Preparation method for multi-component net-shaped nanofiber membrane

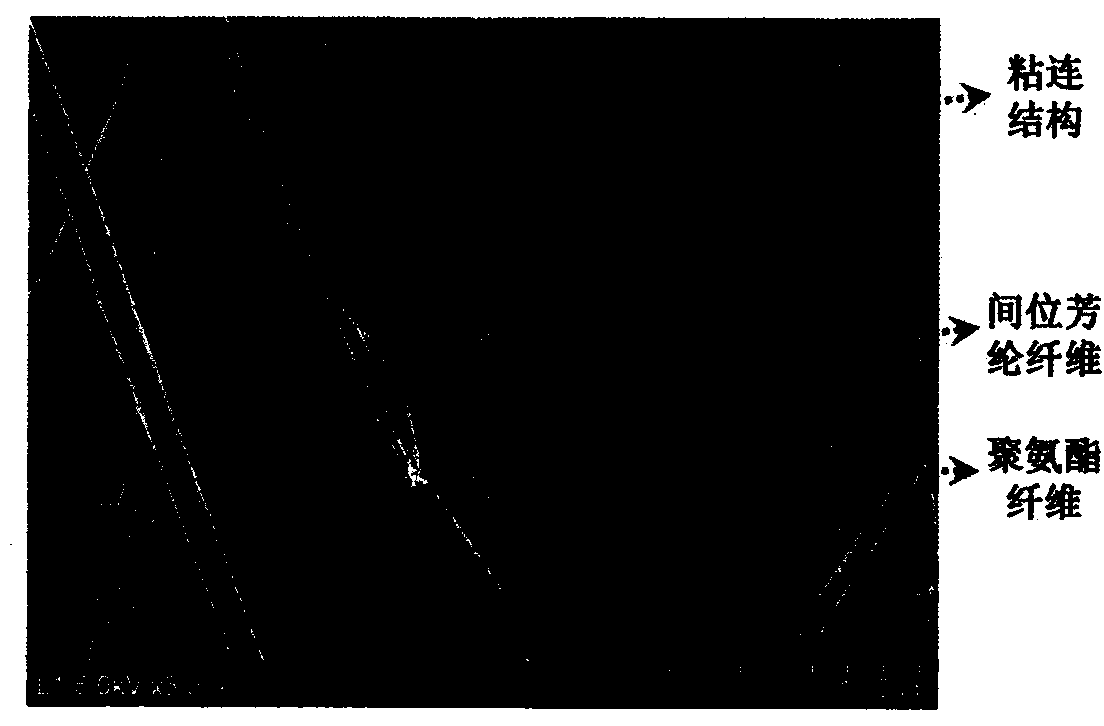

A nanofiber membrane and nanofiber technology, applied in fiber treatment, spinning solution preparation, textiles and papermaking, etc., can solve the problems of single network nanofiber structure components, limited practical application of materials, poor mechanical strength of fiber membranes, etc. , to achieve the effect of expanding functionality, increasing the interaction surface area, and reducing the fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a high-strength multi-component network nanofiber membrane, the specific steps are:

[0030] The first step: add 0.4g lithium chloride to 14.6g N,N-dimethylacetamide and magnetically stir to prepare an ionic liquid solution system, then add 5g meta-aramid fiber and mix it with the experimental dispersion sand mill at a speed of 5000rpm Disperse and beat in the machine for 20 minutes, and stir with a magnetic stirrer at a speed of 100 rpm for 1 hour at 20°C to obtain a homogeneous and stable solution (A solution) with mass fractions of meta-aramid and lithium chloride of 25% and 2%, respectively;

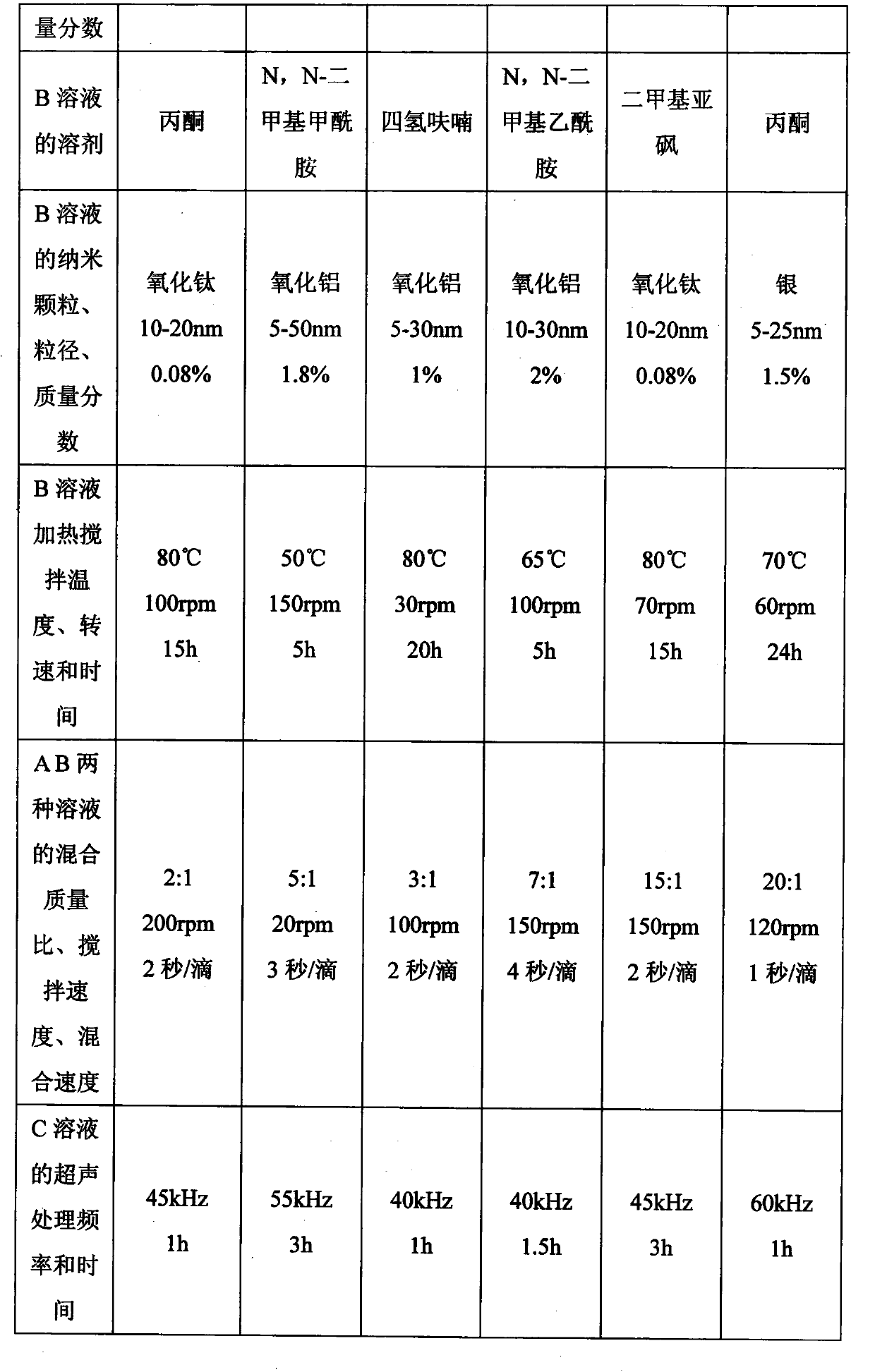

[0031] Step 2: Add 1g of polyurethane to 8.9g of N,N-dimethylacetamide and mix evenly, then add 0.1g of silicon oxide nanoparticles with a particle size distribution of 5-30nm for mixing, and use the A magnetic stirrer was stirred at a speed of 50 rpm for 5 h to obtain a homogeneous stable solution (solution B) with a mass fraction of polyurethane and na...

Embodiment 2

[0035] A method for preparing a high-strength multi-component network nanofiber membrane, the specific steps are:

[0036] The first step: Add 0.2g calcium bromide and 0.2g lithium chloride to 15.6g N-methylpyrrolidone and magnetically stir to prepare an ionic liquid solution system, then add 4g meta-aramid fiber to mix and disperse at a speed of 5000rpm Disperse and beat in a sand mill for 5 minutes, and stir with a magnetic stirrer at a speed of 100 rpm for 10 hours at 80° C. to obtain a homogeneous stable solution (solution A) with a mass fraction of meta-aramid and calcium bromide of 20% and 2%, respectively;

[0037] Step 2: Add 1g of polysulfone to 8.95g of N-methylpyrrolidone and mix evenly, then add 0.05g of alumina nanoparticles with a particle size distribution of 8-30nm for mixing, and stir with magnetic force under heating in an oil bath at 100°C The machine was stirred at a rotating speed of 80rpm for 10h to obtain a homogeneous stable solution (solution B) with a...

Embodiment 3

[0041] A method for preparing a high-strength multi-component network nanofiber membrane, the specific steps are:

[0042] Step 1: Add 0.005g of lithium bromide to 3.795g of dimethyl sulfoxide and magnetically stir to prepare an ionic liquid solution system, then add 0.2g of meta-aramid fiber and mix and disperse and beat in an experimental dispersing sand mill at 8000rpm for 10min , stirring with a magnetic stirrer at a speed of 100 rpm for 5 hours at 80° C. to obtain a homogeneous stable solution (solution A) with a mass fraction of meta-aramid and calcium bromide of 5% and 0.1%, respectively;

[0043] Step 2: Add 1.2g of polyethylene oxide to 8.65g of dimethyl sulfoxide solvent and mix evenly, then add 0.1g of silver nanoparticles with a particle size distribution of 30-50nm and 0.05g of silver nanoparticles with a particle size distribution of 40-50nm The silica nanoparticles were mixed, and stirred with a magnetic stirrer at a speed of 120rpm for 20h under heating in an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com