Radiation refrigeration film, radiation refrigeration composite film and radiation refrigeration product

A technology of radiation refrigeration and composite film, applied in the field of radiation refrigeration films and radiation refrigeration products, can solve the problems of light pollution, obvious specular reflection, serious light pollution, etc., and achieve the effect of low gloss, reduced light pollution and low surface gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

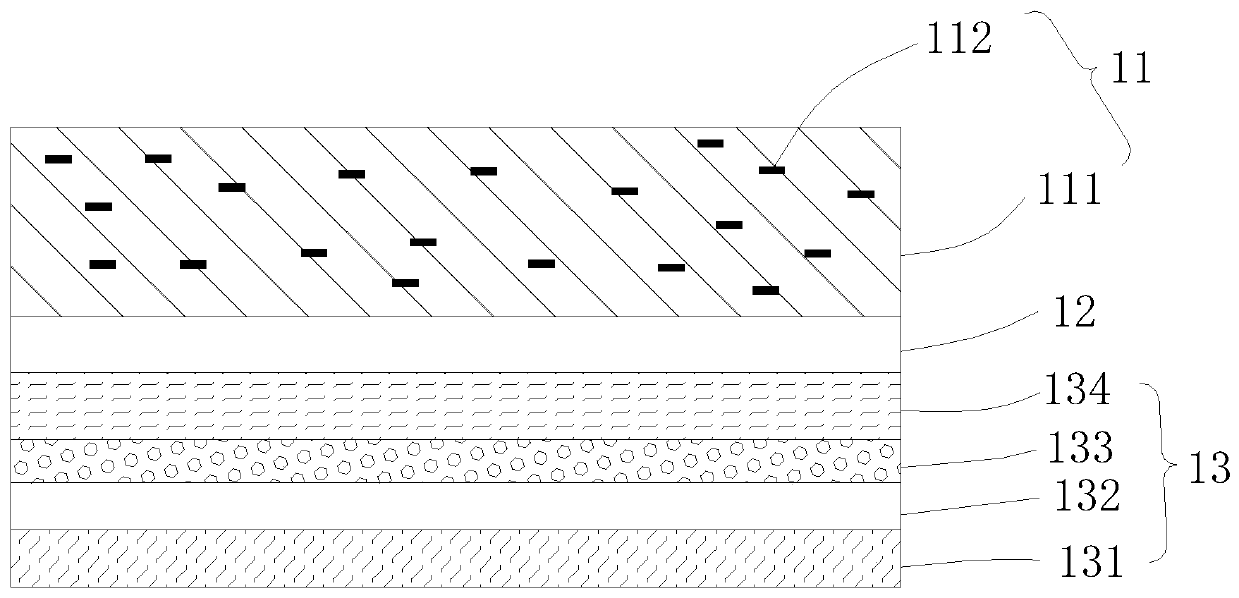

[0073] In the radiative cooling film of this embodiment, the material of the matrix layer is PMMA, and the filler is PS microspheres, which are prepared by a melt blending method. Wherein, the refractive index n of the material of the matrix layer is 1.49%, the refractive index m of the filler is 1.58%, and the absolute value of the refractive index difference x is 0.09%. The thickness of the radiation cooling film is 50 μm, the particle diameter of the filler in the radiation cooling film is 3 μm, and the mass percentage is 2%.

Embodiment 2

[0075] In the radiation cooling film of this embodiment, the material of the matrix layer is PETG, and the filler is PMMA microspheres, which are prepared by melt blending. Wherein, the refractive index n of the material of the matrix layer is 1.54%, the refractive index m of the filler is 1.48%, and the absolute value of the refractive index difference x is 0.06%. The thickness of the radiation cooling film is 50 μm, the particle diameter of the filler in the radiation cooling film is 5 μm, and the mass percentage is 5%.

Embodiment 3

[0077]In the radiation cooling film of this embodiment, the material of the matrix layer is PETG, and the filler is acrylate microspheres, which are prepared by melt blending. Wherein, the refractive index n of the material of the matrix layer is 1.54%, the refractive index m of the filler is 1.43%, and the absolute value of the refractive index difference x is 0.11%. The thickness of the radiation cooling film is 50 μm, the particle diameter of the filler in the radiation cooling film is 3 μm, and the mass percentage is 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com