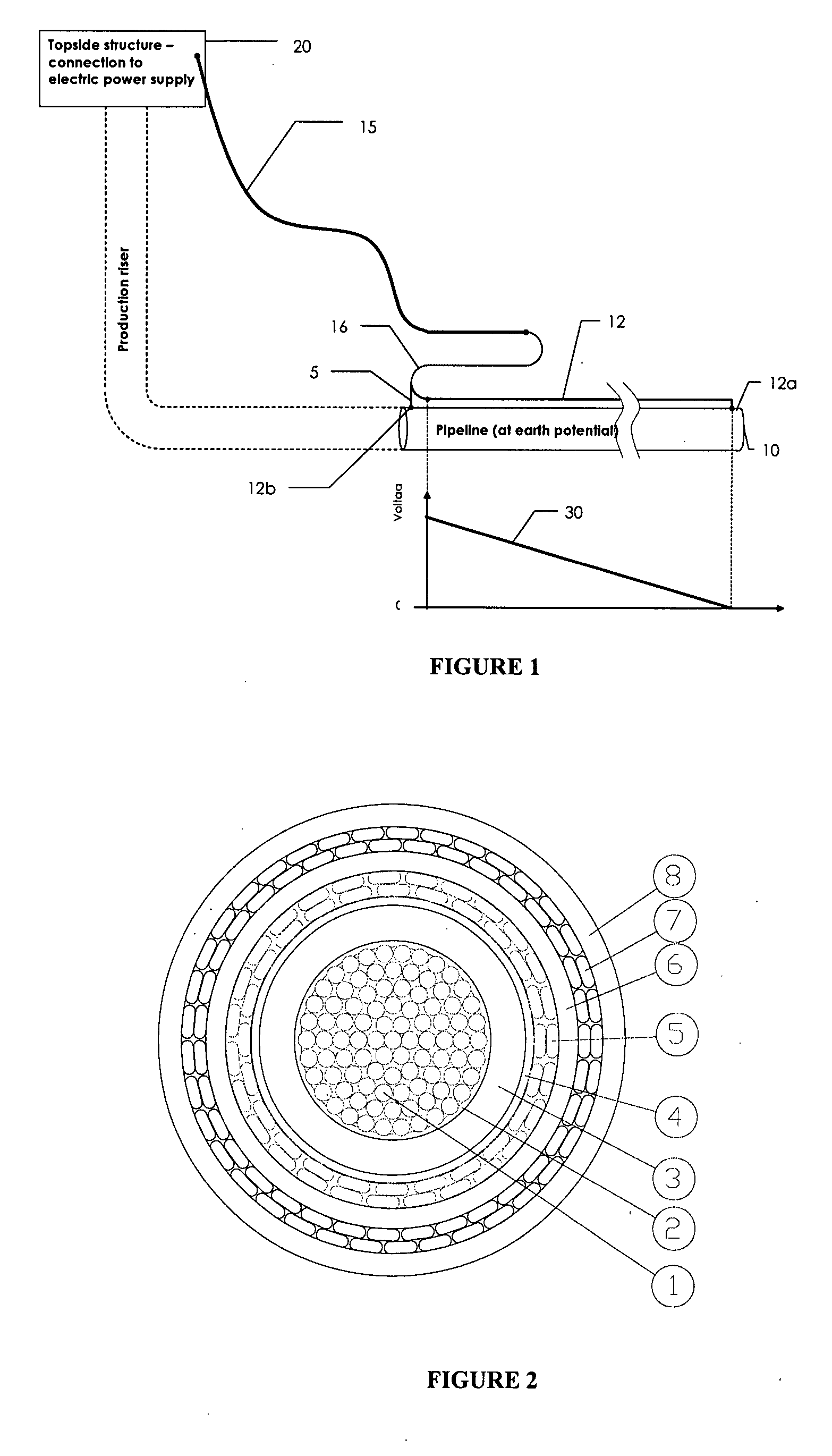

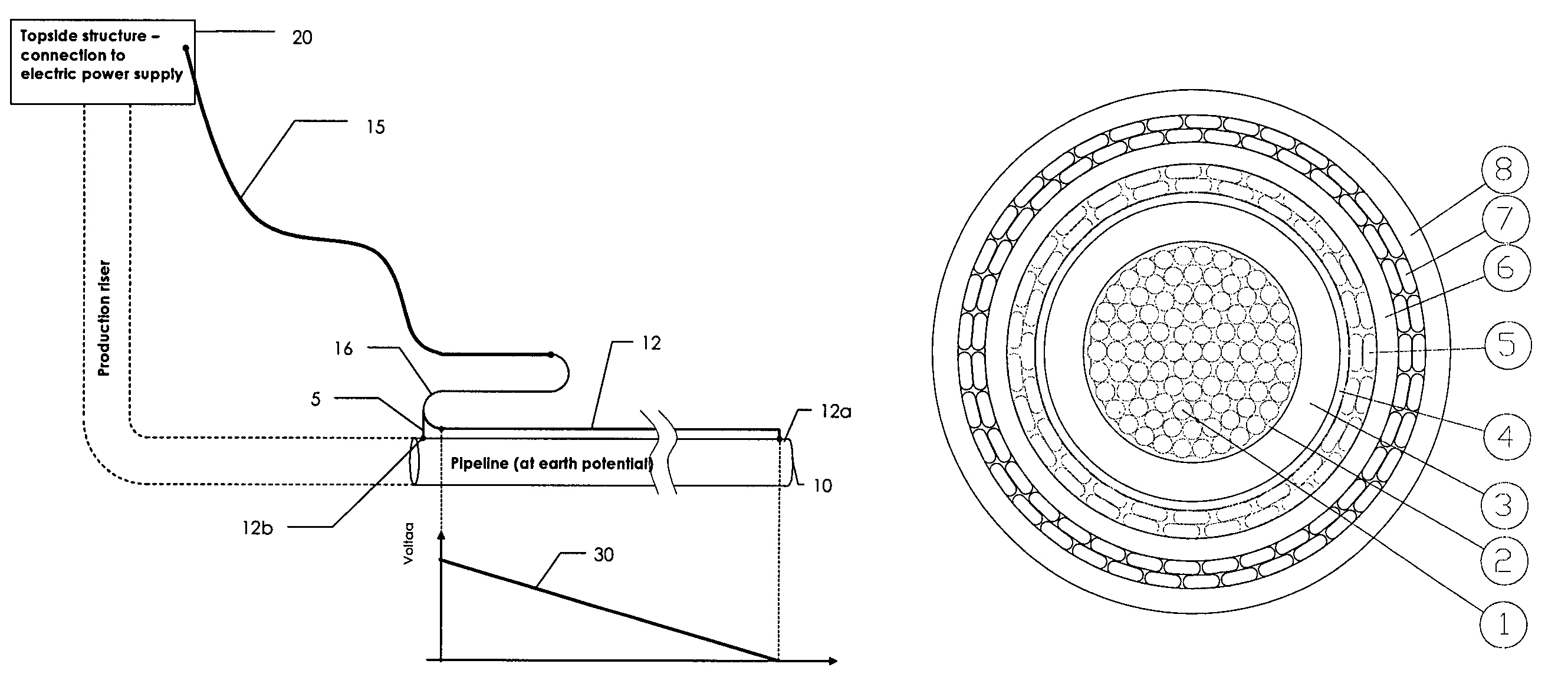

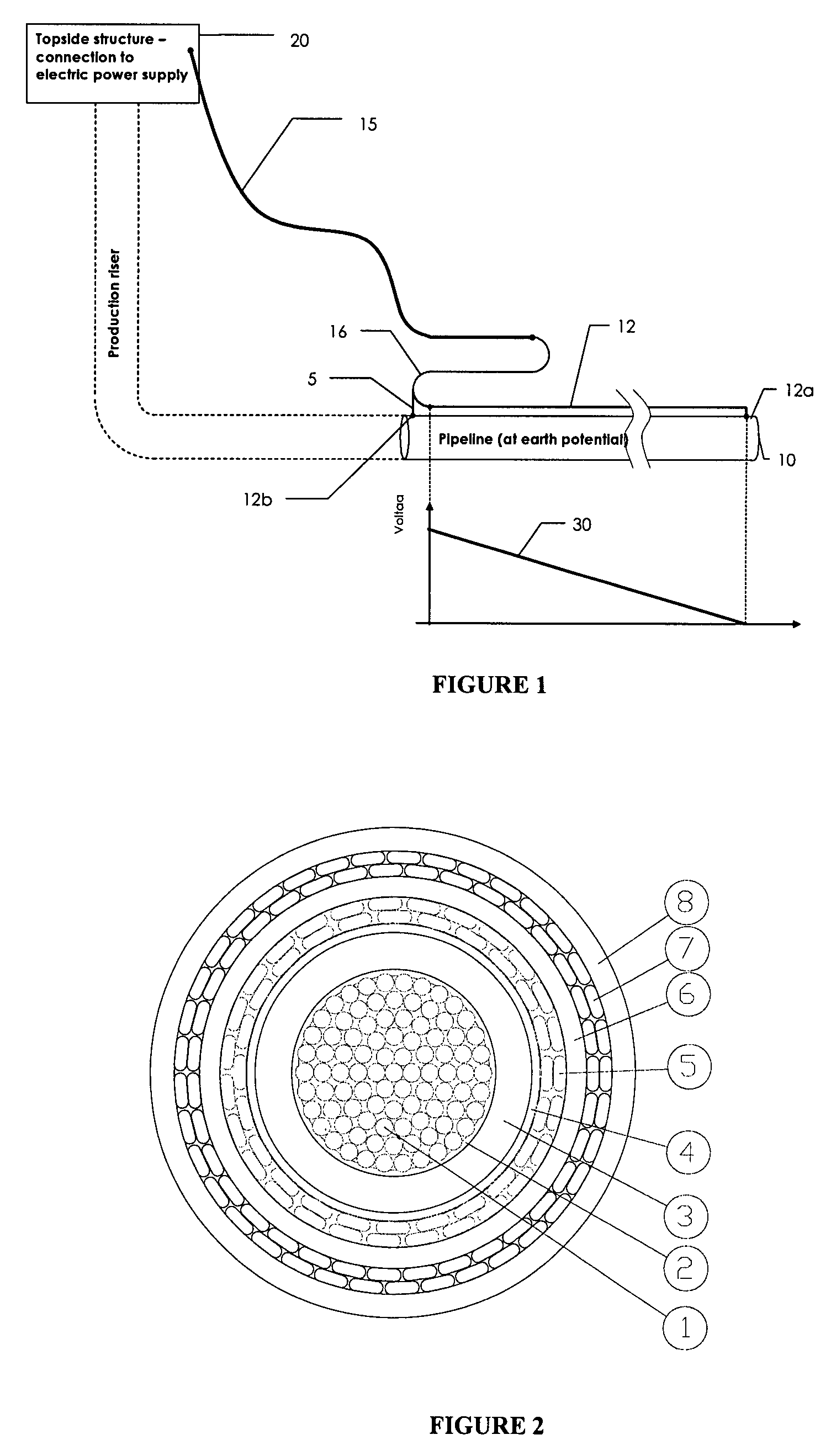

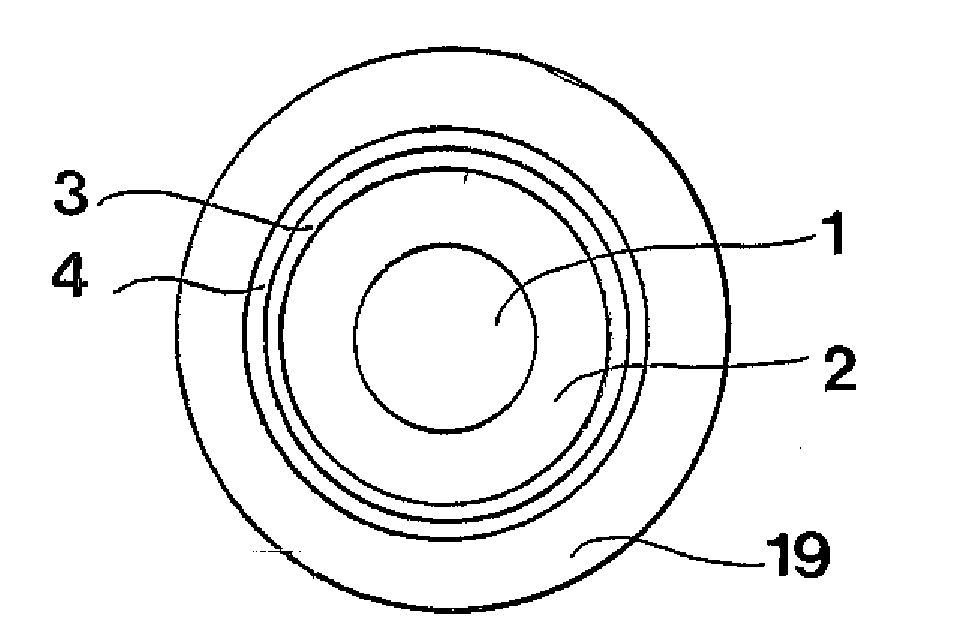

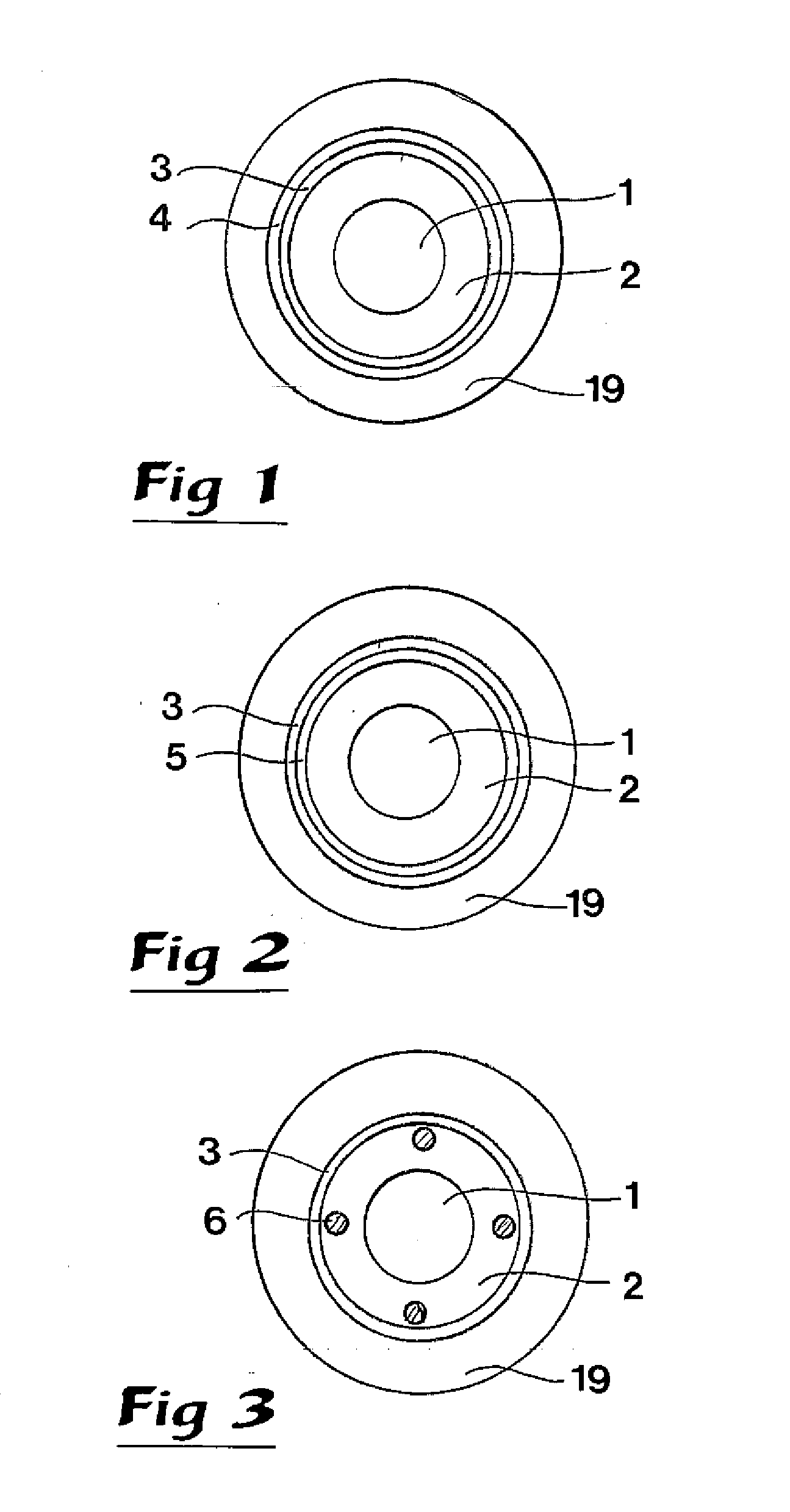

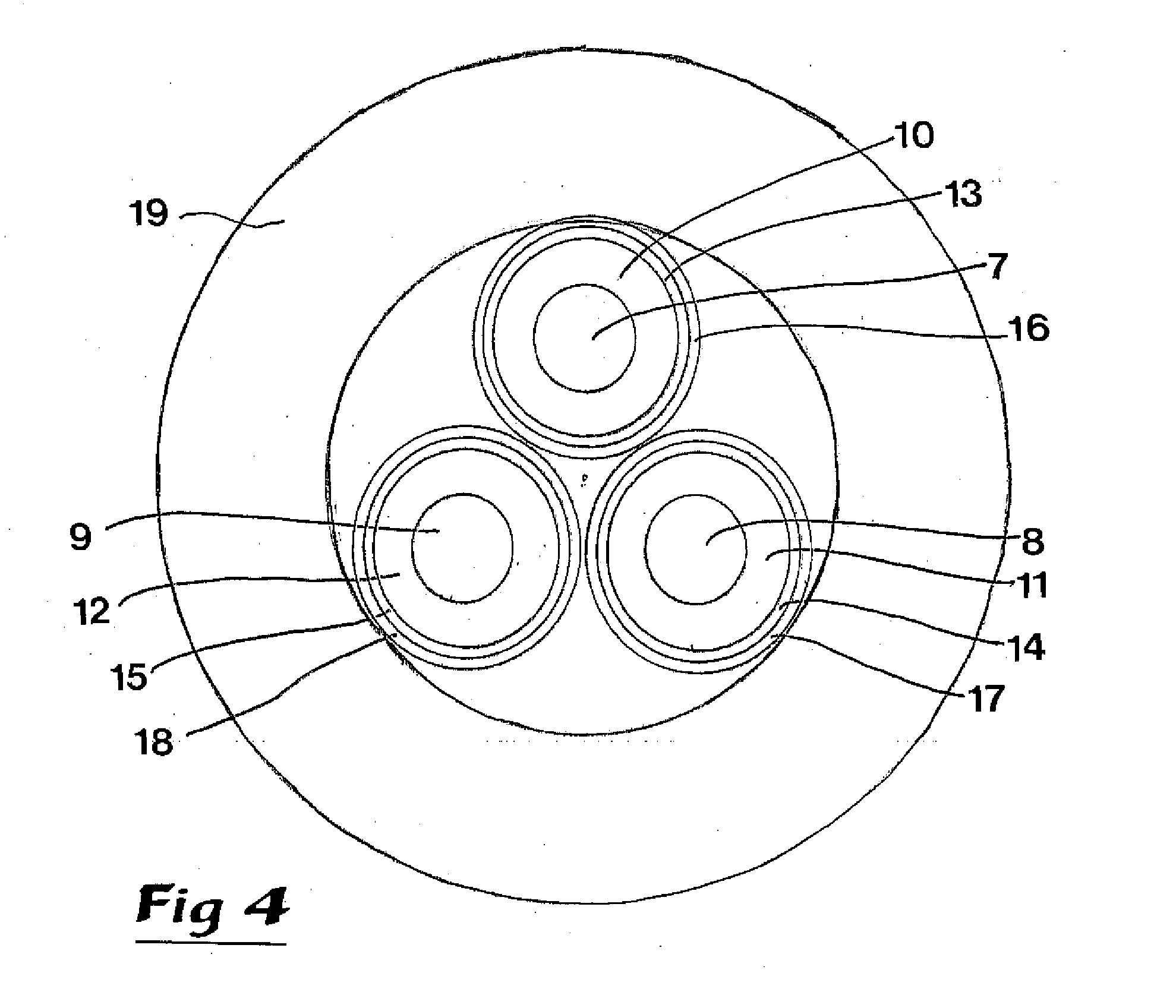

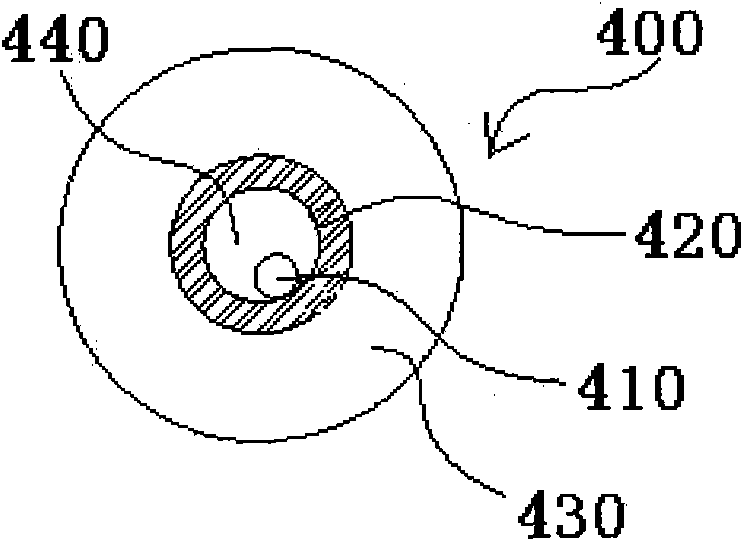

Power cable for direct electric heating system

Electric power cable used as a riser (15) and / or feeder cable (16) in a Direct Electric Heating system for oil or condensate pipelines (10), comprising at least two conductors (1, 5) and insulation layers (3, 6). An outer concentric conductor (5) is connected to a near end of the pipeline, and a central conductor (1) is connected via a piggyback cable (12) to a far end of the pipeline, to provide power for the heating. Another aspect is a terminal assembly adapted to providing an electric connection of the electric power cable with the pipeline (10), where a cone (41) is adapted to squeeze the concentric conductor (5) against a concentric conductor adapter (40).

Owner:NEXANS

Power cable for direct electric heating system

Electric power cable used as a riser (15) and / or feeder cable (16) in a Direct Electric Heating system for oil or condensate pipelines (10), comprising at least two conductors (1, 5) and insulation layers (3, 6). An outer concentric conductor (5) is connected to a near end of the pipeline, and a central conductor (1) is connected via a piggyback cable (12) to a far end of the pipeline, to provide power for the heating. Another aspect is a terminal assembly adapted to providing an electric connection of the electric power cable with the pipeline (10), where a cone (41) is adapted to squeeze the concentric conductor (5) against a concentric conductor adapter (40).

Owner:NEXANS

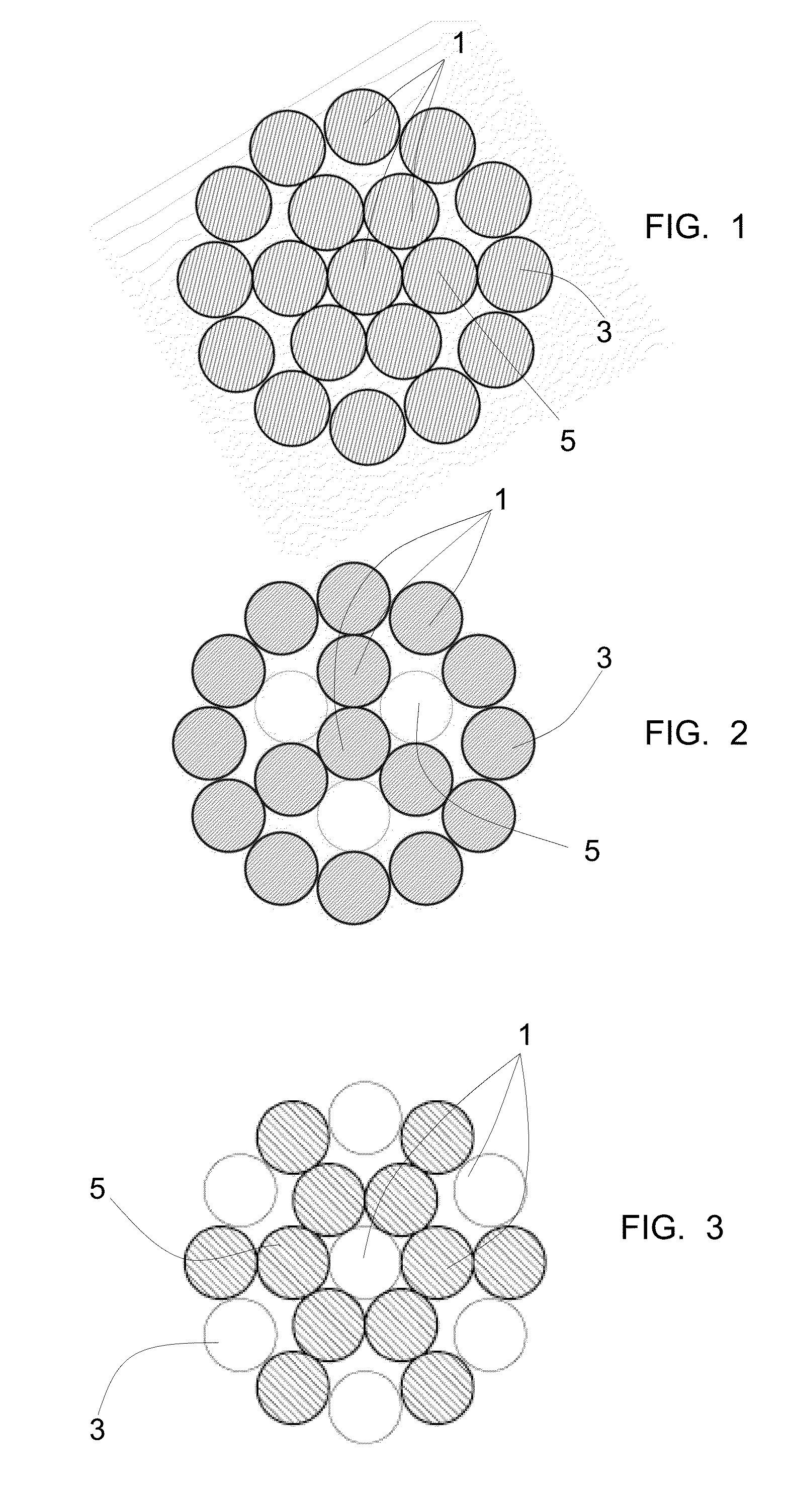

Electrical Conductor for Transporting Electrical Energy and Corresponding Production Method

InactiveUS20130264093A1Small catenary sagImprove electrical performanceNon-insulated conductorsConductive materialElectrical conductorSkin effect

An electrical conductor for transmission of electrical power, having a total cross-section equal to or above 10 mm2 and comprising a plurality of stranded filamentary members, where at least one of the filamentary members is made from microalloyed copper or microalloyed aluminium having annealing temperatures higher than 250° C., and has the side surface thereof totally coated with a fluorinated polymer. The conductor has a better behavior relative to the skin effect and allows operation at high temperatures. Furthermore, if the electrical conductor is suspended, it has a smaller sag and prevents or reduces the accumulation of ice and / or snow.

Owner:LA FARGA LACAMBRA

An electric power cable, an off-shore installation provided therewith, and use thereof

ActiveUS20100025071A1Improve fatigue strengthPermit usePlastic/resin/waxes insulatorsClimate change adaptationOpen seaElectricity

An electric power cable including at least one electric conductor. An electric insulation surround the conductor and includes a polymer. A tubular protective sheath surrounds the electric insulation and acts as a water barrier that prevents water intrusion into the electric insulation. The protective sheath includes a metal as a main constituent. The cable includes at least one density-raising element of a material of higher density than the material of the protective sheath, in order to increase the density of the cable such that too large motions thereof are prevented when the latter is installed in open sea.

Owner:NKT HV CABLES AB

Multifunctional underwater towing line

InactiveCN101281801ASolve slidingUniform tensile forceSubmarine cablesInsulated conductorsUnderwaterEngineering

The present invention relates to a multi-functional submarine towing cable, which is characterized in: the towing cable comprises from center to exterior as follows: water transmission pipe, cables for power supply and data communication, waterproof bushing, and reinforcing rope. With consideration of leak tightness of the submarine towing cable and protection for the internal structure, an outer waterproof bushing is added outside of the reinforcing rope. A cable fixing glue layer is added outside of the cable. The water transmission pipe is made of Nylon 11 material, and the reinforcing rope is braided with Kevlar material. The present invention integrates water transmission, power transmission, and towing function to produce a towing cable that is different to steel wire cables or conventional armored cables. That is to say, the present invention provides a shipboard expendable continuous sampling system, particularly a towing cable that can be used to take water samples in real time, especially a towing cable that is loaded on a towing platform for a continuous water sampling system, with a water transmission pipe and conduction and signal transmission capability, and high tensile strength, designed to accomplish shipboard expendable continuous water sampling tasks at different predefined depths or implement shipboard expendable, quick, and online water quality monitoring.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

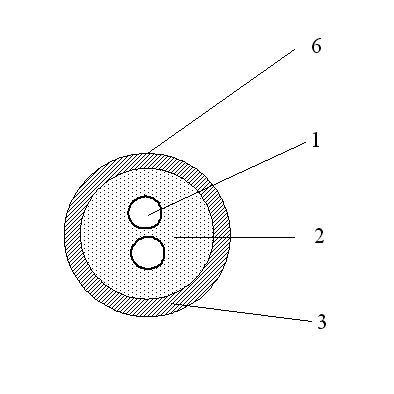

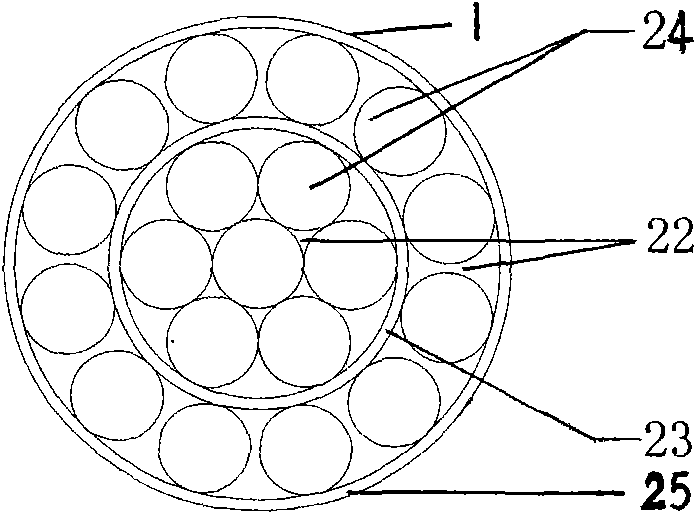

Photoelectric composite submarine cable

InactiveCN102420033AImprove waterproof performanceImprove tensile propertiesCommunication cablesSubmarine cablesEngineeringSubmarine cable

The invention discloses a photoelectric composite submarine cable, which comprises a photoelectric composite module which is axially arranged, two waterproof layers which are axially overlapped on the periphery of the photoelectric composite module, a liner layer which is axially sleeved on the periphery of the waterproof layer, an armoring layer which is axially sleeved outside the liner layer and an outer coat layer which is axially sleeved outside the armoring layer. The photoelectric composite submarine cable can overcome the weaknesses of the prior art that the waterproof performance is poor, the corrosion resistance is poor, the tensile resistance is poor, the cost is high, the installation and pavement difficulty is large and the like, and has the advantages that the waterproof performance is good, the corrosion resistance is good, the tensile resistance is good, the cost is low, and the difficulty in installation and pavement is small.

Owner:SHANDONG YANGGU XINRIHUI CABLE

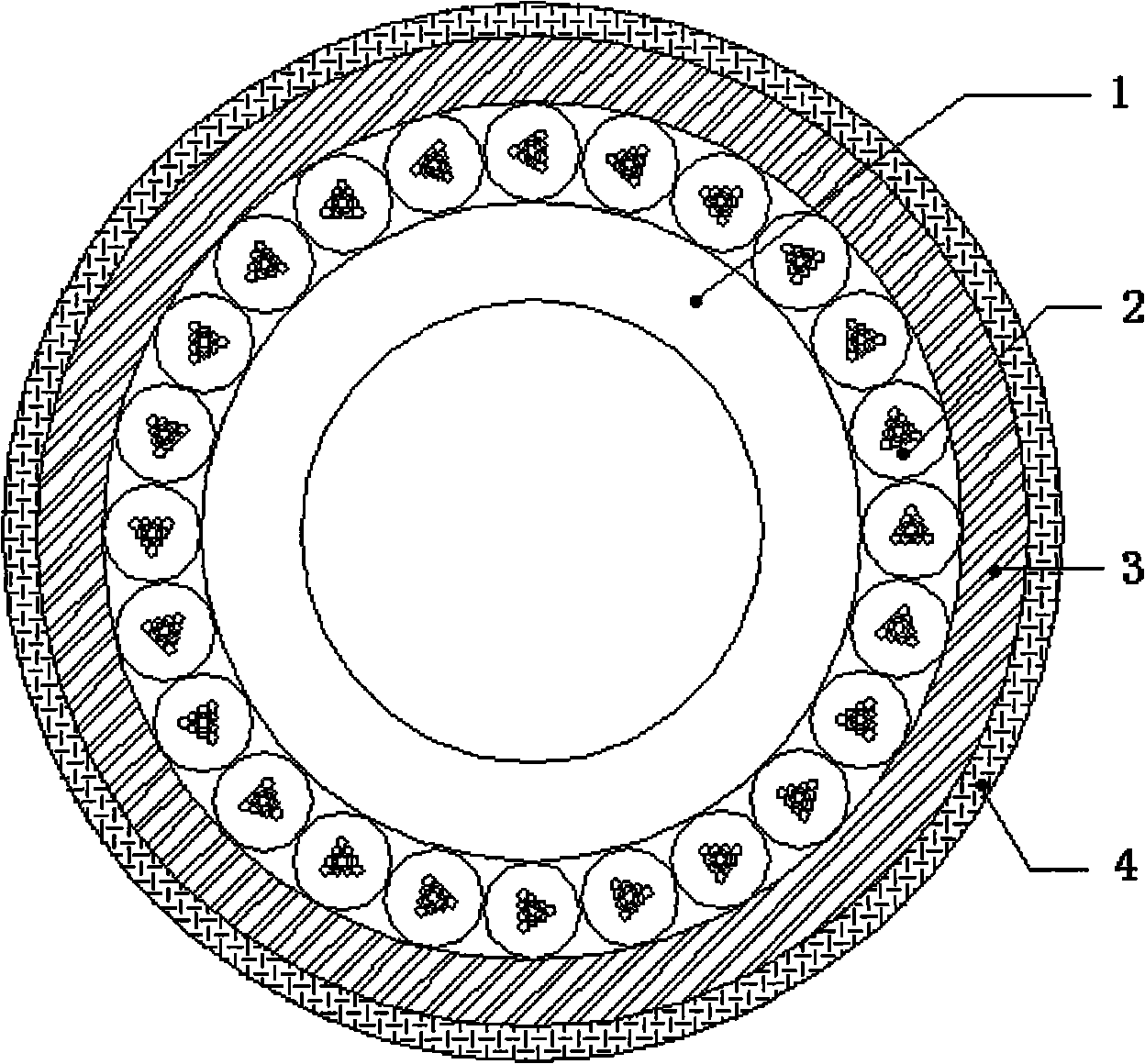

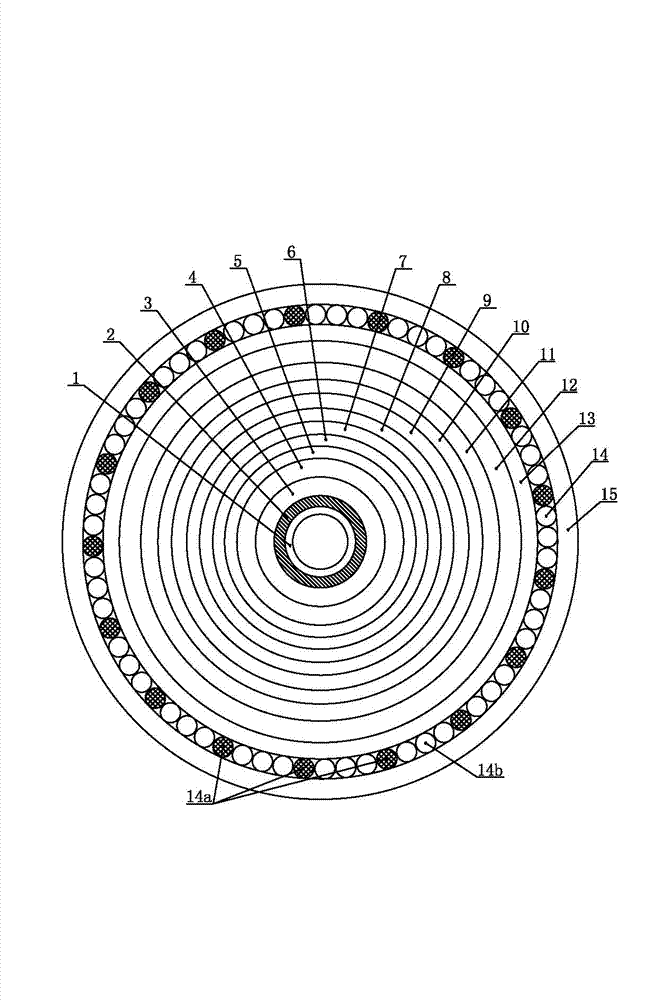

Submarine cable with increased current-carrying capacity

InactiveCN102969071AAvoid lossLarge carrying capacityPower cables with screens/conductive layersSubmarine cablesCopper wireHigh pressure

The invention relates to a submarine cable with an increased current-carrying capacity. Conductor layers comprising a plurality of annealed copper wires with high conductivity are tightly distributed at the periphery of a tin-plated copper spiral pipe; a carbon black paper conductor shielding layer, an oil-filled high-voltage cable paper insulating layer, a carbon black paper insulation shielding layer, a copper strip insulation shielding layer and a seamless lead-alloy sheath are wrapped at the periphery of the conductor layers sequentially; asphalt is evenly coated at the periphery of the seamless lead-alloy sheath; and a self-adhesive polyethylene strip inner cushion layer, double stainless steel strip strengthening layers, a self-adhesive polyethylene strip outer cushion layer, a non-woven fabric liner layer, a high-density polyethylene corrosion resisting layer, an armoured inner cushion layer formed by evenly soaking hemp ropes at intervals through polypropylene ropes in a concentric stranding manner, an armoured layer formed by uniform spacing of aluminum-magnesium-plated alloy steel wires and a copper wire in the concentric stranding manner and an outer protecting layer are wrapped at the periphery of the seamless lead-alloy sheath sequentially. The submarine cable has a larger current-carrying capacity and is excellent in water seepage resistance, seawater corrosion resistance, external water pressure resistance, voltage thermal shock resistance and tension bending resistance. In addition, the submarine cable also has the advantages of long service life and high reliability.

Owner:JIANGSU YUANYANG DONGZE CABLE

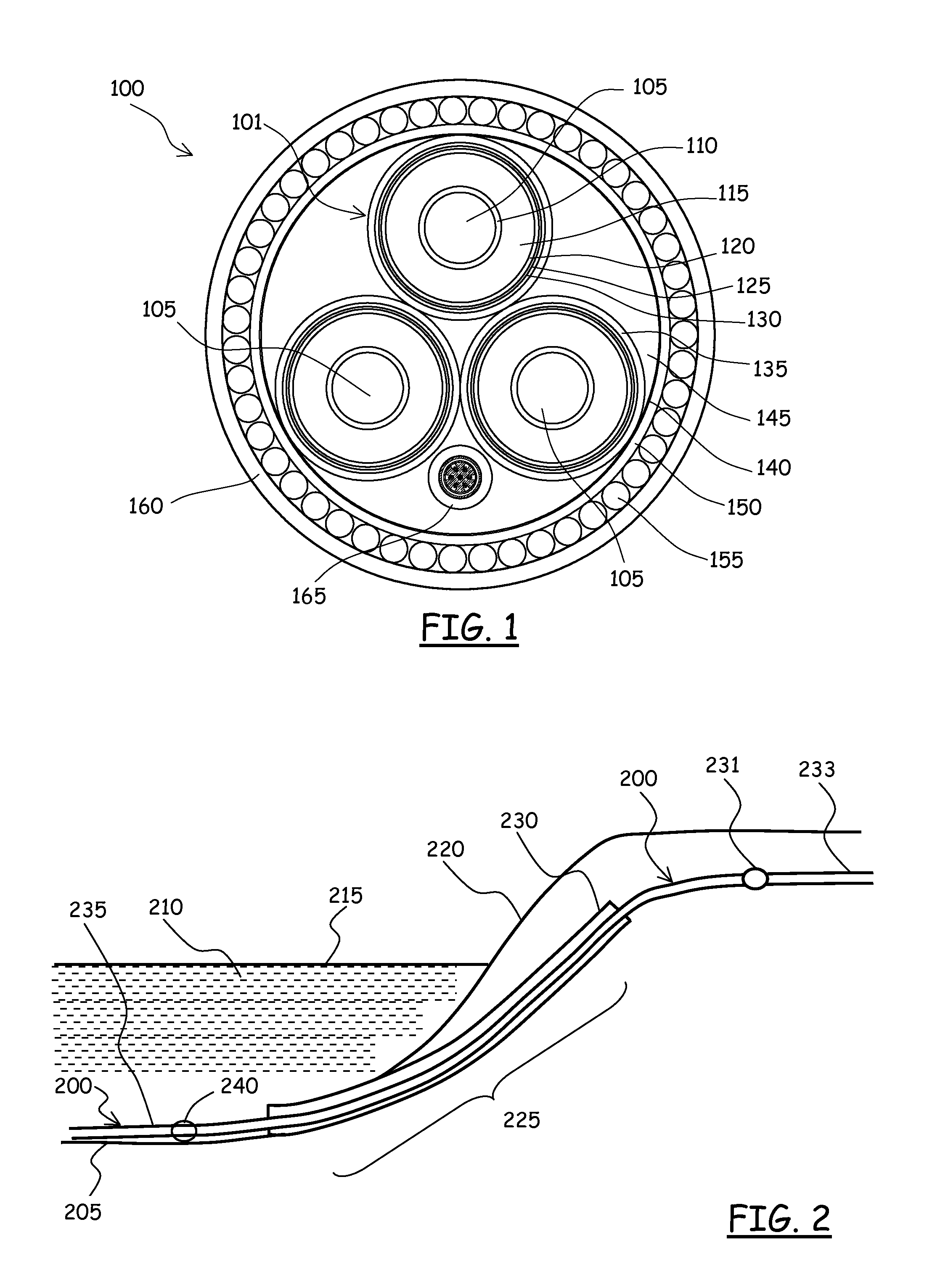

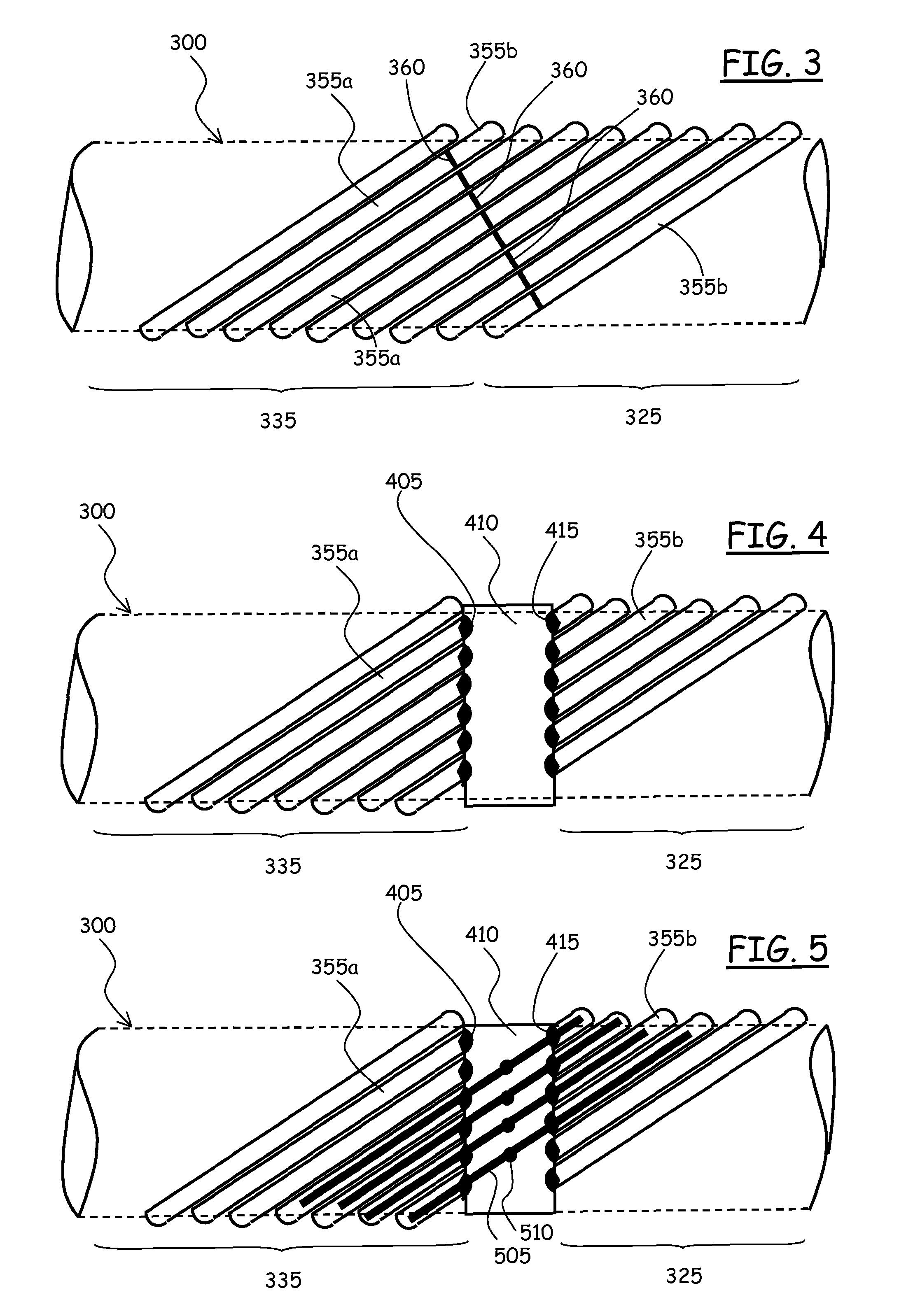

Composite fiber radial compression members in an umbilical

The present inventions relate generally to umbilicals comprising at least one inner tube and at least one composite fiber element to provide greater resistance to radial compressive forces. Such umbilicals may be used in subsea hydrocarbon production applications.

Owner:OCEANEERING INTERNATIONAL

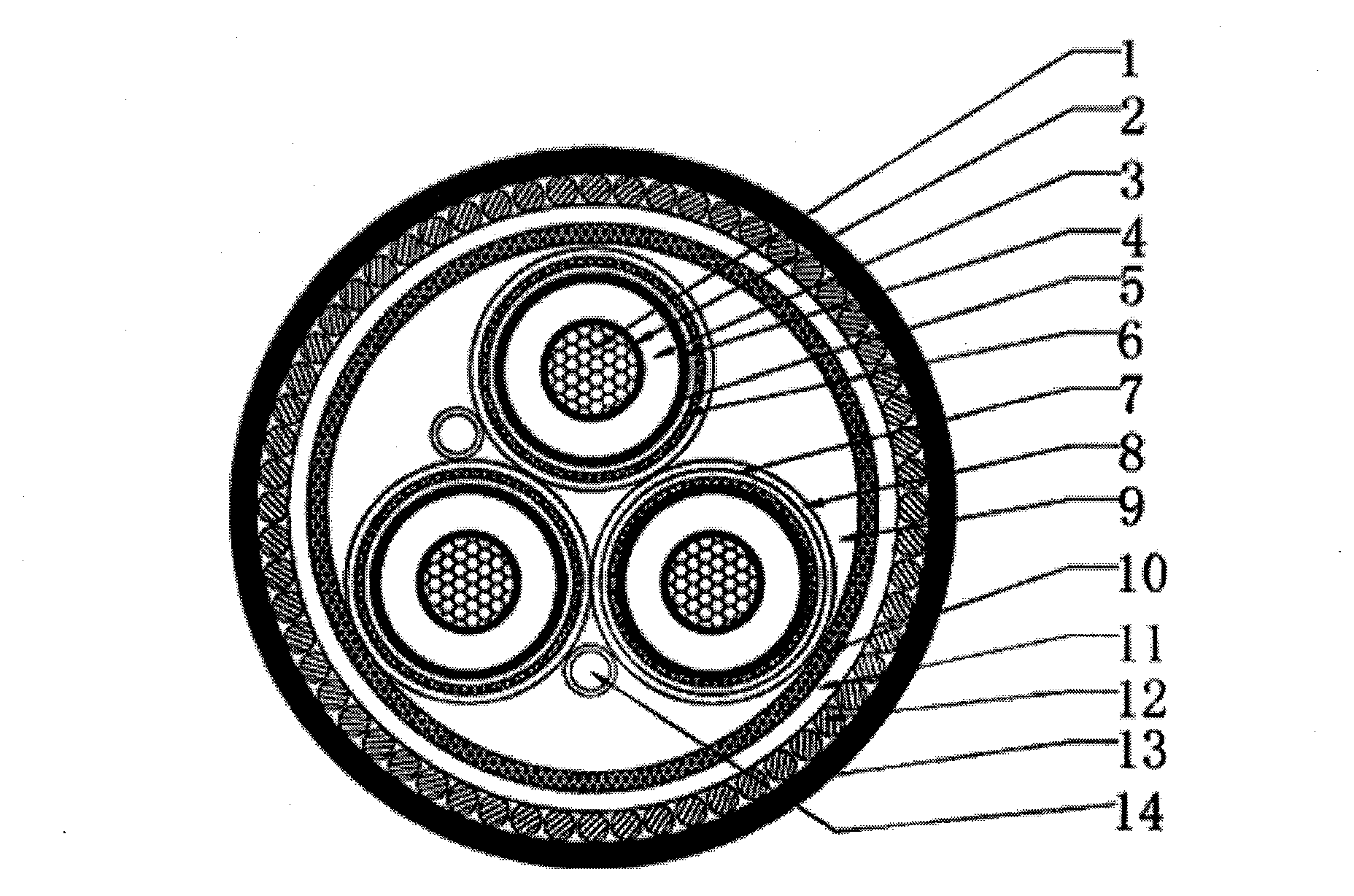

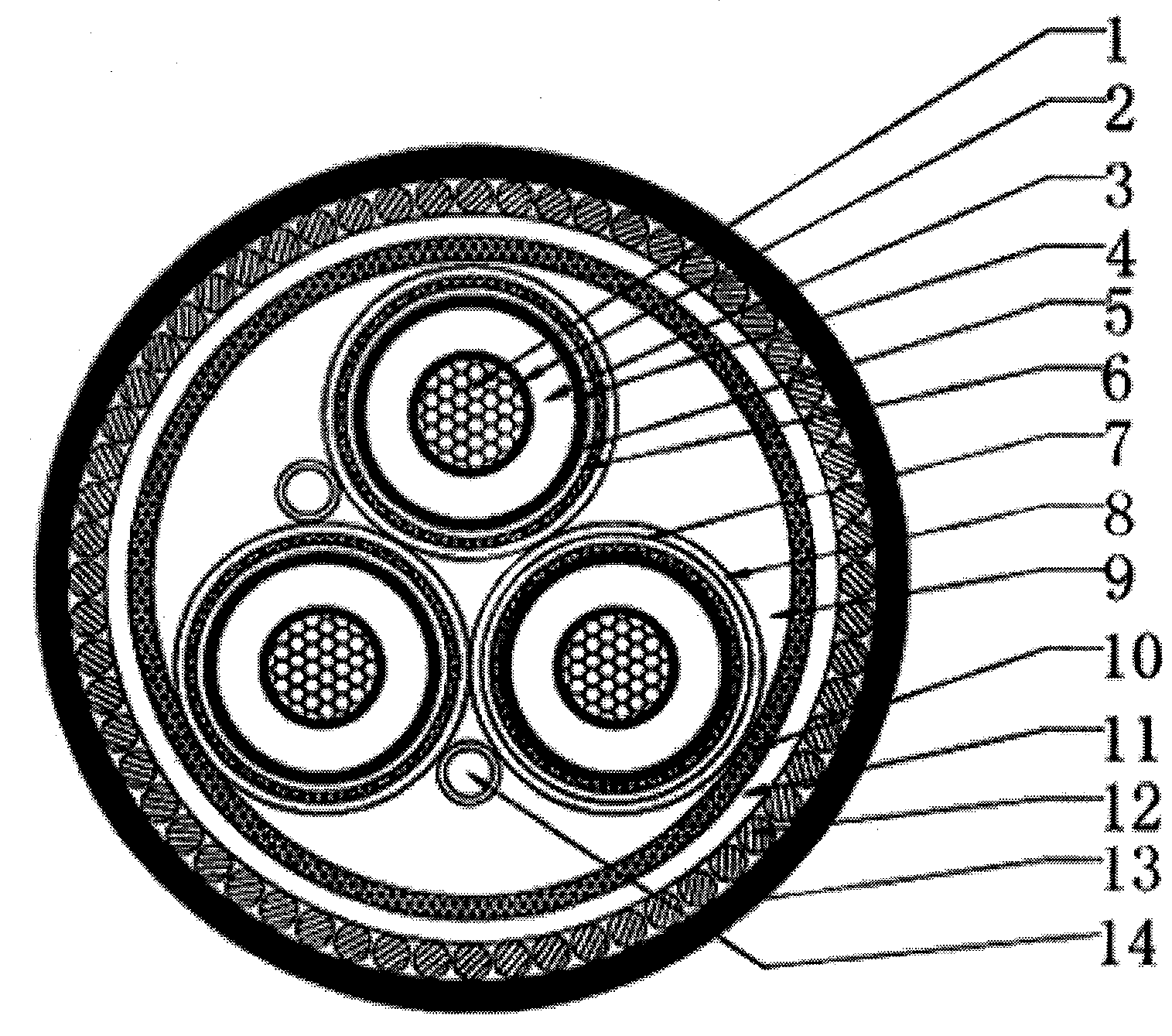

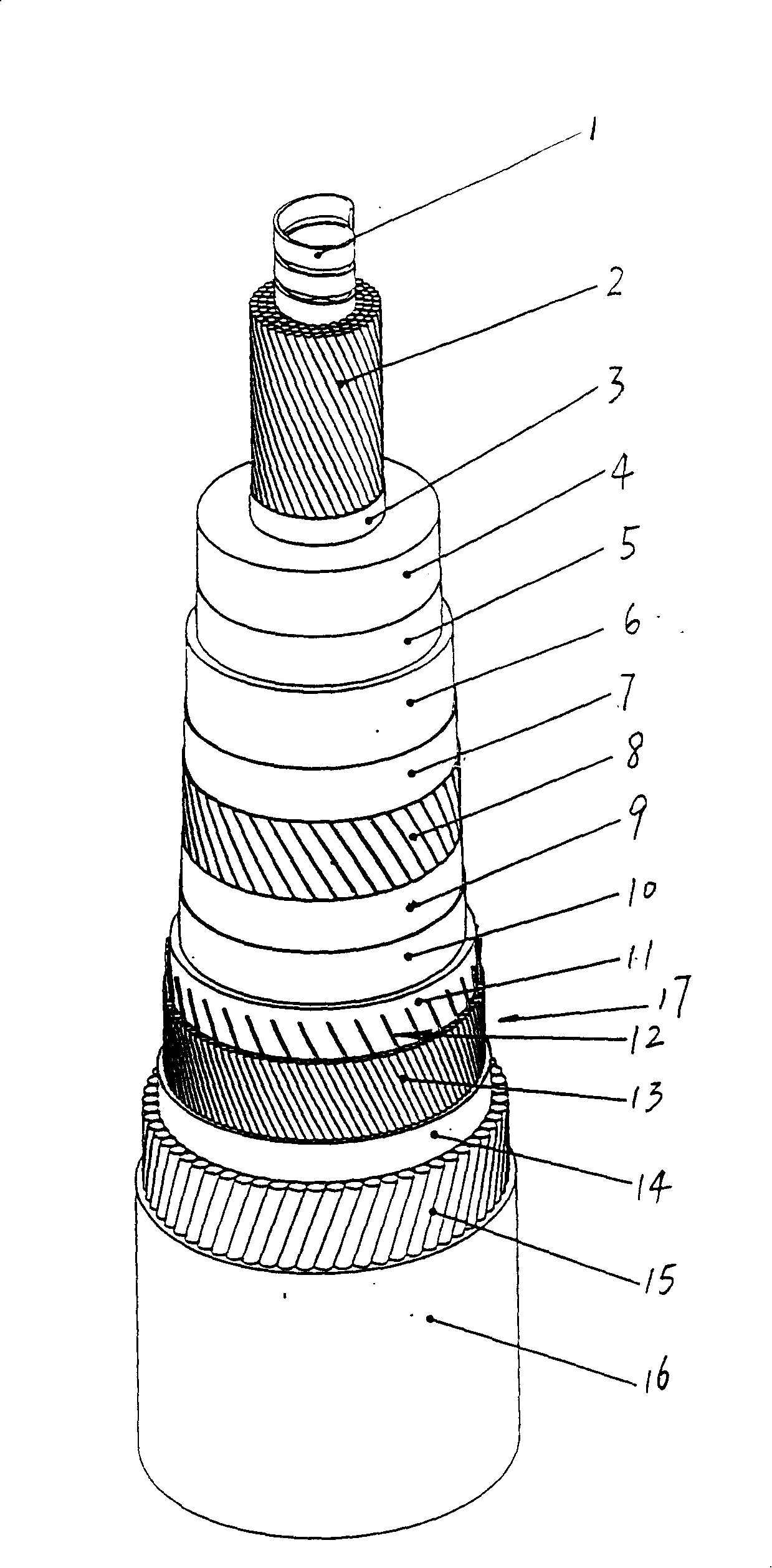

Optical fibre composite electric power seabed oil-filled cable

InactiveCN101211680ASafe and reliable protection performanceIncrease ampacityCommunication cablesSubmarine cablesOcean bottomFilled cable

The invention discloses an optical fiber composite power seabed oil-filled cable, which is characterized in that a light unit layer is arranged in a defending layer. The light unit layer is twisted by an optical fiber and polyethylene filled bar at interval. A metal protecting layer comprises a lead protecting layer, wherein a return feeder layer is arranged outside the lead protecting layer. The return feeder layer is assembled by a flat copper line. A lining layer is arranged between the lead protecting layer and the return feeder layer. The return feeder layer is arranged in the metal protecting layer so as to improve the short circuit current of the metal protecting layer and help to improve the current carrying amount of the cable at the same time. The invention has the advantages of higher electrical performance and sufficient mechanical intensity by combining the seabed optical fiber cable and seabed power cable.

Owner:上海电缆厂集团有限公司

Submarine optical fiber composite high-voltage cable with detection function

InactiveCN102005259ADetect damageLow costMaterial analysis by optical meansPower cables with screens/conductive layersPower cableTransverse pressure

The invention discloses a submarine optical fiber composite high-voltage cable with a detection function. The cable comprises cable cores, an inner armor layer and an outer armor layer, wherein the inner armor layer is twisted on the cable cores; the outer armor layer is twisted on the inner armor layer; an outer sheath is formed on the outer armor layer by extrusion molding; an optical fiber sensor unit is arranged in a gap of the cable cores of the cable for measuring the temperature of the cable; and a bedding layer is arranged between the inner armor layer and the outer armor layer and an optical fiber sensor unit is distributed between the inner armor layer and the outer armor layer for detecting damage of the cable. A natural characteristic that transmission loss is increased when the optical fiber is used for bearing bending or transverse pressure is used, the damage of the cable can be detected, and accurate positioning can be realized through an instrument. The optical fiber sensor in the cable cores is used for measuring the temperature variation of the cable core of power cables.

Owner:HENGYANG HENGFEI CABLE CO LTD

Moisture resistant underground cable

InactiveUS6064007AImprove mechanical propertiesEconomical moisture resistantPlastic/resin/waxes insulatorsClimate change adaptationEngineeringMoisture

An electrical cable protected against moisture by a tubular liquid crystal film having its molecules multiaxially oriented.

Owner:ELECTRIC POWER RES INST INC

Photoelectric composite cable laid in seabed, and manufacture method thereof

ActiveCN104332225ACompact structureSolution to short lifePower cables with screens/conductive layersCommunication cablesFiberInsulation layer

The invention belongs to the technical field of a cable, and relates to a photoelectric composite cable laid in a seabed. The cable comprises multiple fibers, a loose sleeve, a thermal insulation layer, a conductor layer, an insulation layer, a shielding layer, a first protective layer, an inner sheath, a first armored layer, a second protective layer, a second armored layer, a third protective layer and an outer jacket. The first armored layer is formed by spirally twisting first reinforcement elements around the inner sheath in a unidirectional mode by a first pitch; the second armored layer is formed by spirally twisting second reinforcement elements around the second protective layer in a unidirectional mode by a second pitch; the winding directions of the first pitch and the second pitch are opposite; the second pitch is 3 to 5 times the first pitch; the ratio of the first pitch to the external diameter of the inner sheath equals to (3-6):1; the materials of the first reinforcement elements are steel wires or alloy wires; and the materials of the second reinforcement elements are the steel wires or the alloy wires. The cable provided by the invention has the following advantages: the cable can transmit both optical signals and electric power, can also resist bending and torsion, and is more compact in structure, longer in life, smaller in external diameter, lower in cost and lower in transport cost.

Owner:NINGBO RONGHE WIRE CO LTD

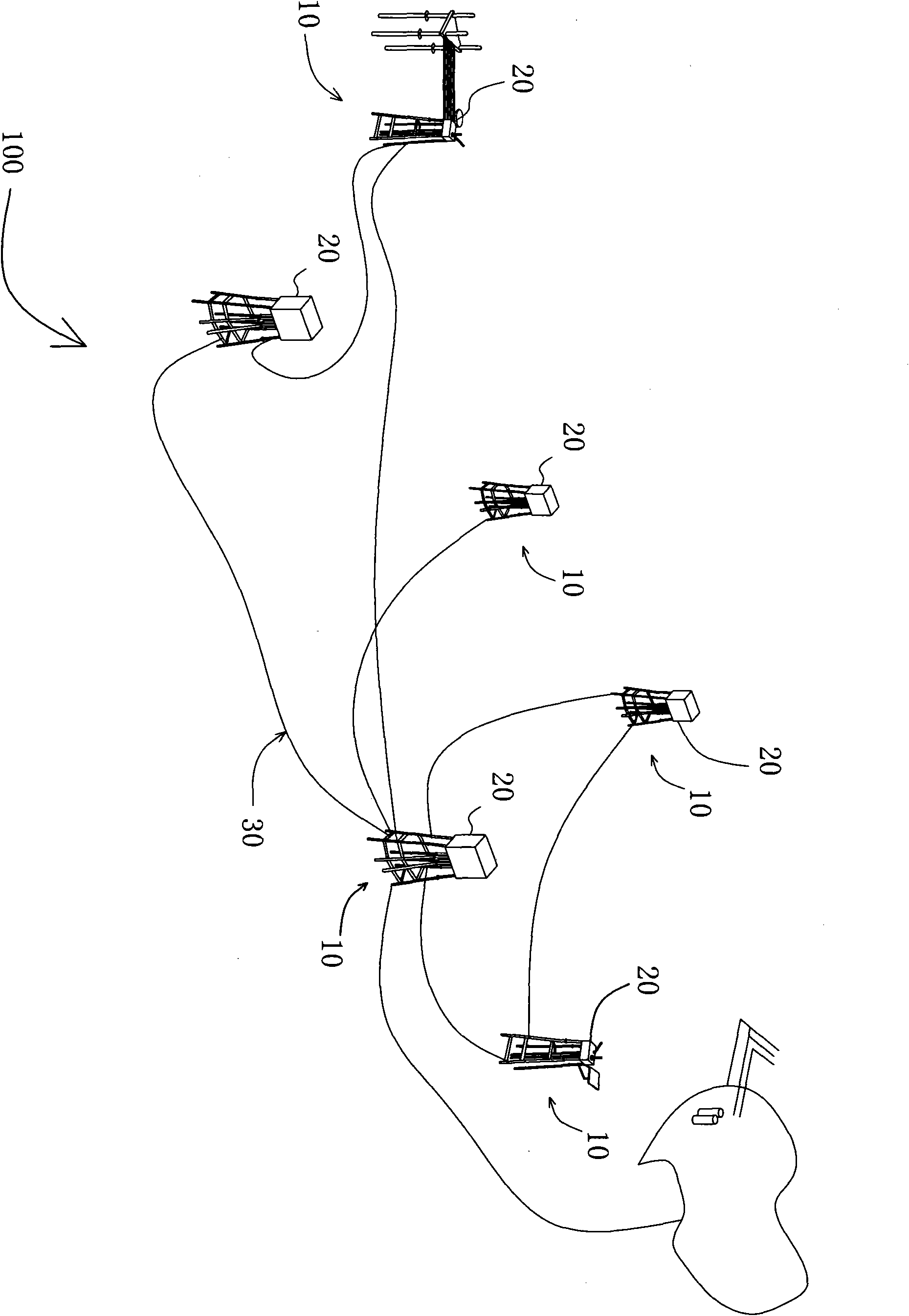

Submarine cable for power grid interlink of offshore oil platform

InactiveCN101916616AGood chemistryStrong communication functionPower cables with screens/conductive layersCommunication cablesOcean bottomElectricity

The invention relates to a submarine cable for a power grid interlink of offshore oil platforms, which is characterized in that a plurality of offshore platform power stations on a plurality of offshore oil drilling platforms distributed in a sea area are connected through submarine cables so as to form a small-sized grid-connected power system. The submarine cables are compound type submarine cables, which are provided with submarine optical cable units and optical fibers with the voltage class of 35KV and the cross section of 3*(150-250)mm<2>. The submarine cables have excellent electric, physical and chemical properties, are beneficial to enhancing the communication capability of the grid interlink among all oil fields, and can effectively guarantee the effectiveness of optical fiber communication, greatly enhance the anti-torque capability of the optical fibers and ensure the smooth communication of the power grid interlink.

Owner:CHINA NAT OFFSHORE OIL CORP +2

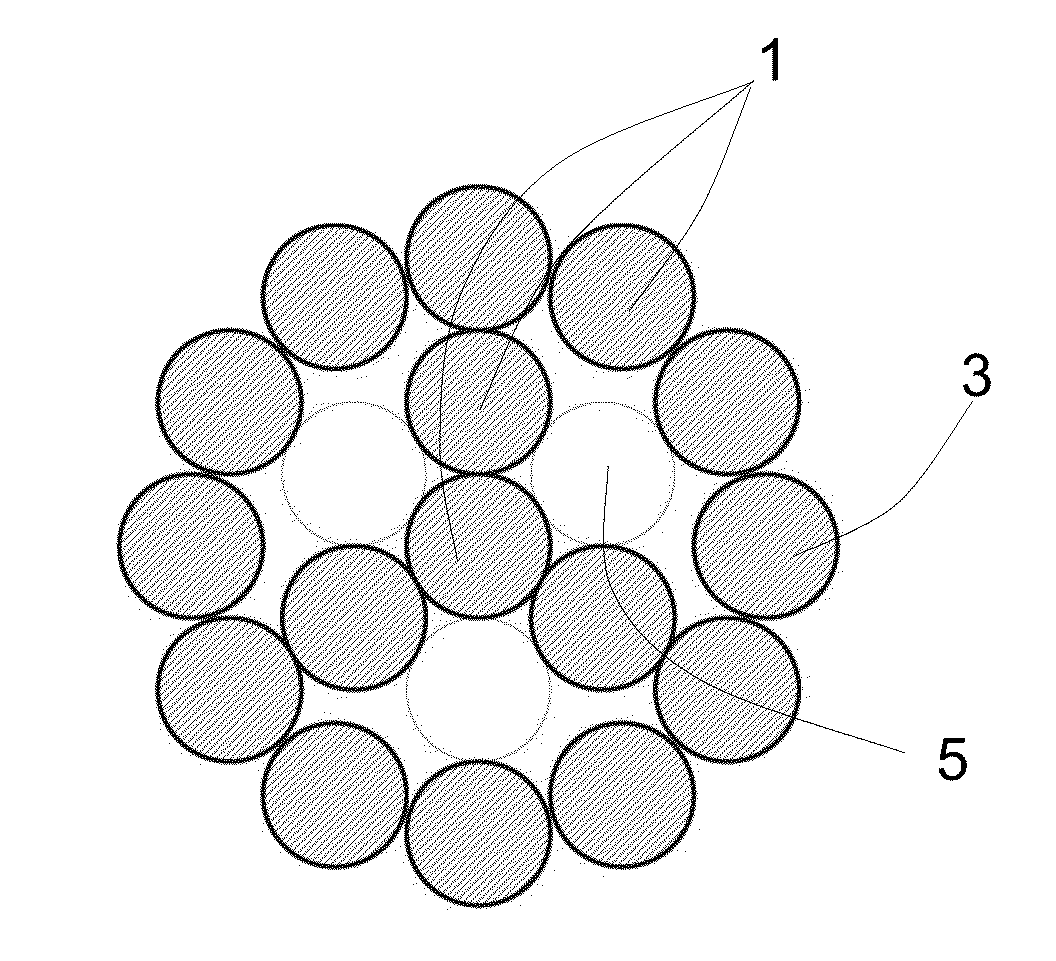

Composite fiber radial compression members in an umbilical

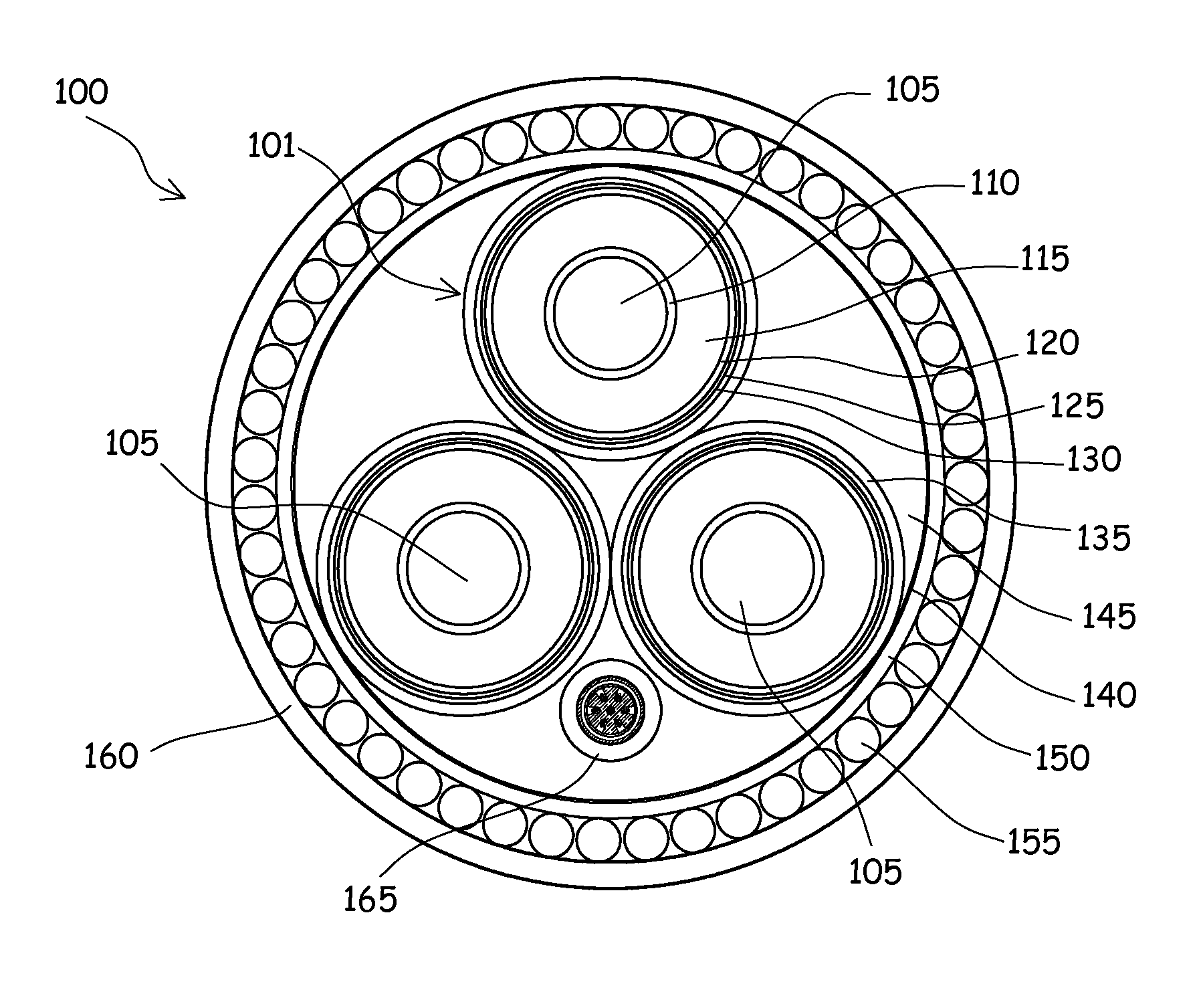

ActiveUS7239781B2Communication cablesPartially enclosed bus-bar installationsFiberRadial compression

The present inventions relate generally to umbilicals comprising at least one inner tube and at least one composite fiber element to provide greater resistance to radial compressive forces. Such umbilicals may be used in subsea hydrocarbon production applications.

Owner:OCEANEERING INTERNATIONAL

Split-phase lead-coated submarine cable

InactiveCN102364600AHigh bendabilityGood anti-aging performancePower cables with screens/conductive layersSubmarine cablesCustomer requirementsThio-

The invention discloses a split-phase lead-coated submarine cable. The split-phase lead-coated submarine cable is characterized in that: a split-phase lead coating is arranged outside a water-blocking buffer layer (5); the split-phase lead coating comprises a metal shielding layer (10); a split-phase sheath (61) is arranged outside the metal shielding layer (10); and an anti-corrosion reinforcing layer (91) is arranged between a winding belt (9) and a liner layer (11). According to different occasions and customer requirements, the invention provides different insulation types of submarine cables, such as cross-linked polyethylene (XLPE) insulating submarine cables which meet general requirements, ethylene propylene rubber (EPR) insulating submarine cables which are bendable and high in anti-aging performance, and thio-rubber (TR)-XLPE insulating submarine cables which are high in waterproof performance and anti-aging performance, low in loss and large in transmission capacity.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD

Flexible electrical elongated device suitable for service in a high mechanical load environment

InactiveUS20050034891A1Reduce strainReliable load-transferring featureSubmarine cablesFlexible cablesElectrical conductorBiomedical engineering

The invention relates to a flexible electrical elongated device, suitable for service in a high mechanical load environment, wherein said device has a longitudinal axis, and comprises: at least one elongated electrical conductor element, an elongated load bearing component along said longitudinal axis and having an external surface including at least one groove disposed along said longitudinal axis, said groove being designed for holding said conductor element within it while allowing said conductor element to move substantially radially when said device is bent.

Owner:NEXANS

Solid cable, manufacturing method thereof, and transmission line therewith

InactiveUS6399878B2High tensile strengthRubber insulatorsOil-pressure cablesPolyolefinElectrical conductor

A cable and cable system is provided having a conductor and an insulation layer on an outer circumference of a conductor. The insulation layer is impregnated with a medium-viscosity insulating oil that has a viscosity of 10 centistokes (cst) to less than 500 cst at 60° C. The insulation layer includes an insulating tape that may be one or a combination of composite tape having a polyolefin resin film laminated with a kraft paper on both its sides and an insulating tape including a polyolefin resin film. The cable includes a metal sheath provided on an outer circumference of the insulation layer, and a reinforcing layer formed on an outer circumference of the metal sheath. The reinforcing layer reinforces the metal sheath by absorbing hoop stress exerted on the metal sheath. The cable system includes a submarine-portion cable and a land-portion cable, an oil stop joint box, and an oil feeding tank. The oil stop joint box connects the submarine-portion cable to the land-portion cable, and the oil feeding tank is connected to the land-portion cable which feeds the medium-viscosity insulating oil to the land-portion cable.

Owner:SUMITOMO ELECTRIC IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com