Anti-reflection coating layer with transparent electric surface layer

A transparent conductive, anti-reflection technology, applied in coating, sputtering, metal material coating process, etc., can solve problems such as damage, inability to guarantee, reduce the pass rate of anti-reflection optical coating layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

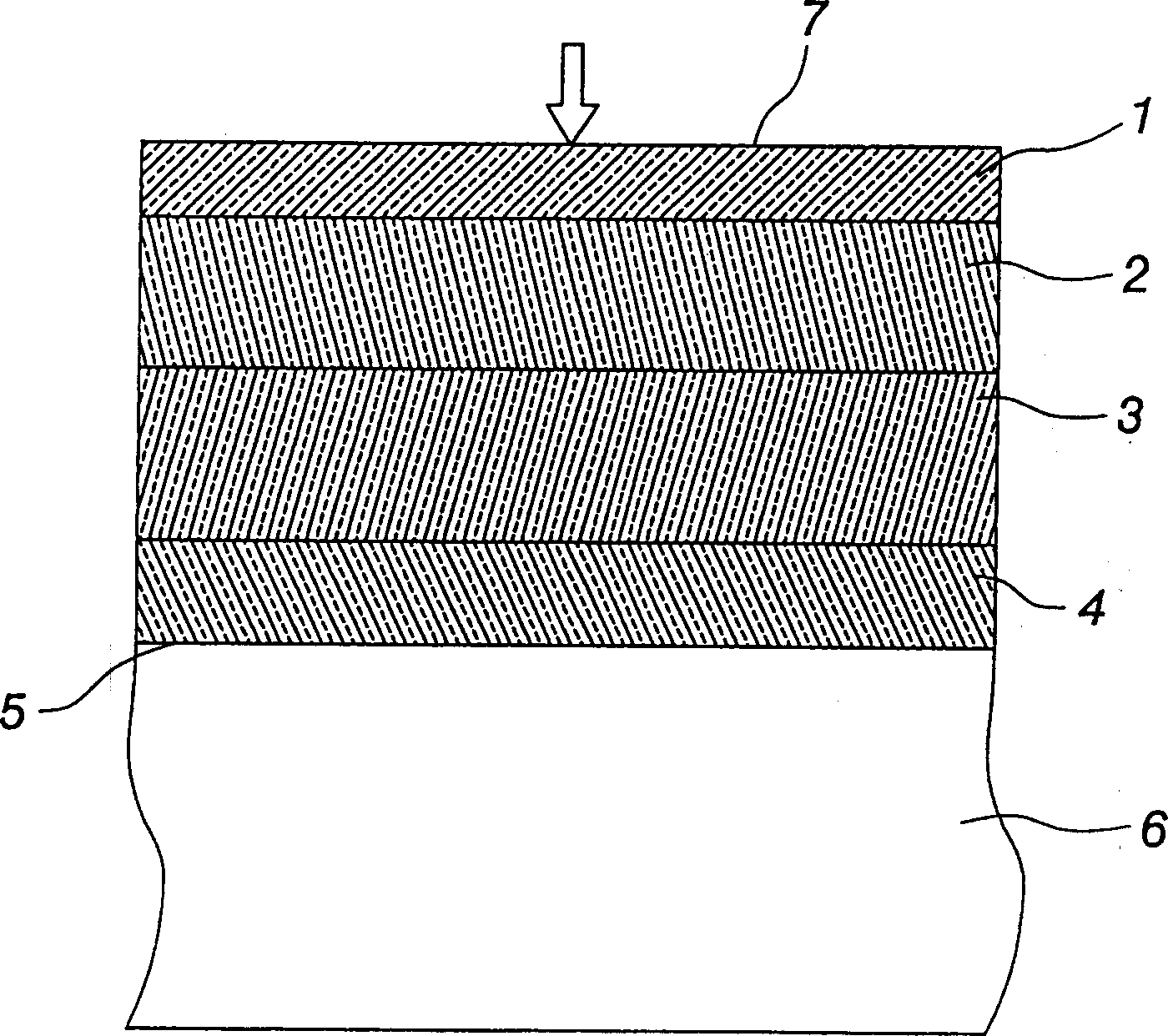

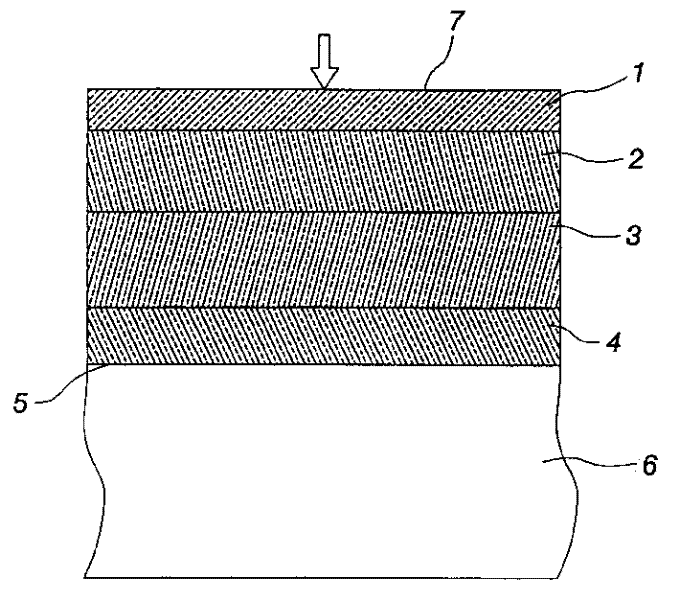

[0017] The present invention has the embodiment cross-sectional view of the anti-reflection coating layer of transparent conductive surface layer (such as figure 1 shown), including: a substrate 6, which is made of transparent materials such as glass and plastic. shown). A fourth layer 4 is in contact with the interface 5 of the substrate 6; along the direction of the observer is followed by a third layer 3, the third layer 3 is located on the fourth layer 4; along the direction of the observer Then there is a second layer 2, which is located on the third layer 3; along the direction of the viewer, there is a first layer 1, which is located on the second layer 2 , the first layer 1 has an upper surface 7; the first layer 1, the second layer 2, the third layer 3 and the fourth layer 4 constitute the four-layer structure of the present invention.

[0018] In the first embodiment of the anti-reflection coating layer with a transparent conductive surface layer of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com