Self-repairing lustering coating composition with high refraction index

A high-refractive-index, brightening coating technology, applied in coatings and other directions, can solve the problems of not showing elastic self-healing performance and scratch resistance performance, not mentioning brightening film coatings, complicated processes, etc. Good elastic self-healing effect, reduced process cost, simple preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

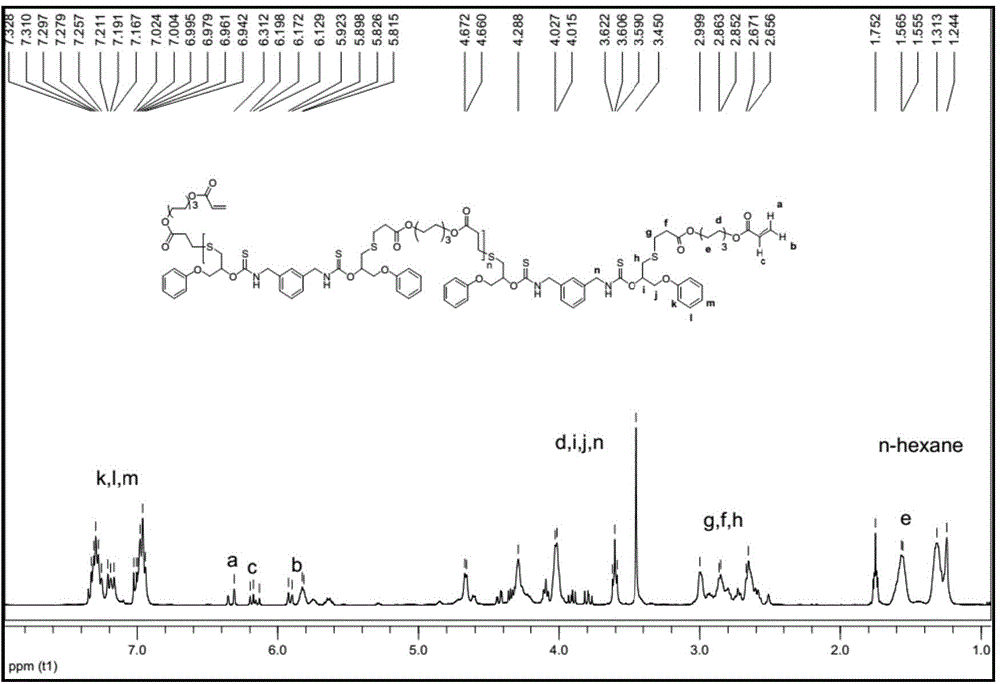

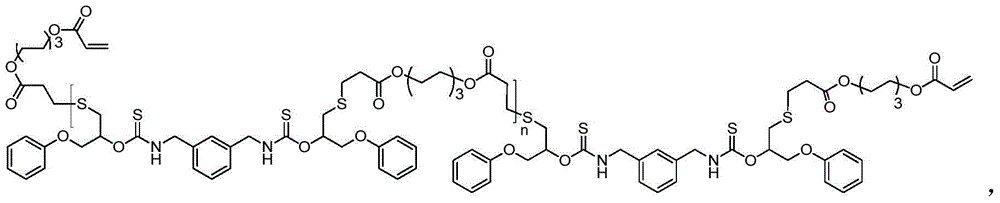

Image

Examples

Embodiment 1~5

[0051] Examples 1 to 5 respectively provide a UV-curable elastic self-repairing coating composition, and the corresponding raw material components, parts by weight and corresponding performance tests of each composition are shown in Table 1;

[0052] The raw material components corresponding to each example were mixed according to their parts by weight, dispersed at a medium speed for 2 hours, and filtered to obtain the corresponding elastic self-healing UV photocurable coating composition.

[0053] Table 1

[0054]

[0055]

[0056] The substances listed in Table 1 are representative of the aforementioned various technical solutions, and are not limited to the substances listed in the table during actual implementation. The monofunctional acrylate can also be selected from 2-phenoxy ethyl acrylate, ethoxylated phenoxy acrylate, o-phenylphenethoxy ethyl acrylate, 2-(to-cumyl-benzene One or more of oxy)-hexyl acrylate, 2-hydroxy-3-phenylphenethoxypropyl acrylate, benzyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com