Constant tension spring compensating unit

A spring compensation, constant tension technology, applied in the direction of overhead lines, etc., can solve the problems of inability to guarantee the constant tension of the catenary, limited use range, oil leakage, air leakage, etc., to achieve light weight, reduce offline rate, no card stagnant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The constant tension spring compensating device of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

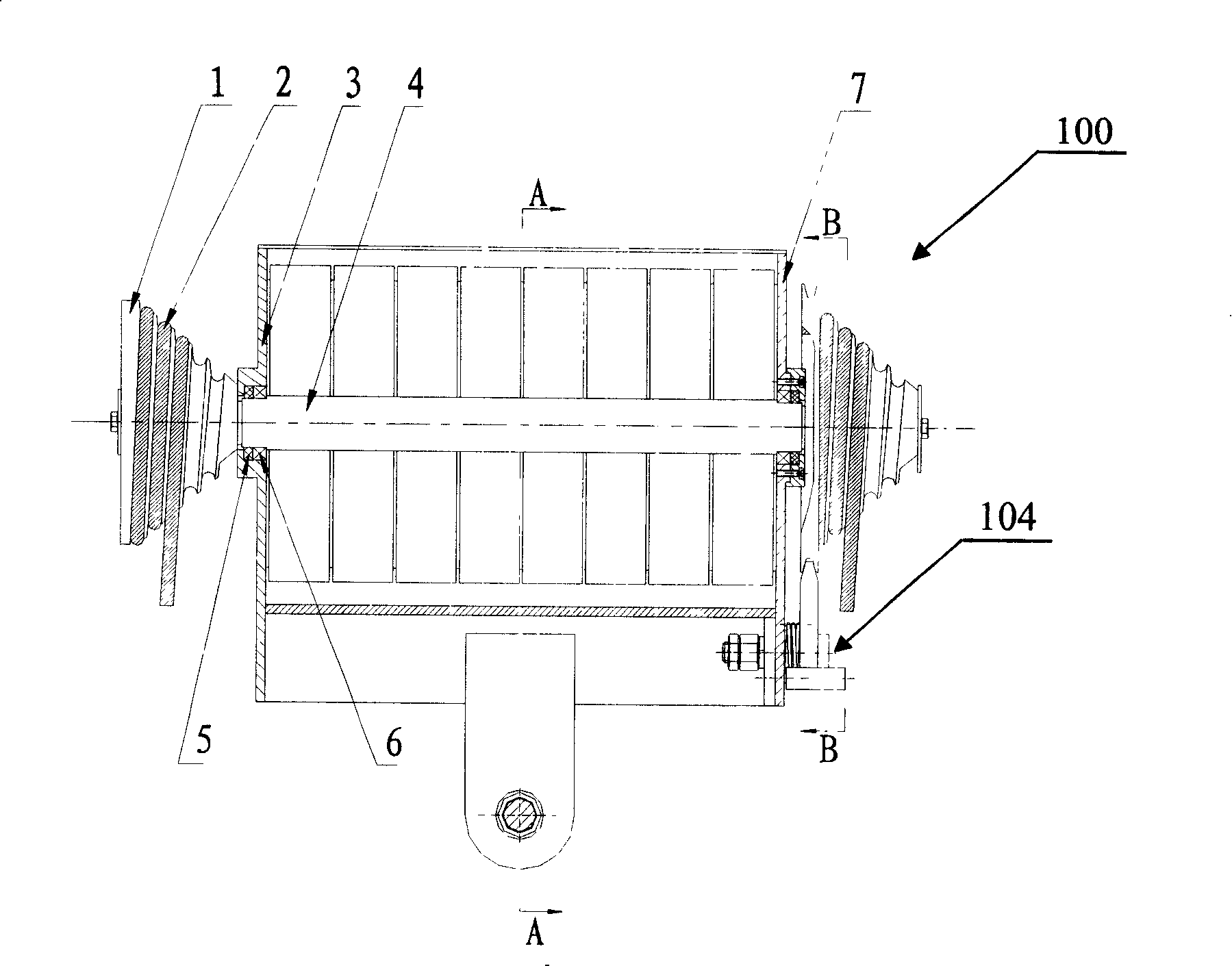

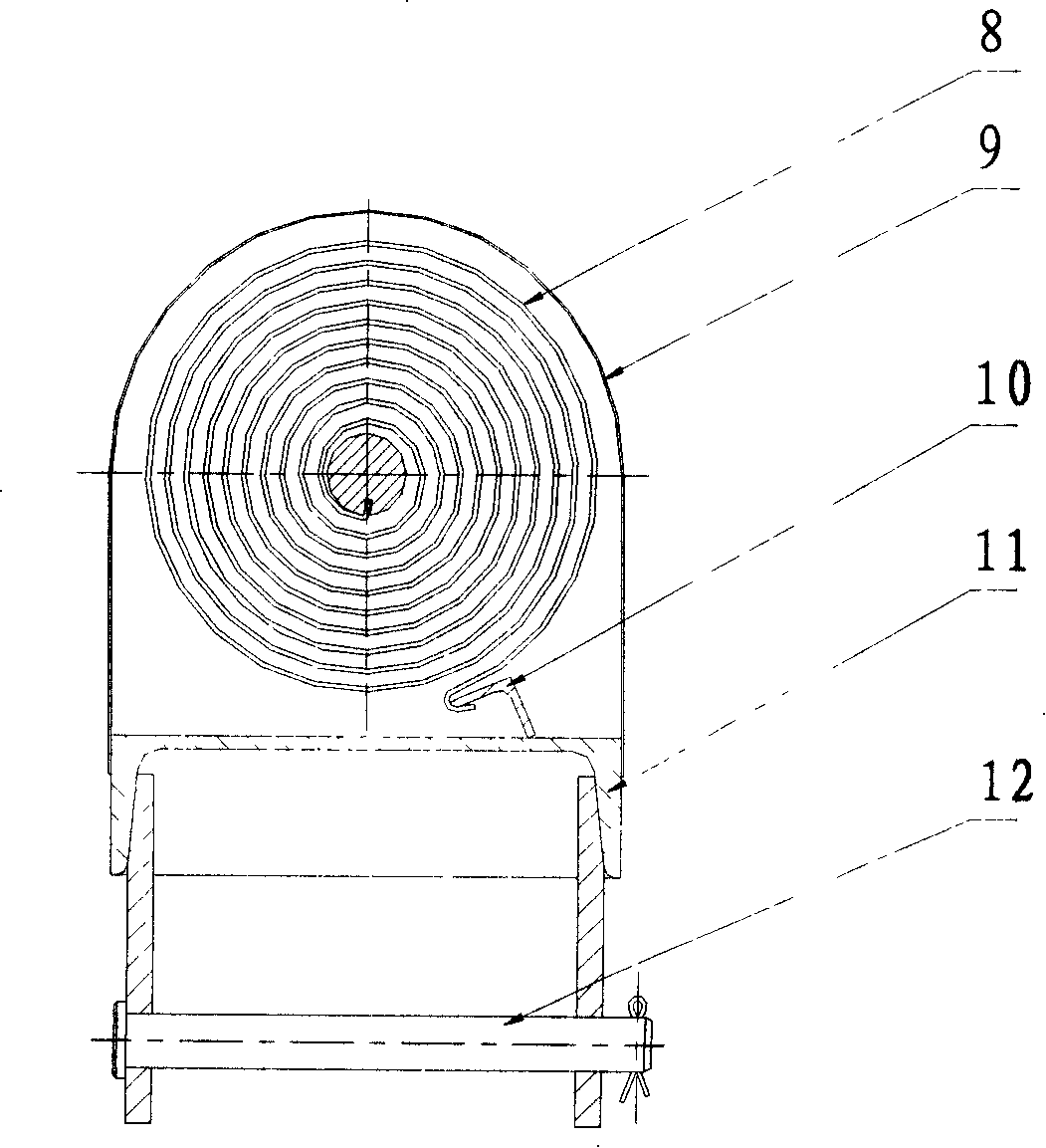

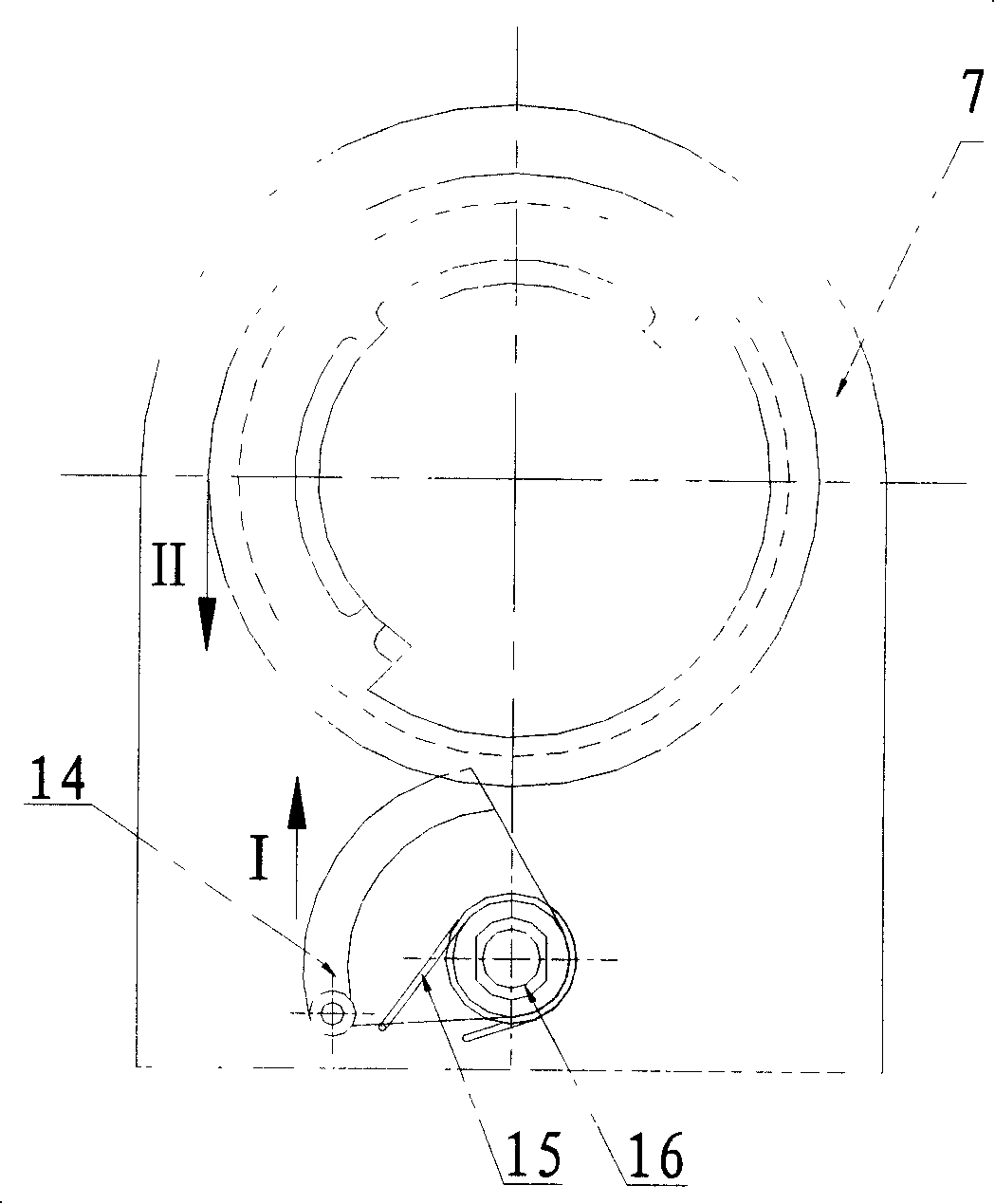

[0063] The structural diagram of the constant tension spring compensation device 100 of the present invention is as follows Figure 1A , Figure 1B As shown, it mainly includes involute sheave 1, compensation rope 2, left end plate 3, main shaft 4, oil seal 5, bearing 6, right end plate 7, contact flat scroll spring 8, outer cover 9, fixed angle steel 10, installation base plate 11. The pin shaft 12, the wire break stop device 104, etc.

[0064] The contact flat scroll spring 8 in the present embodiment is a variable torque flat scroll spring, and the termination radius of the involute sheave 1 can be determined according to the following relationship: termination radius=start radius×(plane scroll spring termination torque / Plane scroll spring starting torque).

[0065] Wherein the left end plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com