Method for cyclically producing taurine at high yield

A taurine and high-yield technology, applied in the field of taurine preparation, can solve the problems of intractability, consumption of a large amount of steam, low yield, etc., and achieves easy large-scale production, simple production process, and waste liquid generation. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

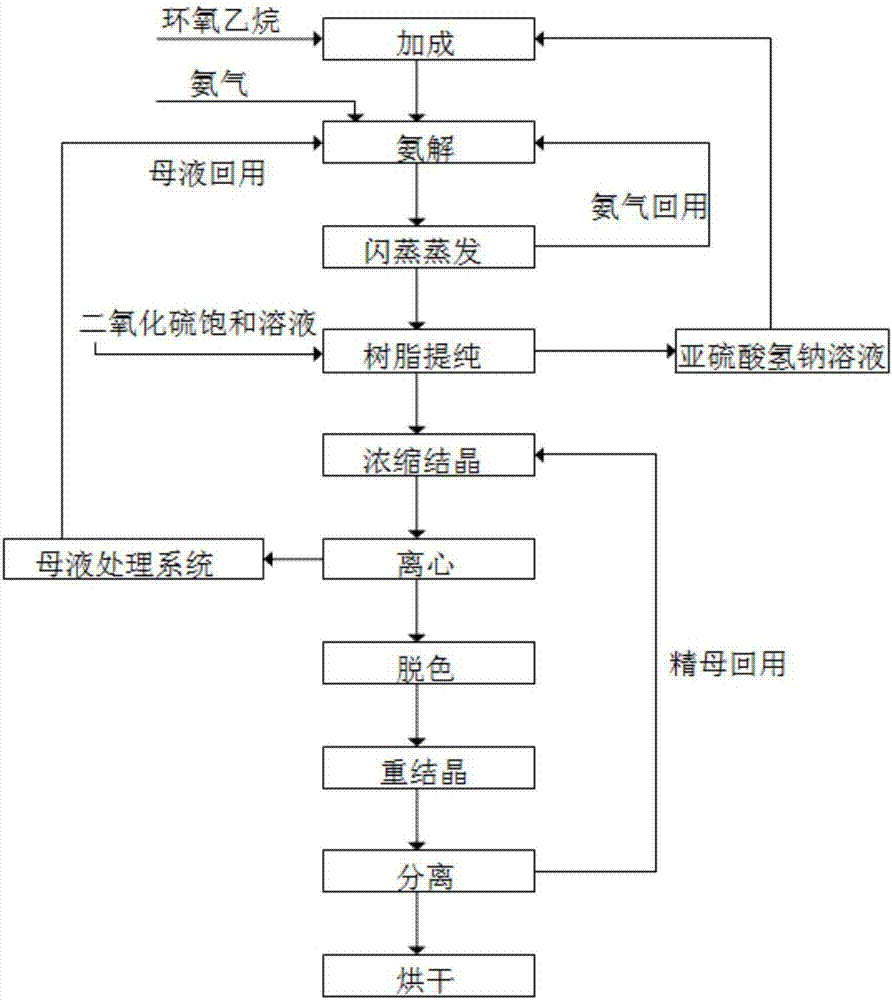

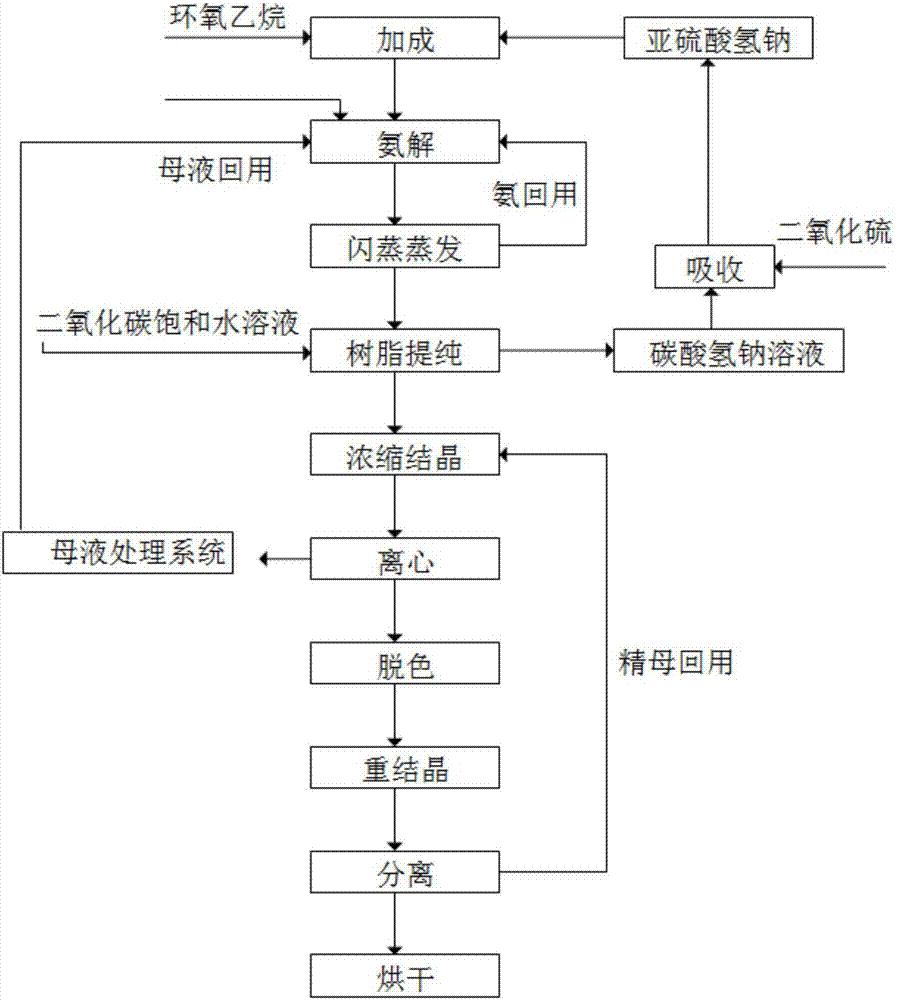

Method used

Image

Examples

Embodiment 1

[0040] This example shows the pretreatment (or regeneration treatment) of the acidic cation exchange resin column: at the initial pretreatment, the carboxylic acid cation exchange resin is wet-packed into the exchange column, and under the protection of nitrogen, 2BV, saturated sulfur dioxide is used The aqueous solution is forwarded through the resin in the exchange column at a flow rate of 1.8-2.2 BV / h (any value), and then washed with deionized water to pH=5 for use. When loading the column, first add the resin to the measuring cylinder by wet method. The upper layer of the resin ensures a water layer of about 5-10cm. Slightly shake the measuring cylinder to make the resin compact, and then transfer it to the exchange column by wet method, leaving 5-10cm of water on the top of the resin layer. No air bubbles should be left in the resin layer.

[0041] During the regeneration process, there is no column packing step, but directly add water to drive out the materials in the resi...

Embodiment 2

[0045] This example shows the treatment of sodium taurate solution with the carboxylic acid type cation exchange resin column after pretreatment or regeneration in Example 1:

[0046] Take 1250ml, 10% mass volume percentage of taurine aqueous solution (based on taurine, 100mL solution contains 10g taurine), and set it to flow rate forward at 0.25-2.5BV / h (any value) Through the resin column, the outlet is initially the water in the resin layer, which can not be collected (you can judge whether the material liquid comes out by detecting the pH, and the pH changes indicate that the material liquid flows out). After the material liquid comes out, start measuring and collecting, every 0.08-0.15 BV (any value) takes a sample to detect pH. When the outlet material index is basically the same as the inlet index (that is, the pH is close), stop feeding; then use deionized water to wash out and recover the material liquid at a flow rate of 2BV / h , The total volume of the collected materia...

Embodiment 3

[0048] This example shows the steps of concentrated crystallization, separation and purification and drying of the material liquid:

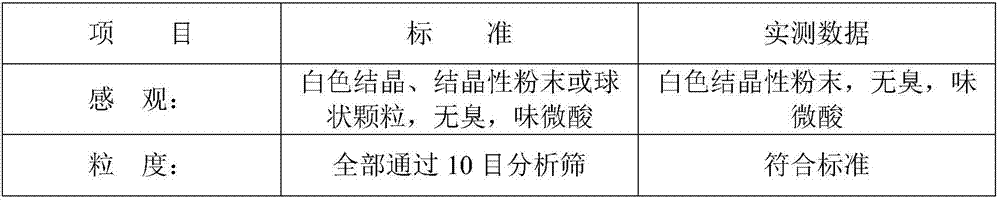

[0049] The total volume of the collected materials is about 1850 mL, and the materials with the taurine content detected at 6.7% are concentrated, then cooled to 20°C for crystallization, and centrifuged to obtain 125 g of crude product with a mass content of 92.5% and a moisture content of 7%. The remaining mother liquor is 72 mL, with a content of 11.56%. Then 125g of the crude product was decolorized and recrystallized, separated again, and dried to obtain 81g of the dried product and 345mL (content 10%). The quality inspection data are as follows:

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com