Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

619results about How to "Improve acid and alkali corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

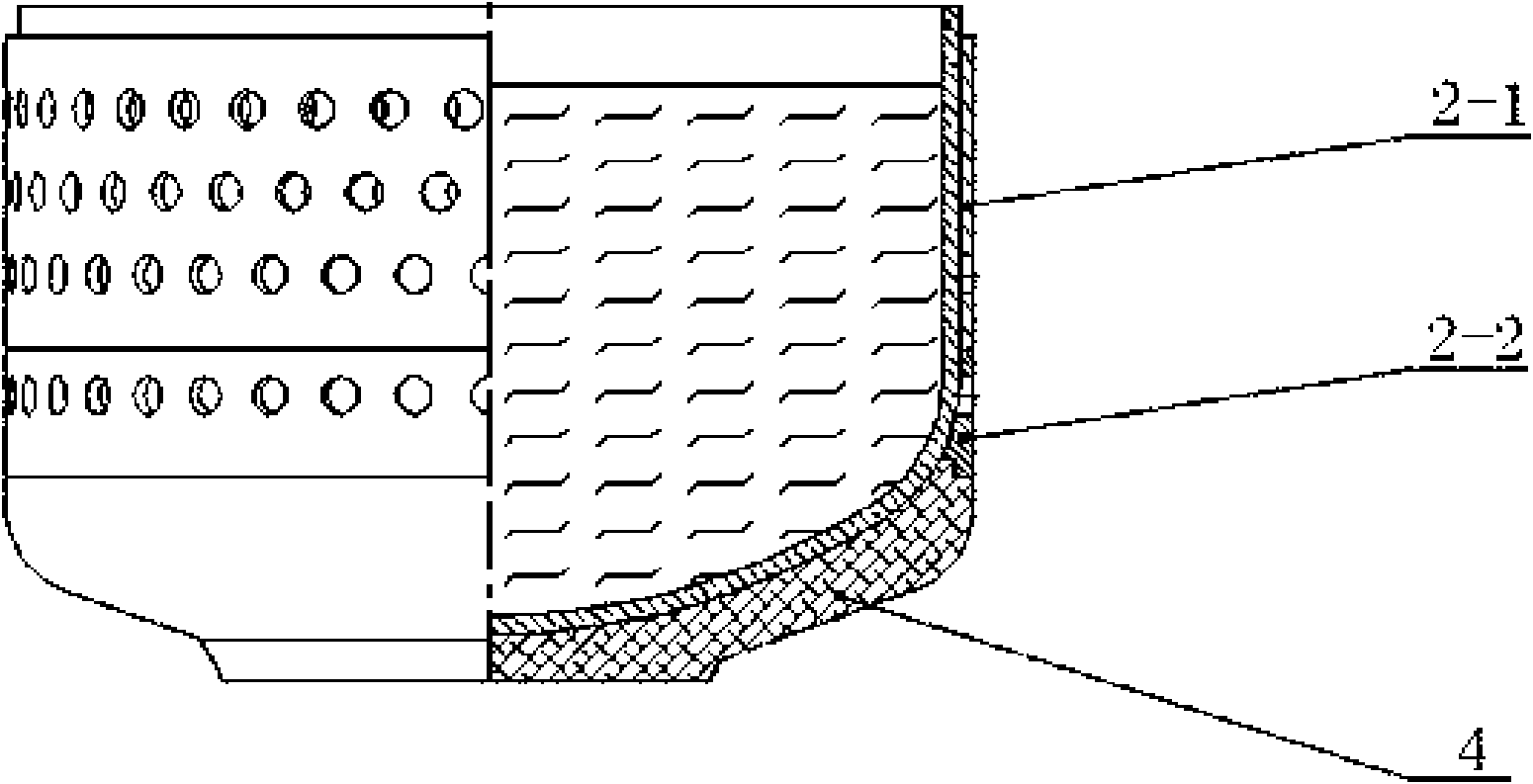

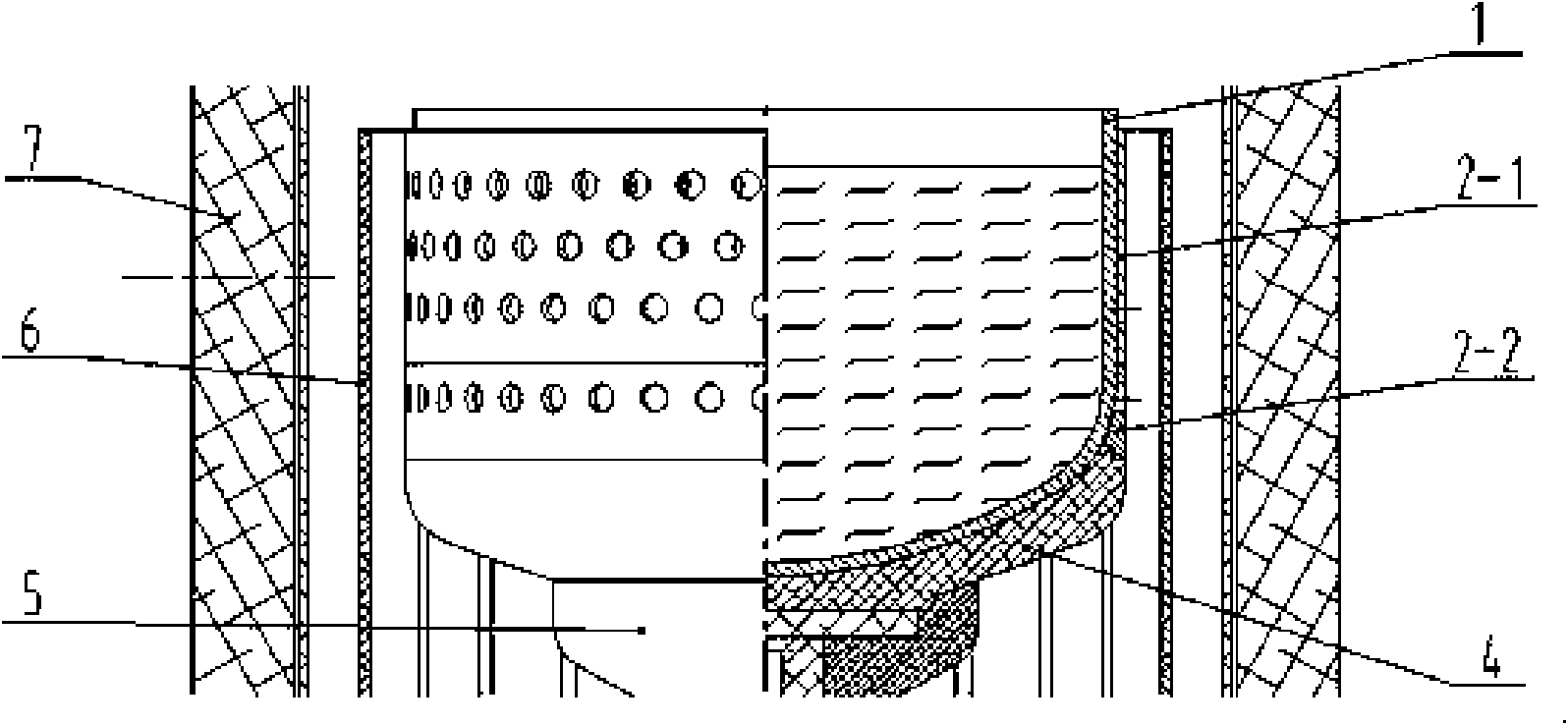

Preparation method of large-size thin-wall hollow flat-plate ceramic film

ActiveCN104258737ALower sintering temperatureReduce production energy consumptionSemi-permeable membranesLarge sizeEnergy consumption

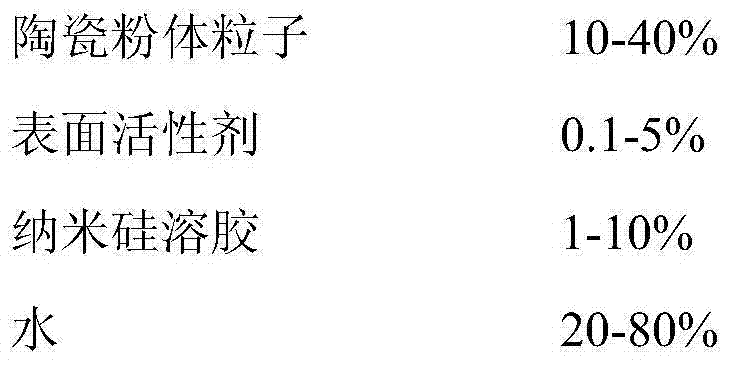

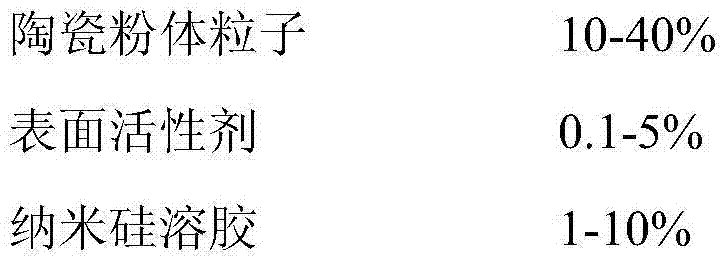

The invention belongs to the technical field of ceramic films, and in particular relates to a preparation method of a large-size thin-wall hollow flat-plate ceramic film. The preparation method comprises preparation of a flat-plate ceramic supporting body and preparation of a separation film layer. According to the preparation method, an alpha-Al2O3 powder body is coated by nano silicon dioxide dispersing liquid, so that the sintering temperature of the flat-plate film supporting body is greatly lowered, and the production energy consumption of a product is reduced; furthermore, chemical components of the supporting body are relatively high in purity, and the acid-alkali corrosion resistance is high; in a process of preparing a large-size thin-wall flat-plate film, deformation of a flat-plate film blank in extrusion, drying and sintering processes can be greatly reduced, and the yield of the flat-plate film is increased; the separation film layer adopts ceramic powder body particles modified by nano-silica sol; the surfaces of the particles are rounded and spheroidized; a duct of the prepared separation film layer is smooth and is low in filtering resistance; the water flux can be increased by over 30 percent.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Preparation method for multi-component net-shaped nanofiber membrane

ActiveCN103806221AIncreased interaction surface areaImprove the degree of purificationFilament/thread formingNon-woven fabricsOrganic solventHalogen

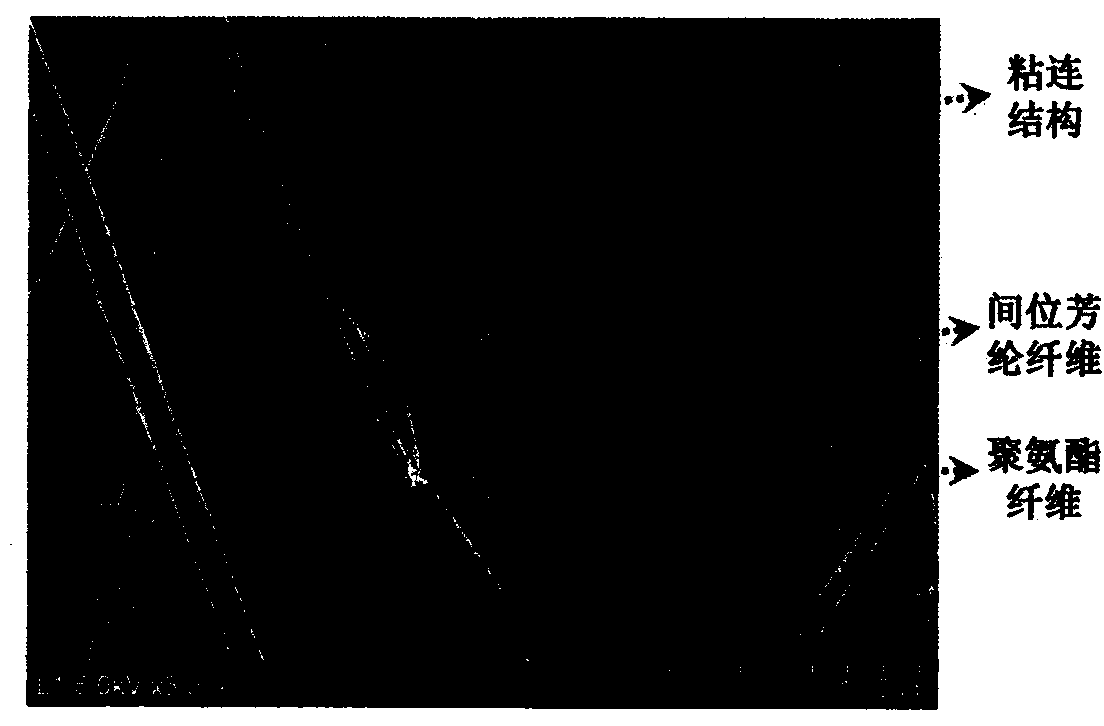

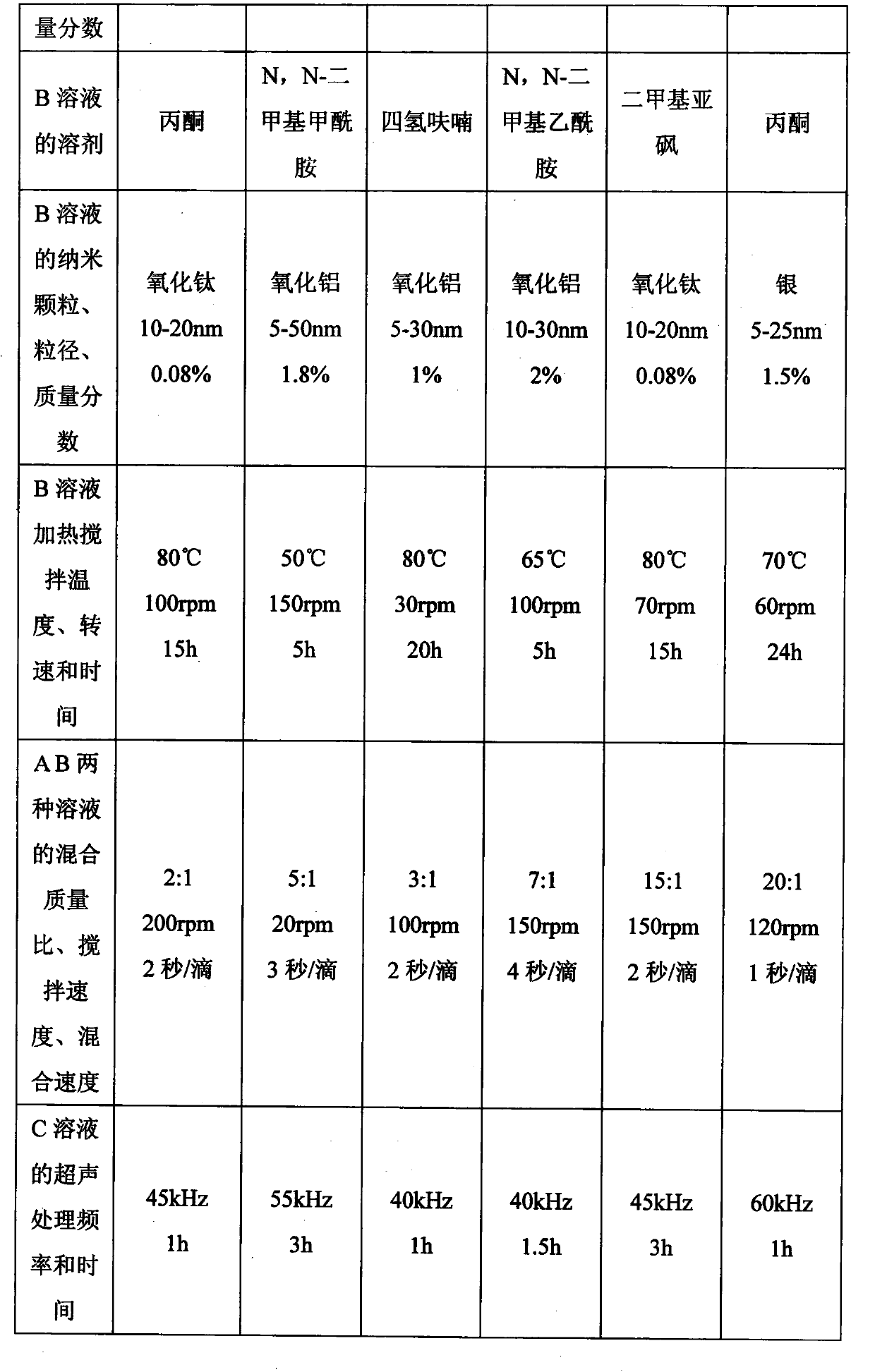

The invention relates to a preparation method for a multi-component net-shaped nanofiber membrane. The preparation method includes the detailed steps that step1, mixing and beating are performed on meta-position aramid fibers, halogen salt and organic solvent by the mass ratio of 1:0.004-0.4:2.996-18.6, and a meta-position aramid fiber solution is prepared through mixing; step2, functionality high-molecular polymers and the solvent are mixed by the mass ratio of 1:5.4-98.99, then nano-particles are added, and heating and mixing are performed to prepare a functionality high-molecular solution, wherein the mass fraction of the nano-particles in the solution is 0.01-5%; step3, the meta-position aramid fiber solution obtained in the step1 and the functionality high-molecular solution obtained in the step2 are mixed by the mass ratio of 1:0.05-0.5 in a dripping mode, and then ultrasonic treatment is performed to obtain a spinning solution; step4, under the conditions of 20 DEG C-30 DEG C indoor temperature and 20-70% relative humidity, the spinning solution is used for electrostatic spinning, and finally the multi-component net-shaped nanofiber membrane with a 5nm-20nm net-shaped nanofiber diameter and reaches over 95% in net-shaped structure coverage rate is obtained. The preparation technology is simple and low in cost, tensile strength of material reaches 100MPa-2000MPa, and the functionality advantage is remarkable.

Owner:DONGHUA UNIV

Method for preparing porous silicon carbide ceramic

ActiveCN102807391AImprove strength propertiesLow costCeramicwareSilica fumeMechanical properties of carbon nanotubes

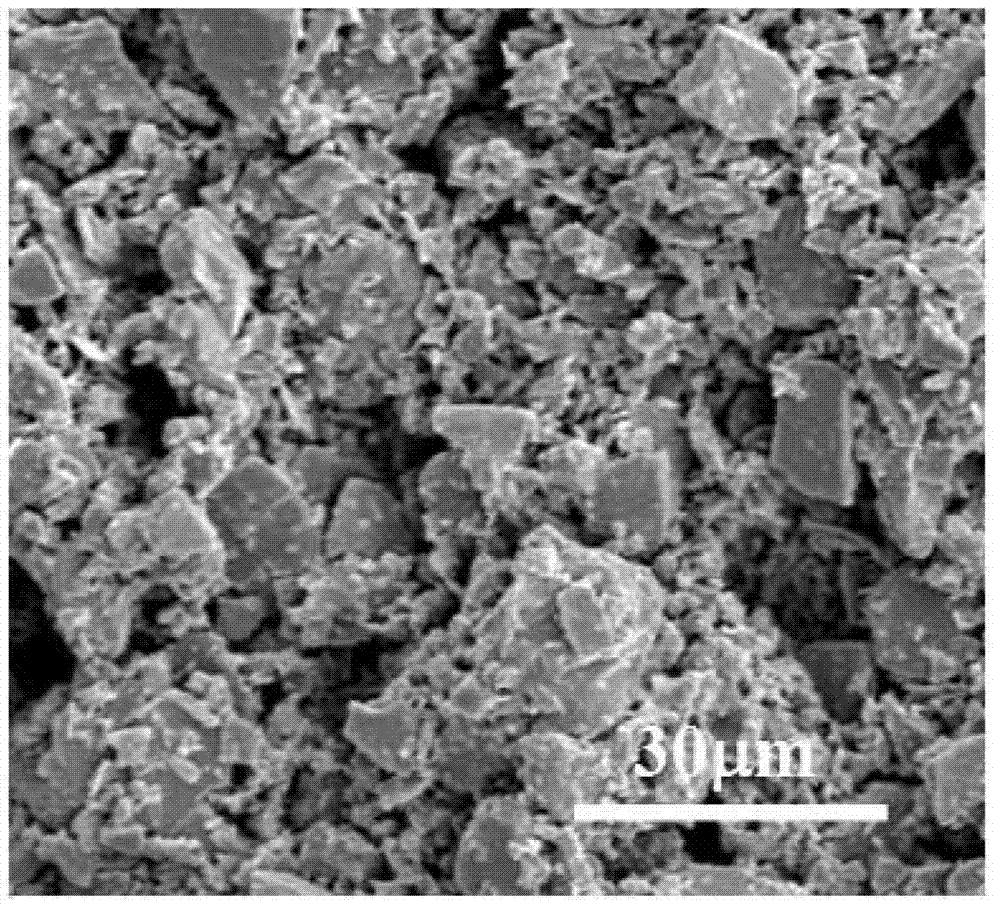

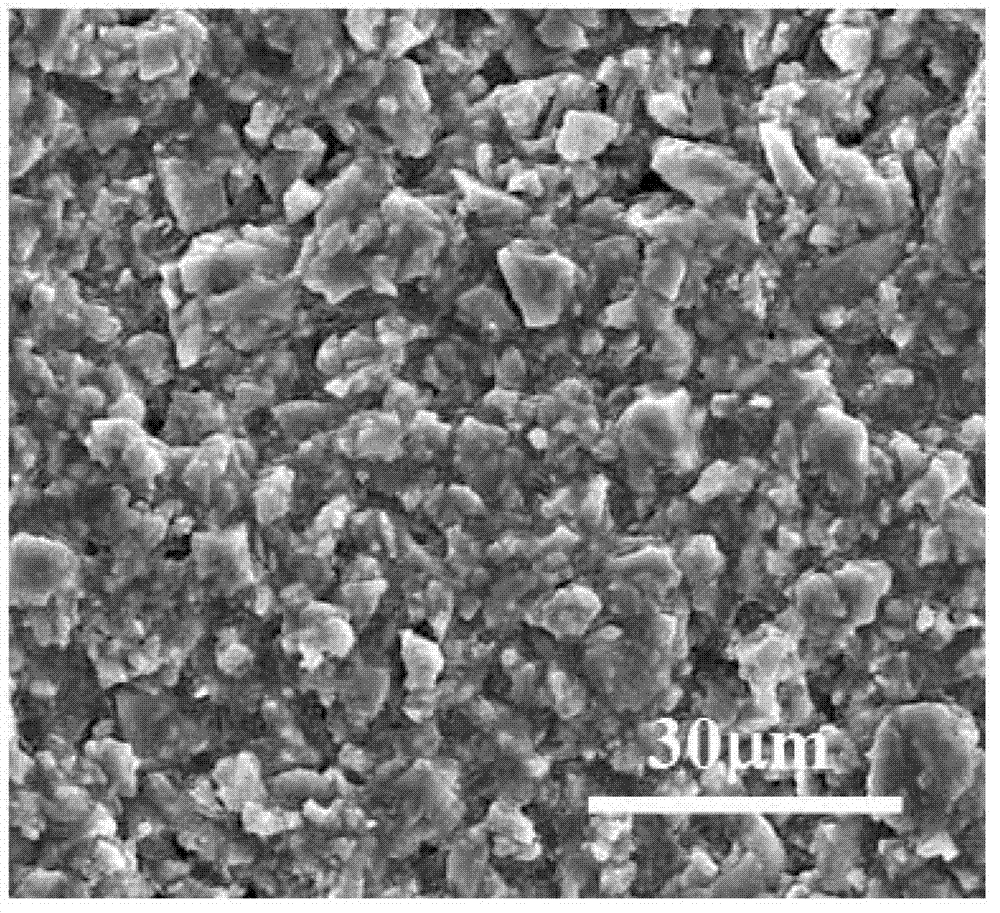

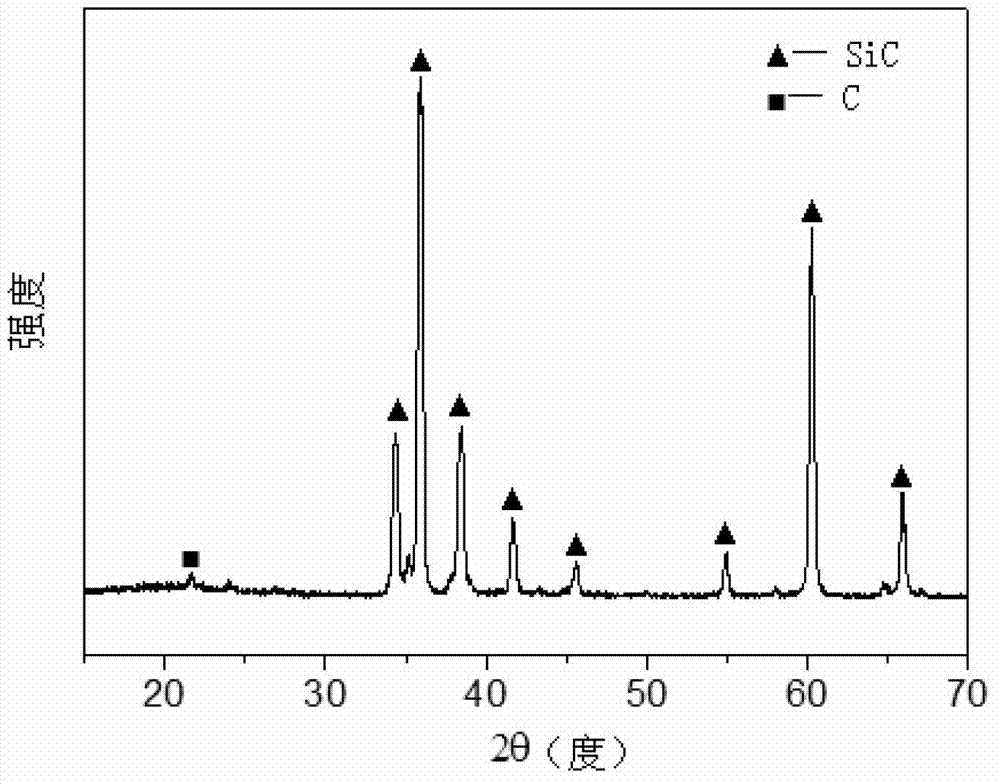

The invention discloses a method for preparing porous silicon carbide ceramic, and relates to a method for preparing silicon carbide ceramic. The invention aims to solve the technical problems of low mechanical properties and low porosity of porous silicon carbide ceramic prepared through the existing method. The method comprises the following steps of 1, preparing pulp; 2, preparing a porous ceramic green body; 3, preparing a prefabricated body; 4, preparing carbon gel; 5, preparing a composite material of silicon carbide and the carbon gel; 6, preparing a composite material of porous silicon carbide and carbon aerogel; and 7, putting the composite material of the porous silicon carbide and the carbon aerogel and monatomic silicon powder into a sintering furnace to be sintered to obtain the porous silicon carbide ceramic. The porosity of the opening of the porous silicon carbide is 30-83 percent, the aperture size is 0.3-100m, and pore spaces can be uniformly distributed or directionally arranged. Through a three-point bending test, the bending strength of the finally prepared porous silicon carbide ceramic material with the porosity of 47.8 percent achieves 164.62 MPa.

Owner:HARBIN INST OF TECH

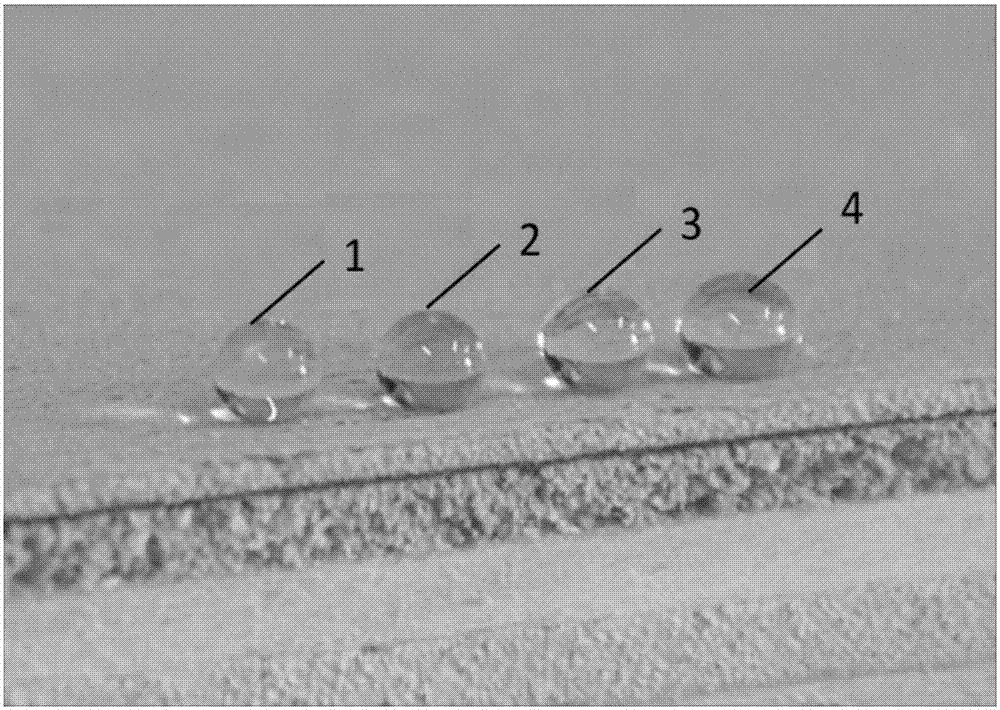

Preparation method of persistent icing-resistant superhydrophobic coating

ActiveCN106883650AImproved long-lasting anti-icing performanceLong-lasting anti-icing performanceAntifouling/underwater paintsPaper coatingSuperhydrophobePolymer science

The invention relates to the field of preparation of superhydrophobic coatings, in particular to a preparation method of a persistent icing-resistant superhydrophobic coating. The preparation method comprises the following steps: firstly, carrying out cleaning and sand-blasting roughen treatment on the surface of a substrate; secondly, blending epoxy resin, a curing agent and a first solvent to obtain an epoxy resin solution; thirdly, dispersing submicron particles and nanoparticles into a second solvent, and then adding a silane coupling agent to obtain particle composite suspension; fourthly, spraying the epoxy resin solution obtained in the second step on the surface of the substrate treated in the first step, and partially curing epoxy resin adhesive; fifthly, spraying the particle composite suspension obtained in the third step on the surface of the substrate obtained in the fourth step and completely curing; sixthly, obtaining the persistent icing-resistant superhydrophobic coating. The persistent icing-resistant superhydrophobic coating disclosed by the invention has the beneficial effects that the superhydrophobic coatings prepared on the surfaces of all the substrates have good durability and firmness and persistent icing-resistant property.

Owner:哈尔滨毓干科技有限公司

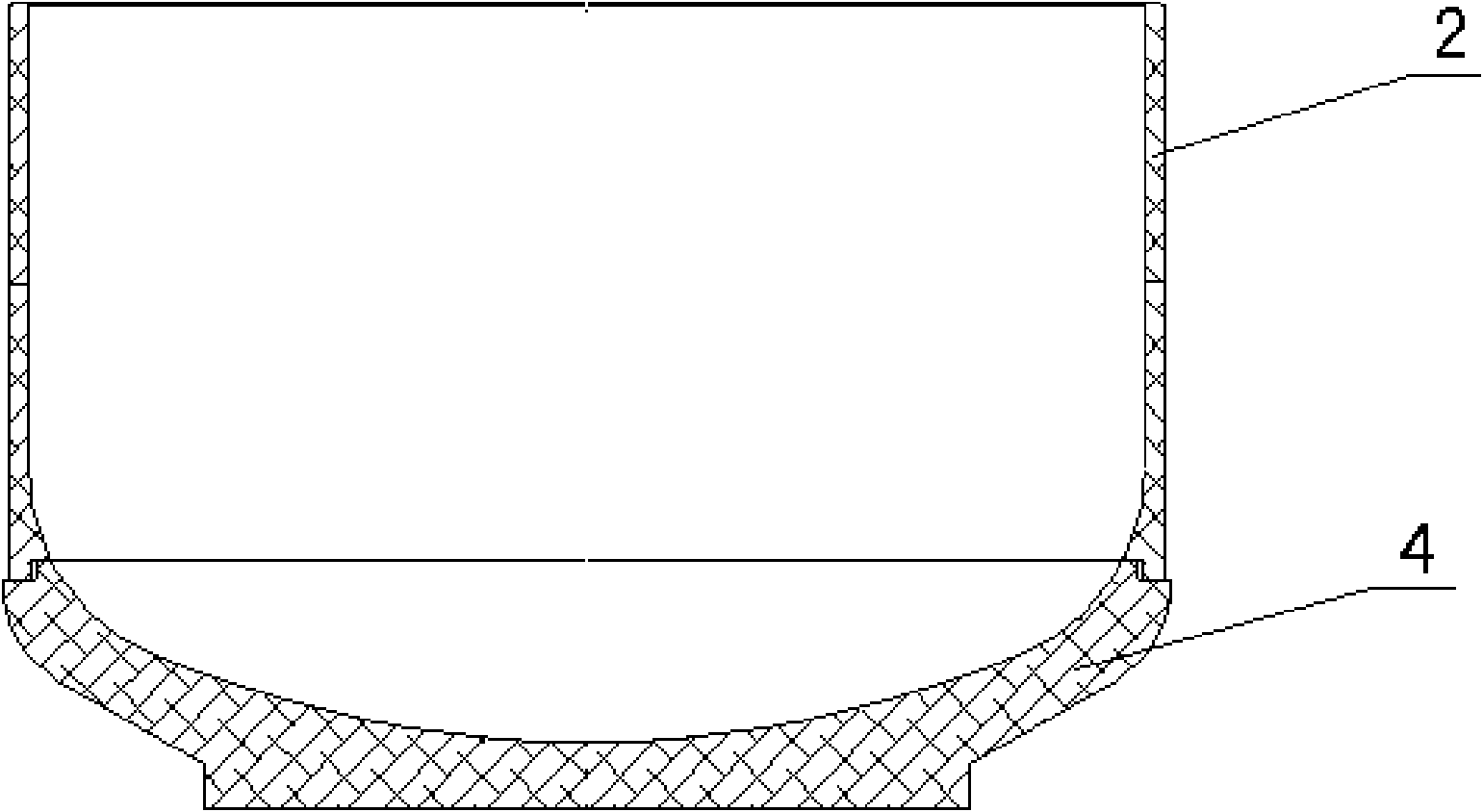

CZ method silicon single crystal growth furnace quartz crucible carbon protection crucible and manufacturing process thereof

InactiveCN101643933AExtended service lifeGuaranteed radiationBy pulling from meltCarbon coatingFiber

The invention relates to a CZ method silicon single crystal growth furnace quartz crucible carbon protection crucible and a manufacturing process thereof. The CZ method silicon single crystal growth furnace quartz crucible carbon protection crucible comprises an upper crucible edge, a lower crucible edge and a crucible support, wherein the upper crucible edge and the lower crucible edge comprise green bodies and matrix carbon, the surface is provided with a silicon carbide coating, each green body is formed by the superposition of two-dimensional carbon fiber fabrics or is formed by a quasi-three-dimensional punched carbon fiber felt body, and the weight is not lower than 40 percent of weight of the protection crucible; the matrix carbon comprises carbon resin and chemical vapor depositioncarbon, wherein the content of the chemical vapor deposition carbon is not higher than 30 percent of total weight of the product; the density of materials of the upper crucible edge and the lower crucible edge is higher than or equal to 1.3g / cm <3>; holes with the diameters ranging from 5 to 30 mm are uniformly distributed on the upper crucible edge and the lower crucible edge, the walls of the holes and the inner surfaces of the crucible edges are provided with silicon carbide coatings, and the thickness ranges from 10 to 100 mu m; and the crucible support comprises high strength and high purity graphite and surface deposited carbon coatings, the density thereof is higher than or equal to 1.7g / cm <3>, and the thickness of the surface deposited carbon coatings ranges from 10 to 100 mu m.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Cable sheath material for coal mine

ActiveCN101538380AImprove stabilityEasy to useInsulated cablesInsulated conductorsPolymer sciencePolyvinyl chloride

The invention discloses a cable sheath material for a coal mine, which is characterized by comprising the following raw materials for preparing effective constituents according to the parts by weight: 70-100 of butyronitrile-polyvinyl chloride compound, 10-30 of neoprene, 30-60 of white carbon black, 2-8 of magnesium oxide, 20-60 of aluminum hydroxide, 30-60 of chlorcosane, 2-6 of accelerant CZ, 3-8 of zinc oxide, 1-5 of stearic acid, 3-8 of age inhibitor, 4-15 of diantimony trioxide, 2-7 of titanium pigment and 3-9 of vulcanizing agent. The cable sheath material for the coal mine has better performance of stink resistance, cold resistance, flame resistance, oil resistance, ageing resistance, and the like and has good elasticity, high tensile strength, good tear resistance, good extrusion performance and low cost.

Owner:阳谷新太平洋电缆有限公司

Sintering preparation method of boron carbide ceramic

The invention discloses a sintering preparation method of boron carbide ceramic, which comprises the following steps: 1. sintering: carrying out mixing and ball milling on boron carbide powder, carbon powder, metal powder, a dispersant, an adhesive and deionized water to make a slurry, carrying out spray granulation, pressing into a biscuit, presintering for debonding, and carrying out thermal-insulation sintering at lower sintering temperature (slightly higher than the melting point of metal), thereby implementing primary shrinkage sintering of the product by utilizing the surface tension of the molten metal in the system; and 2. sintering: continuing enhancing the sintering temperature, carrying out in-situ reaction to generate metal carbide, metal boride or metal boro-carbide and nano B4C which have higher sintering activity, and forming a solid solution with boron carbide granules by using the metal carbide, metal boride or metal boro-carbide and nano B4C as sintering assistants to promote the further shrinkage sintering of the system, thereby obtaining the high-performance boron carbide ceramic. The method has the advantages of both the normal-pressure sintering technique and the reactive sintering technique.

Owner:NINGBO VULCAN TECH CO LTD

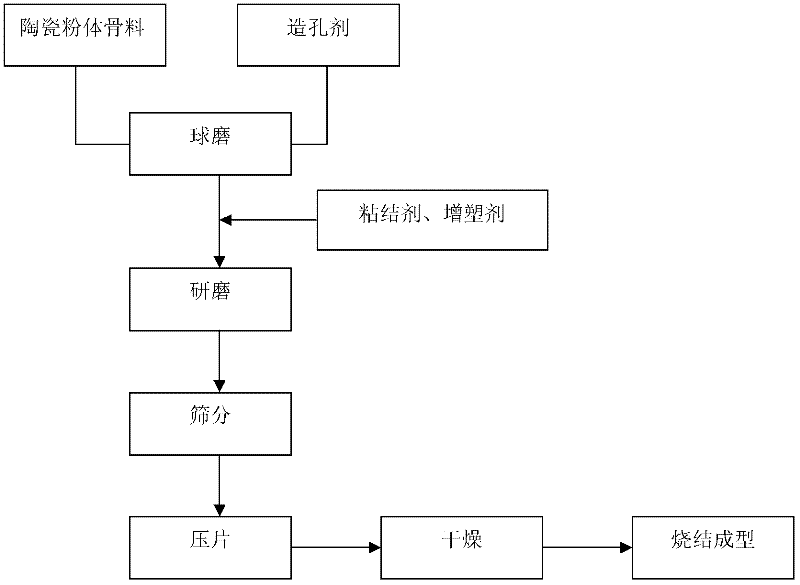

Method for preparing high-porosity porous ceramic membrane support

The invention relates to a method for preparing a high-porosity porous ceramic membrane support, comprising the following specific steps of: performing mixed ball milling and dispersion on a ceramic powder aggregate and a pore-forming agent, adding in a binder and a plasticizer, and then performing grinding, sieving, tabletting, drying and sinter molding. The method provided by the invention overcome the problem of easy formation of large pores in the presence of the pore-forming agent and further improves the porosity of the support without reducing the overall performance of the support by improving the purity of the ceramic powder aggregate and adjusting the content of the pore-forming agent, the size distribution and the sintering schedule; and as a result, the penetrating quality of the support is improved.

Owner:NANJING UNIV OF TECH

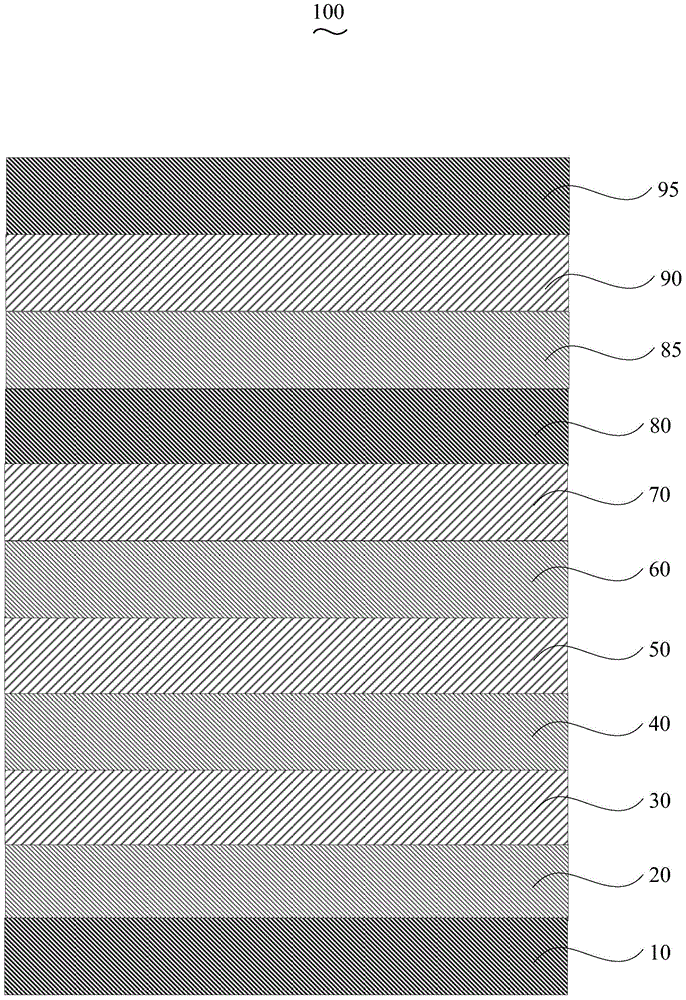

Antireflection glass and preparation method thereof

ActiveCN104553126AImprove anti-reflection effectGuaranteed Optical PerformanceGlass/slag layered productsReflectivityTransmittance

The invention discloses a piece of antireflection glass. The antireflection glass is prepared by using aluminosilicate glass as a substrate; the visible light full-wave band average transmittance is higher than or equal to 94.5%, and the film coated surface single-side full-wave band average reflectivity is smaller than or equal to 1%; the antireflection glass is high in hardness, scrape resistance, acid-base resistance and follow-up processability. The antireflection glass comprises the aluminosilicate glass substrate, a first low-refractive index layer, a first high-refractive index layer, a second low-refractive index layer, a second high-refractive index layer, a third low-refractive index layer, a third high-refractive index layer, a fourth low-refractive index layer, a fourth high-refractive index layer, a fifth low-refractive index layer, and a fifth high-refractive index layer, wherein the first low-refractive index layer is made of SiO2; the first high-refractive index layer is made of Nb2O5. The antireflection glass is lower in the film coated surface single-side full-wave band average reflectivity, higher in hardness, and very suitable for acid and alkali treatment in the follow-up manufacturing procedures, so as to be adapted to more working procedures and achieve wider application range. The invention further discloses a preparation method of the antireflection glass.

Owner:YICHANG NANBO DISPLAY

Enamel and preparation method thereof

The invention provides enamel, which comprises a substrate and a ceramic glaze layer enamel-fired on the substrate, wherein the ceramic glaze layer is prepared by firing ceramic glaze powder which contains 60 and 90 weight percent of glass frit, 5 to 18 weight percent of crushed sand, 3 to 12 weight percent of clay, 0.3 to 5 weight percent of borax and 0.3 to 5 weight percent of soda ash. The enamel has excellent physiochemical performance such as low sintering temperature, corrosion resistance and the like. The method for preparing the enamel has the advantages of obtaining an enamel coating with high bonding strength and acid and alkali corrosion resistance at lower sintering temperature, solving the problem of substrate deformation, saving energy, and reducing production cost.

Owner:CHERY AUTOMOBILE CO LTD

Prepn process of hydrophilic paint for superthin air conditioner aluminium foil heat exchanger

InactiveCN101020798ADoes not affect heat exchange performanceIncrease contentCoatingsSpecial surfacesCross-linkPolymer science

The present invention discloses preparation process of hydrophilic paint for heat exchanger aluminum foil of air conditioner. The paint consists of one kind of base paint, and one kind of top paint. The base paint consists of hydroxyl emulsion 15.0-20.0 wt%, amino resin 1.5-3.0 wt%, cross-linking assistant 0.05-0.5 wt%, color paste 1.5-2.5 wt%, and mixed solvent for the rest. The top paint includes two components, component A and component B, in the weight ratio of 9.0-11.0 to 1, the component A consists of hydrophilic polymer 25.0-35.0 wt%, hydrophilic reinforcer 5.0-10.0 wt%, surfactant 0.5-3.5 wt%, and mixed solvent for the rest; and the component B consists of curing agent 60.0-65.0 wt% and deionized water 35.0-40.0 wt%. The paint of the present invention has high adhesion, high hydrophilicity, and capacity of forming very thin coating to ensure the heat exchange performance of the heat exchanger.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing room-temperature self-crosslinking water-based polyurethane emulsion

ActiveCN101709108AImprove water resistanceImprove acid and alkali corrosion resistancePolyurea/polyurethane coatingsWater basedMechanical property

The invention discloses a method for preparing water-based polyurethane emulsion with a room-temperature self-crosslinking characteristic. The emulsion is prepared from the following raw materials in part by mass: 1) 100 parts of low-polymer diol, 2) 50 to 150 parts of polyisocyanate, 3) 8 to 28 parts of hydrophilic compound, 4) 5 to 50 parts of acetoacetyl compound, 5) 1 to 20 parts of micro-molecule dolichol compound, 6) 0.5 to 10 parts of polyamine compound, 7) 1 to 21 parts of ammonia or organic amine, selectively, 8) 0.01 to 0.1 parts of polyurethane reaction catalyst, and selectively, 9) 20 to 310 parts of organic solvent. After being formed into a film, the emulsion prepared by the method has excellent water resistance, acid and alkali resistance and chemical resistance, and also has the excellent physical and mechanical properties of high hardness, high elasticity, scratch resistance and the like.

Owner:WANHUA CHEM BEIJING +3

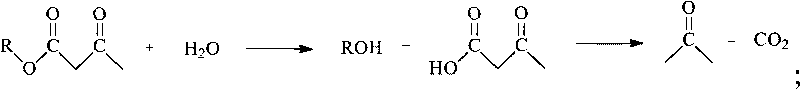

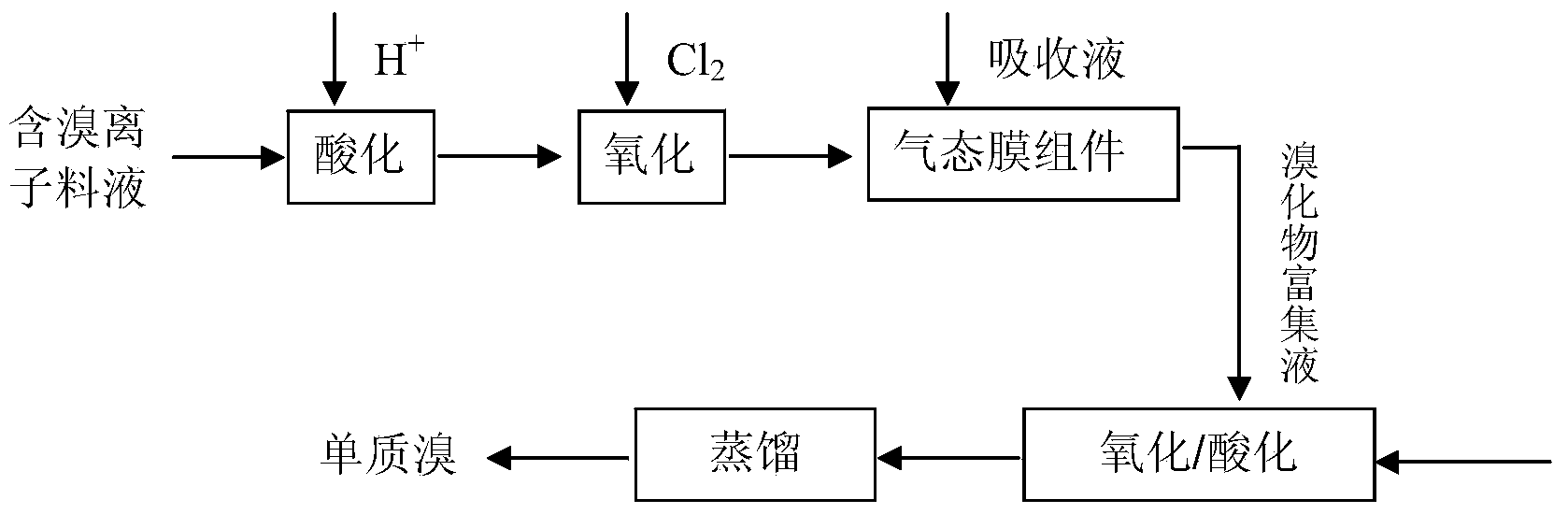

Method for preparing/gathering bromine from bromine-containing feed liquid or waste water

The invention relates to a method for preparing / gathering bromine from bromine-containing feed liquid or waste water. The method comprises the following steps of: (1) acidification or acidification oxidation of the bromine-containing feed liquid or waste water, namely regulating the pH value of the bromine-containing feed liquid or waste water to 3-4, wherein the bromine contained in the acidified feed liquid or waste water exists in a bromine form; (2) bromine extraction in the separation process of a gaseous film, namely carrying out bromine extraction treatment by introducing the bromine-containing feed liquid or waste water which is formed after the acidification or the acidification oxidation into a gaseous film assembly to obtain a bromide-containing gathered solution; (3) post treatment, namely carrying out the post treatment on the gathered solution, and distilling to obtain elemental bromine. According to the method, a polytetrafluoroethylene or polytetrafluoroethylene hollow fiber microporous film assembly is adopted as a bromine extraction core device, and the film assembly has the advantages of oxidation resistance and long service life. The method disclosed by the invention has the advantages of low energy consumption, high bromine mass transfer efficiency and high bromine recovery rate in a process flow, simple equipment, convenience for operation and low operating cost, can be widely applied to the bromine extraction of the bromine-containing feed liquid with various concentration ranges and various scales.

Owner:TIANJIN PURESEA SPRING MEMBRANE TECH CO LTD

Dosage for producing micro crystal glass or cast stone from iron containing metallurgical waste slag and its method

The present invention relates to material composition and method of producing microcrystalline glass or cast stone with iron containing metallurgical slag, relates to the method of recovering and melting metallurgical slag, and aims at recovering iron containing slag, utilizing its iron in melting cast iron or steel, melting the slag into microcrystalline glass or cast stone, raising resource utilization rate and lowering environmental pollution. The iron containing metallurgical slag used as main material accounts for 45-65 wt%; and the supplementary material accounts 44-55 wt%. The supplementary material includes compounded material, reductant, crystal kernel agent and deairing agent; and the compounded material consists of quartzite, limestone and bauxite, or consists of coal gangue and cinder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

High-strength high-mold corrosion-resistant vinyl ester resin SMC sheet molding compound and preparation method thereof

The invention discloses a high-strength high-mold corrosion-resistant vinyl ester resin SMC sheet molding compound and a preparation method thereof. The high-strength high-mold corrosion-resistant vinyl ester resin SMC sheet molding compound is prepared from the following raw materials: phenolic aldehyde-type epoxy vinyl ester resin capable of being thickened by magnesium oxide, a high-modulus fiber combination, oxidized graphene powder, a low shrinkage agent, a thickening agent, an inorganic mineral filler, a wetting dispersant, a coupling agent, a curing agent and a mold release agent. The preparation method comprises the following steps: preparation of graphene-based vinyl ester resin size, preparation of the thickening agent, preparation of resin paste, impregnation, layering, and curing. The preparation method is simple and easy to operate. The product is high in not only corrosion resistance and solvent resistance, but also strength and modulus, and has excellent performances in the aspects of heat, power, electricity and the like.

Owner:四川远鸣科技有限公司

Preparation method of high-strength corrosion-resistant copper pipe for heat exchanger

The invention discloses a preparation method of a high-strength corrosion-resistant copper pipe for a heat exchanger. The high-strength corrosion-resistant copper pipe comprises a copper matrix and alloy metals. The alloy metals comprise, by weight, 0.5-0.6% of magnesium, 0.08-0.09% of silver, 0.2-0.4% of tin. 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.05-0.06% of nickel, 0.005-0.008% of titanium and 0.02-0.04% of mischmetal. The mischmetal comprises yttrium, berkelium and lanthanum according to a mass ratio of 1: (0.15-0.2): (0.4-0.5). The preparation method utilizes upward continuous casting, rolling and drawing processes to replace casting, sawing, heating, extrusion and pickling processes of the traditional preparation method so that processes are greatly simplified, continuous production is realized, a period is short, and efficiency is high. A copper pipe prepared by the preparation method has oxygen content satisfying the oxygen-free copper level standard, has fine grains, and has mechanical strength, high temperature resistance, corrosion resistance and wear resistance obviously superior to the same performances of the existing copper pipe.

Owner:山东兴鲁有色金属集团有限公司

Building heat preservation material

InactiveCN106588108AReduce weightImprove insulation effectCeramicwareCelluloseEnvironmental resistance

The invention discloses a building heat preservation material. The building heat preservation material is mainly prepared from, by weight, 15-30 parts of bentonite, 15-30 parts of coal ash, 10-20 parts of mica, 2-5 parts of polyacrylamide, 12-27 parts of kaolin, 11-25 parts of expanded perlite, 7-15 parts of phenolic resin, 0.5-2 parts of calcium stearate, 1-3 parts of foaming agent, 6-13 parts of soapstone, 35-55 parts of modified environment-friendly adhesive, 3-6 parts of starch ether, 6-13 parts of centrifugal glass fibers, 2-8 parts of hydroxymethyl propyl cellulose, 15-25 parts of cement, 8-17 parts of ceramsite and 11-23 parts of diatomite. The building heat preservation material is low in weight, can replace a traditional building heat preservation material, and can be used for coating protection of building side walls. The heat conductivity coefficient of the material is tested based on the GB / T10297-1998 standard, the heat conductivity coefficient is only 0.038-0.040, the heat preservation performance is extremely excellent, high acid-base corrosion resistance is achieved, no abnormities exist after the experimental test is carried out for 150 h, superhigh weather fastness is achieved, and no discoloring or pulverization or bubbles or stripping or cracks are generated 420 h later.

Owner:南宁市大江保温材料有限公司

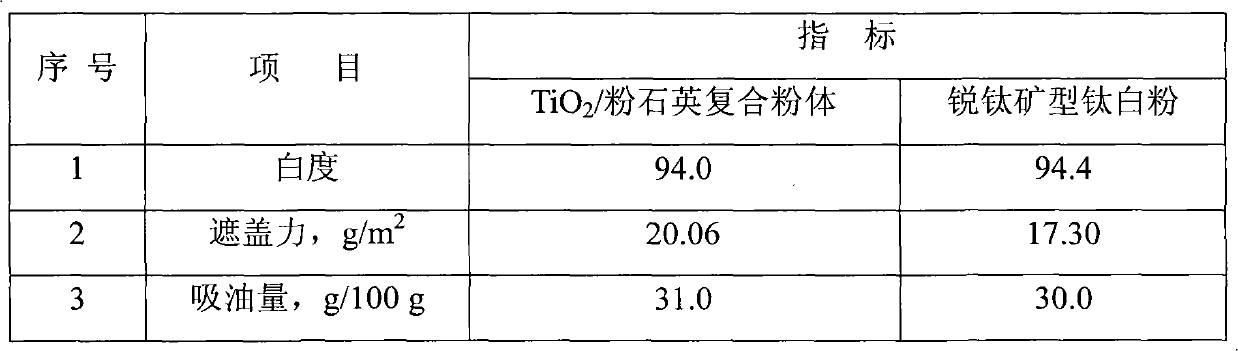

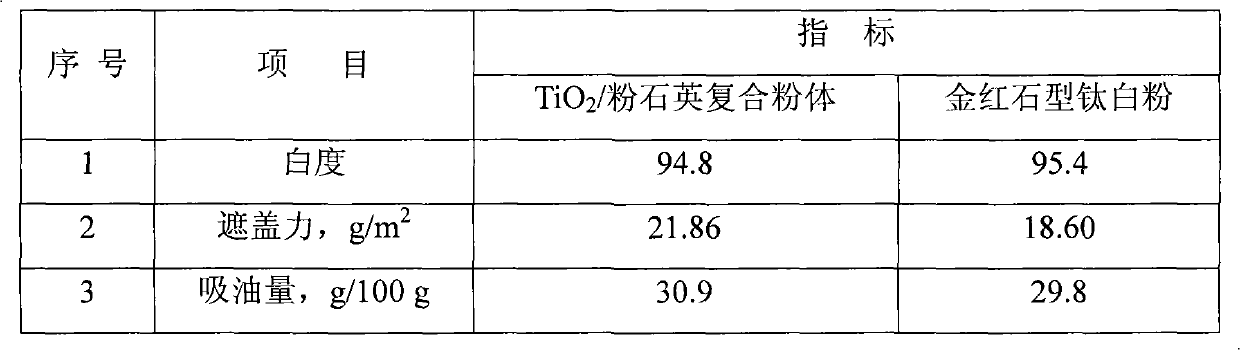

A kind of preparation method of tio2/powder quartz composite powder material

InactiveCN102260422AHigh refractive indexGood acid and alkali resistancePigment physical treatmentTitaniumQuartz

The invention provides a method for preparing a TiO2 / powdered quartz composite powder material. In the invention, the used powdered quartz is a nucleated substrate, crystalline TiO2 is a coating material, the surface of the nucleated substrate is coated and modified with TiO2 by reaction in a mechanical and chemical modifying mode in a wet-process superfine grinding system, and thus, the TiO2 / powdered quartz composite powder material is prepared. In the composite powder material disclosed by the invention, the TiO2 is uniformly coated on the surface of the powdered quartz particles and is stably bonded with the surface of the powdered quartz particles. The powder material has high covering performance, dye performance such as high compatibility with an application system and high acid and alkali resistance. The TiO2 / powdered quartz composite powder material can be used in place of natural titanium white.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

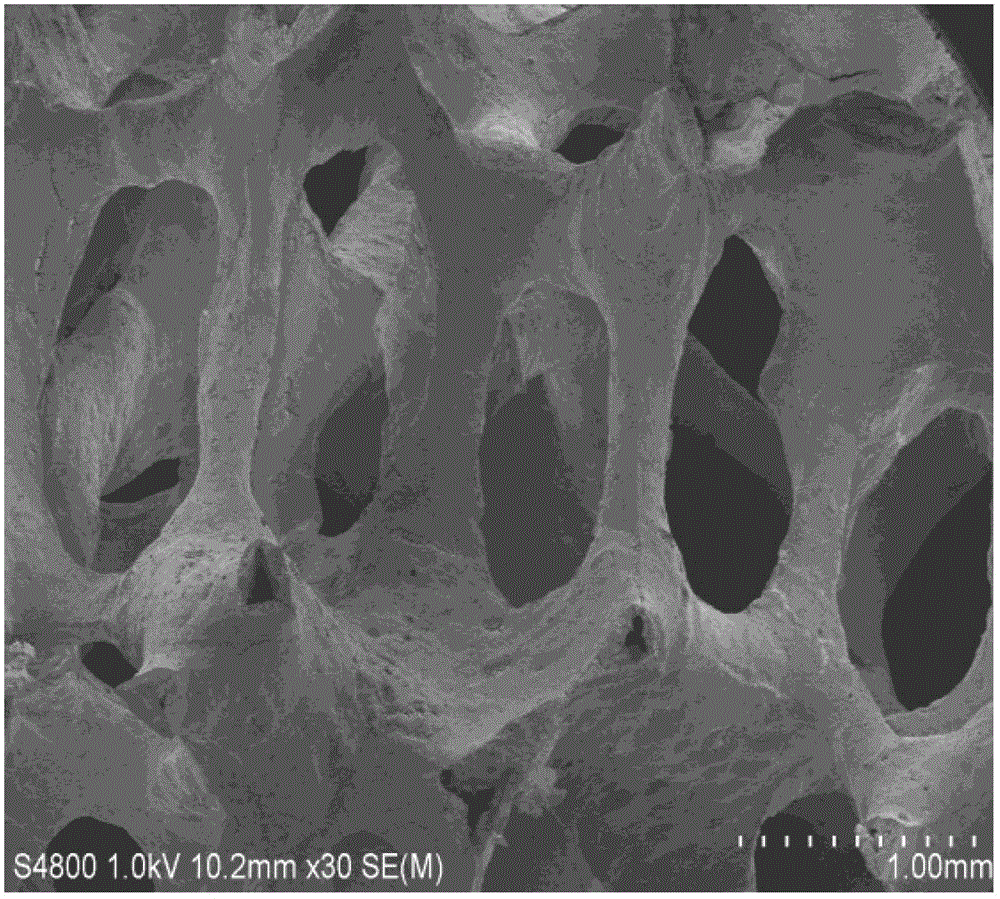

Process for preparing TiO2 (titanium dioxide) film on aluminum-oxide foamed ceramic

InactiveCN102744049AIncrease the effective areaImprove acid and alkali corrosion resistancePhysical/chemical process catalystsIndustrial waste waterPtru catalyst

The invention discloses a process for preparing a TiO2 (titanium dioxide) film on aluminum-oxide foamed ceramic. The process adopts a concrete implementation scheme that coating aluminum oxide slurry is coated on a foam rib by dipping and extruding, then foam is burned up, and finally, the aluminum-oxide foamed ceramic with high porosity is obtained in a high-temperature sintering manner; Ti collosol is uniformly coated on a pore wall of an aluminum-oxide foamed ceramic carrier by negative-pressure infiltration; and the TiO2 film which is uniformly and continuously distributed on the pore wall of the aluminum-oxide foamed ceramic is prepared by drying and thermal treatment. According to materials disclosed by the invention, the porous aluminum-oxide foamed ceramic serves as a base body; meanwhile, the base body has good resistance to acid and alkali corrosion due to the stable chemical properties of the Al2O3 (aluminum oxide) ceramic; in addition, the carrier material has good high-temperature resistance and oxidation resistance by virtue of a high-melting point of the Al2O3 ceramic. These properties of the materials well meet the requirements on properties of catalysts and the carrier which are used for purifying industrial wastewater, domestic sewage and toxic waste gas in extremely serious corrosive environments.

Owner:CHANGAN UNIV

Method for preparing ultra hydrophobic surface on surface of metal copper

InactiveCN101091947ASuperhydrophobicSupersulfuric acidAntifouling/underwater paintsPretreated surfacesAir atmosphereSulfur water

The invention publics a method of preparing super sulfur-water surface on the metal copper surface, especially involves a method that it can prepare super sulfur-water surface, super vitriol surface and super sulfur-alkalescence surface simultaneously. The method puts the metal copper plate in the oversaturation solution full of vitriol copper for 10-15 days,and cleans with the deionized water, and has a air-dry; smearing the ethylene-dimethyl siloxanes on the metal copper plate surface reelingly, and drying 1-2 hours in air atmosphere 100-120deg.c.Then dropping the pure water, the acid or the alkali on the copper sign surface to make a determination of the contact angle which needs to be bigger than 150deg.The invention simultaneously has the super sulfur-water, super vitriol and super sulfur-alkalescence on the copper surface, it may help to prevent the metal copper surface from being polluted and rusted and so on.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

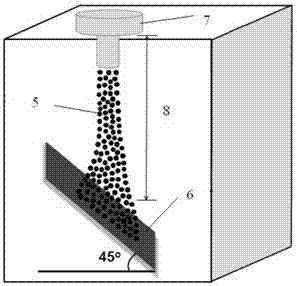

Production method of alumina multichannel ceramic membrane support

InactiveCN106242624AHigh bonding strengthImprove flexural strengthCeramic shaping apparatusClay processing apparatusTunnel kilnMicrowave

A production method of an alumina multichannel ceramic membrane support belongs to the technical field of multichannel ceramic membranes. The production method of the alumina multichannel ceramic membrane support comprises the following steps: carrying out a plastic extrusion molding technology on alumina adopted as a main raw material, drying the molded material in a natural drying and microwave drying combination mode, and sintering the dried material in a shuttle kiln or a tunnel kiln. Rare earth oxide, nanometer alumina sol and a sintering aid are mixed, so the flexural strength and the acid and alkali corrosion resistance of the above obtained product are improved; introduction of an organic binder in the production process of an alumina multichannel ceramic membrane greatly reduces deformation of a green body in the extruding, drying and sintering processes and improves the yield of the product; and the nanometer alumina sol has high intergranular binding strength, so the granule morphology is kept, thereby the channels of the produced product are smooth and have small filtering resistance, and the water flux is improved by 20% or above.

Owner:山东华瓷环保设备科技有限公司

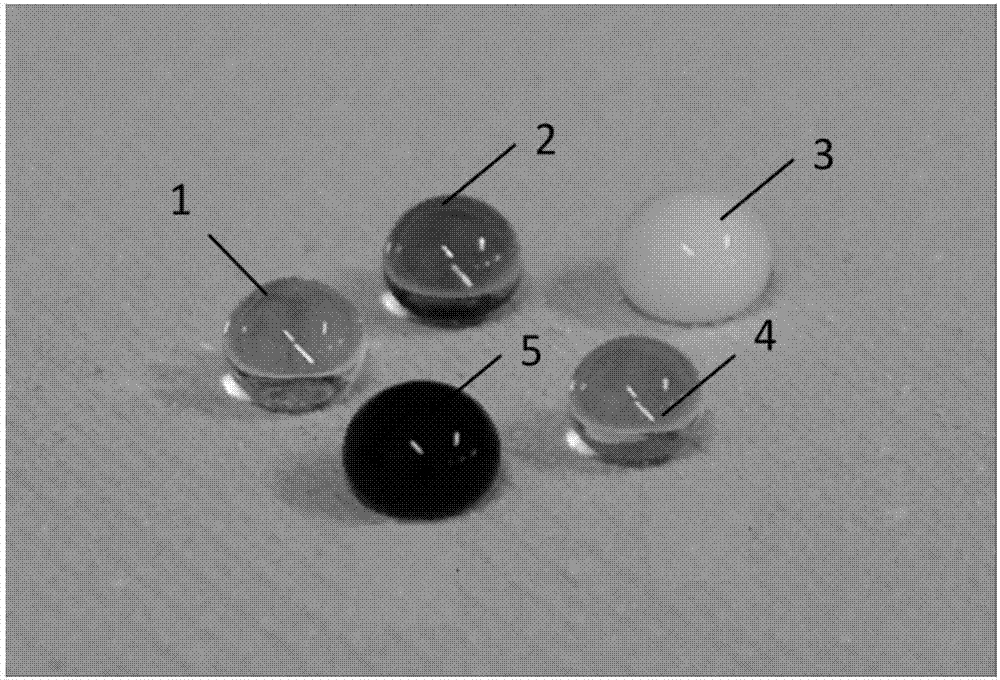

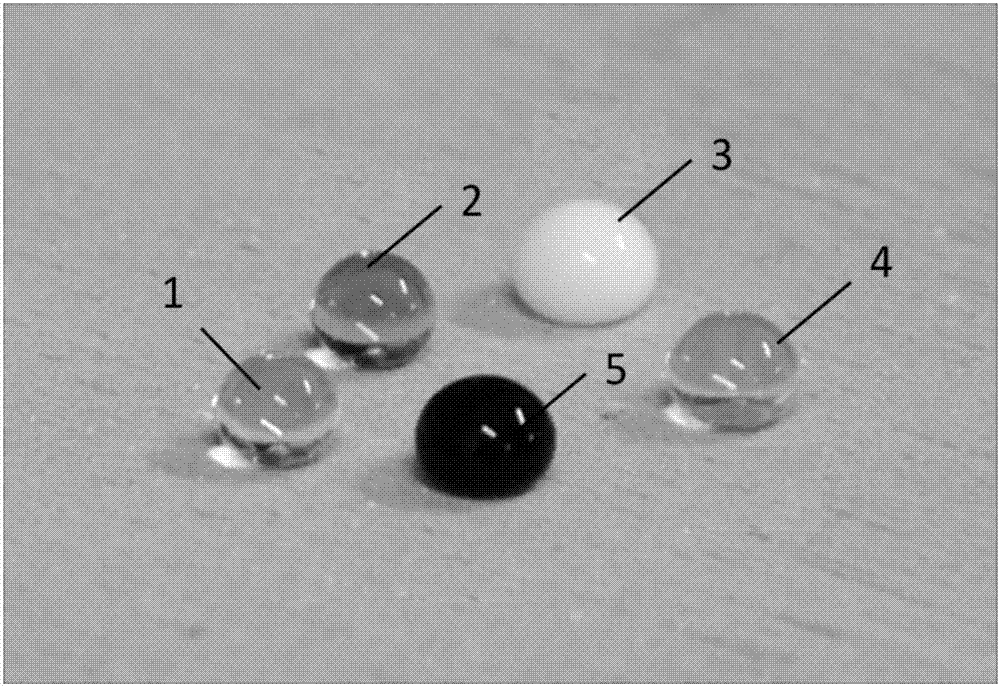

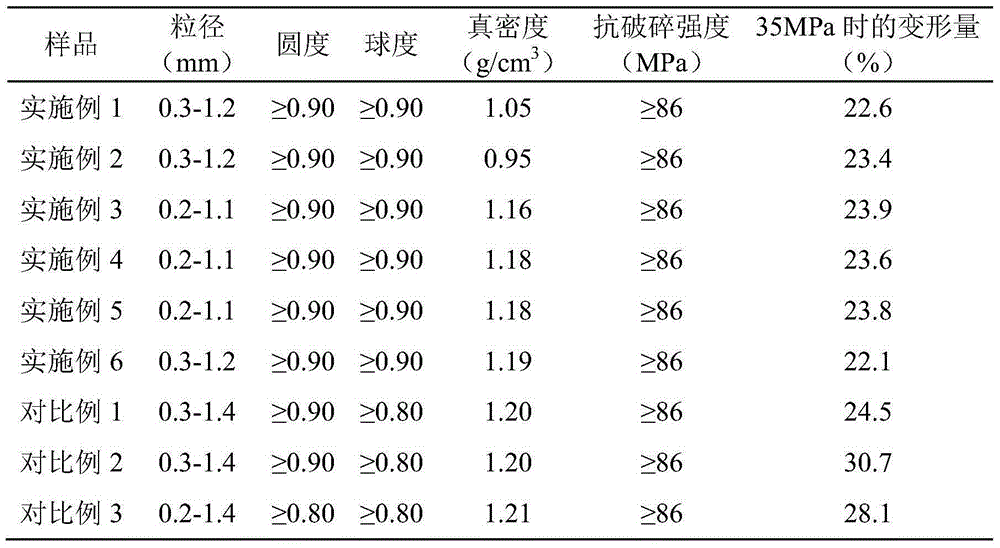

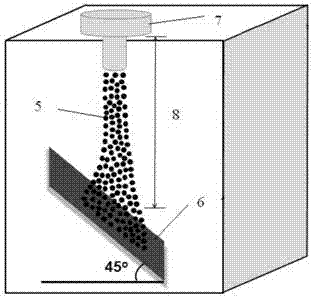

Low-density composite proppant, preparation method and applications thereof

The present invention provides a low-density composite proppant, which is prepared by carrying out a polymerization reaction on an oil phase and an aqueous phase, wherein the oil phase comprises, by weight, 60-90 parts of a monomer, 5-25 parts of a cross-linking agent, 0.01-10 parts of a filler, 0.1-5 parts of an initiator and 0-2 parts of a filler dispersant, and the aqueous phase comprises, by weight, 90-100 parts of water, 0.1-5 parts of a dispersant and 0.1-5 parts of an inorganic salt. The present invention further provides a preparation method of the proppant, wherein the preparation method comprises: uniformly mixing the dispersant, the inorganic salt and the water to obtain the aqueous phase, uniformly mixing the monomer, the cross-linking agent, the initiator, the filler and the optional filler dispersant to obtain the oil phase, mixing the oil phase and the aqueous phase, carrying out a polymerization reaction at a certain temperature to obtain a polymerization product system, and post-treating the obtained polymerization product system. The present invention further discloses applications of the proppant or the proppant prepared according to the method in reservoir fracturing reforming.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of sustainable anti-icing super-amphiphobic coating

ActiveCN107116017AImproved long-lasting anti-icing performanceLong-lasting anti-icing performancePretreated surfacesAnti-corrosive paintsEpoxySilanes

The invention relates to the field of preparation of super-hydrophobic or super-amphiphobic coatings, in particular relates to a preparation method of a sustainable anti-icing super-amphiphobic coating. The method comprises the following steps: 1, cleaning a substrate surface and carrying out sand-blasting roughening treatment; 2, blending epoxy resins, epoxy resin curing agents and a first solvent to obtain an epoxy resin solution; 3, dispersing submicron particles and nanoparticles into a second solvent, and then adding fluoroalkyl silane to obtain particle composite suspension liquid; 4, spraying substrate surface subjected to the treatment in step 1 with the epoxy resin solution obtained in step 2, and carrying out semi-curing on the epoxy resin adhesive; 5, spraying the substrate surface subjected to the treatment in step 4 with the particle composite suspension liquid obtained in step 3, and carrying out complete curing; 6, obtaining the sustainable anti-icing super-amphiphobic coating. The method has the advantages that the super-amphiphobic coating prepared on all substrate surfaces has good durability and fastness, and has sustainable anti-icing performance.

Owner:哈尔滨毓干科技有限公司

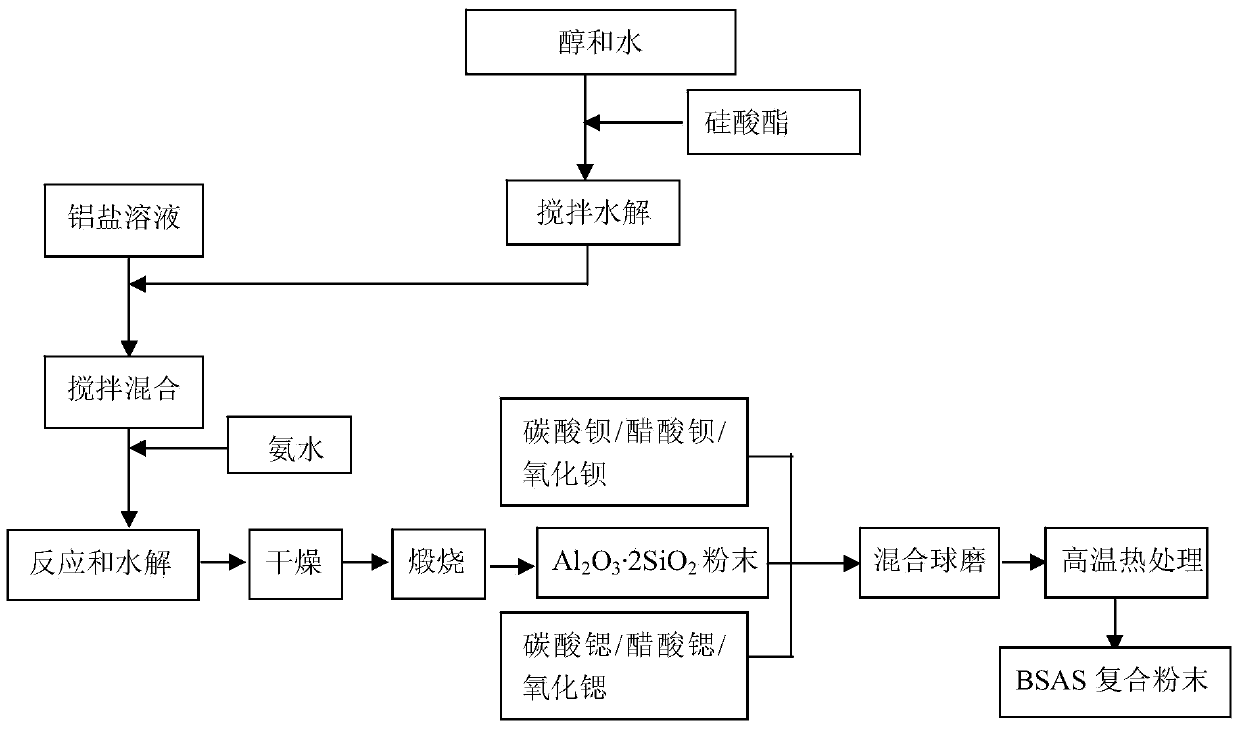

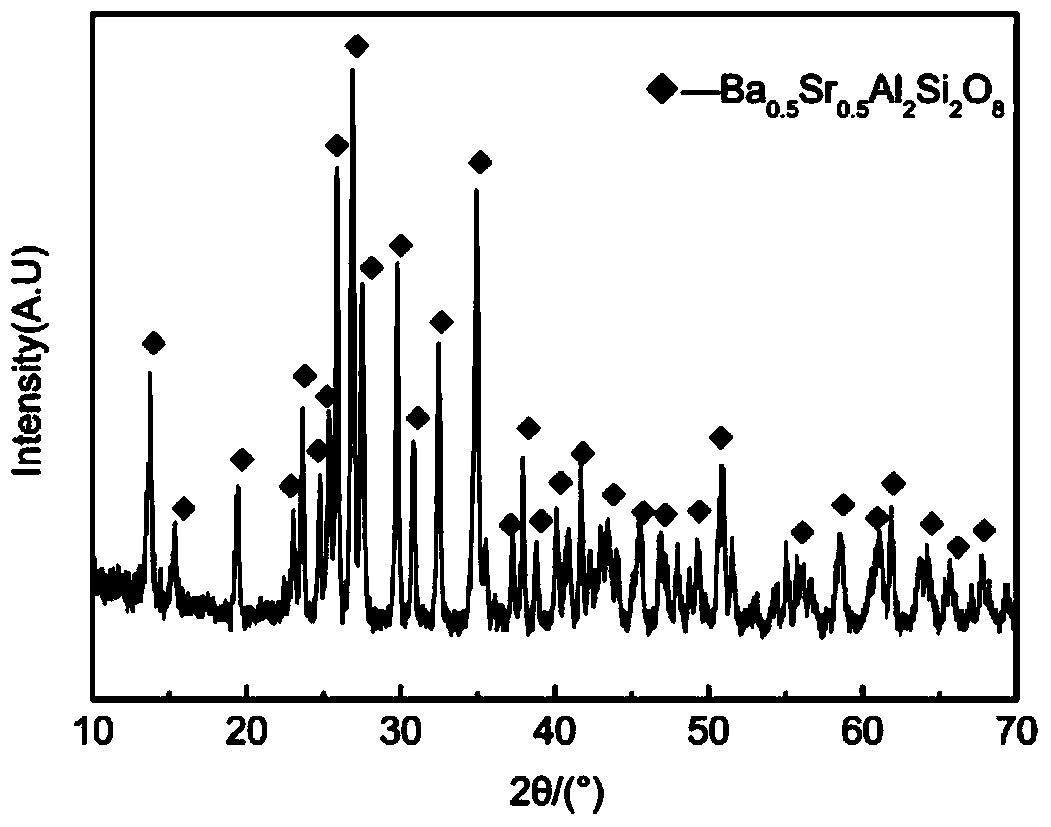

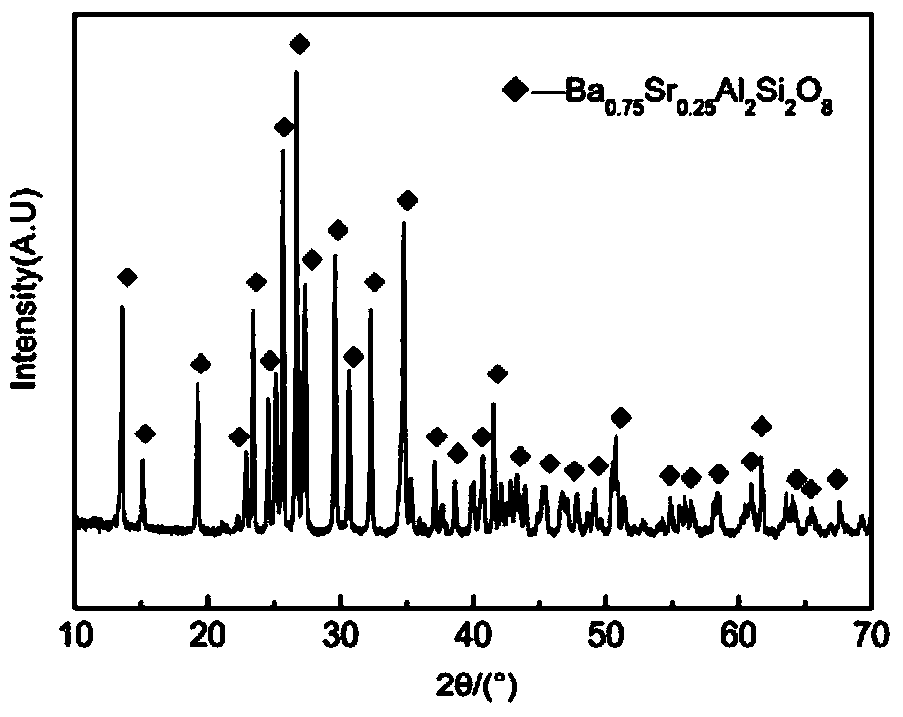

Preparation method of BSAS composite ceramic powder

ActiveCN104003697AProcess raw materials are cheapThe process is simple and easy to controlComposite ceramicCrystallinity

The invention discloses a preparation method of a composite ceramic powder material used for an environmental barrier coating. The composite ceramic powder is composed of single phase BSAS (1-xBaO-xSrO-Al2O3-2SiO2, x is more than 0 and less than 1). The obtained BSAS composite ceramic powder has the advantages of easiness for ingredient control, high purity, high crystallinity and low synthesis temperature. The composite ceramic powder can be used for plasma spraying after being subjected to ball milling, agglomeration, pelletizing and high-temperature heat treatment, so that the environmental barrier coating is prepared on the surface of a C / C-SiC composite material, the coating can be used for effectively improving high-temperature water oxygen corrosion resistance performance of a C / C-SiC matrix, is applicable to surface high-temperature protection of other silicon substrate materials, can be used for solving the problem of high-temperature water oxygen corrosion of a silicon substrate composite material and has an important application value.

Owner:CENT SOUTH UNIV

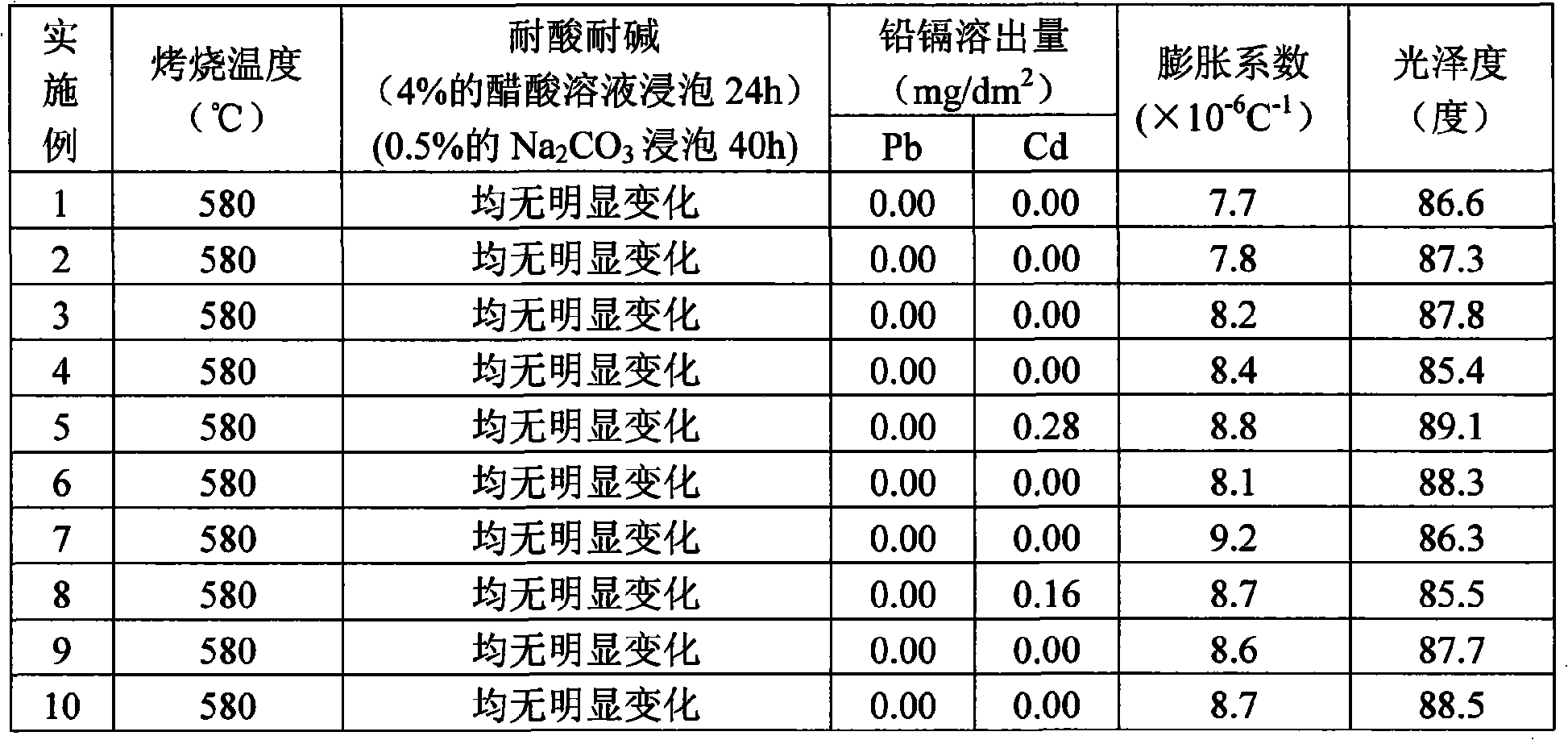

Glass lead-free pigment and method for preparing the same

The invention discloses a glass lead-free pigment comprising a 5-20% of lead-free toner and an 80-95% of lead-free flux by a weight percentage, wherein the weight percentage composition of the flux is as follows: SiO2 46-49%, B2O3 15-20%, Al2O3 0.1-1%, Li2O5 2-3.5%, Ta2O3 0-0.5%, Nb2O5 0-1%, ZrO2 0-0.5%, CeO2 0-2%, La2O3 0-0.5%, Y2O3 0-1%, ZnO 8-13%, MgO 0-0.5%. The invention also discloses a preparation method of the lead-free glass pigment. The glass lead-free pigment of the invention has advantages of compact structure, antiacid-alkali erosion, good chemical stability, low fired temperature and high glossiness and the like.

Owner:JIANGSU BAIFU TECH CO LTD

Heat insulation energy-saving material and preparation method thereof

InactiveCN107324776AExtended service lifeLow thermal conductivityCeramic materials productionClaywaresSodium silicateSodium carboxymethylcellulose

The invention discloses a heat insulation energy-saving material. The heat insulation energy-saving material comprises the following components in parts by weight: 60-80 parts of cement, 30-40 parts of mineral cotton, 20-30 parts of sodium silicate, 10-30 parts of natural zeolite powder, 10-20 parts of coal ash, 5-15 parts of mullite fibers, 3-8 parts of floating beads, 5-10 parts of polyvinyl alcohol, 2-8 parts of carboxymethyl cellulose, 5-10 parts of a nano inorganic oxide, 8-15 parts of glass beads, 3-8 parts of glass fibers and 4-10 parts of an additive. The heat insulation energy-saving material is prepared by such processes as grinding dispersion, high-temperature mixing, standing cooling, sieving separation, pressing molding and high-temperature sintering. The heat insulation energy-saving material has the advantages of fire resistance, long service life, small heat conduction coefficient, environmental friendliness and the like, and meanwhile, has good acid and alkali corrosion resistance and ultrahigh weatherability.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

Low-cost corrosion-resistant unsaturated polyester resin, and preparation method and use thereof

ActiveCN103626931AImprove stabilityImprove ester bond stabilityPolymer sciencePolyethylene terephthalate glycol

The invention discloses low-cost corrosion-resistant unsaturated polyester resin, and a preparation method and use thereof, and belongs to the technical field of unsaturated polyester resin. The unsaturated polyester resin is prepared by the following steps: carrying out degradation reaction on polyethylene terephthalate (PET) and dihydric alcohol; carrying out condensation polymerization on the degradation product and dihydric alcohol or binary anhydride; finally diluting the condensation polymer by a diluent, wherein the dihydric alcohol comprises D33 dihydric alcohol and common dihydric alcohol; the diluent is a mixture of methyl methacrylate and styrene. The preparation method of the low-cost corrosion-resistant unsaturated polyester resin disclosed by the invention is simple; the obtained product is in a liquid state at normal temperature, and has higher mechanical property retaining rate, lower bending strength drop rate, and better bending strength than the traditional unsaturated polyester resin under the condition of high-concentration acid and alkali. The low-cost corrosion-resistant unsaturated polyester resin is used for fabricating high-grade corundum, SMC and the like together with an inorganic material, so that the product has good resistance to acid and alkali corrosion, the service life is prolonged, and the market requirements of special purpose products can be met.

Owner:浙江天和树脂有限公司 +1

Preparation method of modified composite ultrafine talcum powder

InactiveCN101864199AFine granularityStrong water resistancePigment treatment with organosilicon compoundsPigment physical treatmentSodium stearateMicrometer

The invention discloses a preparation method of modified composite ultrafine talcum powder, which comprises the following steps: (1) breaking raw material, and grinding the broken material to fine powder; (2) adding water and grinding-assistant medicine into the ground material to be configured into pulp with the concentration of 50 to 70 percent and to be uniformly mixed; (3) configuring composite modifier, silane coupling agent and sodium stearate to surface modification solution to be poured into the pulped material so as to modify the material; (4) carrying out the wet-method ultra-fine grinding on the modified material, and requiring the particles with the granularity being less than 2 micrometers for the mineral pulp ultra-fine grinding to be more than 95 percent; (5) forcibly drying and collecting the material after being ultra-fine ground. By utilizing the wet-method ultra-fine grinding and mightiness drying process, the prepared modified composite ultra-fine talcum powder has smaller granularity than that of ordinary talcum powder and wider distribution, resists the insolation and high temperature, has good water resistance, resists pollution, and has strong anti-aging performance.

Owner:朱自学

Wear-resistant and corrosion-resistant waterproof coating for environmental protection equipment

InactiveCN107573811AImprove compactnessHigh strengthAnti-corrosive paintsEpoxy resin coatingsWear resistantFar infrared

The invention relates to a wear-resistant and corrosion-resistant waterproof coating for environmental protection equipment. The wear-resistant and corrosion-resistant waterproof coating has the advantages of having good acid and alkali corrosion resistance, oil and water resistance, scratch resistance and wear resistance, effectively avoiding the corrosion damage on the outer surface of the equipment, reducing the frictional damage, and prolonging the service life of the equipment; modified graphene has the advantages of having better dispersibility, increasing the density and strength of thecoating, and effectively improving the waterproof performance of the coating and the permeability of a solvent; modified attapulgite has the advantages of having better viscosity, dispersibility andcompatibility, improving the adhesion between various components, and increasing the adhesion and anti-stripping performance of a paint; tourmaline powder, medical stone, far-infrared ceramics and other functional accessories are added to enhance the functionality of the coating, and benefit the human health; reflective glass beads are used to enhance the recognition capability of operators; a preparation method is simple in process, and low in energy consumption and cost.

Owner:SUZHOU TIANJIANHENG ELECTRONICS INFORMATION TECH CO LTD

Molding sand for casting

ActiveCN106040965AImprove high temperature resistanceImprove acid and alkali corrosion resistanceFoundry mouldsFoundry coresAdhesiveOlivine

The invention discloses molding sand for casting. The molding sand for casting comprises the following raw materials in parts by weight: 35-40 parts of chromite sand, 40-45 parts of ceramsite, 0.2-1 part of adhesive, 20-30 parts of silica sand, 5-10 parts of white sand, 18-25 parts of magnesium sand, and 3-6 parts of olivine sand. The molding sand for casting uses the silica sand, the magnesium sand, the white sand and the olivine sand as main components of raw sand; the expansion coefficients of the white sand and the magnesium sand are lower during heating; the white sand, the magnesium sand and the silica sand are mixed as the the raw sand of the molding sand for casting; the expansion coefficient of the silica sand is reduced; the structure stability is improved; the casting condensation speed is uniform; condensed castings are not easy to generate cracks and shrinkage holes in surfaces; the ceramsite is added to improve the high-temperature resistance and the acid-alkali erosion resistance of the molding sand, and can be recycled; and a little adhesive is added to enhance the viscosity of the molding sand for casting.

Owner:HEFEI JAC CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com