Wire and cable damage detection device

A detection device, wire and cable technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problems of wire clamping error, unstable pulling force, affecting detection results, etc., to achieve rapid detection , the effect of constant tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

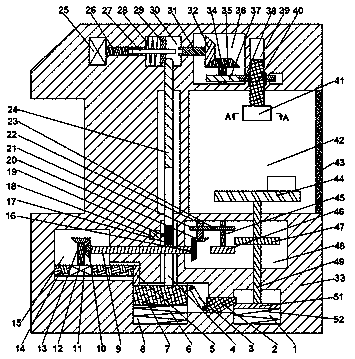

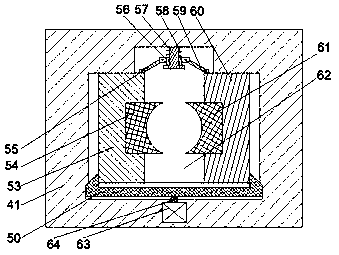

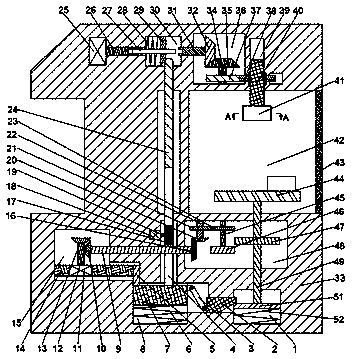

[0012] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0013] Combine below Figure 1-2 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0014] A wire and cable damage detection device of the device of the present invention includes a body 33, the right side of the body 33 is provided with a working chamber 42 that opens to the right, and the right side of the working chamber 42 is provided with a separation plate 43, and the working chamber 42 is provided with a transmission chamber 48 below the transmission chamber 48. A pull-down chamber 1 is provided below the transmission chamber 48. A pressure chamber 8 is provided on the left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com