Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1506results about "Refrigeration machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

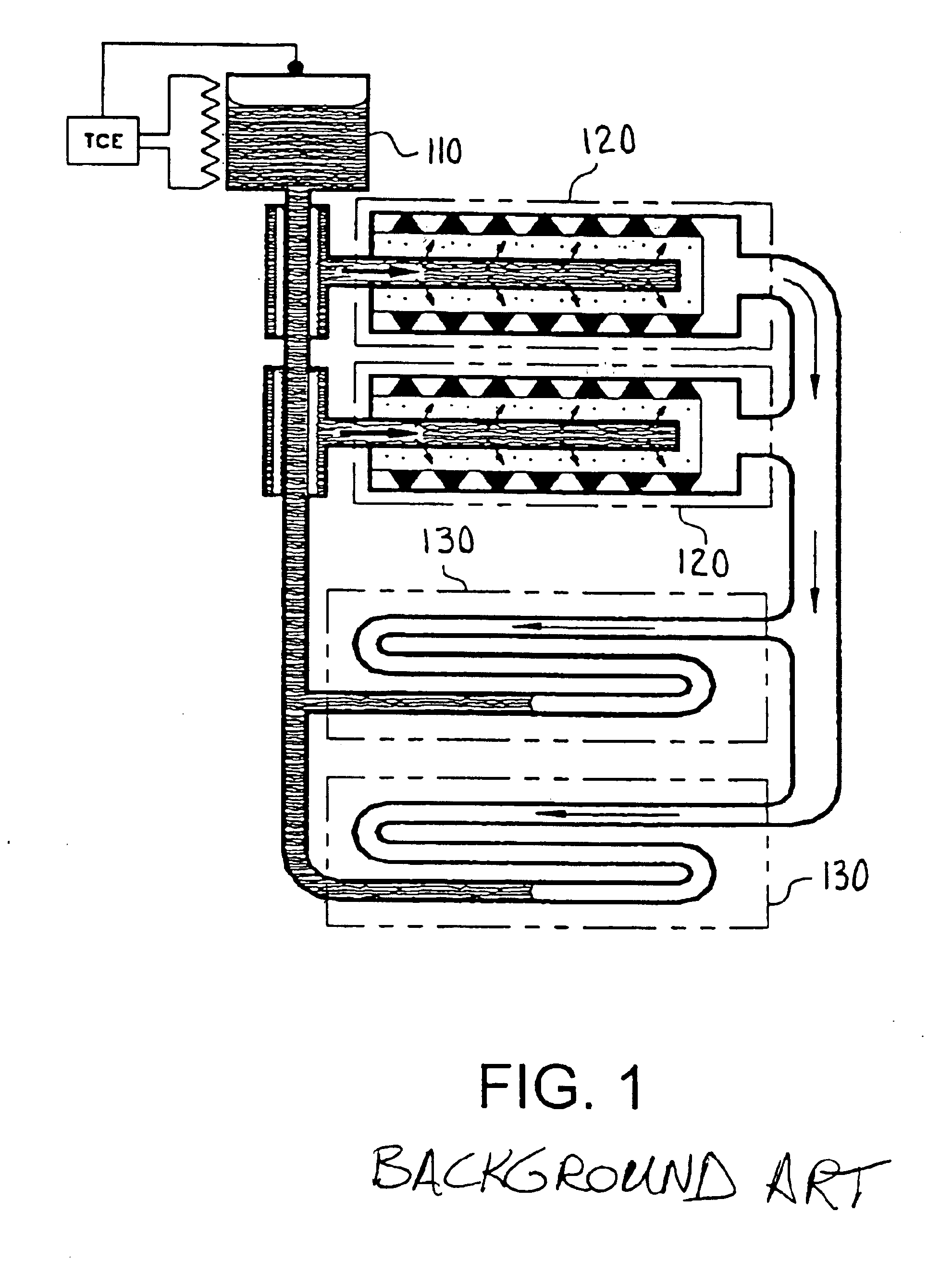

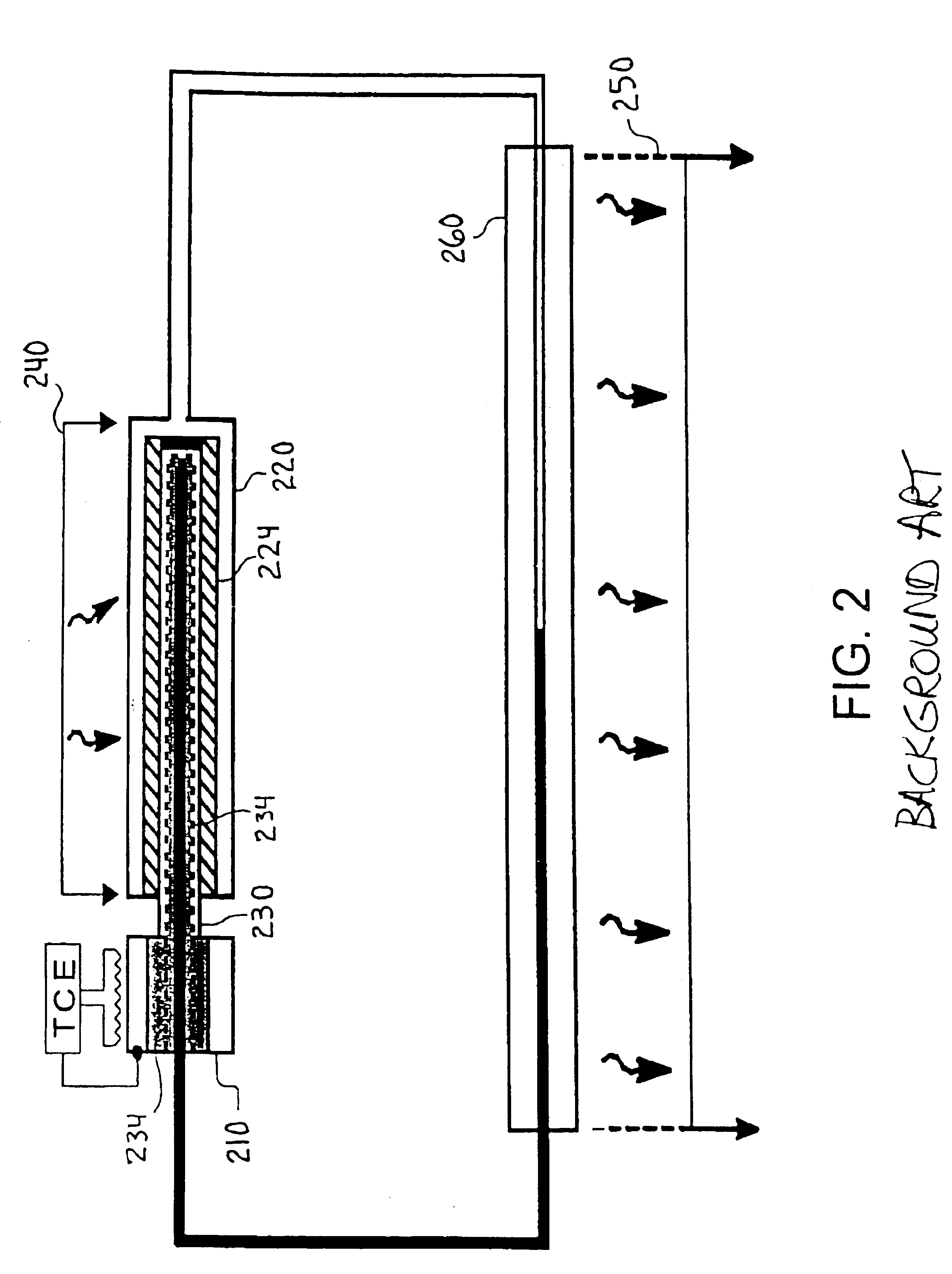

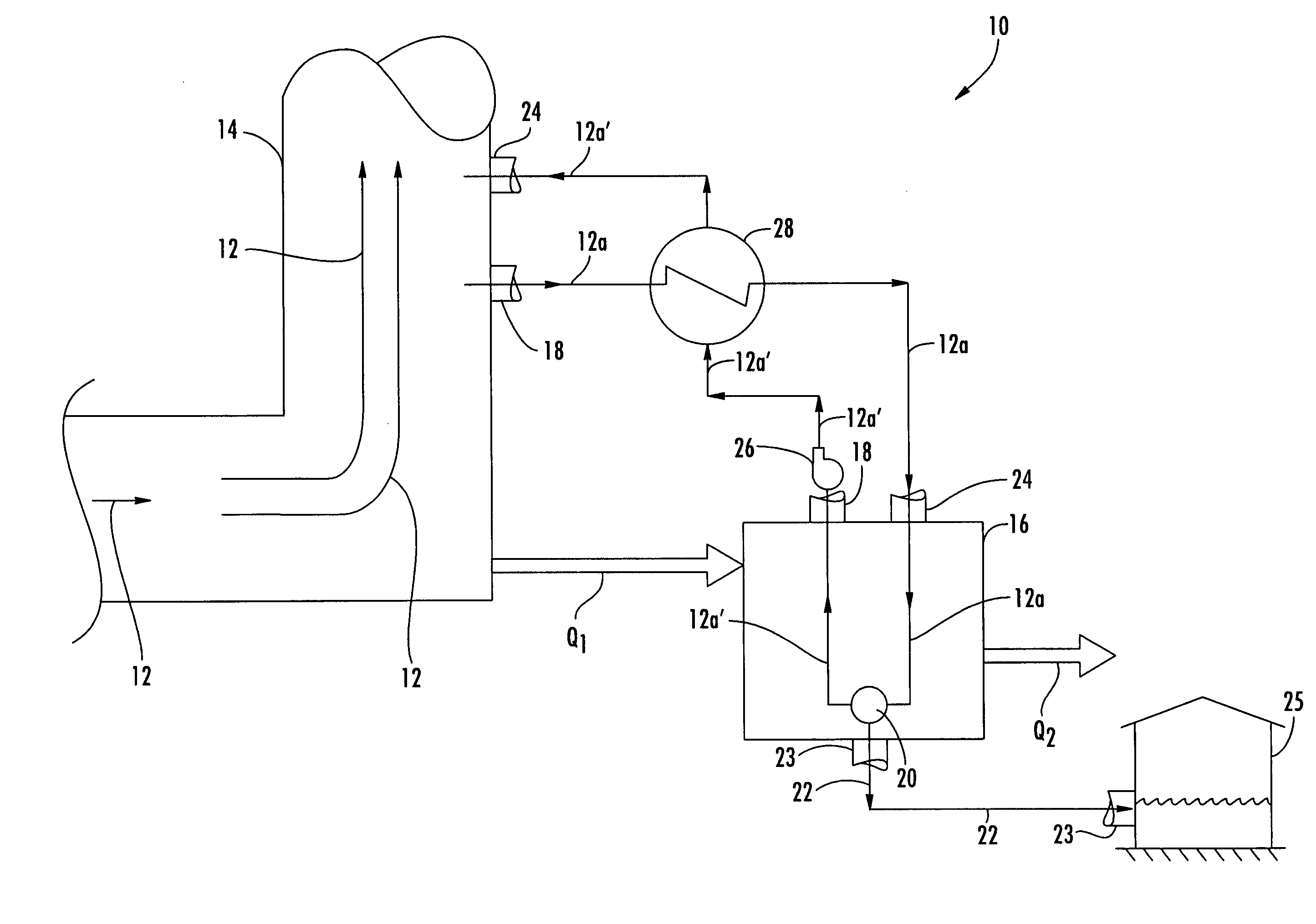

Two-phase heat-transfer systems

InactiveUS6866092B1Prevent freezingImprove the overall coefficientLiquid coolingCasingsLiquid jetInternal pressure

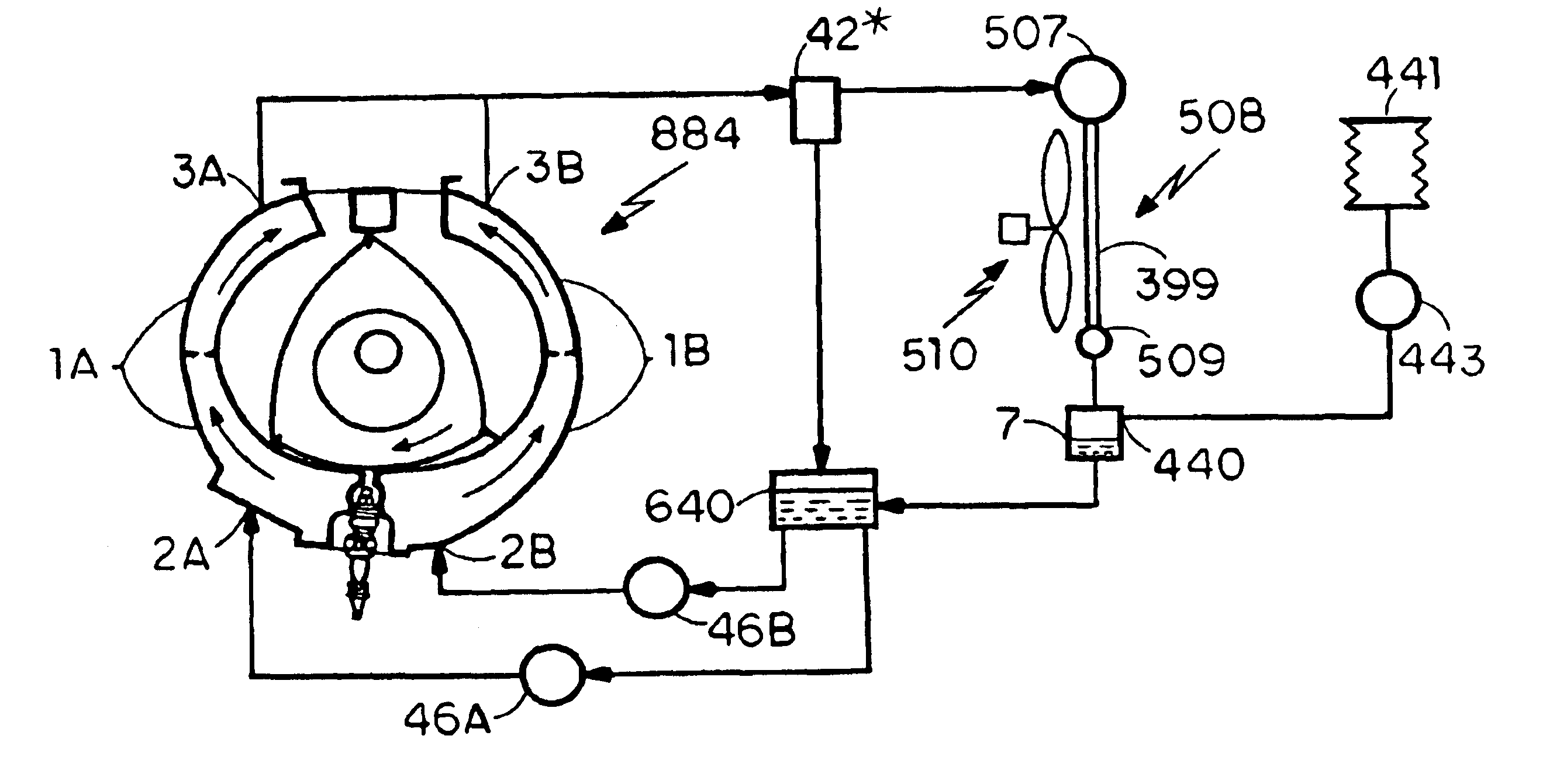

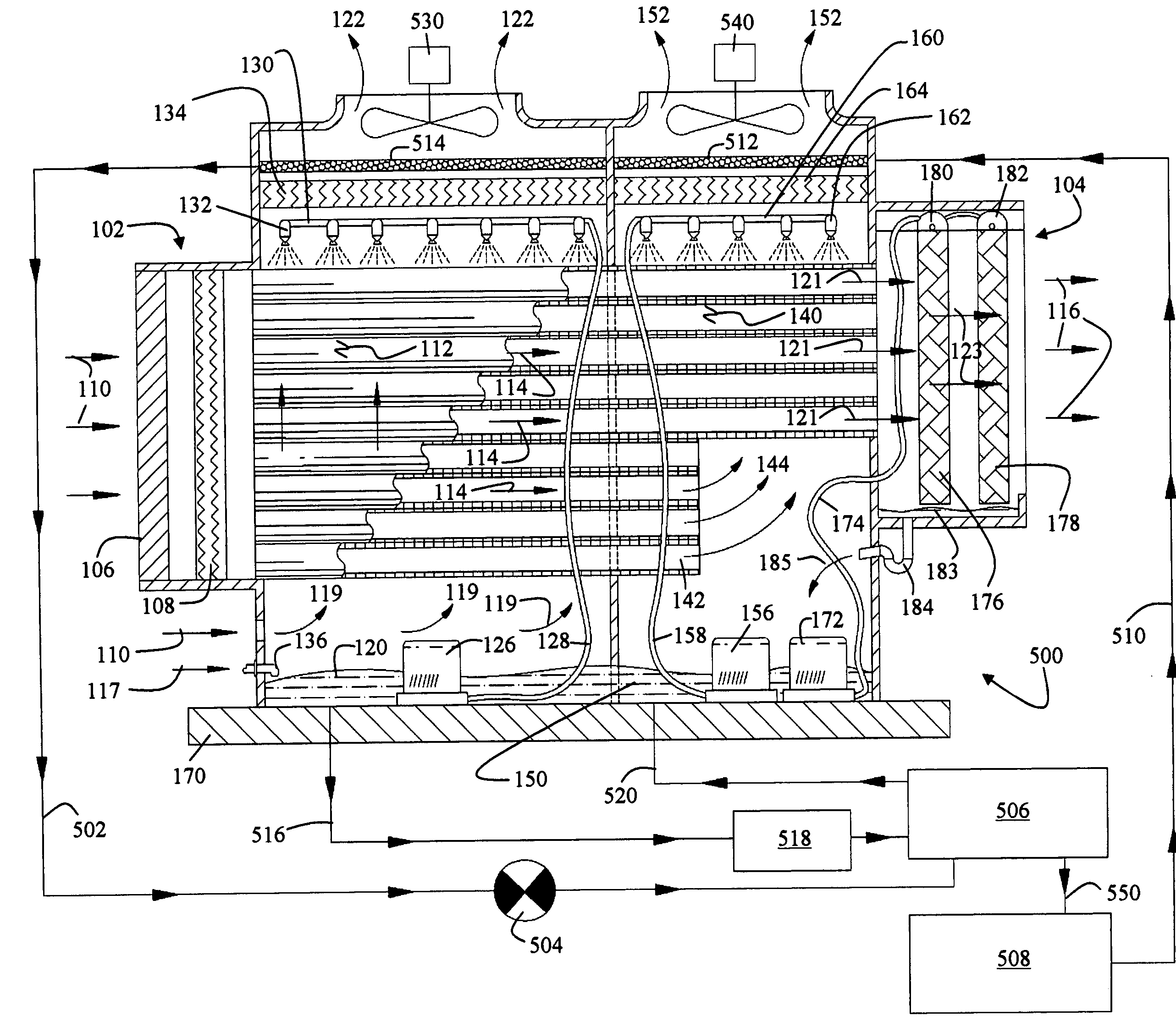

Various techniques are disclosed for improving airtight two-phase heat-transfer systems employing a fluid to transfer heat from a heat source to a heat sink while circulating around a fluid circuit, the maximum temperature of the heat sink not exceeding the maximum temperature of the heat source. The properties of those improved systems include (a) maintaining, while the systems are inactive, their internal pressure at a pressure above the saturated-vapor pressure of their heat-transfer fluid; and (b) cooling their internal evaporator surfaces with liquid jets. FIG. 43 illustrates the particular case where a heat-transfer system of the invention is used to cool a piston engine (500) by rejecting, with a condenser (508), heat to the ambient air; and where the system includes a heat-transfer fluid pump (10) and means (401-407) for achieving the former property.

Owner:MOLIVADAS STEPHEN

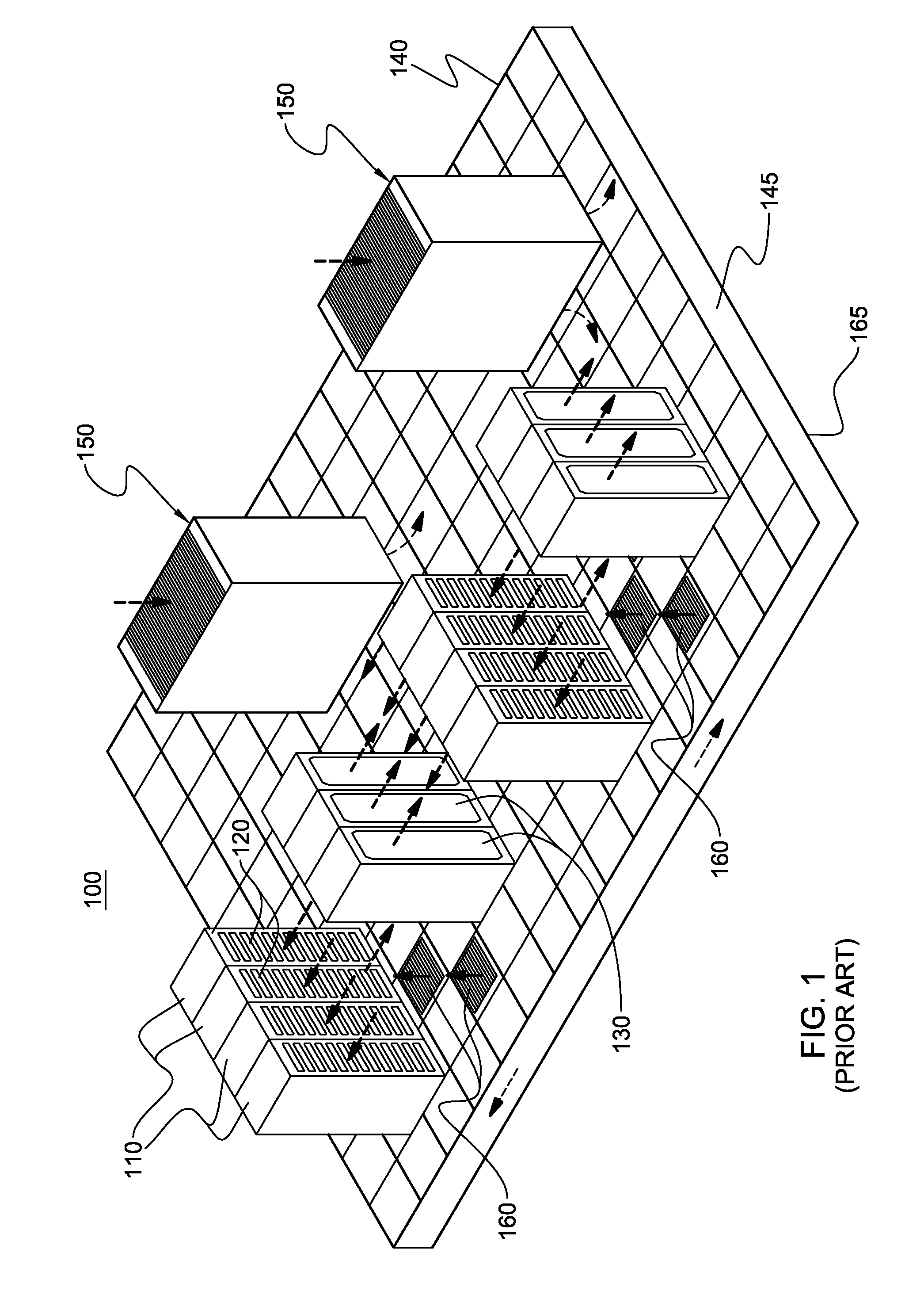

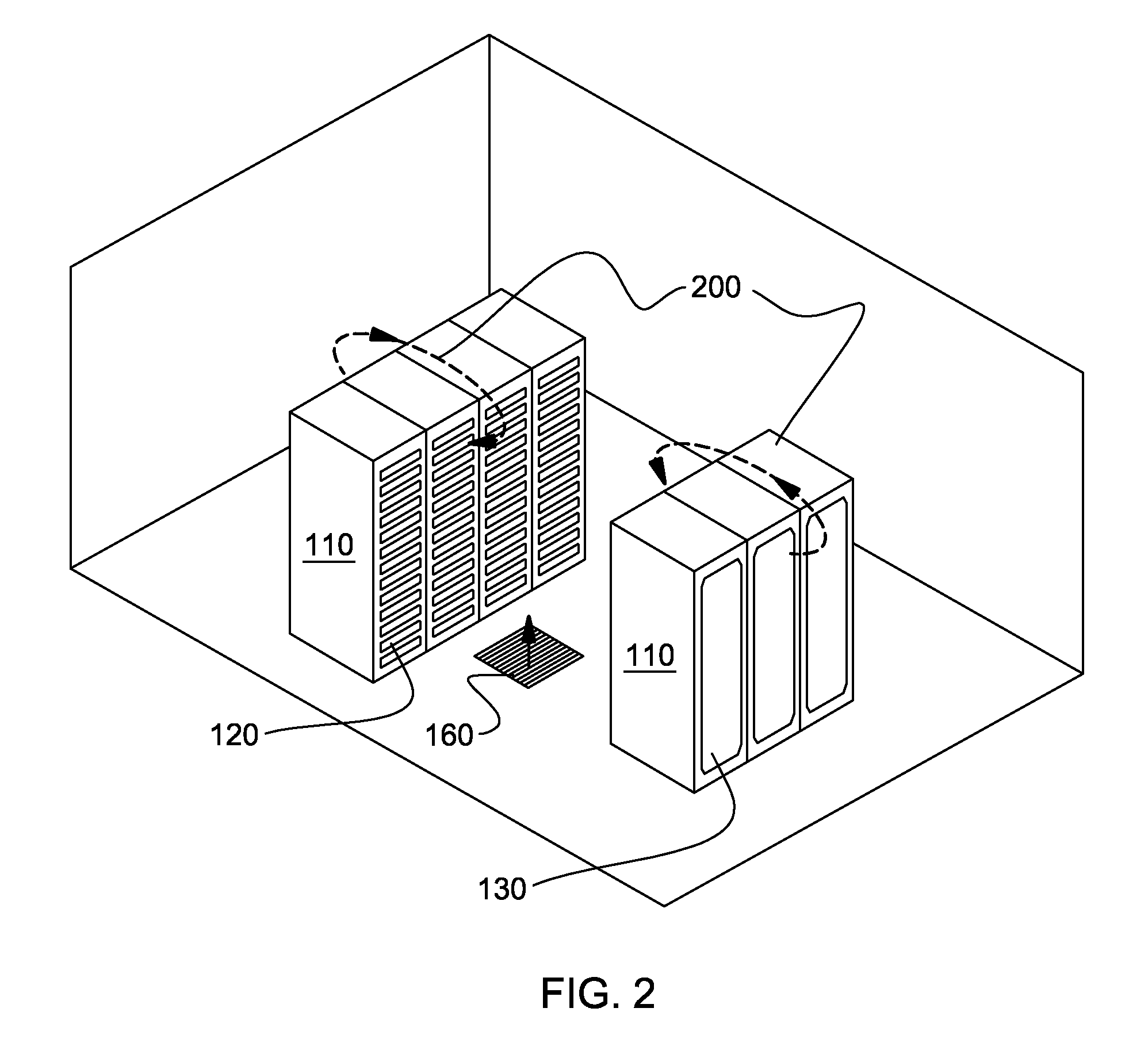

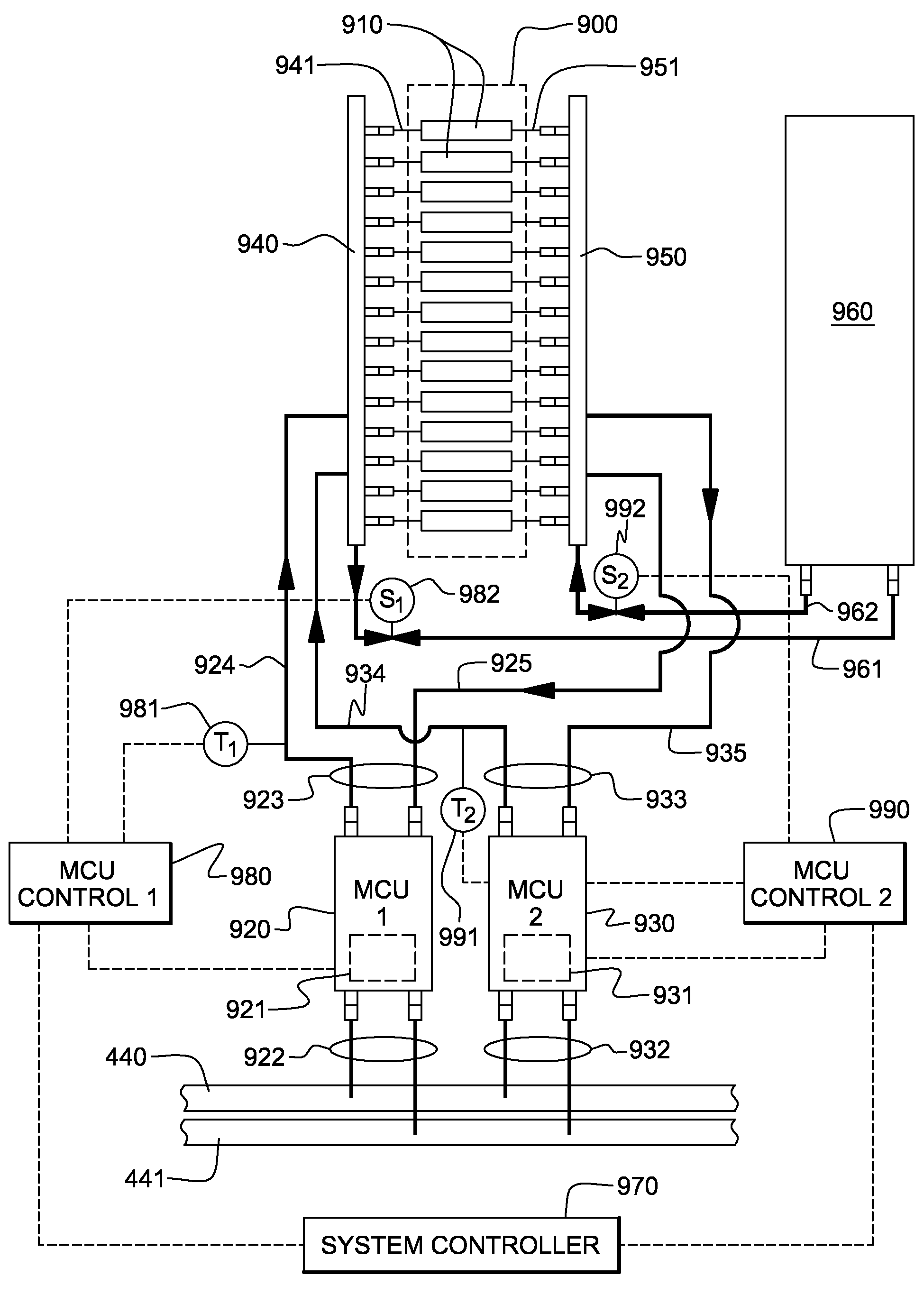

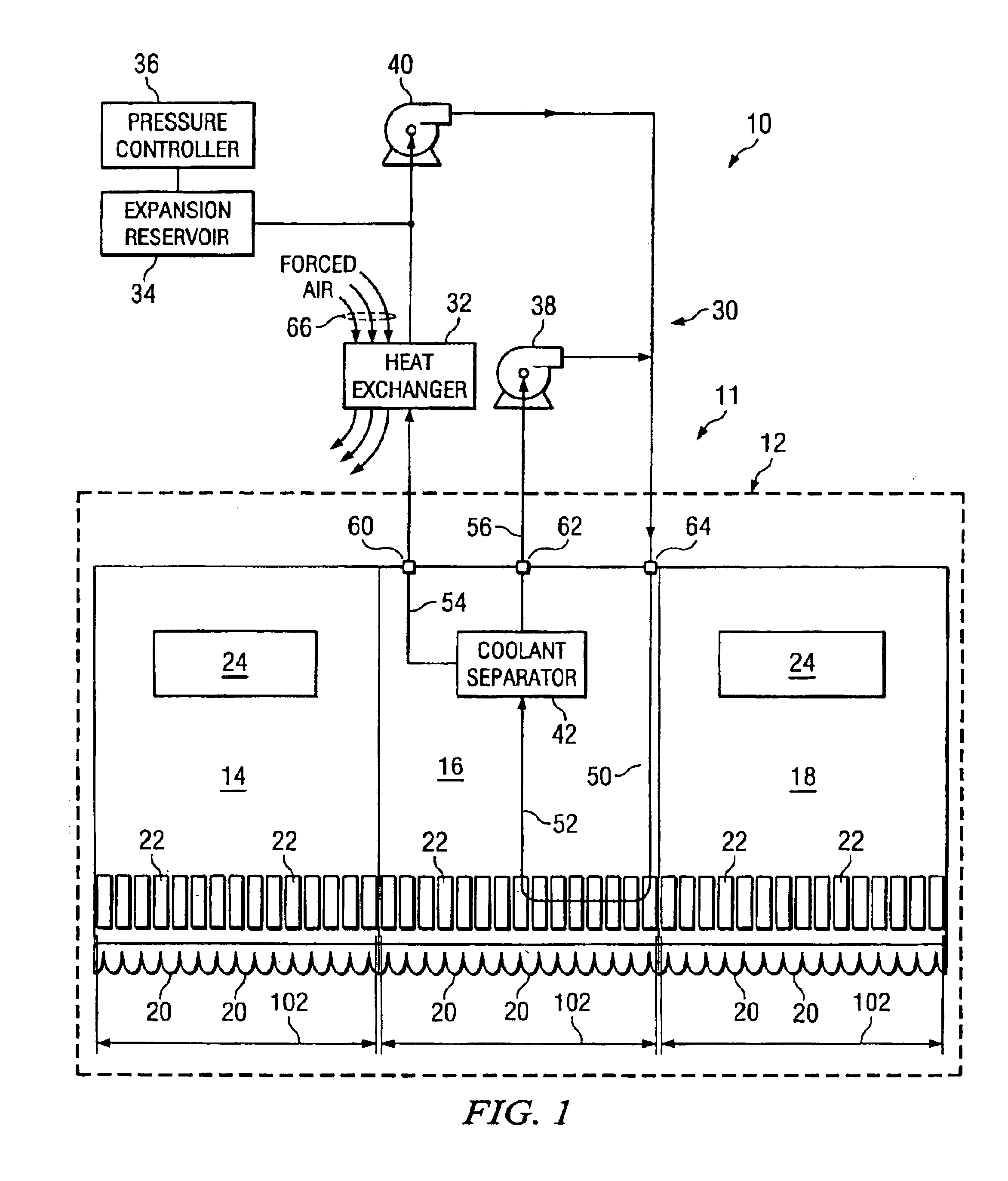

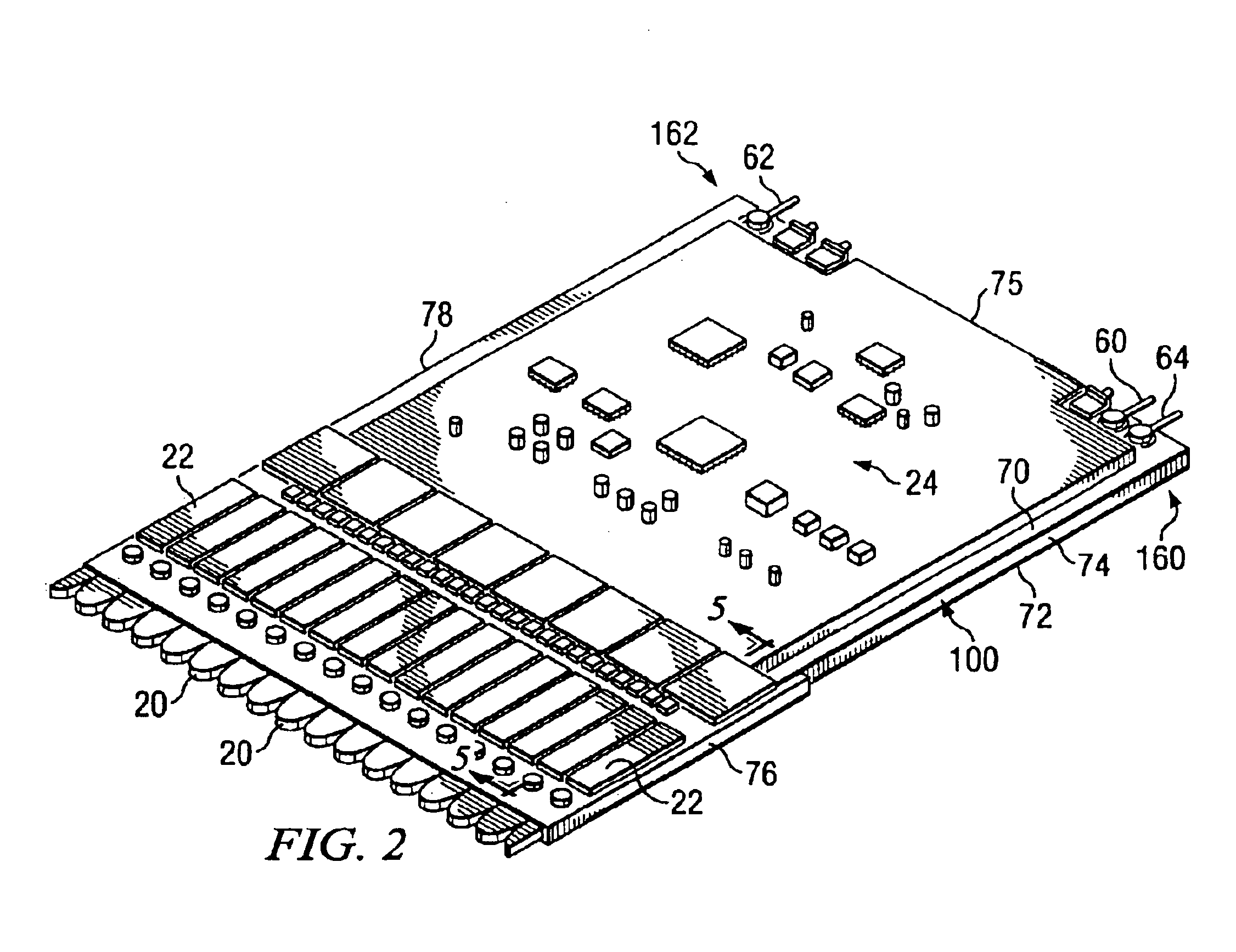

System and method for facilitating cooling of a liquid-cooled electronics rack

InactiveUS20090126909A1Easy to detectEasy to monitorDomestic cooling apparatusIndirect heat exchangersIsolation valveNuclear engineering

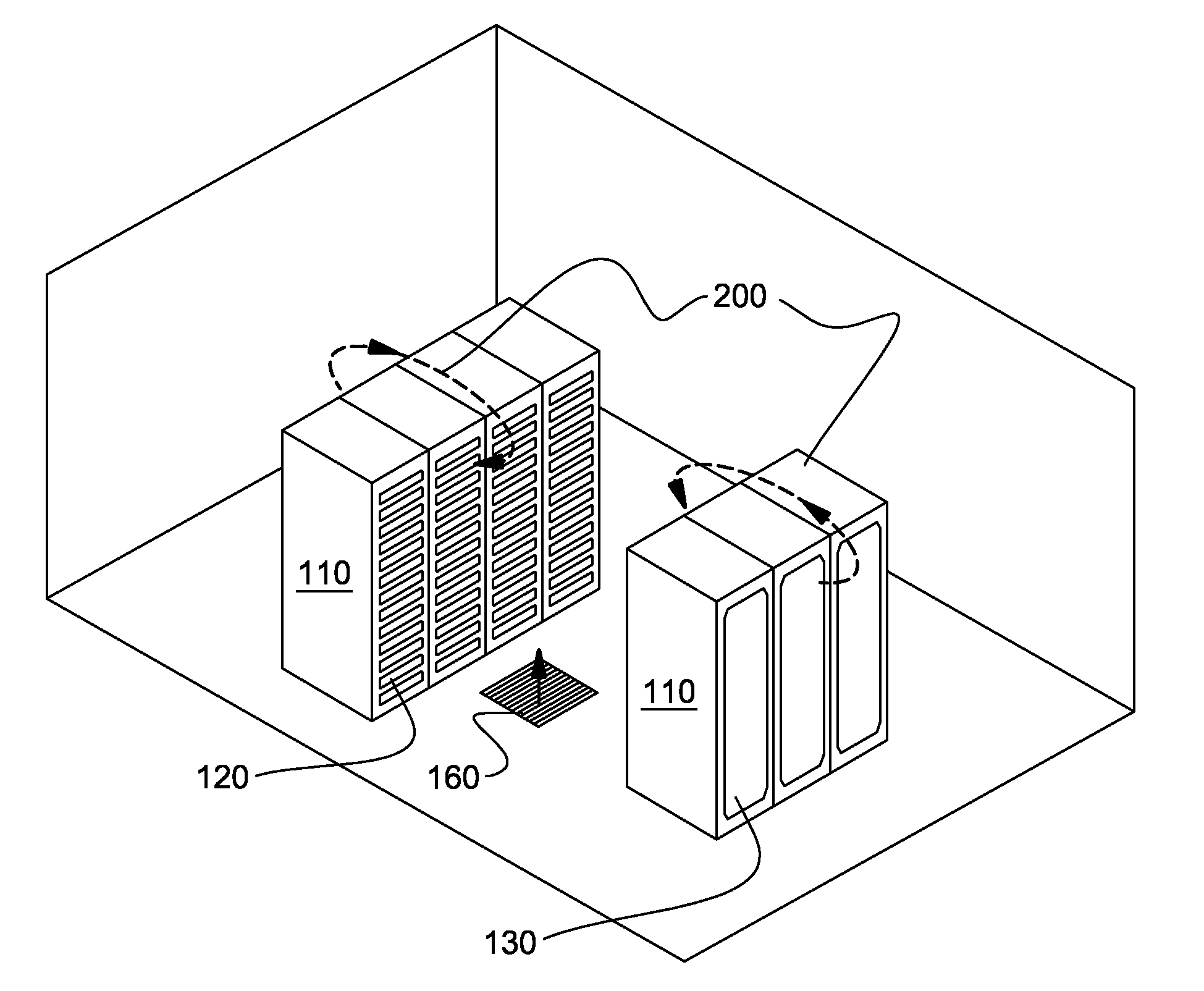

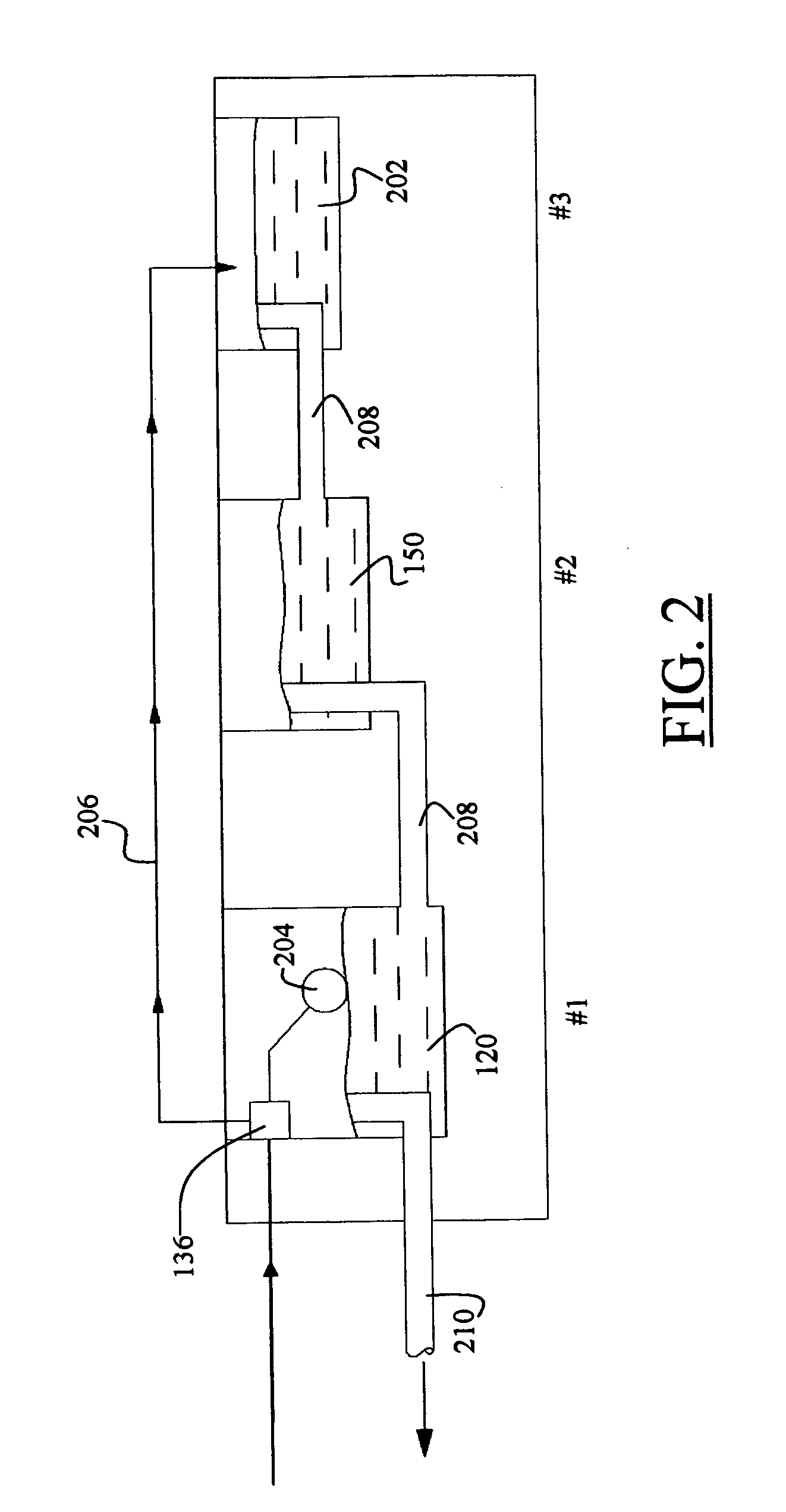

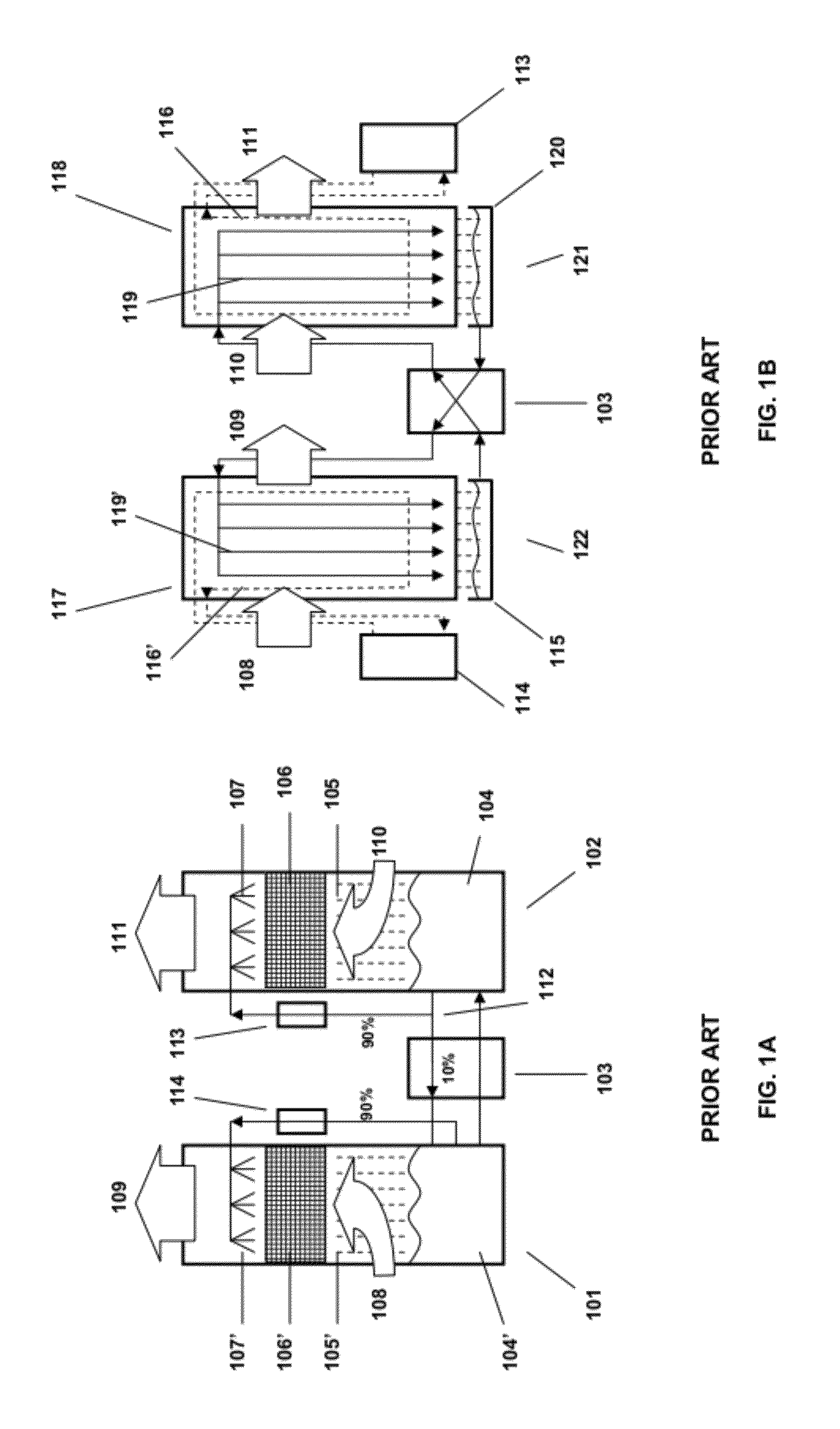

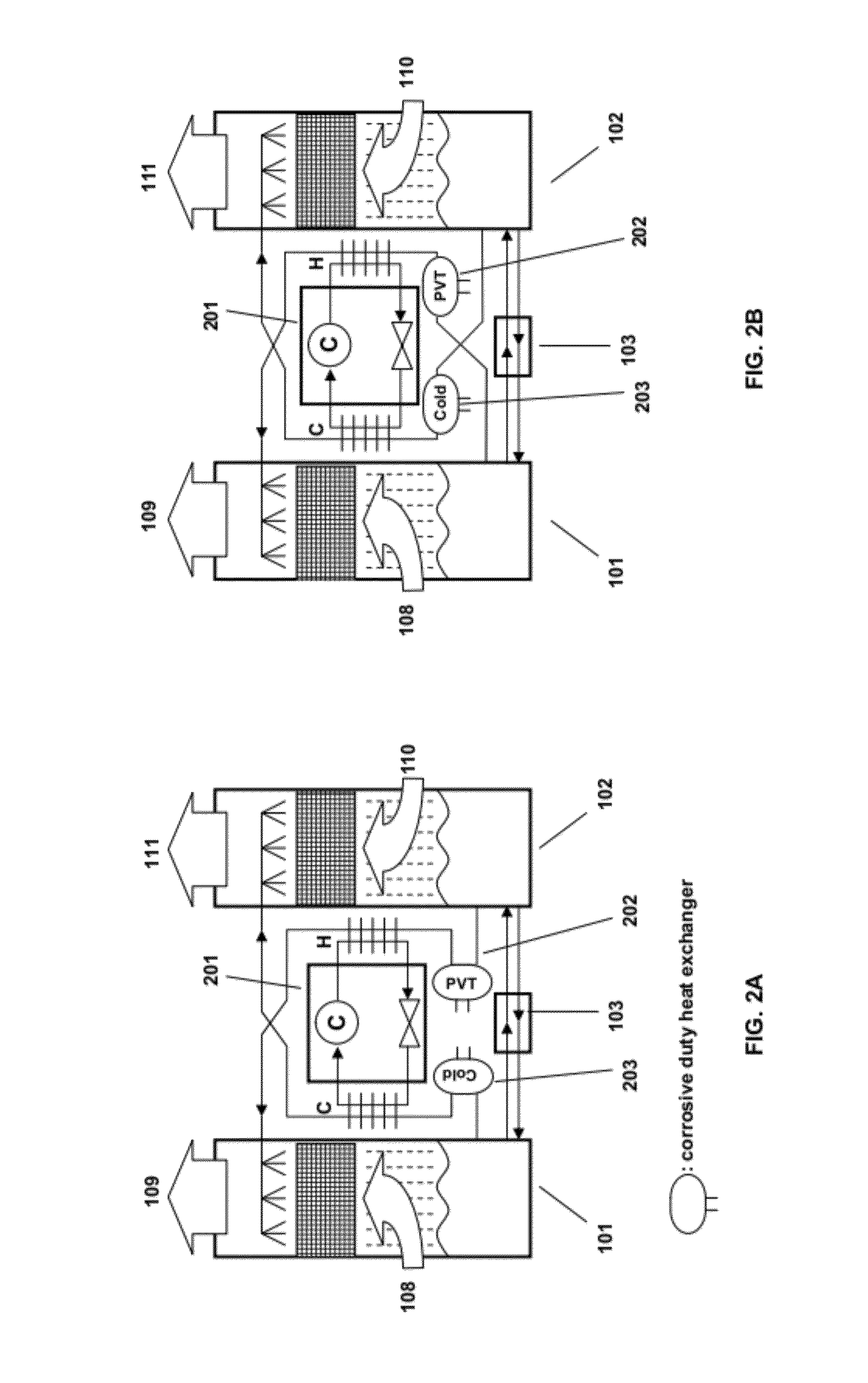

Systems and methods are provided for cooling an electronics rack, which includes a heat-generating electronics subsystem across which air flows from an air inlet to an air outlet side of the rack. First and second modular cooling units (MCUs) are associated with the rack and configured to provide system coolant to the electronics subsystem for cooling thereof. System coolant supply and return manifolds are in fluid communication with the MCUs for facilitating providing of system coolant to the electronics subsystem, and to an air-to-liquid heat exchanger associated with the rack for cooling air passing through the rack. A controller monitors the system coolant and automatically shuts off flow of system coolant through the heat exchanger, using at least one isolation valve, upon detection of failure at one of the MCUs, while allowing the remaining operational MCU to provide system coolant to the electronics subsystem for liquid cooling thereof.

Owner:IBM CORP

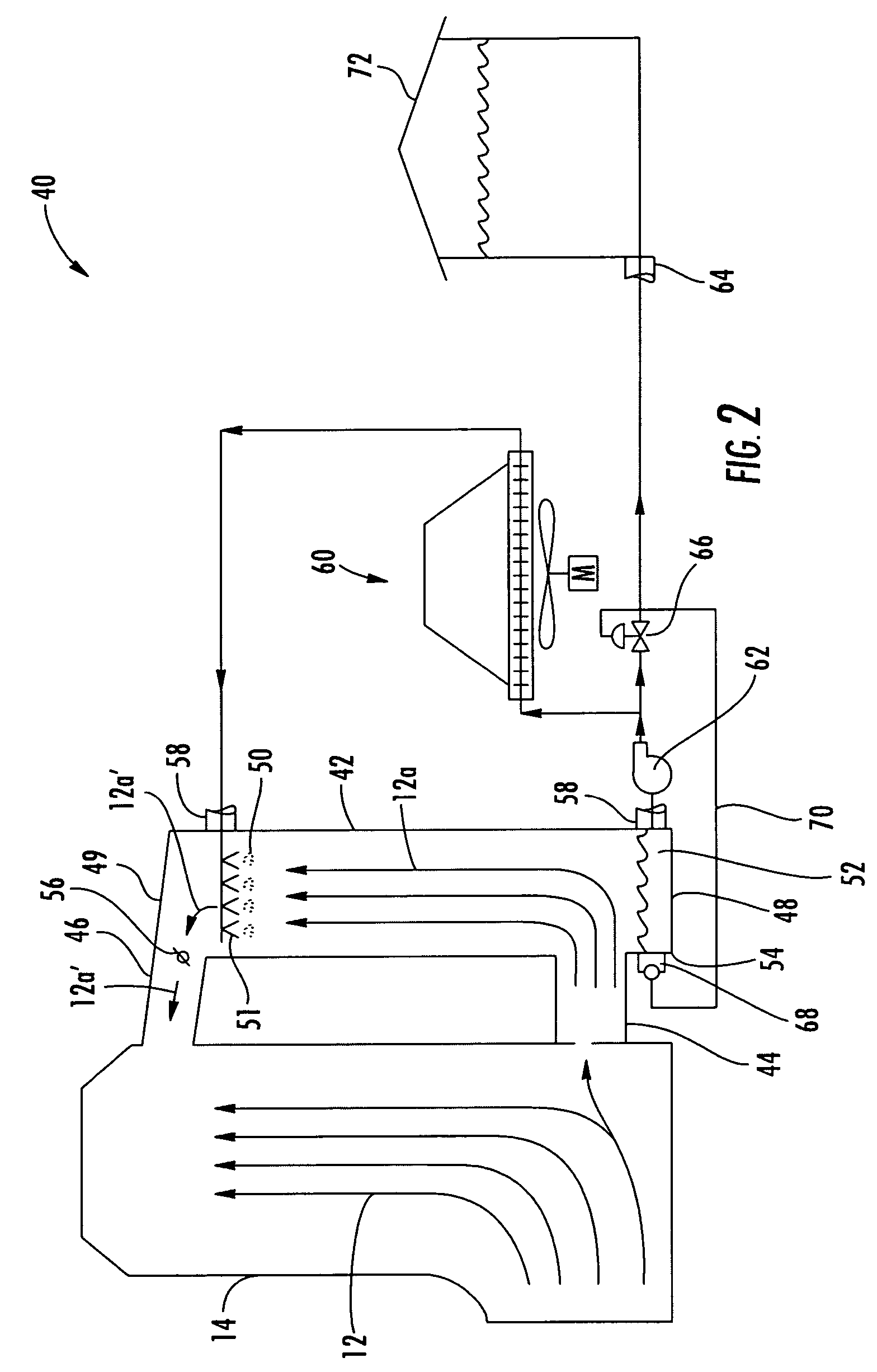

Hydronic rooftop cooling systems

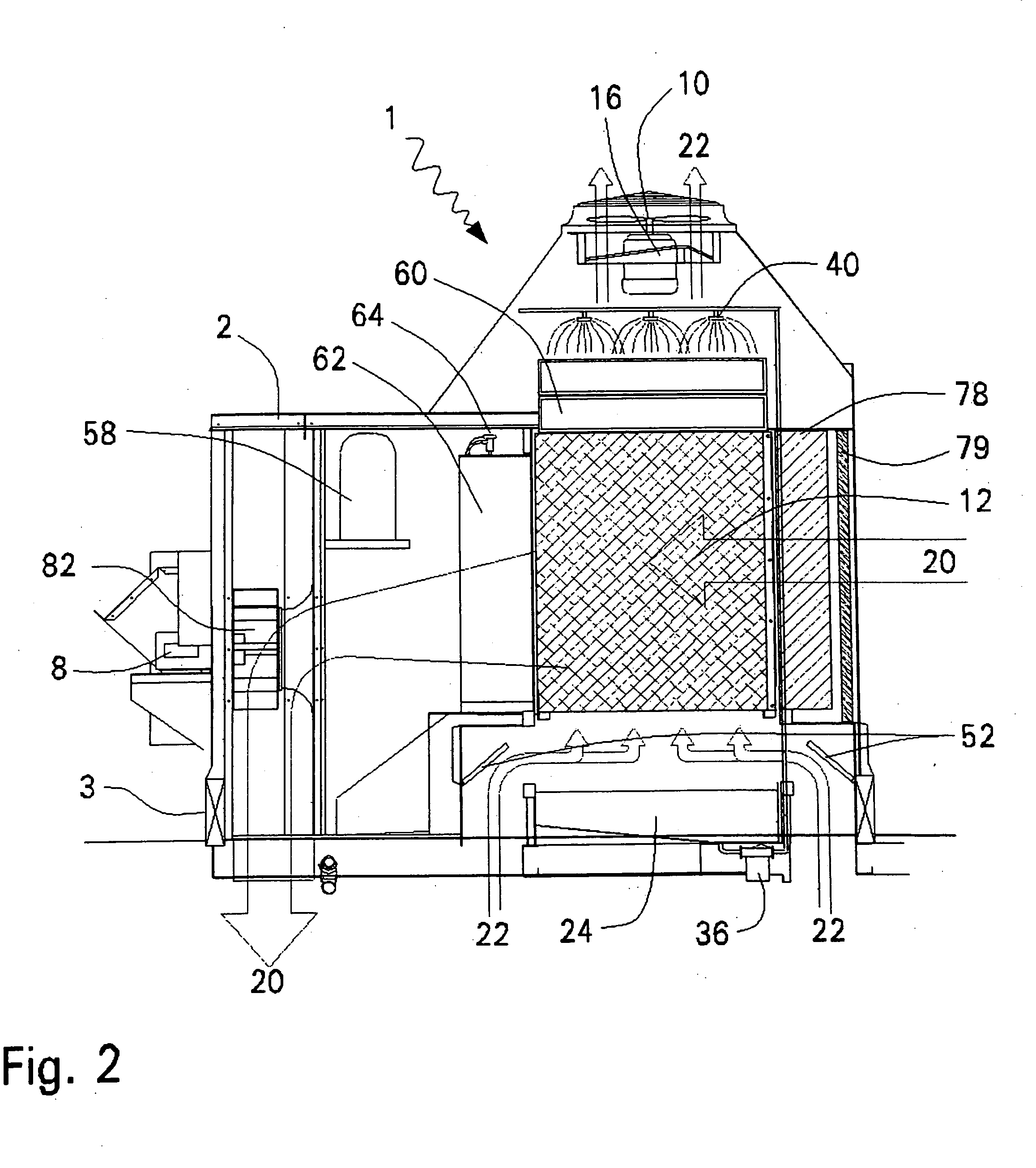

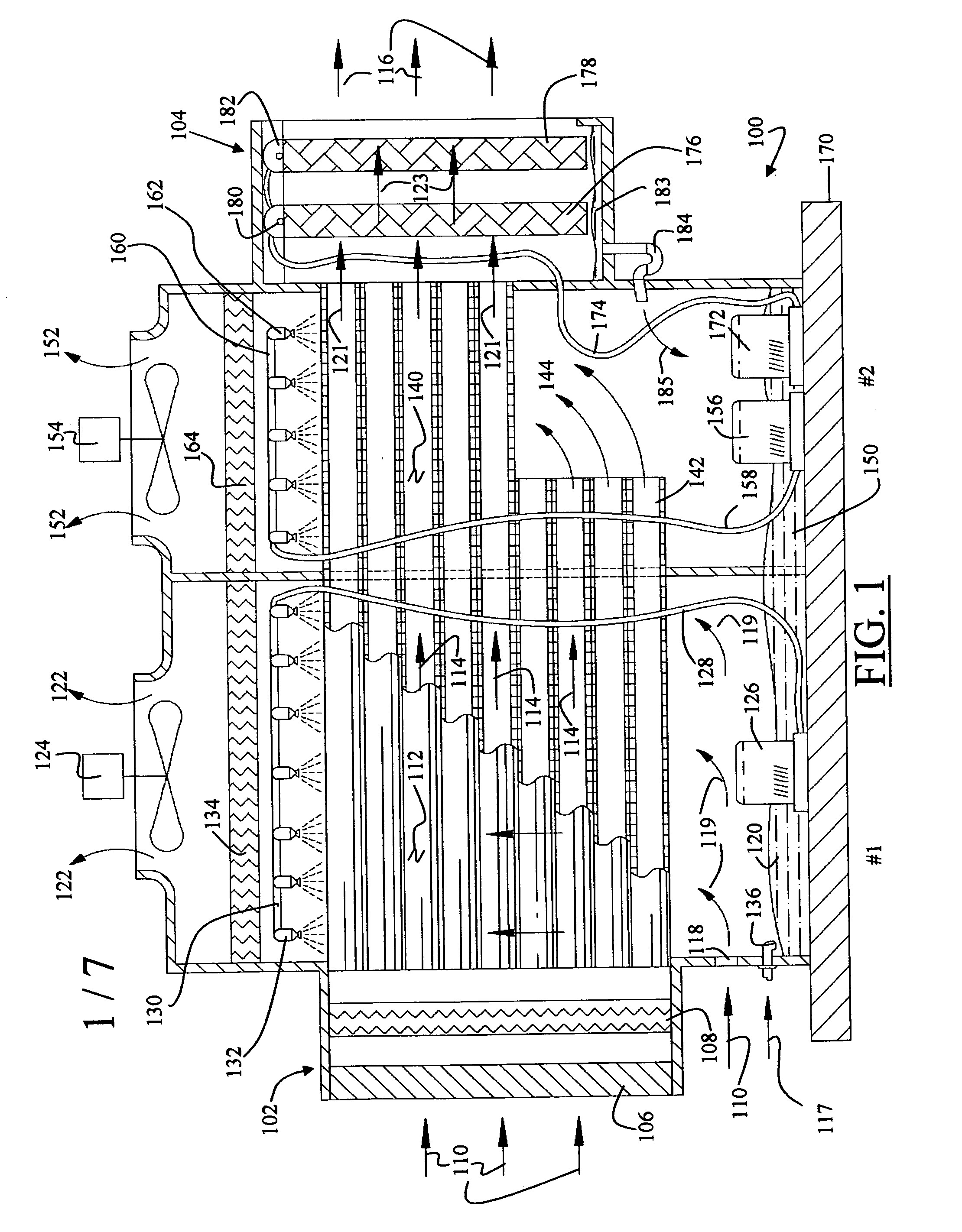

InactiveUS20050056042A1Improve RTU efficiencyEnhanced evaporative cooling effectEnergy recovery in ventilation and heatingHeat recovery systemsAir filterEngineering

A roof top cooling unit has an evaporative cooling section that includes at least one evaporative module that pre-cools ventilation air and water; a condenser; a water reservoir and pump that captures and re-circulates water within the evaporative modules; a fan that exhausts air from the building and the evaporative modules and systems that refill and drain the water reservoir. The cooling unit also has a refrigerant section that includes a compressor, an expansion device, evaporator and condenser heat exchangers, and connecting refrigerant piping. Supply air components include a blower, an air filter, a cooling and / or heating coil to condition air for supply to the building, and optional dampers that, in designs that supply less than 100% outdoor air to the building, control the mixture of return and ventilation air.

Owner:DAVIS ENERGY GROUP

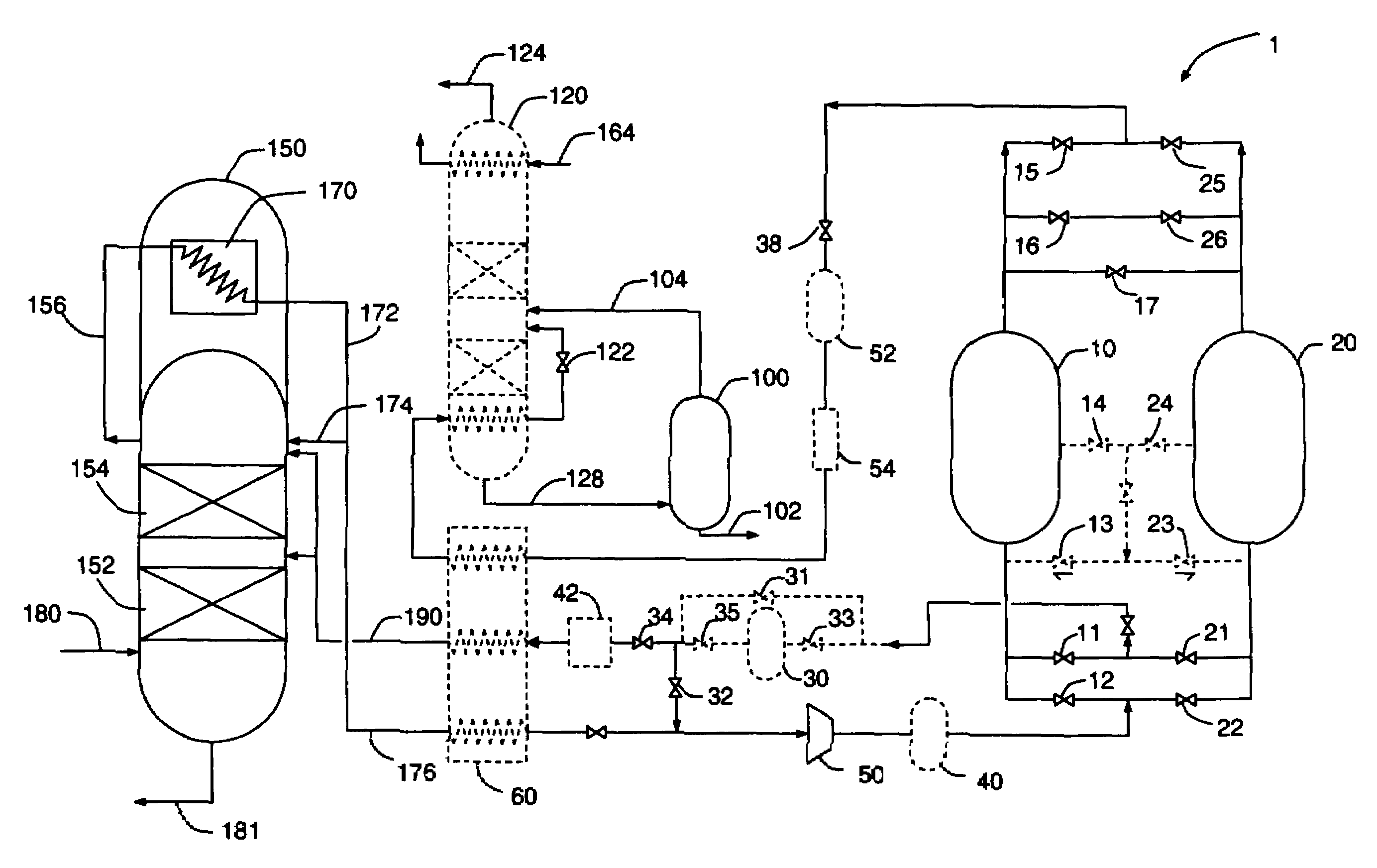

Purification of carbon dioxide

Impure carbon dioxide (“CO2”) comprising a first contaminant selected from the group consisting of oxygen (“O2”) and carbon monoxide (“CO”) is purified by separating expanded impure carbon dioxide liquid in a mass transfer separation column system. The impure carbon dioxide may be derived from, for example, flue gas from an oxyfuel combustion process or waste gas from a hydrogen (“H2”) PSA system.

Owner:AIR PROD & CHEM INC

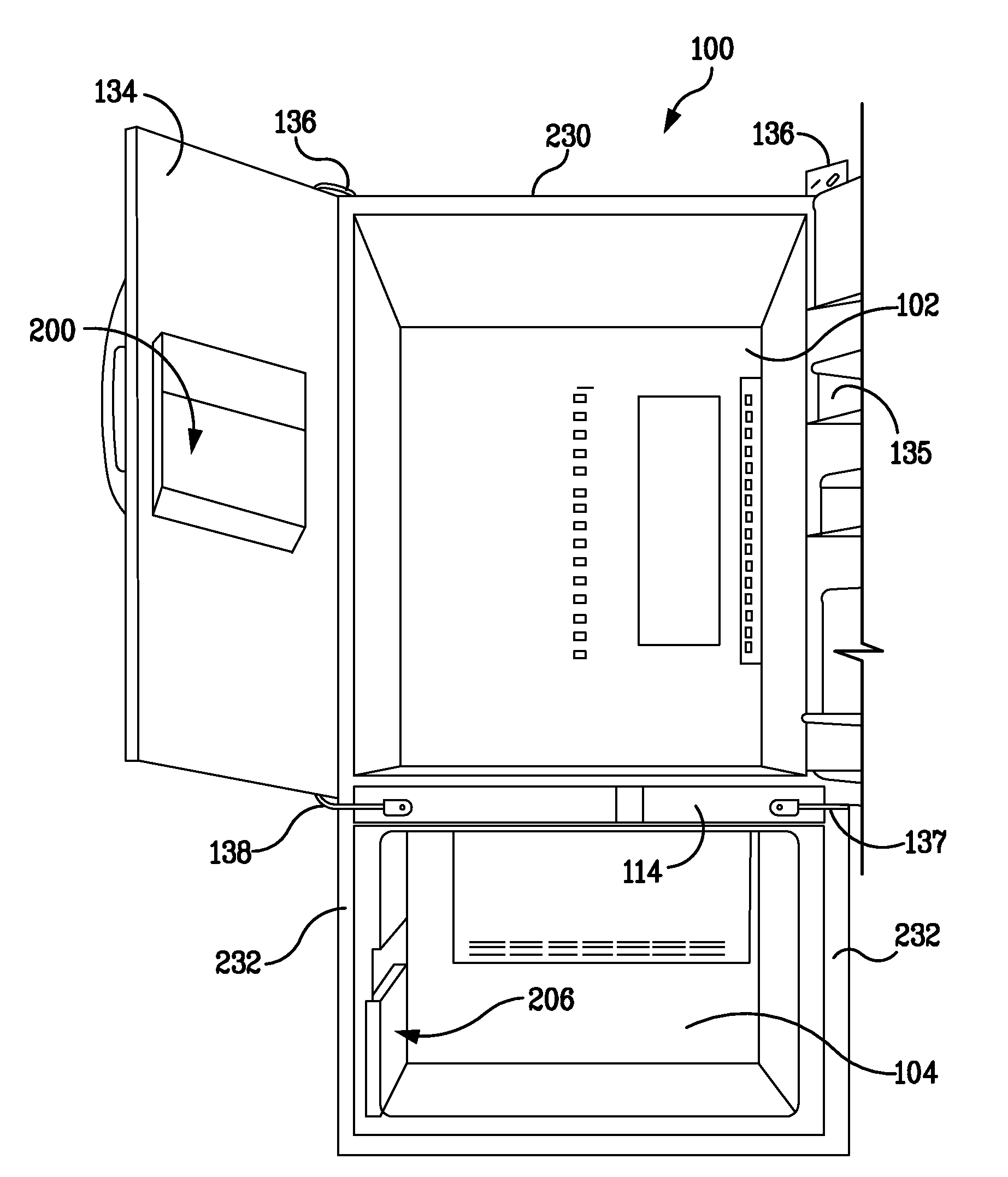

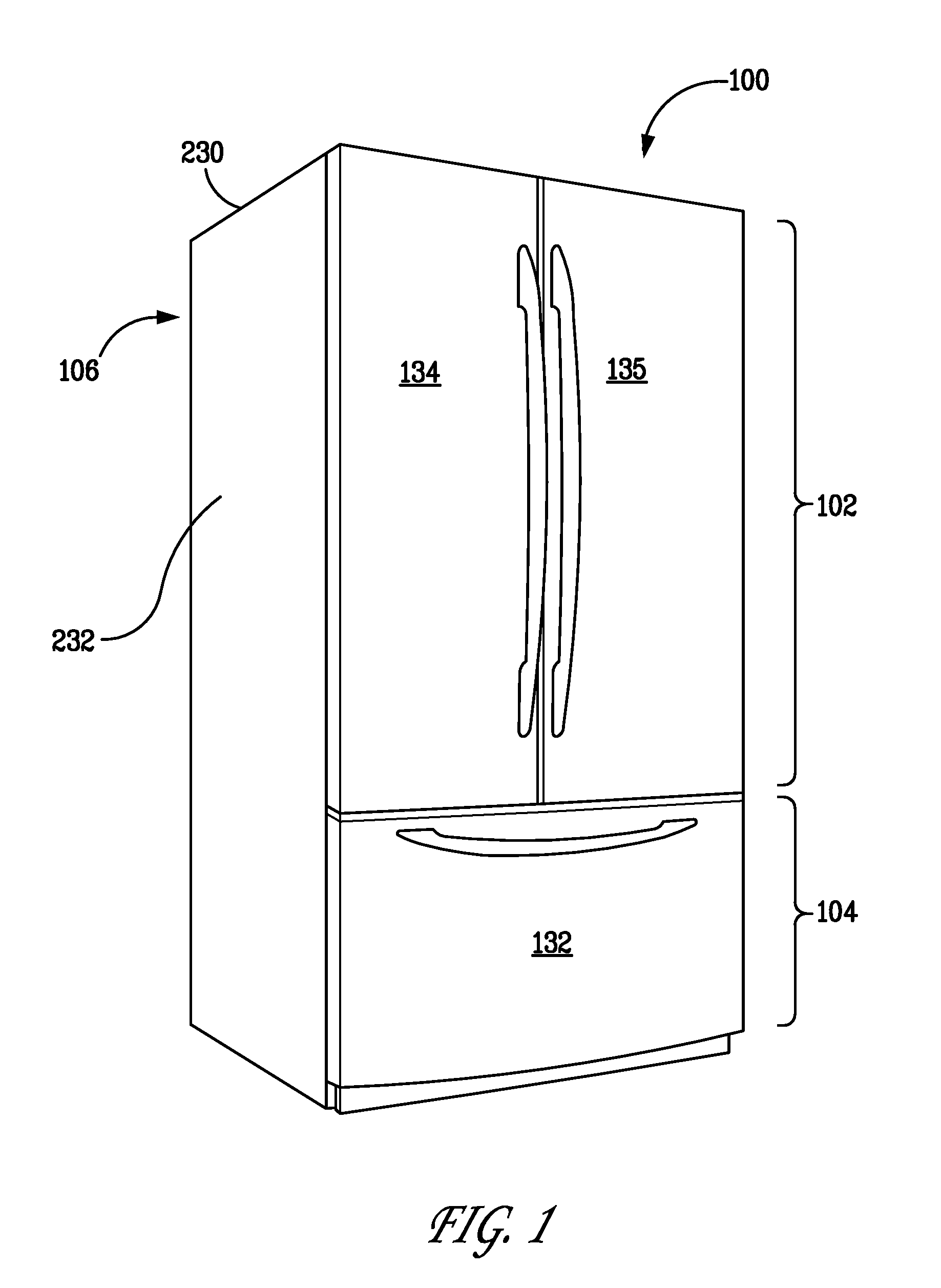

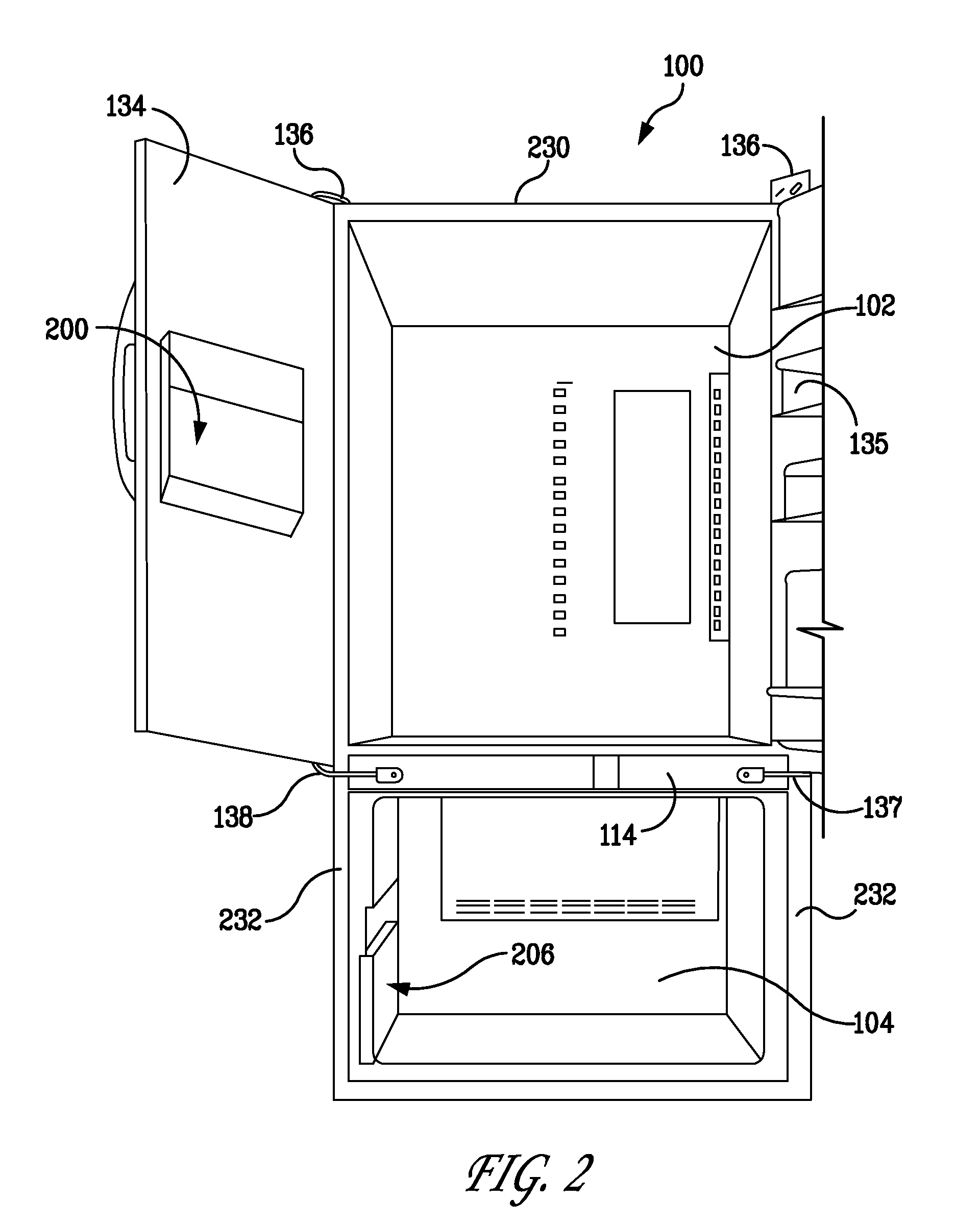

Temperature controlled compartment and method for a refrigerator

A secondary loop temperature control circuit for a temperature-controlled region in a compartment of a refrigerator is shown. The secondary loop temperature control circuit has a reservoir, configured to have a medium flow there through. A first heat exchanger is in flow communication with the reservoir and is configured to have the medium flow there through. The first heat exchanger is in thermal communication with the temperature-controlled region.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Multi-stage hybrid evaporative cooling system

InactiveUS20070101746A1Improve efficiencyFree-cooling systemsEfficient regulation technologiesEngineeringRefrigeration

A multi-stage hybrid evaporative cooling system is described as having a direct evaporative cooling subsystem and an indirect evaporative cooling subsystem having one of a horizontal and a vertical set of heat exchanger channels. The multi-stage hybrid evaporative cooling system with a horizontal set of heat exchanger channels has a portion of the horizontal heat exchanger channels partially extended into a next stage of the multi-stage system. The multi-stage hybrid evaporative cooling system with the vertical set of heat exchanger channels includes a first set of vertical set of heat exchanger channels spanning a substantial vertical height of the stage of the hybrid evaporative cooling system, and a second set spanning approximately half the height of the stage. The multi-stage hybrid evaporative cooling system further includes a refrigeration system for lowering the temperature of the indirect evaporative cooling subsystem air without affecting its pressure flow.

Owner:S&T MFG CO

Combined cooling and power plant with water extraction

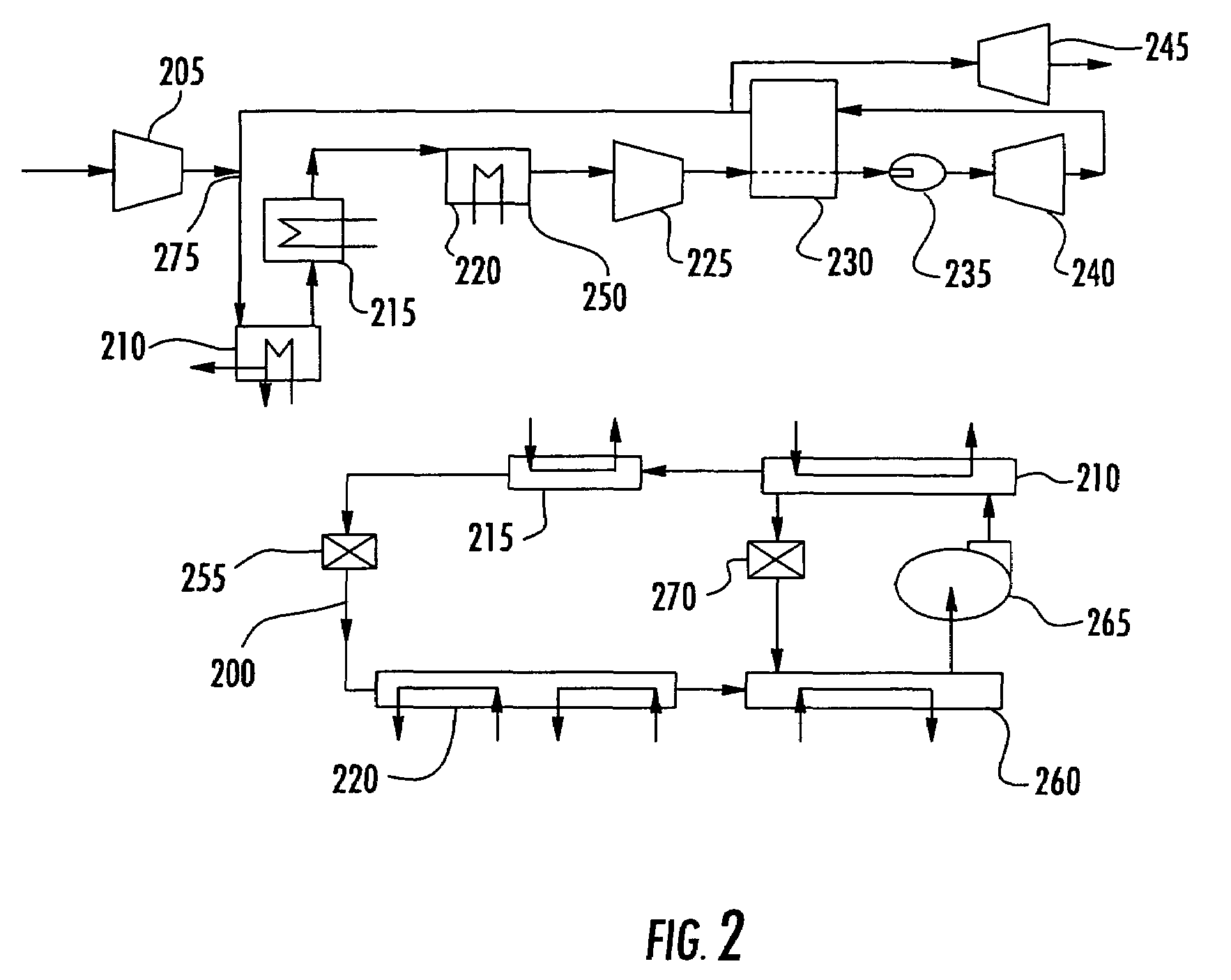

InactiveUS7472550B2Work lessImprove thermal efficiencyEngine fuctionsGas turbine plantsPower stationEngineering

A turbine engine system and a method for using the turbine engine system that includes at least one low-pressure compressor, at least one high-pressure compressor, at least one low-pressure turbine, and at least one high-pressure turbine. In addition, the turbine engine system includes an absorption refrigeration system that is used to pre-cool an air-gas mixture before it enters the high-pressure compressor. As such, the pre-cooled mixture is easier to compress, thereby increasing the thermal efficiency of the turbine engine. Additionally, the exhaust heat from the air-gas mixture that is pre-cooled may be used to drive the absorption refrigeration system. Lastly, water, may be extracted from the evaporator of the absorption refrigeration cycle.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

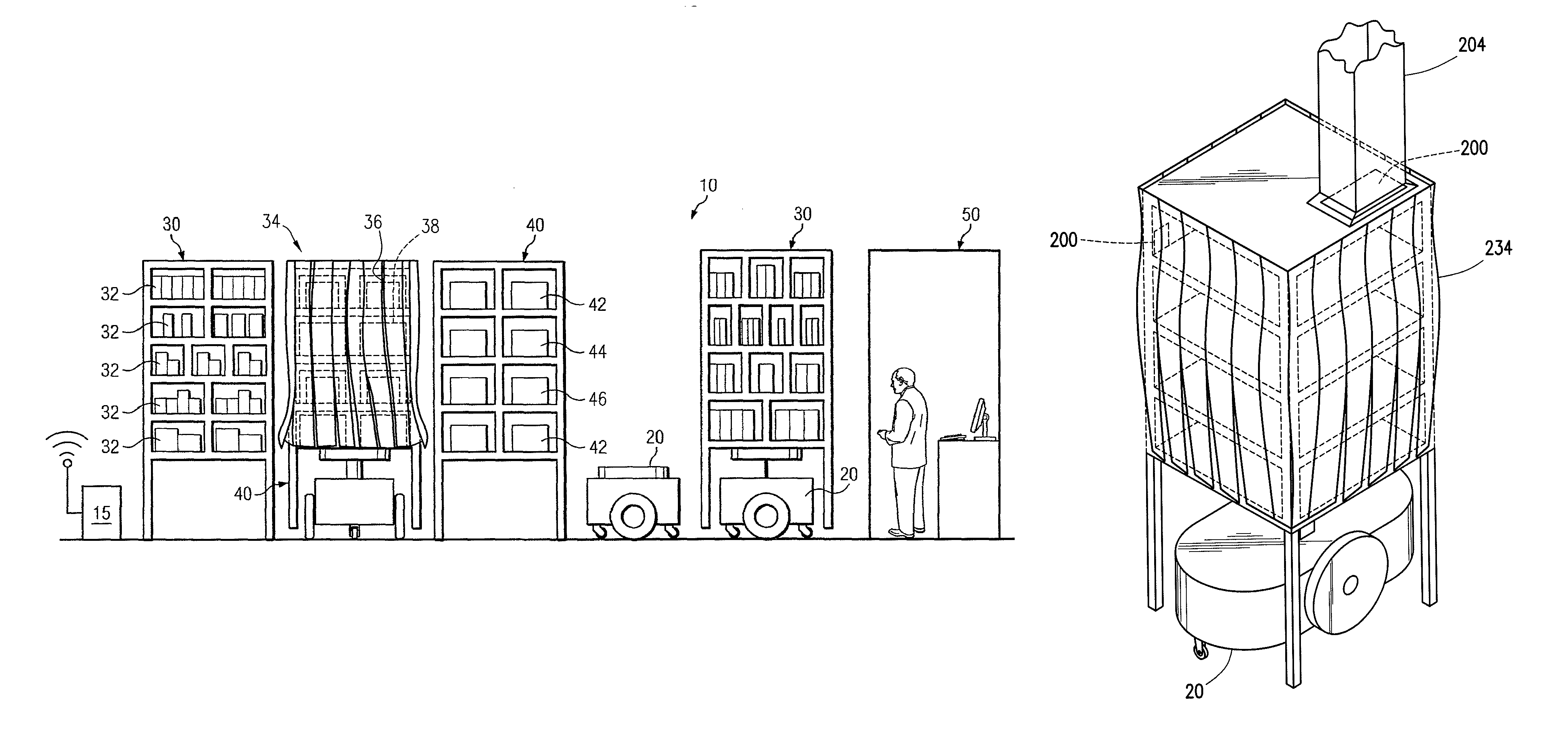

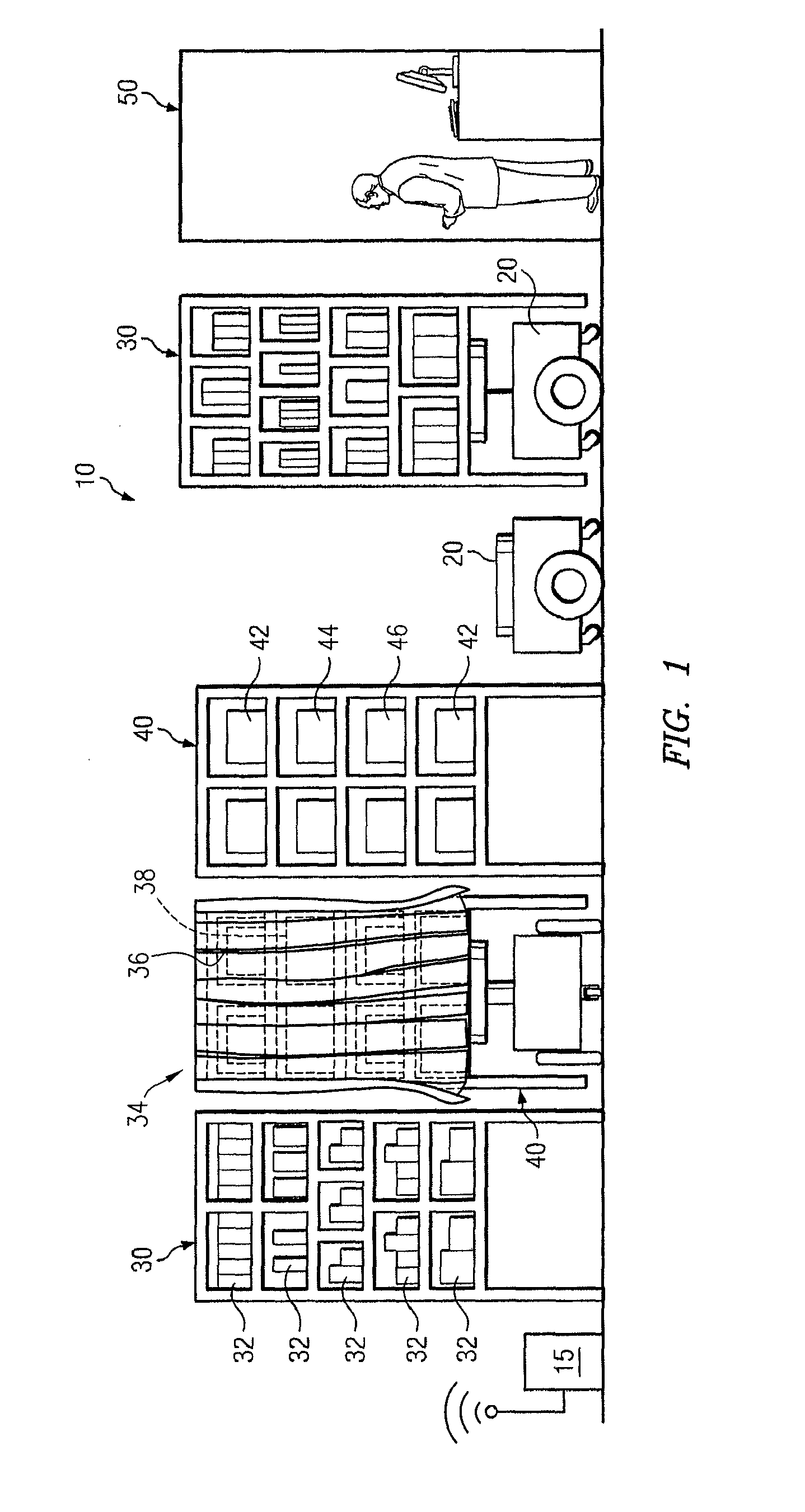

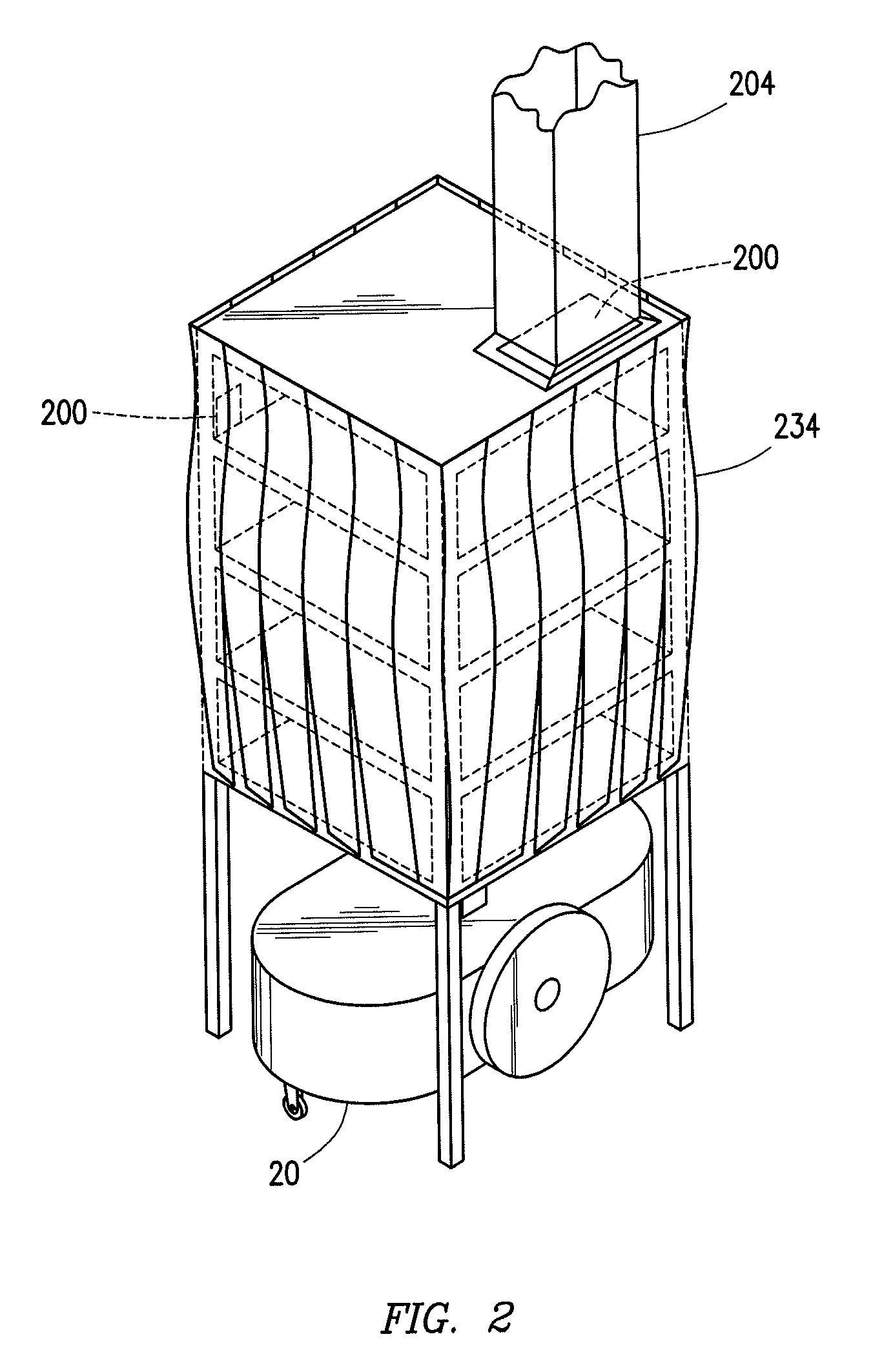

Inventory system with climate-controlled inventory

A system includes a climate-controlled inventory holder, a mobile drive unit, and a management module. The climate-controlled inventory holder is configured to control a climate of one or more inventory items stored by the inventory holder. The mobile drive unit is operable to transport the climate-controlled inventory holder from a first location to a second location based at least in part upon one or more instructions received from a management module. The management module is operable to receive an order for an inventory item, determine that the inventory holder stores the inventory item, and instruct the mobile drive unit to transport the climate-controlled inventory holder from the first location to the second location.

Owner:AMAZON TECH INC

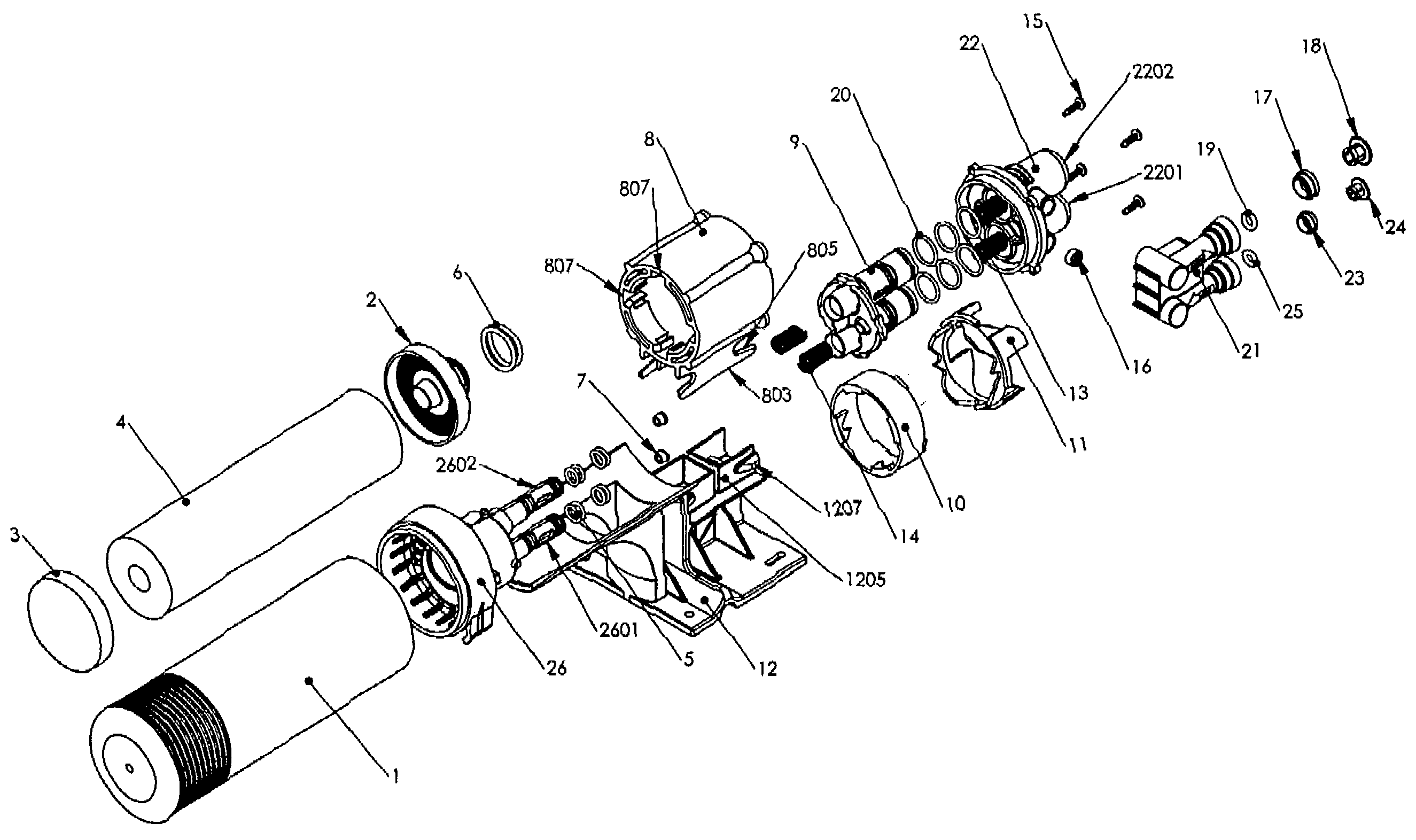

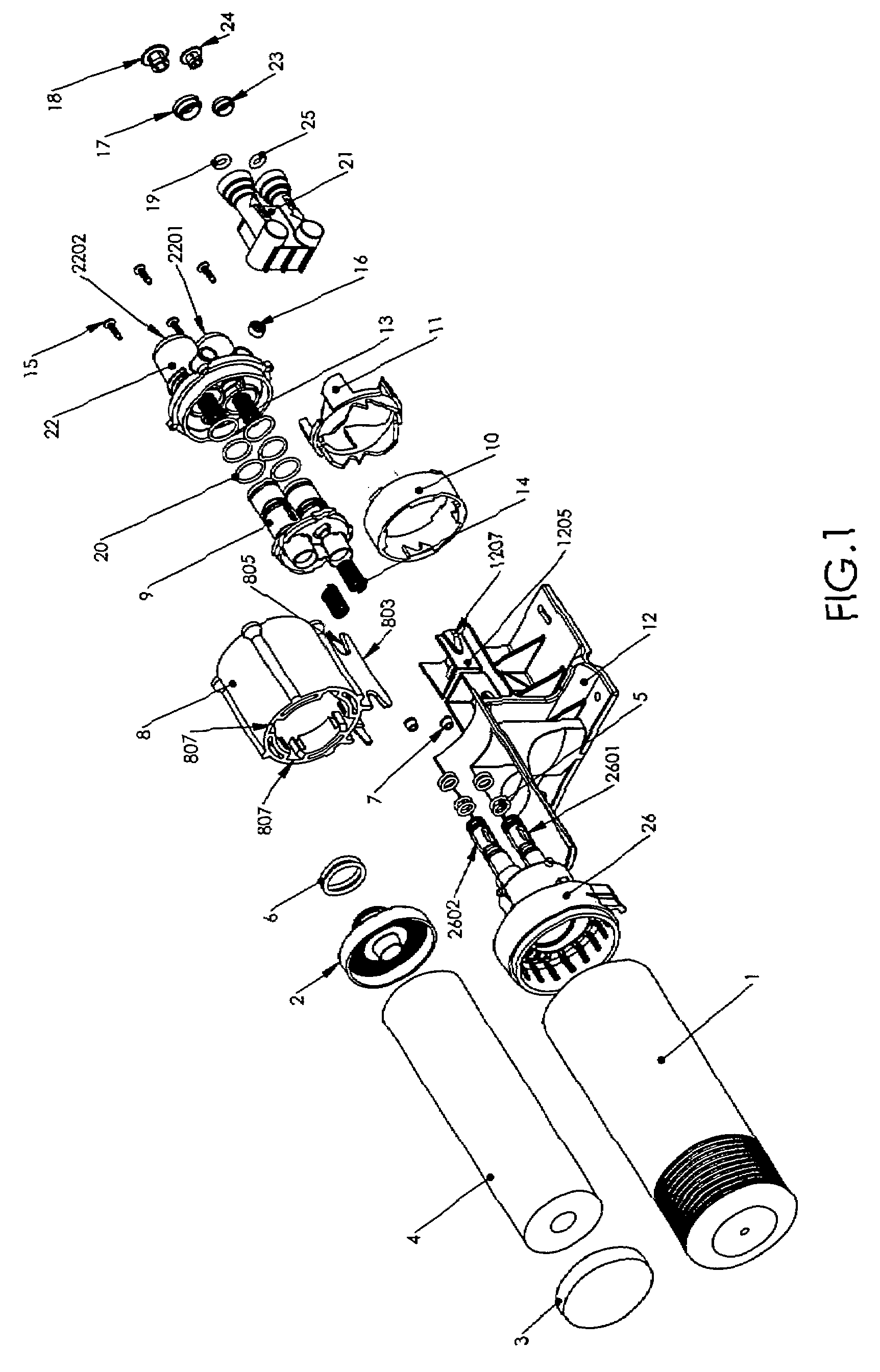

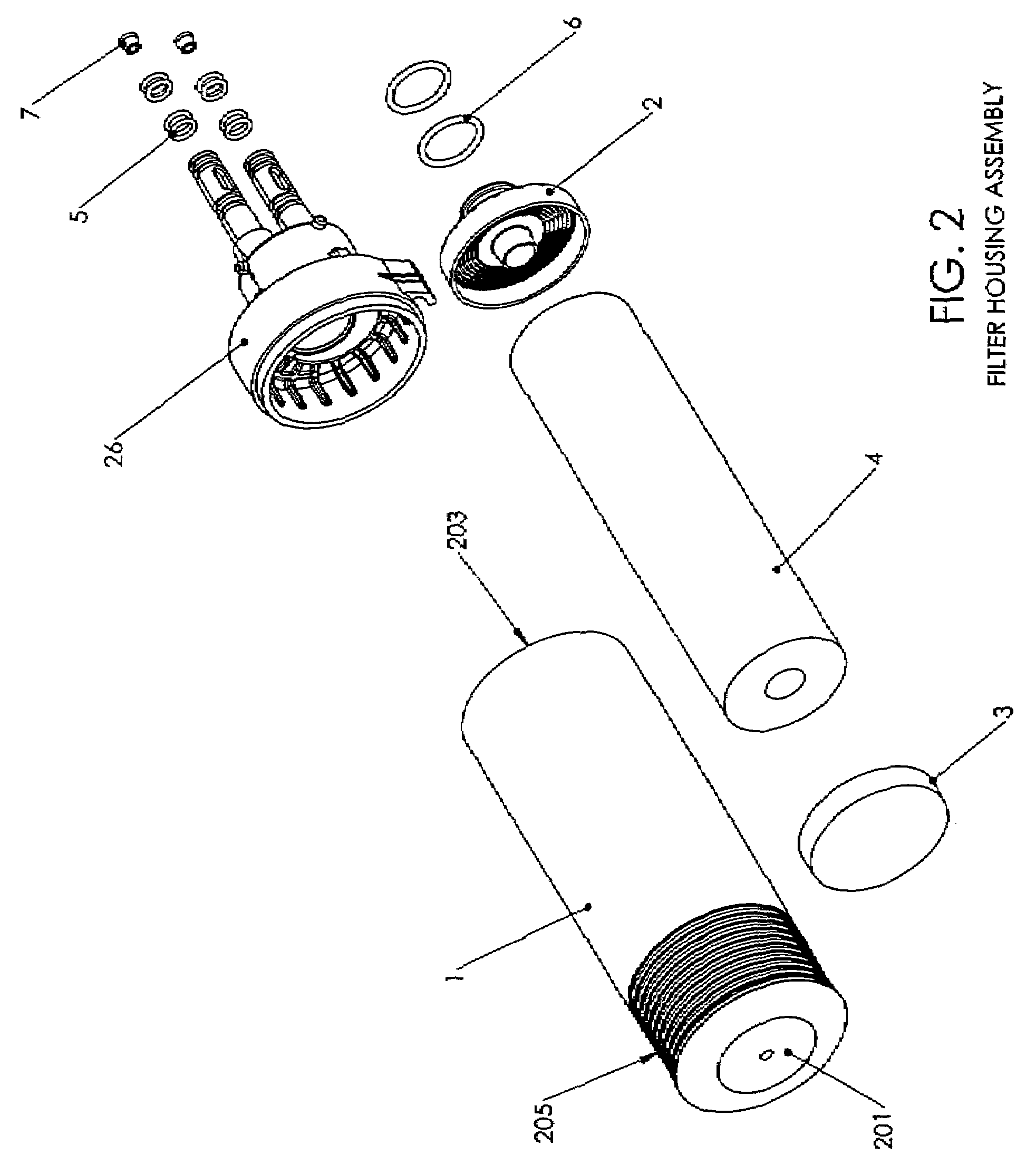

Filter housing apparatus with roatating filter replacement mechanism

InactiveUS20080047889A1Easy to disassembleSimple replacement and removalDomestic cooling apparatusSettling tanks feed/dischargeFilter mediaFluid filtration

A filter assembly for fluid filtration having a push-activated lock and release mechanism. The filter housing has a sump for enclosing the filter media, a filter head, and at least one standoff protruding outwards for use in securing the filter head to a filter manifold. The filter manifold supports the filter housing with a filter locator. A filter guide having a rotator actuating mechanism secures and holds the filter head in place when the filter head is axially inserted. The rotator actuating mechanism has tabs and slots that rotate upon a transverse axial force from the standoff and from tabs on an internal shutoff. The internal shutoff has an inlet extension and an outlet extension with apertures for fluid ingress and egress. The internal shutoff tabs slidably contact and align the rotator actuating mechanism to secure and remove the filter head.

Owner:KX TECH LLC (DW US)

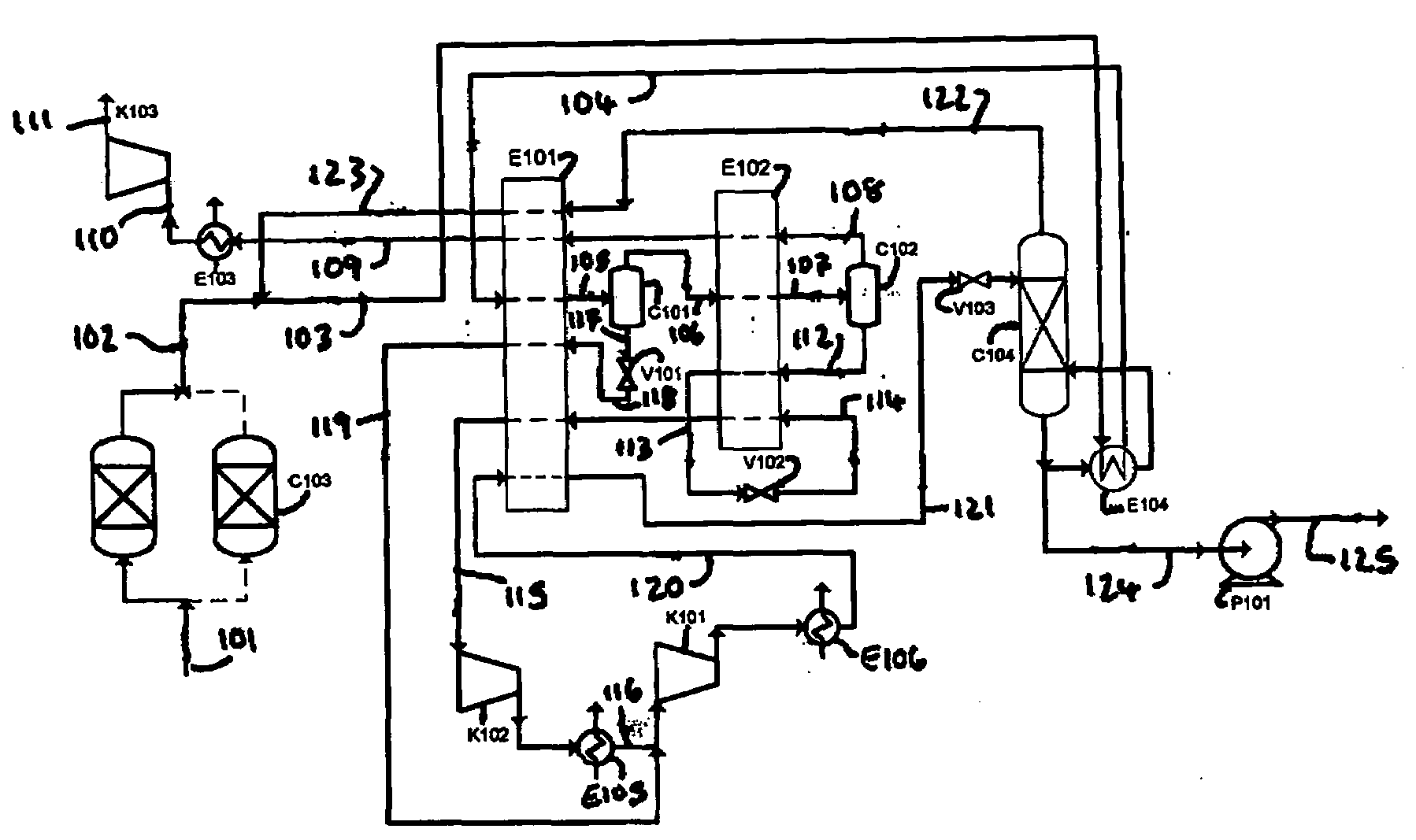

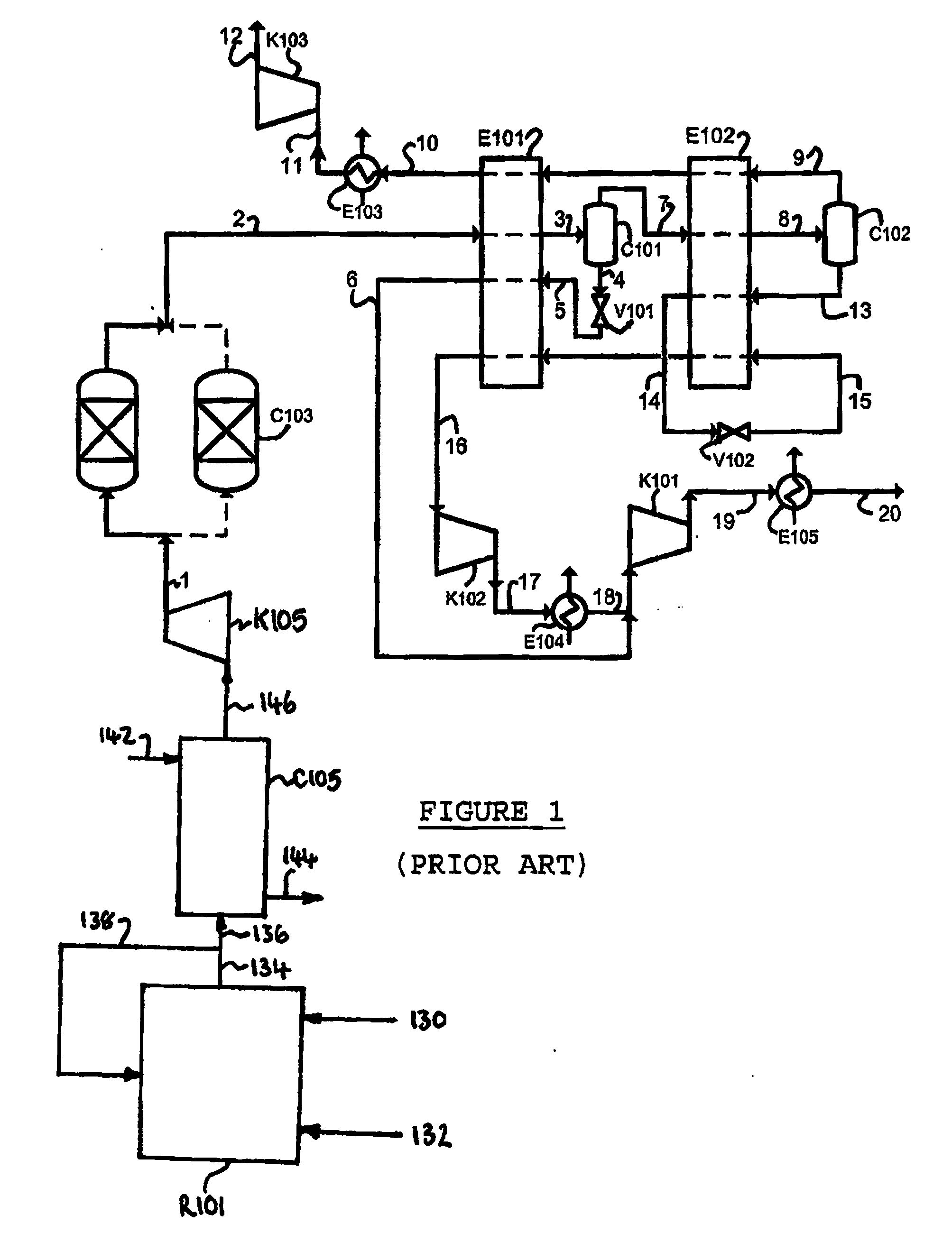

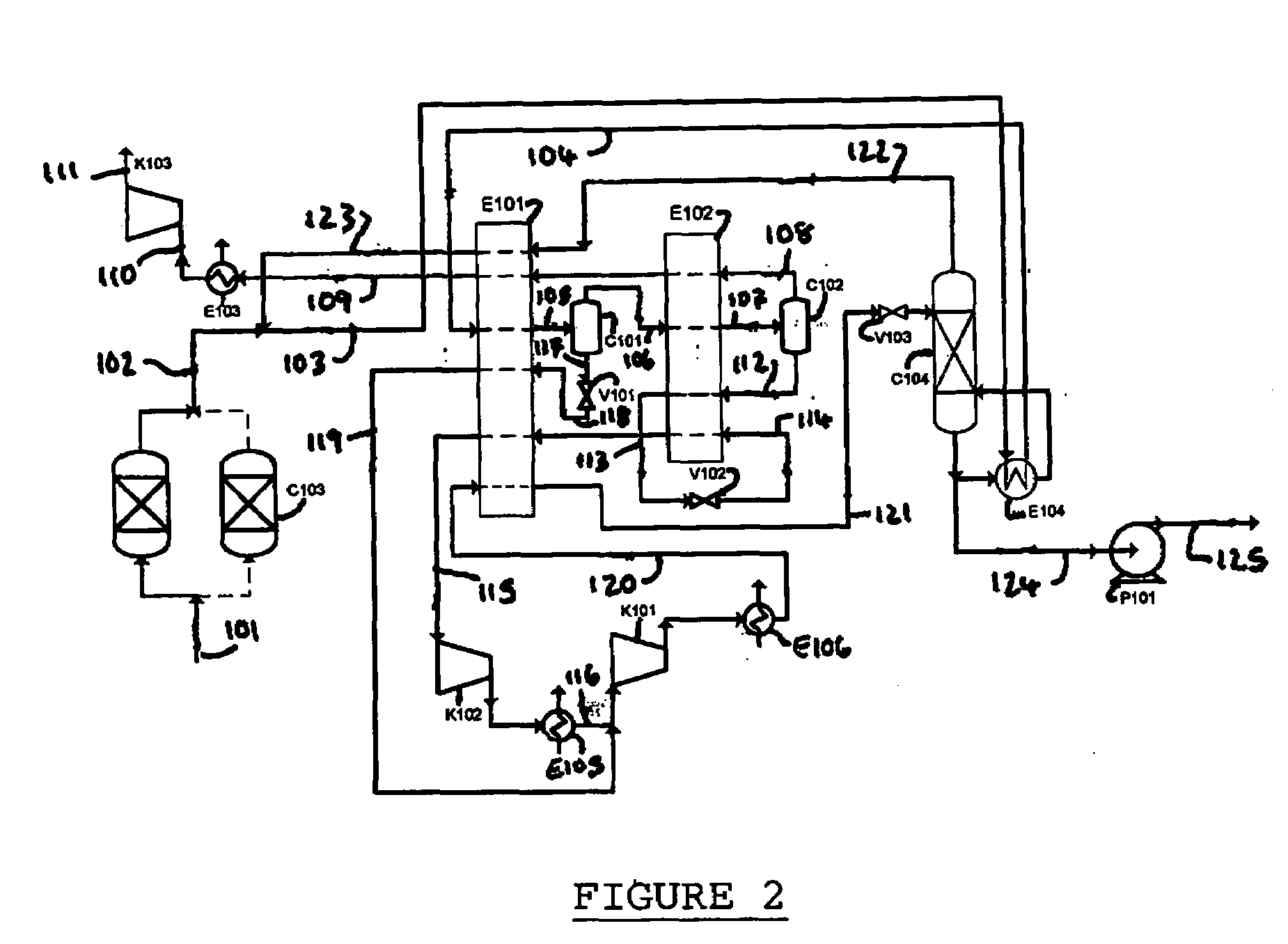

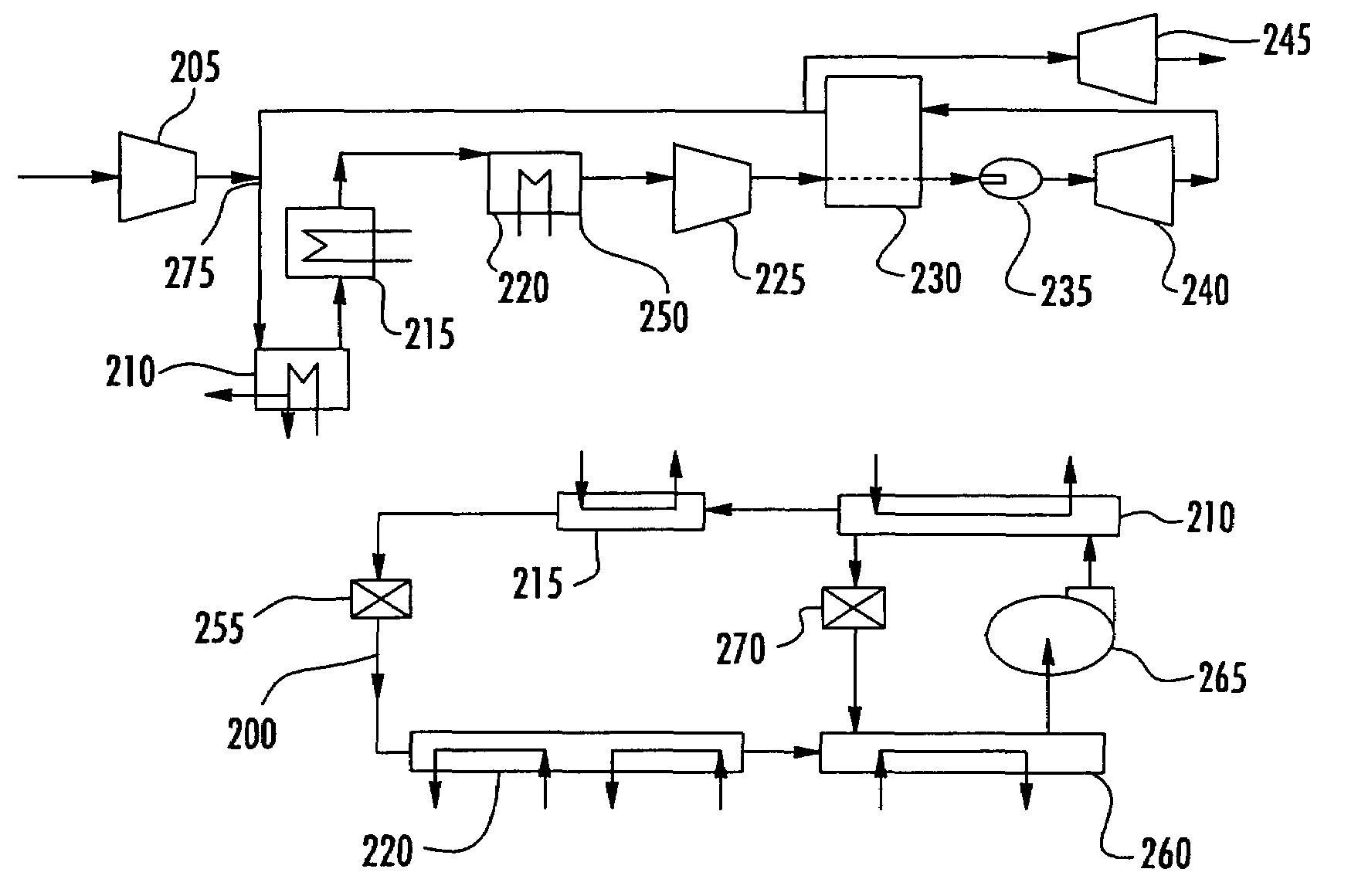

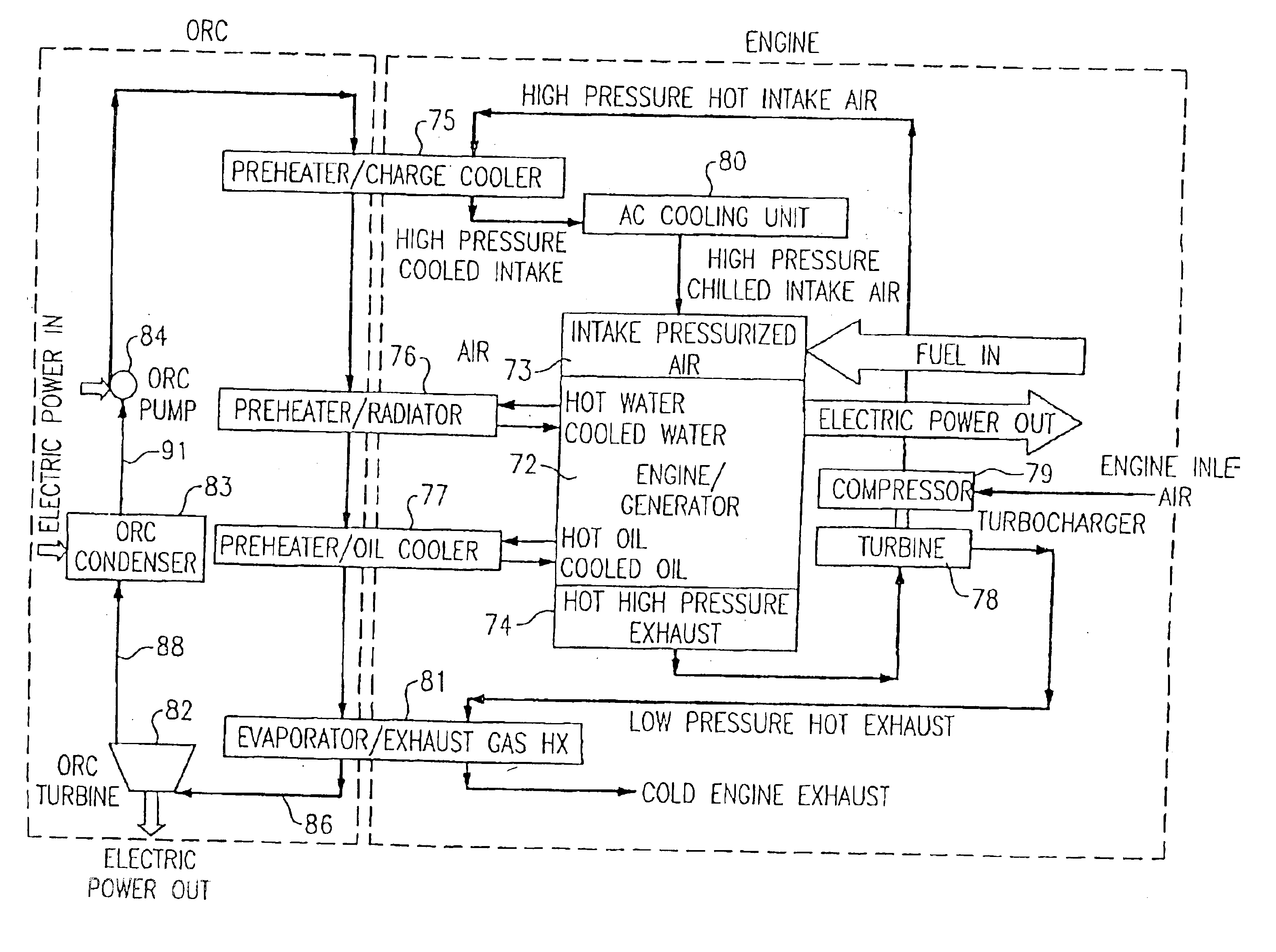

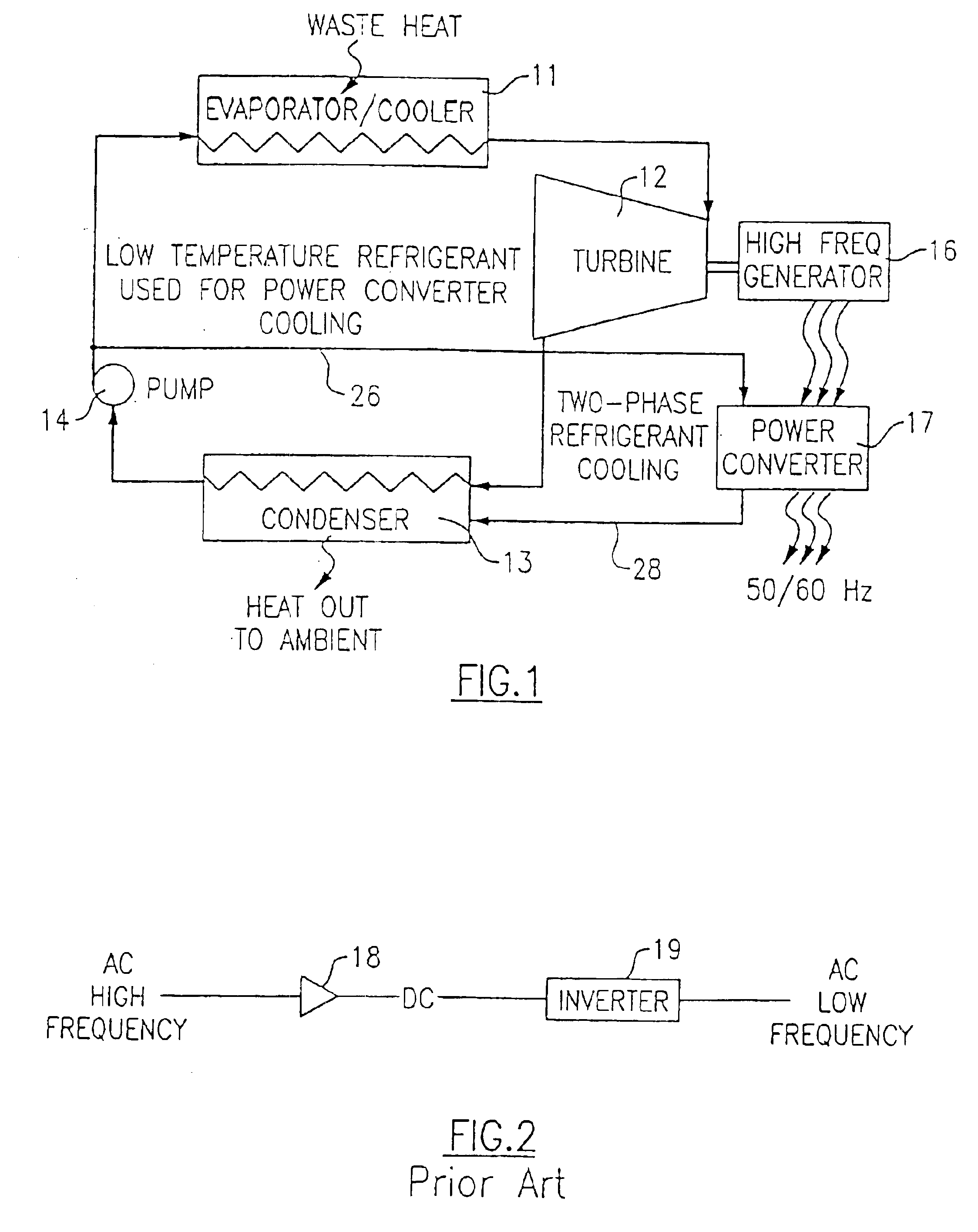

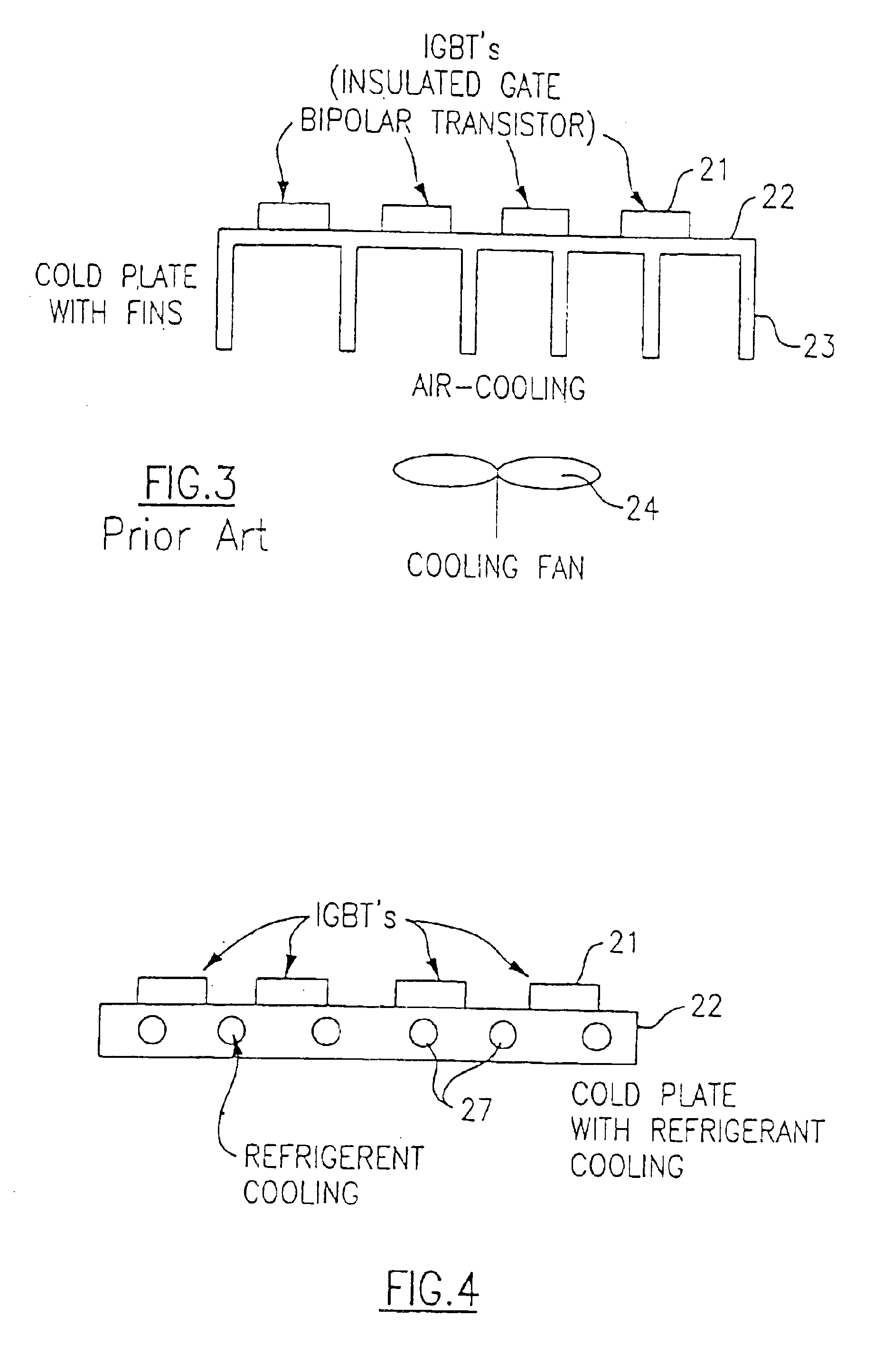

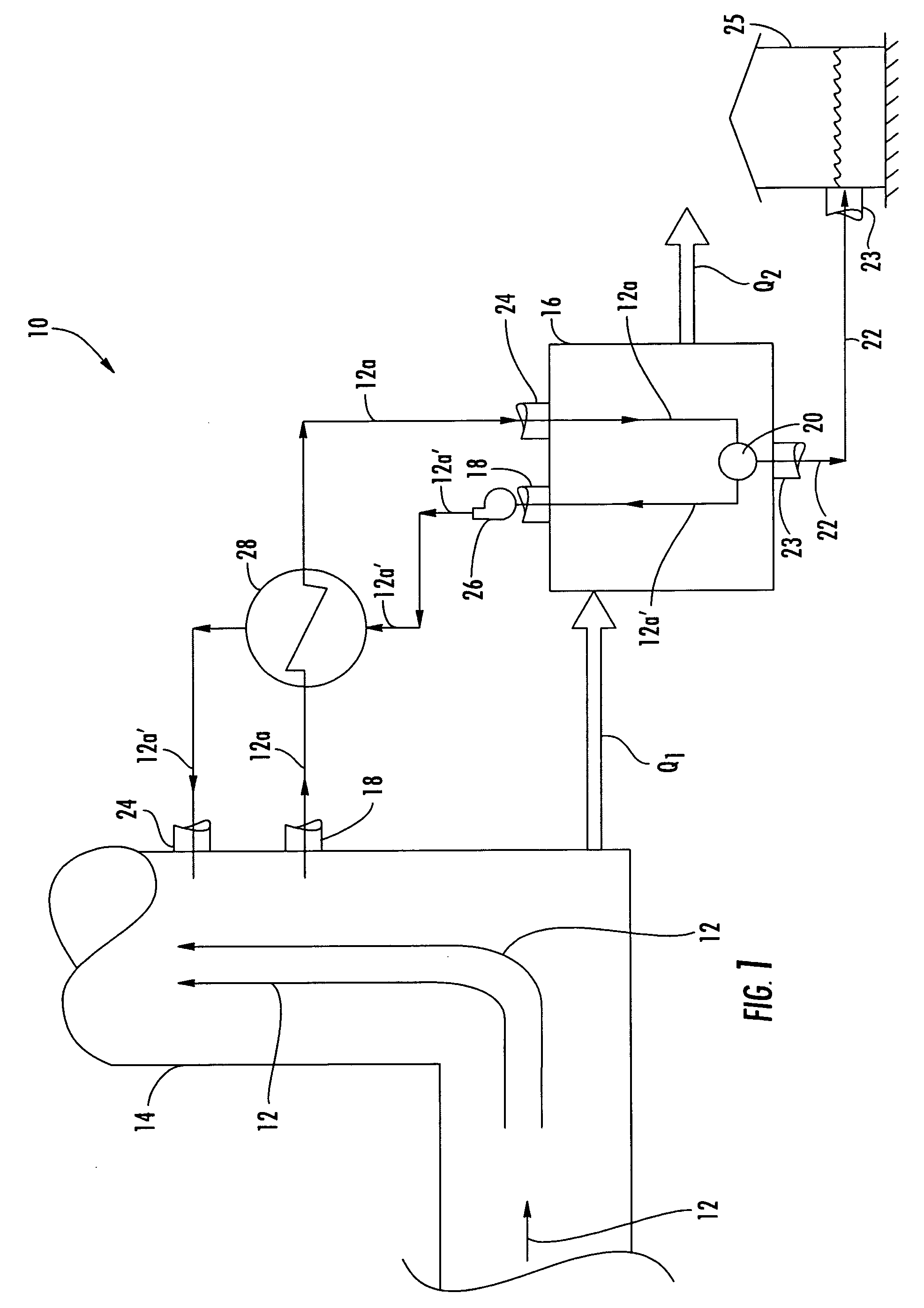

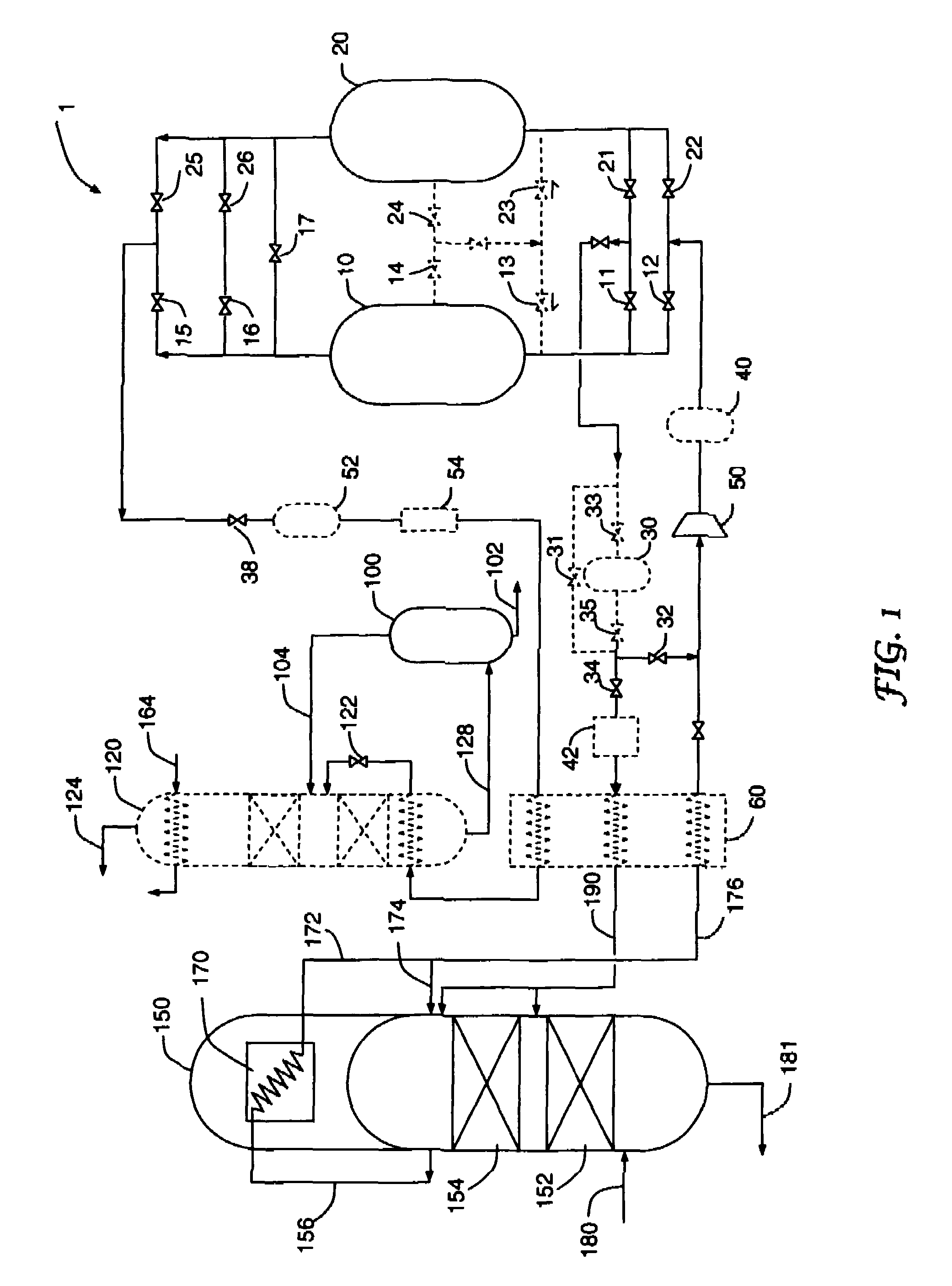

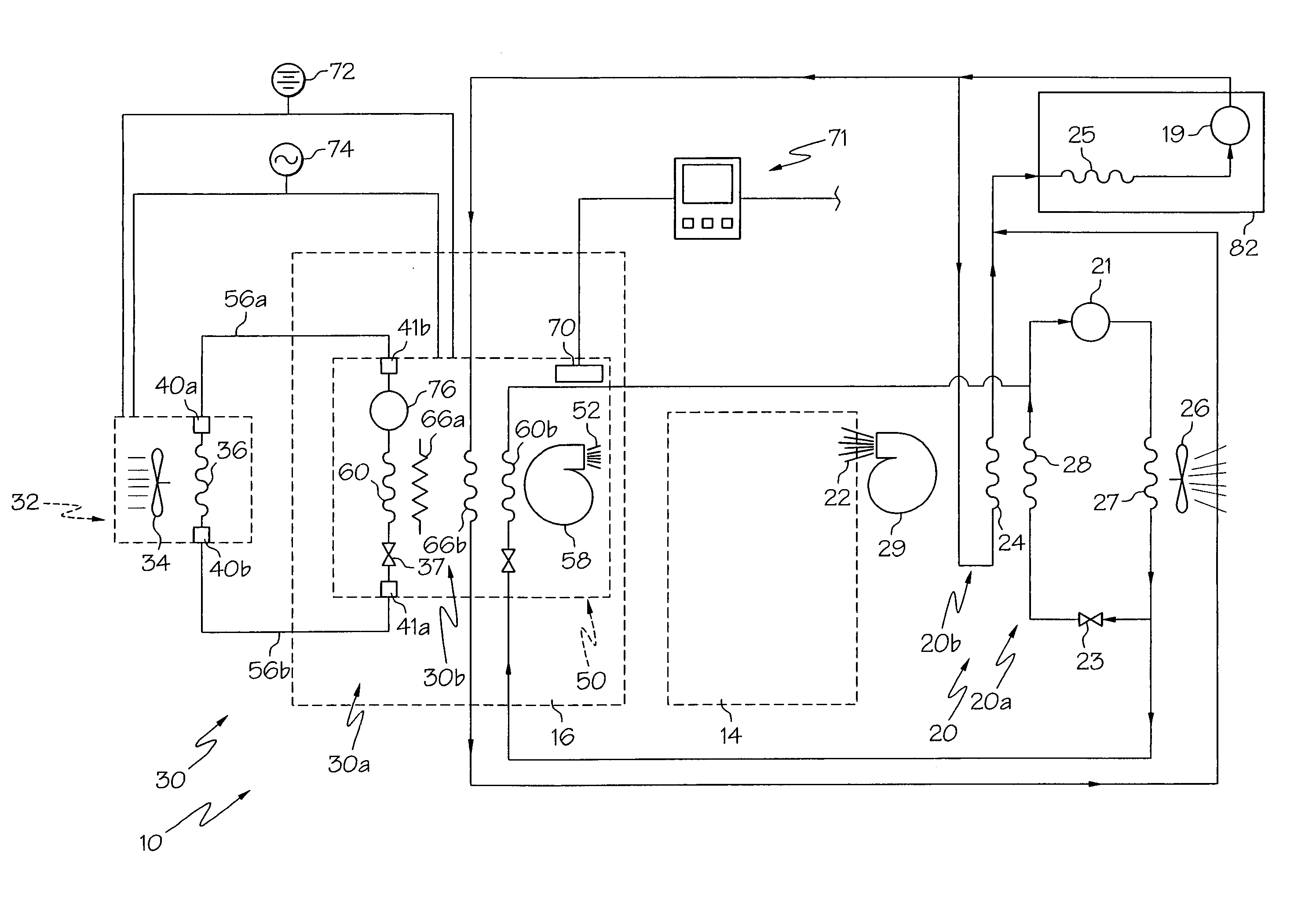

Combined rankine and vapor compression cycles

InactiveUS6880344B2Effective use of wasteEasy to useInternal combustion piston enginesBiofuelsOrganic Rankine cycleEngineering

An organic rankine cycle system is combined with a vapor compression cycle system with the turbine generator of the organic rankine cycle generating the power necessary to operate the motor of the refrigerant compressor. The vapor compression cycle is applied with its evaporator cooling the inlet air into a gas turbine, and the organic rankine cycle is applied to receive heat from a gas turbine exhaust to heat its boiler within one embodiment, a common condenser is used for the organic rankine cycle and the vapor compression cycle, with a common refrigerant, R-245a being circulated within both systems. In another embodiment, the turbine driven generator has a common shaft connected to the compressor to thereby eliminate the need for a separate motor to drive the compressor. In another embodiment, an organic rankine cycle system is applied to an internal combustion engine to cool the fluids thereof, and the turbo charged air is cooled first by the organic rankine cycle system and then by an air conditioner prior to passing into the intake of the engine.

Owner:NANJING TICA AIR CONDITIONING CO LTD

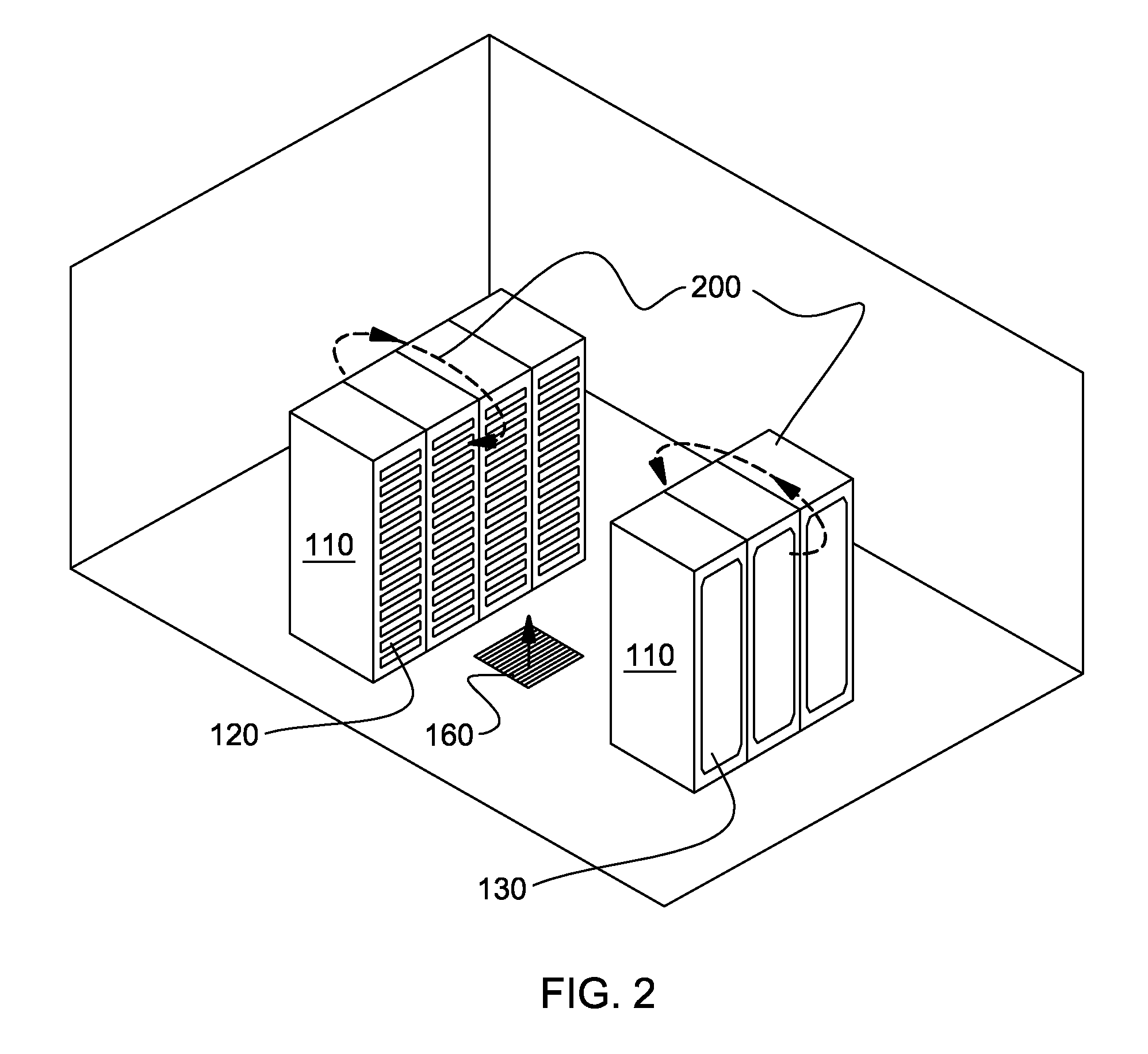

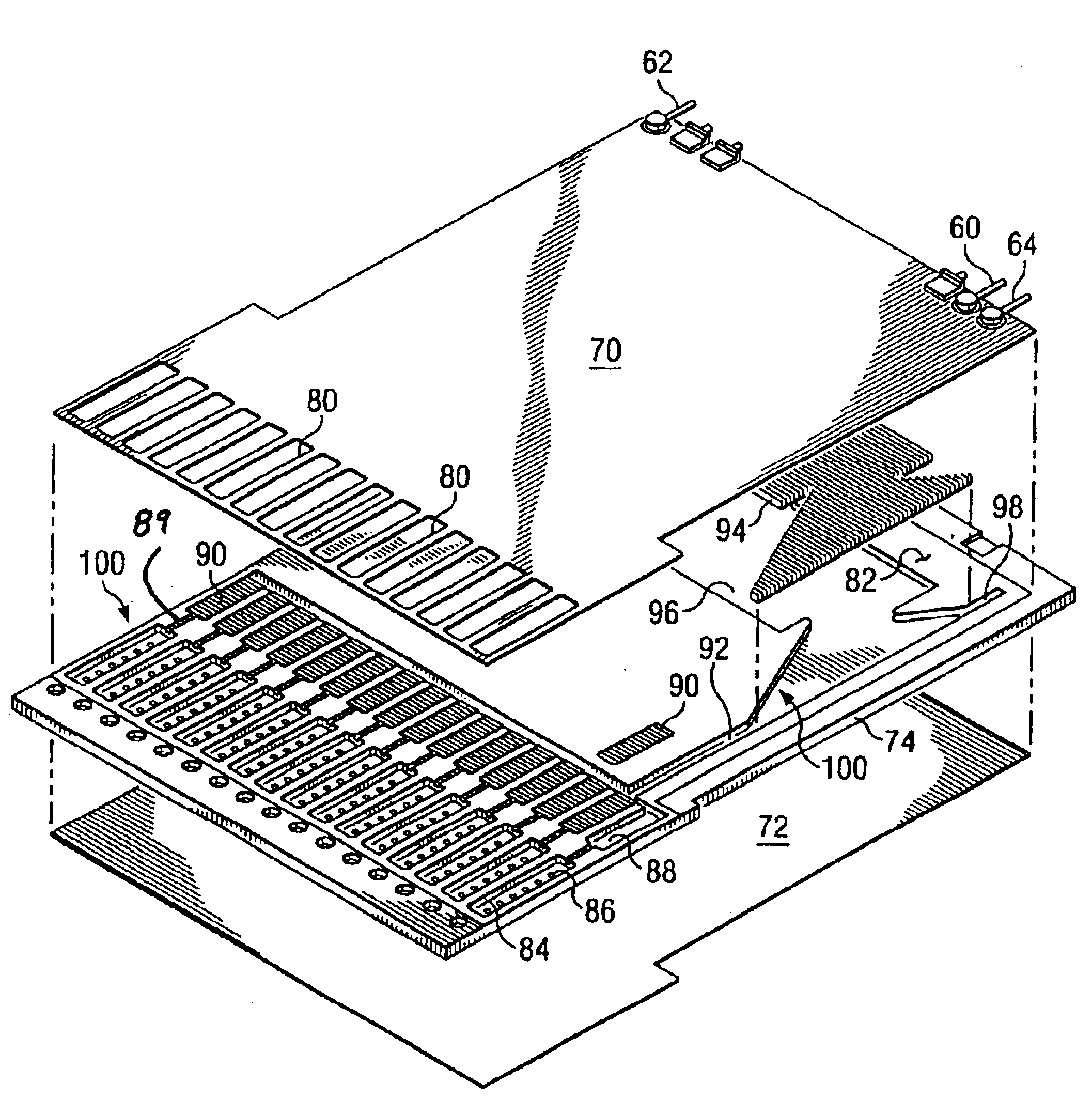

System and method for facilitating cooling of a liquid-cooled electronics rack

InactiveUS7757506B2Domestic cooling apparatusIndirect heat exchangersIsolation valveNuclear engineering

Systems and methods are provided for cooling an electronics rack, which includes a heat-generating electronics subsystem across which air flows from an air inlet to an air outlet side of the rack. First and second modular cooling units (MCUs) are associated with the rack and configured to provide system coolant to the electronics subsystem for cooling thereof. System coolant supply and return manifolds are in fluid communication with the MCUs for facilitating providing of system coolant to the electronics subsystem, and to an air-to-liquid heat exchanger associated with the rack for cooling air passing through the rack. A controller monitors the system coolant and automatically shuts off flow of system coolant through the heat exchanger, using at least one isolation valve, upon detection of failure at one of the MCUs, while allowing the remaining operational MCU to provide system coolant to the electronics subsystem for liquid cooling thereof.

Owner:INT BUSINESS MASCH CORP

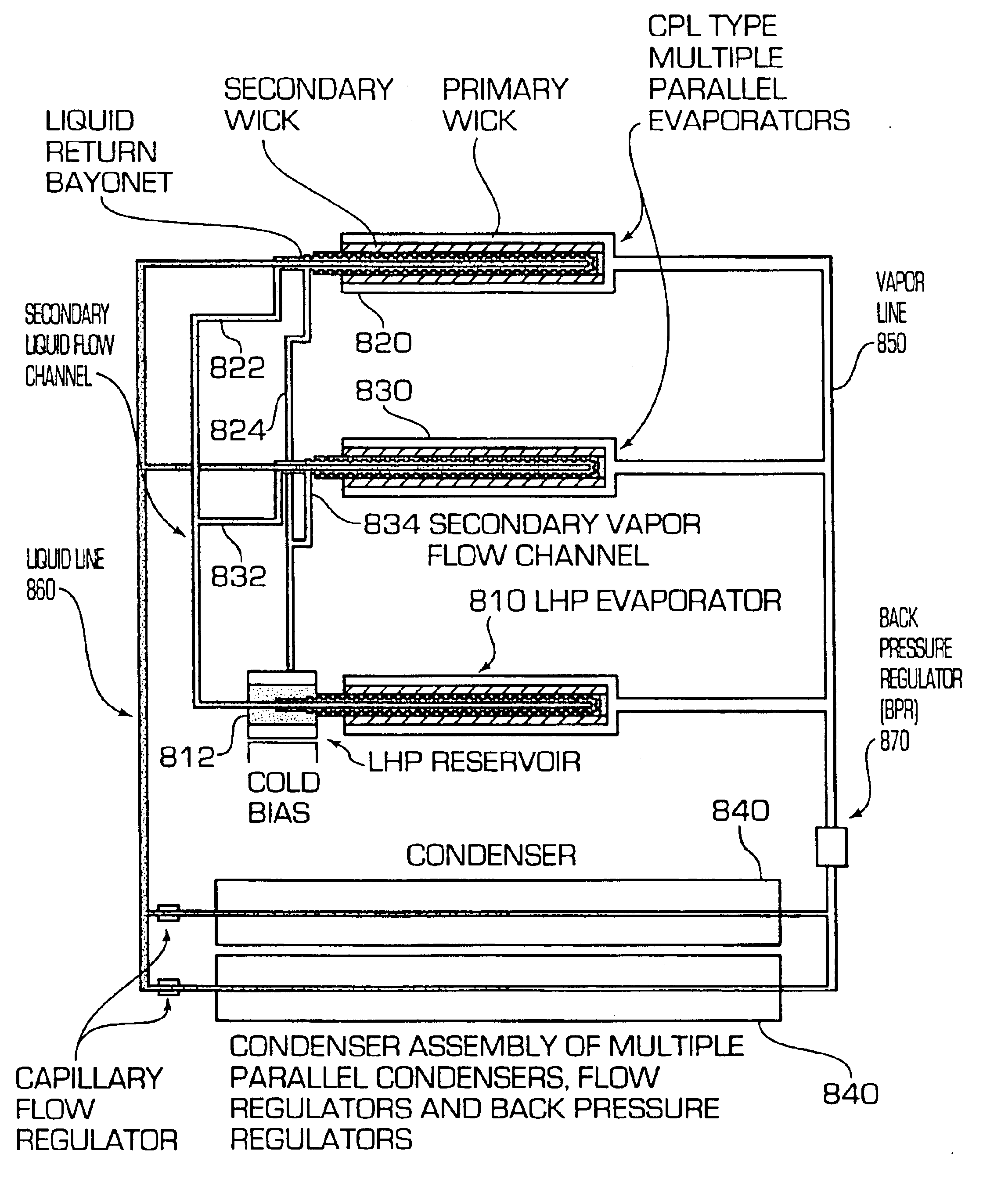

Phase control in the capillary evaporators

InactiveUS6889754B2Guaranteed uptimeIndirect heat exchangersRefrigeration machinesTransport systemEngineering

A capillary pump two phase heat transport system that combines the most favorable characteristics of a capillary pump loop (CPL) with the robustness and reliability of a loop heat pipe (LHP). Like a CPL, the hybrid loop has plural parallel evaporators, plural parallel condensers, and a back pressure flow regulator. Unlike CPLs, however, the hybrid system incorporates elements that form a secondary loop, which is essentially a LHP that is co-joined with a CPL to form an inseparable whole. Although secondary to the basic thermal management of the system thermal bus, the LHP secondary loop portion of the system provides for important operational functions that maintain healthy, robust and reliable operation. The LHP secondary loop portion provides a function of fluid management during start-up, steady state operation, and heat sink / heat source temperature and power cycling.

Owner:NORTHROP GRUMMAN SYST CORP

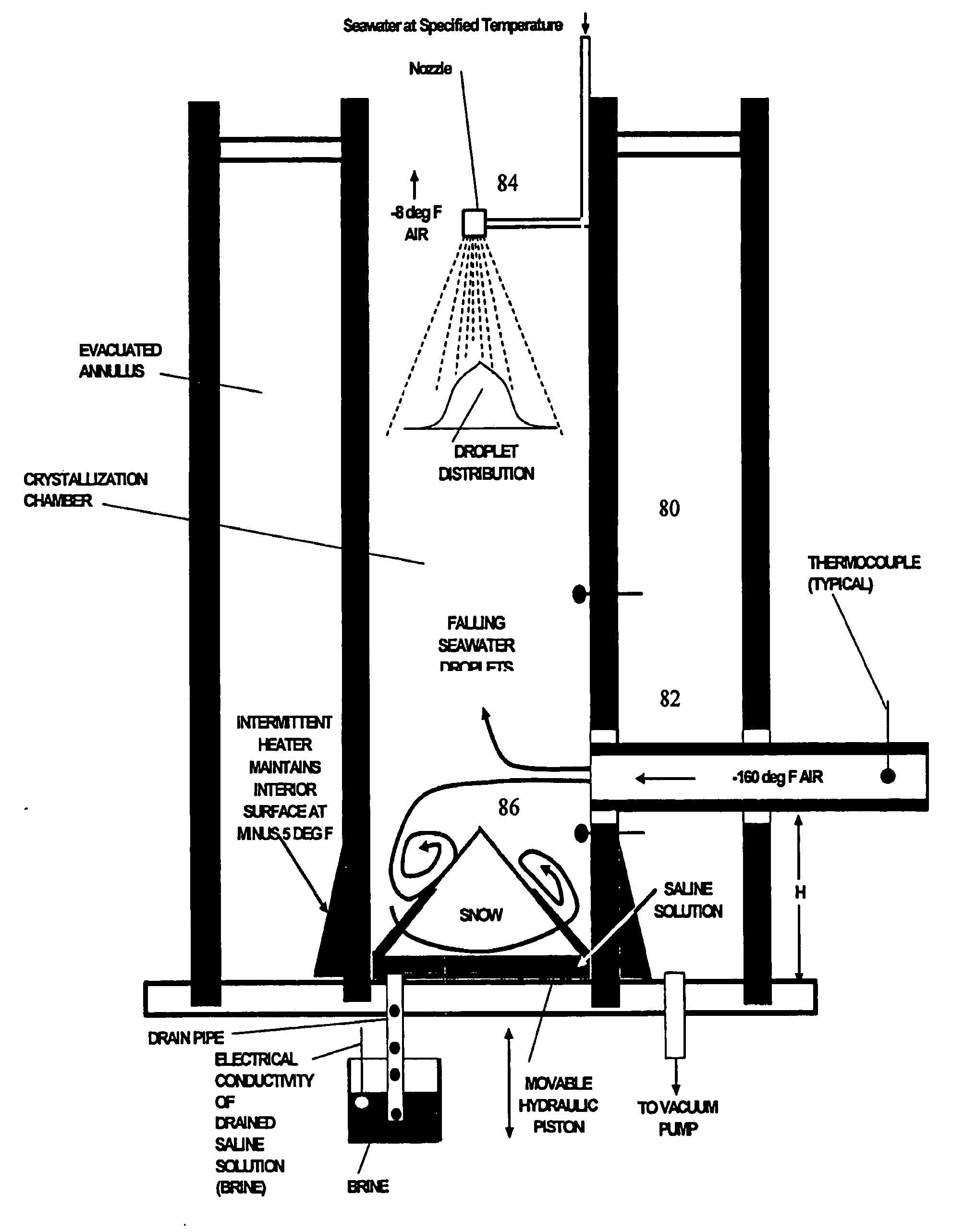

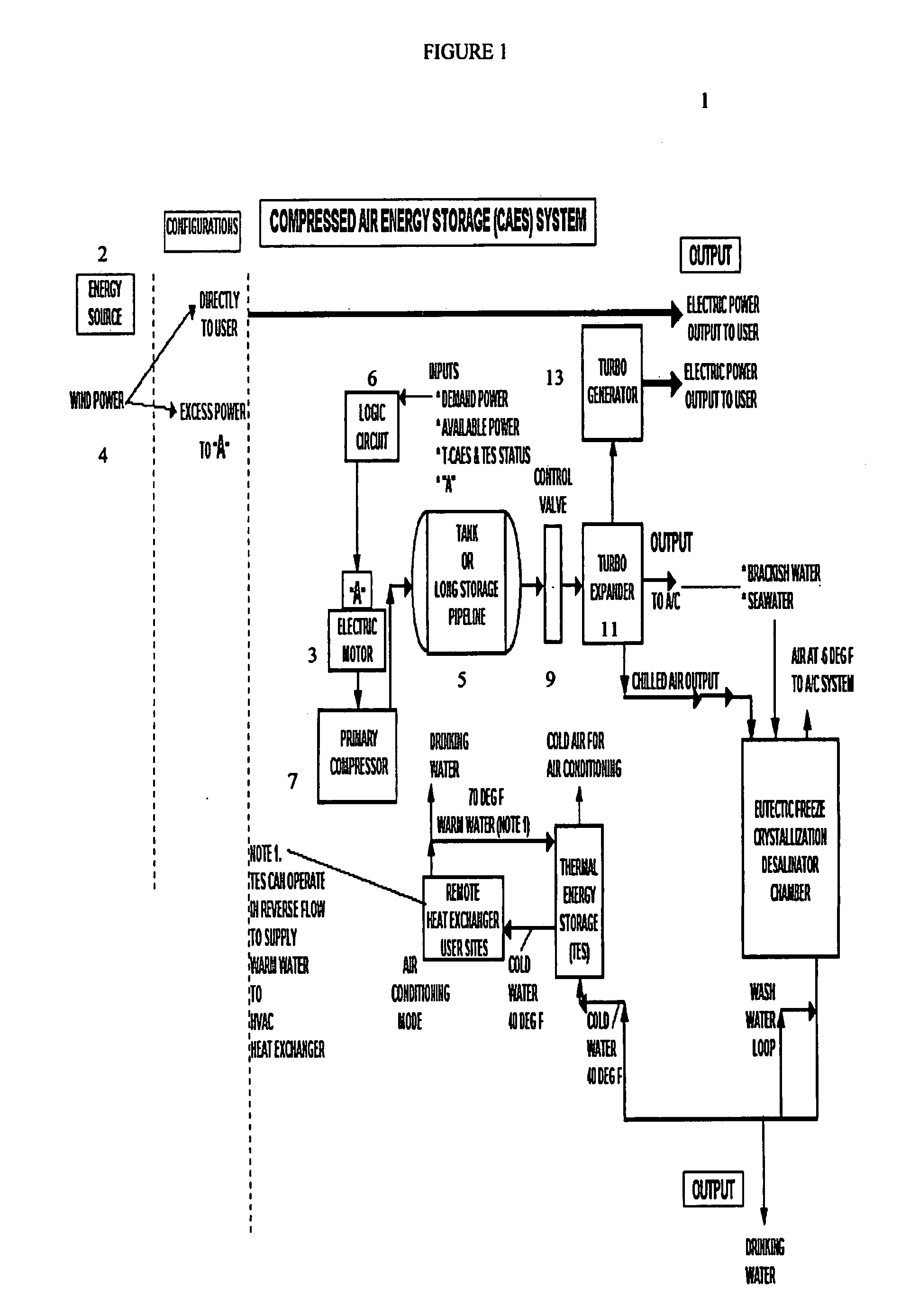

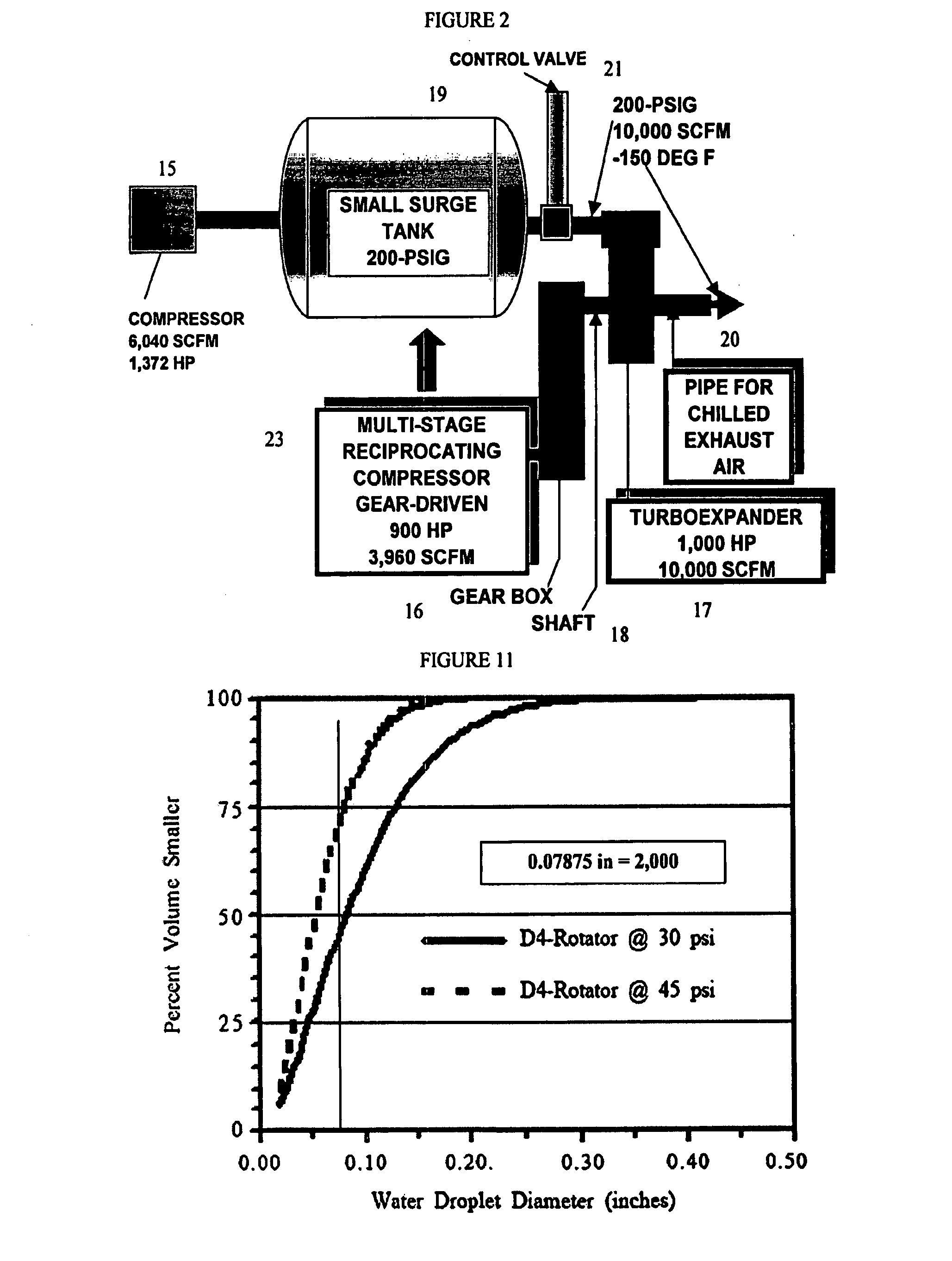

Desalination Method and System Using Compressed Air Energy Systems

InactiveUS20100037653A1Facilitate runoffClean the ice massGeneral water supply conservationSeawater treatmentDesalinationSalt water

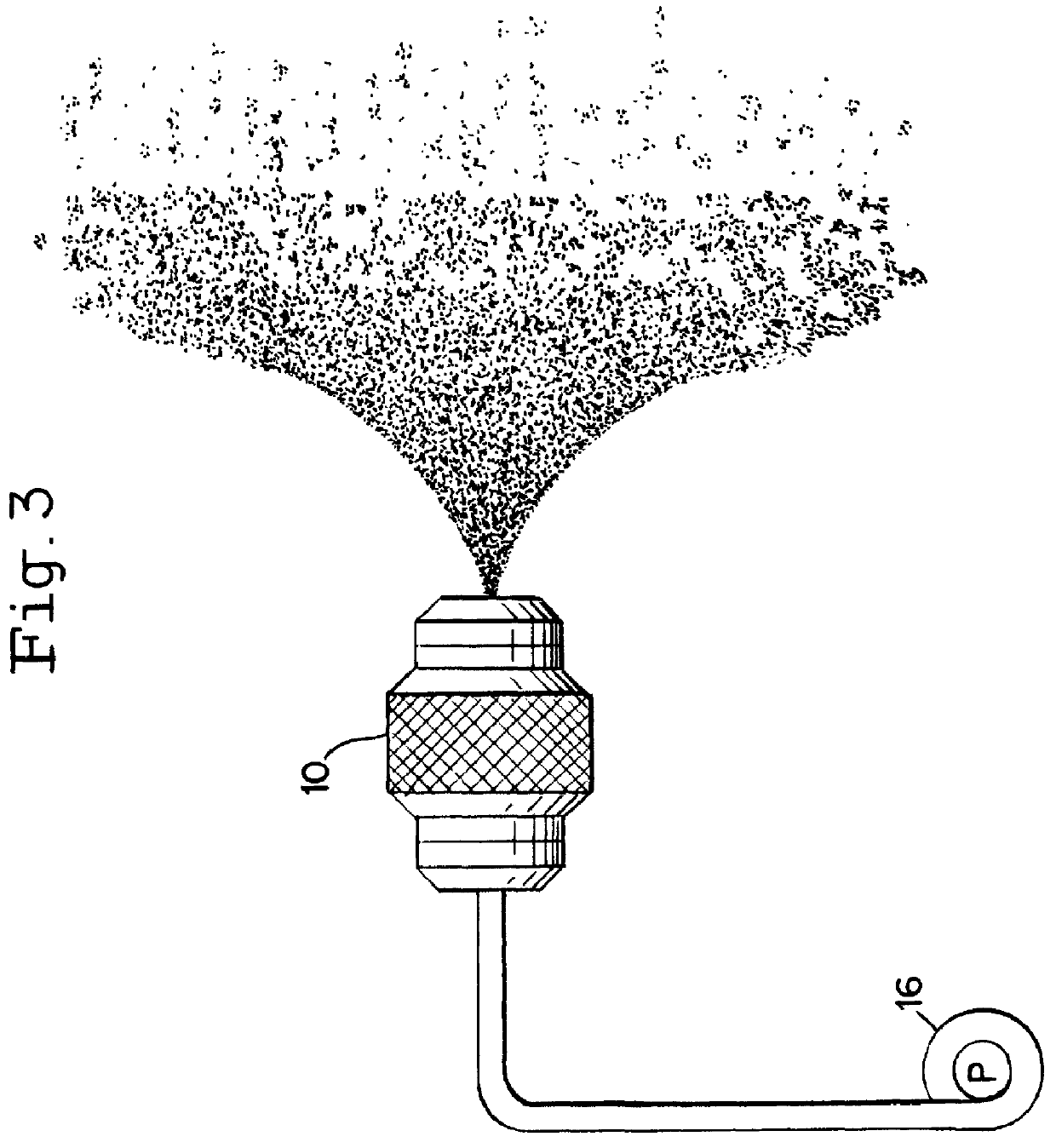

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a crystallization chamber. Also injected into the chamber is a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, and which is then circulated and exposed to the chilled air in the chamber. The sizes of the droplets can vary, but are preferably predetermined, along with the relative temperatures, flows and speeds of the spray and chilled air, such that when the droplets are circulated within the chilled air, and settle at the bottom of the chamber, they are deposited at slightly above the eutectic temperature. This way, the ice / snow mass that forms at the bottom of the chamber will consist of frozen ice crystals, and a residue of salt water brine, which can runoff from the mass, either from the sides, or through any voids or channels that may form within the mass.

Owner:ENIS BEN M +1

Turbine exhaust water recovery system

ActiveUS7194869B2Reduce the temperaturePromote sportsUsing liquid separation agentGas turbine plantsWater sourceLiquid water

The exhaust gas of a turbine engine can include water vapor. Aspects of the invention relate to various systems for recovering water from the exhaust gas of a gas turbine engine. In one system, a portion of the exhaust gas can be routed to an absorption chiller. In another system, a portion of the exhaust gas can be routed to a direct contact heat exchanger. In a third system, a portion of the exhaust gas can be routed to a fin-fan cooler. In each of these systems, the portion of gas can be cooled below its dew point temperature to release a portion of its humidity as liquid water. Aspects of the invention can be used with the turbine exhaust of simple and combined cycle power plants. A water recovery system according to aspects of the invention can minimize or eliminate a power plant's dependence on local water sources.

Owner:AMEC FOSTER WHEELER IND POWER CO INC

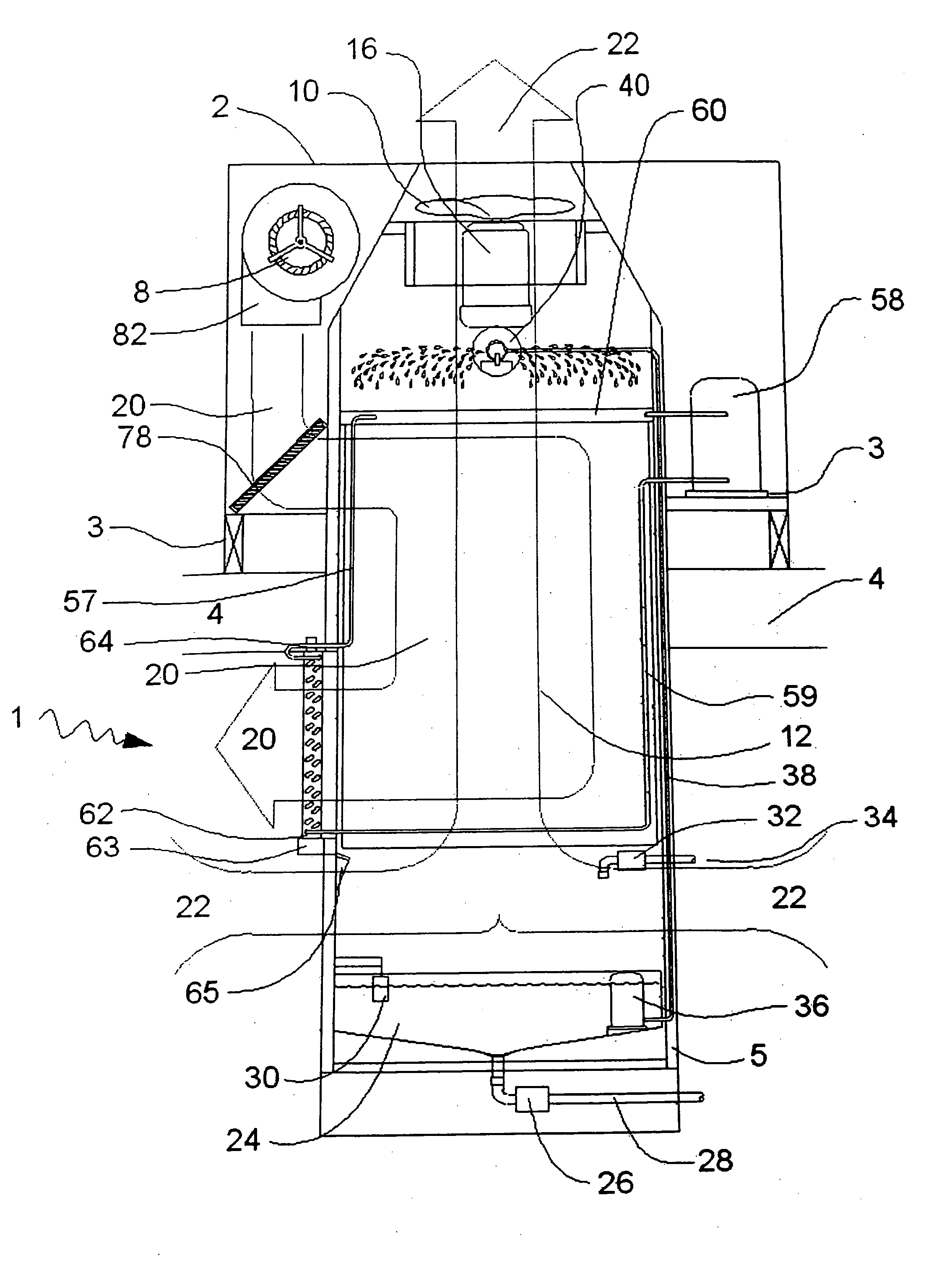

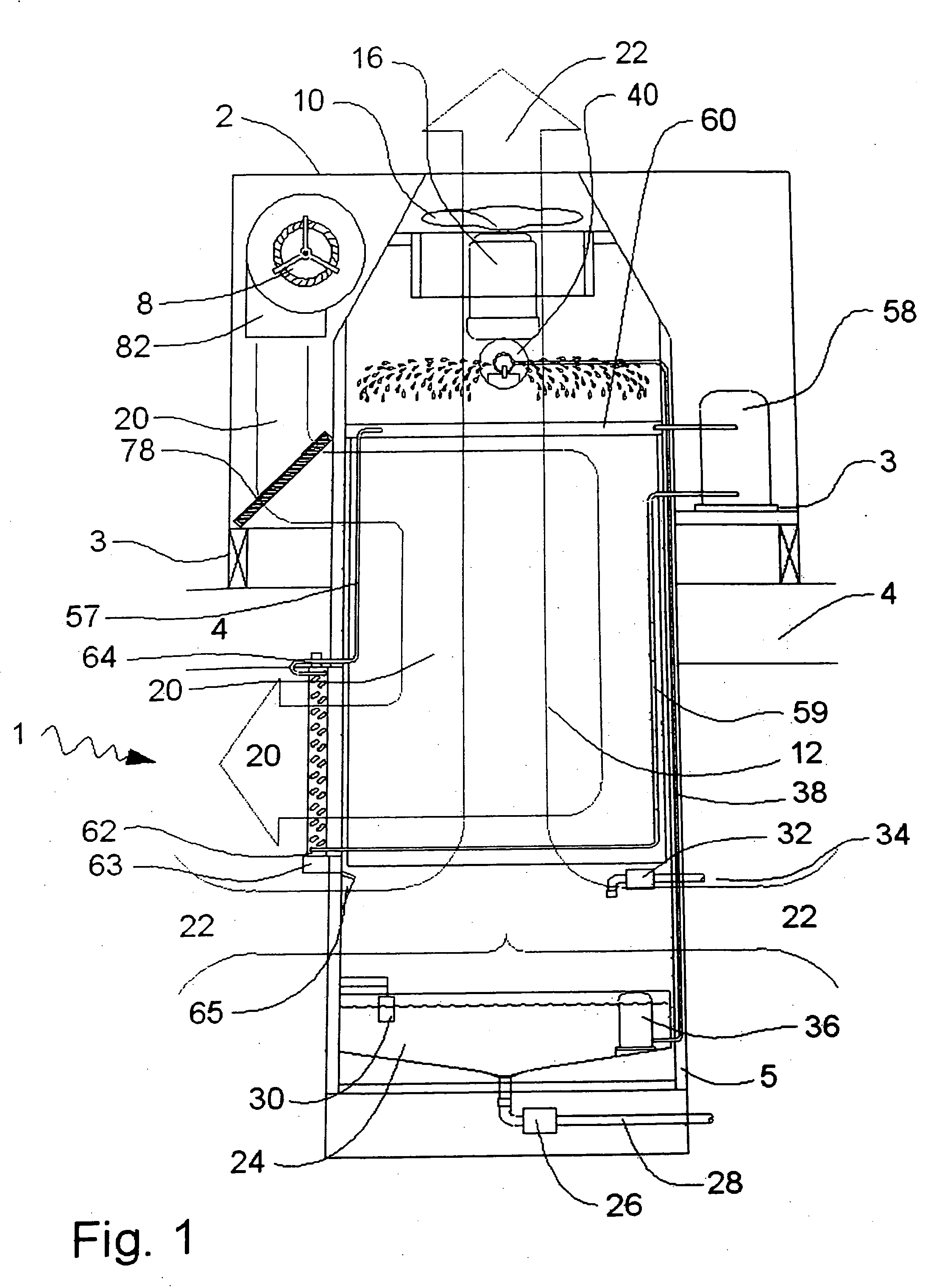

Indirect supplemental evaporation cooler

InactiveUS6141986ARemove heatEasy to eliminateFree-cooling systemsStationary conduit assembliesEvaporative coolerEvaporation

A cooler for an air conditioning system or other system having a heated surface to be cooled has an array of nozzles for issuing a fine spray of liquid. A fan of the cooler induces flow of air over a surface to be cooled, the nozzles issuing into the flow of air the fine spray at a distance from the heated surface such that the liquid of the fine spray is fully evaporated prior to contact with the heated surface. Drop sizes of 20 to 30 microns are typical.

Owner:X NTH INC

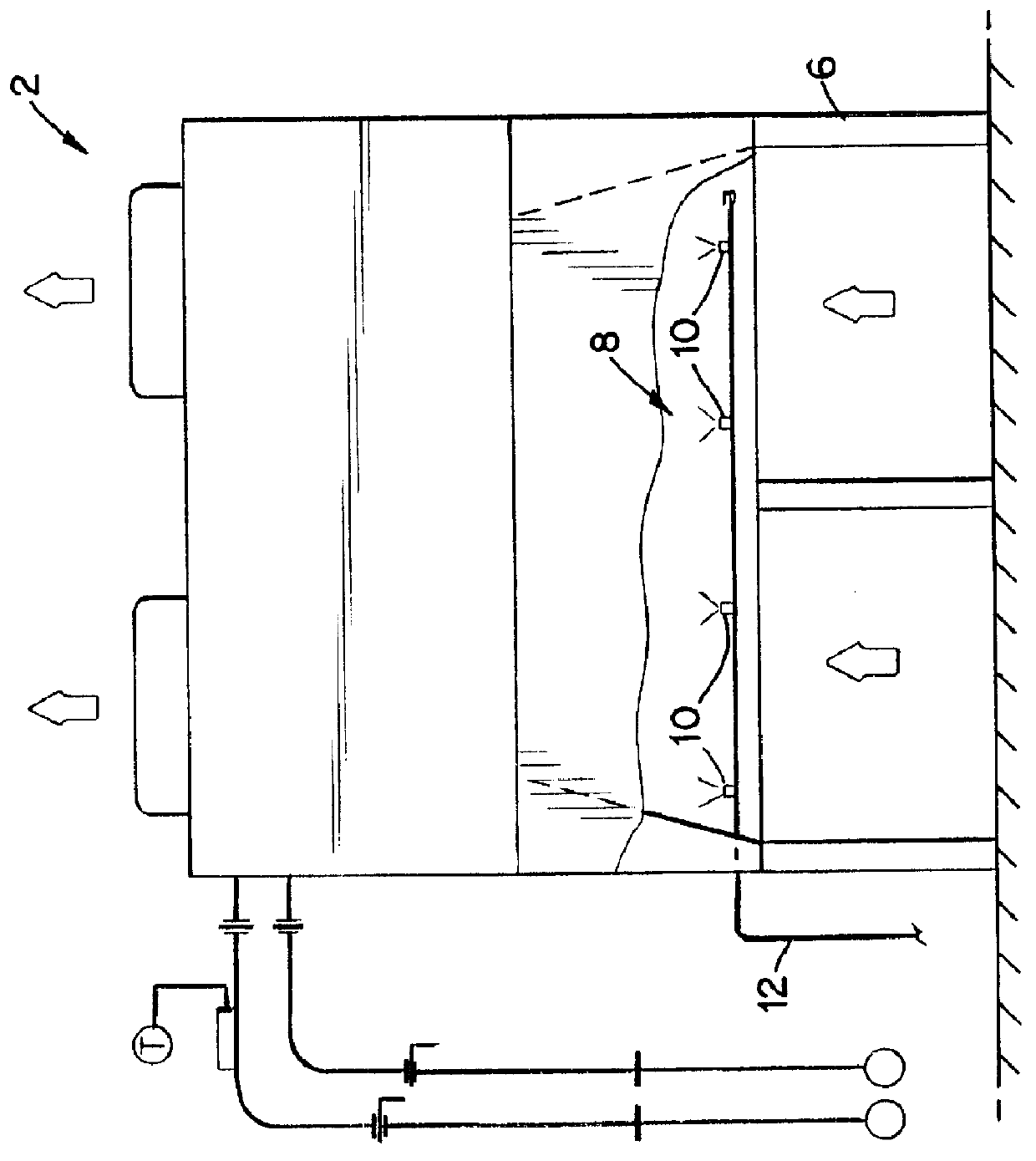

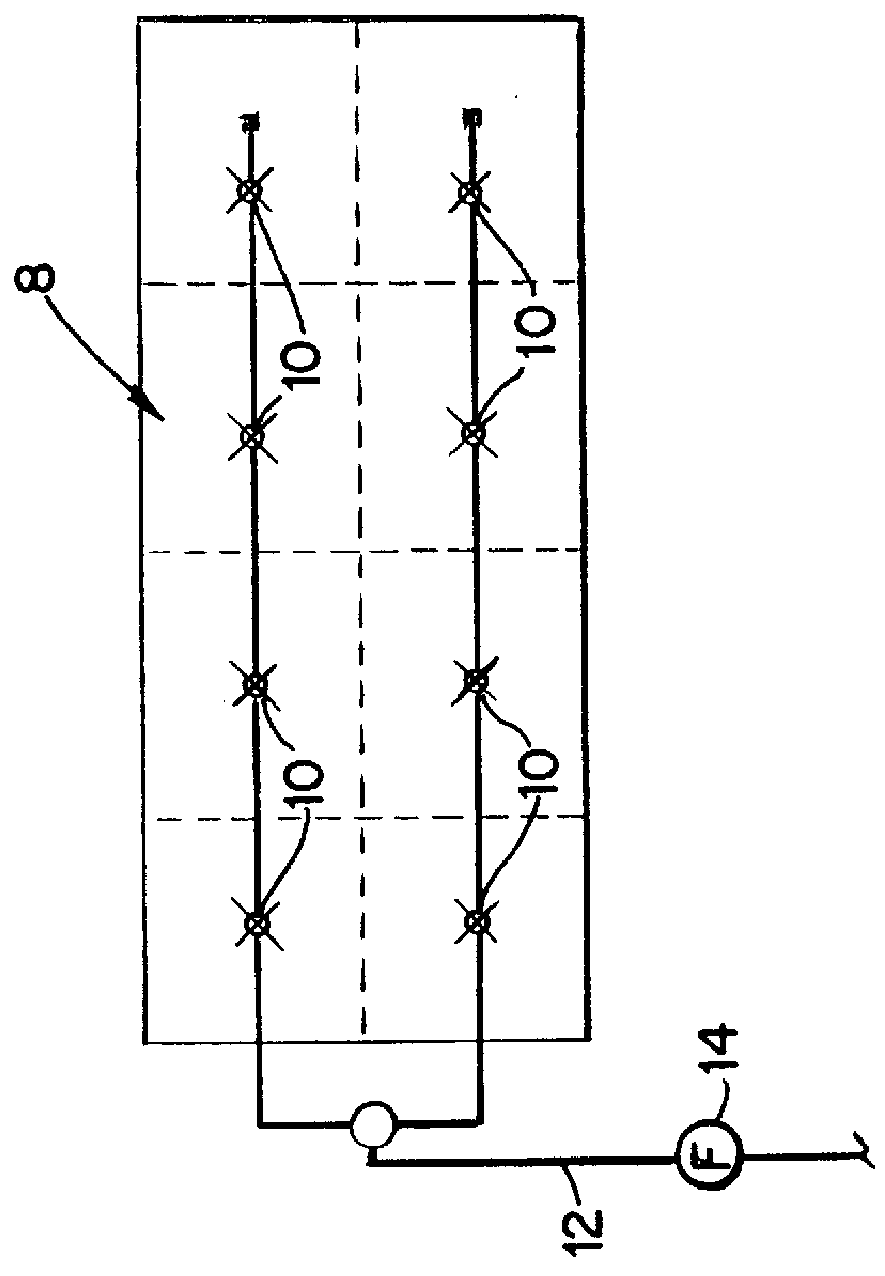

Evaporator, a heat absorber, a thermal transport system and a thermal transport method

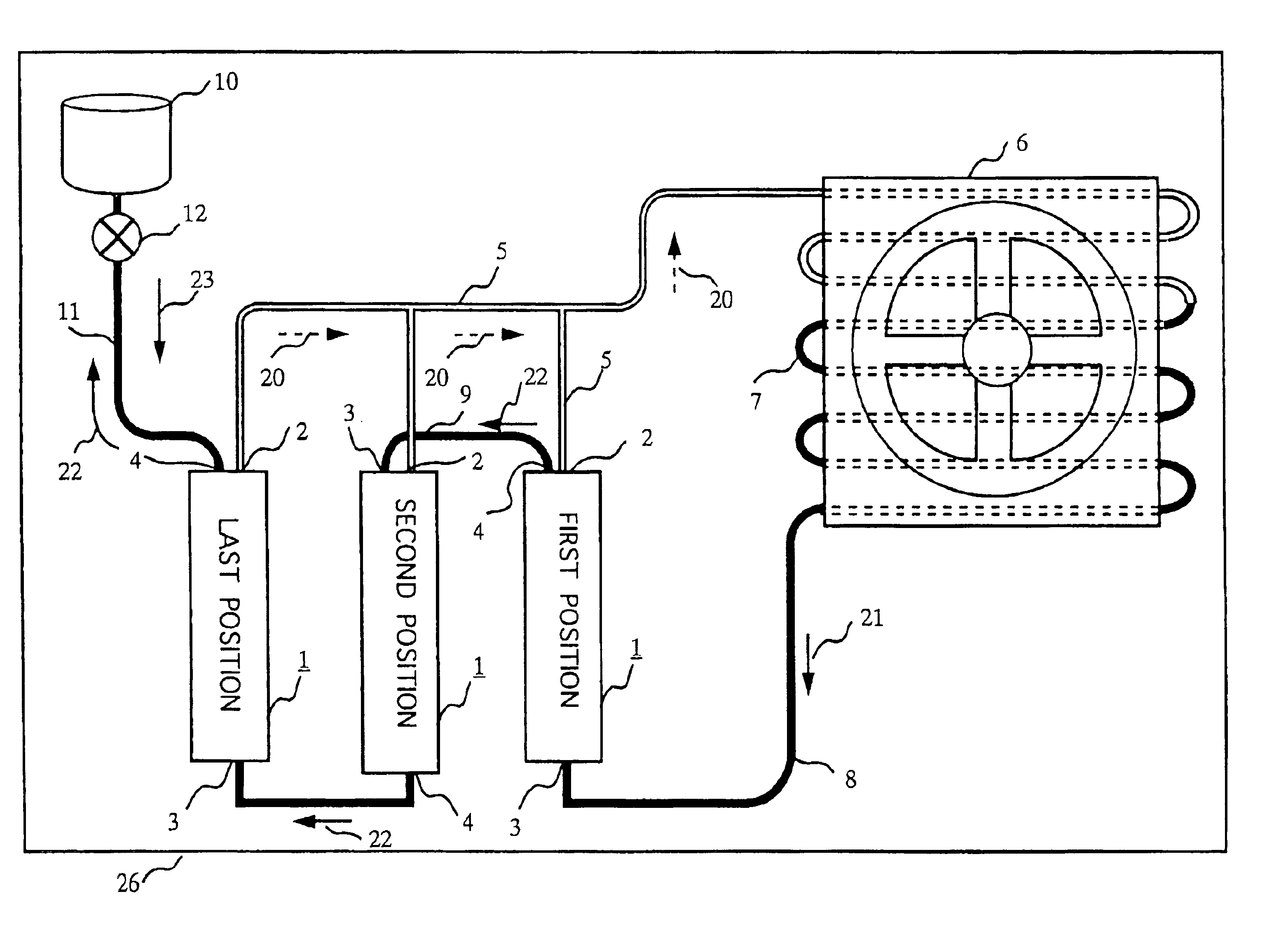

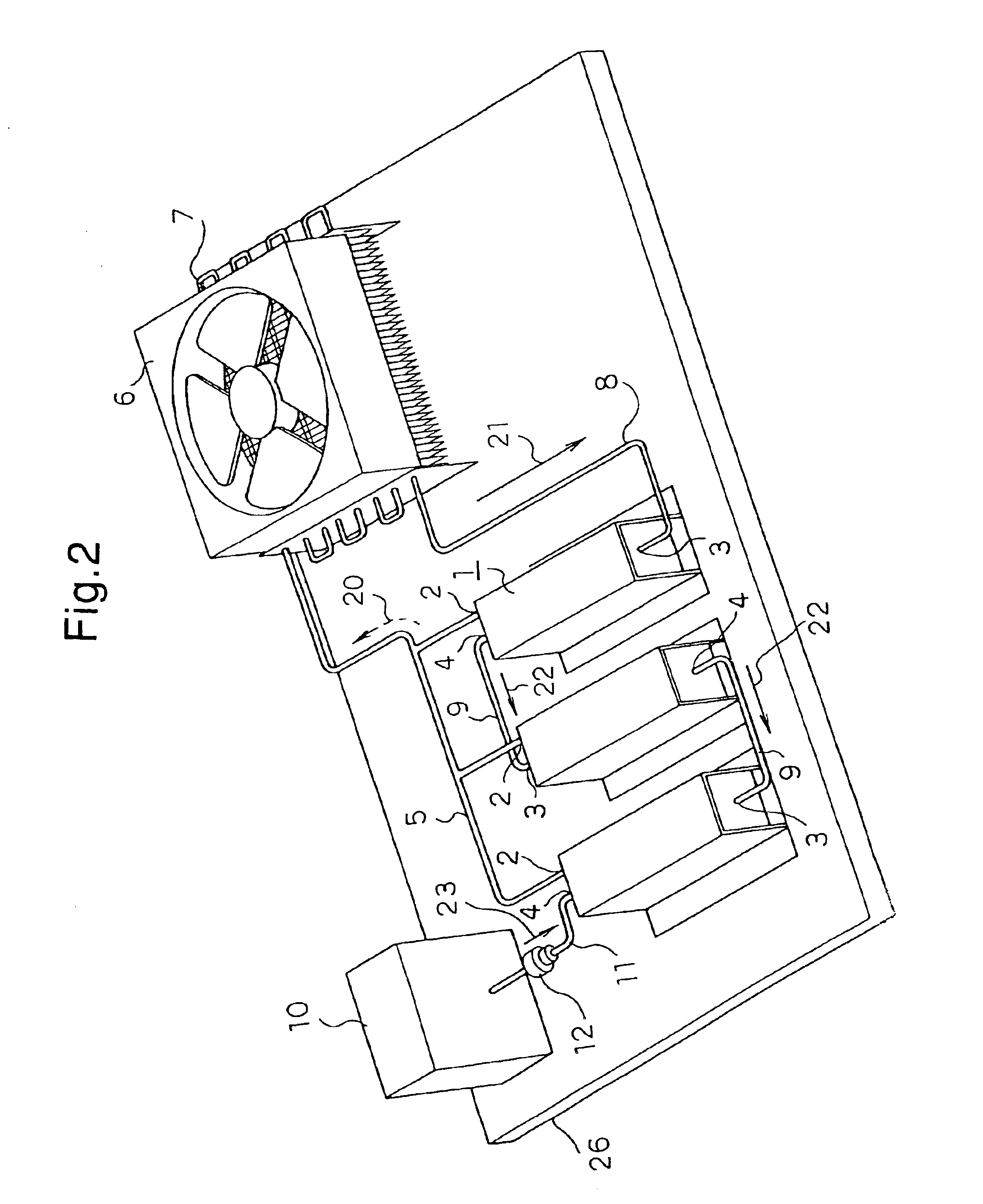

InactiveUS6840304B1Air-treating devicesEnergy recuperation in distillationThermal transportLiquid tank

The conventional thermal transport system has disadvantages of the configuration being complex, large, heavyweight and expensive. In the present invention, a plurality of evaporators are connected in series via the liquid flow line, the evaporator of the first position is connected to the condenser via the liquid supply line, the evaporator of the last position is connected to the reservoir tanks for adjusting the amount of the liquid. The liquid amount measuring sensor is installed to measure the amount of the liquid in the liquid reservoir of the evaporator. Based on the measured result of the liquid amount measuring sensor, the control valve operates so as to supply the liquid accommodated in the reservoir tanks to each evaporator.

Owner:MITSUBISHI ELECTRIC CORP

Combined cryogenic distillation and PSA for argon production

ActiveUS7501009B2Improvements in the refining of crude argonSpeed up the processSolidificationLiquefactionParticulatesFiltration

A method and apparatus for producing high purity argon by combined cryogenic distillation and adsorption technologies is disclosed. Crude argon from a distillation column or a so-called argon column is passed to a system of adsorption vessels for further purification. Depressurization gas from adsorption is introduced back, in a controlled manner, to the distillation column and / or a compressor or other means for increasing pressure. Particulate filtration and getter purification may optionally be used.

Owner:AIR PROD & CHEM INC

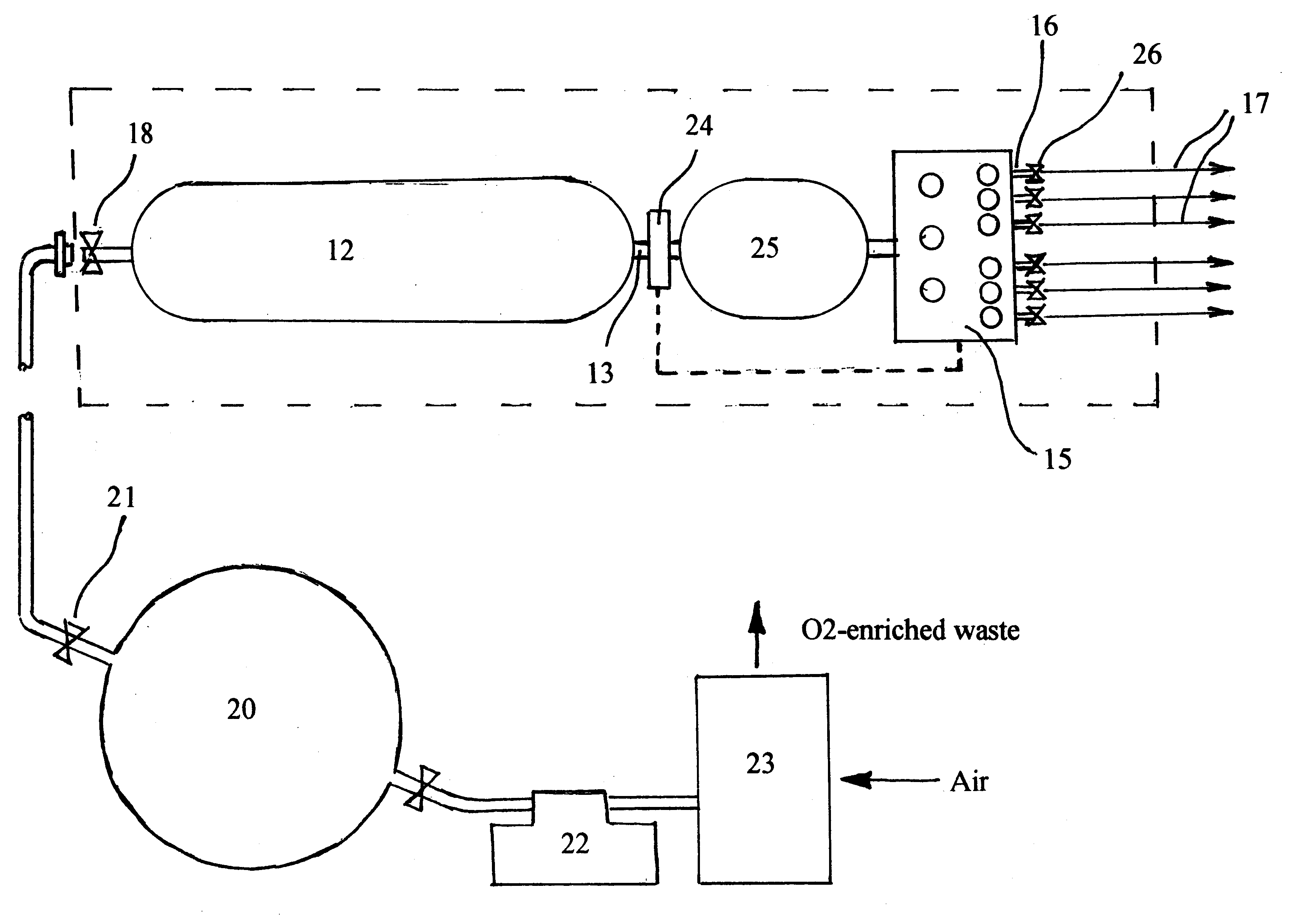

Mobile firefighting systems with breathable hypoxic fire extinguishing compositions for human occupied environments

Mobile fire-fighting systems and a method of producing breathable fire-suppression compositions are provided for extinguishing fires in buildings, and other human occupied structures, being also effective in suppressing fires under ruins of collapsed buildings. The systems employ a transportable high-pressure container having the breathable composition or nitrogen gas, or a liquid nitrogen container, vaporizer and a mixing chamber, wherein a vaporized nitrogen gas is mixed with an ambient air in order to produce said breathable fire-suppression composition. Refilling stations are provided for refilling the mobile systems with said composition, nitrogen gas or liquid nitrogen, all being generated at site from the ambient air. The method of producing said composition at a fire site employs mixing of nitrogen gas with ambient air or, alternatively, vaporizing of liquid nitrogen in necessary quantities and mixing it with ambient air in provided proportions. A method of delivery of the breathable fire-suppressive composition inside a building on fire is provided as well. The systems are also suitable for installation as a stationary fire-suppression system for a building or other structure. A breathable fire-suppression composition is provided for use in said mobile systems, said composition having an oxygen content below 16% or from 10% to 12% for the majority of civil applications.

Owner:FIREPASS CORP

Nitrogen rejection method and apparatus

Nitrogen is rejected from a feed natural gas stream comprising methane and nitrogen so as to form a primary methane product. The mole fraction of nitrogen in the feed natural gas increases over a period of time. The feed natural gas stream is cooled in a main heat exchanger and is rectified in a double rectification column. A primary product methane stream and a secondary nitrogen-enriched product stream are withdrawn from the rectification column. The secondary nitrogen-enriched product stream has a mole fraction of methane at or above a chosen minimum value when the said mole fraction of nitrogen is at a minimum. When the said mole fraction of nitrogen rises to a value at which the mole fraction of methane in the secondary nitrogen-enriched product stream falls below the chosen minimum, a part of the feed gas is introduced through conduit into the secondary nitrogen-enriched product stream so as to restore its mole fraction of methane to the chosen minimum value or a value thereabove.

Owner:THE BOC GRP PLC

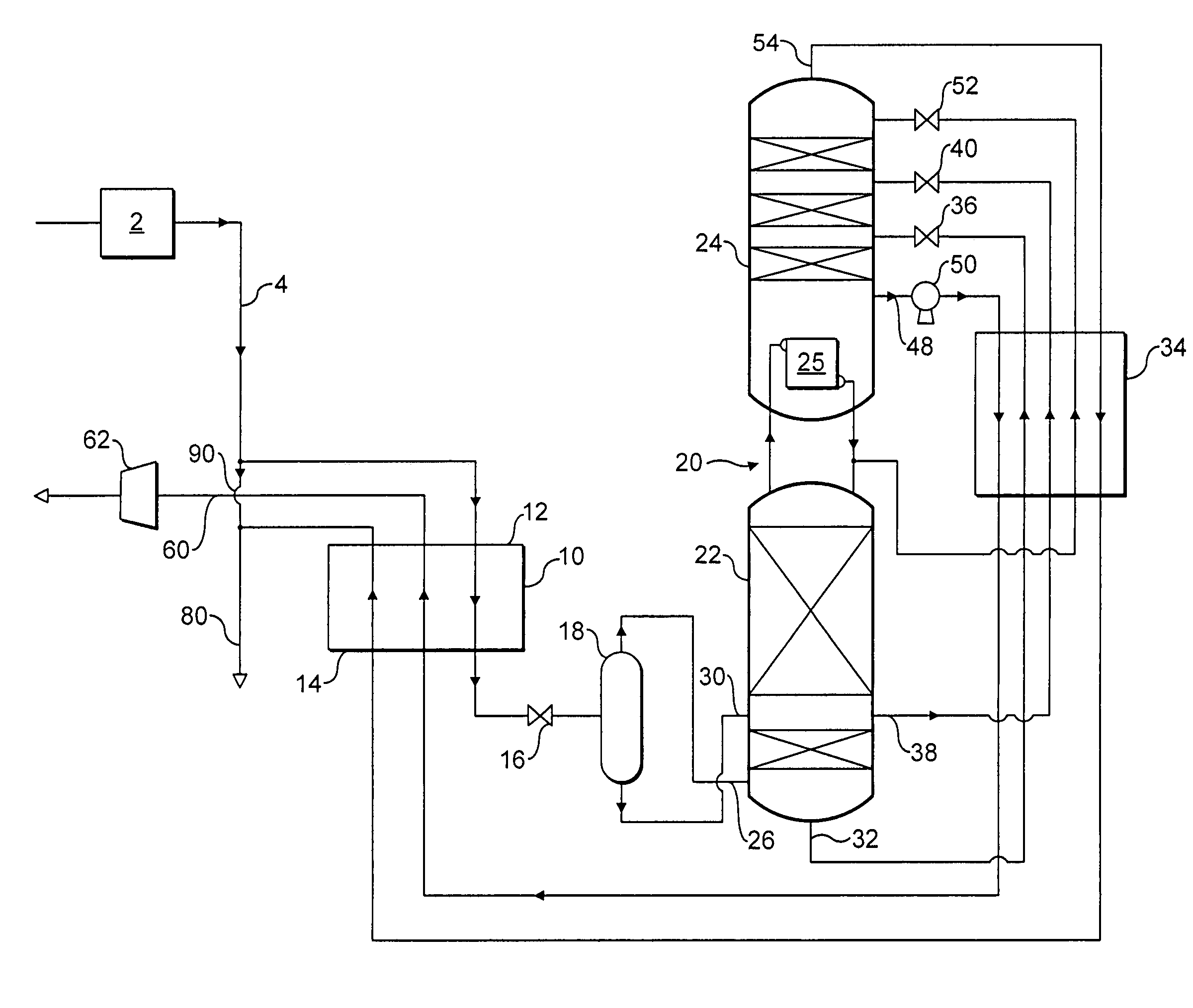

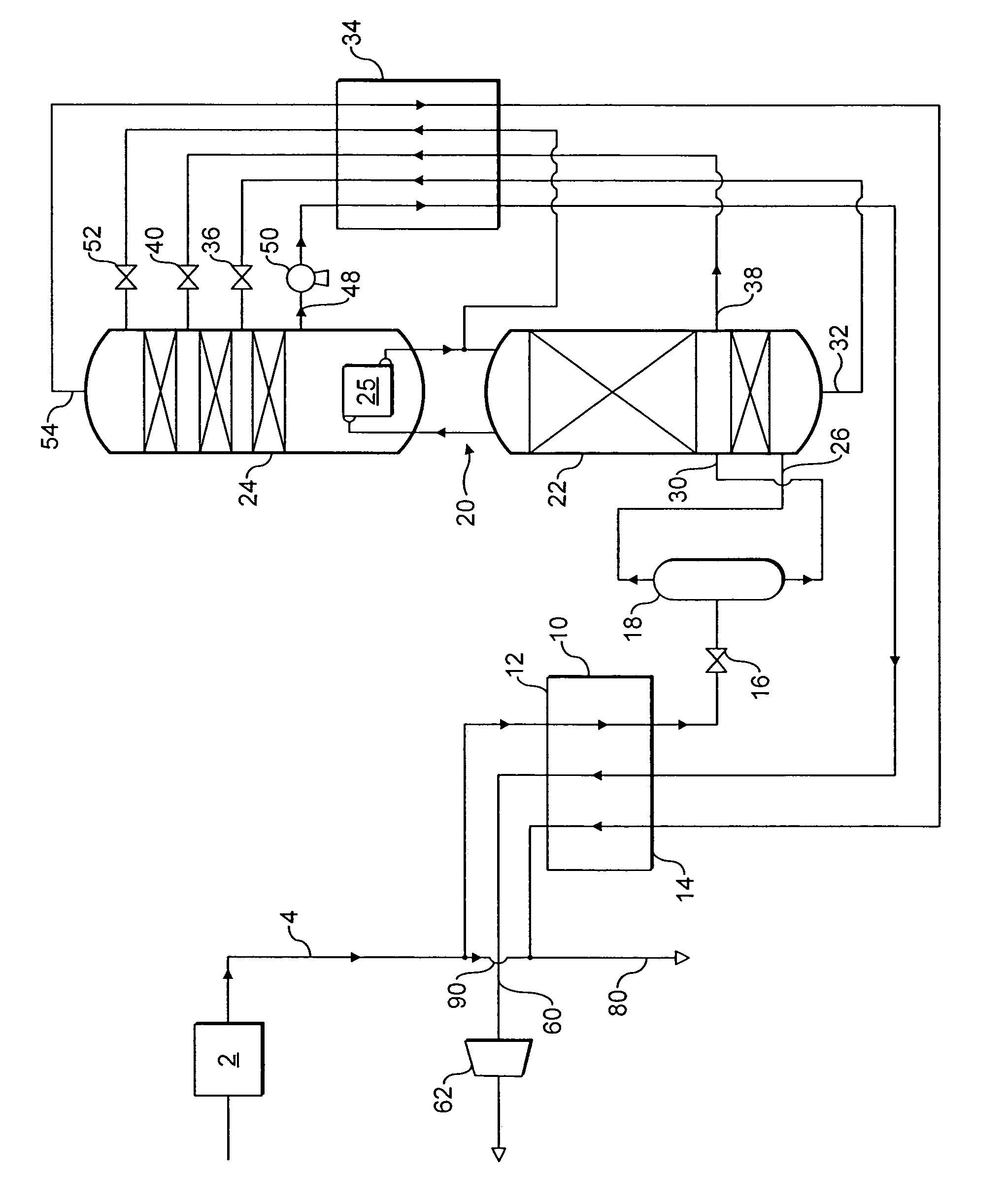

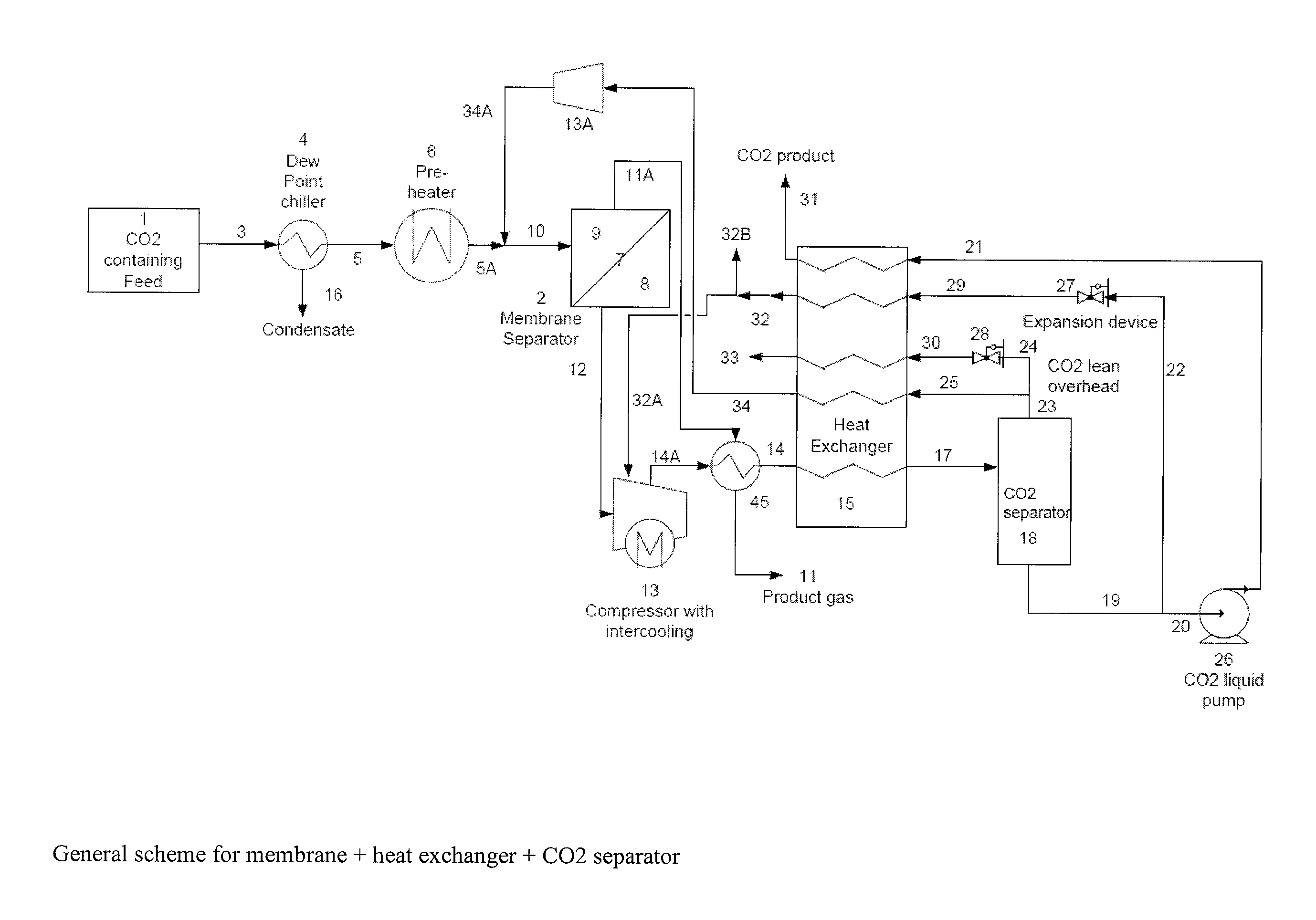

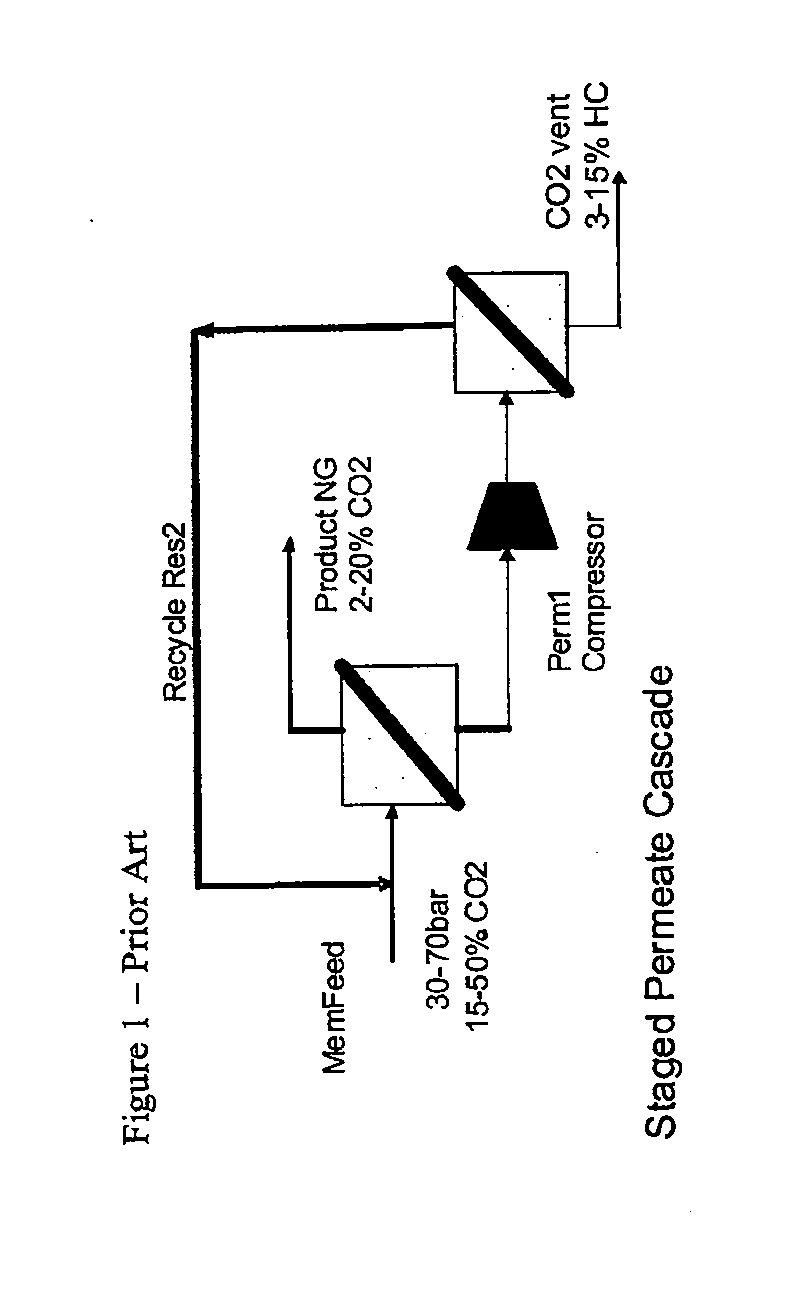

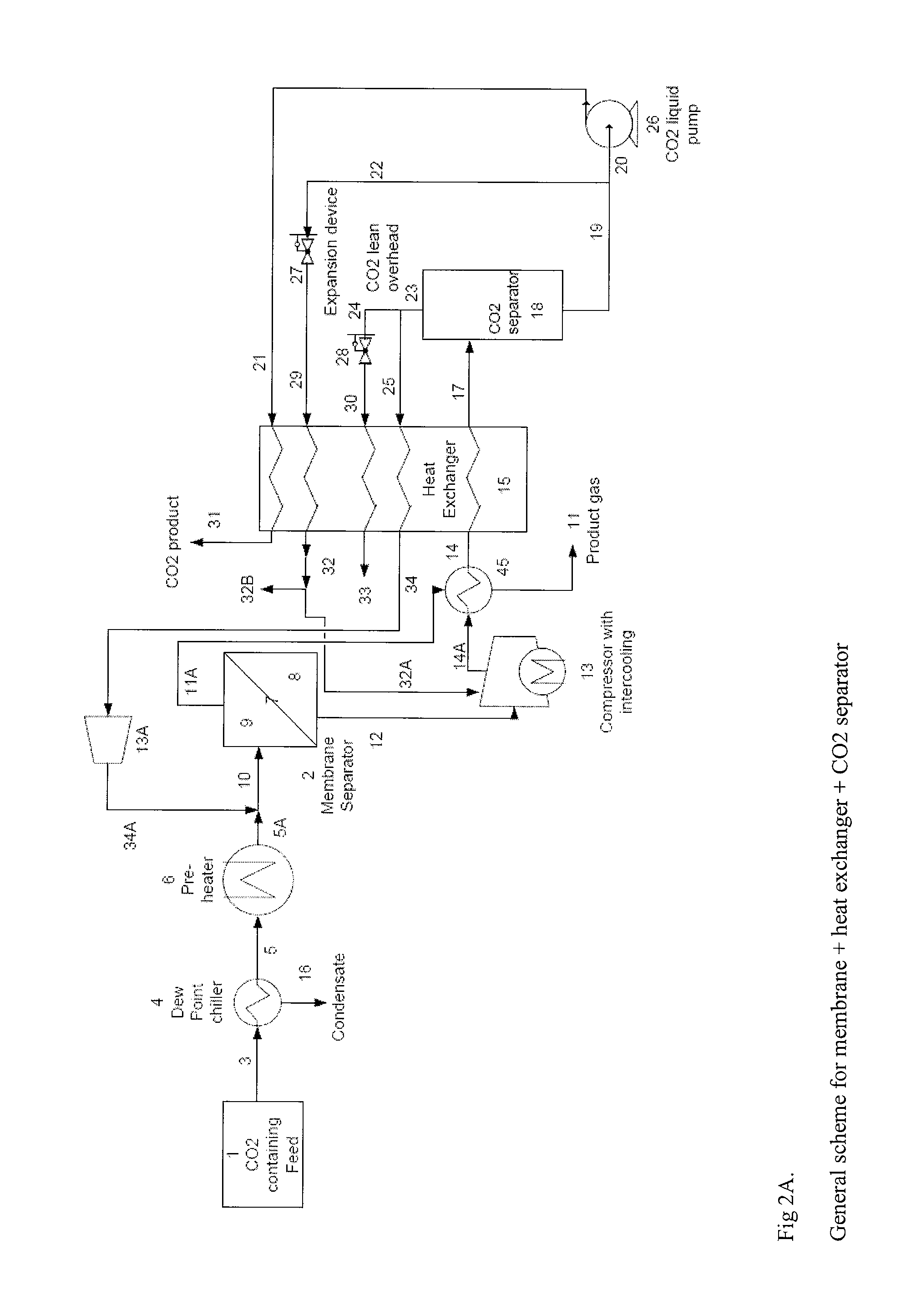

Carbon Dioxide Removal Process

ActiveUS20120111051A1Reduce lossesIncrease pressureSolidificationLiquefactionCooling effectHydrocarbon

A process for efficiently removing carbon dioxide from a hydrocarbon containing feed stream utilizing a membrane separation unit in conjunction with a heat exchanger and a carbon dioxide separation unit wherein the streams obtained in the carbon dioxide separation unit are utilized to provide the cooling effect in the heat exchanger.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

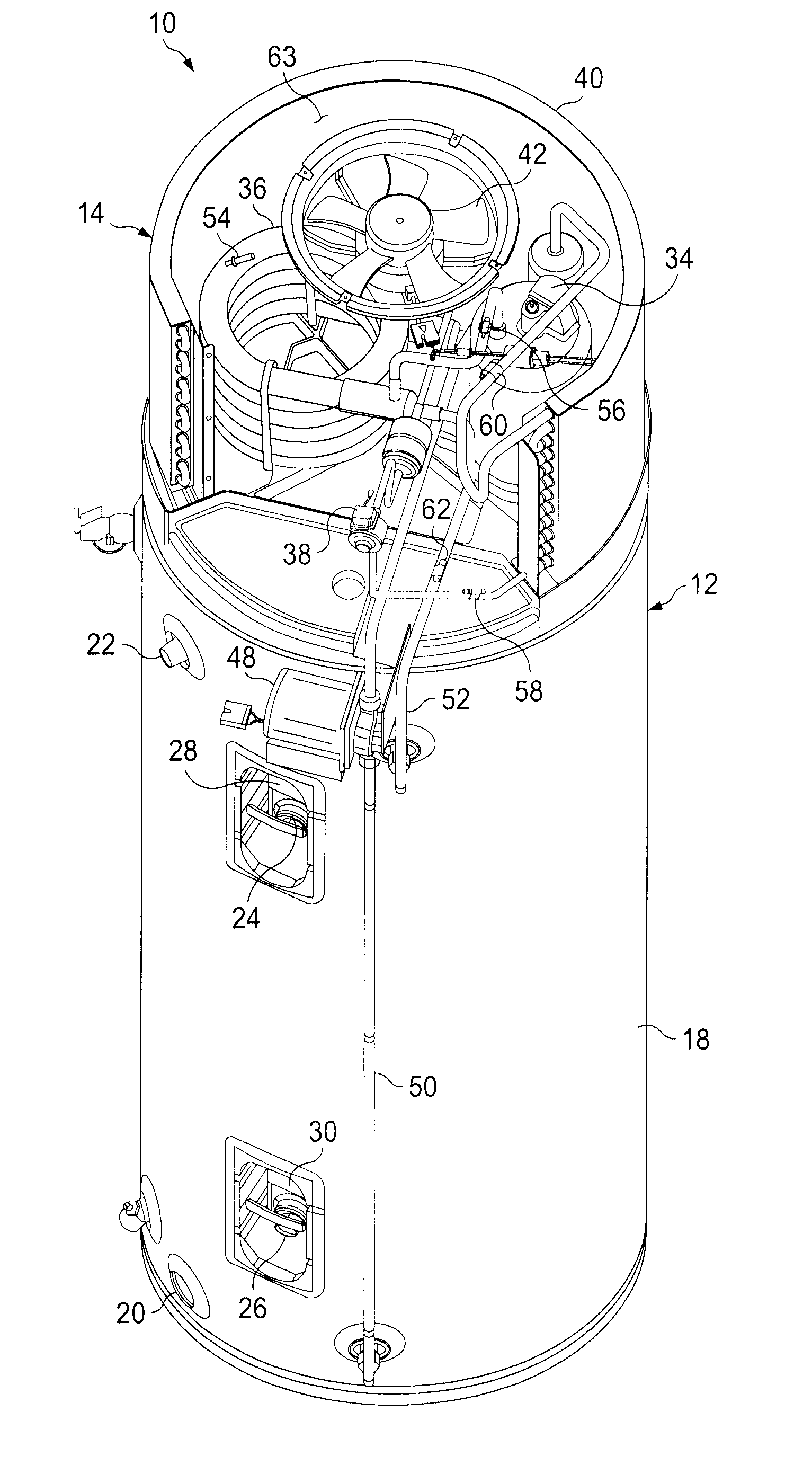

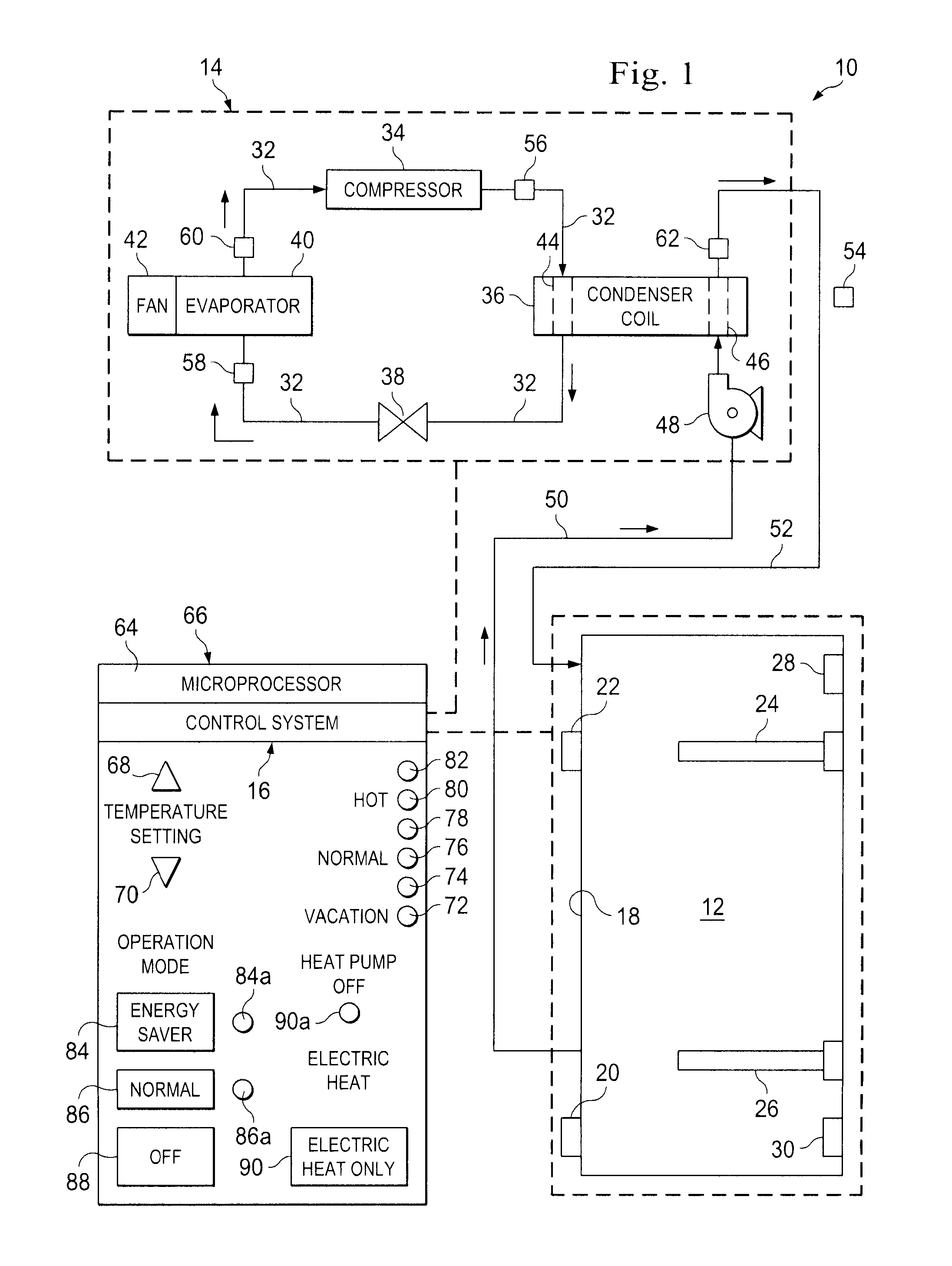

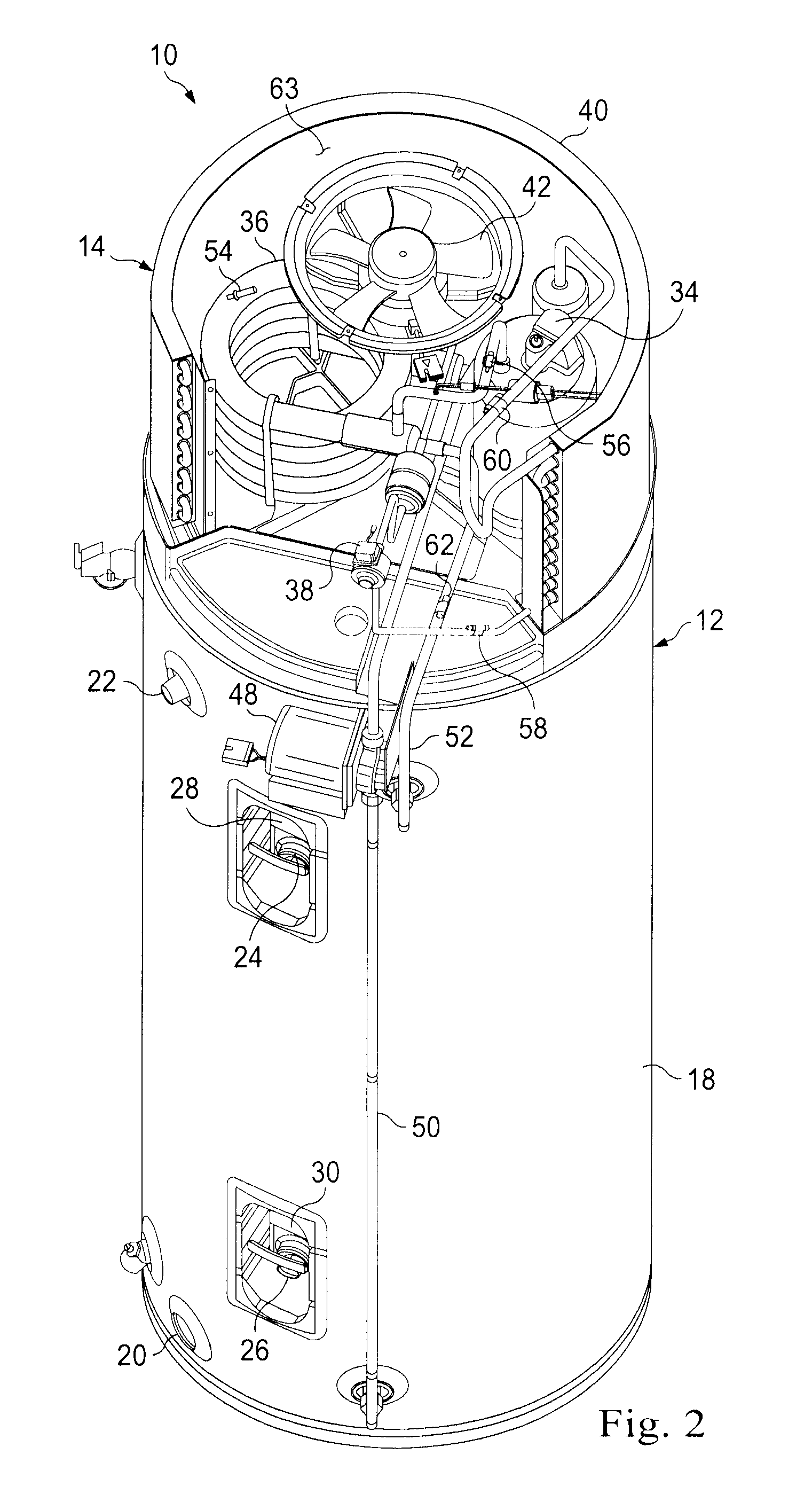

Heat pump water heater and associated control system

ActiveUS20110058795A1Maintain water temperatureDomestic stoves or rangesElectric heatingControl systemEngineering

A heat pump water heater has a tank portion, an electric heating structure for adding electrical heat to water stored in the tank, and a heat pump for adding refrigerant heat to the tank water. A control system associated with the water heater has three user-selectable heating modes for heating the tank water during a given heating demand cycle—a first mode that initially heats the tank water with refrigerant heat while the electric heat is locked out for a first predetermined period before supplementing the refrigerant heat if necessary, a second mode similar to the first mode but with a longer electric heat lockout period, and a third mode in which only the electric heat is utilized to satisfy a tank water heating demand. Illustratively, the heat pump is disposed in a compact component arrangement on the top end of the water heater tank.

Owner:RHEEM MFG CO

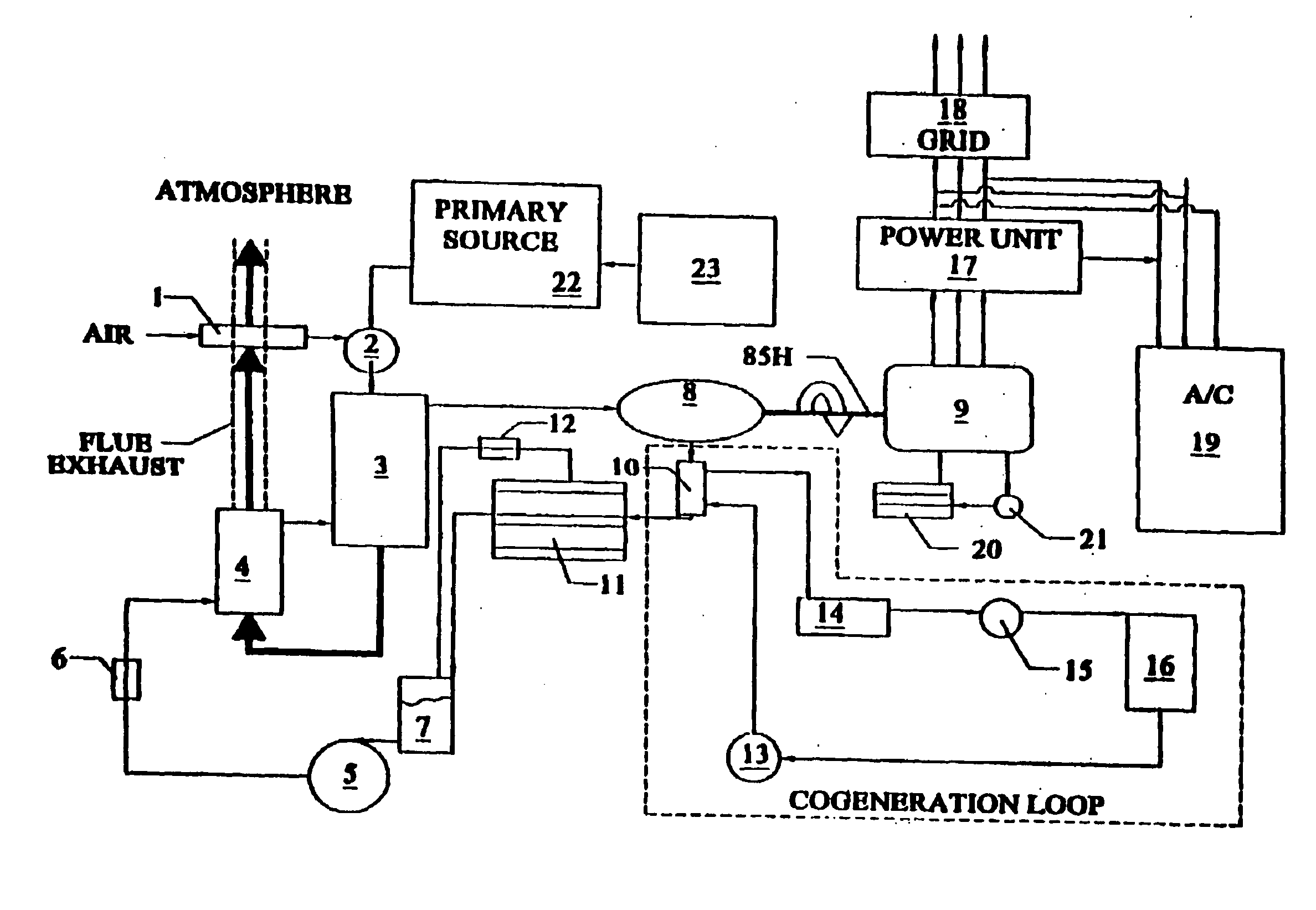

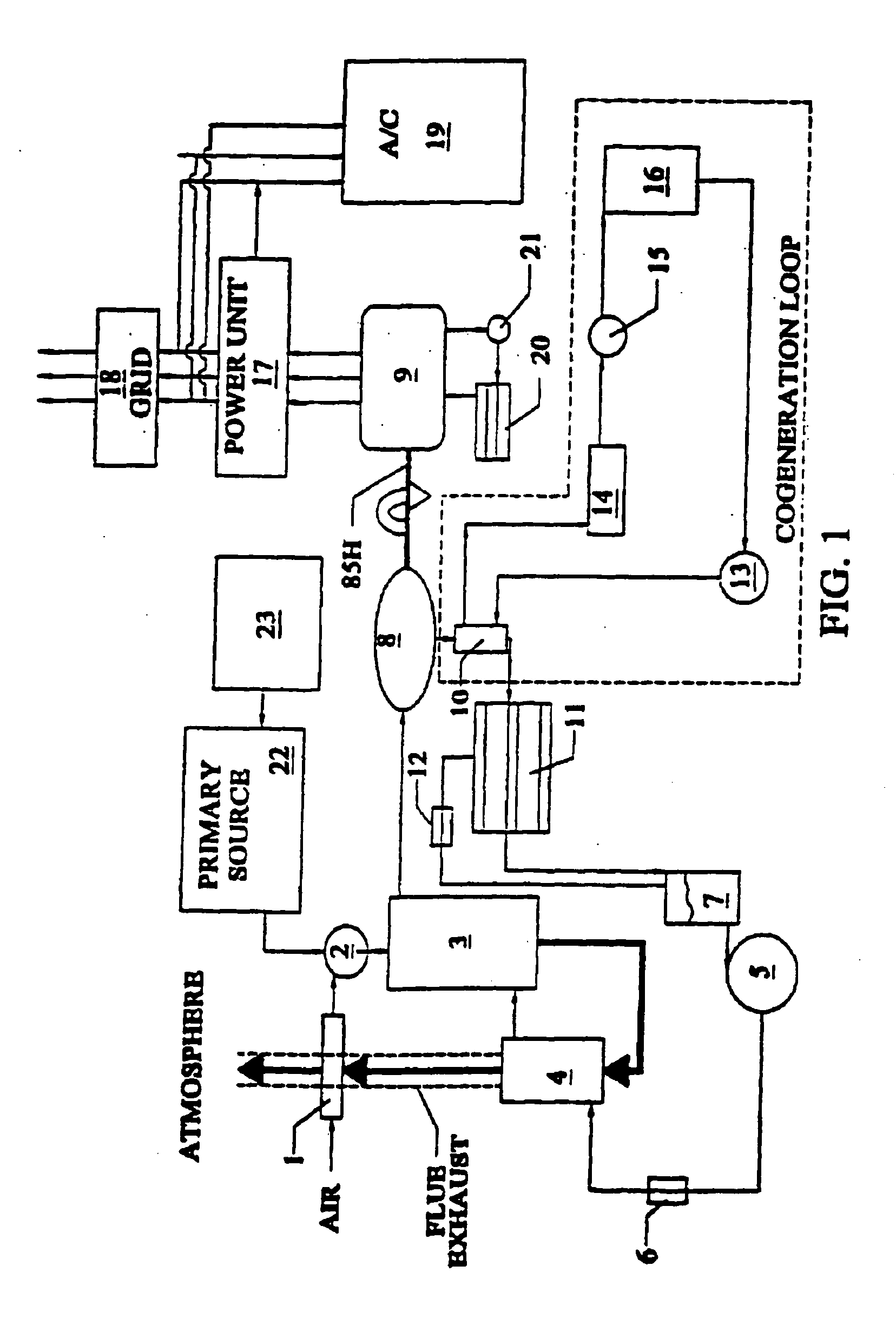

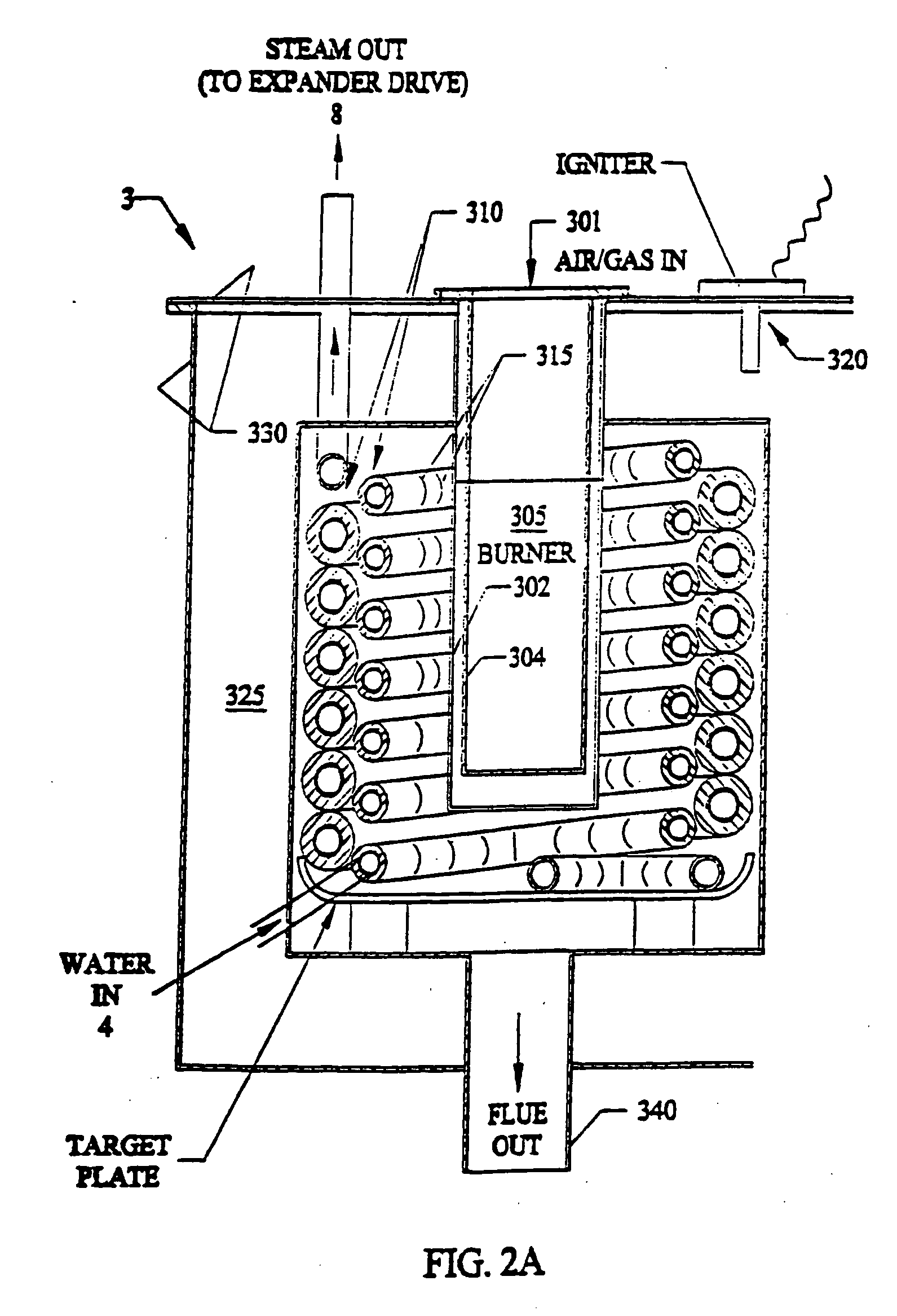

Power generation methods and systems

A closed loop system for generating mechanical energy at high efficiencies from hydrogen, fossil fuels, bio-fuels, solar or other renewable and recoverable energy sources. The system can have a heating source, a superheater, an expander, a receiver, a condenser, vacuum pump, or absorber, a desorber, and regenerator with pumps and controls. The heating source and superheater are used to heat a working fluid (including ammonia, other refrigerants, a combination of refrigerants, or steam). A positive displacement liquid / vapor expander expands the heated working fluid to the near saturated or saturated state utilizing a reduced pressure, low-pressure, or sub-atmospheric exhaust sink. A condenser, vacuum pump, or absorber is used to generate the reduced pressure, low pressure, or sub-atmospheric sink. The desorber is used to reconstitute inlet vapor (for reuse) and the regenerator recovers heat generated by the process. The system can generate mechanical energy (or power) which can be used to drive a wide range of mechanical systems (including pumps, compressors, vehicles, conveyances, or other similar mechanical devices); or used to drive an electrical generator to meet electrical power needs-for residences, businesses or office buildings, or commercial and industrial applications. The system can supply electrical energy to power grids, and can be an alternative to power generation plants.

Owner:RES SCI

HVAC system for truck sleepers

Owner:DOMETIC APPLIANCES

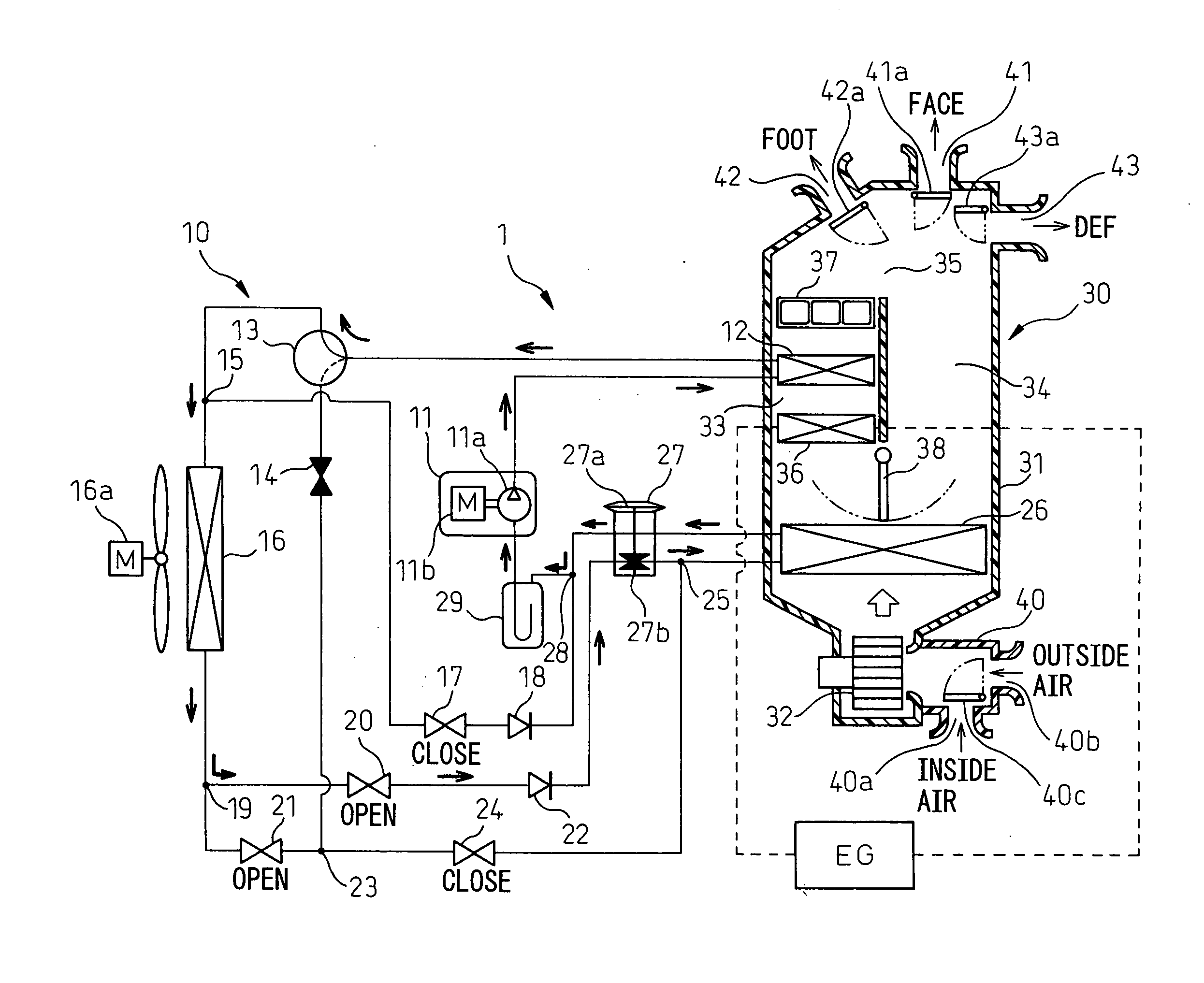

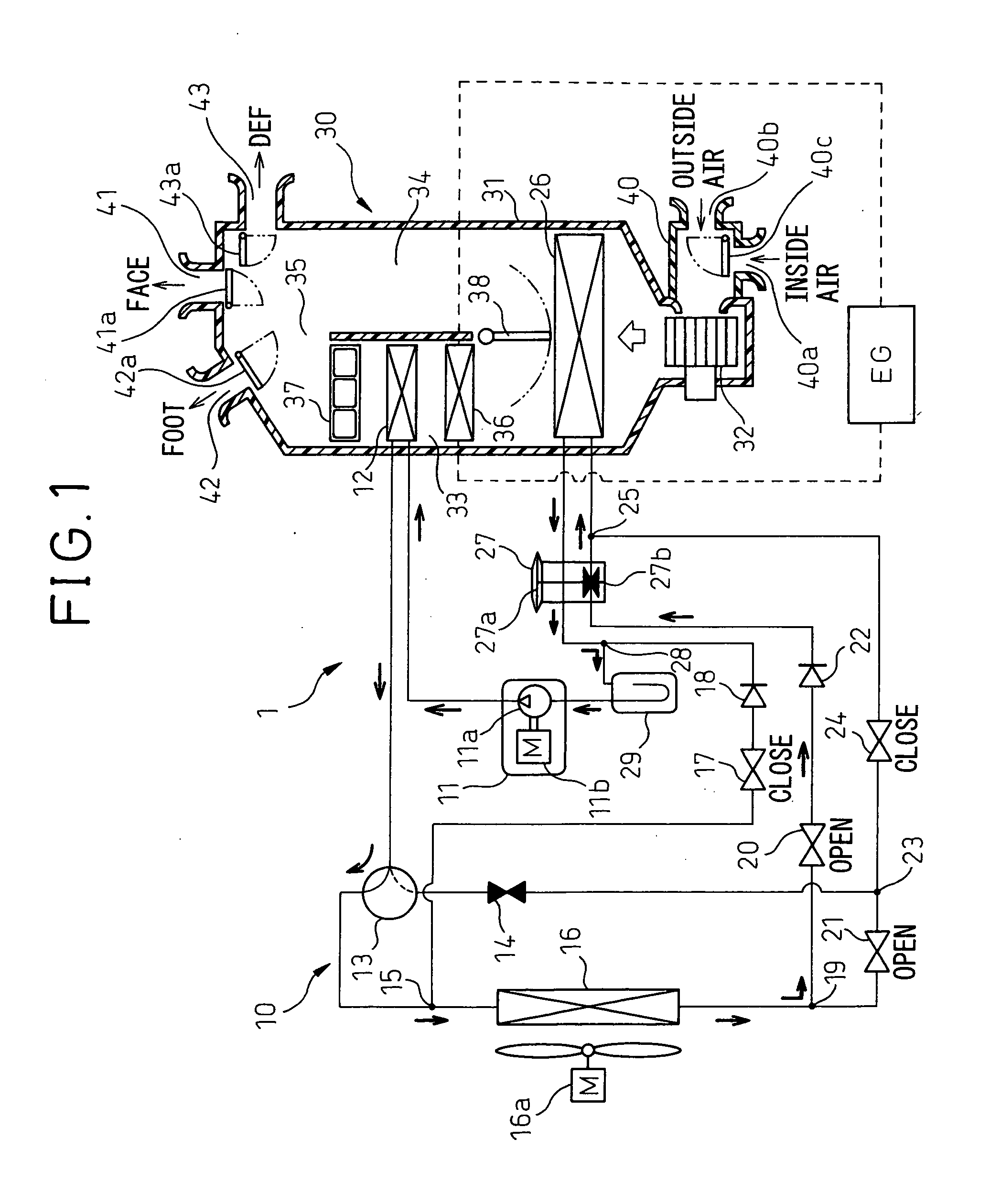

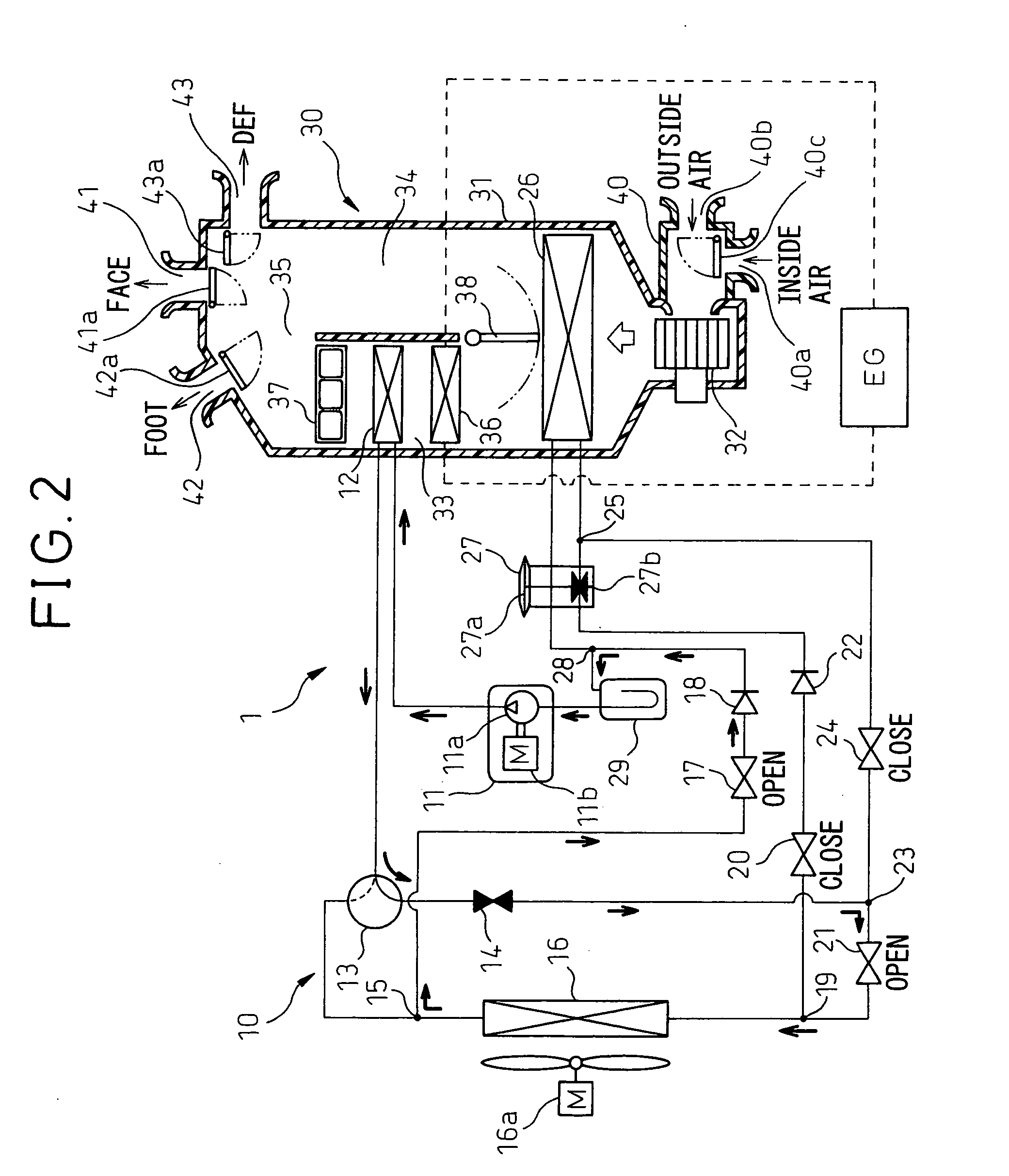

Vehicular air-conditioning system

InactiveUS20110005255A1Improve defogging effectImprove practicalityAir-treating devicesVehicle heating/cooling devicesEngineeringControl switch

A vehicular air-conditioning system provided with a vapor compression type refrigerating machine improved in practicality, provided with a vapor compression type refrigeration cycle 10 having a compressor 11 compressing and discharging a refrigerant and an outside heat exchanger 16 exchanging heat with the air outside of the cabin and the refrigerant and designed to be able to switch between a cooler cycle cooling vented air blown into the cabin and a heat pump cycle heating the vented air, a heating means 36 for using cooling water of an internal combustion engine EG as a heat source for heating the vented air, a vent mode switch 60c setting a defogging mode blowing out vented air toward the vehicle window glass by operation by a passenger, and a control means 50 controlling switching between the cooler cycle and heat pump cycle, the control means 50 selecting the cooler cycle and outputting a signal requesting operation to the internal combustion engine EG when the vent mode switch 60c is used to set the defogging mode.

Owner:DENSO CORP

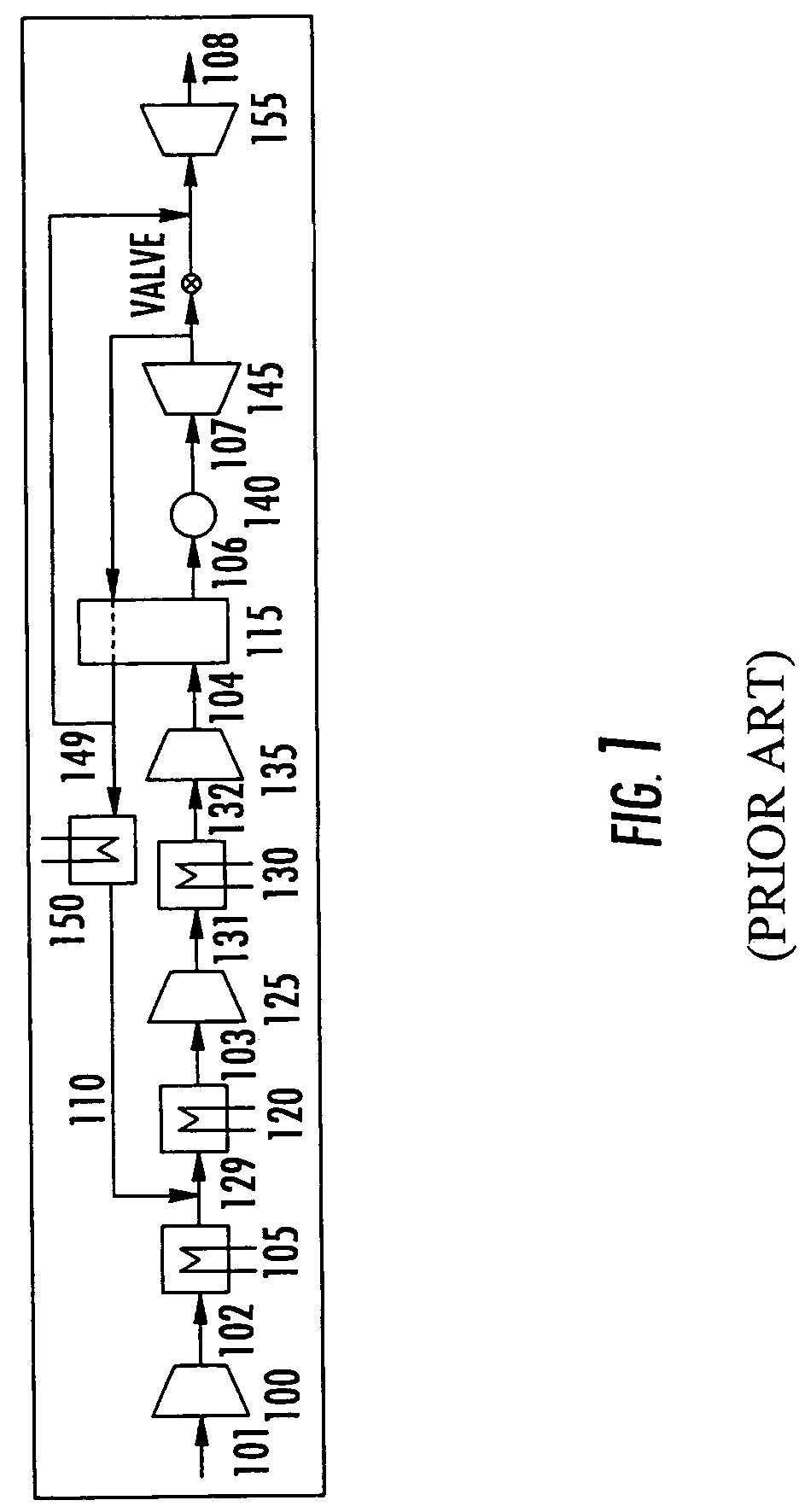

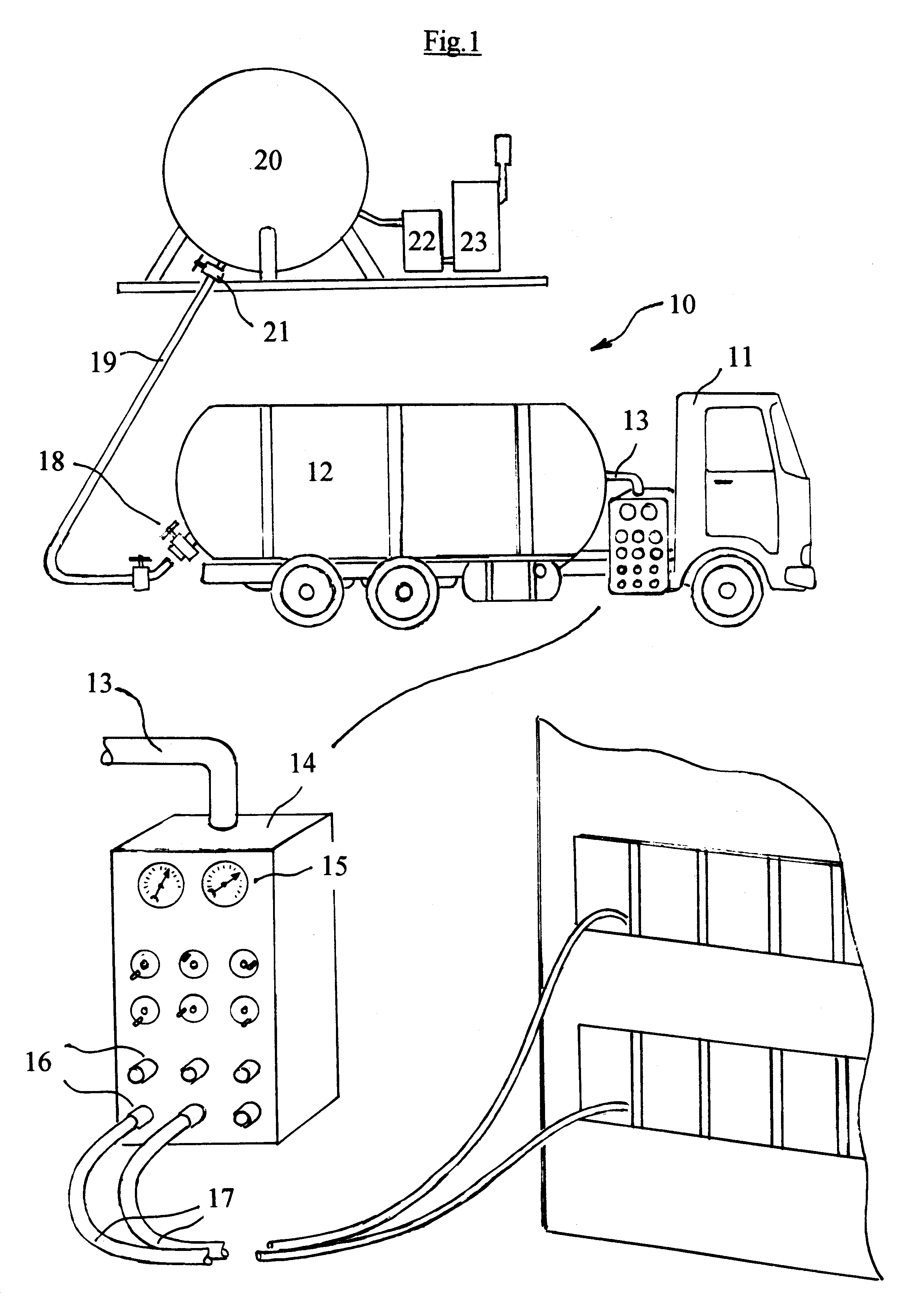

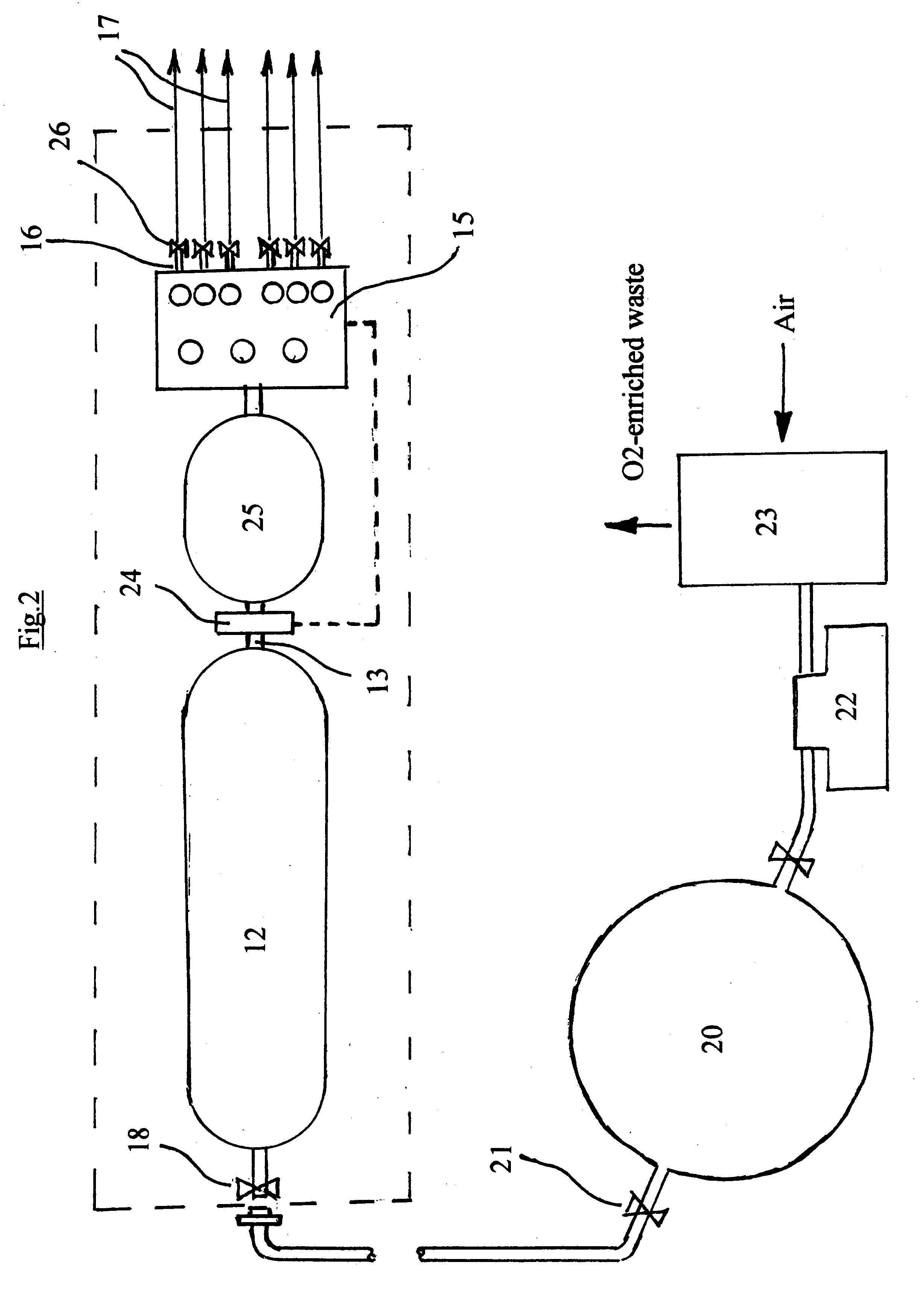

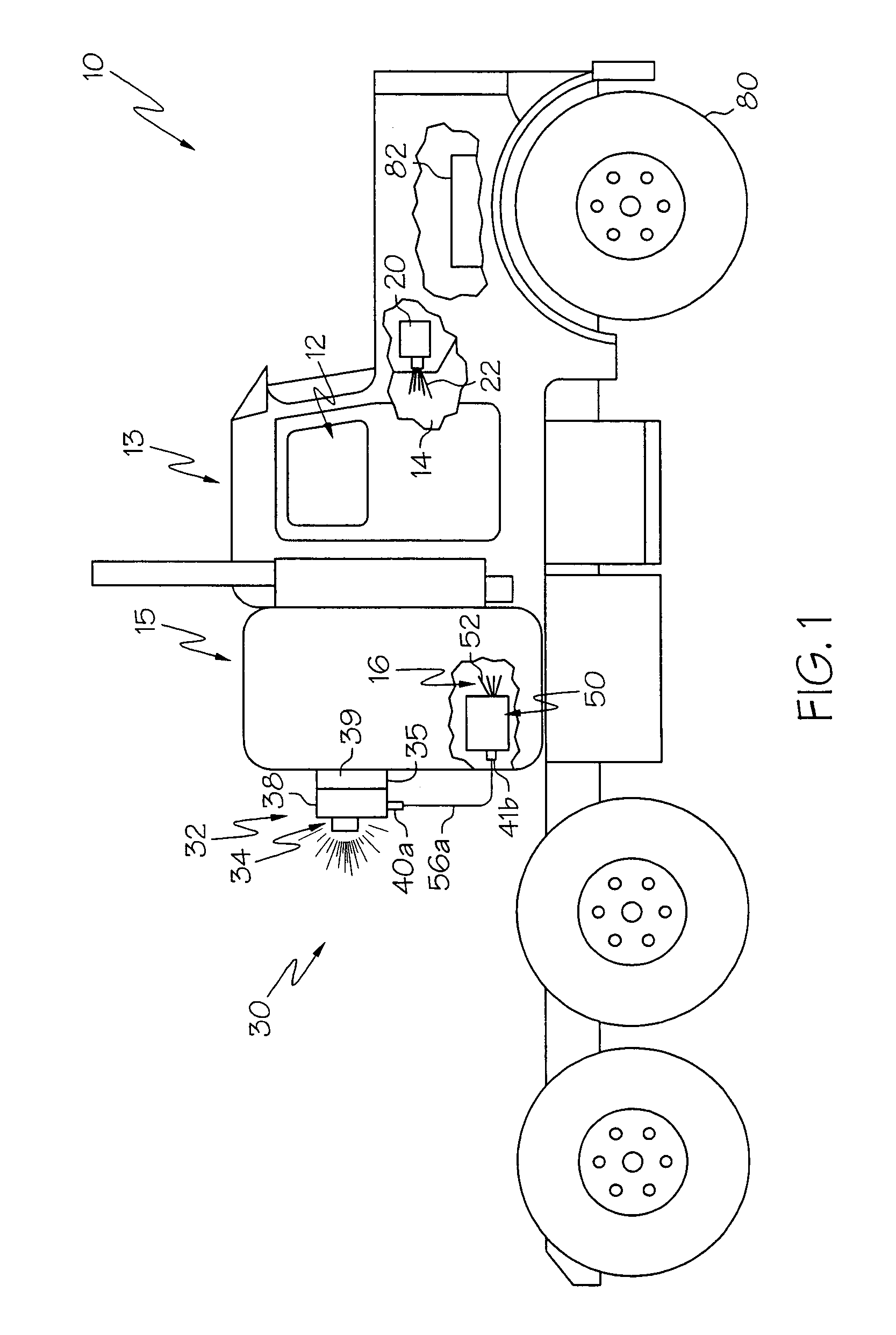

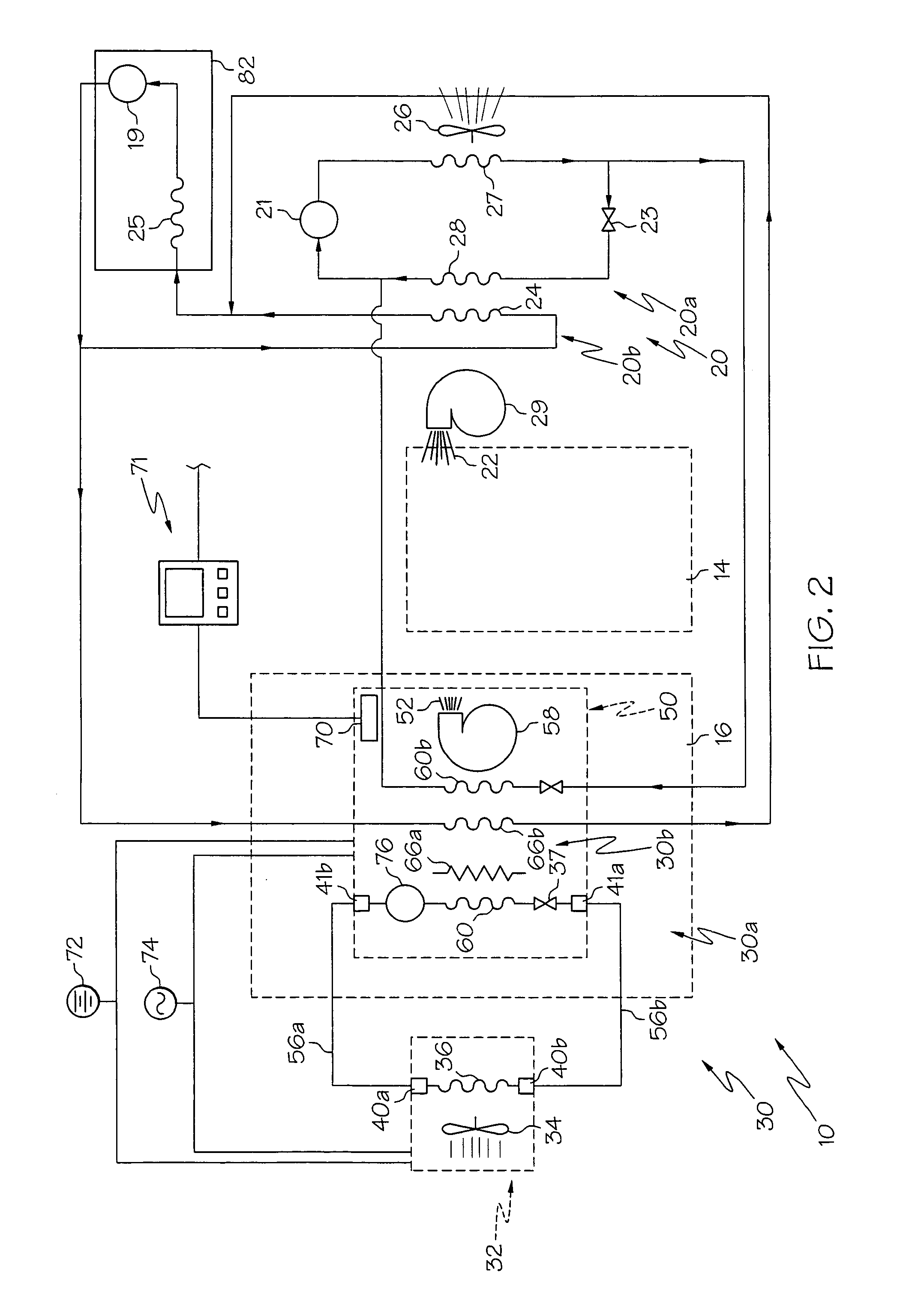

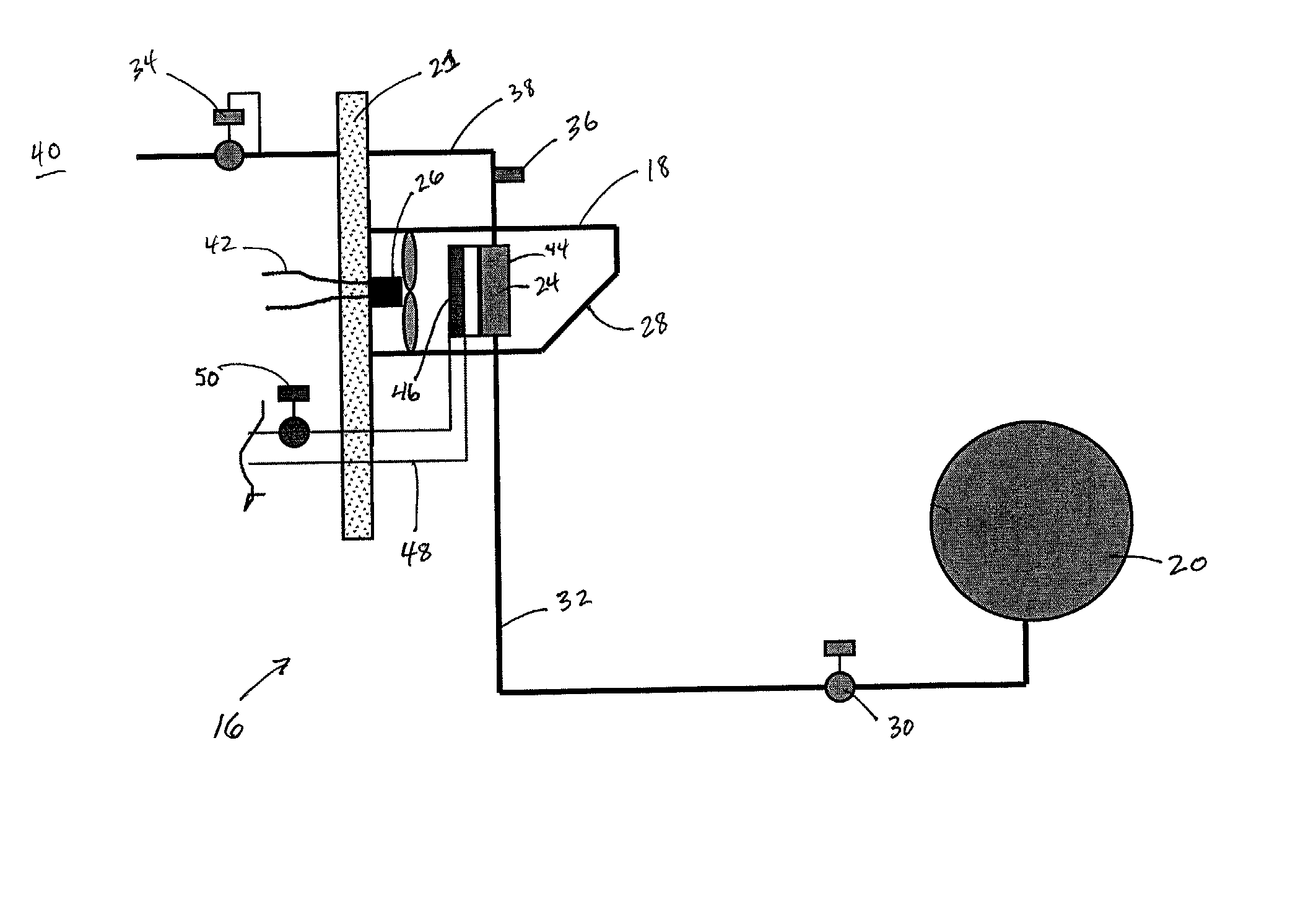

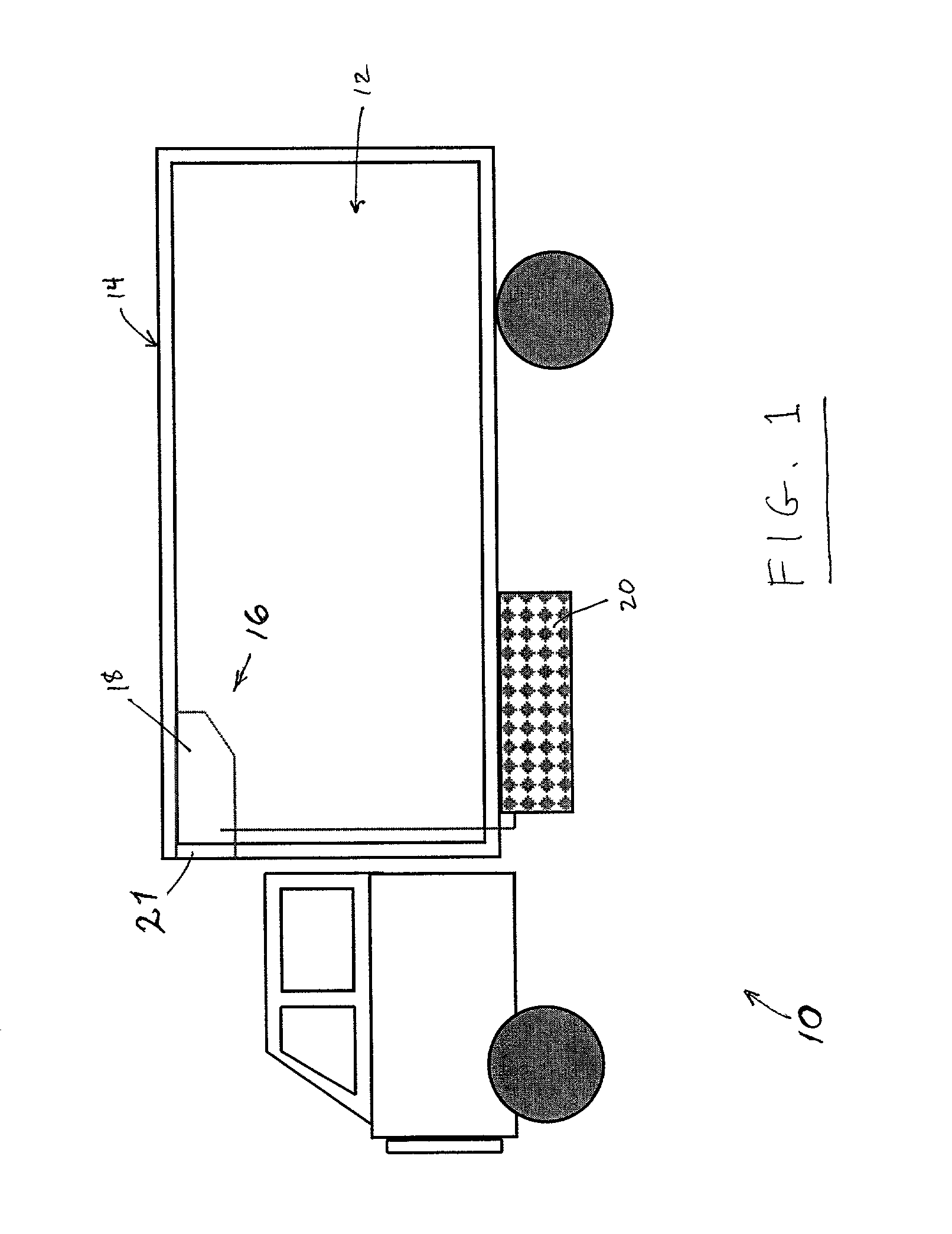

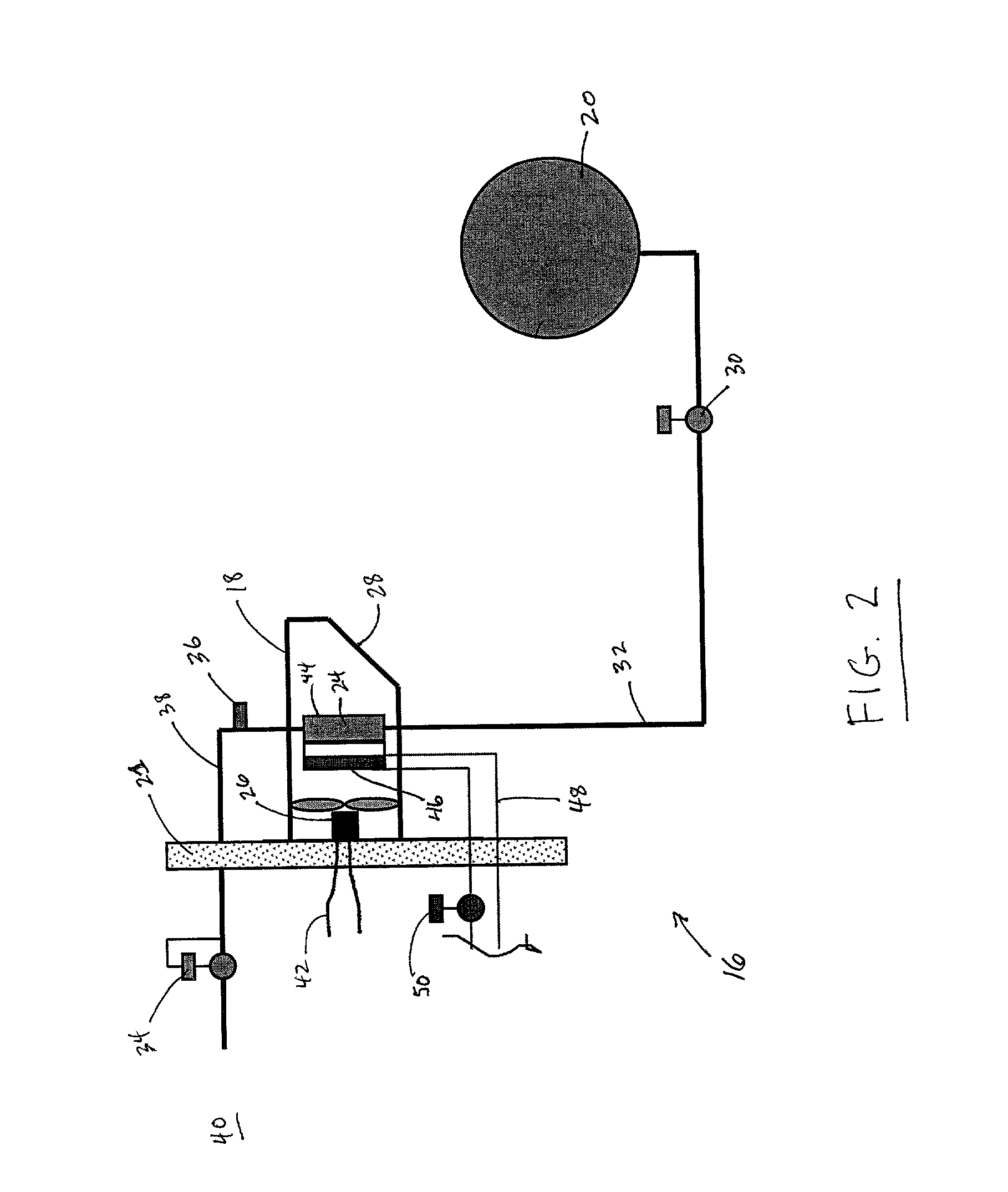

Cryogenic refrigeration unit suited for delivery vehicles

InactiveUS20020129613A1Reduce the temperatureNot contaminate atmosphereAir-treating devicesRefrigerated goods vehicleAir cycleDelivery vehicle

An apparatus to refrigerate the cargo space of delivery vehicles. It provides an environmentally friendly alternative to conventional mechanical a / c and refrigeration units. Cooling is provided by controlled evaporation of a liquefied gas such as CO.sub.2 or nitrogen. Defrost and heating requirements, if needed, are provided by hot engine coolant or by electric heaters powered from the vehicle electrical system. Airflow for the evaporator and for circulation in the temperature controlled space is provided by a blower which is mechanically or electrically driven from vehicle power. This invention can also be applied to multi-temperature control applications. The apparatus is compact and is particularly suited for small inner city delivery vehicles. FIG. 1: The sketch shows an inner city delivery truck for which this invention is most suitable. Refrigerated goods are placed in roller cages that are designed to maximize cargo hauled by use of roller cages that extend to within 2 inches of the ceiling. The evaporator section of this invention is mounted at or near the front wall of the truck and is separated from the cargo by a vertical bulkhead. The conditioned air is delivered at the bottom of the truck to avoid top freeze of perishable cargo that is in close proximity to the ceiling. FIG. 2: This shows the piping schematic and is similar to the invention described in U.S. Application Serial No. 60 / 238,929 (the '929 application) incorporated herein by reference. FIG. 2 shows the engine coolant coil located ahead of the CO.sub.2 coil in the direction of airflow. This prevents the coldest air from coming in contact with the engine coolant--in the cooling mode the air leaving the CO.sub.2 coil can be as low as -50.degree. F. for frozen load applications and this may cause the engine coolant to start freezing. Arrangements must be made to circulate air between the two coils in defrost mode. One means to accomplish this is to place a damper at the outlet of the evaporator section and run the fans. The damper would be closed during defrost. Another method is to place the engine coolant coil on the discharge side of the CO.sub.2 coil and use a cut-out switch if the engine coolant temperature drops below a predetermined value. In this arrangement there is no need for the damper arrangement as the heat will rise to melt any frost on the CO.sub.2 coil. If electric heat is used for defrost and heating freezing of the engine coolant is not a concern and the heaters can be fastened to the discharge side of the CO.sub.2 coil. An electric stand-by mode can be provided to power the system for cooling, heating and defrost when the vehicle is parked with the engine off. A plug-in electrical cable can provide the power needed for the controls, the fans and for heating and defrost. The figure shows the electric heaters attached on the discharge side of the CO.sub.2 coil. Operation: Detailed description is in the '929 application except for the following: The evaporator section is designed for vertical installation to maximize cargo space. Air is discharged at the bottom but may be a conventional top discharge if needed for specific applications. Conventional methods can be used to provide defrost and heating. If engine coolant is used for a heat source, it is preferable to thermally isolate the CO.sub.2 coil from the engine coolant coil to avoid freezing the coolant. The evaporator blower may be located on the inlet side of the coils rather than as shown in the figures. Unique Features: 1. Absence of a conventional condensing section on the exterior of the vehicle makes this an ideal refrigeration unit for small inner city delivery vehicles. Many of the truck cabs are now almost full height (same as the truck body) and there is limited space for the condensing section. 2. Cold plates can be used and still maximize cargo cube. However, this invention has 30-40% less weight than comparable "cold plate" systems. 3. Other features are described in the '929 application.]

Owner:THERMO KING CORP

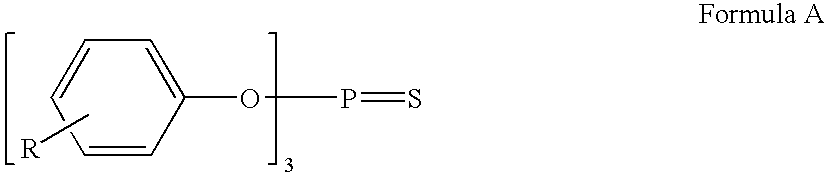

Phenol stabilizers for fluoroolefins

ActiveUS8075796B2Improve stabilityAvoid instabilityHeat-exchange elementsRefrigeration machinesFoaming agentRefrigeration

The present invention relates to compositions comprising at least one fluoroolefin and an effective amount of stabilizer that may be at least one phenol or a mixture of at least one phenol with other stabilizers. The stabilized compositions may be useful in cooling apparatus, such as refrigeration, air-conditioning, chillers, and heat pumps, as well as in applications as foam blowing agents, solvents, aerosol propellants, fire extinguishants, and sterilants.

Owner:THE CHEMOURS CO FC LLC

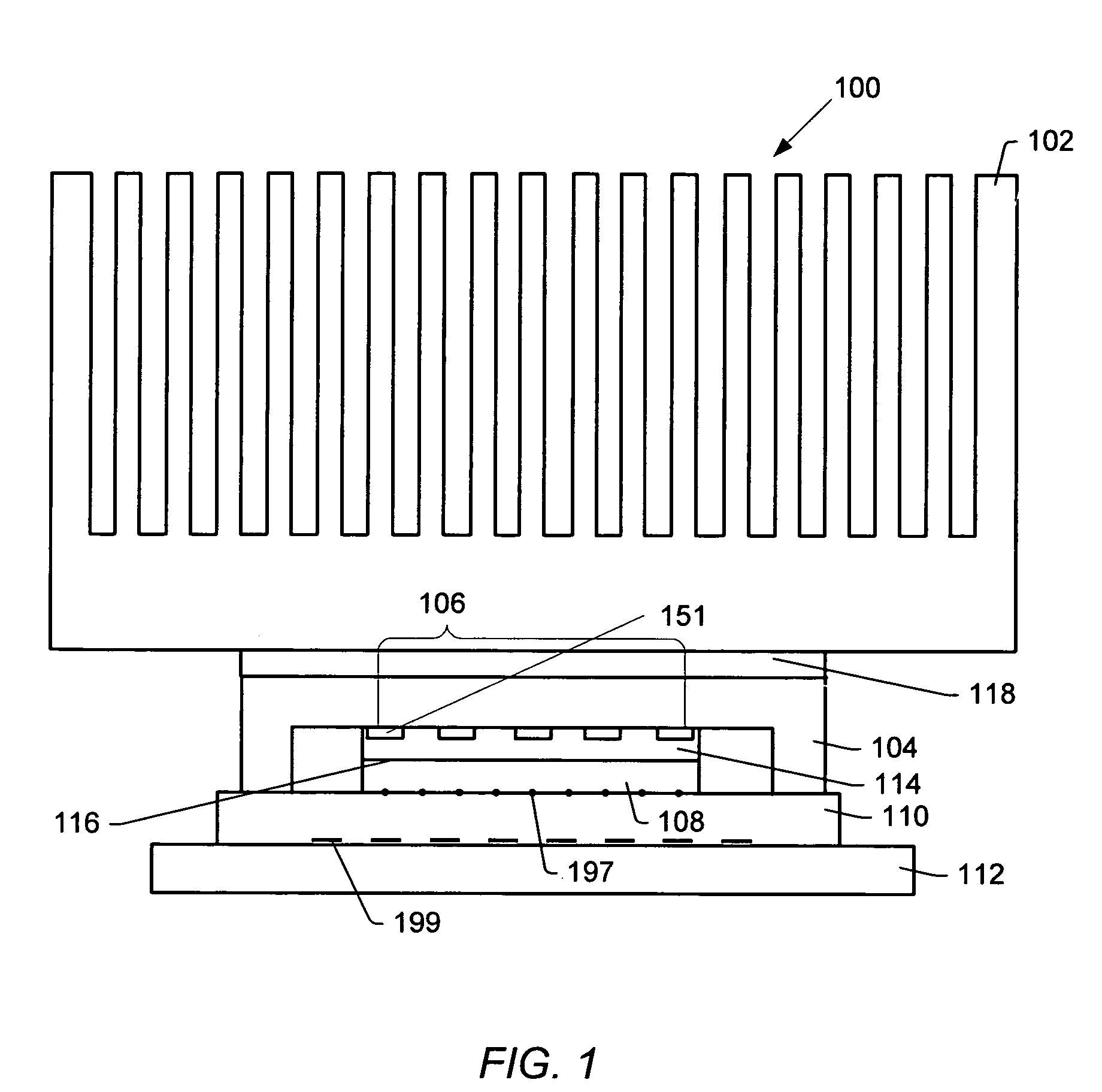

Method and apparatus for cooling heat-generating structure

InactiveUS6952345B2Improve cooling effectSemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringCoolant

An apparatus includes a heat receiving portion which receives heat within a footprint from a heat generating structure, and a cooling arrangement which causes flow of a coolant that absorbs heat at the heat receiving portion, the cooling arrangement being disposed in its entirety within a width of the footprint in a particular direction. A different feature involves an apparatus which includes a heat receiving portion at which a coolant receives heat, and a coolant separating portion which receives coolant traveling away from the heat receiving portion, and which separates liquid coolant from vapor coolant.

Owner:RAYTHEON CO

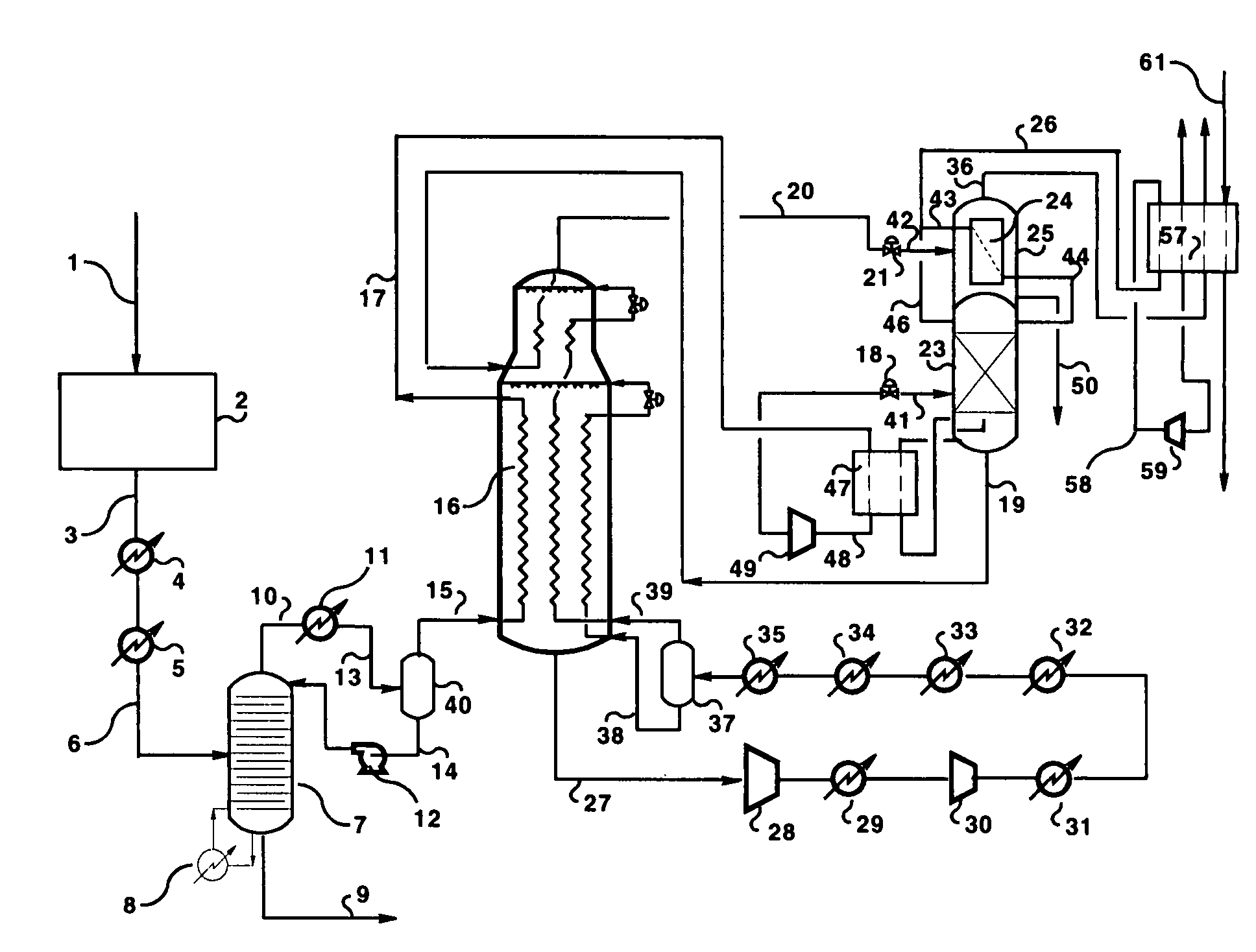

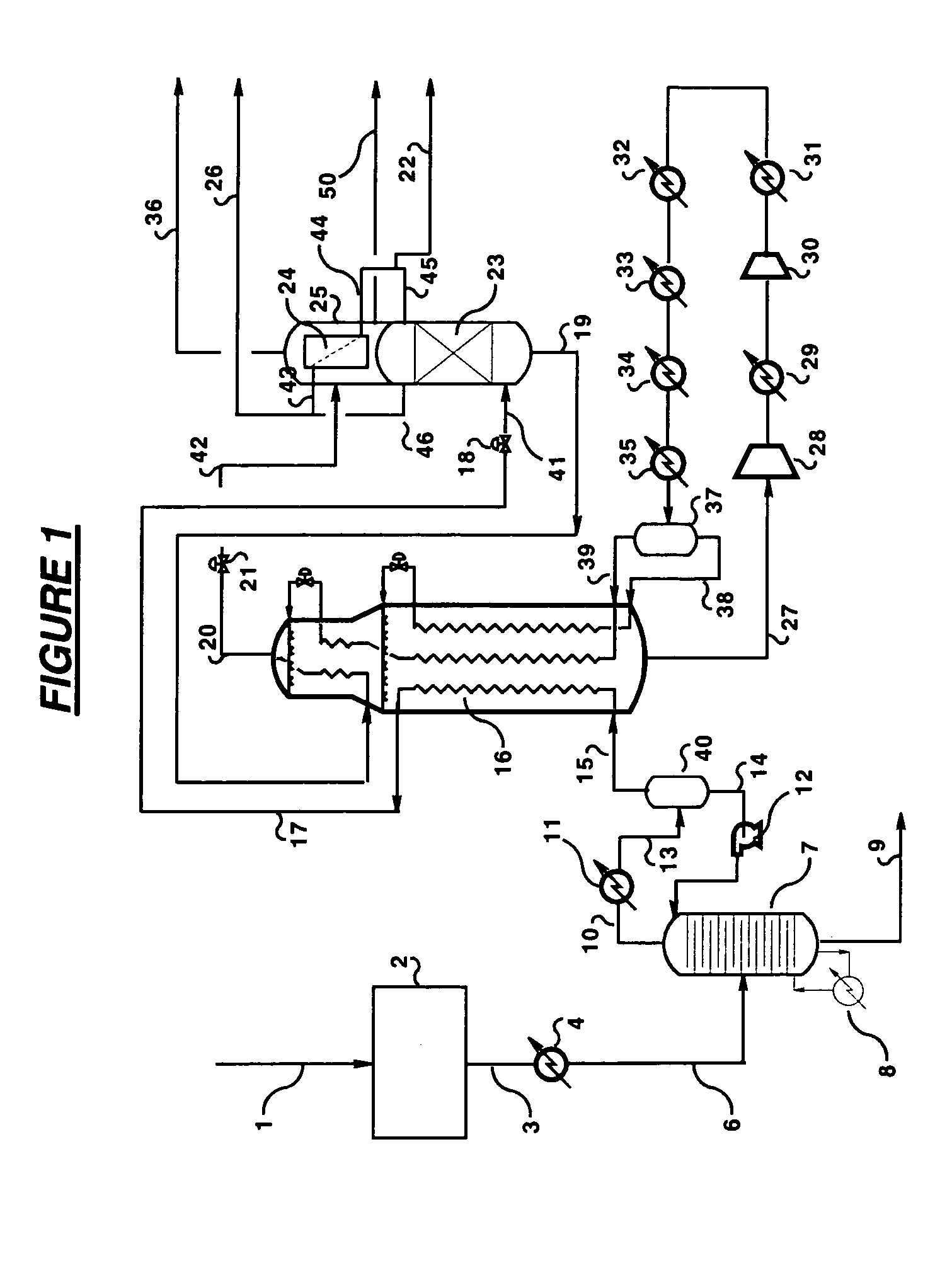

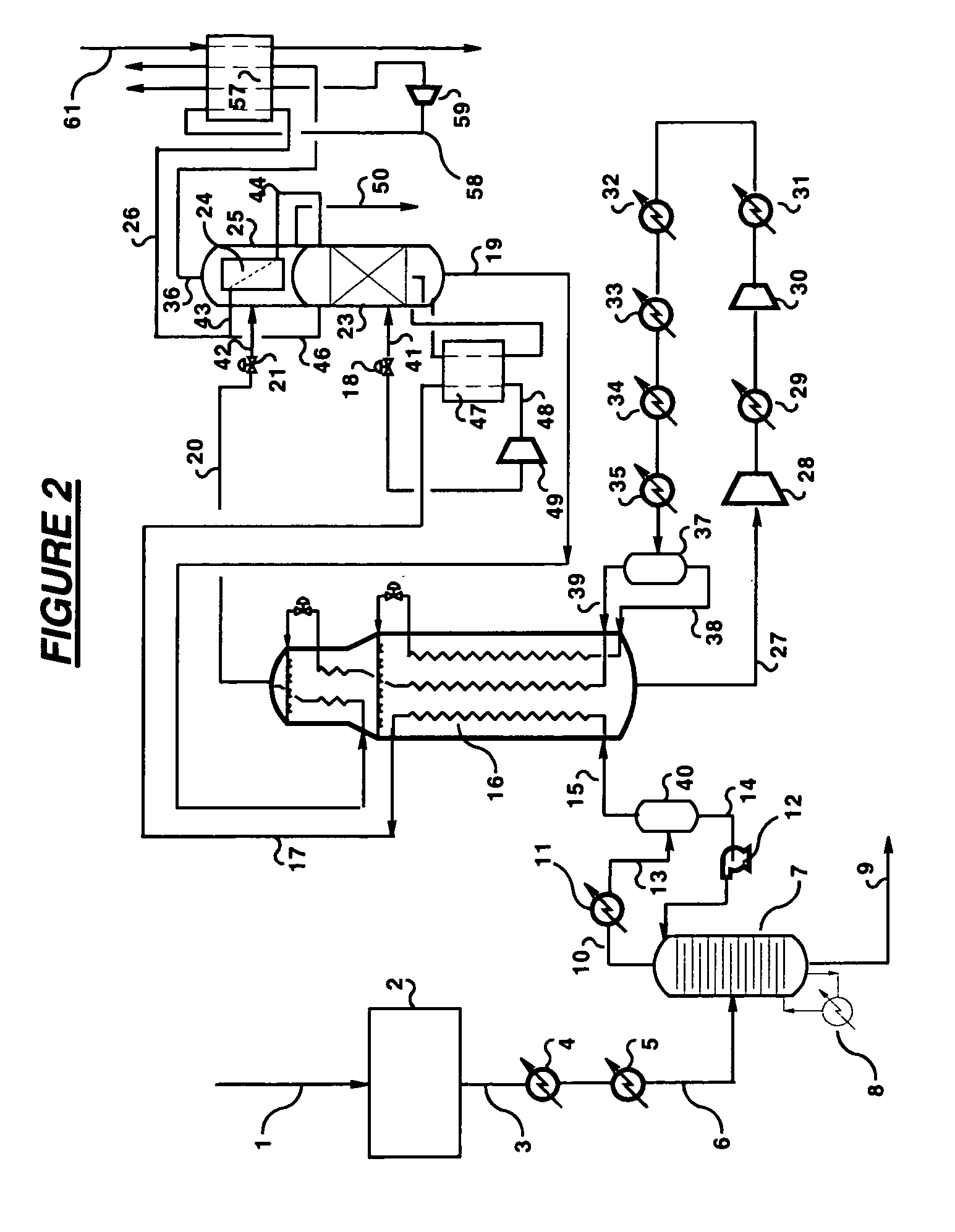

Dual stage nitrogen rejection from liquefied natural gas

Nitrogen is removed from a liquefied natural gas feed (41) by a two stage separation in which the liquefied natural gas (41) is first fractionated (23) to provide a first nitrogen-enriched overhead vapour stream (46) and a nitrogen-containing bottoms liquid stream (19) and then at least a portion of said bottoms liquid stream (19) is fractionated (25) to provide a second nitrogen-enriched overhead vapour stream (36) that is of lower purity than said first overhead vapour stream (46) and a purified liquefied natural gas stream (50). The first fractionation is conducted in a distillation column (23) refluxed (45) with nitrogen overhead (43) condensed in a condenser (24) located in a flash drum (25) in which the second fractionation is conducted. The second nitrogen-enriched overhead vapour stream (36) provides fuel gas for use in the natural gas liquefaction plant.

Owner:AIR PROD & CHEM INC

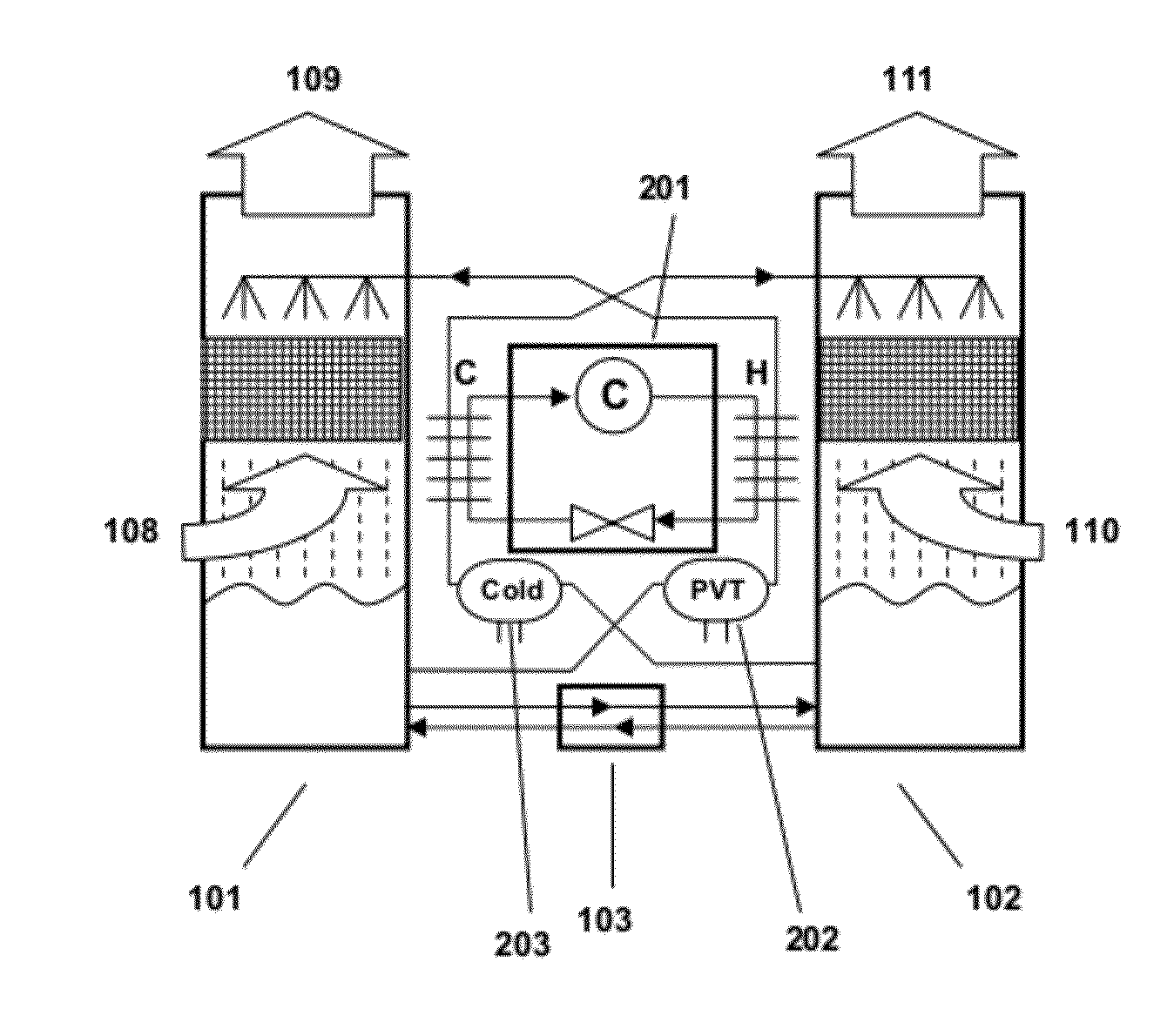

Methods and systems for desiccant air conditioning

Owner:COPELAND LP

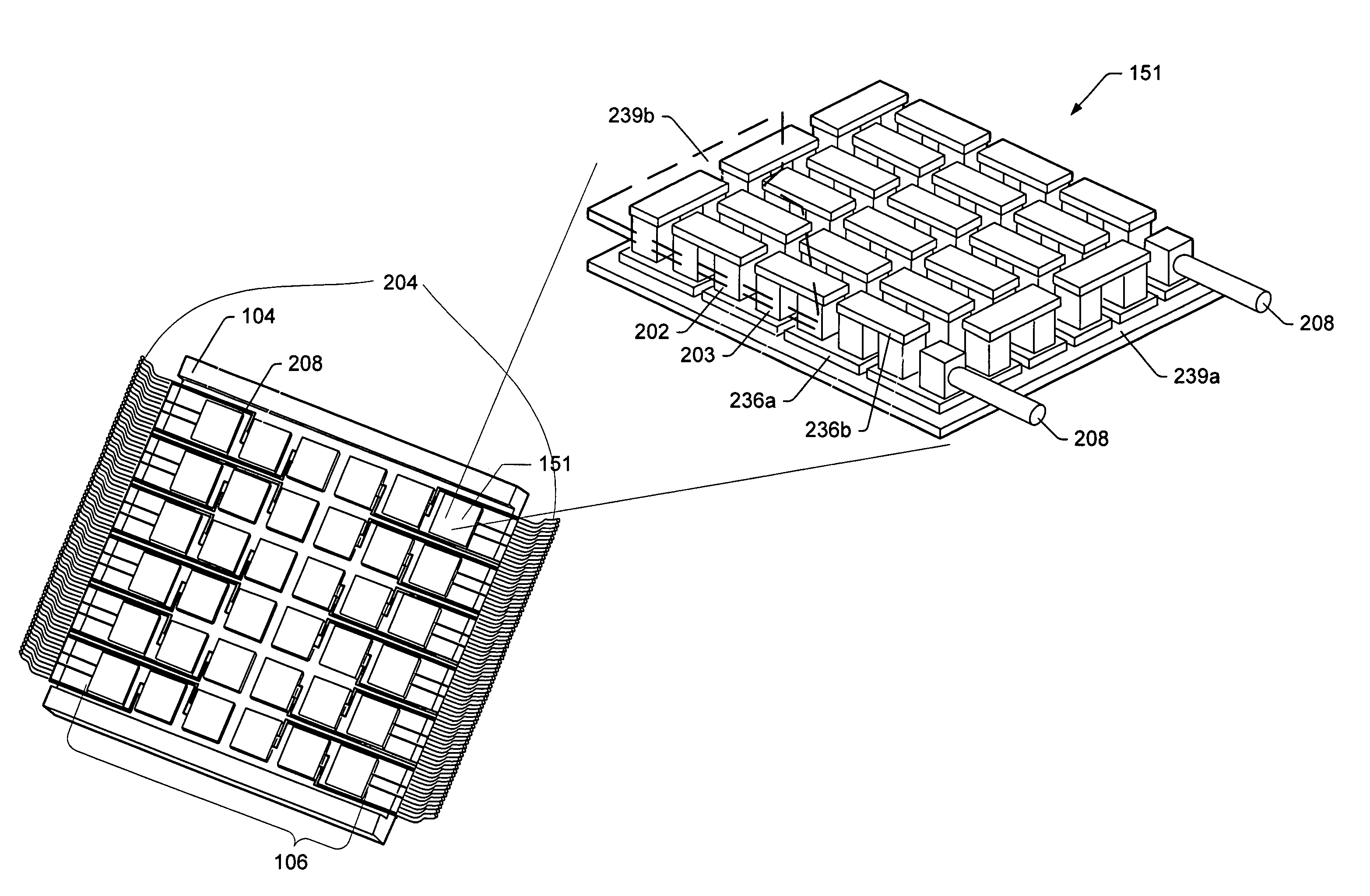

Thermoelectric cooling device arrays

ActiveUS7436059B1Speed up coolingReduce cooling rateThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsThermoelectric coolingEngineering

In various embodiments, a TEC device array may be coupled to a chip and a heat sink to cool the chip. The TEC device array may include multiple TEC devices separately controlled to provide different cooling rates at different points in the TEC device array coupled to the chip. In some embodiments, temperature data for areas on the chip or for separate electronic components may be determined using one or more thermal sensors and then sent to a controller. The controller may then determine an appropriate response for the TEC devices in the TEC device array near the area of the thermal sensor(s). The controller may thus control the cooling rates (which may be different) of several TEC devices in the TEC device array.

Owner:ORACLE INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com