A kind of color radiation cooling flexible composite film and its preparation method

A technology of radiation refrigeration and composite film, which is used in rayon manufacturing, textile and papermaking, adding pigments in spinning solution, etc. It can solve the problems of difficult architectural appearance and matching, and achieve good strength and flexibility, and excellent radiation refrigeration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

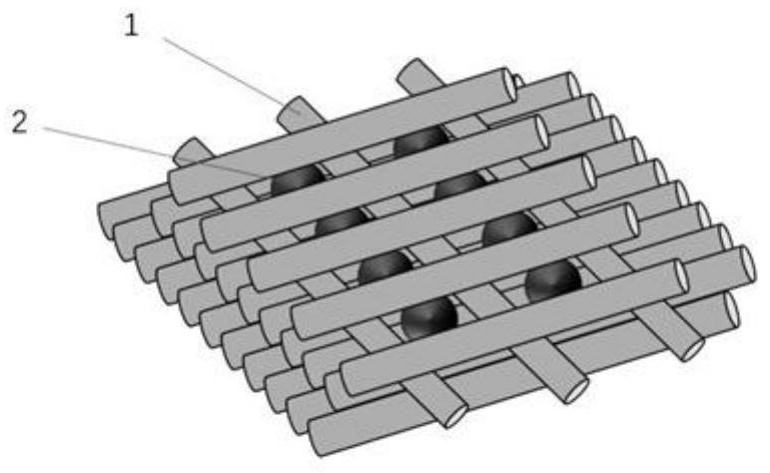

[0033] A method for preparing a color radiation refrigeration flexible composite film, comprising the following steps:

[0034] S1; preparing phase change microcapsules, the phase change microcapsules are core-shell structure microspheres wrapped in paraffin by silica;

[0035] The specific preparation method is: prepare paraffin wax emulsion and cetyltrimethylammonium bromide alkaline solution, stir at 30-50°C for 10-15h, filter and vacuum-dry at 20-30°C to obtain phase-change microcapsules , the diameter of the phase change microcapsule is 0.1-2 μm;

[0036] Wherein, the paraffin wax emulsion is paraffin wax / tetraethyl orthosilicate emulsion, wherein the mass ratio of paraffin wax to tetraethyl orthosilicate is 1:1~3;

[0037] Cetyltrimethylammonium bromide alkaline solution is composed of cetyltrimethylammonium bromide, deionized water, absolute ethanol, ammonia water according to 1.2:100:80:3~1.2:100:80: Mixed with a mass ratio of 5, wherein the concentration of ammonia ...

Embodiment 1

[0045] First prepare phase change microcapsules, put n-octadecane into tetraethyl orthosilicate according to the mass ratio of 1:1, and magnetically stir for 10 minutes to obtain paraffin wax emulsion; then cetyl trimethyl bromide Ammonium chloride, deionized water, absolute ethanol, and 10mol / L ammonia water are mixed according to the mass ratio of 1.2:100:80:5 and magnetically stirred to obtain a cetyltrimethylammonium bromide alkaline solution, and the paraffin is emulsified The solution was slowly added to the cetyltrimethylammonium bromide alkaline solution, stirred magnetically at 40°C for 15 hours, filtered and dried under vacuum at room temperature to obtain phase-change microcapsules;

[0046] Then configure the electrospinning solution, dissolve polyvinylidene fluoride in N,N-dimethylformamide, stir magnetically for 1 h, prepare a polyvinylidene fluoride sol with a mass fraction of 3% for use, and then add orthosilicic acid Tetraethyl ester, ethanol, and 0.01mol / L hy...

Embodiment 2

[0050] First prepare phase change microcapsules, put n-octadecane into tetraethyl orthosilicate according to the mass ratio of 1:1, and magnetically stir for 10 minutes to obtain paraffin wax emulsion; then cetyl trimethyl bromide Ammonium chloride, deionized water, absolute ethanol, and 10mol / L ammonia water are mixed according to the mass ratio of 1.2:100:80:5 and magnetically stirred to obtain a cetyltrimethylammonium bromide alkaline solution, and the paraffin is emulsified The solution was slowly added to the cetyltrimethylammonium bromide alkaline solution, stirred magnetically at 40°C for 15 hours, filtered and dried under vacuum at room temperature to obtain phase-change microcapsules;

[0051] Then configure the electrospinning solution, dissolve polyvinylidene fluoride in N,N-dimethylformamide, stir magnetically for 1 h, prepare a polyvinylidene fluoride sol with a mass fraction of 3% for use, and then add orthosilicic acid Tetraethyl ester, ethanol, and 0.01mol / L hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com