Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

A low expansion coefficient, polyvinyl chloride technology, applied in the field of low expansion coefficient polyvinyl chloride alloy materials and its preparation, can solve the problem of reducing the thermal expansion coefficient of PVC composite and/or blended materials, reducing mechanical properties, and degrading processing performance, etc. problems, to achieve the effect of high performance, improved dispersion and compatibility, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

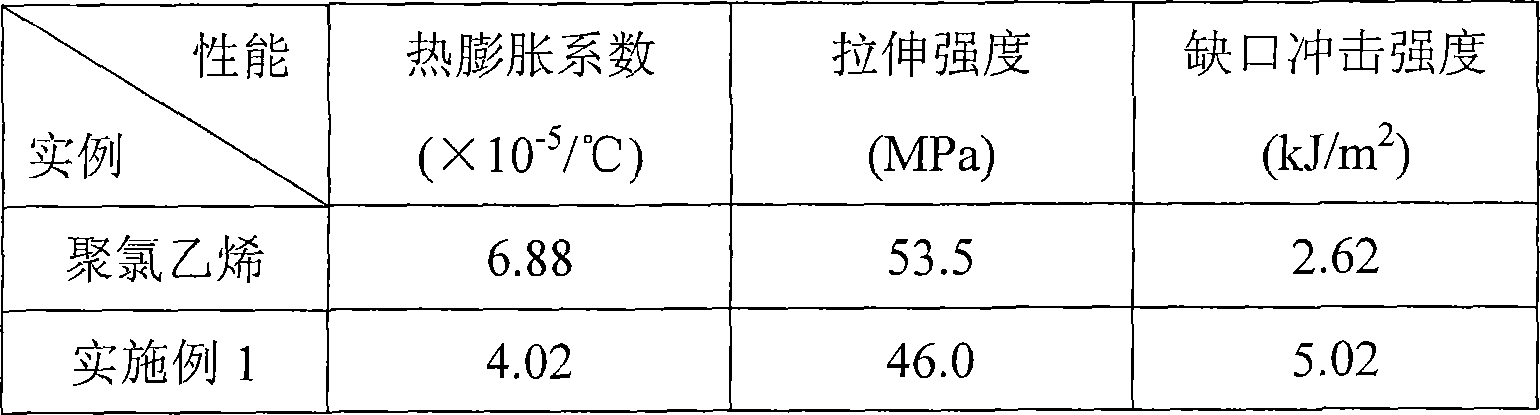

Embodiment 1

[0037] Put 100g of PVC resin, 1.5g of tribasic lead sulfate, 3.5g of calcium stearate and hindered phenol compound into mechanochemical reaction equipment, and react at about 20°C (15-30°C) for about 0.5h to obtain mechanochemical Modified processing aids.

[0038] Dilute 1.5g of titanate coupling agent with 5g of white oil, add it into 100g of calcium carbonate whisker (filler) and stir for about 0.5h to obtain organically modified calcium carbonate whisker filler.

[0039] 100g of PVC resin and 20g of the above-mentioned organically treated modified calcium carbonate whisker filler, 4g of composite lead salt (FZ-101), 0.5g of calcium stearate, and 2g of the above-mentioned modified processing aid were prepared in a high-speed mixer Mix in medium temperature, discharge at about 110°C, melt and blend on a twin-roller plastic mixer at a temperature of about 170°C, and release the sheet after 8 minutes to prepare a polyvinyl chloride alloy material with a low expansion coefficie...

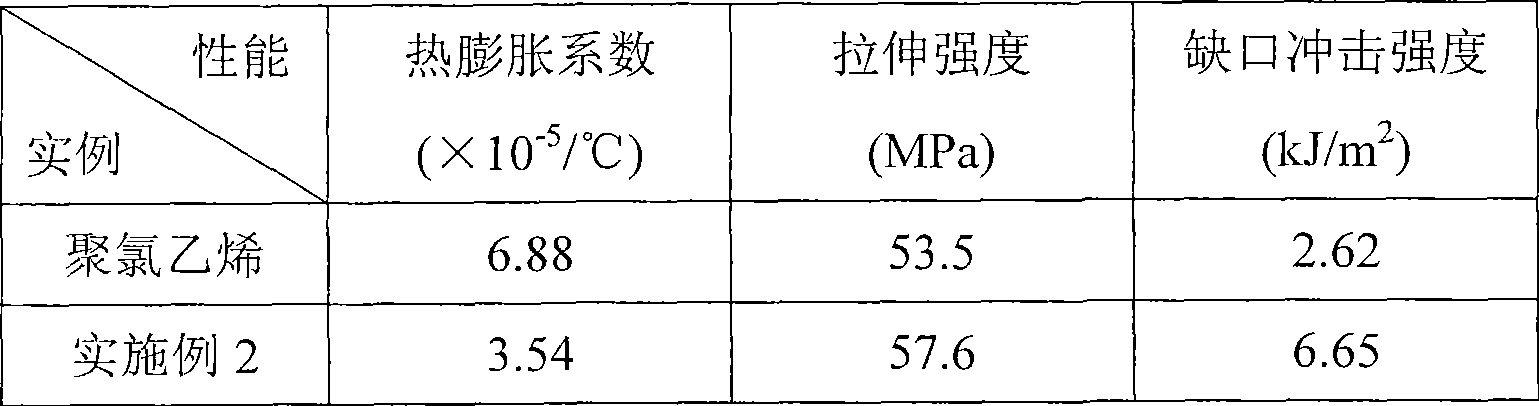

Embodiment 2

[0043] Put 100g of PVC resin, 2.0g of composite lead salt (FZ-101), 5g of calcium stearate and phosphite compound into the mechanochemical reaction equipment, and react at about 15°C (15-30°C) for about 0.5h, Mechanochemically modified processing aids are obtained.

[0044] Dilute 1.5g of coupling agent (TC-201) with 10g of alcohol, add it into 100g of talc (filler) and stir for 0.5h to obtain organic treated talc filler.

[0045] Mix 100g of PVC resin with 20g of the organically treated talc filler prepared above, 4g of composite lead salt (FZ-101), 0.5g of stearic acid, and 1g of the modified processing aid prepared above in a high-speed mixer. The material is melted and blended on a twin-roller plastic mixer at a temperature of about 170°C, and the sheet is released after 8 minutes to prepare a polyvinyl chloride alloy material with a low expansion coefficient. In order to measure the performance of the material, the prepared low-expansion coefficient polyvinyl chloride al...

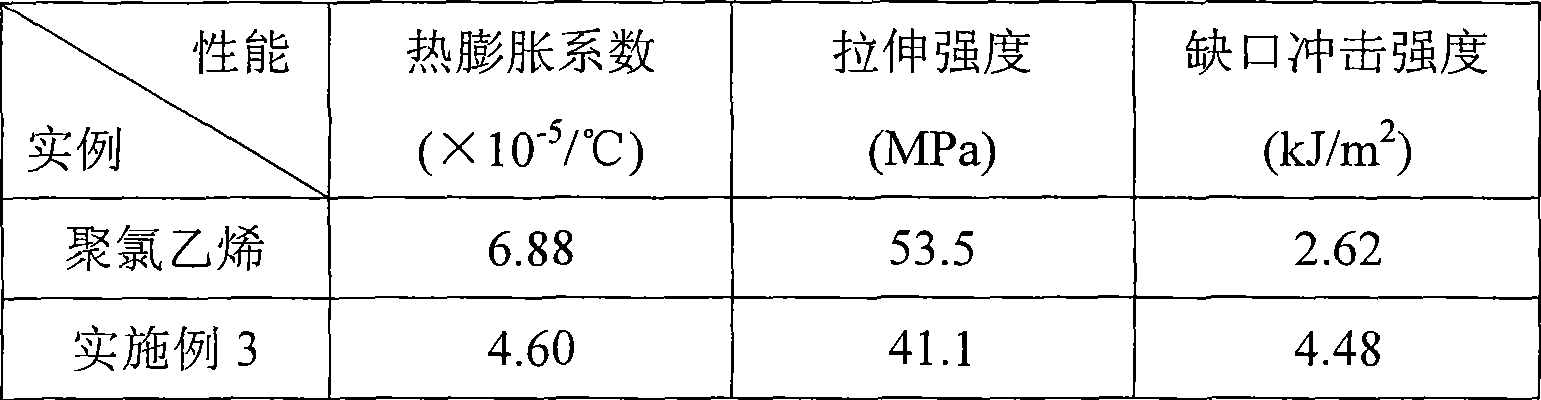

Embodiment 3

[0049] Put 100g of PVC resin, 2.5g of calcium zinc stabilizer (Bear brand 9700), 4.0g of lubricant (ZB-60) and antioxidant (1010) into the mechanochemical reaction equipment, at about 25°C (15~30 °C) for about 0.5 h to obtain a mechanochemically modified processing aid.

[0050] First bake the wood powder at 110°C for 3.5 hours, then add 50g of dry wood powder (filler) and alcohol solution containing 1.0g of coupling agent (PM-200) into the high-speed mixer and stir, activate for 10 minutes, then add 100g of PVC, 3.5 g of the processing aid prepared above, 4.5 g of calcium zinc stabilizer (Bear brand 9700), 1.4 g of stearic acid, and 16 g of CPE were treated in a mechanochemical reaction device for 2 hours to obtain PVC composite material powder. The powder is then melt-blended on a twin-roller plastic mixer at a temperature of about 170°C, and the sheet is released after 8 minutes to obtain a polyvinyl chloride alloy material with a low expansion coefficient. In order to mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com