A kind of transparent PET optical hardening film based on radiation curing and preparation method thereof

A radiation curing and hardening film technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of low hardness and low longitudinal shrinkage rate of PET optical hardened film, achieve low longitudinal shrinkage rate, increase compatibility, The effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

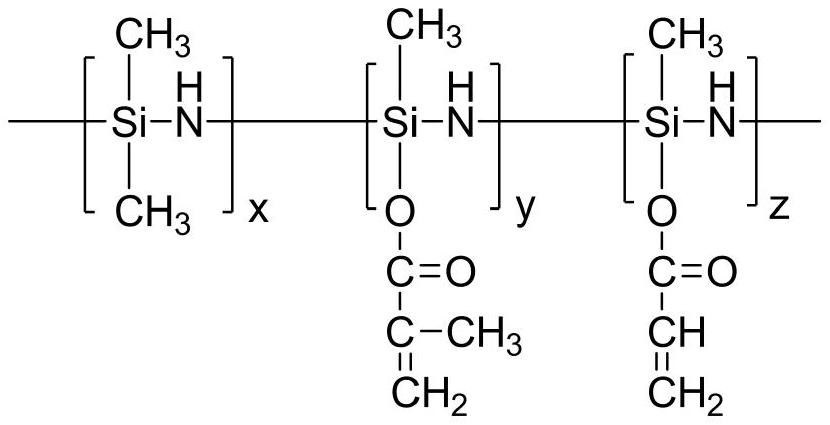

Method used

Image

Examples

Embodiment 1

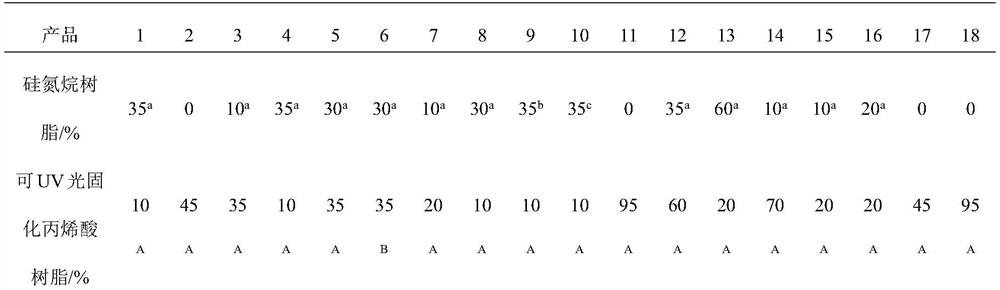

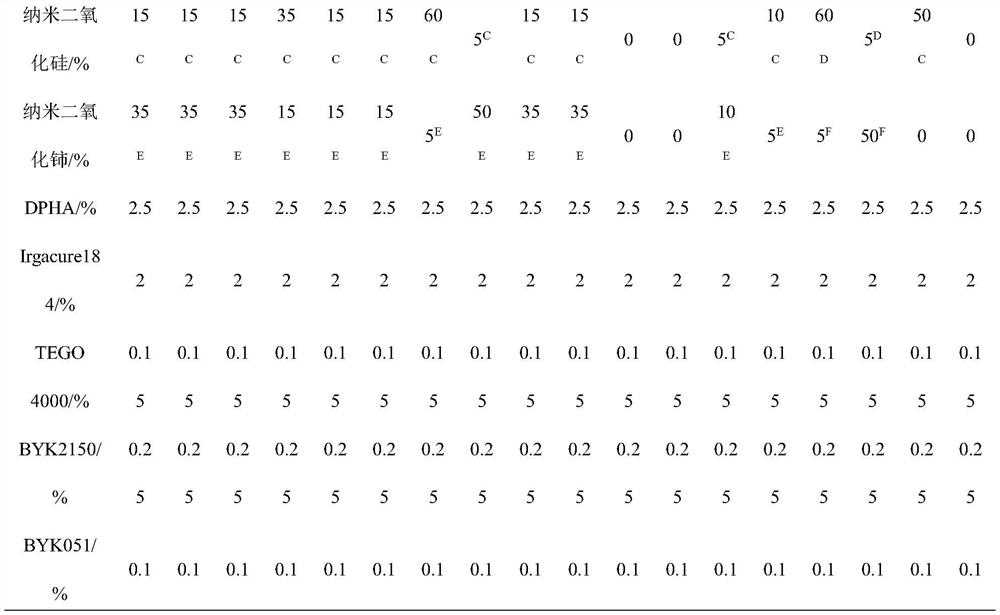

[0031] A transparent PET optical hardening film based on radiation curing, the optical hardening film is composed of a PET base film and a high hardness transparent coating coated on the base film. The high-hardness transparent coating contains the following components by weight: 35% photocurable organosilazane resin (OPSZ, acrylic acid is 30% by weight, weight average molecular weight is 200,000), 10% Sartomer's CN9013NS (aliphatic urethane acrylate oligomer, functionality=9, as UV-curable acrylic resin), 15% nano-silica, 35% flake nano-ceria, 2.5% dipentaerythritol hexaacrylate (DPHA , as reactive diluent), 2% Irgacure184 (as photoinitiator), 0.15% TEGO4000 (as leveling agent), 0.25% BYK2150 (as dispersant) and 0.1% BYK051 (as defoamer). Among them, D50=10nm and D90=50nm of nano-silica. D50=30nm, D90=100nm of nano ceria.

[0032] The preparation method of the above-mentioned optical hardened film is proportioned according to the content of the above components, and the det...

Embodiment 2

[0041] A transparent PET optical hardening film based on radiation curing, which is basically the same as that of Example 1, except that the high-hardness transparent coating of this example does not contain OPSZ, and the weight percentage of Sartomer's CN9013NS is 45% , other components and contents are the same as in Example 1.

[0042] The preparation process steps of this example are the same as those of Example 1, and the prepared PET optical hardened film is denoted as product 2.

Embodiment 3

[0044] A transparent PET optical hardening film based on radiation curing, which is basically the same as that of Example 1, except that in the high-hardness transparent coating of this example, the weight percent of OPSZ is 10%, and the weight percent of Sartomer's CN9013NS is 10%. is 35%, and other components and contents are the same as those in Example 1.

[0045] The preparation process steps of this example are the same as those of Example 1, and the prepared PET optical hardening film is denoted as product 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com