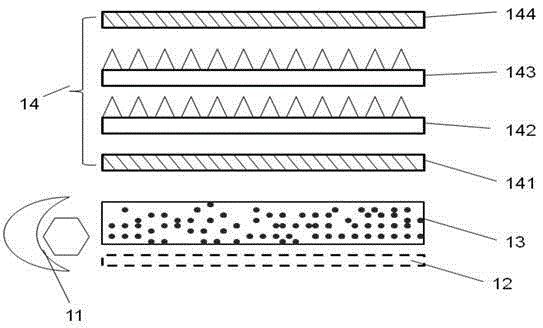

Basal membrane of composite brightness enhancement film

A technology of brightness enhancement film and base film, applied in optics, instruments, nonlinear optics, etc., can solve the problems of the protective film not being covered, the protective film being prone to residual glue, and poor adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 40.0g hexafunctional aliphatic urethane acrylate prepolymer (Changxing Chemical Materials Co., Ltd., trade name: 5105A, functionality: 6, viscosity: 70000-90000cps), 29g trifunctional active monomer pentaerythritol triacrylate monomer (manufactured by Changxing Chemical (Zhuhai) Industrial Co., Ltd., trade name: EM235), 5.0g of photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: 184), 3.0g of leveling agent (including acrylic leveling agent 1.5g, BYK-350; 1.5g of silicone leveling agent, BYK-307), 3.0g of dispersing aid BYK-111, 1.0g of diffusion particles and 20g of toluene in a stirring pot , stirred at a speed of 1500r / min for 5h, then stirred at a speed of 100r / min for 5h, and finally stirred evenly to obtain a coating material. The diffusion particles used here are organic particles of polystyrene (PS), with an average particle size D2 of 1.5 μm. The number of particles with a particle size of 1 μm to 2 μm accounted for 95%, and the nu...

Embodiment 2

[0045] Mix 5.0g of hexafunctional aliphatic urethane acrylate prepolymer (Changxing Chemical Materials Co., Ltd., trade name: 6195-100, functionality: 10, viscosity: 75000-95000cps), 30g of 2-hydroxyethyl methacrylate phosphoric acid Ester (manufactured by Changxing Chemical (Zhuhai) Industrial Co., Ltd., trade name: EM39), 2.3g of photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: 1173), 2.0g of leveling agent (including acrylic leveling agent) Agent 1.33g, BYK-352; Silicone leveling agent 0.67g, BYK-333), 0.65g dispersing aid (BYK-108), 0.05g diffusion particles and 60g ethanol Place in a stirring pot, stir at a speed of 1500r / min for 5h, then stir at a speed of 100r / min for 5h, and finally stir evenly to obtain a coating material. The diffusion particles used are organic particles of polymethyl acrylate (PMMA), with an average particle size D2 of 9 μm. The particle size range of the particles is: the number of particles with a particle size of ...

Embodiment 3

[0048] 35.0g of hexafunctional aliphatic urethane acrylate prepolymer (Changxing Chemical Materials Co., Ltd., trade name: 6196-100, functionality: 15, viscosity: 200000-300000cps), 10g of hydroxyethyl methacrylate monomer ( Nippon Shokubai, HEMA), 4g photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: TPO), 2.5g leveling agent (including 2g acrylic leveling agent, BYK-354 of BYK; silicone fluid 0.5g leveling agent, BYK-337), 2.5g dispersion aid (BYK-2000), 0.5g diffusion particles and 45.5g ethyl acetate were placed in a stirring pot at a speed of 1500r / min Stir for 5 hours, then stir at a speed of 100 r / min for 5 hours, and finally stir evenly to obtain a coating material. The diffusion particles used are organic particles of polybutylacrylate (PBMA), with an average particle size D2 of 3 μm, and the particle size range is: the number of particles with a particle size of 2.8 μm to 3.2 μm accounts for 91%, and the particle size is The number of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com