Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Detect damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

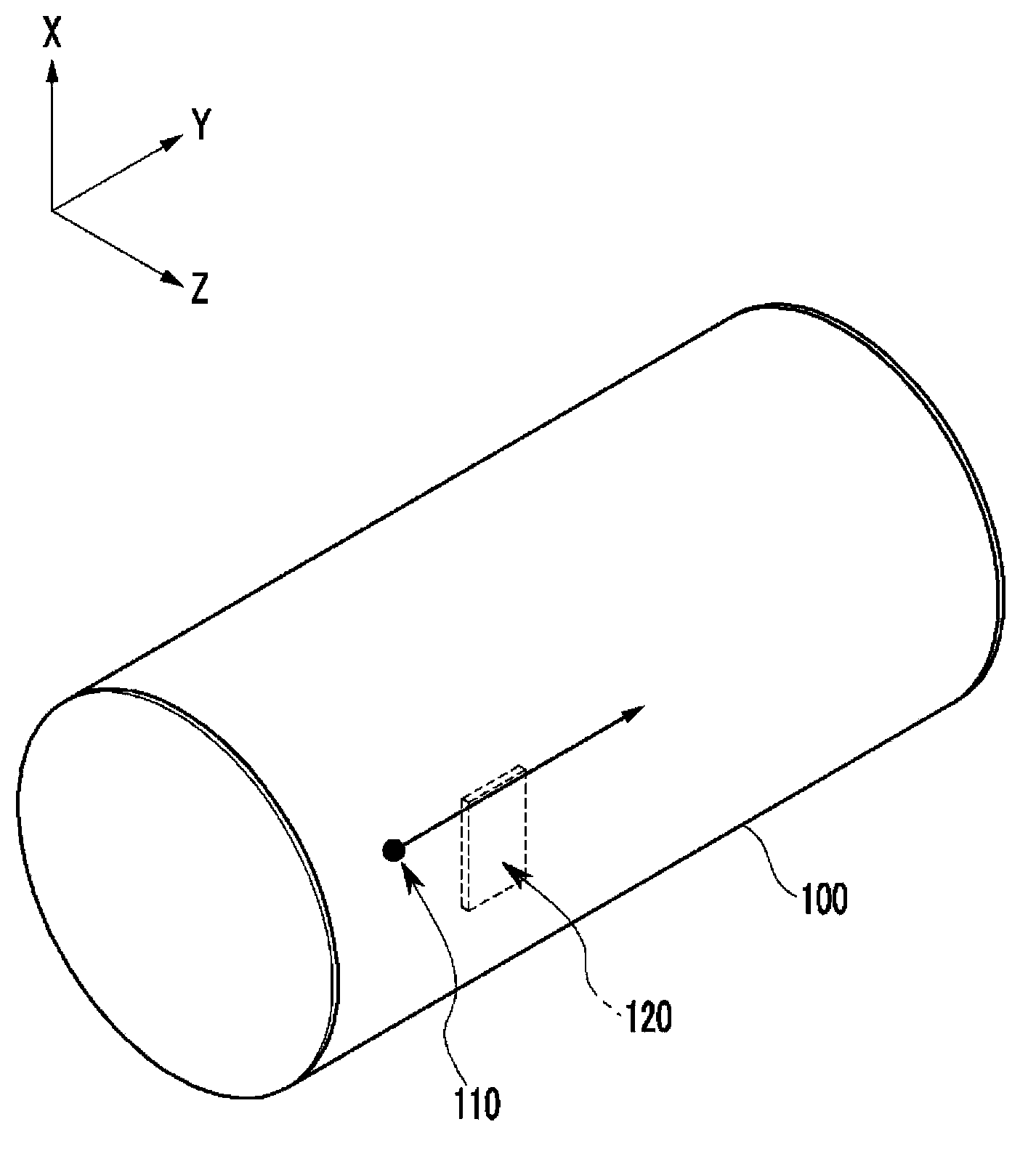

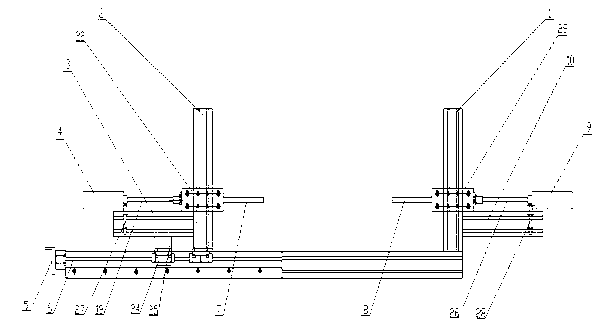

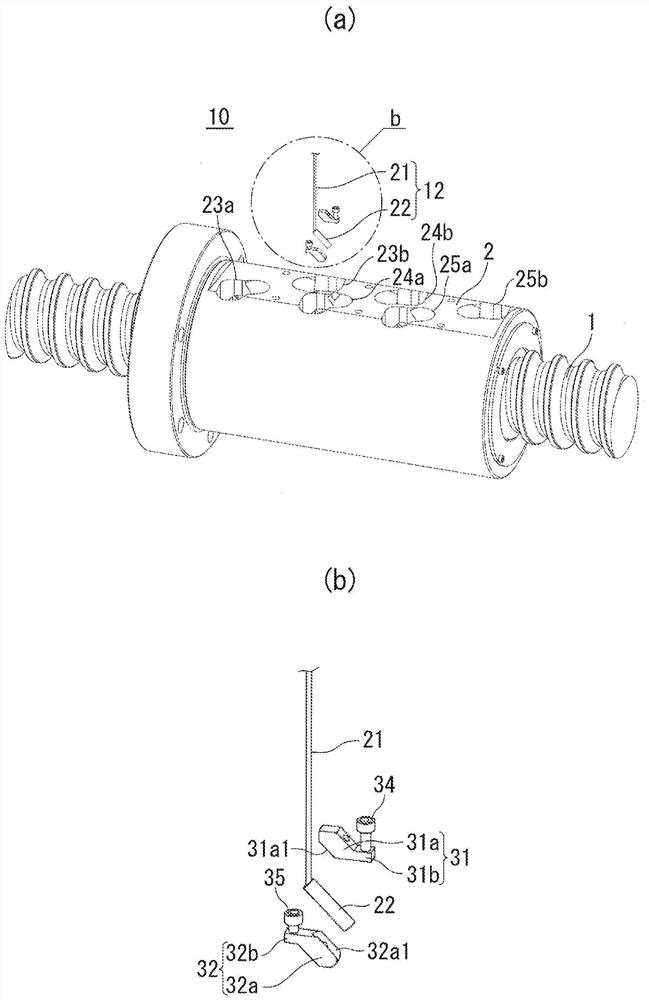

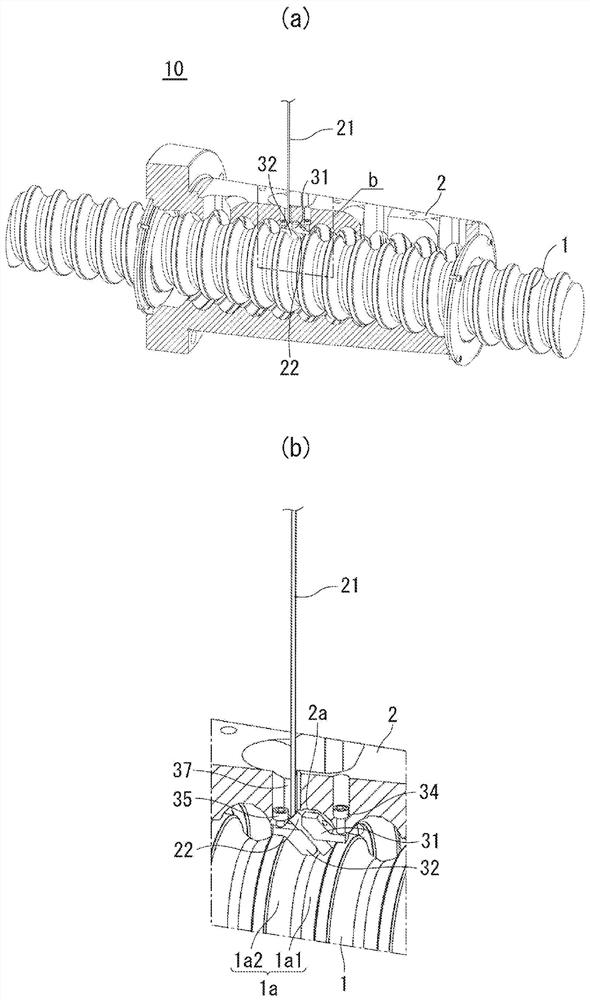

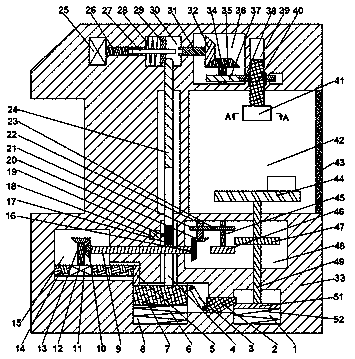

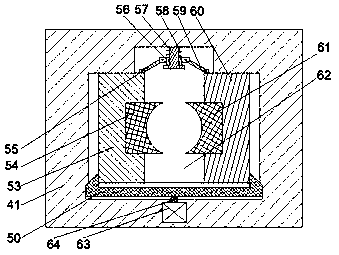

Wheel type pipeline robot with steering of driving wheels being controllable

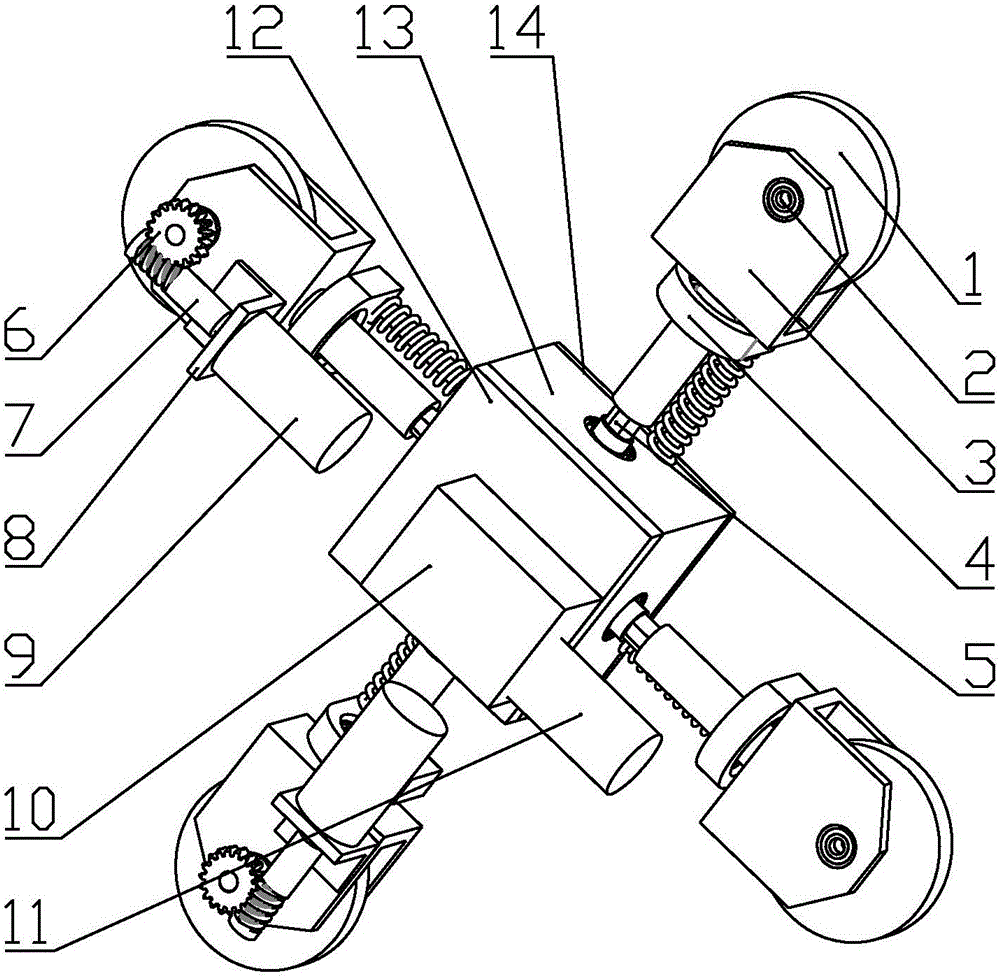

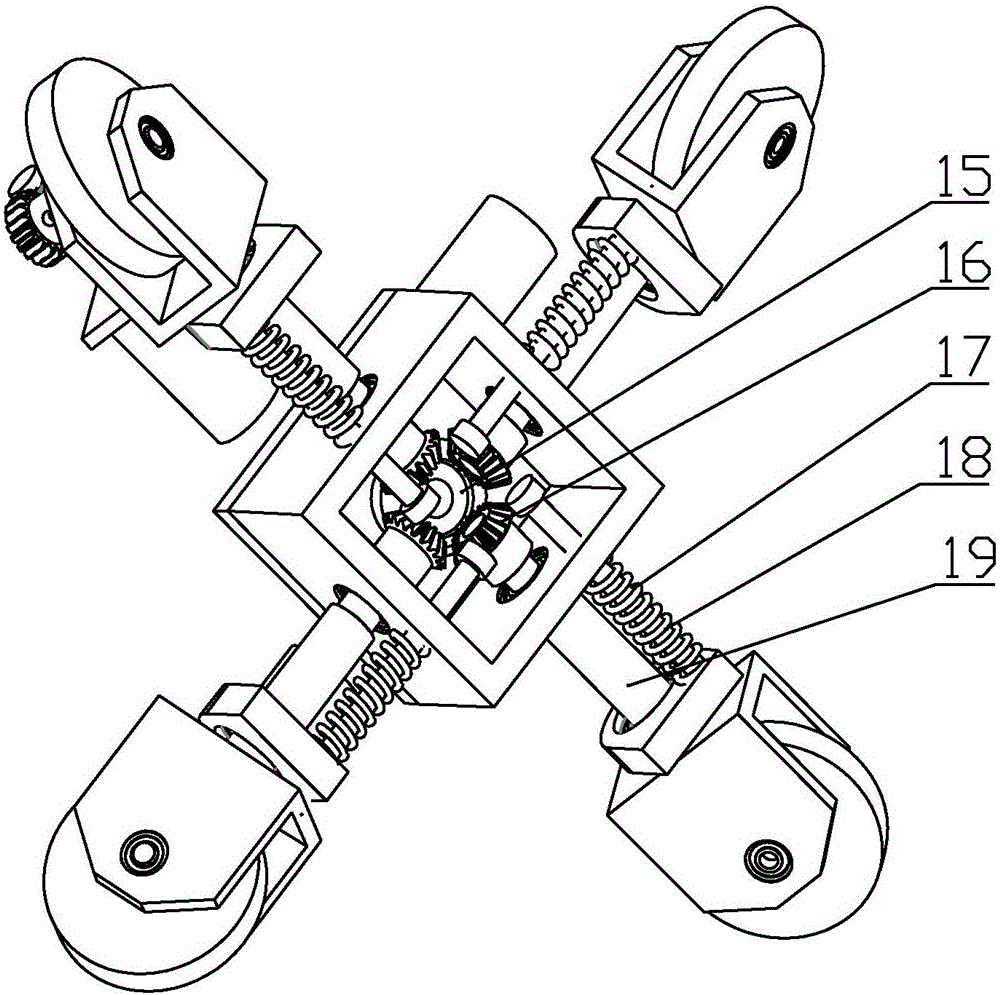

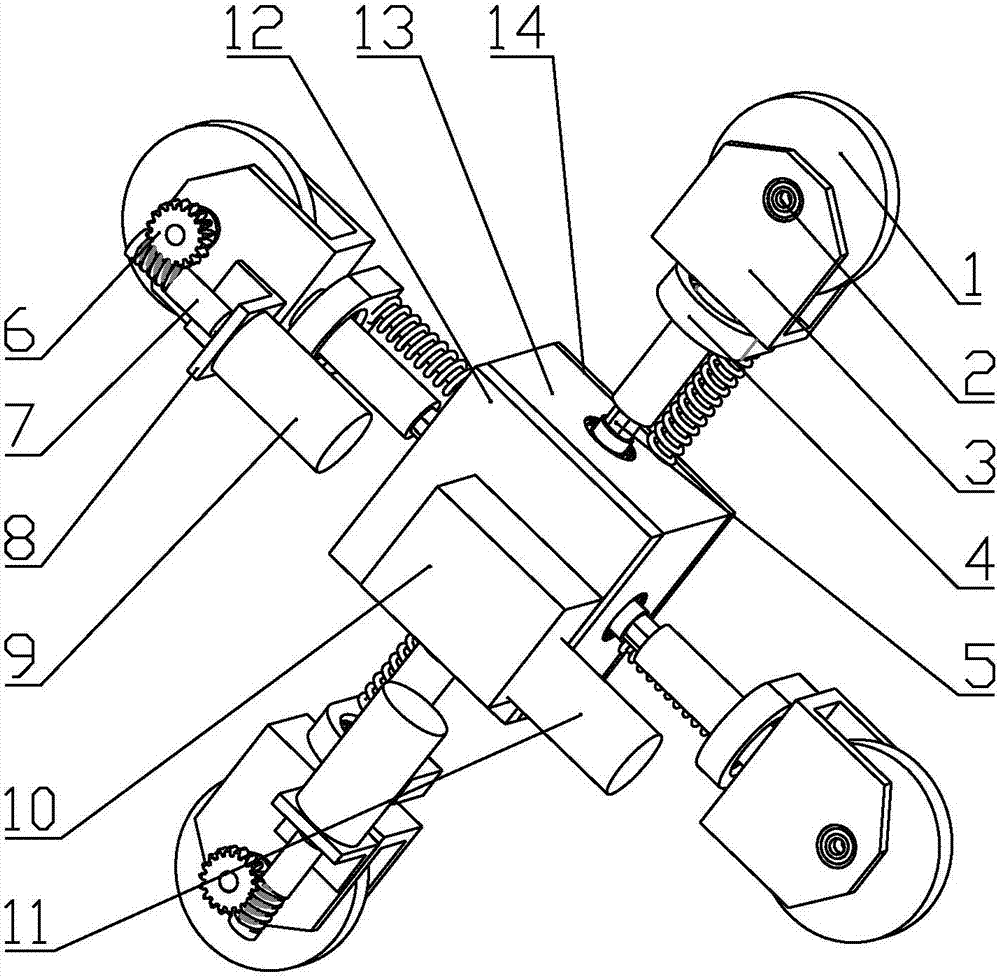

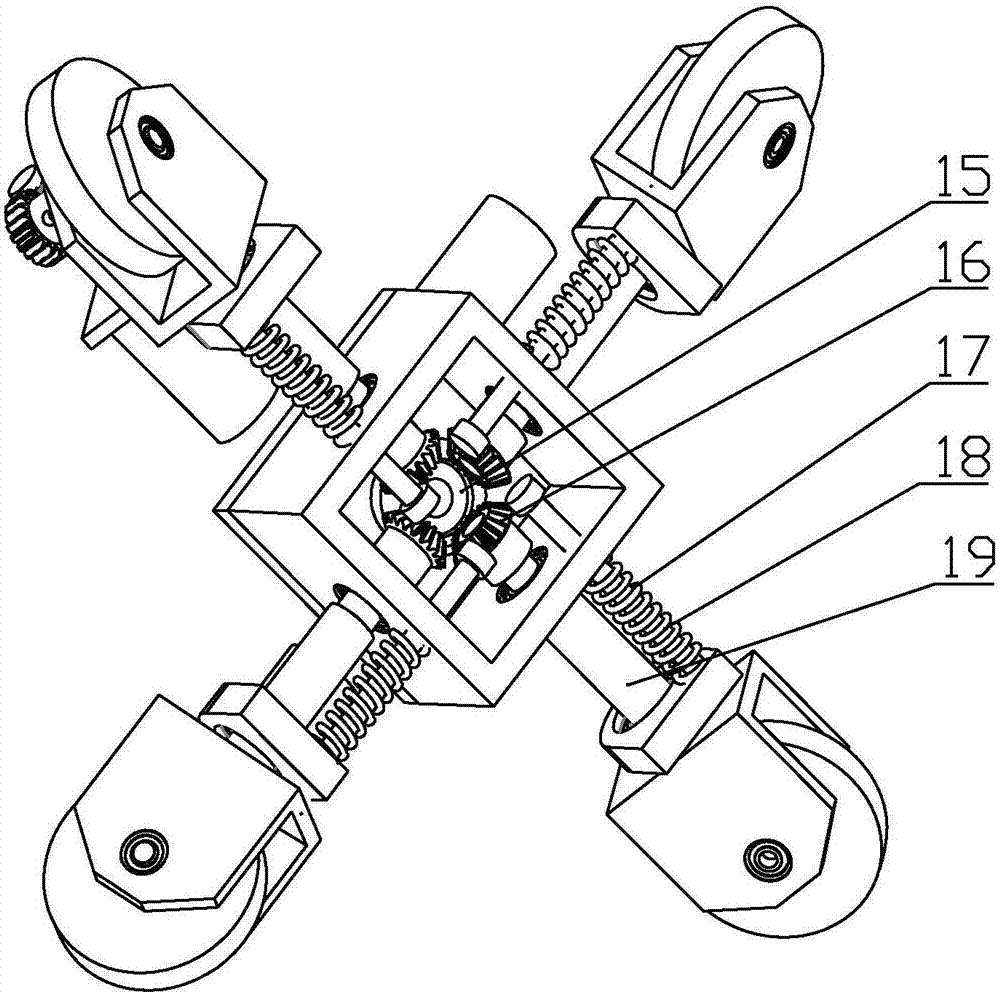

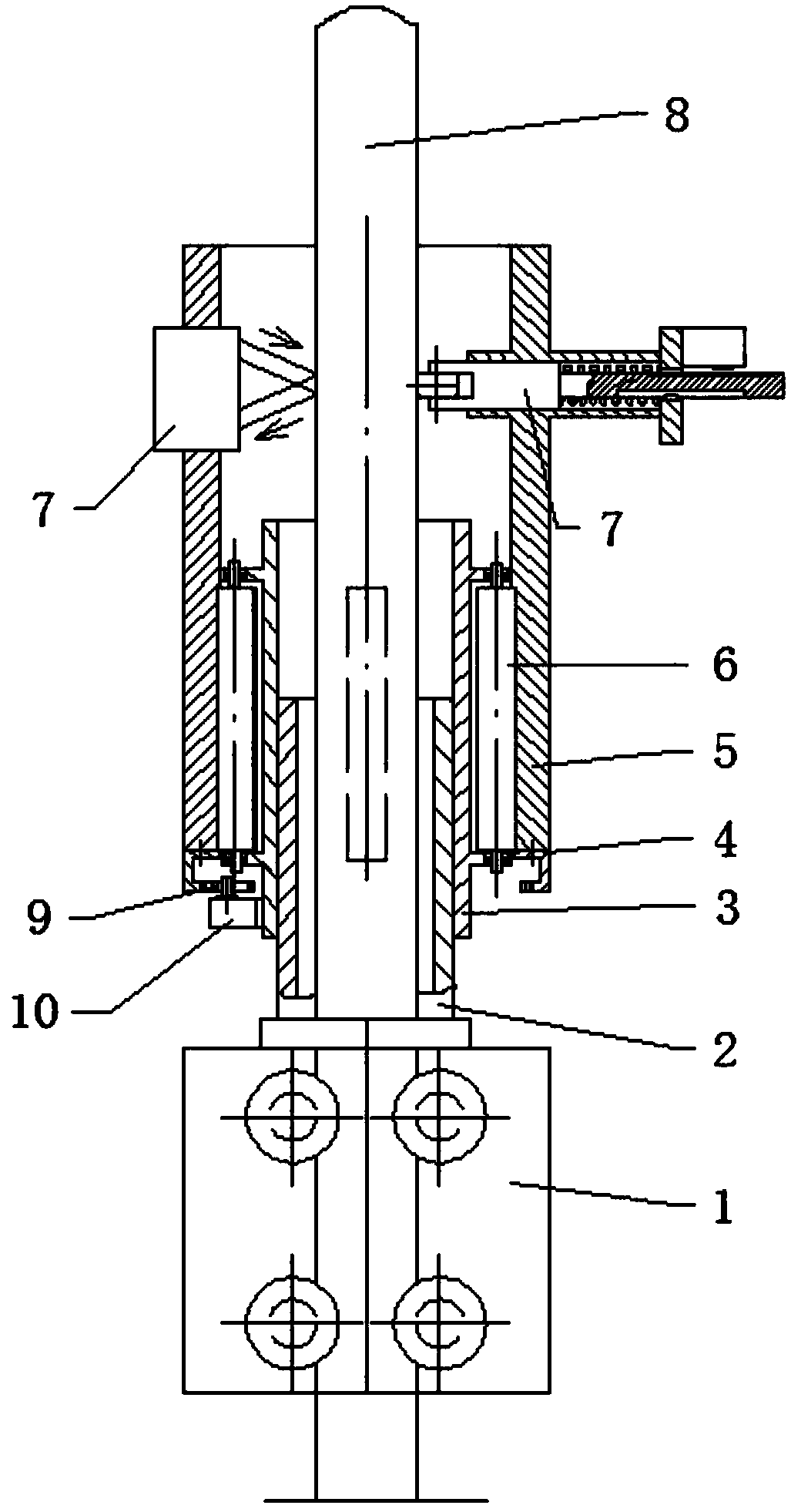

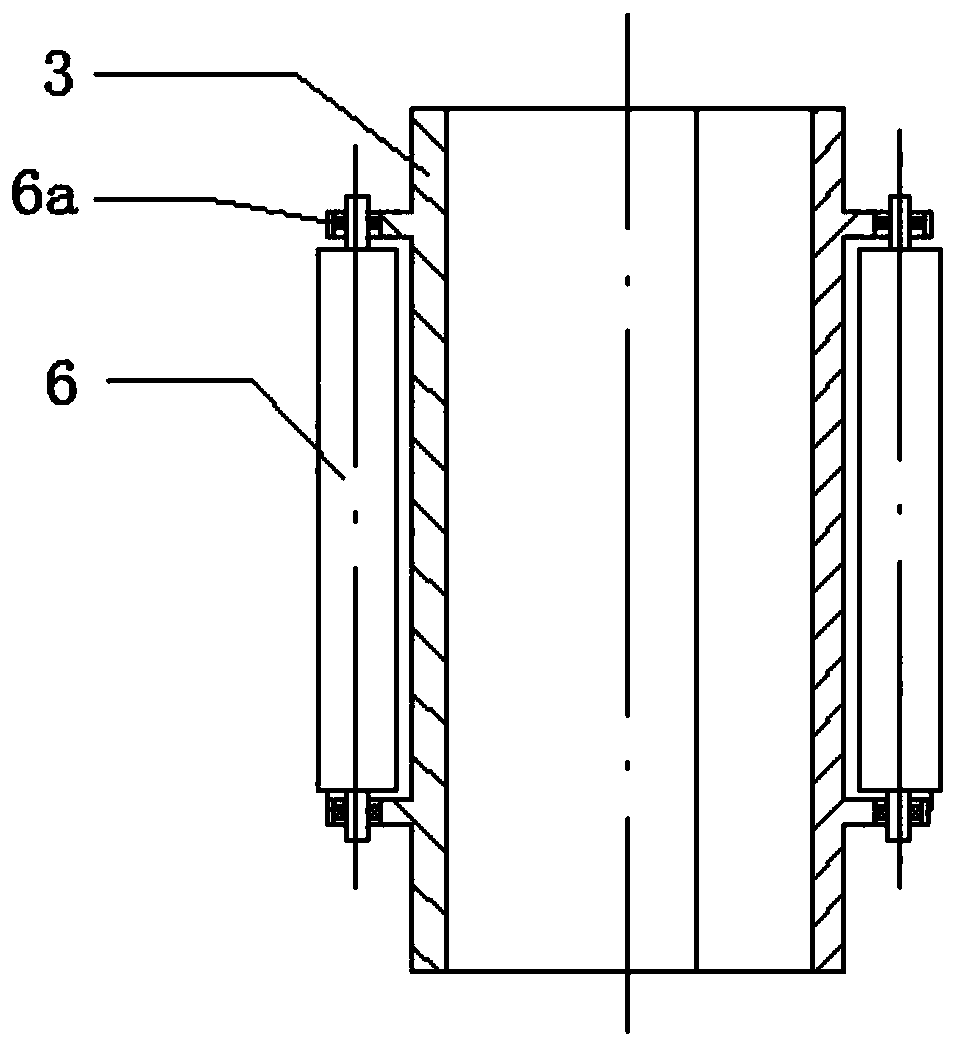

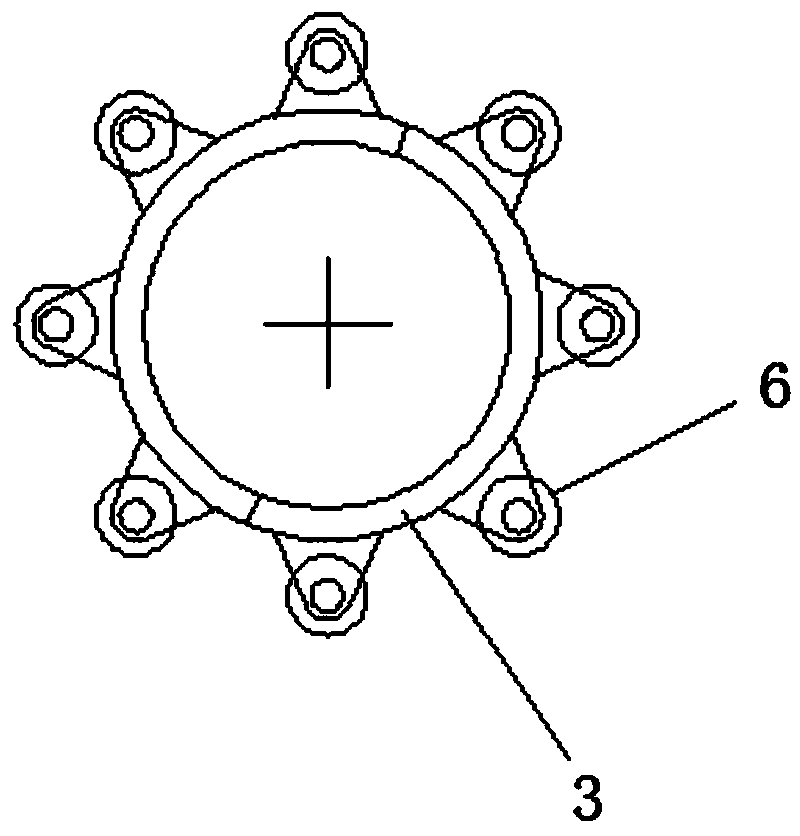

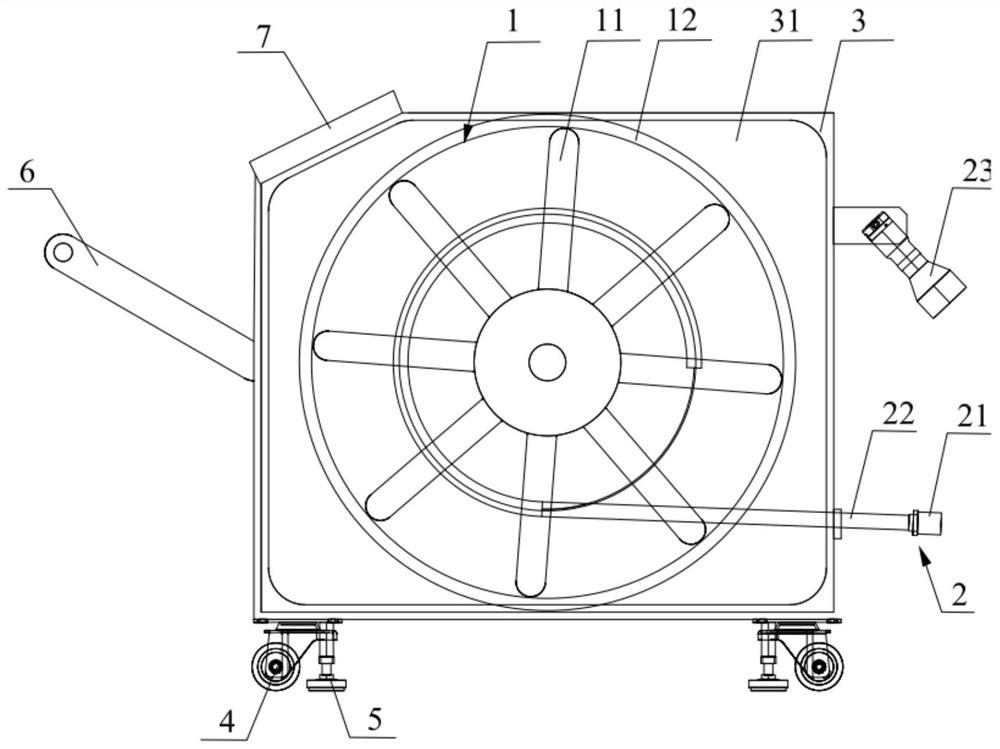

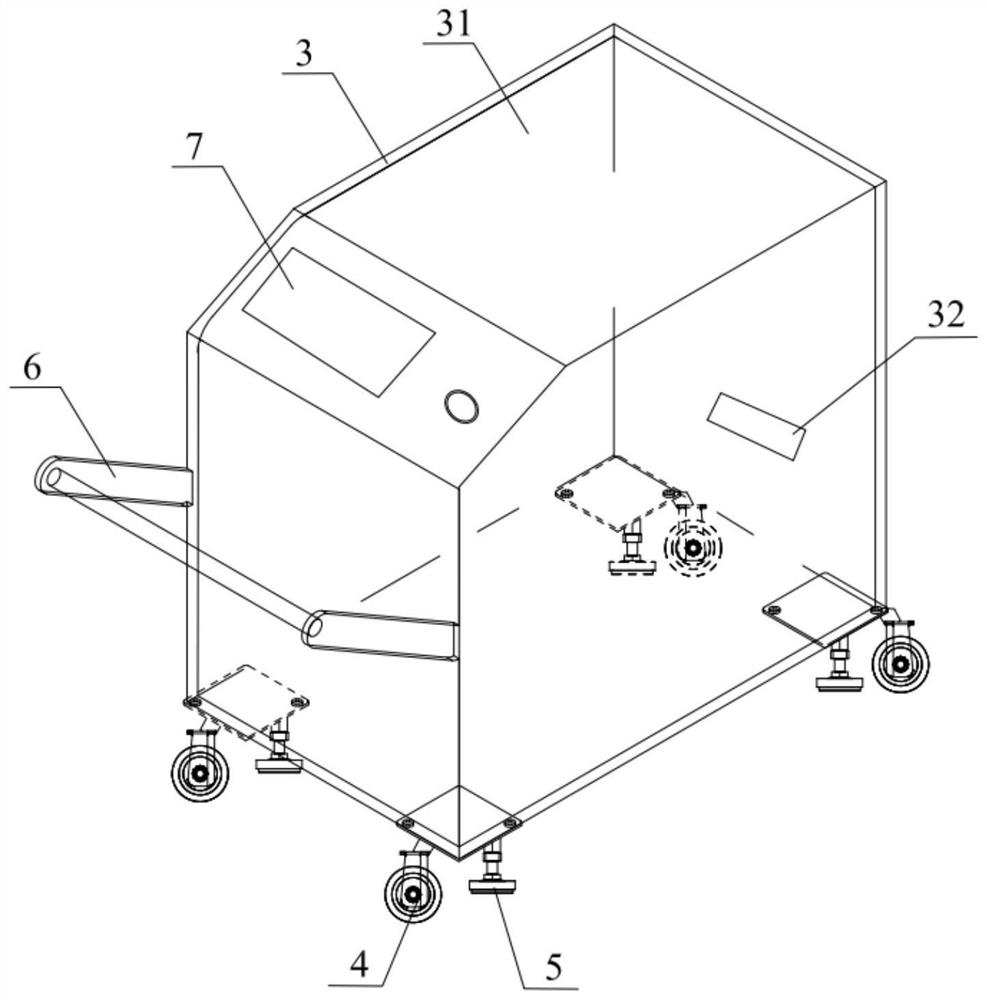

The invention relates to a wheel type pipeline robot with steering of driving wheels being controllable. The wheel type pipeline robot with steering of the driving wheels being controllable mainly consists of two front elastic arm units, two rear elastic arm units and a robot body. Driving motors are arranged on the two front elastic arm units separately to drive the robot to move forward or backward. The robot can pass through a bent pipeline efficiently and stably by differential speed control. A driving wheel steering and reversing mechanism is arranged in the robot body and the attitude of the robot in a pipeline can be adjusted rapidly by adjusting the included angles between the four driving wheels and the section of the pipeline simultaneously. The pipeline robot is simple in structure and capable of self-adaption of a tiny change of a pipe diameter and rapid adjustment of the attitude of the robot in the pipeline; furthermore, the pipeline robot has an obstacle crossing ability for efficiently and stably passing through the complicated pipeline such as the bent pipeline and a reducing pipeline with the best attitude angle, so that the normal inspection and maintenance of the pipeline can be guaranteed.

Owner:HEFEI UNIV OF TECH

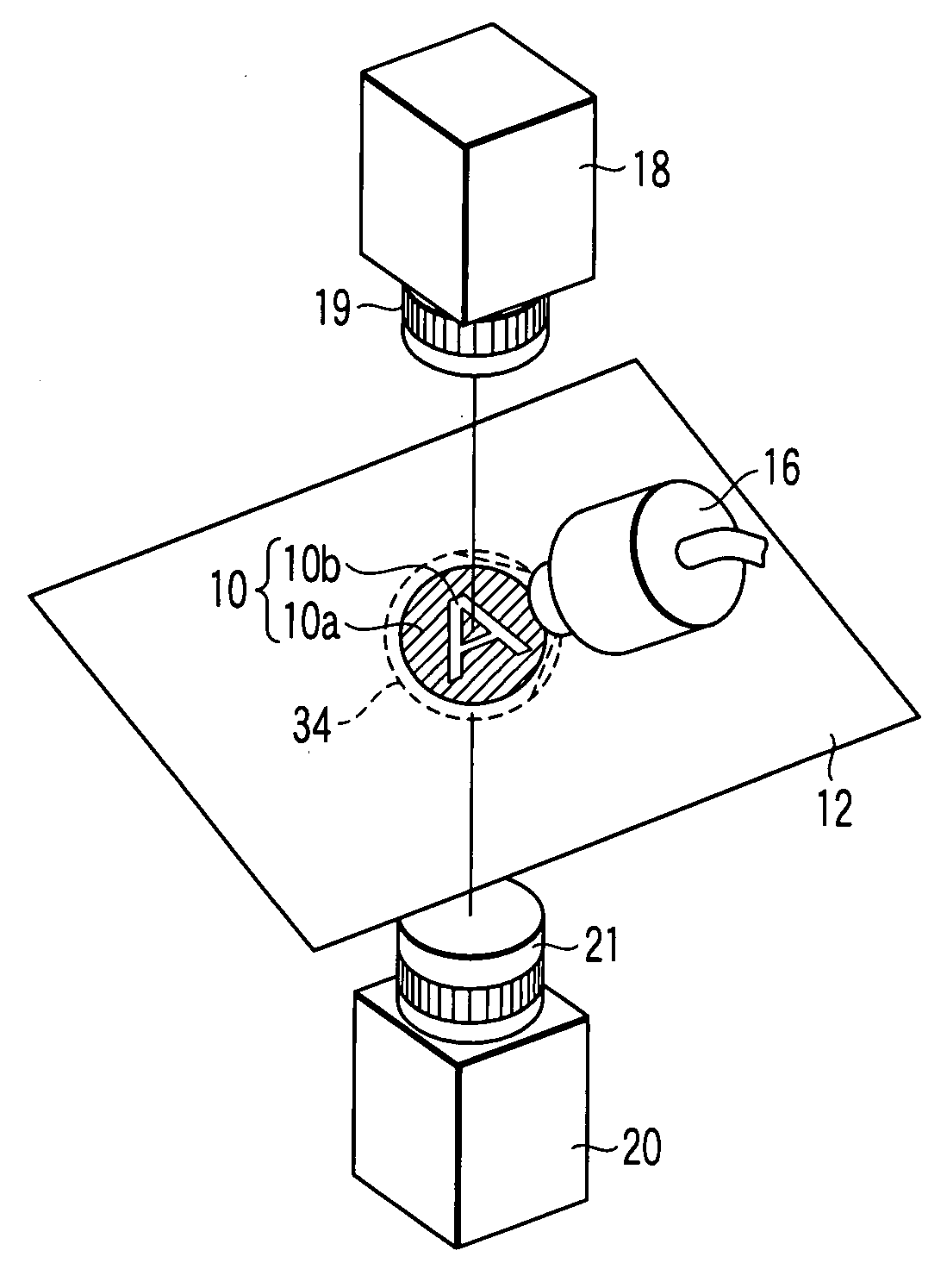

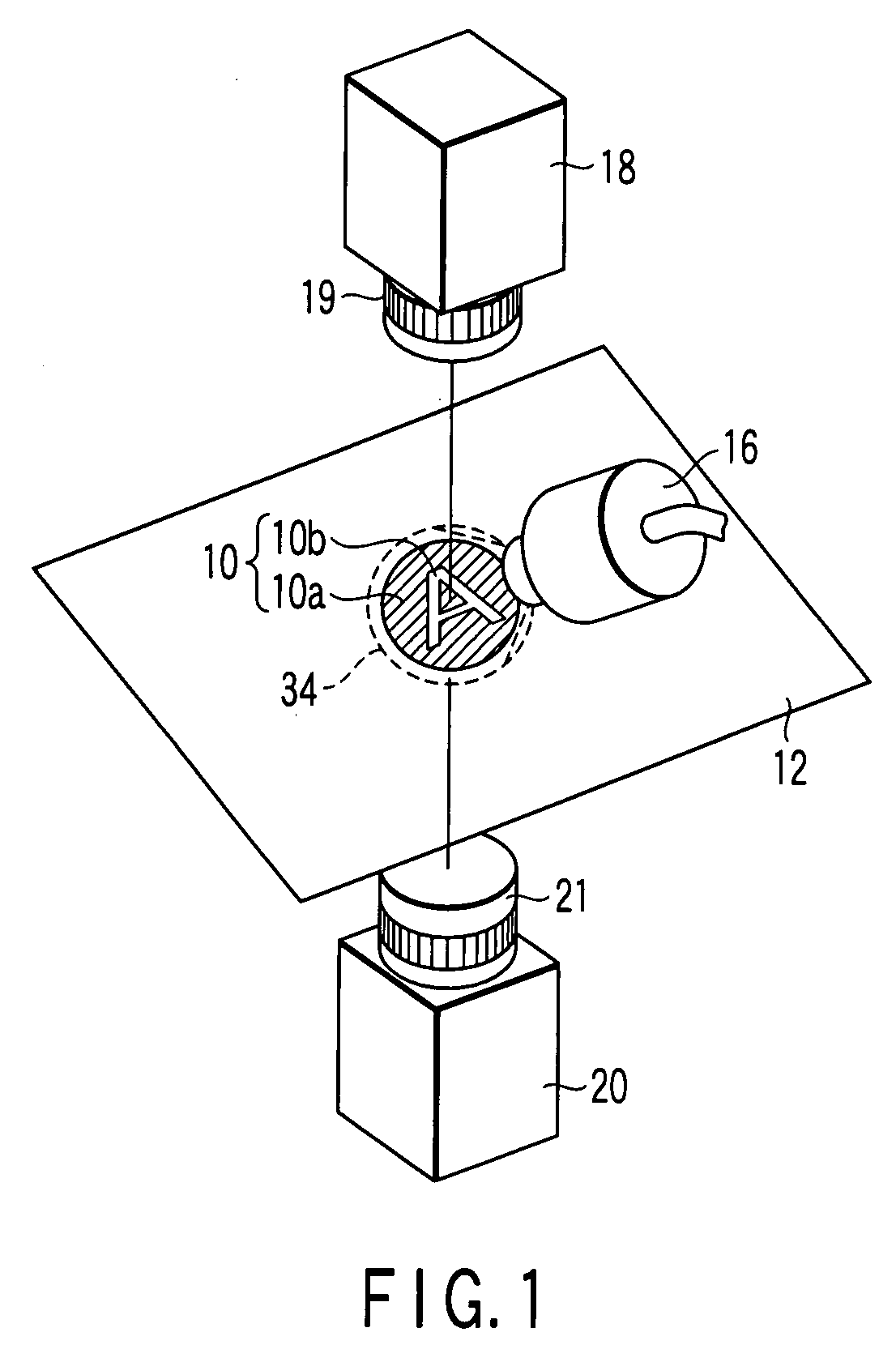

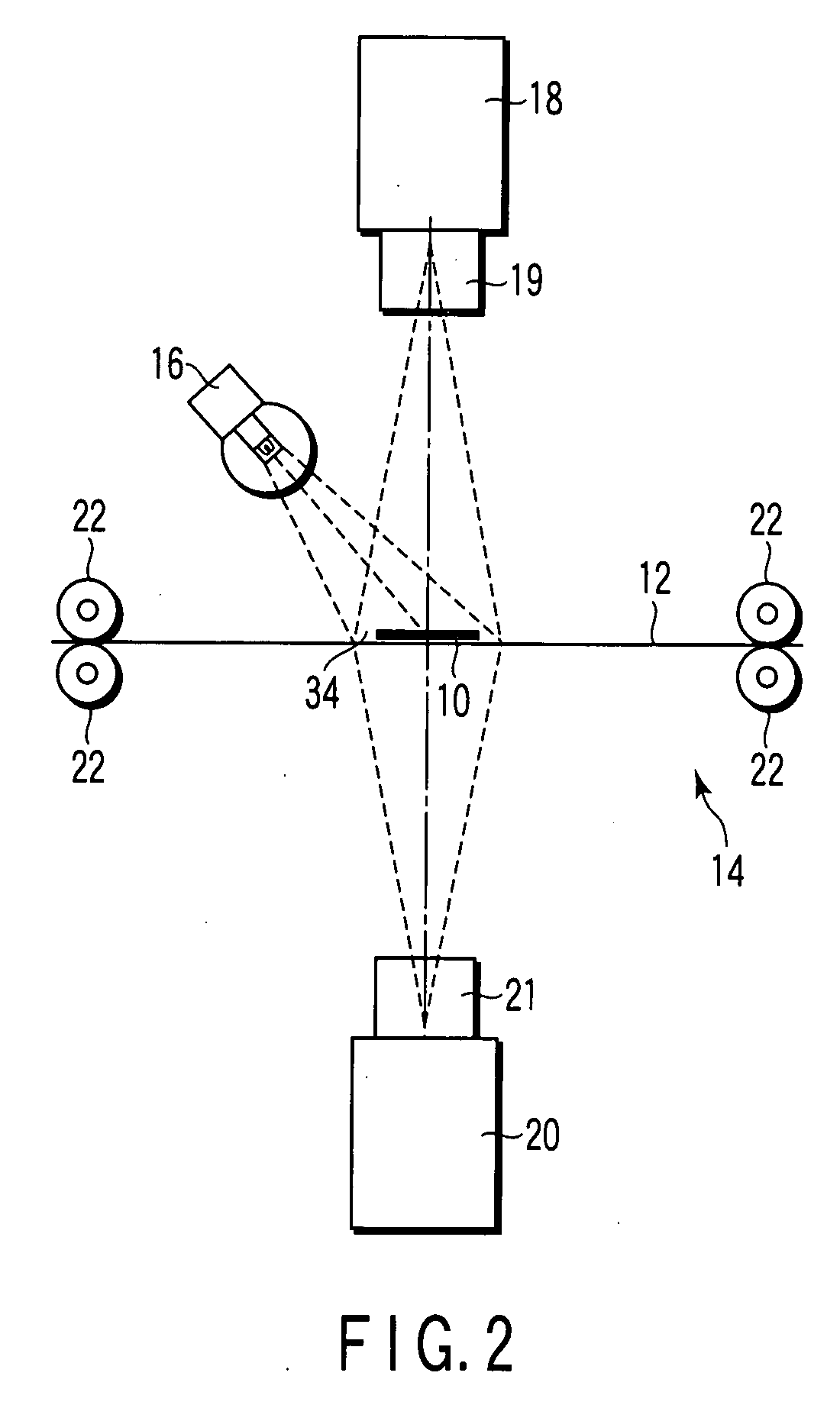

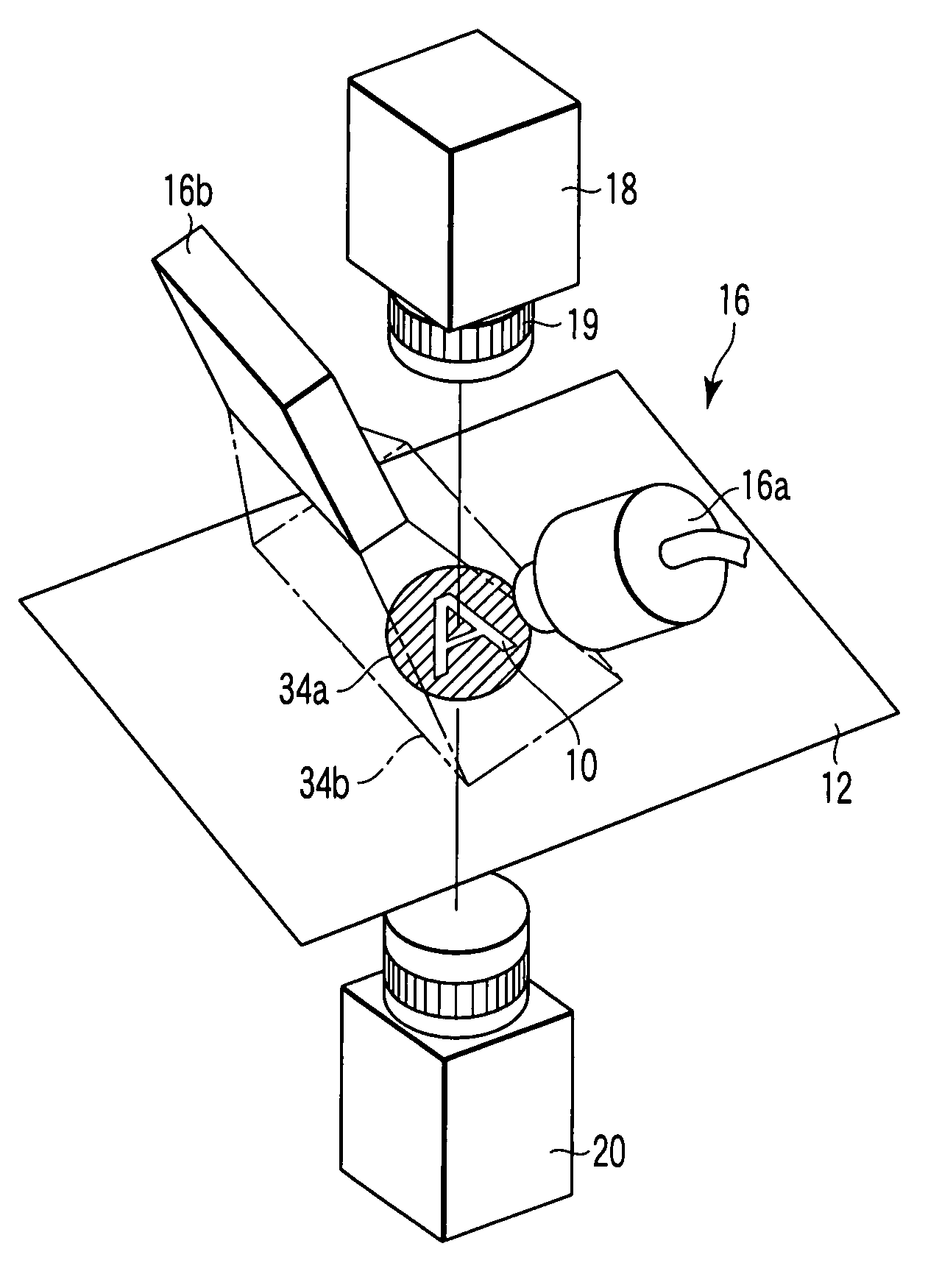

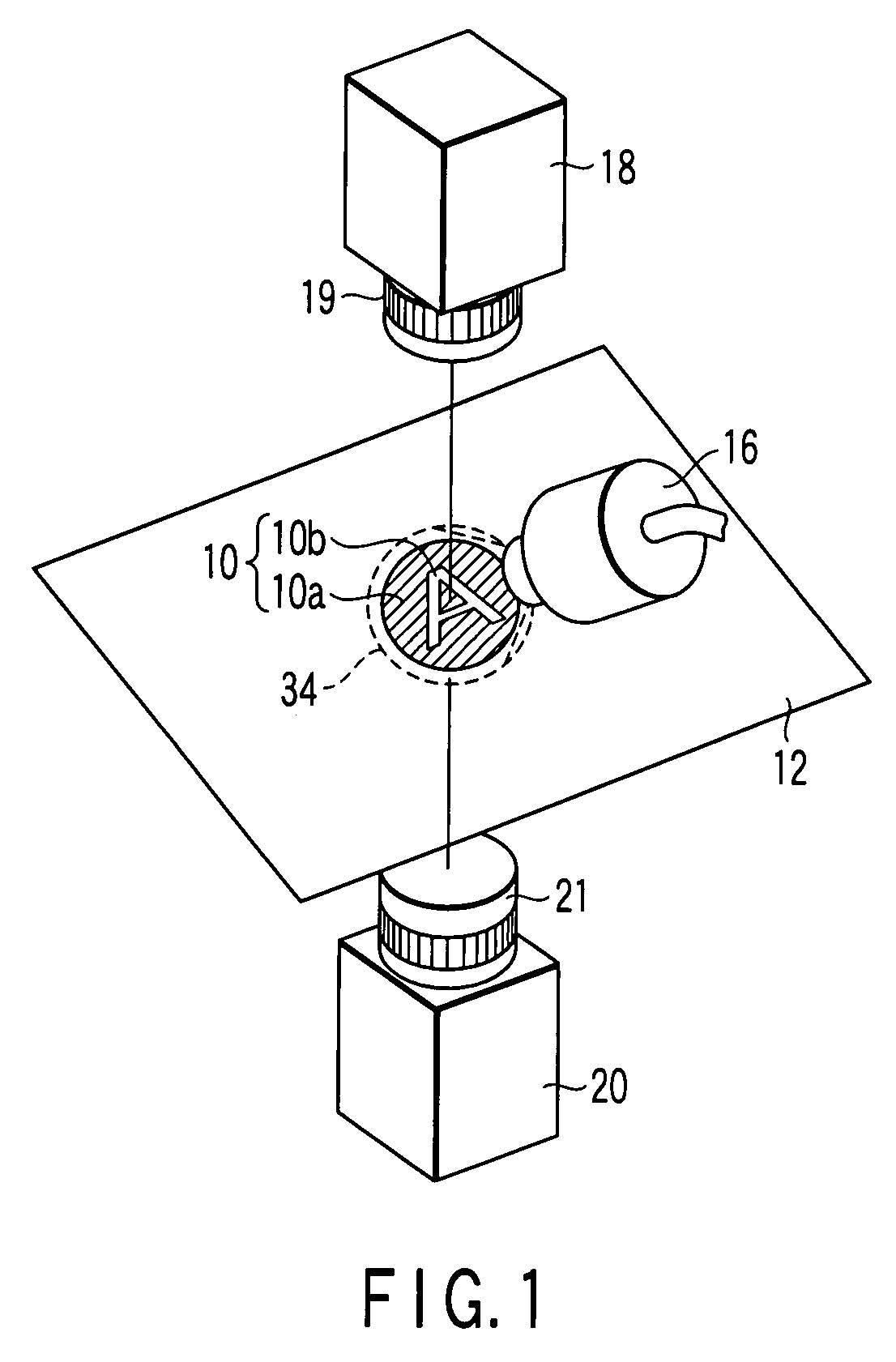

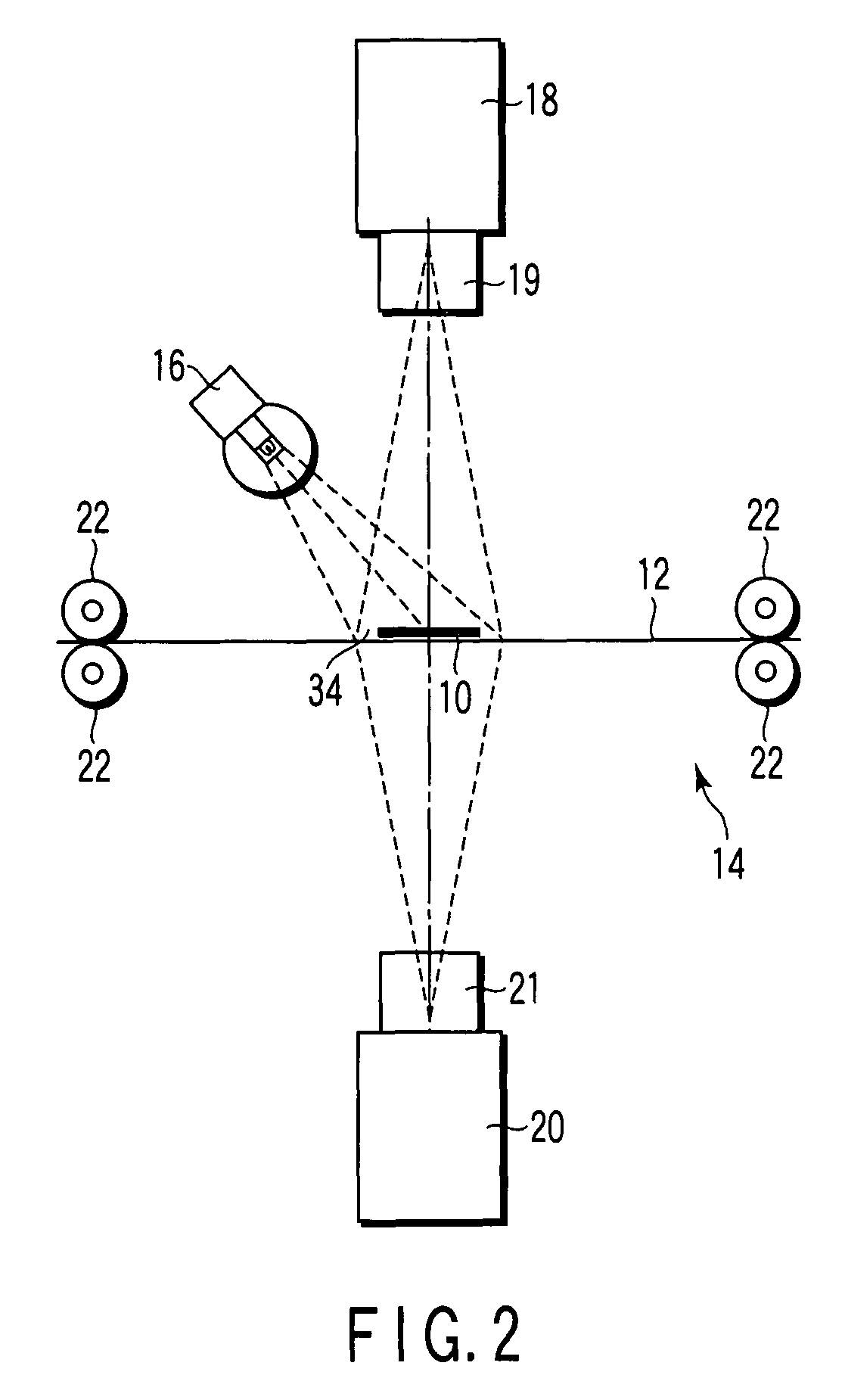

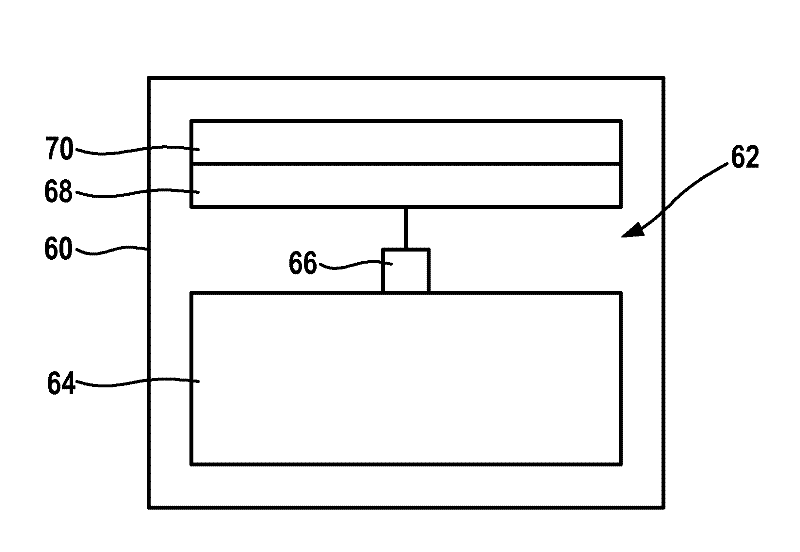

Optical fiber illumination device and inspection apparatus

ActiveUS20070211318A1Stable lightingHigh strengthPaper-money testing devicesHolographic light sources/light beam propertiesTransmitted lightLight source

An inspection apparatus includes a light source unit which irradiates illumination light onto a hologram of a medium from a predetermined direction at which diffraction light from the hologram is obtained, a first light receiving member which receives the diffraction light from the hologram, a second light receiving member which receives transmitted part of illumination light irradiated onto the hologram, having passed through the medium, and an identification processing unit which identifies authenticity of the hologram from the diffraction light received by the first light receiving member and identifies a defect of the hologram from the transmitted light received by the second light receiving member.

Owner:KK TOSHIBA

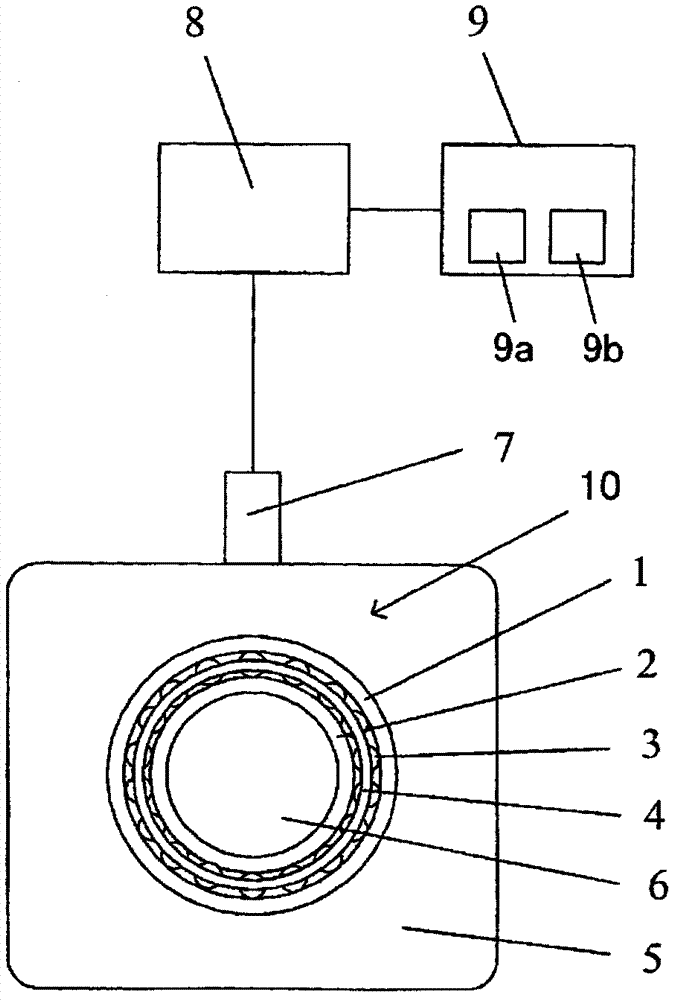

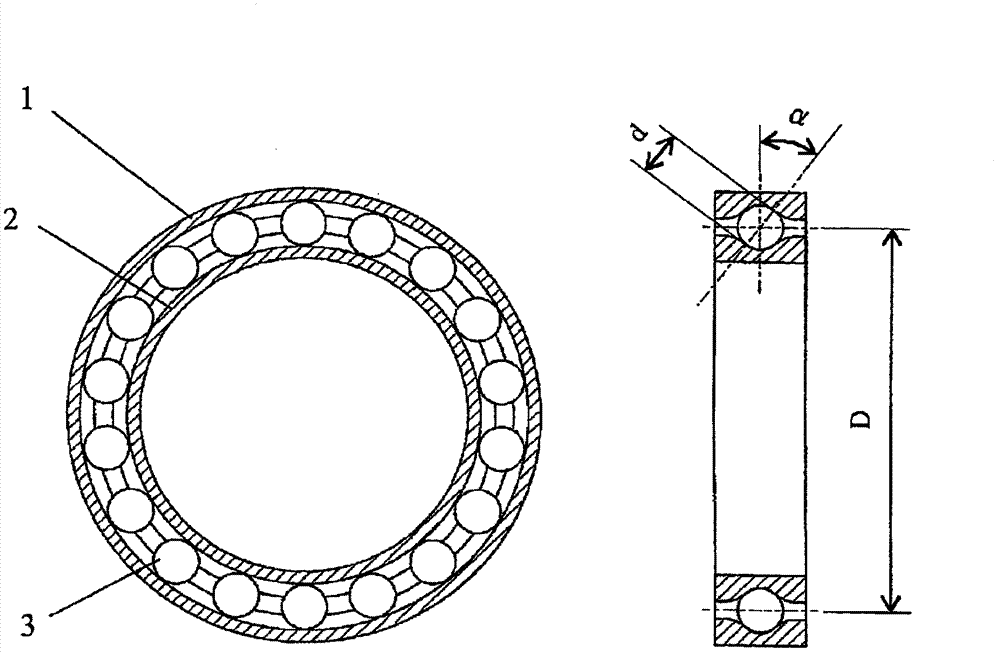

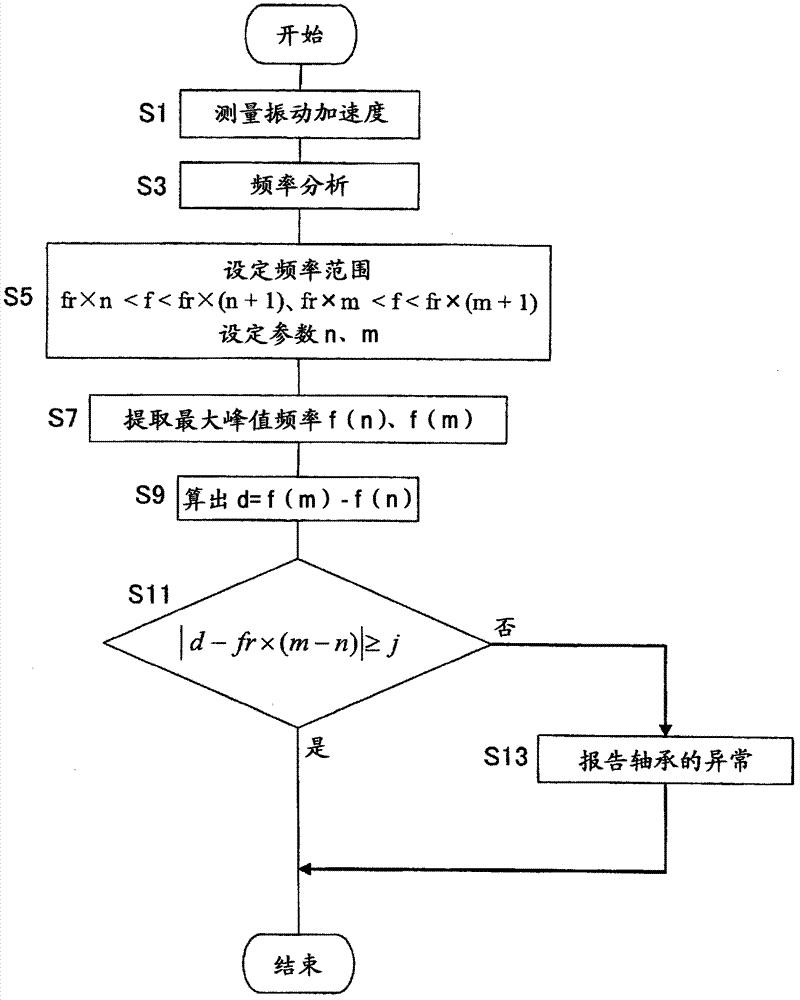

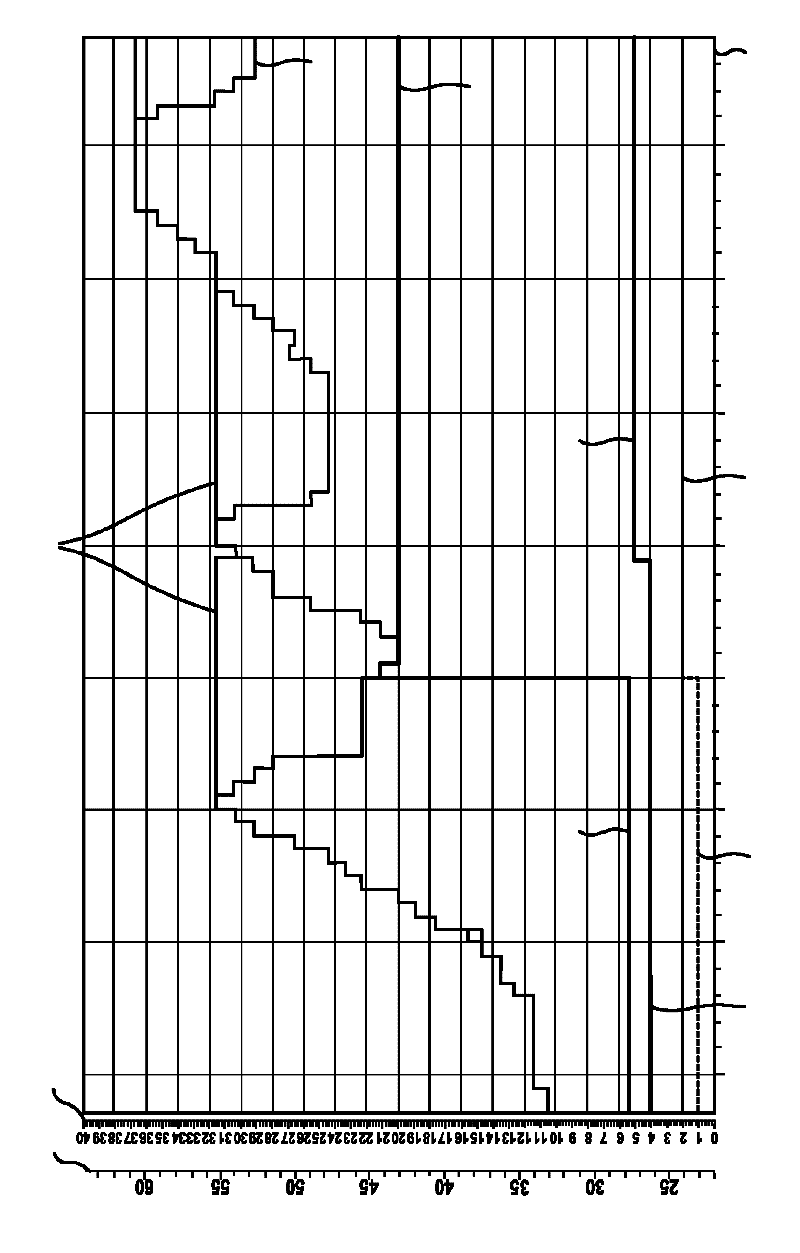

Method for detecting damage of bearing

InactiveCN103026085ADetect damageRolling contact bearingsMaterial analysis using acoustic emission techniquesEngineeringFrequency analysis

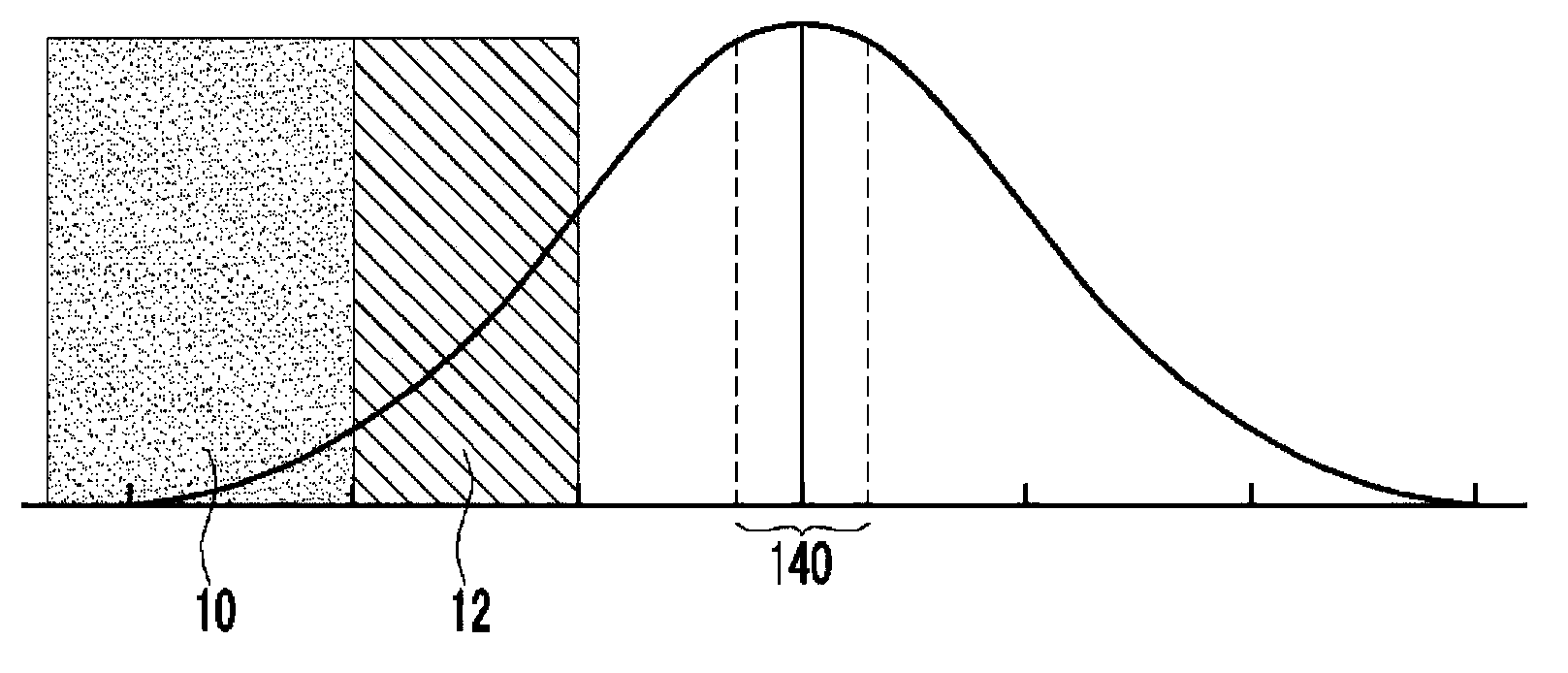

Disclosed is a method for detecting damage to a bearing which comprises an inner ring, an outer ring, a rolling body which rolls while being in contact with the inner ring and the outer ring, and a holder for holding the rolling body, wherein, vibration of the bearing is measured by a sensor while the movable side of the inner ring or the outer ring is rotating, a vibration waveform of the bearing obtained by the measurement by the sensor is subjected to frequency analysis, whether the bearing is damaged is determined on the basis of the result of the frequency analysis, wherein two or more frequency ranges are set so that the ranges do not overlap with each other and have ranges substantially equal to the rotation frequency (fr) of the movable side of the inner ring or the outer ring, peak frequencies are respectively obtained in the set plurality of frequency ranges, the difference between the obtained peak frequencies is compared with the value obtained by k-times the rotation frequency (fr) (k is an integer of 1 or more) to determine whether both compared values can be deemed as a match or not, and if both compared values are deemed to match, the bearing is judged as damaged.

Owner:NIHON KENKI CO LTD

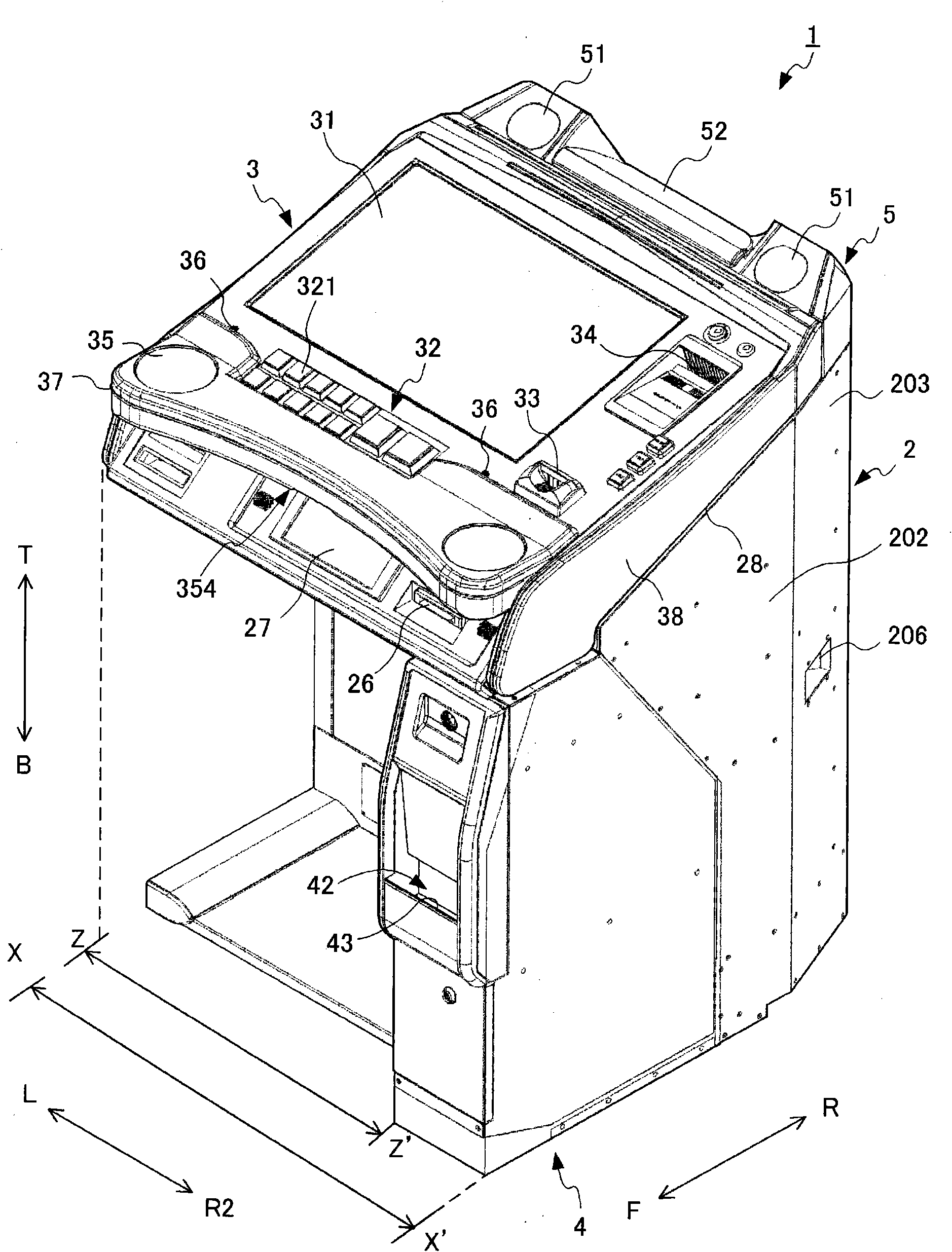

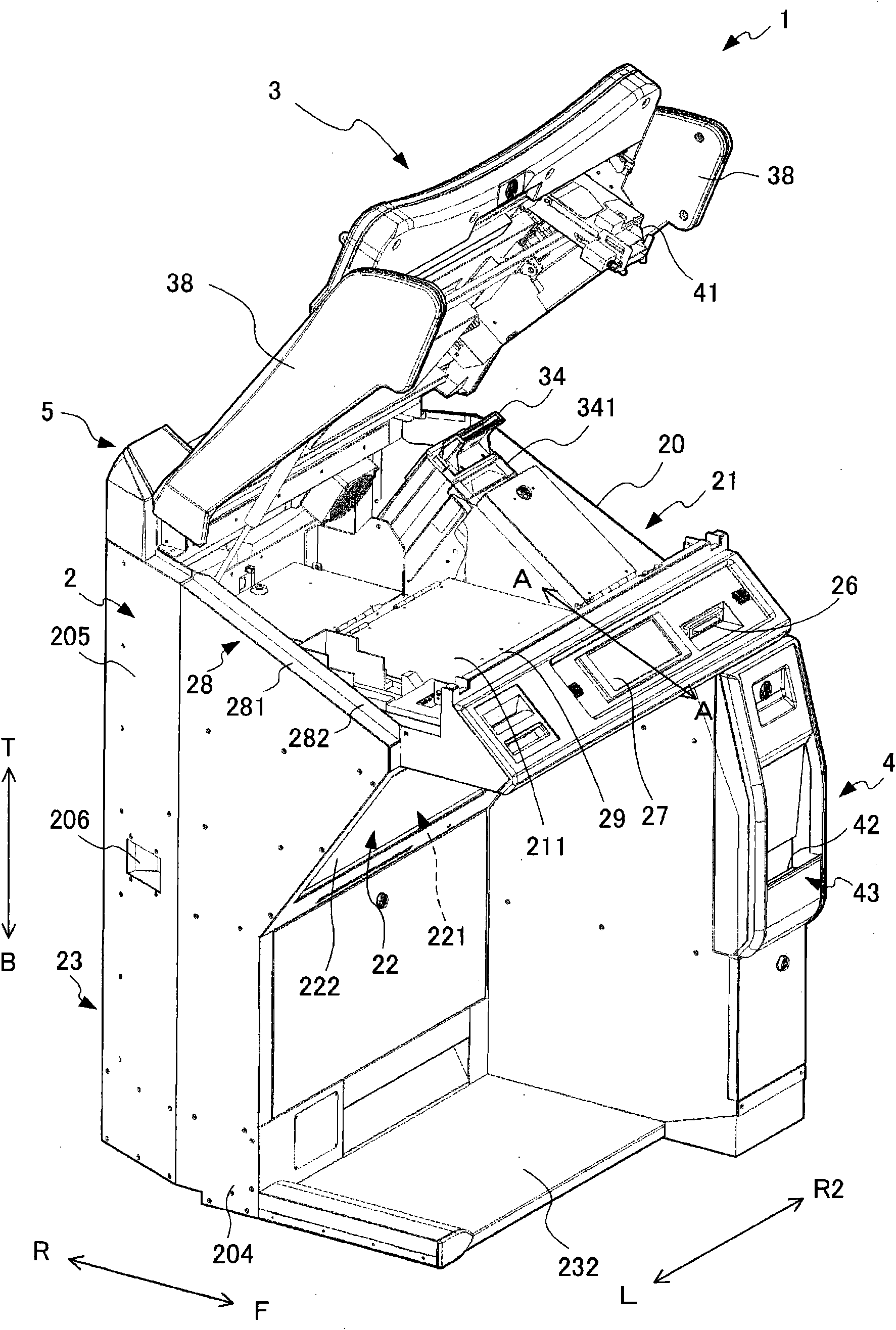

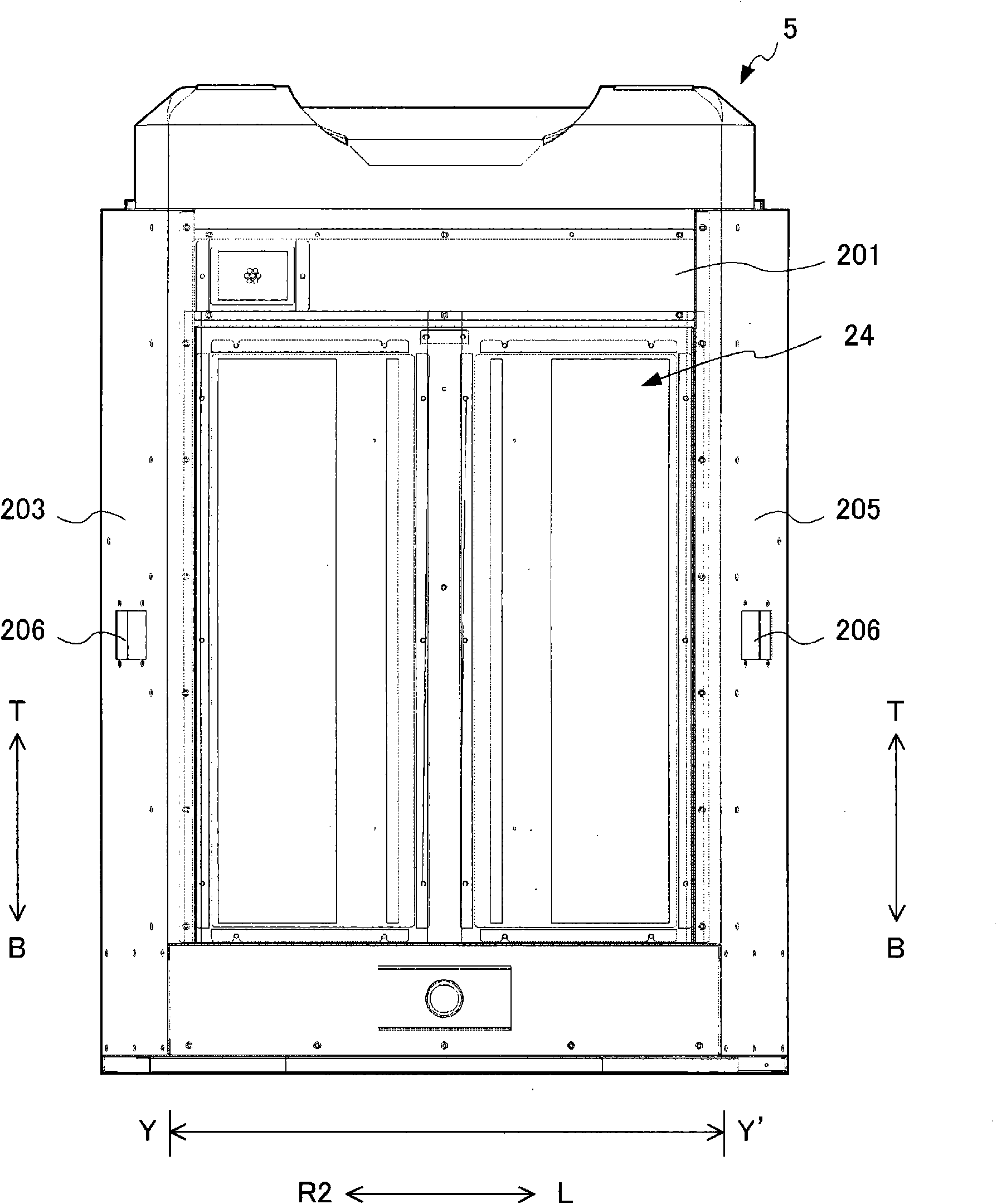

Gaming machine of reduced installation area and improved visibility

InactiveCN102143784ADetect damageCorruption detectedApparatus for meter-controlled dispensingVideo gamesVisibilityEngineering

Provided is a gaming machine having a cabinet. Between the back as a back face and the right side face of the sides of the cabinet, the gaming machine has a right end side, which is formed by cutting a plane parallel to the gravitational direction in a manner to join lines spaced at predetermined distances in the individual directions of the back and the right side face from a line of intersection, on which the back and the right side face intersect when extended. The gaming machine also has a left end side between the back and a left side face. Moreover, the right end side and the left end side are symmetric with respect to a plane dividing the cabinet equally to the right and left.

Owner:ARUZE GAMING AMERICA

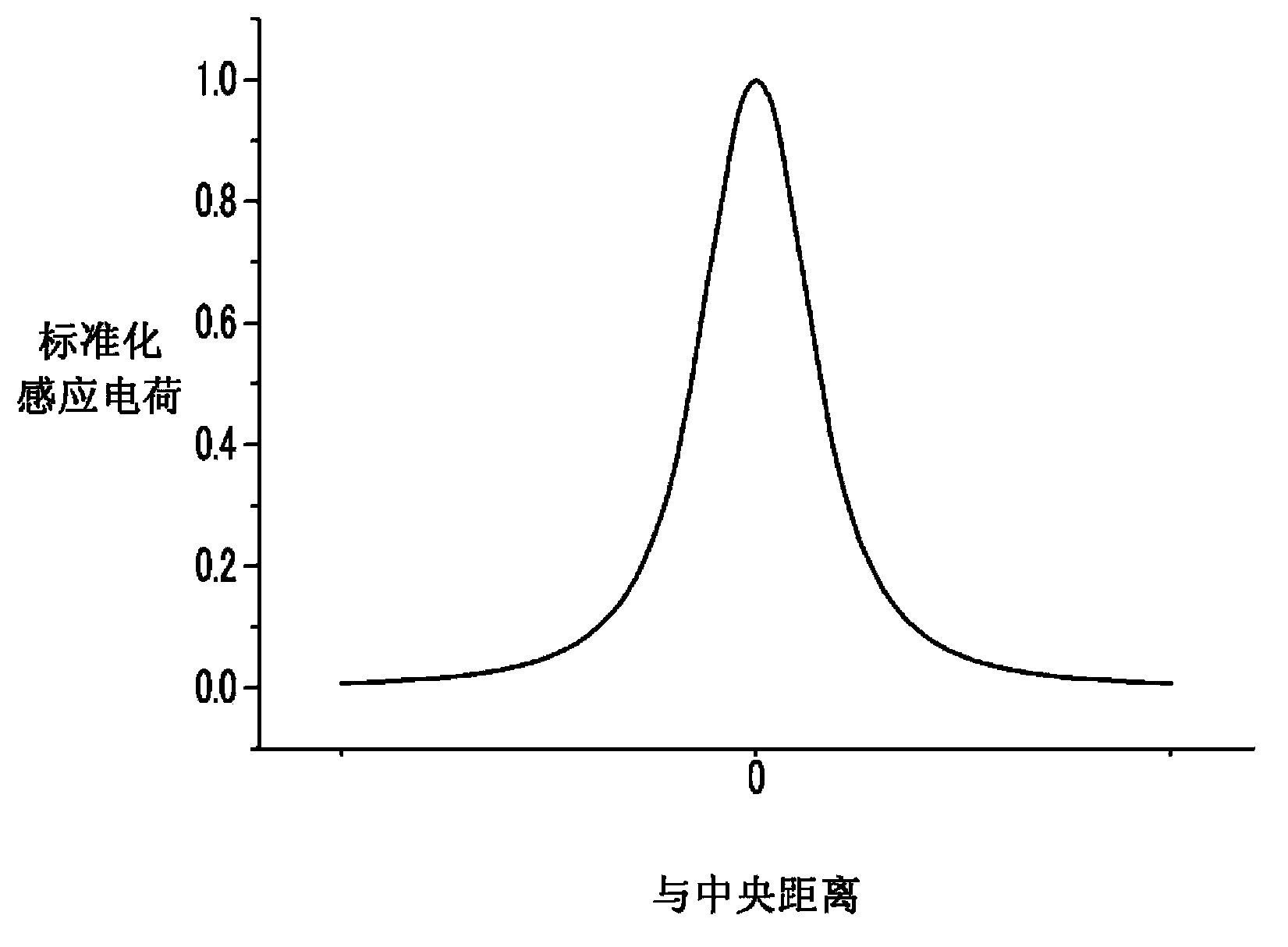

Particulate matter sensor unit

ActiveCN103776752AAccurately detect damageDetect damageExhaust apparatusEngine testingParticulatesLine tubing

Disclosed is a particulate matter sensor unit. A particulate sensor apparatus may include an exhaust line through which exhaust gas flows, and a sensor that may be disposed at one side in the exhaust line and generates electrical charges when a particulate passes near vicinity of the sensor, wherein an electrode portion may be formed on a front surface of the sensor facing the particulate.

Owner:HYUNDAI MOTOR CO LTD +2

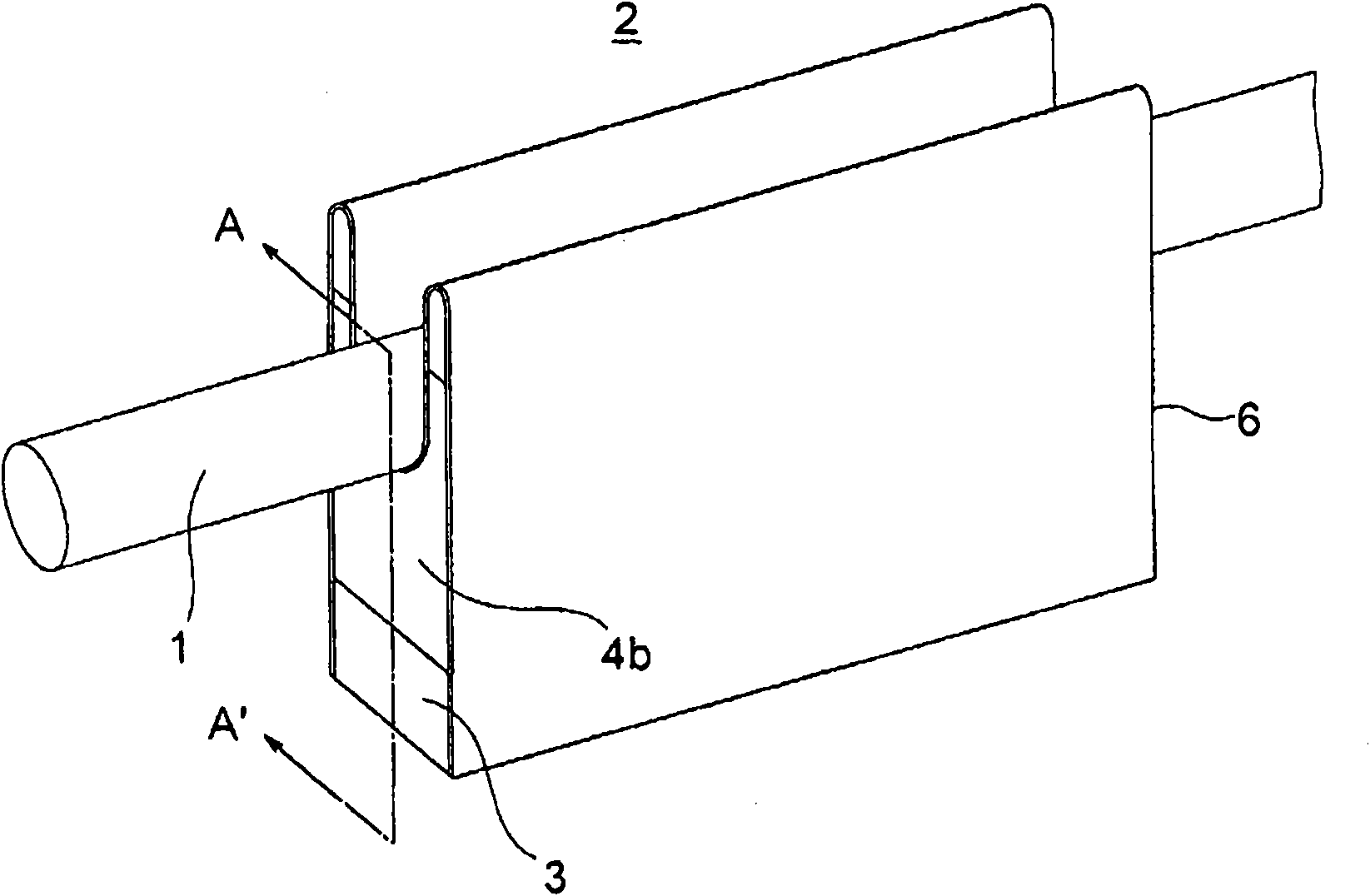

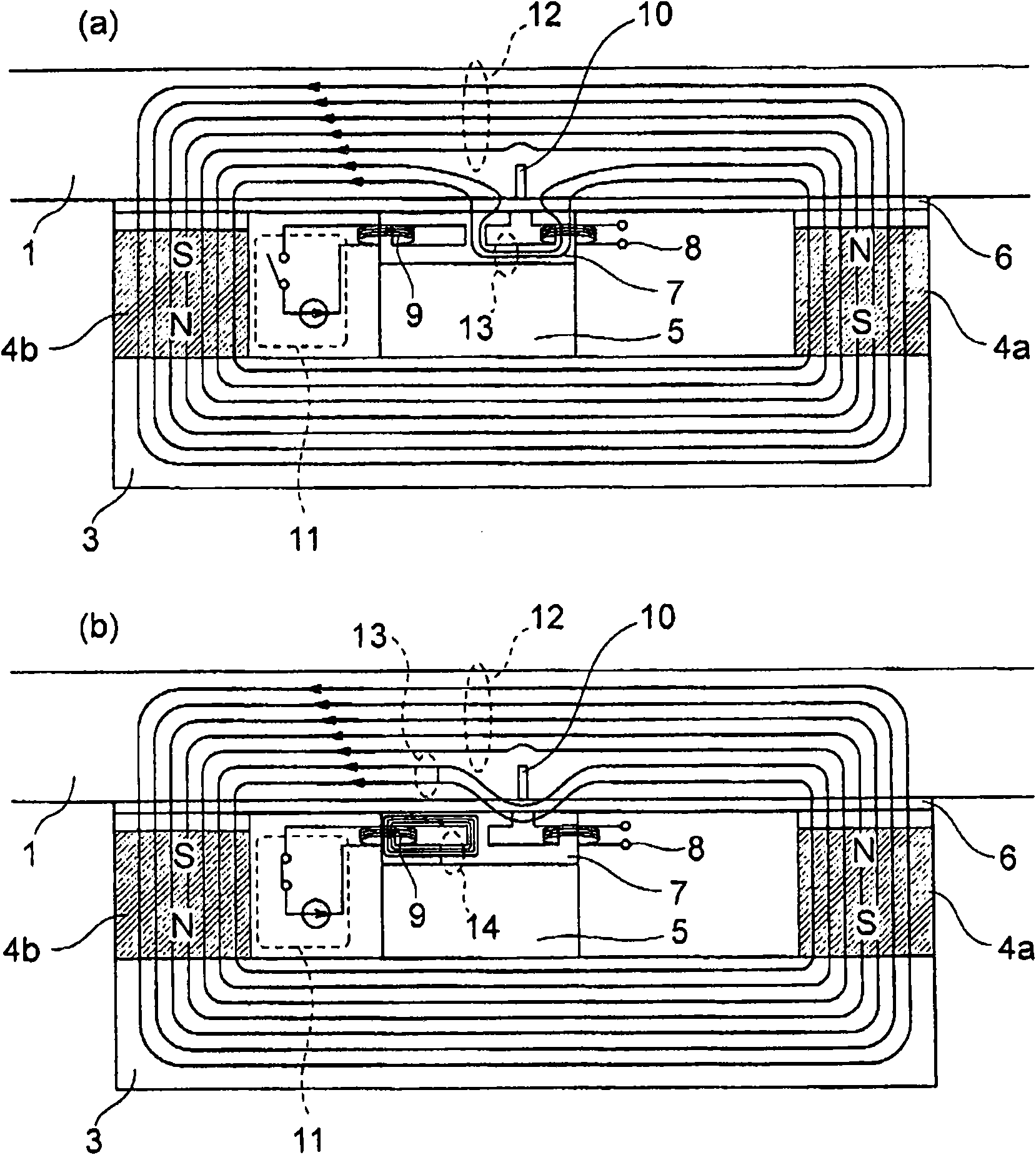

Wire rope flaw detector

ActiveCN101978261ADetect damageAvoid skin effectMaterial magnetic variablesSuperimpositionAmpere-turn

A magnetic flux generated by current excitation is allowed to run over a portion of the magnetic path of a leakage magnetic flux or the entire magnetic path thereof. The amount of the magnetic flux generated by the current excitation is changed in terms of time to change the amount of the leakage magnetic flux crossing a detection coil, an induction voltage is generated in the detection coil, and consequently a flaw can be detected even in the case where there is no relative rate between a wire rope and a wire rope flaw detector. Further, the shape of the magnetic path and the number of ampere turns of the exciting coil are set to be appropriate to prevent the magnetic flux generated by the current excitation from running through the detection coil and make the magnetic flux get balanced out. Thus, noise superimposition to the detection coil generated by current excitation can be prevented.

Owner:MITSUBISHI ELECTRIC CORP

Optical fiber illumination device and inspection apparatus

ActiveUS7839547B2Stable lightingHigh strengthPaper-money testing devicesHolographic light sources/light beam propertiesTransmitted lightLight source

Owner:KK TOSHIBA

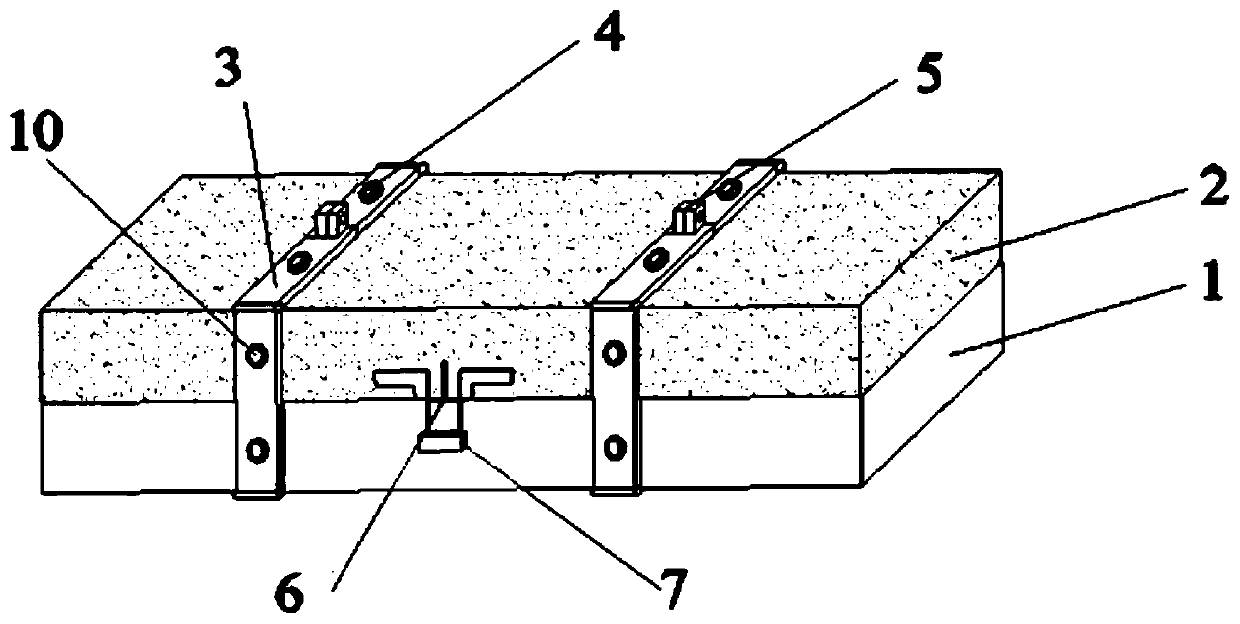

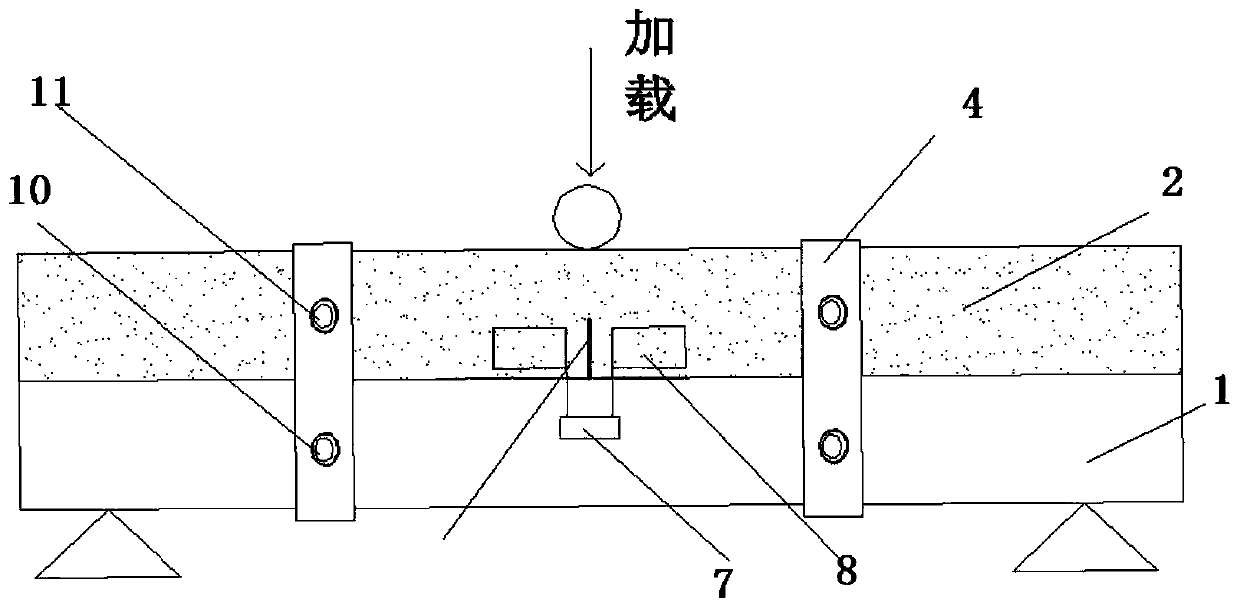

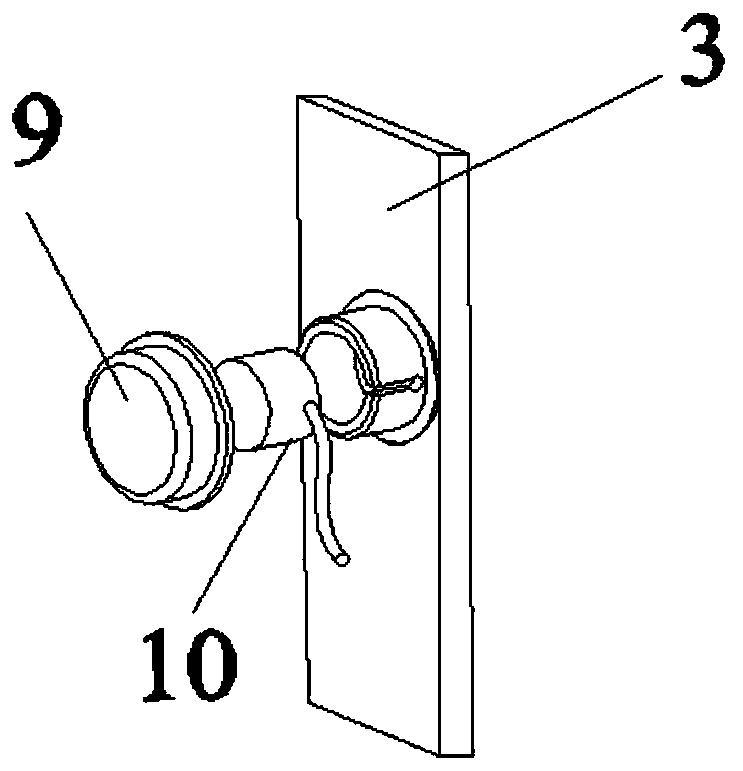

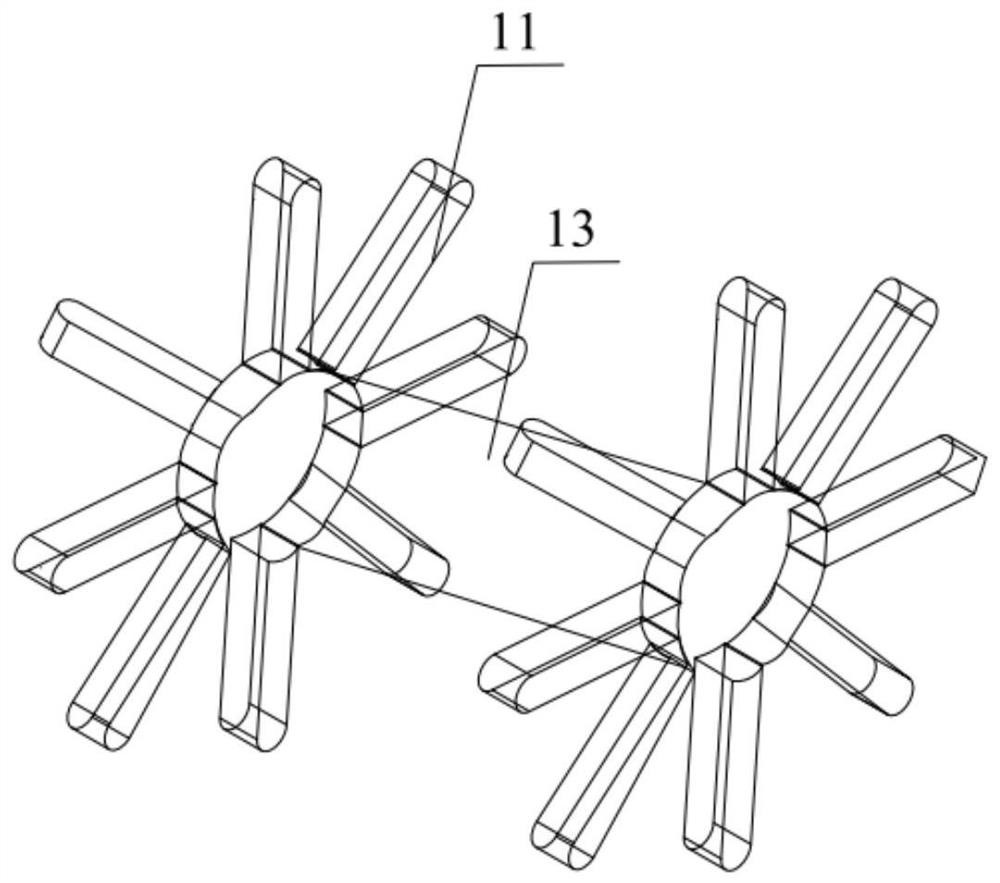

A wheeled pipeline robot with controllable driving wheel steering

InactiveCN106015831BPass smoothly and efficientlyCompact structurePigs/molesSteering wheelDrive wheel

The invention relates to a wheel type pipeline robot with steering of driving wheels being controllable. The wheel type pipeline robot with steering of the driving wheels being controllable mainly consists of two front elastic arm units, two rear elastic arm units and a robot body. Driving motors are arranged on the two front elastic arm units separately to drive the robot to move forward or backward. The robot can pass through a bent pipeline efficiently and stably by differential speed control. A driving wheel steering and reversing mechanism is arranged in the robot body and the attitude of the robot in a pipeline can be adjusted rapidly by adjusting the included angles between the four driving wheels and the section of the pipeline simultaneously. The pipeline robot is simple in structure and capable of self-adaption of a tiny change of a pipe diameter and rapid adjustment of the attitude of the robot in the pipeline; furthermore, the pipeline robot has an obstacle crossing ability for efficiently and stably passing through the complicated pipeline such as the bent pipeline and a reducing pipeline with the best attitude angle, so that the normal inspection and maintenance of the pipeline can be guaranteed.

Owner:HEFEI UNIV OF TECH

Method for determining a state of at least one component of a control unit

InactiveCN102246051ADetect damageRealize the testProgramme controlRegistering/indicating working of machinesComputer scienceControl equipment

The invention relates to a method for determining a state of at least one component of a control unit, wherein a temperature of the at least one component is determined, wherein a type of a temperature change is detected and recorded for a number of temperatures that are determined over a time period, wherein recorded temperature changes are used to determine the state. The invention further relates to an arrangement for determining a state of at least one component of the control unit, a control unit, a computer program, and a computer program product.

Owner:ROBERT BOSCH GMBH

Electrochemical judgment method of fire-damaged concrete reinforcement damage

InactiveCN107064246ADetect damageImprove detection efficiencyMaterial electrochemical variablesData acquisitionEngineering

The invention discloses an electrochemical judgment method of fire-damaged concrete reinforcement damage. The method comprises the steps as follows: (1) preparation of a test piece; (2) simulation of a fire damage test; (3) electrochemical detection and data acquisition; (4) data analysis and damage evaluation. Test study is conducted on fire-damaged concrete reinforcement damage according to the basic principle of electrochemical detection of reinforcement corrosion on the basis of three electrochemical elements, an electrochemical criterion of the fire-damaged concrete reinforcement damage is established, and then, diagnostic assessment is performed on actual fire-damaged concrete structures by use of the criterion and an auxiliary analysis model.

Owner:TAIYUAN UNIV OF TECH

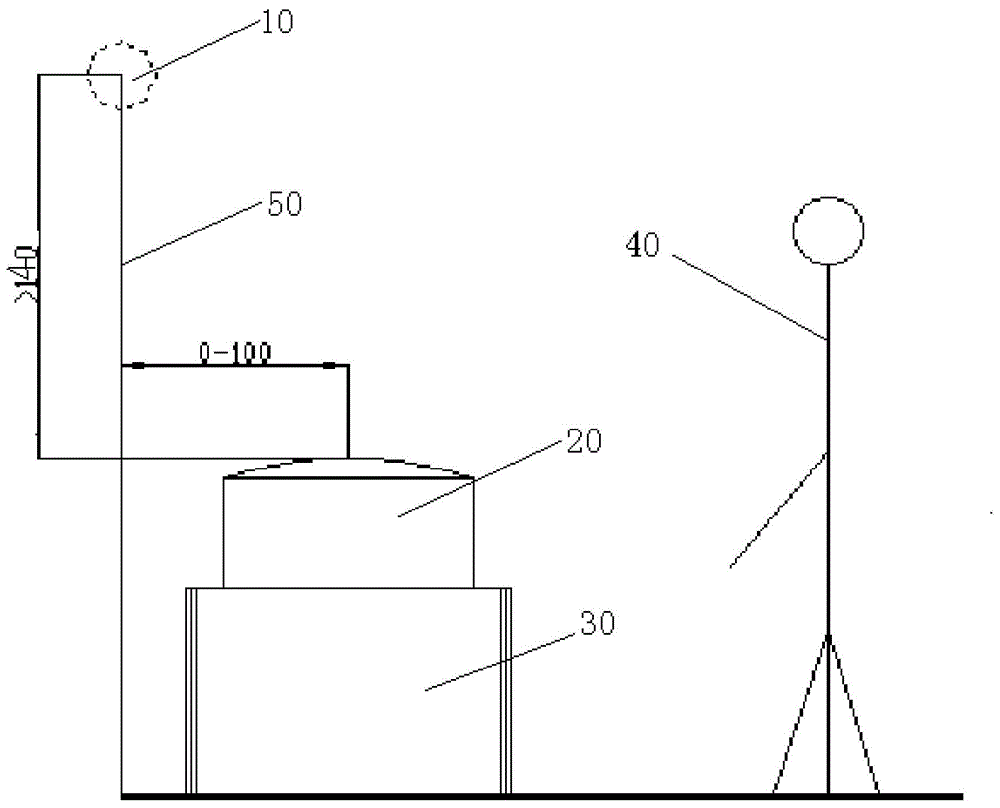

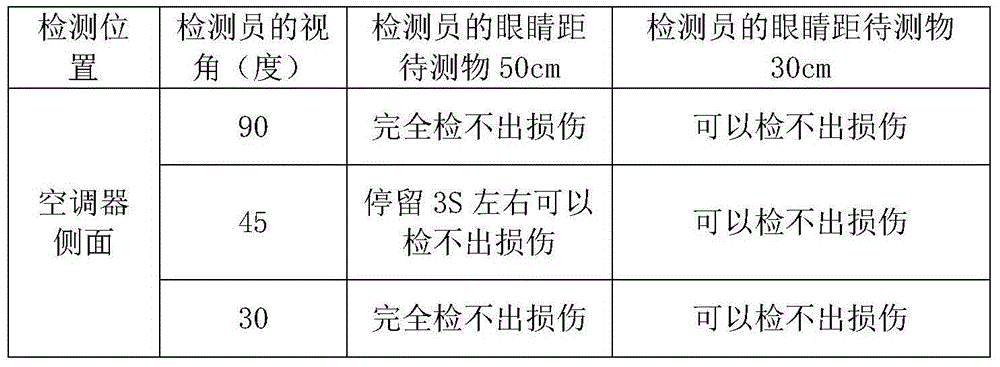

Appearance inspection method

InactiveCN104677915ADetect damageEasy to observe damageOptically investigating flaws/contaminationIlluminanceLight source

The invention provides an appearance inspection method. The appearance inspection method comprises the following steps: a pretreatment step: detecting intensity of illumination on the outer surface of an object to be inspected, and regulating a light source according to the intensity of illumination to enable the intensity of illumination of the object to be inspected to reach a preset value; an inspection step: observing the object to be inspected to check whether the appearance of the object to be inspected is damaged. According to the appearance inspection method disclosed by the invention, before inspection of the appearance of the object to be inspected, the pretreatment step is conducted to regulate the intensity of indoor illumination to the preset value; under the preset intensity of illumination, whether the appearance of the object to be inspected is damaged can be observed conveniently, further the appearance damage situation of the object to be inspected can be inspected quickly and accurately, and the inspection rate of the appearance of the object to be inspected can be increased.

Owner:GREE ELECTRIC APPLIANCES INC

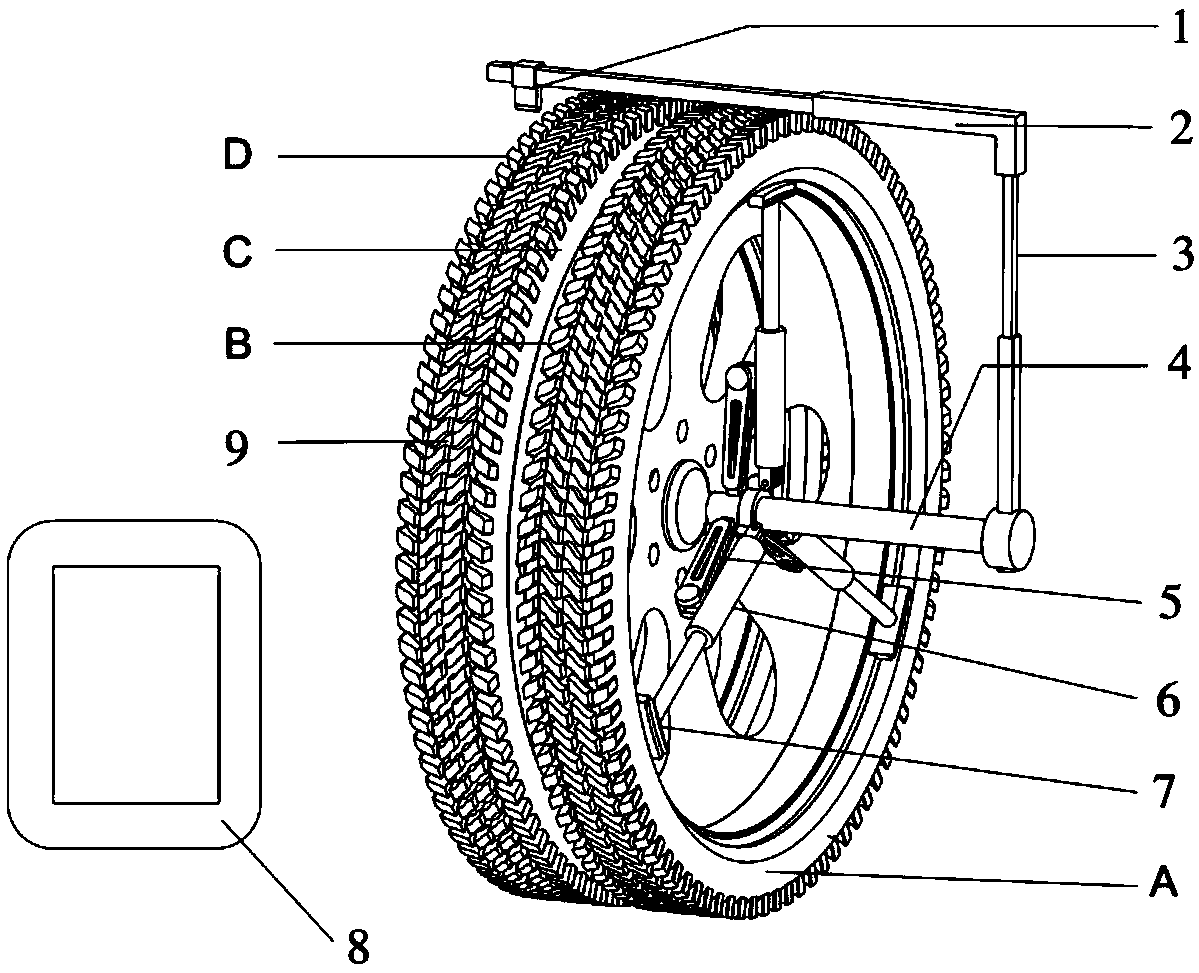

Portable dual wheel tire inner treads detection device and detection method

PendingCN109540922AEasy to carryReduce traffic accidentsOptically investigating flaws/contaminationVehicle tyre testingEngineeringSelf locking

The invention relates to a portable dual wheel tire inner treads detection device and detection method. The detection device comprises a mini camera, a horizontal self-locking telescopic rod, a vertical self-locking telescopic rod, a locking pull rod, a support rod, a pen type electric push rod, an anti-slip rubber mat, and a terminal display device. The detection device positions through a wheelhub clamping device, collects images of dual wheel tire inner treads, and displays images on the terminal device through methods of wireless data transmission and image splicing, so as to rapidly detect whether the dual wheel tire inner treads are scratched or damaged. The detection device is suitable for detecting dual wheel tire inner treads of different sizes and models, completes detection rapidly and accurately, and breaks limitation that a traditional detection method cannot be used universally and has a detection dead zone. The device has a compact structure, is convenient to operate, can be carried along with a vehicle, and allows a car owner to detect dual wheel tire inner treads independently any time any place.

Owner:JILIN UNIV

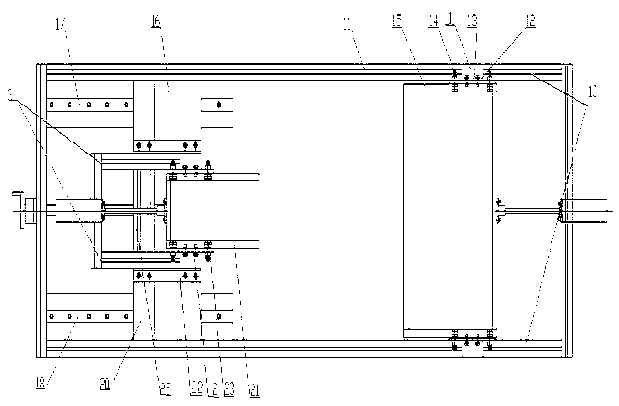

Testing machine for detecting child tricycle falling performance

The invention relates to a testing machine for detecting child tricycle falling performance. The testing machine comprises a bottom portion framework, a front wheel disengaging mechanism, a back wheel disengaging mechanism, a child tricycle front wheel supporting plate, and a child tricycle back wheel supporting plate, wherein the right end of the bottom portion framework is connected with a right vertical aluminum section and the left end of the bottom portion framework is connected with a left vertical aluminum section through a lead screw and a nut. The middle portion of the right vertical aluminum section and the middle portion of the left vertical aluminum section are respectively connected with the back wheel disengaging mechanism and the front wheel disengaging mechanism through a right horizontal aluminum section and left horizontal aluminum section. The front wheel disengaging mechanism and the back wheel disengaging mechanism are connected with the child tricycle front wheel supporting plate and the child tricycle back wheel supporting plate. During a testing process, the child tricycle front wheel supporting plate and the child tricycle back supporting plate are stretched out through the movement of the front wheel disengaging mechanism and the back wheel disengaging mechanism, a cart is placed on the supporting plates which are stretched out, then a supporting plate of a front wheel and supporting plates of back wheels retract backwards at the same time, and due to the fact that the front wheel of a child tricycle and the back wheels of a baby tricycle are not supported, the three wheels fall onto the ground under the action of gravity, so that a once dropping test is achieved.

Owner:SHANGHAI UNIV

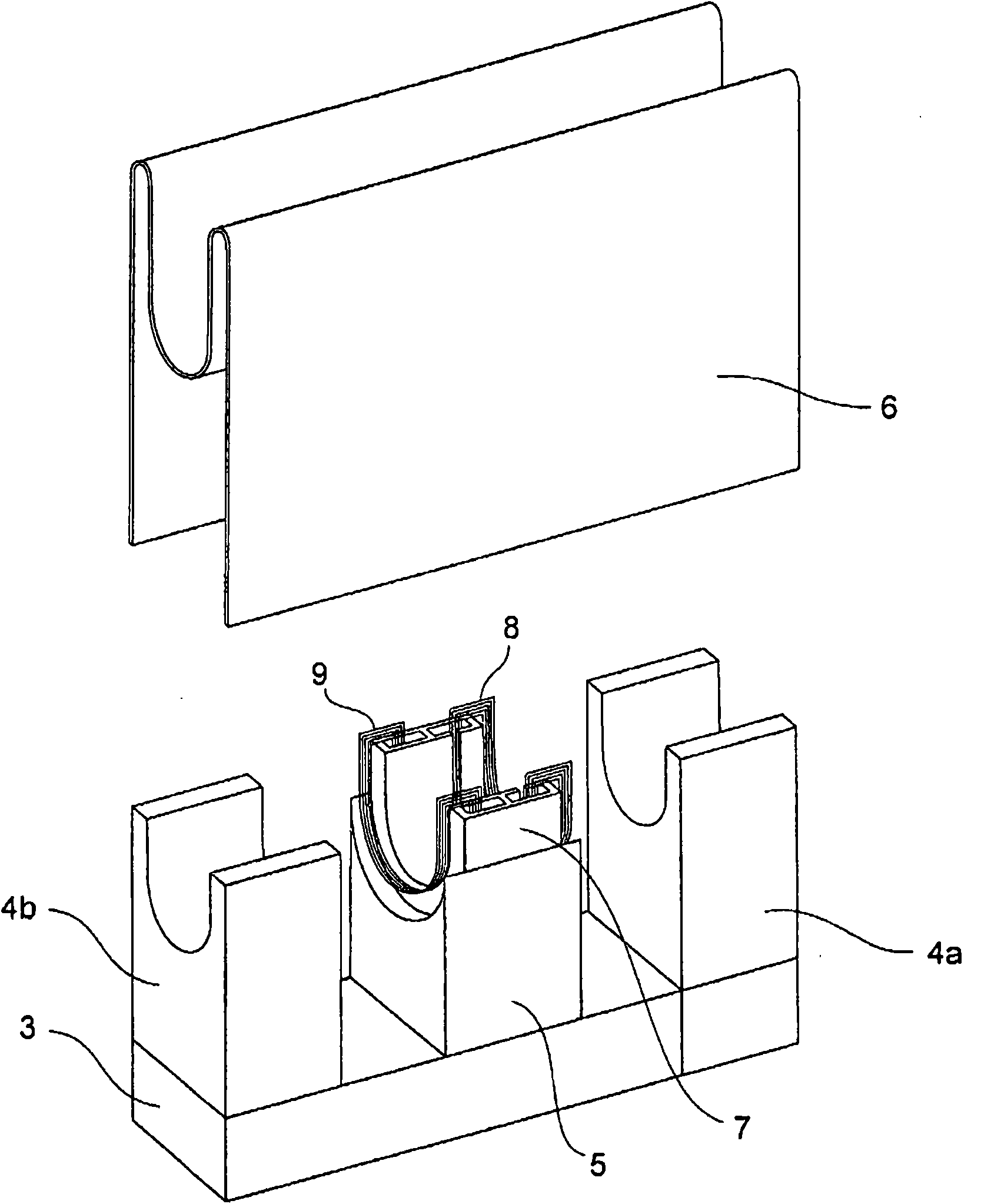

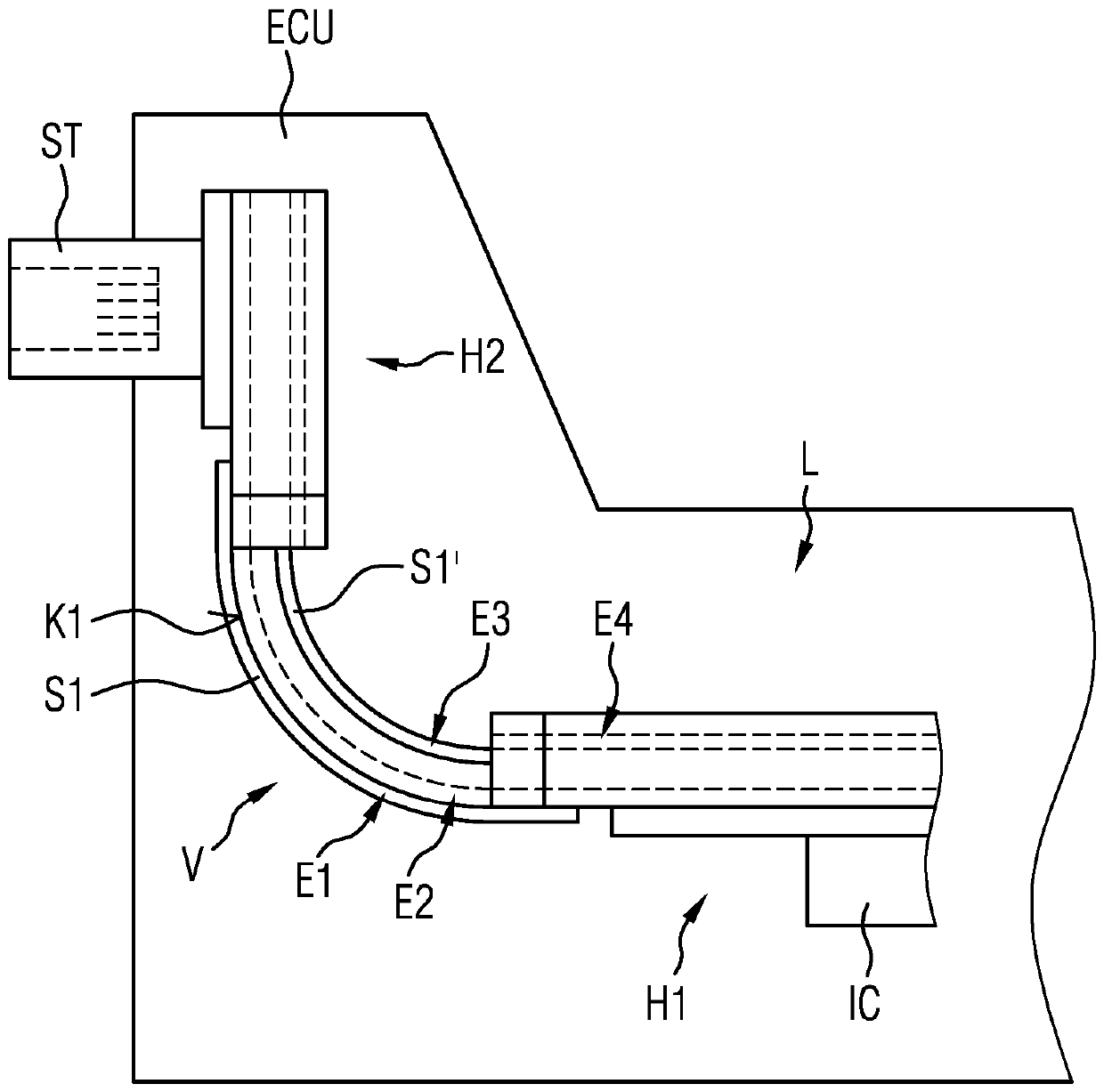

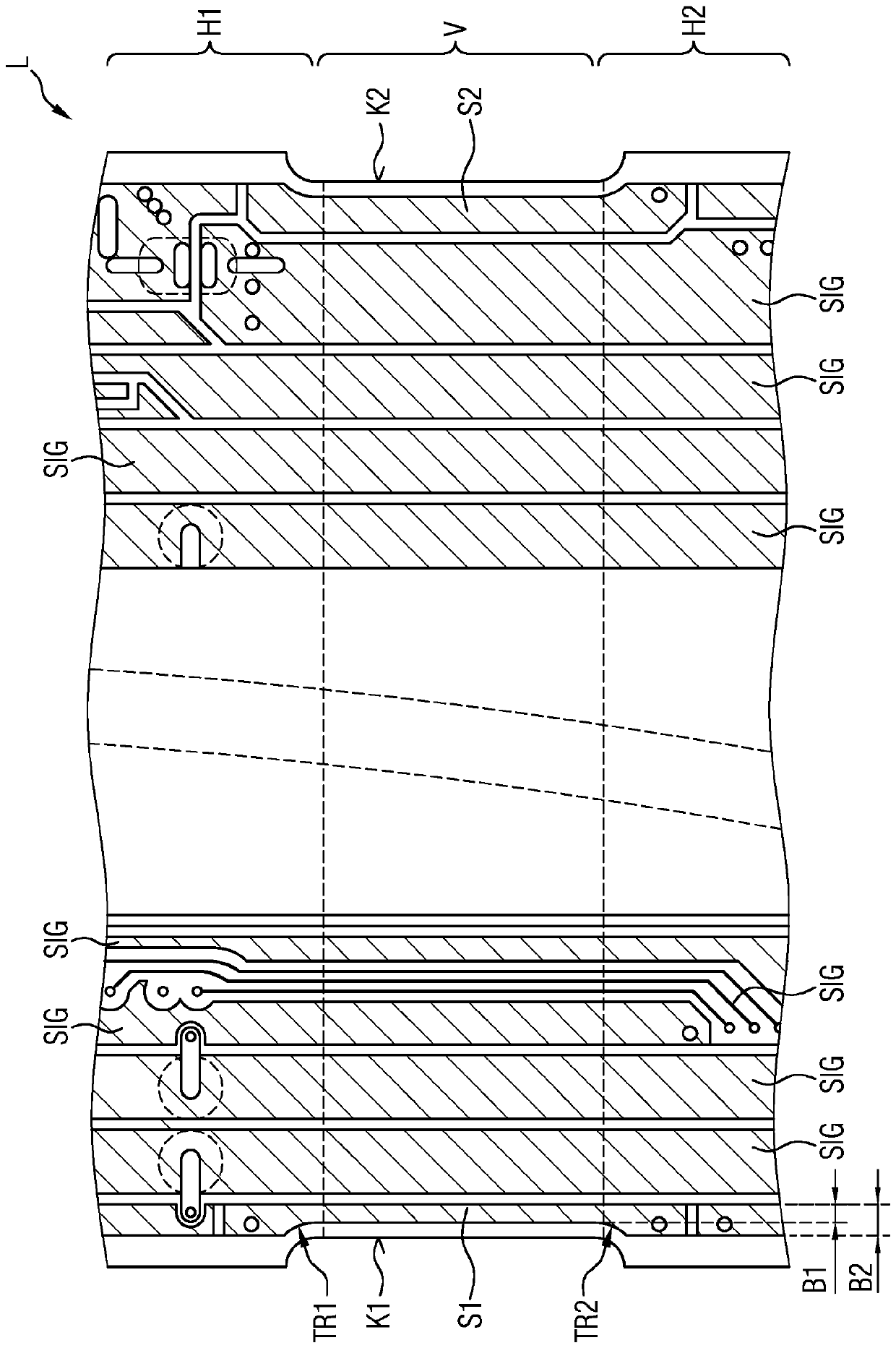

PRINTED CIRCUIT BOARD WITH BENT CONNECTING SECTION AND METHOD FOR TESTING or PRODUCING SAID PRINTED CIRCUIT BOARD, AND ALSO ELECTRONIC CONTROL UNIT AND METHOD FOR OPERATING SAID ELECTRONIC CONTROL UNIT

ActiveCN109863415ADetect damageSignal transmission is not affectedCircuit bendability/stretchabilityElectronic circuit testingElectrical conductorEngineering

The invention specifies a method for testing a printed circuit board (L), in which method a printed circuit board (L) is provided with a first main section (H1), a second main section (H2), a bent connecting section (V) and at least one monitoring conductor track (S, S1', S2). The connecting section (V) is arranged between the first main section (H1) and the second main section (H2). The monitoring conductor track (S, S1', S2) runs from the first main section (H1), in a curved manner through the connecting section (V), to the second main section (H2). At least one electrical measurement valuewhich is representative of the integrity of the at least one monitoring conductor track (S, S1', S2) is detected in the method. In addition, a printed circuit board (L), a control unit (ECU), and alsomethods for producing the printed circuit board (L) and for operating the control unit (ECU) are specified.

Owner:VTESCO TECH GMBH

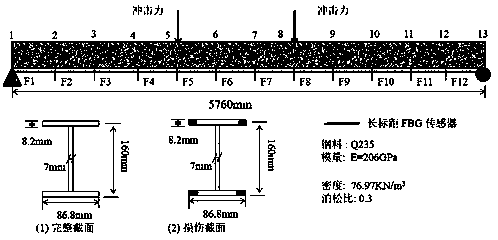

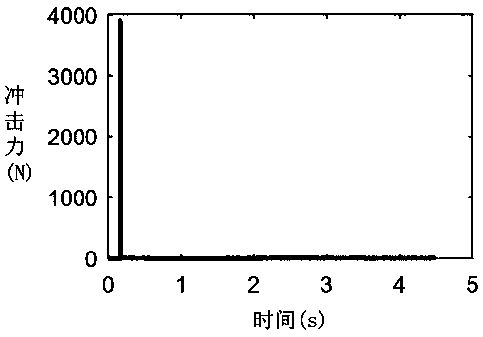

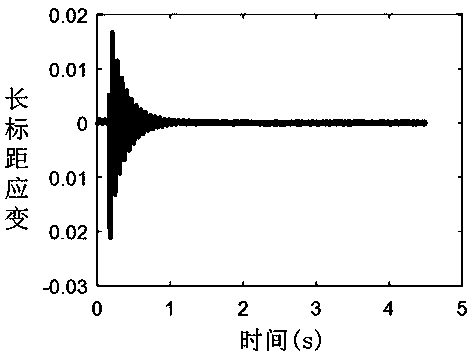

Structure corrosion two-stage detection method and system based on rapid vibration testing

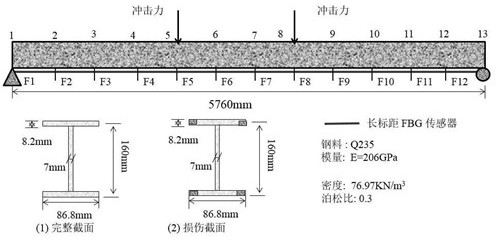

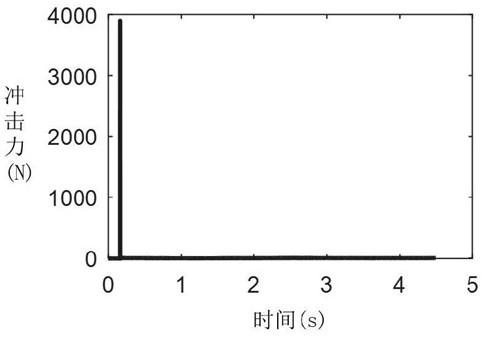

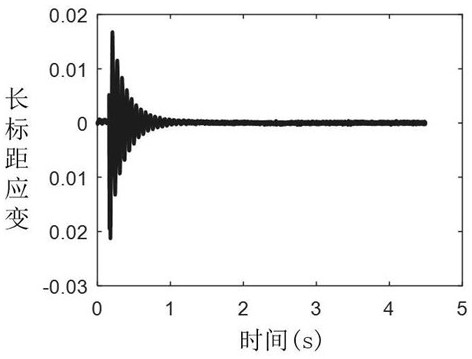

ActiveCN109781863AEnable long-term monitoringShorten test timeAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFiber Bragg gratingData acquisition

The invention discloses a structure corrosion two-stage detection method and system based on rapid vibration testing, and the method comprises the steps: judging the strain flexibility of a structureaccording to the strain response and impact force time history of a long-scale-distance FBG sensor, positioning a corrosion part through employing the strain flexibility difference of the structure before and after corrosion, and achieving the corrosion positioning of a first stage; after the corrosion part is determined, reducing the rigidity of the unknown parameter to be identified of the structure from the rigidity of all units to the rigidity of the corrosion unit, establishing a sensitivity matrix for the structural section rigidity based on the long gauge length strain flexibility, solving the rigidity of the structural corrosion unit according to a sensitivity equation, and judging the corrosion amount according to the rigidity change; meanwhile, forming a two-stage strategy structure corrosion detection system based on rapid vibration by a rapid detection vehicle, a data acquisition system and a data analysis system which are matched with an impact device, wherein the two-stage strategy structure corrosion detection system is mainly used for current safety state evaluation and long-term performance evaluation of the structure, high in test precision and high in noise resistance, and can realize long-term monitoring of structure corrosion.

Owner:SOUTHEAST UNIV

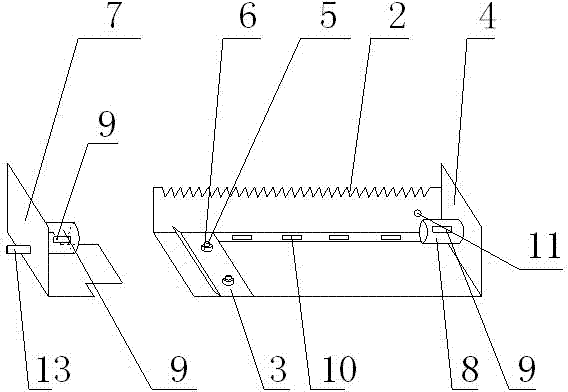

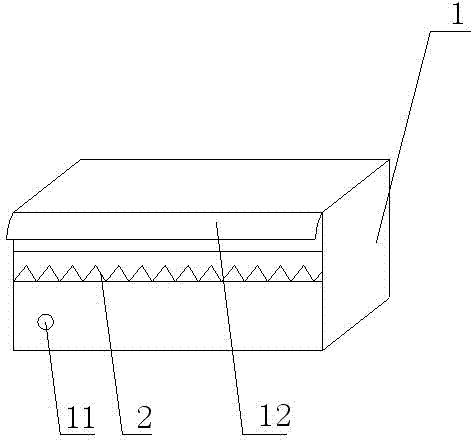

Improved film cutter

The invention discloses an improved film cutter which comprises a rectangular box, a sawtooth cutter, a press plate, a fixed support and a movable support. The sawtooth cutter is arranged on one side of the rectangular box, the press plate is installed at the bottom of the rectangular box and is installed at the bottom of the box through a screw and a spring washer, and the fixed support is fixedly installed at one end of the box. The improved film cutter is characterized in that the movable support is arranged on the other side of the box and is inserted between the bottom of the box, mandrels are installed on the movable support and the fixed support, alarming devices are installed on the mandrels, an infrared detection device is installed at the bottom of the rectangular box, a detecting lamp connected with the infrared detection device is arranged outside the rectangular box, and the rectangular box is provided with a movable upper cover. The improved film cutter has the advantages that the rectangular box is provided with the movable upper cover, and dust can be blocked; the alarming devices can remind people of timely replacing a roll type film when no film is available; and an ultraviolet detecting device is arranged in the rectangular box and can be used for detecting whether the film is damaged.

Owner:南通环球塑料工程有限公司

Detector for detecting outline cross section shape of bridge cable

PendingCN109668538AHigh application valueSimple and reliable measurement workMeasurement devicesClimbing robotsEngineering

The invention discloses a detector for detecting the outline cross section shape of a bridge cable. The detector comprises a climbing robot, a transition sleeve, a rotary supporting seat, a rotary sleeve and a ranging sensor. The detecting object is a bridge cable cylinder, the climbing robot is located on the to-be-detected bridge cable cylinder, the transition sleeve is coaxially installed on the climbing robot by adopting two semicircles with same diameters, and the rotary supporting seat is fixedly connected with the transition sleeve. The rotary sleeve wraps a plurality of circumferentially distributed rolling columns through two semicircular structures, and the rotary sleeve can rotate positively and negatively around the bridge cable cylinder. The ranging sensor is located on the rotary sleeve and used for measuring the cross section shape of the bridge cable cylinder. The detector provided by the invention can conveniently penetrate through the to-be-detected cable and be arranged around the cable, and can rotate flexibly according to requirements. The detector fills in the gap that rotation of traditional cable movable detection cannot be achieved, cable damage detection meets the requirement for no blind angles, meanwhile cable damage detection is simple and reliable, and the detector has the great application value.

Owner:WUHAN GUANYOU TECH CO LTD

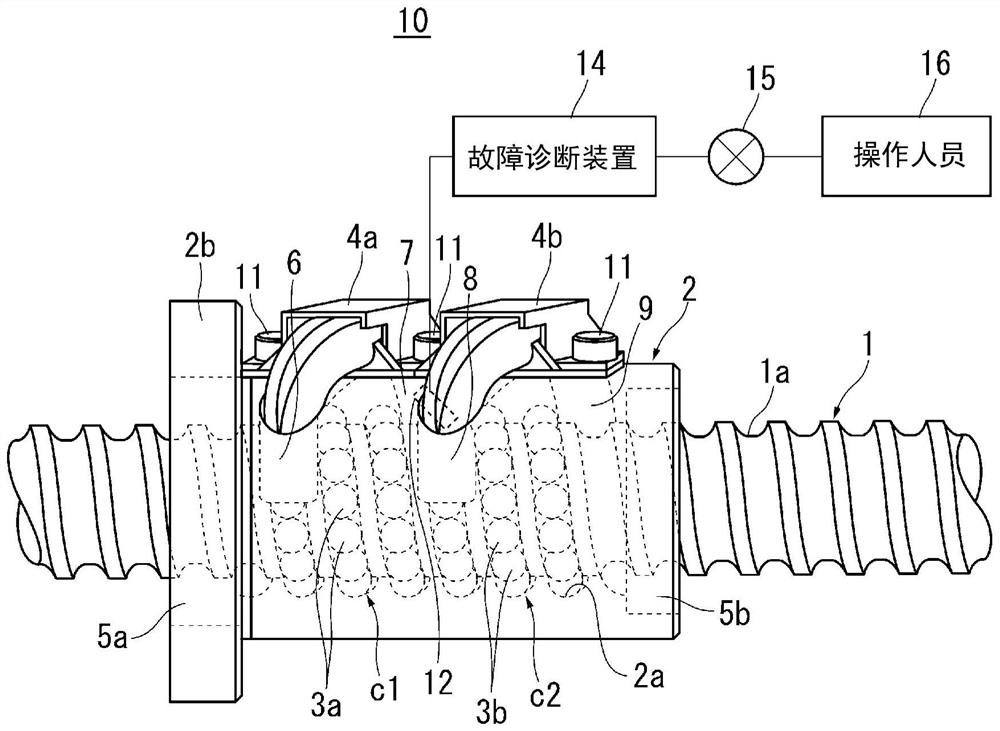

Screw device

Owner:THK CO LTD

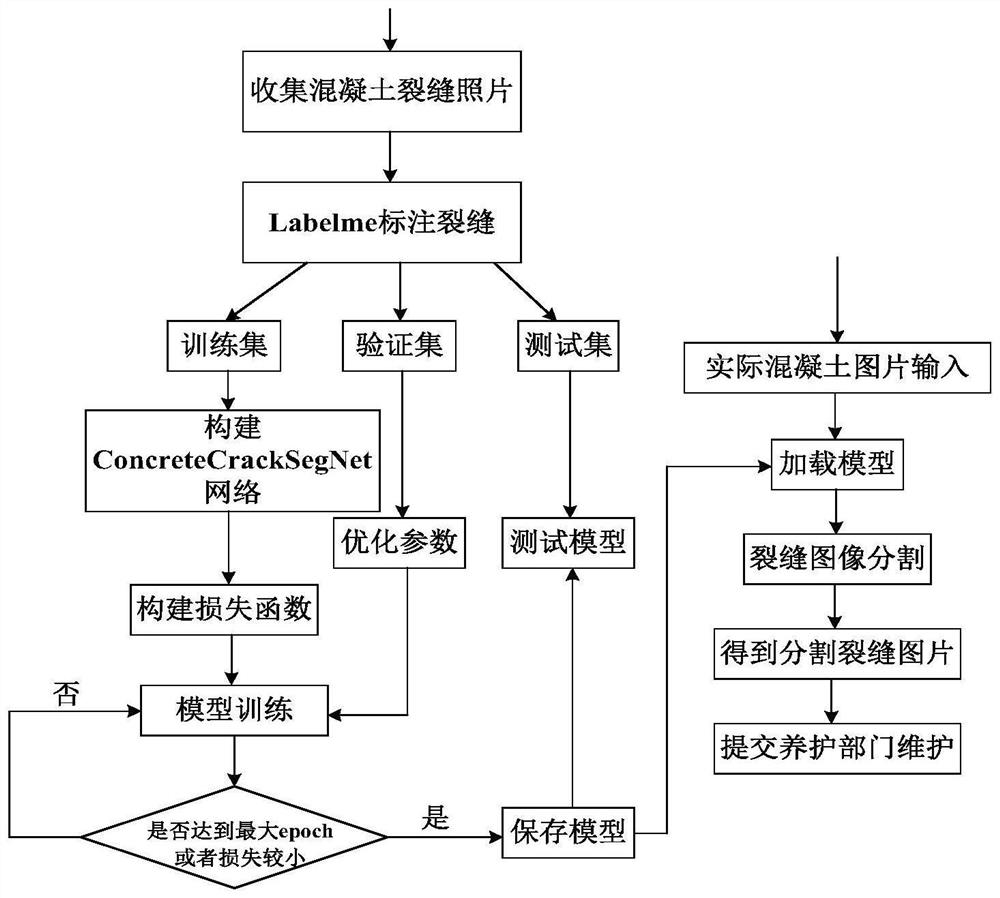

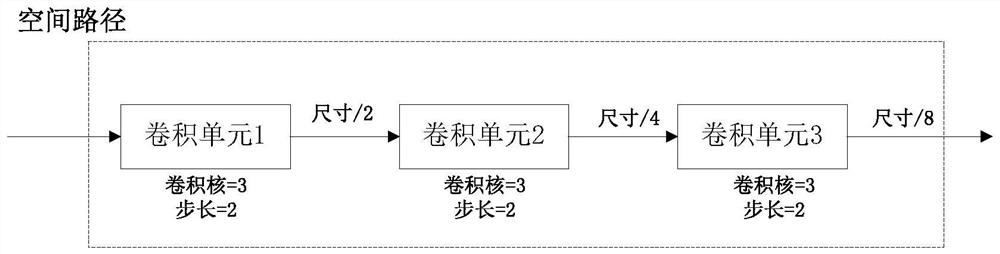

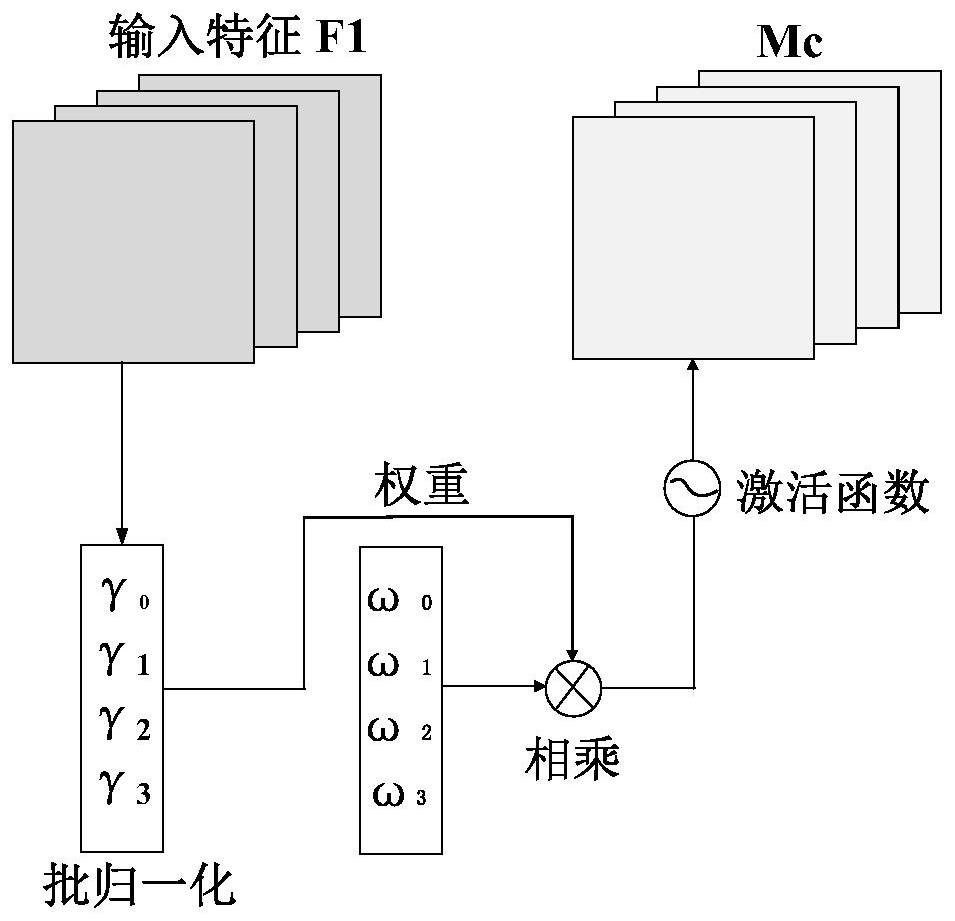

Concrete crack detection method based on ConcreteCrackSegNet model

PendingCN114596266AImprove Segmentation AccuracySave manpower and material resourcesImage enhancementImage analysisStructural engineeringArchitectural engineering

The invention provides a concrete crack detection method based on a ConcreteCrackSegNet model, and the method comprises the steps: inputting a picture shot by an unmanned aerial vehicle into the ConcreteCrackSegNet model for detection, and then outputting a predicted segmented concrete crack image through prediction; the ConcreteCrackSegNet model provided by the invention has the characteristics that the concrete crack color boundary is not obvious and the crack has certain continuity according to the concrete crack segmentation specific characteristics combined with the test, the actual concrete crack picture is collected, the picture set comprises various cracks which are not obvious, and the concrete crack color boundary is not obvious. The test fully considers the difficulty in distinguishing and the continuity of the crack. According to the method, the picture segmentation precision is high, and crack damage of the concrete structure can be detected, so that derivation of cracks of the concrete structure can be monitored in an early stage, support is provided for a scientific pre-maintenance decision provided by a maintenance department, and meanwhile, a large amount of manpower and material resources can be saved.

Owner:YANTAI UNIV

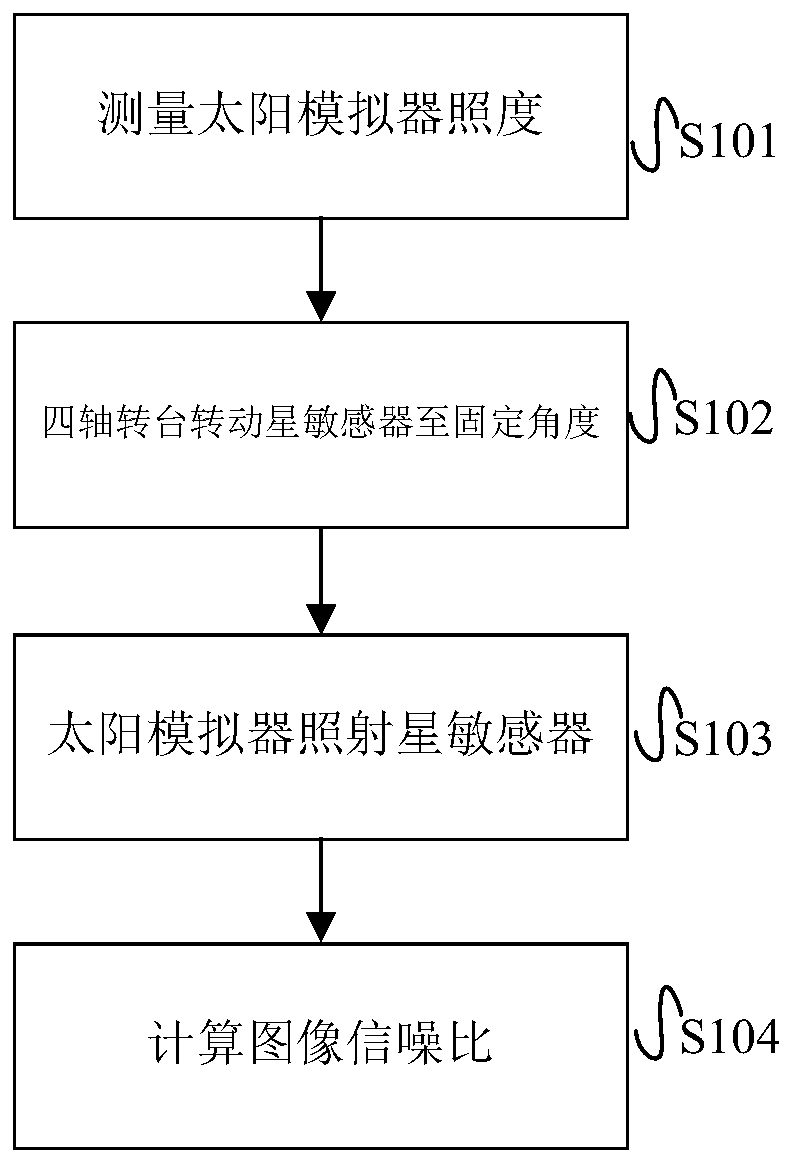

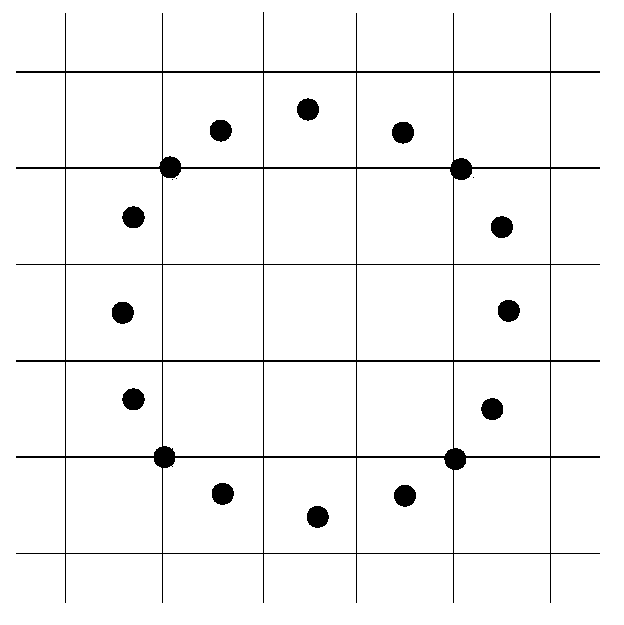

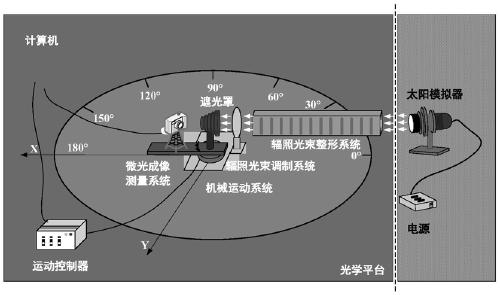

Method for testing damage of star sensor detector caused by strong light irradiation

The invention discloses a method for testing damage of a star sensor detector caused by strong light irradiation. The utilizes a solar simulator to simulate a light source to irradiate the star sensordetector and comprises the following steps: (1) measuring the illuminance of the solar simulator to determine the illuminance of the solar simulator; (2) forming a specified included angle between the optical axis of the star sensor and the solar simulator; (3) irradiating the star sensor by the solar simulator; and (4) shooting by the star sensor detector to obtain an image, and determining thedamage degree of the detector after irradiation by utilizing the image signal-to-noise ratio of the image. The problem of how to measure the damage degree of the star sensor detector when the star sensor is irradiated in a complex illumination environment can be solved, and the damage degree of illumination of different incident angles to the star sensor detector can also be detected.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Sprayed concrete and surrounding rock fracture detection device and method

ActiveCN111487322ADetect damageAnalysing solids using sonic/ultrasonic/infrasonic wavesShotcreteClassical mechanics

The invention discloses a sprayed concrete and surrounding rock fracture detection device. The detection device comprises a plurality of detection units, an extensometer and a prefabricated joint. Thedetection units are located on two sides of the prefabricated joint, and the extensometer is installed at the prefabricated joint. Each detection unit comprises a bracket, an ultrasonic transmittingdevice and an ultrasonic receiving device; and the ultrasonic transmitting device and the ultrasonic receiving device are mounted on the bracket. The device can be used for detecting damage in the sprayed concrete and the surrounding rock. The invention further discloses a sprayed concrete and surrounding rock fracture detection method, on the basis of ensuring a lossless state, a crack initiationtime point of sprayed concrete and surrounding rock fracture can be measured, and then whole-process evolution of fracture damage is obtained.

Owner:HOHAI UNIV

Pipe penetrating device

PendingCN113252690ADetect damageOptically investigating flaws/contaminationApparatus for laying cablesEngineeringElectric cables

The invention belongs to the technical field of power construction, and discloses a pipe penetrating device which comprises a pay-off assembly, a detection assembly, a driving source and a box, the pay-off assembly comprises two supporting frames and a cable reel which are oppositely arranged, the two supporting frames are connected through a connecting piece, the supporting frames are used for supporting the cable reel, and the cable reel is used for containing a cable; the detection assembly comprises a probe and a probe connecting wire connected to the probe, the probe connecting wire is wound on the connecting piece, a containing cavity is formed in the box body and used for containing the pay-off assembly and the detection assembly, a pay-off hole is formed in the box body, the cable penetrates through the pay-off hole to be arranged in the pipeline, and a through hole is formed in the box body so that the probe can penetrate through the through hole. The driving source is connected to the connecting piece and can drive the connecting piece to rotate, so that the probe connecting line is shrunk or lengthened, and the probe can penetrate through the through hole to be far away from or extend into the pipeline. The pipe penetrating device can detect the internal damage condition of the pipeline and improve the working efficiency.

Owner:GUANGDONG POWER GRID CO LTD +1

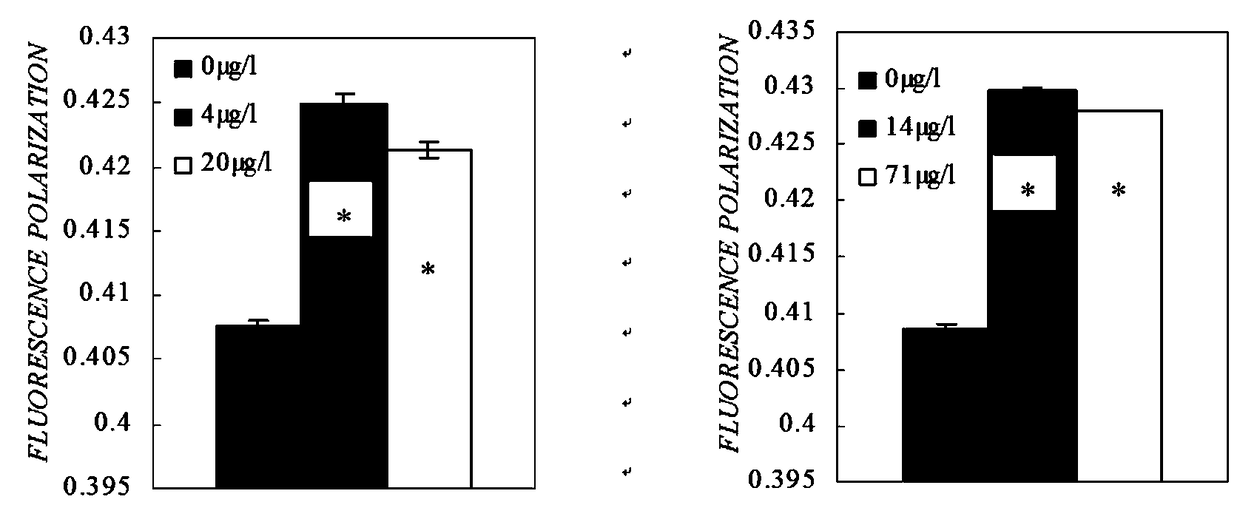

An In Vivo Test Method for Mitochondrial Membrane Fluidity in the Liver of Osprey carp

ActiveCN107449766BAvoiding pitfalls of ex vivo assays for mobilityTrue reflection of biological activityFluorescence/phosphorescenceInner mitochondrial membranePseudorasbora parva

The invention relates to testing of fluidity of fluidity of a mitochondrial membrane of the liver of fish, in particular to an in-vivo test method for the fluidity of the mitochondrial membrane of the liver of pseudorasbora parva. The method comprises steps as follows: S1, a fish body exposure experiment; S2, preparation of the mitochondrial membrane of the liver of the pseudorasbora parva; S3, preparation of a DPH solution; S4, marking of a DPH fluorescent probe of the mitochondrial membrane; S5, determination of the fluidity of the membrane; S6, determination of the content of protein in mitochondria. With the adoption of the in-vivo test method for the fluidity of the mitochondrial membrane of the liver of pseudorasbora parva, influence of an agent on the fluidity of the mitochondrial membrane of the fish is determined accurately and conveniently.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

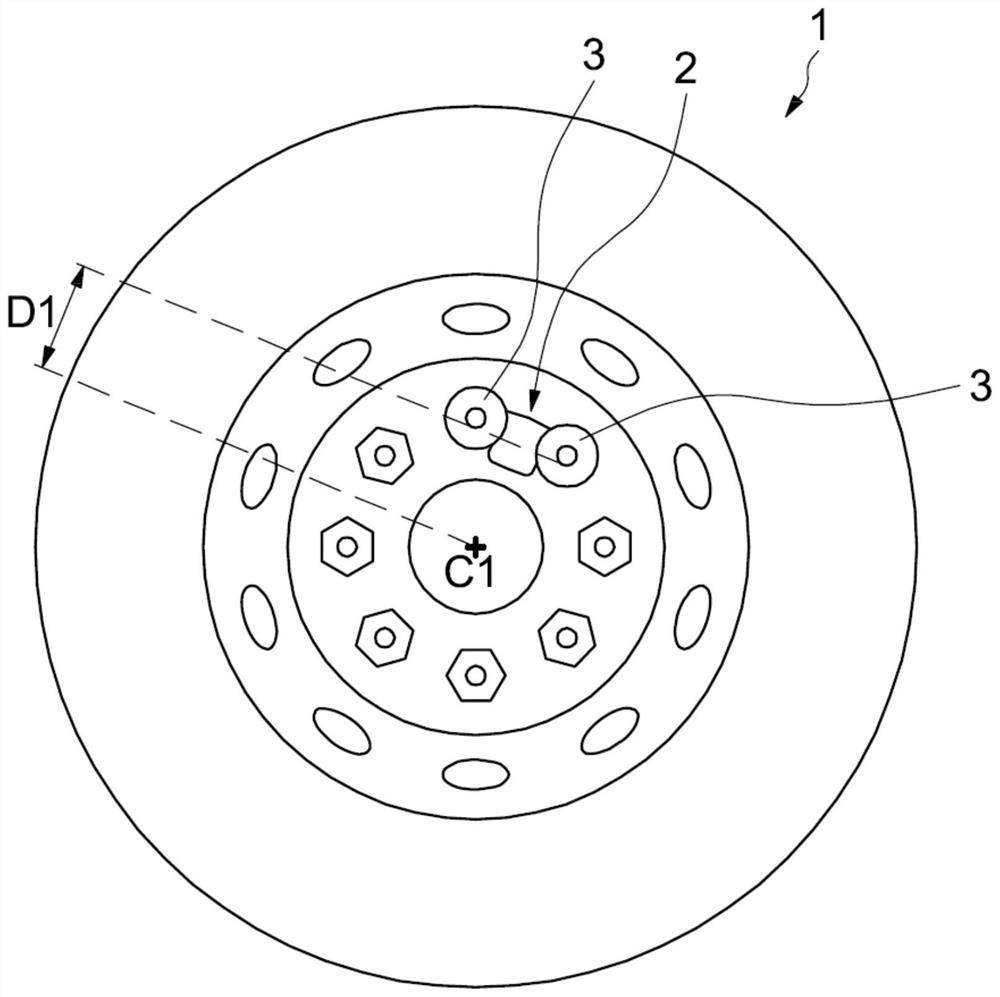

Method and device for determining rotation frequency of wheel of vehicle

PendingCN114148130ADetect damageMachine part testingTyre measurementsProcessing elementControl theory

Owner:AB SKF

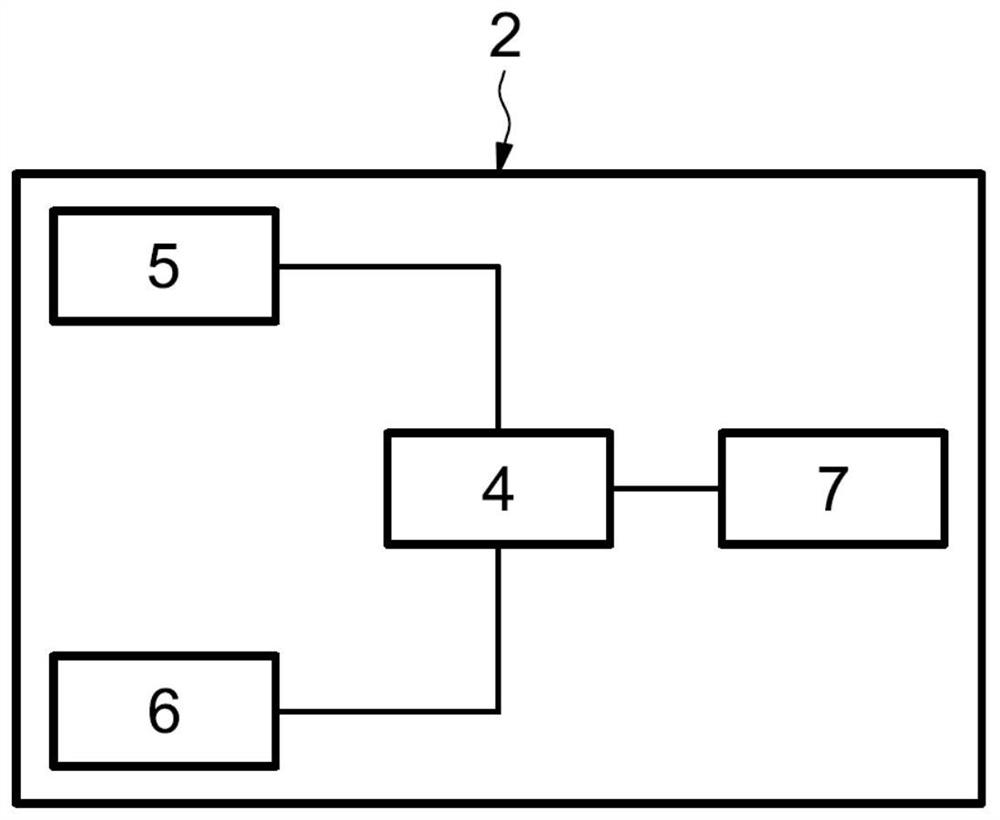

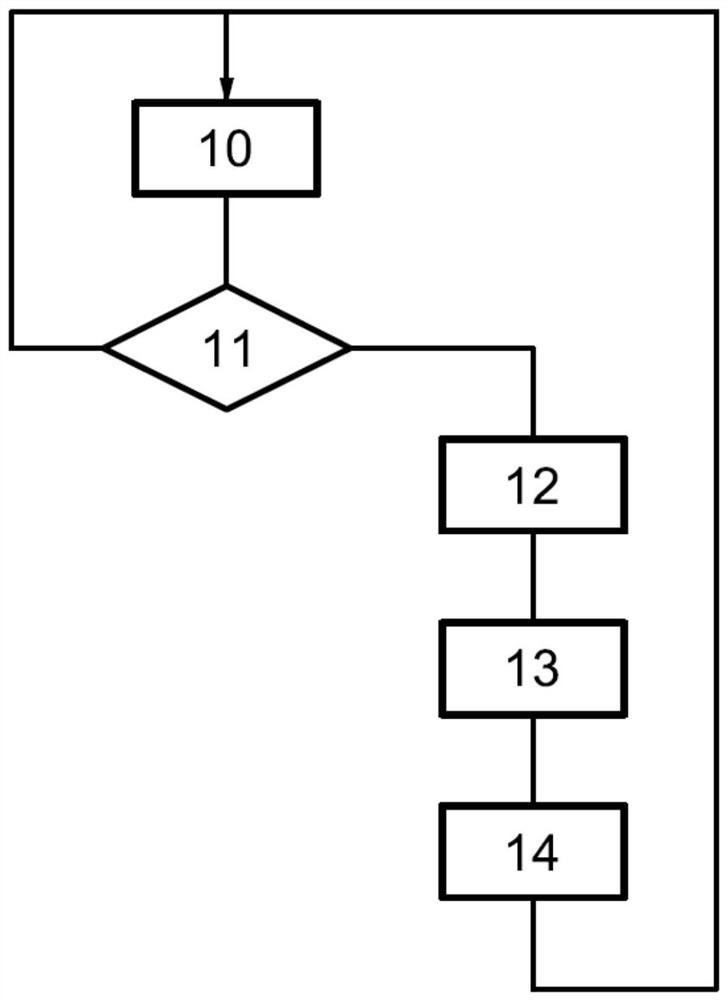

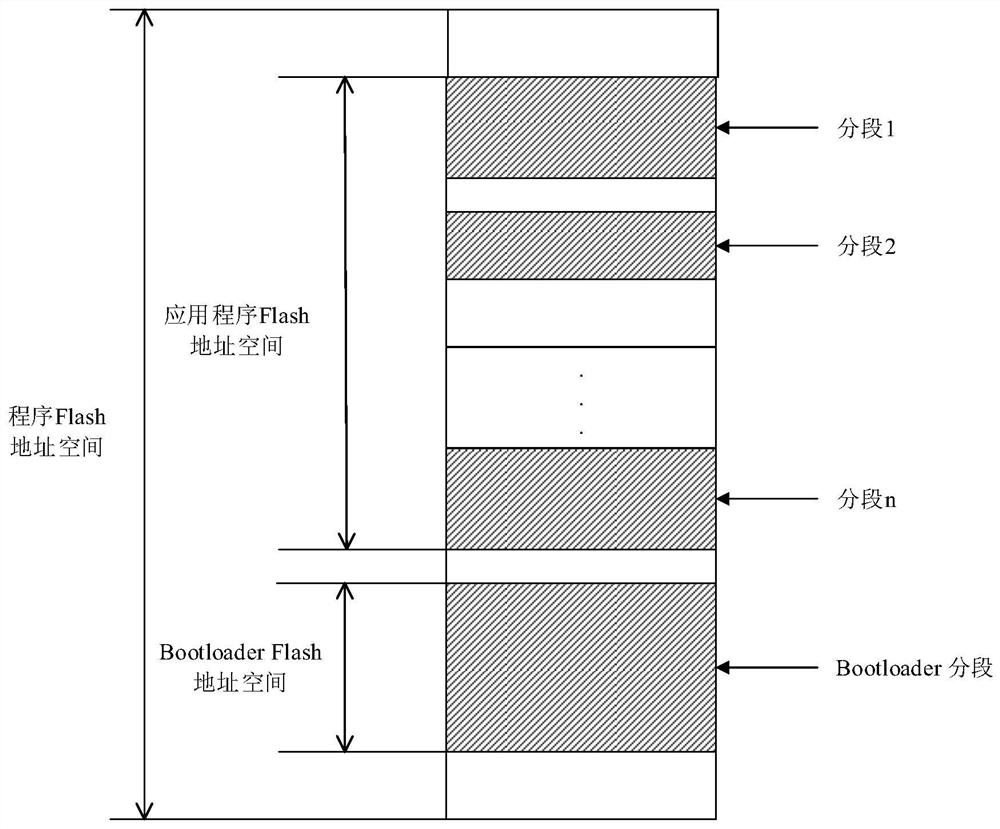

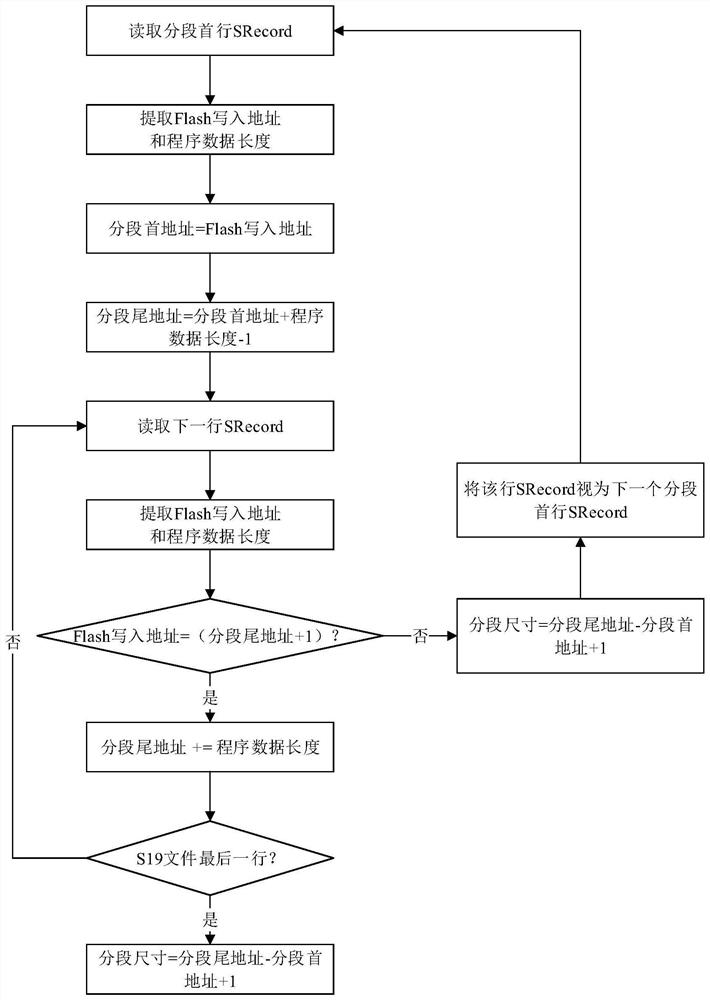

A method and system for verifying program flash data consistency

ActiveCN109189405BDetect damageImplement Consistency CheckSoftware deploymentSoftware engineeringComputer engineering

The invention discloses a method and system for verifying program Flash data consistency, which downloads and burns the application program to the Flash; extracts and calculates the verification information of the application program during the downloading process; Compare the verification information sent by the computer program, if the data is consistent, it means that the programming is successful, and the verification information is stored in the Flash; when the power is turned on, read the verification information stored in the Flash, and read all the segmented data of the application program And perform verification, compare the calculated verification value with the stored verification information, if the data is consistent, it means that the data in the program Flash is not damaged.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

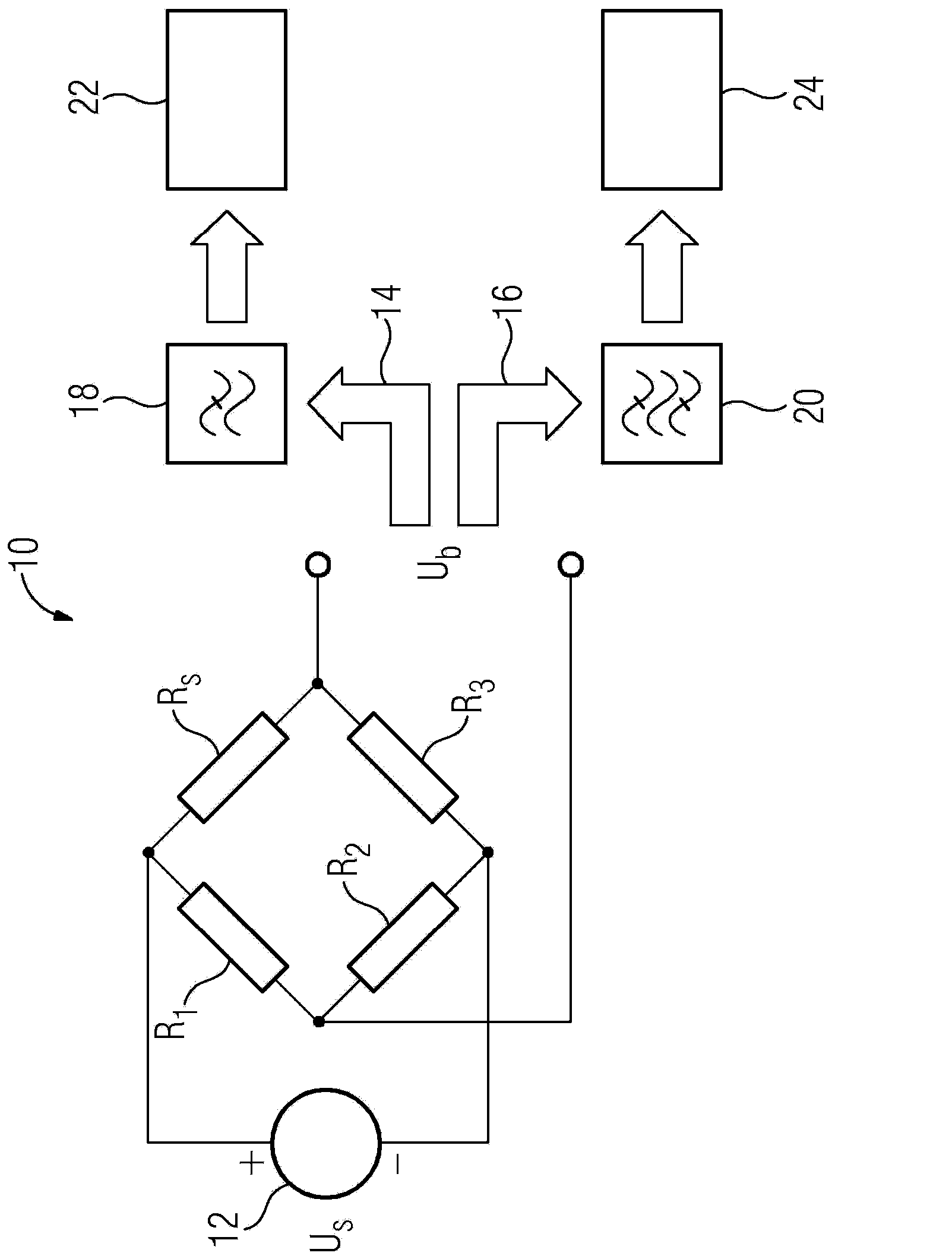

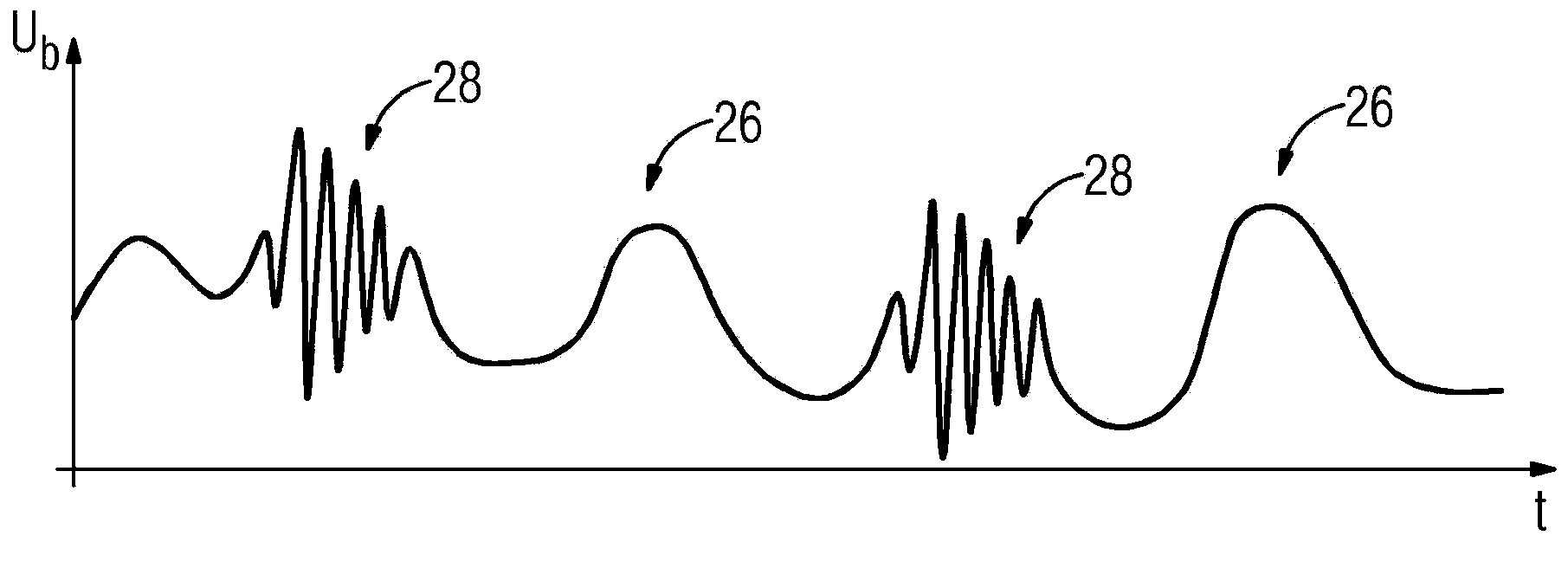

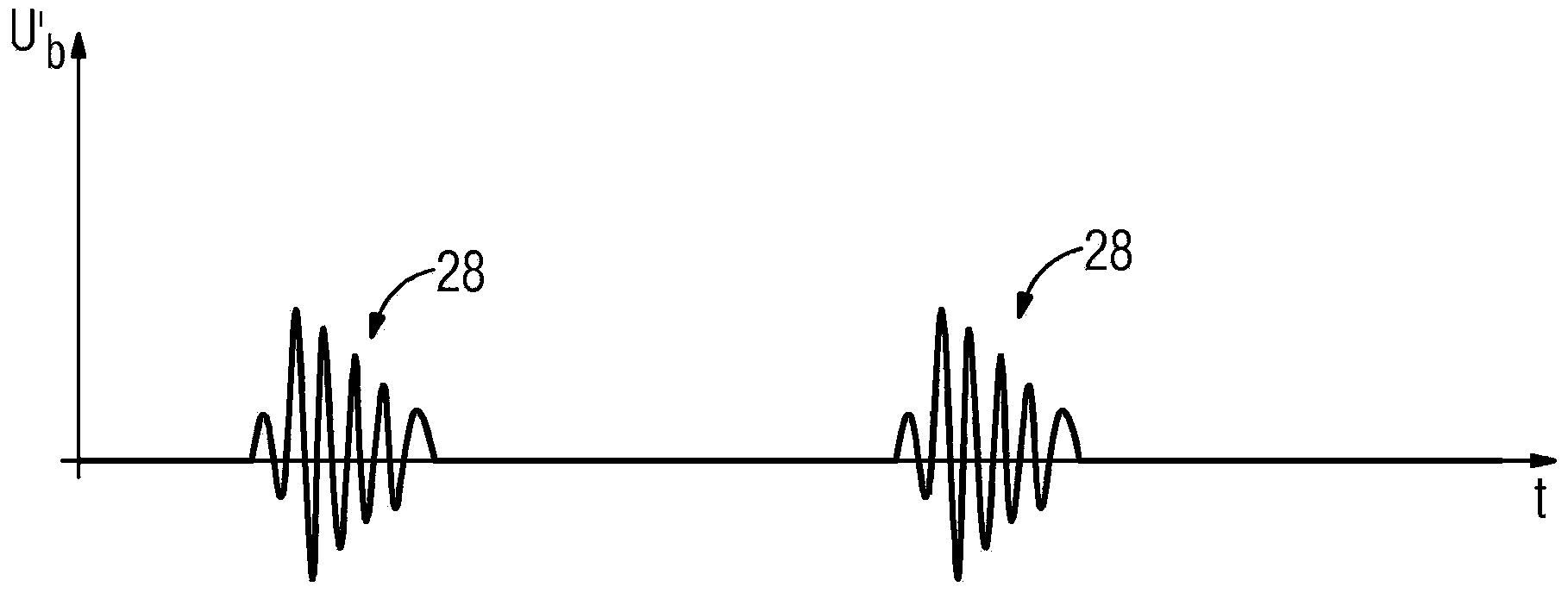

Method for monitoring damage to a shaft

InactiveCN104272077ADamage monitoringDetect damageMachine part testingElasticity measurementEngineeringStrain gauge

The invention relates to a method for monitoring damage to a shaft by arranging at least one strain gauge (RS) on an outer surface of the shaft, detecting deformation of the shaft using a measurement signal (Ub) from the at least one strain gauge (RS) and detecting sound emissions of the shaft by evaluating the measurement signal (Ub) in the ultrasonic range.

Owner:SIEMENS AG

Wire and cable damage detection device

InactiveCN111122330AConstant tensionQuick checkMaterial strength using tensile/compressive forcesPull forceElectrical and Electronics engineering

The invention discloses a wire and cable damage detection device. The device comprises a machine body, and a working cavity with a rightward opening is formed in the right side of the machine body; anisolation plate is arranged on the right side of the working cavity; a transmission cavity is formed below the working cavity; a pull-down cavity is formed below the transmission cavity; a pressure cavity is formed in the left side of the pull-down cavity, a power cavity is formed in the upper portion of the left side of the pressure cavity, a driving device is arranged in the power cavity, and therefore it can be guaranteed that in the detection process, the detection result is not affected by errors generated in the clamping process of a wire, and it can be guaranteed that tension receivedby the wire in the detection process is constant and accurate.

Owner:YIWU WANJU ELECTRONICS CO LTD

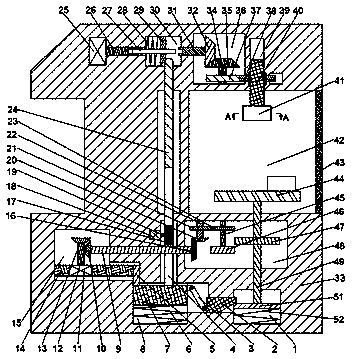

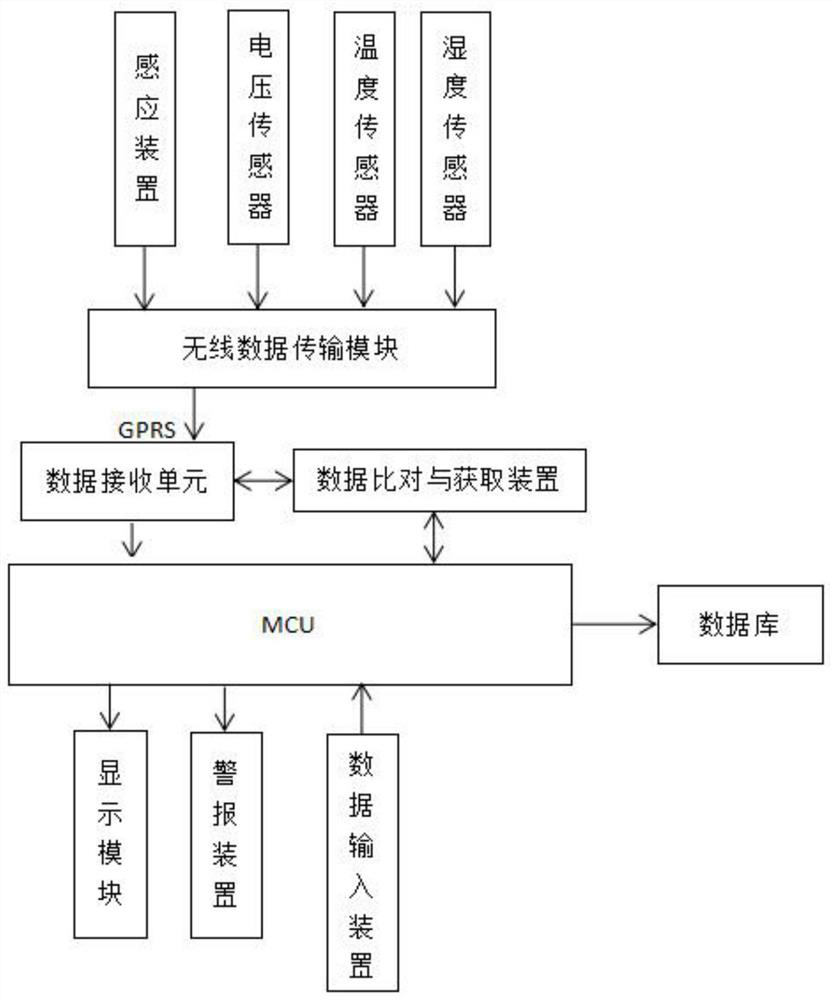

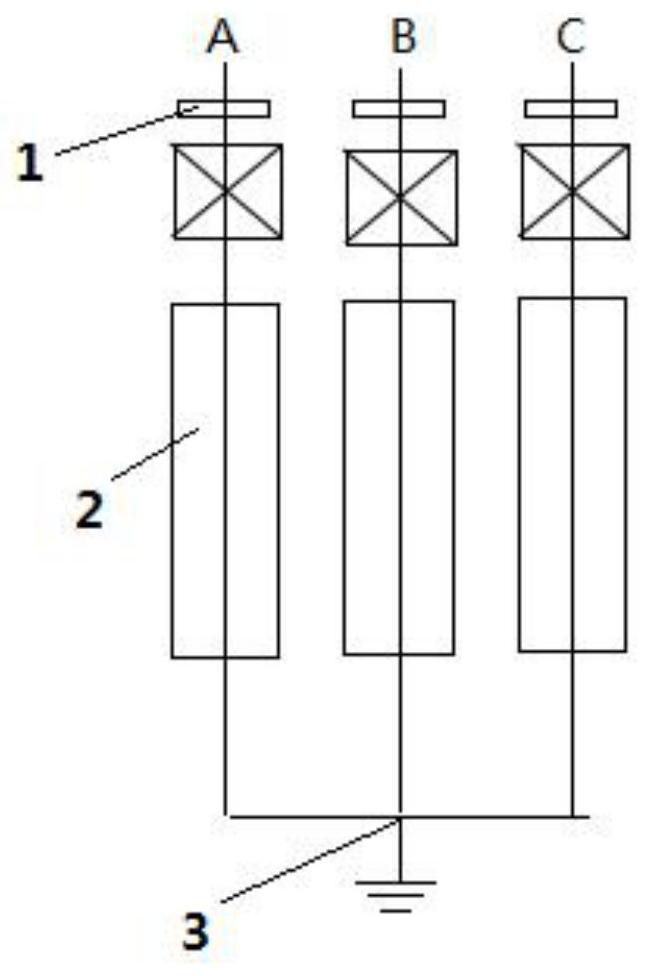

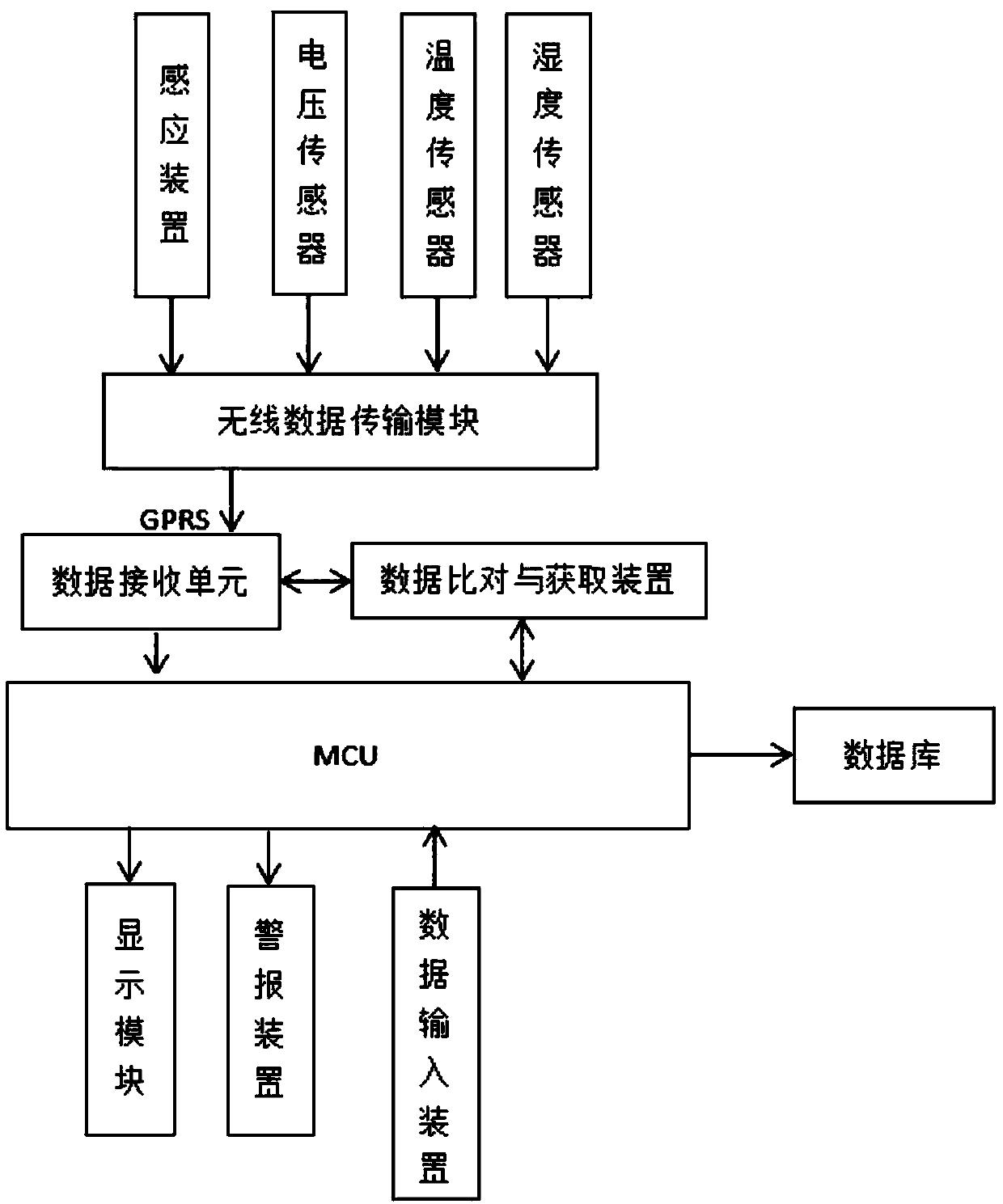

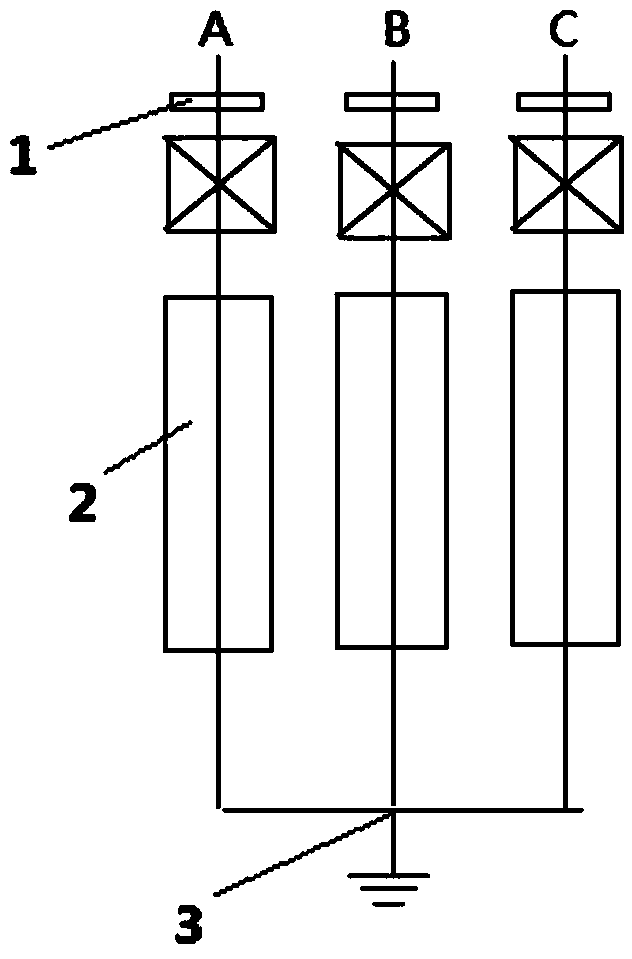

A monitoring system and monitoring method for an overvoltage protector

ActiveCN107894253BDetect damageEasily and accurately damageMeasurement devicesTransmission systemsOvervoltageNetwork communication

The invention discloses a monitoring system for an overvoltage protector. The monitoring system comprises an MCU, a display module, an alarm device, a data input device, a database, a data comparisonand acquisition device, a data receiving unit, a wireless data transmission module, an inductive device, a voltage sensor, a temperature sensor and a humidity sensor. According to the invention, the inductive device is arranged, so that the pressure relief operation of an overvoltage protector in the invention can be detected immediately, and at this time, whether the overvoltage protector is damaged or not can be easily and accurately detected by comparing a voltage value detected by the voltage sensor and a voltage value within a normal range; the wireless data transmission module communicates with the data receiving unit through GPRS network communication, so that the monitoring device realizes wireless remote monitoring; and the temperature sensor and the humidity sensor are arranged to allow working staff to understand clearly and intuitively whether the damage of the overvoltage protector is due to the service life or external reasons such as temperature and humidity.

Owner:合肥奇骏自动化控制有限公司

Two-stage detection method and system for structural corrosion based on rapid vibration test

ActiveCN109781863BEnable long-term monitoringShorten test timeAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFiber Bragg gratingData acquisition

The invention discloses a two-stage detection method and system for structural corrosion based on rapid vibration testing. The strain compliance of the structure is judged according to the strain response of the long gauge FBG sensor and the time history of the impact force, and the strain compliance of the structure before and after corrosion is used. Corrosion locations can be located in order to realize the corrosion location problem in the first stage; after the corrosion location is determined, the unknown parameters to be identified in the structure are reduced from the stiffness of all elements to the stiffness of corrosion elements, and the relationship between structural section stiffness and structural section stiffness based on long gauge length strain flexibility is established. According to the sensitivity matrix, the stiffness of the structural corrosion unit is solved according to the sensitivity equation, and the corrosion amount is judged according to the change of the stiffness; at the same time, the rapid detection vehicle equipped with the impact device, the data acquisition system and the data analysis system form a two-stage strategic structural corrosion detection system based on rapid vibration , mostly used for the current safety status assessment and long-term performance assessment of the structure, with high test accuracy and strong anti-noise ability, and can realize long-term monitoring of structural corrosion.

Owner:SOUTHEAST UNIV

Monitoring system for overvoltage protector and monitoring method

ActiveCN107894253ADetect damageEasily and accurately damageMeasurement devicesTransmission systemsOvervoltageMonitoring system

The invention discloses a monitoring system for an overvoltage protector. The monitoring system comprises an MCU, a display module, an alarm device, a data input device, a database, a data comparisonand acquisition device, a data receiving unit, a wireless data transmission module, an inductive device, a voltage sensor, a temperature sensor and a humidity sensor. According to the invention, the inductive device is arranged, so that the pressure relief operation of an overvoltage protector in the invention can be detected immediately, and at this time, whether the overvoltage protector is damaged or not can be easily and accurately detected by comparing a voltage value detected by the voltage sensor and a voltage value within a normal range; the wireless data transmission module communicates with the data receiving unit through GPRS network communication, so that the monitoring device realizes wireless remote monitoring; and the temperature sensor and the humidity sensor are arranged to allow working staff to understand clearly and intuitively whether the damage of the overvoltage protector is due to the service life or external reasons such as temperature and humidity.

Owner:合肥奇骏自动化控制有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com