UV elastic self-repairing coating

A self-healing and elastic technology, applied in the field of coatings, can solve the problems of not showing elastic self-healing performance and sharp object scratch resistance, and achieve the effect of good elastic self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

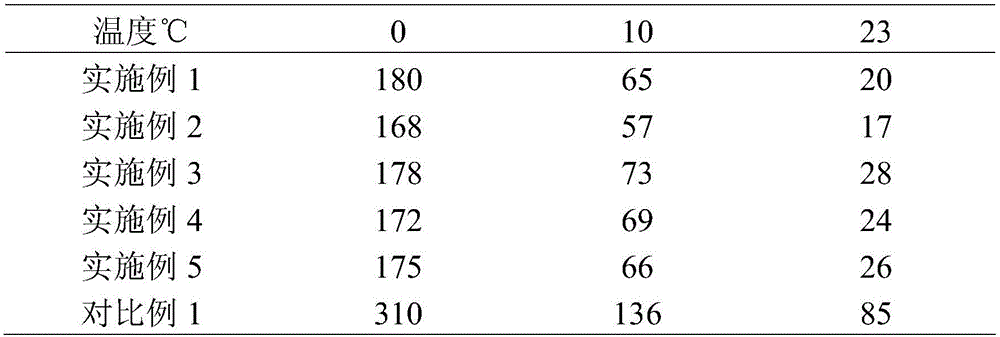

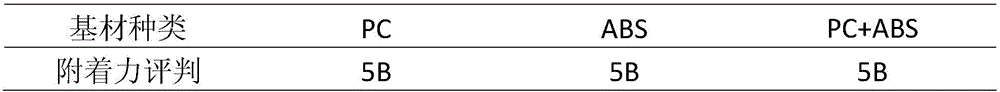

Examples

Embodiment 1

[0020] A kind of UV elastic self-healing coating, is made up of following raw material by mass percentage: elastic photocurable resin 50%, photopolymerization monomer 10%, photoinitiator 2%, solvent 25.2%, auxiliary agent 12.8%, described elastic The photocurable resin is composed of 80% polyurethane acrylate unsaturated polymer, 10% tricyclic phenol alkane polyurethane elastic resin, and 10% tetraethylene bisphenol epoxy acrylic oligomer. The photoinitiator is composed of 1-hydroxy ring 40% of hexyl phenyl ketone, 60% of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and the solvent is composed of 25% of ethylene glycol dimethyl propoxy ester, dimethylol dipropyl 75% ester, and the additives are composed of 92% silicon dioxide elastic powder and 8% BYK306 leveling agent;

[0021] A kind of UV elastic self-healing coating, the preparation steps are as follows:

[0022] A. Add 1-hydroxycyclohexyl phenyl ketone, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide in the mixing tank...

Embodiment 2

[0026] A UV elastic self-healing coating, composed of the following raw materials by mass percentage: 70% of elastic photocurable resin, 2% of photopolymerizable monomer, 1% of photoinitiator, 22.2% of solvent, 4.8% of auxiliary agent, the elastic The photocurable resin is composed of 60% of polyurethane acrylate unsaturated polymer, 25% of tricyclic phenol alkane polyurethane elastic resin, and 15% of tetraethylene bisphenol epoxy acrylic oligomer. The photoinitiator is composed of 1-hydroxy ring 40% of hexyl phenyl ketone, 60% of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and the solvent consists of 50% of ethylene glycol dimethyl propoxy ester, dimethylol dipropyl 50% of ester, and the auxiliary agent is composed of 92% of silicon dioxide elastic powder and 8% of BYK306 leveling agent;

[0027] A kind of UV elastic self-healing coating, the preparation steps are as follows:

[0028] A. Add 1-hydroxycyclohexyl phenyl ketone, 2,4,6-trimethylbenzoyl-diphenylphosphine oxi...

Embodiment 3

[0032] A UV elastic self-healing coating, composed of the following raw materials by mass percentage: 67.45% elastic photocurable resin, 8% photopolymerizable monomer, 1.5% photoinitiator, 23% solvent, 0.05% auxiliary agent, the elastic The photocurable resin is composed of 70% polyurethane acrylate unsaturated polymer, 18% tricyclic phenol alkane polyurethane elastic resin, and 12% tetraethylene bisphenol epoxy acrylic oligomer. The photoinitiator is composed of 1-hydroxy ring Hexyl phenyl ketone 40%, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 60%, the solvent is composed of ethylene glycol dimethyl propoxy ester 20%, dimethylol dipropyl 80% ester, and the additives are composed of 92% silicon dioxide elastic powder and 8% BYK306 leveling agent;

[0033] A kind of UV elastic self-healing coating, the preparation steps are as follows:

[0034] A. Add 1-hydroxycyclohexyl phenyl ketone, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide in the mixing tank, use ethylene glycol d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com