Low-density composite proppant, preparation method and applications thereof

A composite support, low-density technology, applied in earth-moving drilling, production fluids, wellbore/well components, etc., can solve the problems of high fracturing fluid performance requirements, high crush resistance strength, high proppant density, etc. The effect of high crushing strength, enhanced mechanical strength and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

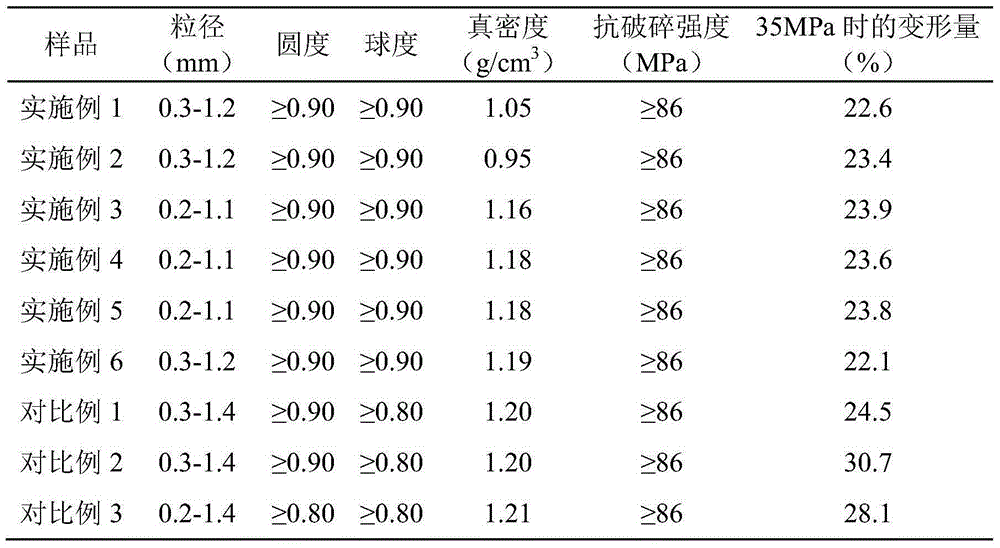

Examples

Embodiment 1

[0058] Preparation of water phase and oil phase: Add 2.0g of polyvinyl alcohol, 0.6g of sodium nitrite, 1.0g of sodium carbonate and 200mL of water into a 500mL four-neck flask, keep the temperature at 60°C, and stir for 20min under mechanical stirring at 120rpm. Obtain the aqueous phase; add 70mL styrene, 15mL divinylbenzene, 1.0g dibenzoyl peroxide, 0.4g TAEC, 0.6g carbon black and 0.05g dispersant Disperbyk-161 into a 200mL beaker, ultrasonically disperse for 10min, An oily phase is obtained.

[0059] Suspension polymerization reaction: Add the water phase to the prepared oil phase slowly at a stirring speed of 90 rpm, keep the temperature at 60°C, and stir for 20 minutes; slowly raise the temperature to 75°C within 1 hour, then raise the temperature to 92°C, adjust the stirring speed to 150rpm, Polymerize for 3 hours, then continue to heat up to 108° C., polymerize and crosslink for 3 hours to obtain a polymer product system.

[0060] Post-treatment: naturally cool the po...

Embodiment 2

[0063] Pretreatment of filler: Add 8.0g of hollow glass microspheres (model S60HS) into 80mL of anhydrous ethanol / water (volume ratio 3 / 1) mixed solution, disperse under high-speed stirring at 3500rpm, adjust the stirring after 10min Speed up to 1500rpm, control the system temperature at 60°C, add 2.2mL of silane coupling agent A-171 to the system, adjust the pH value of the system to 4.0 with oxalic acid, and react for 60min; The hollow glass microspheres were placed in a dry box.

[0064] Preparation of water phase and oil phase: Add 1.5g hydroxyethyl cellulose, 0.8g sodium nitrate, 0.8g magnesium carbonate and 200mL secondary water into a 500mL four-neck flask, keep the temperature at 65°C, and mechanically stir at 130rpm Stirring at low temperature for 30min to obtain the water phase; add 80mL styrene, 16mL ethylene glycol dimethacrylate, 0.7g azobisisobutyronitrile, 0.5g TBEC and 7.0g hollow glass microspheres that have been treated with surface modification Put it int...

Embodiment 3

[0069] Preparation of water phase and oil phase: Add 1.8g of polyvinylpyrrolidone, 0.6g of sodium nitrite, 1.2g of calcium carbonate and 200mL of secondary water into a 500mL four-necked bottle, keep the temperature at 55°C, and mechanically stir at 150rpm Stir for 40min to obtain the aqueous phase; mix 65mL methyl methacrylate, 15mL triallyl cyanurate, 1.0g cumene hydroperoxide, 0.4g TAPEH, 0.5g carbon black and 0.05g dispersant Disperbyk-162 Pour into a 200mL beaker, and ultrasonically disperse for 10min to obtain an oil phase.

[0070] Suspension polymerization reaction: Add the water phase to the prepared oil phase slowly at a stirring speed of 100rpm, keep the temperature at 55°C, and continue stirring for 30min; slowly increase the temperature to 80°C within 1h, then raise the temperature to 95°C, and adjust the stirring speed to 180rpm , polymerized for 3.5 hours, then continued to heat up to 105°C, polymerized and crosslinked for 3 hours, and obtained a polymerized pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com