Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157 results about "Hexyl acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PE (polyurethane) protective film glue and preparation method thereof

InactiveCN102206476AStrong adhesionHigh bonding strengthFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateWater based

The invention discloses PE (polyurethane) protective film glue and a preparation method thereof. The PE protective film glue consists of the following components in parts by weight: monomers: 20-60 parts of butyl acrylate, 25-45 parts of methyl methacrylate, 12-32 parts of methyl acrylate, 5-15 parts of acrylic acid, 10-24 parts of hydroxyethyl acrylate, 120-140 parts of enthyl hexyl acrylate; emulsifying agents: 0.5-1.5 parts of polyoxyethylene octyl phenyl ether, 0.5-1.5 parts of sodium dodecyl sulphate, 0.5-1.5 parts of sodium dodecyl benzene sulfonate; a solvent: 280-350 parts of deionized water; and an initiating agent: 0.6-1.5 parts of ammonium persulfate. The PE protective film glue provided by the invention is the water-based adhesive and has the advantages of environment friendliness, no pollution, strong adhesive force and adhesive strength, and short drying time. A PE protective film coated with the PE protective film glue provided by the invention can be used for a vehicleprotective film, the protective films of all home appliances and so on. The effects of non-degumming and no residue glue can be realized.

Owner:BOLEX SHENZHEN ADHESIVE PROD

Waterborne acrylate resin emulsion and synthetic method and application thereof

InactiveCN101565484AImprove performanceGood film formingFibre treatmentEster polymer adhesivesIsooctyl acrylateEmulsion

The invention pertains to the technical field of polymer materials and particularly relates to a waterborne resin emulsion for car cleaning cloth or common cleaning cloth and a textile finishing adhesive agent, a synthetic method and application of the waterborne resin emulsion. The resin emulsion consists of a waterborne resin polymer, an emulsifier, an evocating agent, a pH value modulator and water; the waterborne resin polymer is obtained by polymerization of 3-5 monomers such as butyl acrylate, ethyl hexyl acrylate and methyl methacrylate and the like. The synthesis comprises two steps of monomer pre-emulsion and polymerization by the evocating agent. The product of the invention has stable performance and good film formation performance, as well as soft hand feeling, good moisture permeability, long-term moisture and environment protection by absorbing fine dusts when used as cleaning cloth, and when used as a textile adhesive agent, the product can not only realize the characteristics and requirements above, but also decrease electrostatic interaction of the textile, thus having good and wide application in the textile field.

Owner:JILIN UNIV

Water-based acrylic emulsion and preparation method and application thereof

InactiveCN101974184ATransparent appearanceImprove wettability and dispersibilityNon-fibrous pulp additionInksIsooctyl acrylateWater based

The invention discloses water-based acrylic emulsion and a preparation method and application thereof. The water-based acrylic emulsion is prepared by the following steps of: performing radical polymerization on methyl methacrylate, styrene, ethyl hexyl acrylate, glycidyl methacrylate, ammonia water, an emulsifier, an initiator and deionized water to form a macromolecular substance so as to form a main body of the water-based acrylic emulsion; and matching the main body with a film forming substance, an aid and a defoaming agent. The water-based acrylic emulsion has a transparent, fine and smooth appearance, fine grain size, high wetting dispersability and stable quality, is not broken when dispersed by a high-shear dispersing machine for 24 hours, is not broken and generates particles in color paste grinding, is not sensitive to calcium and magnesium ions, and has high lustre equivalent to that of similar products abroad; and because the consumption of the emulsifier in the system is low, a dry film has good water resistance, the applied product has high mechanical stability, wear resistance, adhesion and excellent picking resistance, and paper printed and polished has the characteristics of no scratch and the like.

Owner:苏州凯康化工科技有限公司

Hot melt adhesive composition

A low application temperature, high heat resistant hot melt adhesive comprising an ethylene vinyl acetate and / or ethylene 2-ethyl hexyl acrylate polymer having a melt index of at least 550 grams / 10 minutes, a paraffin wax and a rosin derived tackifier.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

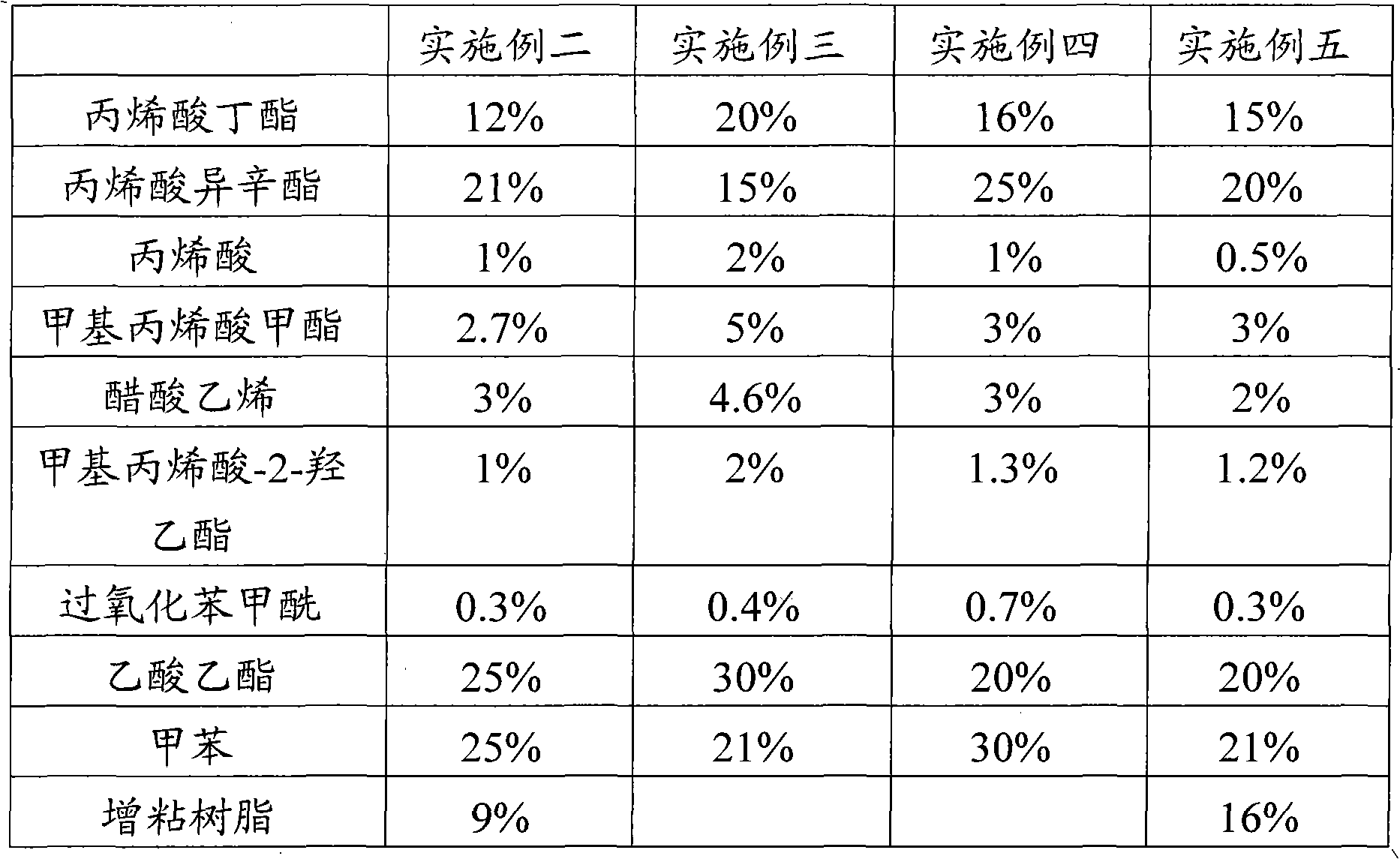

Pressure-sensitive adhesive for PET (Polyester) adhesive tapes and preparation method thereof

InactiveCN102040930ANo pollution in the processIncrease stickinessFilm/foil adhesivesEster polymer adhesivesPolyesterIsooctyl acrylate

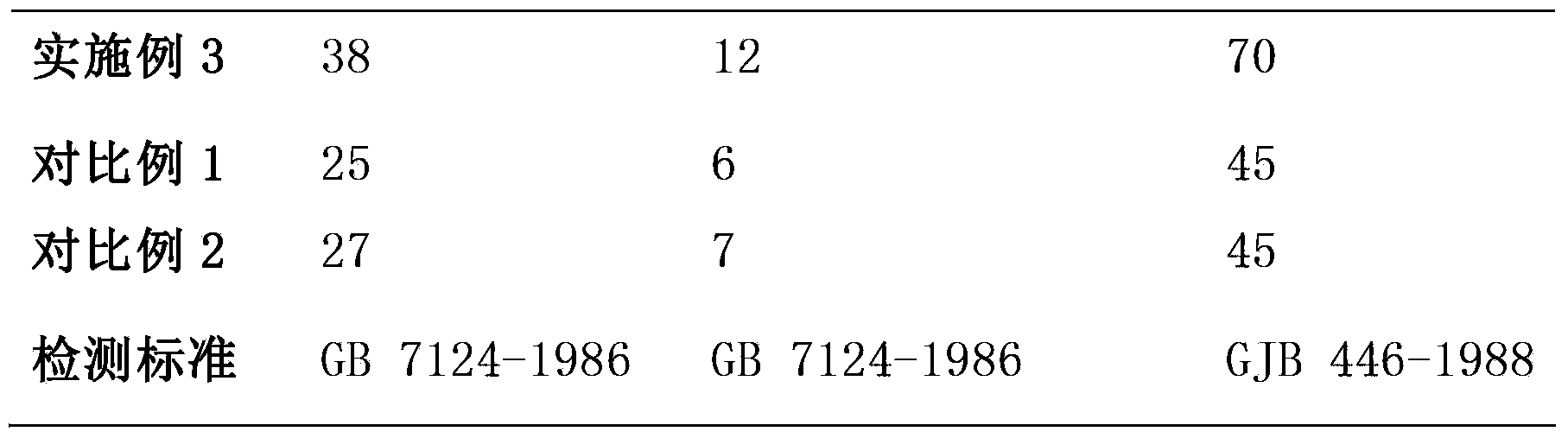

The invention discloses a pressure-sensitive adhesive for PET (Polyester) adhesive tapes and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing 10-20% butyl acrylate, 15-30% of ethyl hexyl acrylate, 0.5-2% of acrylic acid, 2-5% methyl methacrylate, 2-5% vinyl acetate, 0.5-2% methacrylate-2-hydroxyethyl ester, 20-30% toluene and 20-30% ethyl acetate; heating to 80-85 DEG C in a reaction kettle, and then adding benzoyl peroxide 1-3 times in a heat holding process, wherein the heat holding time is 2-10h; and finally, adding tackifying resin as required on adhesiveness. In the invention, the prepared pressure-sensitive adhesive has high stripping resistance between 1000g and 2000g, and has no adhesive remained to pollute an adhered object in a tearing process.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Aqueous laminating adhesive for gold and silver cards and preparation method thereof

InactiveCN102229789AImprove initial tack performanceHigh bonding strengthEster polymer adhesivesHydrocarbon polymer adhesivesIsooctyl acrylateFunctional monomer

Belonging to the field of aqueous binder preparation, the invention discloses an aqueous laminating adhesive for gold and silver cards and a preparation method thereof. With a solid content of 45-55%, the laminating adhesive is an aqueous laminating adhesive employing monomers, an emulsifier, an initiator, a buffering agent, a pH conditioning agent, aqueous auxiliary agents and deionized water asthe raw materials, which undergo the steps of pre-emulsification, seed reaction, polymerization and complex formulation. Wherein, the monomers include hard monomers, soft monomers and functional monomers containing -COOH and -OH groups; the hard monomers consist of methyl methacrylate and styrene; the soft monomers consist of butyl acrylate monomer and enthyl hexyl acrylate; the functional monomers containing -COOH and -OH groups are composed of any of methacrylic acid and acrylic acid, any of hydroxyethyl acrylate and hydroxypropyl acrylate, and ethylene glycol diacrylate; the emulsifier is composed of alkyl ether ammonium sulfate and KD AHPS with a ratio of 1:0.4-0.8 by weight.

Owner:BEIJING COMENS YANSHAN TECH

Fur-imitating static flocking binder and preparation method thereof

ActiveCN102220099AGood flexibilityImprove cold resistanceEster polymer adhesivesIsooctyl acrylateAcrylonitrile

The invention relates to a fur-imitating static flocking binder and a preparation method thereof; and the fur-imitating static flocking binder is prepared by the following raw materials: lauryl alcohol polyoxyethylene (40) ether, lauryl sodium sulfate, butyl acrylate, ethylene glycol dimethacrylate, N-hydroxymethyl acrylamide, ethyl hexyl acrylate, acrylonitrile, acrylic acid, ammonium persulfate and deionized water, which are made into polymer emulsion through seed emulsion polymerization. The fur-imitating static flocking binder has remarkable advantages of cold resistance, wear resistance, drapability and wrinkle resistance and other indexes, thus greatly improving the quality of the fur-imitating static flocking product.

Owner:LIAONING FIXED STAR FINE CHEM

Method for preparing hard polyvinyl chloride plastic toughening and reinforcing agent

InactiveCN101705022AFully coveredImprove stabilityPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsIsooctyl acrylatePolyvinyl chloride

The invention discloses a method for preparing a hard polyvinyl chloride plastic toughening and reinforcing agent. The method mainly comprises the following steps: (1) preparation and ultrasonic auxiliary dispersion for inorganic powder slurry, namely mixing inorganic mineral powder calcium carbonate (or calcium sulfate, talc powder, mica powder or kaolin) and ethylene glycol methyl ether solvent, and heating, stirring and ultrasonically dispersing the mixed slurry to obtain powder slurry; (2) coupling modification for inorganic mineral powder, wherein a silane coupling agent adopted by the coupling modification is one of vinyl triethoxy silane and vinyl trimethoxy silane; (3) multilayer modification for organic monomers of the inorganic mineral powder, wherein a soft organic monomer adopted by the inorganic mineral powder modification is one of ethyl acrylate, butyl acrylate and ethyl hexyl acrylate; and a hard organic monomer is one of styrene, methyl methacrylate and vinyl acetate, acrylonitrile and acrylic amide; and (4) post treatment for the modified powder. The method is suitable for preparing the hard polyvinyl chloride plastic toughening and reinforcing agent.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Water-based coating and preparation method thereof

ActiveCN101942256AReduce pollutionPollution meetsAnti-corrosive paintsPotassium persulfateSodium acetate

The invention relates to a water-based coating. The water-based coating is prepared form the following raw materials in percentage by weight: 52 to 55 percent of water, 0.5 to 0.7 percent of sodium dodecyl sulfate, 20 to 25 percent of methyl methacrylate, 3 to 4.5 percent of butyl acrylate, 0 to 2 percent of ethyl hexyl acrylate, 1 to 1.5 percent of acrylic acid, 10 to 15 percent of butyl methacrylate, 1 to 2 percent of butyl maleate, 0.6 to 1 percent of ethyl acrylate, 0.4 to 1 percent of itaconic acid, 0.8 to 1 percent of ammonia water, 0.1 to 0.2 percent of antifoaming agent, 0.05 to 0.1 percent of sodium acetate, 0.1 to 0.2 percent of preservative and 0.1 to 0.2 percent of potassium persulfate. The invention also provides a method for preparing the water-based coating. The water-based coating of the invention is innoxious and has a small amount of environmental pollution; and a coating layer formed by coating has the advantages of high brightness, toughness, excellent anti-explosion performance, excellent subsequent processing performance, capability of stamping gold rapidly and efficiently and good gold stamping effect.

Owner:SHANTOU XINYUAN CHEM TECH CO LTD

UV moisture dual-curing type acrylate pressure-sensitive adhesive and preparation method thereof

ActiveCN104974709AImprove removal effectImprove aging resistancePolyureas/polyurethane adhesivesGraft polymer adhesivesEpoxyCarbamate

The invention provides a UV moisture dual-curing type acrylate pressure-sensitive adhesive and a preparation method thereof. The adhesive is prepared by mixing and polymerizing the following components step by step: a (methyl) butyl acrylate monomer and / or a (methyl) ethyl acrylate monomer, a (methyl) acrylic 2-hexyl acetate monomer, a (methyl) methyl acrylate monomer, an N-methylol acrylamide monomer and / or an N-methylol methyl acrylamide monomer, carbamate acrylate, a polyamide type thermoplastic elastomer, rosin resin, epoxy modified polyurethane copolymer and a photoinitiator. The pressure-sensitive adhesive provided by the invention can be particularly suitable for a process for adhering TP to a shell bracket in portable electronic equipment.

Owner:深圳沃尔提莫电子材料有限公司

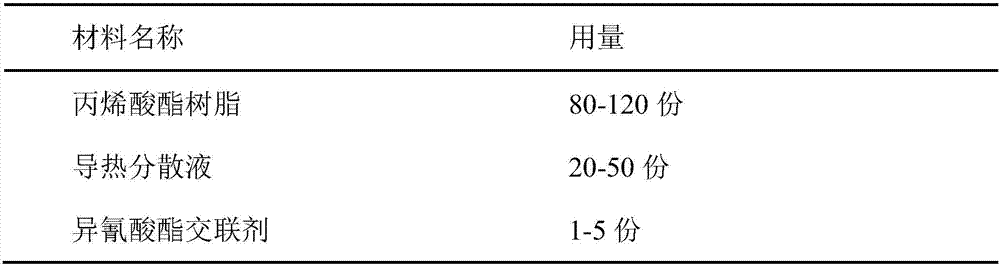

Thermal conductive adhesive and substrate-free high-thermal-conductivity double-faced adhesive tape made of thermal conductive adhesive

InactiveCN107880822AIncrease stickinessHigh peel strengthNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPolymer scienceArray data structure

The invention relates to the technical field of adhesives, in particular to a thermal conductive adhesive and a substrate-free high-thermal-conductivity double-faced adhesive tape made of the thermalconductive adhesive. The thermal conductive adhesive is prepared from the following component raw materials in parts by weight: 80 to 120 parts of acrylate resin, 20 to 50 parts of thermal conductivedispersion liquid, and 1 to 5 parts of isocyanate crosslinking agent, wherein the acrylate resin is prepared from an acrylate monomer, an initiator, a solvent, rosin pentaerythritol ester and rosin sorbitol ester; the acrylate monomer is prepared from butyl acrylate, diethyl hexyl acrylate, hydroxyethyl acrylate, methyl methacrylate and acrylic acid phosphate; the solvent is ethyl acetate; the initiator is azodiisobutyronitrile or dicumyl peroxide. The substrate-free high-thermal-conductivity double-faced adhesive tape comprises the thermal conductive adhesive and a first release liner and a second release liner respectively arranged on two faces of the thermal conductive adhesive. After a thermal conductive filler is added, the thermal conductive adhesive provided by the invention is highin viscidity and firm to adhere at high temperature, and has a higher thermal conductivity coefficient under the condition of adding the same proportion of thermal conductive filler.

Owner:DONGGUAN TARRY ELECTRONICS

Pilling resistant agent emulsion for wool fabrics and preparation method thereof

InactiveCN103044627AGood anti-pillingNo emissionsAnimal fibresPolymer scienceEmulsion polymerization

The invention discloses pilling resistant agent emulsion for wool fabrics and a preparation method thereof. The emulsion comprises the following raw materials in percentage by weight: 2-8 percent of ethyl hexyl acrylate monomer, 6-16 percent of butyl acrylate monomer, 2-8percent of hydroxyl ester acrylate monomer, 0.1-1.5 percent of anionic surfactant, 0.1-1.5 percent of non-ionic emulsifier, 0.01-0.1 percent of initiator, 0.8-5 percent of siloxane monomer, 5-15 percent of vinyl-contained silane coupling agent, 0.1-1 percent of silane hydrolysis inhibitor and 50-70 percent of de-ionized water; and the emulsion is prepared by adopting the semi-continuous seed emulsion polymerization technique. The pilling resistant agent emulsion has the characteristics of small particle size, low emulsion dosage, easy control of reaction process, no environmental pollution and the like. The pilling resistant grade of the wool fabrics which are treated by the pilling resistant agent emulsion is improved by more than 2 grades; the hydrophily is basically not changed; and the original hand feel and style of the fabrics are little influenced.

Owner:SUZHOU UNIV +1

Weather resistant, impact resistant and economical PVC promoter

The invention relates to a PVC auxiliary agent with good weathering resistance, shock resistance and economical efficiency, which is characterized in that: the PVC auxiliary agent is a copolymer with a nuclear shell structure, wherein, a nuclear layer of the PVC auxiliary agent is formed by emulsion polymerization of butyl acrylate, chlorinated polyethylene and 2-ethyl hexyl acrylate under the protection of a surfactant and nitrogen and through initiation of an initiator, and a core shell is formed by continuous emulsion polymerization and grafting reaction of methyl methacrylate on the nuclear layer. By adoption of the total weight of a monomer polymer as 100 percent, the butyl acrylate occupies 30 to 40 percent; the chlorinated polyethylene occupies 30 to 40 percent; the 2-ethyl hexyl acrylate occupies 15 to 35 percent; and the methyl methacrylate occupies 5 to 20 percent. The PVC auxiliary agent has superior shock resistance and weathering resistance and simultaneously has superior powder fluidity, and the shock resistance of the PVC auxiliary agent is higher than that of MBS and acrylic ester shock modifiers which are widely applied in the industry.

Owner:SHANDONG RUIFENG CHEM

Aqueous binder emulsion for pre-coating and thermally laminating PET film and preparation method thereof

ActiveCN103936916AParticle size andSmall particle sizeFilm/foil adhesivesEster polymer adhesivesPolyesterSurface-active agents

The invention provides an aqueous binder emulsion for pre-coating and thermally laminating a PET film for a crystal album, and a preparation method of the aqueous binder emulsion. The aqueous binder emulsion is characterized in that seed emulsion containing styrene (St), methyl methacrylate (MMA) and ethyl acrylate (EA) of which the hydrophily is mild and the number-average diameter is less than 50nm is adopted; styrene (St), butyl acrylate (BA), acrylic acid (AA), hydroxyethyl acrylate (HEA), and 2-ethyl hexyl acrylate (EHA) are copolymerized with crosslinking monomer, namely, diacetone-acryloamide or vinyl urea monomer in the presence of proper amount of emulsifying agent and multifunctional additive or surface active agent, so as to obtain the aqueous binder emulsion. The binder is transferred and coated on the PET polyester film, and then dried through a drying channel and combined with a PE film, and finally a user removes the PE film and laminates the PET film with the hot pre-coating binder to a photo album.

Owner:ANHUI DEPU POLYMER MATERIAL

Metal paint and preparation method thereof

InactiveCN102993791AHigh hardnessScratch resistantCoatingsPigment treatment with organosilicon compoundsGlycidyl methacrylateMeth-

The invention discloses a metal paint, which is prepared from the following raw materials in parts by weight: 180 to 190 parts of dodecenylsuccinic acid, 130 to 135 parts of propylene glycol, 210 to 215 parts of glycidyl methacrylate, 360 to 365 parts of 2-ethyl hexyl acrylate, 430 to 435 parts of methylpropanediol, 105 to 108 parts of phenolic resin, 85 to 90 parts of styrene, 100 to 110 parts of ethylenediamine, 300 to 310 parts of titanium dioxide, 20 to 30 parts of modified diatomite, 7 to 8 parts of formic acid, 100 to 105 parts of water, and 14 to 16 parts of sodium hydroxyethyl sulfonate. The raw materials are mixed, dispersed at a high speed, and grinded into nano-grade metal paint. The coating formed by the metal paint has the advantages of high hardness, scratch prevention, strong attachment, salt mist resistance, saline water resistance, acid and alkali resistance, water and oil resistance, recycling on oil paint film surface, paint film hurt prevention, super-strong paint film flexibility and the like. The service life of a conventional paint film can be between 5 and 8 years.

Owner:怀远县巨龙机械制造有限公司

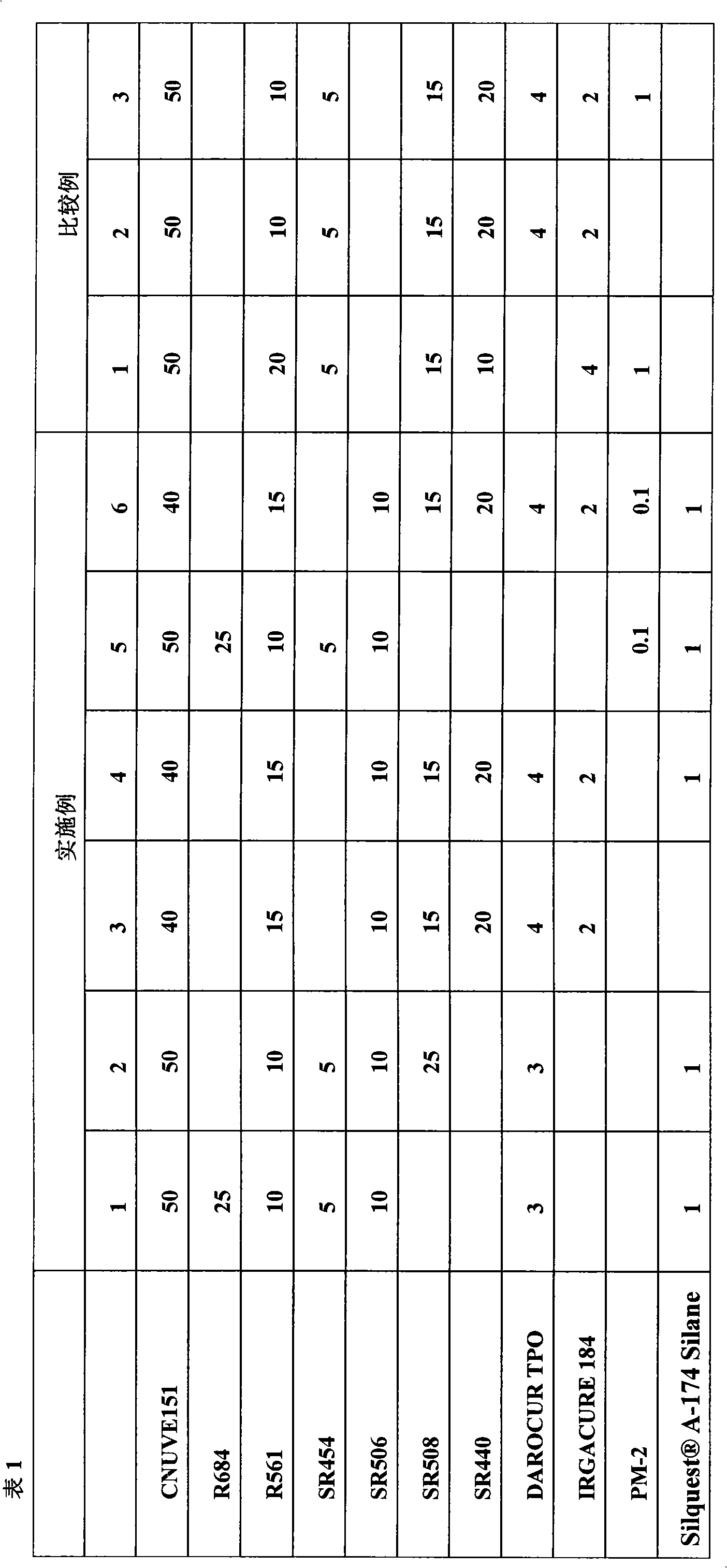

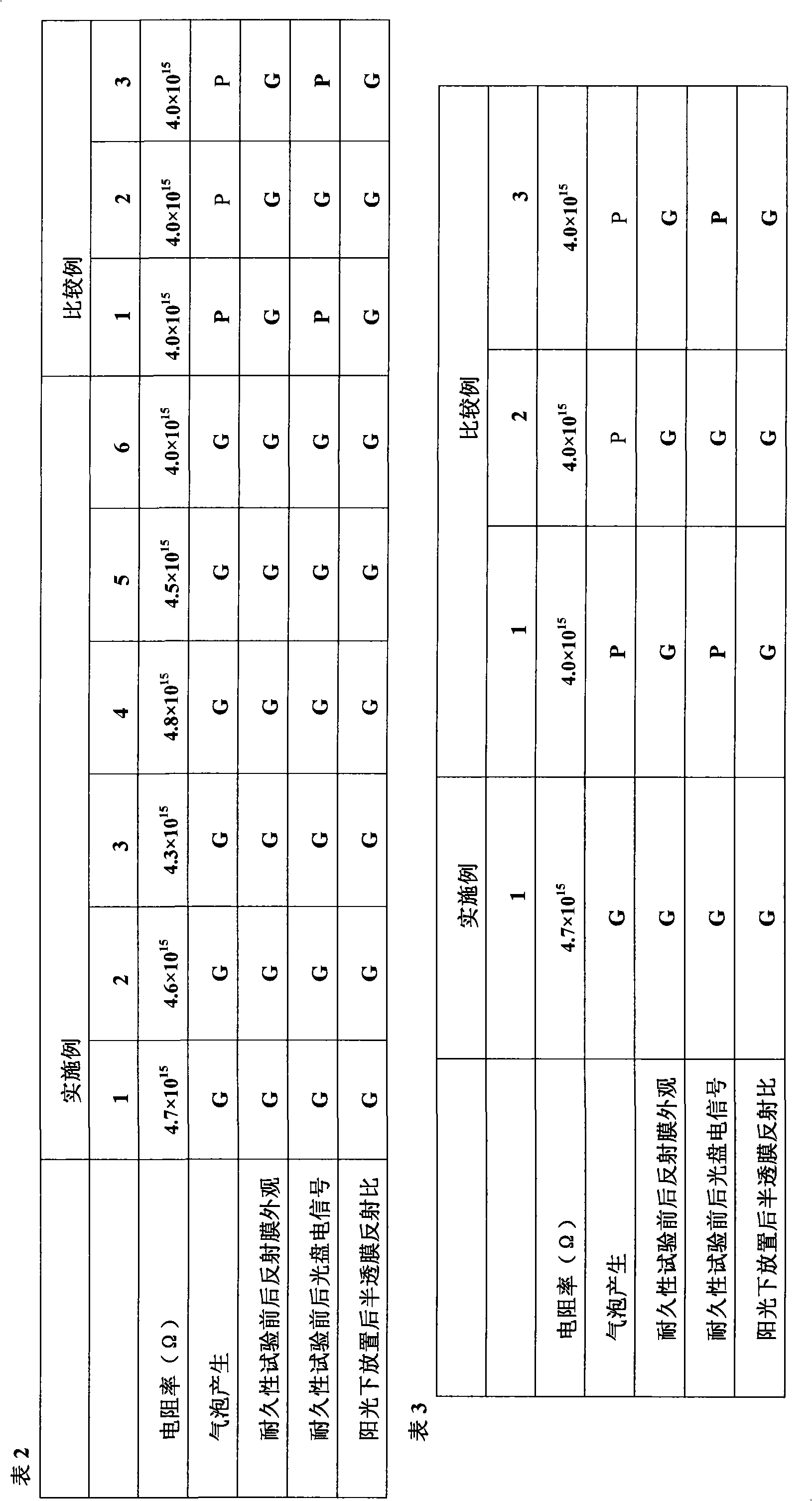

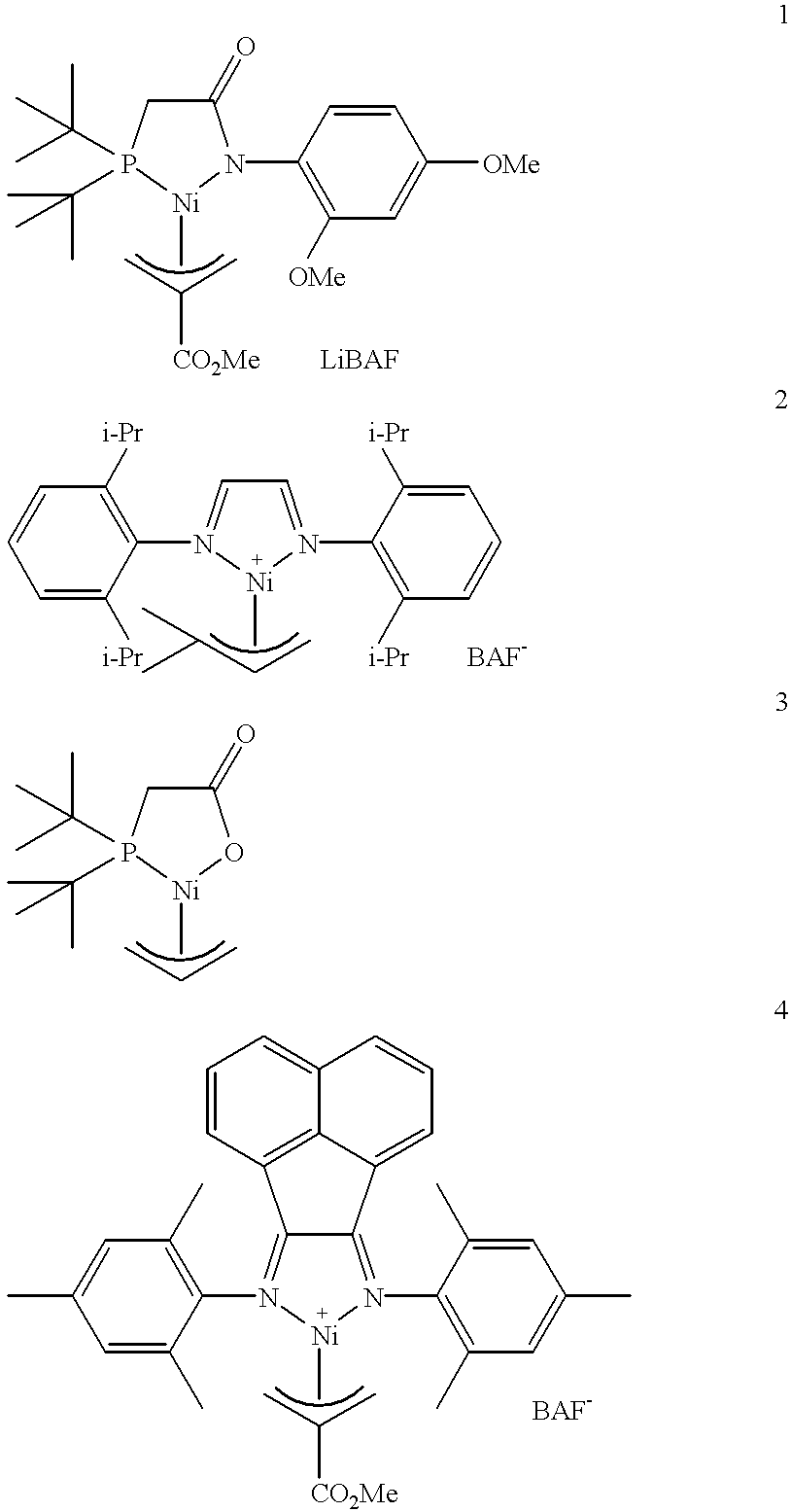

UV-curable adhesive composition for compact discs

InactiveCN101857776AExcellent heat and humidity resistanceImprove aging resistanceRecord information storageOrganic non-macromolecular adhesiveIsooctyl acrylateDipropylene glycol diacrylate

The invention provides a UV-curable adhesive composition for compact discs, which consists of bisphenol epoxy acrylate (A), acrylate compound (B) and photopolymerization initiator (C), wherein the acrylate compound (B) consists of iso-Bornyl acryl (B-1) and at least one of the following acrylate compounds: phenoxyethyl acrylate (B-2), tricyclodecane dihydroxymethyl diacrylate (B-3), ethoxylated trihydroxymethyl tricrylate (B-4), dipropylene glycol diacrylate (B-5) and enthyl hexyl acrylate (B-6). The composition can be utilized to bond two compact disc substrates together to produce a bonded compact disc.

Owner:上海拓引数码技术有限公司

Water-soluble acrylic-modified epoxy organic silicon resin and preparation method and application

The invention discloses water-soluble acrylic-modified epoxy organic silicon resin and a preparation method and application. The water-soluble acrylic-modified epoxy organic silicon resin is prepared from the following components in parts by weight: methyl methacrylate, butyl acrylate, ethyl hexyl acrylate, hydroxypropyl acrylate, methacrylic acid, acrylic acid, silanoxide, benzoyl peroxide, fumed silica, epoxy resin, an initiator, propylene glycol monomethyl ether, an ether solvent and a neutralizer. The water-soluble acrylic-modified epoxy organic silicon resin and water can be mixed and dissolved at any ratio, so that the water-soluble acrylic-modified epoxy organic silicon resin is green, clean and free of pollution, meanwhile, the production cost is greatly reduced, and a water-based coating prepared from the resin is stable in storage and also has excellent brightness, hardness and adhesive force.

Owner:佛山市顺德区地缘电子科技有限公司

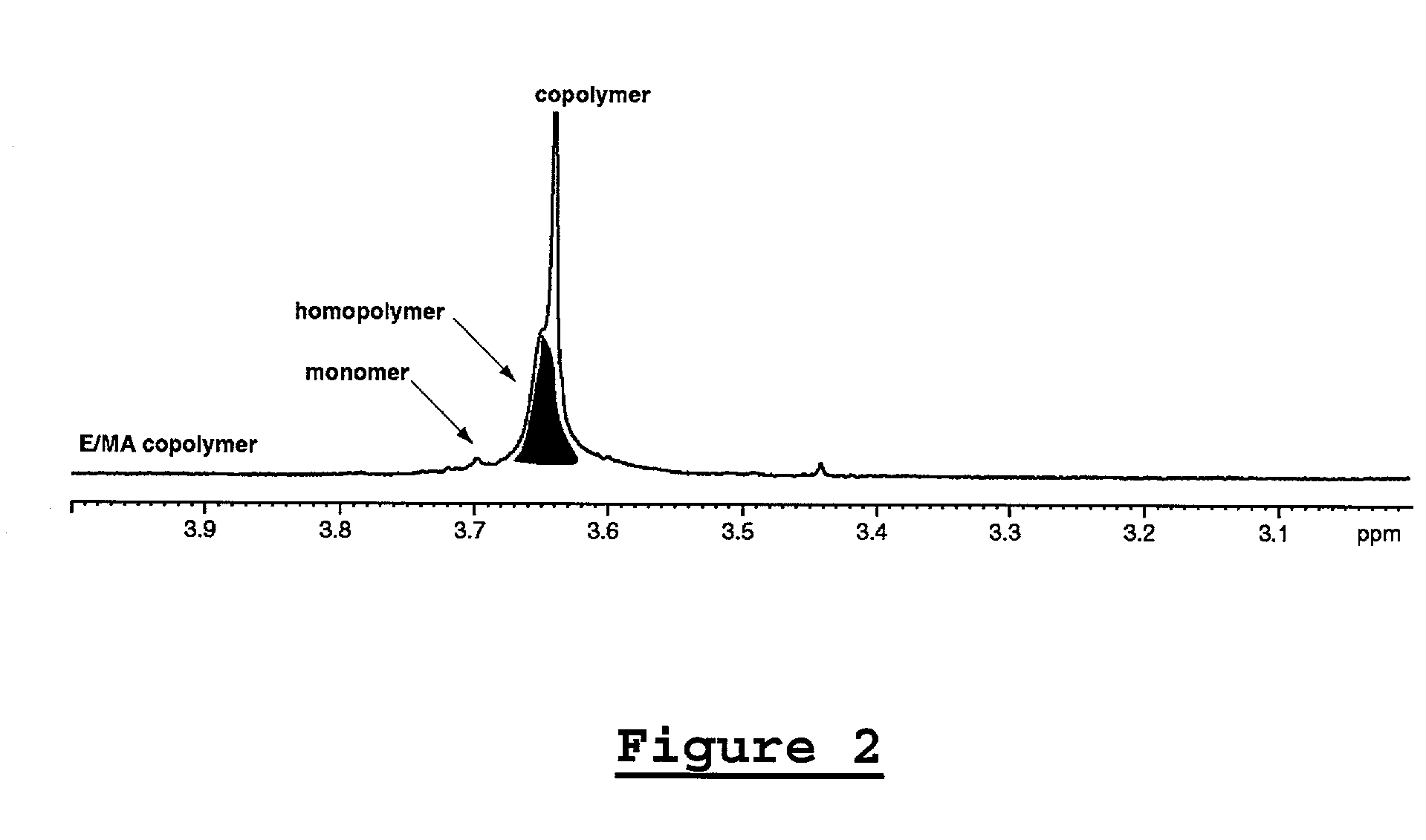

Copolymers of ethylene and selected acrylate esters

InactiveUS20020028897A1Group 4/14 element organic compoundsGroup 5/15 element organic compoundsEthylene HomopolymersHexyl acrylate

In the copolymerization of ethylene and acrylate esters, the use of selected acrylate esters suppresses the formation of acrylate ester homopolymer, and / or allows the rapid analysis by 1H-NMR of the amount of homopolymer byproduct present in the copolymer, both aids in manufacturing high quality copolymers. Useful such acrylates include hexyl acrylate, 3,5,5-trimethylhexyl acrylate, 2-phenoxyethyl acrylate and 2-phenylethyl acrylate. The polymers are useful for films and molding resins.

Owner:EI DU PONT DE NEMOURS & CO

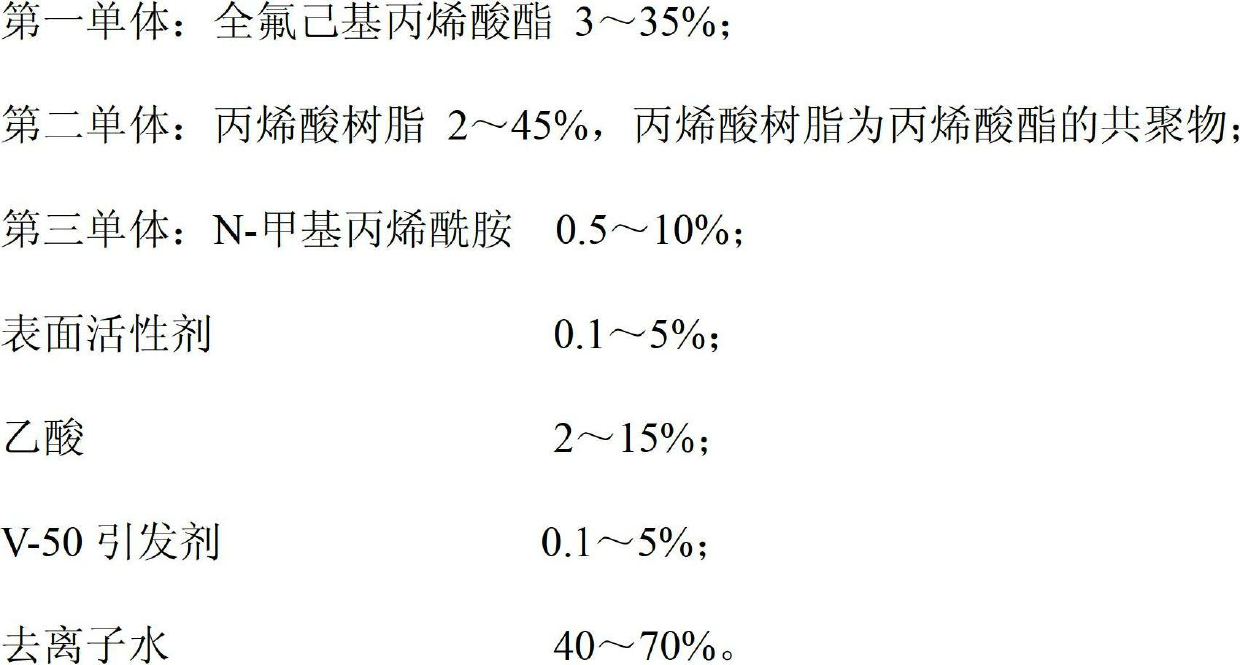

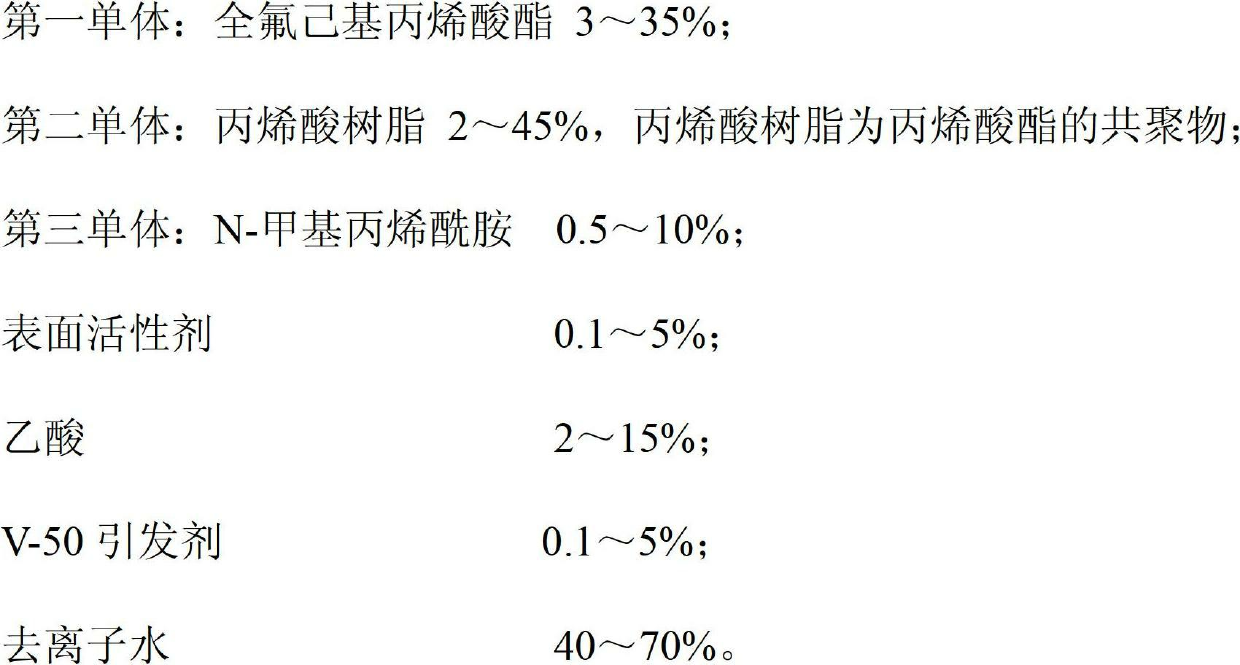

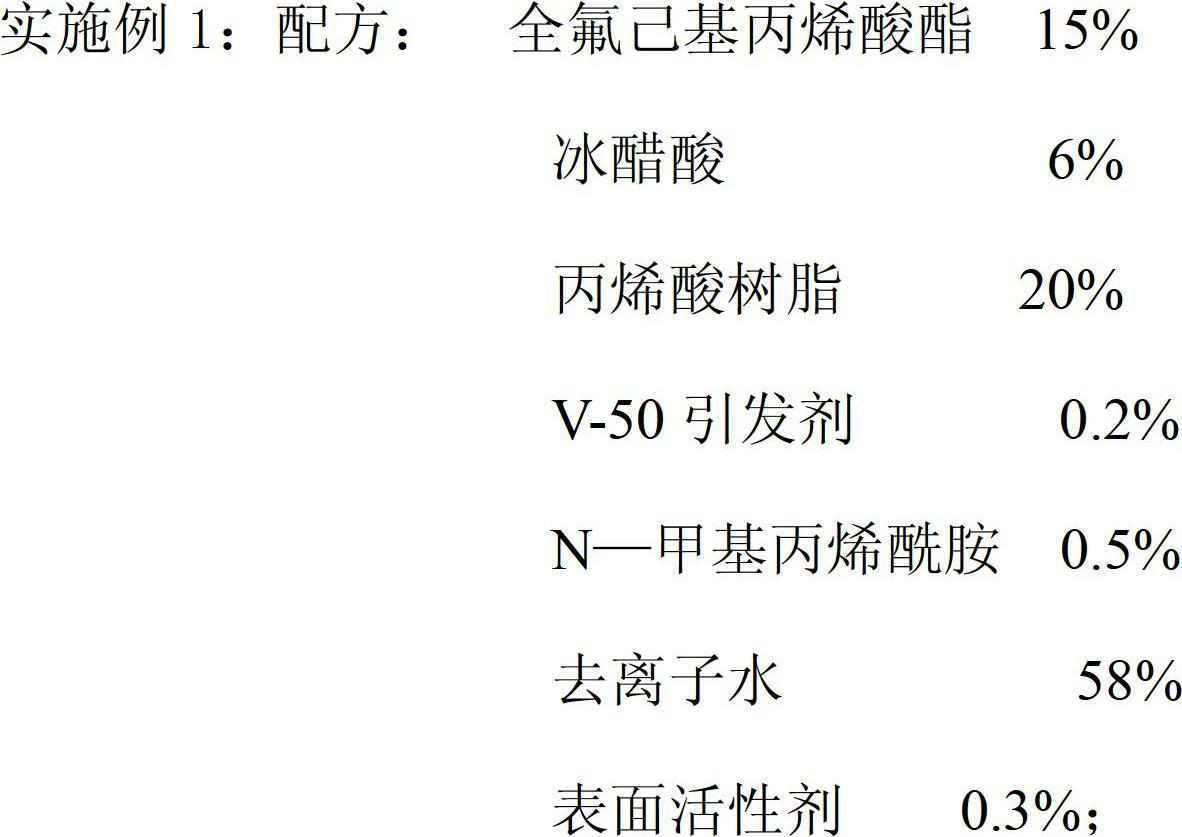

Ultramicron three-proofing finishing agent and preparation method thereof

The invention discloses an ultramicron three-proofing finishing agent and a preparation method thereof. The ultramicron three-proofing finishing agent is prepared in a way that 3 to 35 percent of perfluor hexyl acrylate, 2 to 45 percent of acrylate copolymer, 0.5 to 10 percent of N-methyl acrylamide, 0.1 to 5 percent of surfactant, 0.1 to 5 percent of V-50 initiating agent, 2 to 15 percent of acetic acid, 40 to 70 percent deionized water are selected as raw materials and are combined; and a blend range with better comprehensive performance and lower cost is provided so as to give full play to all the components. Through effective selection and proportional combination of the components, the three-proofing finishing agent provided by the invention is enabled to have the advantages of innocuity, harmlessness, good wash fastness, excellent air permeability, environmental friendliness, simple process, low cost and the like and perfectly meet market demands.

Owner:王峥轲 +1

Medium and high viscosity emulsion type acrylic ester pressure-sensitive adhesive used for protective films, preparation method and application thereof

ActiveCN108285508ANo pollution in the processNo special smellEster polymer adhesivesPressure sensitive film/foil adhesivesTectorial membranePolymer science

The invention relates to a medium and high viscosity emulsion type acrylic ester pressure-sensitive adhesive used for protective films, a preparation method and application thereof. According to the scheme provided by the invention, a polyacrylic ester emulsion synthesized by adopting a pre-emulsification semi-continuous polymerization process is adopted by using acrylic acid-2-ethyl hexyl acrylate, butyl acrylate, butyl methacrylate, methyl acrylate, vinyl acetate, 2-hydroxypropyl acrylate, 2-hydroxyethyl acrylate, acrylic acid, an inner cross-linking agent, a latent curing agent and a chaintransferring agent. The obtained emulsion type acrylic ester pressure-sensitive adhesive is relatively high in solid content, few in gel, high in stability, high in peel strength and high in originaladhesion, has excellent damp-heat aging resistance, is a single-component adhesive, can be directly used, and can be prepared into various materials of protective films such as pitted fluorocarbon profiles, aluminum-plastic composite panels and plastic profile protective films.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

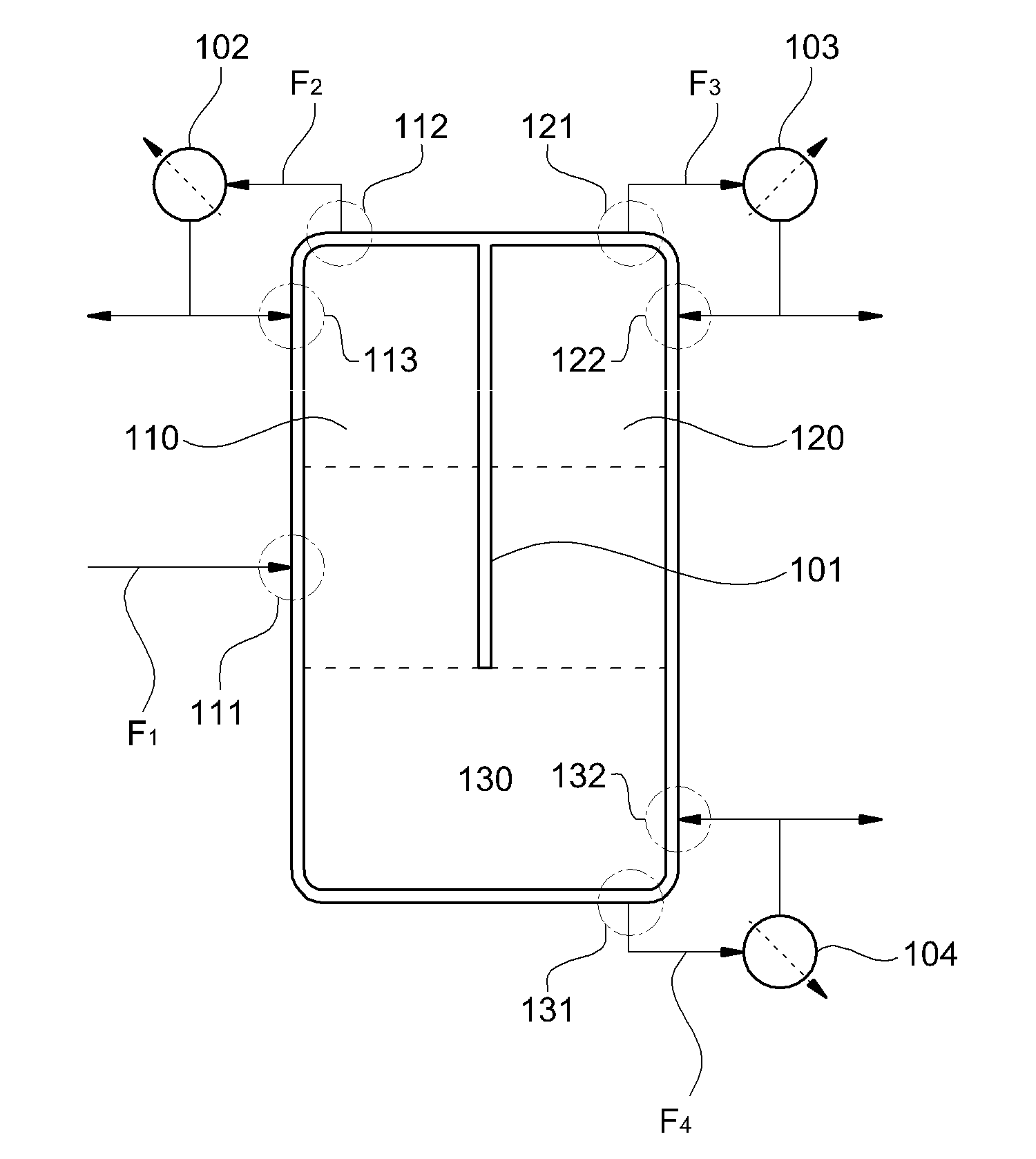

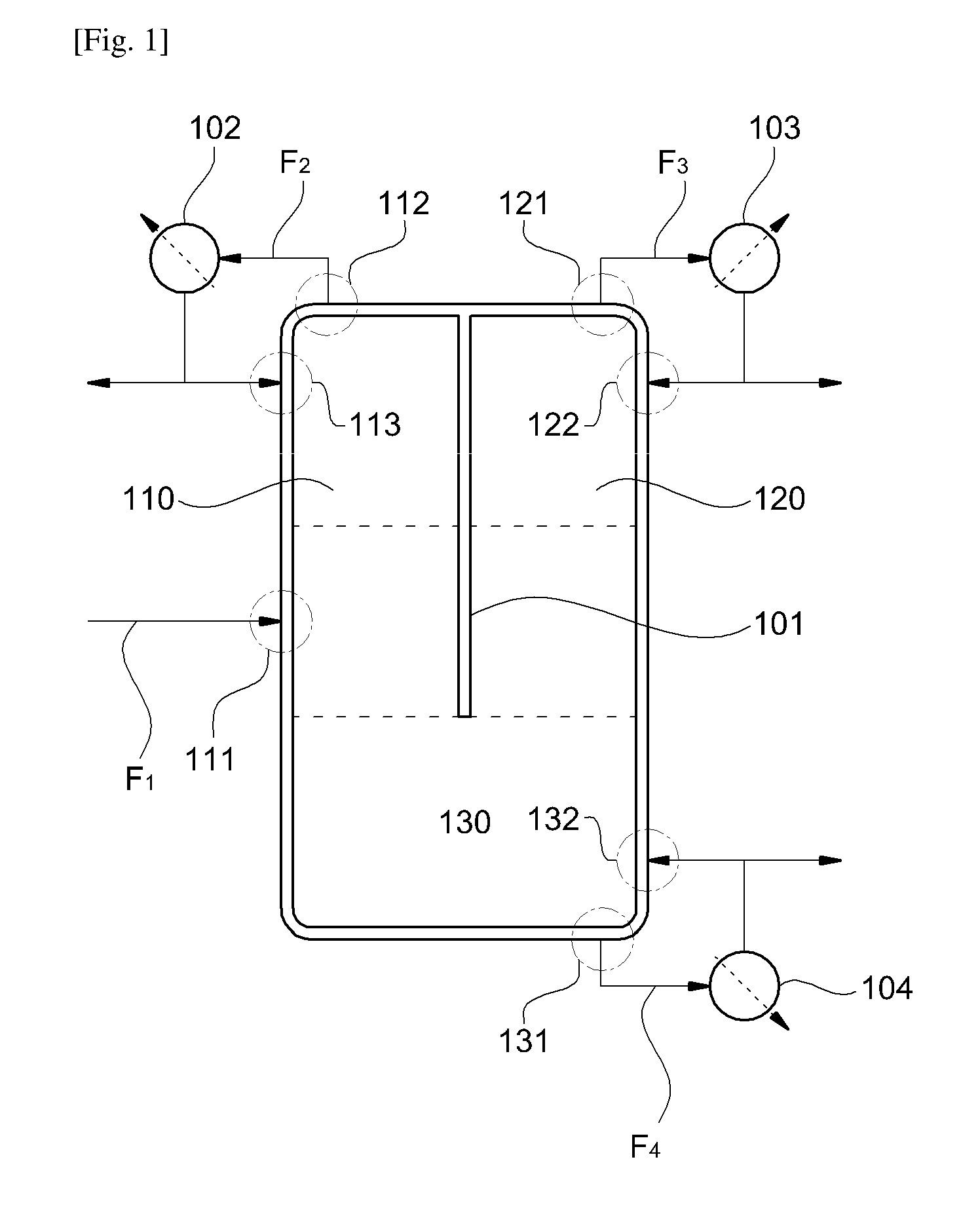

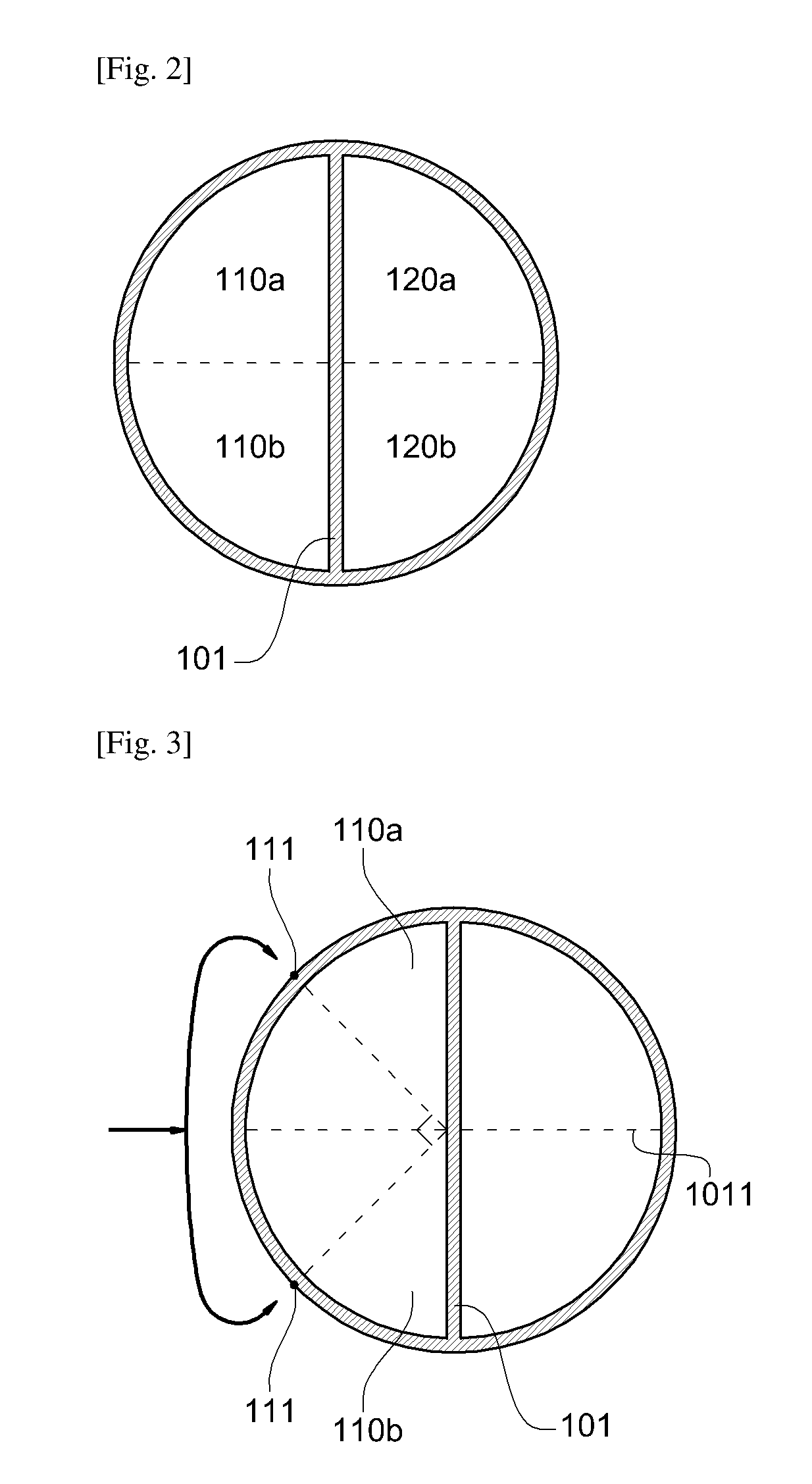

DIVIDED WALL DISTILLATION COLUMN (As Amended)

ActiveUS20160193540A1High purityReduce processEther separation/purificationOrganic compound preparationDistillationEnergy reduction

Owner:LG CHEM LTD

Self-dry water-soluble acrylic organic silicon resin and preparation method thereof and application

The invention discloses a self-dry water-soluble acrylic organic silicon resin and a preparation method thereof and an application. The self-dry water-soluble acrylic organic silicon resin comprises, by weight, 20-30 parts of methyl methacrylate, 35-45 parts of butyl acrylate, 5-10 parts of ethyl hexyl acrylate, 3-7 parts of hydroxypropyl acrylate, 6-10 parts of methacrylic acid, 2-5 parts of acrylic acid, 5-40 parts of silicone oil, 1-4 parts of silanoxide, 5-7 parts of benzoyl peroxide, 4-7 parts of isopropyl alcohol, 25-35 parts of propylene glycol monomethyl ether, 10-20 parts of ether solvents and 7-9 parts of neutralizers. The self-dry water-soluble acrylic organic silicon resin reaches water solubility by adjusting monomers and improving processes, the organic silicon resin and tap water can be infinitely mixed and dissolved, the organic silicon resin has the advantages of high brightness and hardness, impact resistance, bending resistance, boiling resistance, salt-fog resistance and the like, the brightness of the resin is larger than 90, the hardness of the resin is larger than 5H, the use cost of the resin is reduced by 60% as compared with oil paint, and the resin is safe and environmentally friendly and saves energy.

Owner:佛山市顺德区地缘电子科技有限公司

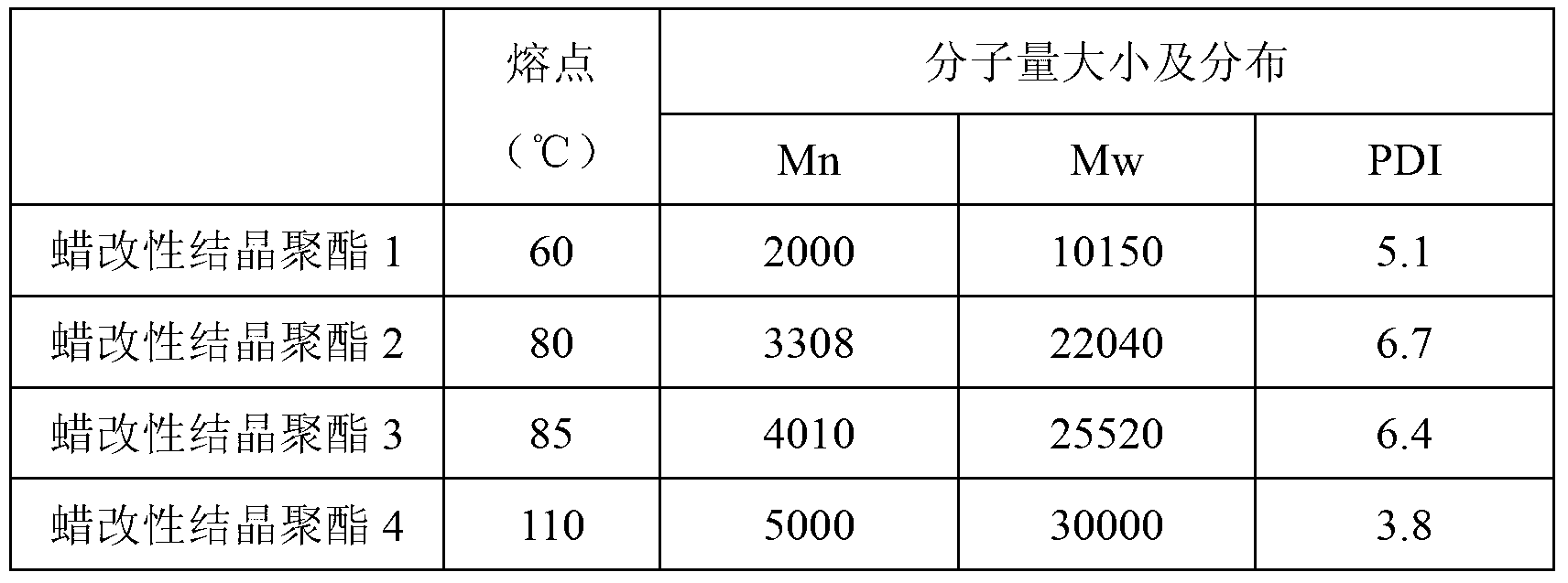

Adhesive composition for ink powder and preparation method of adhesive composition

The invention discloses an adhesive composition for ink powder for printers and copying machines. The composition is prepared from 85-99% by mass of mixed liquid and 1-15% by mass of wax-modified crystalline polyester, wherein the mixed liquid is mainly prepared from styrene, butyl methacrylate, crylic acid hexyl, crylic acid and ethylene glycol monomers. The invention further discloses a preparation method of the adhesive composition for the ink powder for the printers and the copying machines. The adhesive composition disclosed by the invention is added into the ink powder applied to electromagnetic induction heating devices, so that the ink powder has excellent low-temperature fixation property, high-temperature anti-excursion property and storability.

Owner:天津市合成材料工业研究所有限公司

Thermally stable plastic filler and preparation method thereof

InactiveCN104194065AImprove thermal stabilityHigh strengthPolyethylene glycolPotassium peroxodisulfate

The invention provides a thermally stable plastic filler. The thermally stable plastic filler is prepared from the following raw materials in parts by weight: 1-2 parts of xanthan gum, 2-3 parts of acrylic acid, 1-2 parts of ethyl hexyl acrylate, 0.1-0.2 part of potassium peroxodisulfate, 1-2 parts of sodium hypophosphite, 2-3 parts of sodium citrate, 1-2 parts of polyethylene glycol octylphenol ether, 2-3 parts of methyl tin mercaptide, 4-5 parts of nano sepiolite powder, 100-120 parts of attapulgite clay, an appropriate amount of water, 5-10 parts of auxiliaries and 30-40 parts of 8-10% hydrochloric acid solution. The thermally stable plastic filler is added with the attapulgite clay and activated and modified, so that the thermal stable plastic filler is improved in suspension property, thickening property and compatibility with plastics; as the thermally stable plastic filler is added with the methyl tin mercaptide, the thermal stability of the plastics (in particular PVC) can be improved; furthermore, due to the added nano sepiolite powder, the strength and tenacity of the plastics are enhanced.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

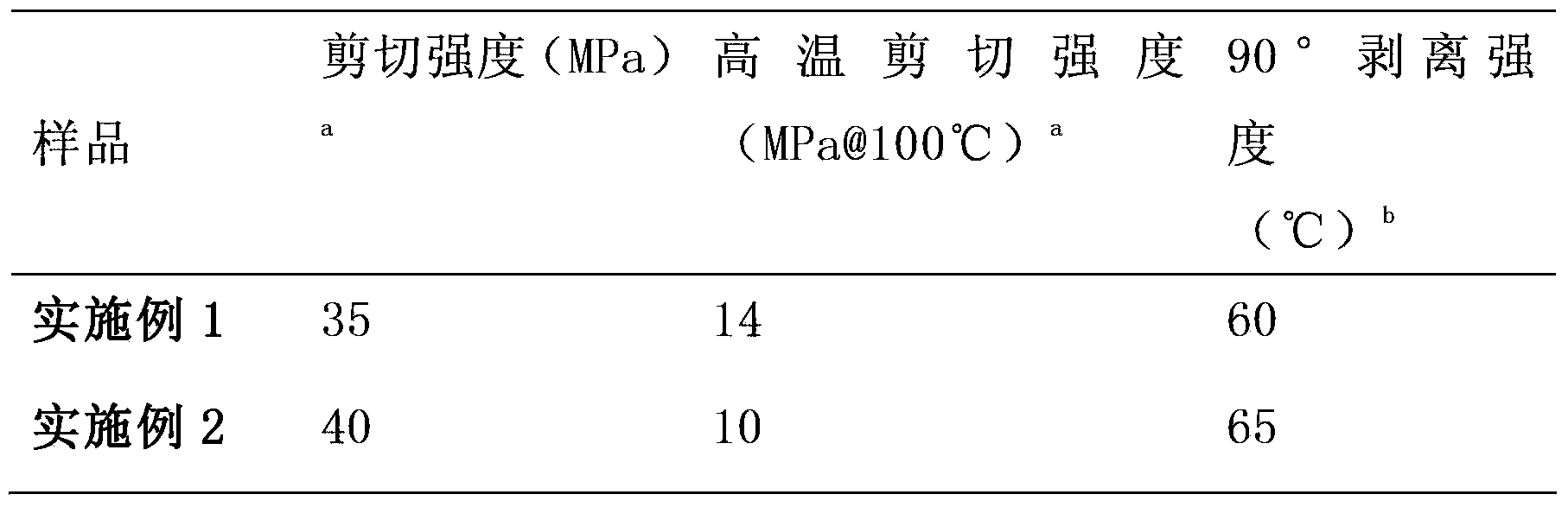

Epoxy glue membrane

The invention discloses an epoxy glue membrane. The epoxy glue membrane is obtained by pressing 35-75wt% of an epoxy resin, 20-60wt% of a flexibilizer, 3-10wt% of a curing agent, 0.5-3wt% of a coupling agent, 0.5-3wt% of a rheological auxiliary agent and 1-3wt% of a promoter. A preparation method of the flexibilizer comprises the following step that 73-78.3 parts of the epoxy resin 618, 1-1.44 parts of methacrylic acid and 0.6-0.9 parts of triphenyl phosphine are mixed in a reactor; the mixture undergoes a reaction at a rotation rate of 300-500r / min at a temperature of 110-130 DEG C for 1.5-3h; 18-20 parts of ethyl hexyl acrylate and 0.64-1 part of azodiisobutyronitrile are dropwisely added into the reaction products with stirring at a rotation rate of 200-300r / min; the mixture undergoes a reaction at a temperature of 120-140 DEG C at a rotation rate of 300-500r / min for 20-45min; and the products are discharged. Aiming at an aluminum material, the epoxy glue membrane has high-temperature shearing strength of 14(MPA@100 DEG C) and 90-degree peel strength of 70 (DEG C) b.

Owner:上海康达新材料科技有限公司

Pressure-sensitive adhesive used for cotton paper or non-woven fabrics and preparation method thereof

InactiveCN102101996AIncrease stickinessImprove cohesionFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention discloses a pressure-sensitive adhesive used for cotton paper or non-woven fabrics and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing 15 to 25 percent of butyl acrylate, 20 to 35 percent of ethyl hexyl acrylate, 0.2 to 4 percent of crylic acid, 0.5 to 2 percent of methyl methacrylate, 0.2 to 1.5 percent of vinyl acetate, 0.1 to 1 percent of 2-hydroxyethyl methacrylate and 40 to 60 percent of ethyl acetate; heating to the temperature of between 80 and 85DEG C in a reaction kettle, and adding benzoyl peroxide by 1 to 3 times in the temperature keeping process, wherein the temperature keeping time is 2 to 10 hours; and adding tackifying resin according to viscosity requirement. The pressure-sensitive adhesive prepared by the method has large stripping force of 1,000-2,000g, and ensures that the cotton paper or the non-woven fabrics are not layered in the tearing process and adverse effect cannot occur.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Cold-mounted film for jet printing of advertisements

InactiveCN102352196AImprove anti-corrosion performanceHas erosionFilm/foil adhesivesOrganic non-macromolecular adhesiveLow-density polyethyleneLinear low-density polyethylene

The invention discloses a cold-mounted film for the jet printing of advertisements, which consists of a substrate layer and a backing adhesive layer, wherein the substrate layer is a PVC (polyvinyl chloride) film, and the backing adhesive layer consists of the following components in part by weight: 30 to 45 parts of ethylene-vinyl acetate resin, 5 to 10 parts of butyl acrylate, 5 to 10 parts of ethyl hexyl acrylate, 5 to 10 parts of methyl methacrylate, 10 to 15 parts of styrene-butadiene-styrene block copolymer, 5 to 10 parts of linear low-density polyethylene and 0.5 to 2 parts of microcrystalline wax. The cold-mounted film for the jet printing of advertisements can ensure that the image of a picture has high corrosion resistance and resists the erosion of ultraviolet rays, so that the picture can be ever new and cannot fade or become yellow, and the cold-mounted film can also add a strong stereoscopic effect and produce unexpected effects. The cold-mounted film can be widely used in aspects such as wedding pictures, oil painting production, calligraphies and paintings, outdoor posters, advertisements, various pictures, files, documents and the like.

Owner:SHANGHAI JIAHUA ADVERTISEMENT

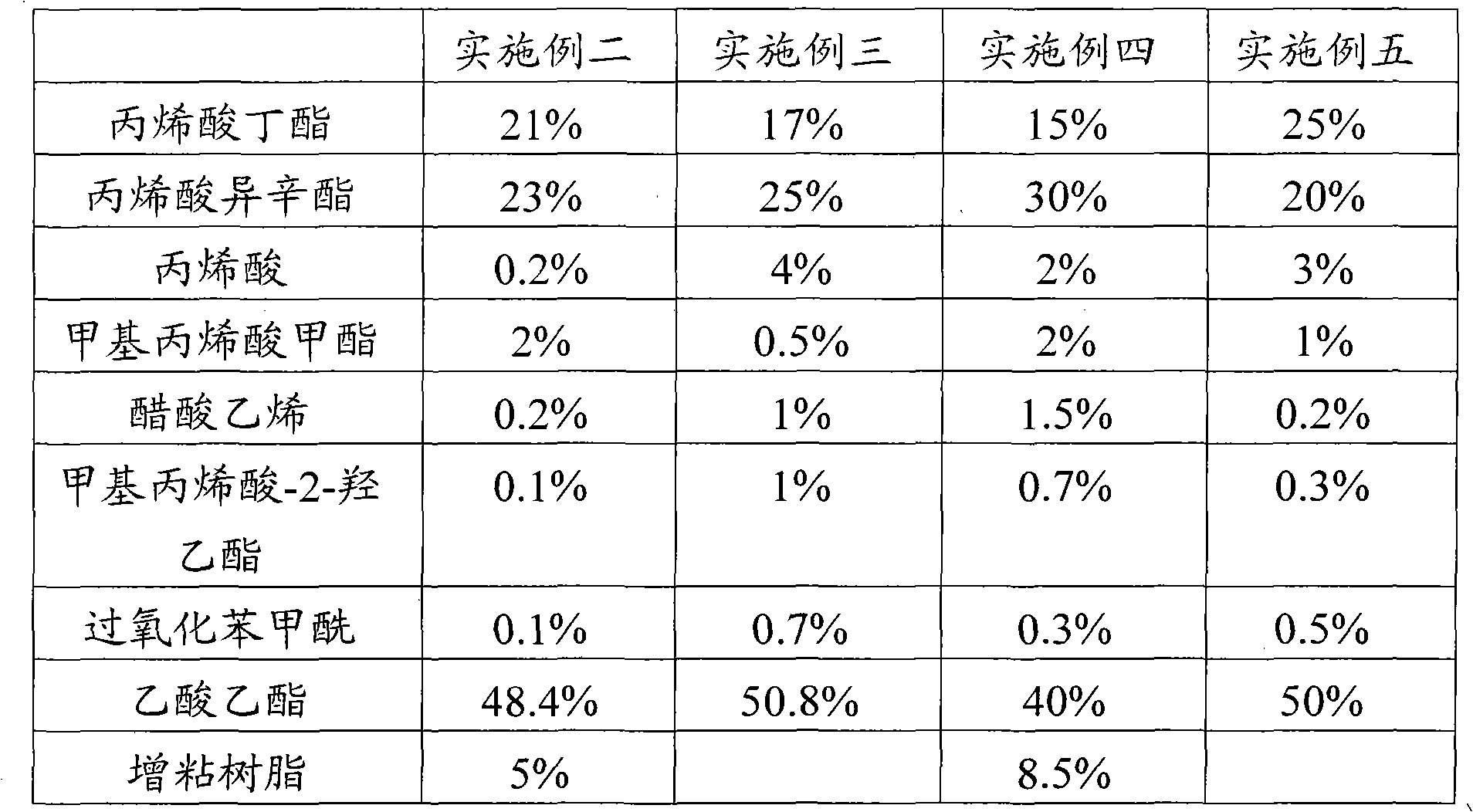

Production process of glass fiber reinforced plastic paint

The invention relates to a production process of glass fiber reinforced plastic paint, aiming at providing glass fiber reinforced plastic paint with high adhesion and a production process thereof. The technical scheme for realizing the aim of the invention is as follows: a process for preparing base stock of the glass fiber reinforced plastic paint comprises the following steps of: adding 10-15 parts by mass of epoxy resin and 10-15 parts by mass of dimethylbenzene into a reaction kettle, heating to 78-82 DEG C under the condition of stirring, stirring to be uniform, dropping 3-10 parts by mass of acrylic acid within 28-33 minutes, reacting for 2-2.5 hours, dropping a uniform mixture of 20-25 parts by mass of methyl methacrylate, 15-20 parts by mass of ethyl hexyl acrylate, 10-15 parts by mass of hydroxypropyl acrylate, 2-5 parts by mass of trimethylol propyl triacrylate, 10-15 parts by mass of styrene and 2-4 parts by mass of benzoyl peroxide into the reaction kettle within 50-60 minutes, and then reacting for 2-3 hours at the temperature of 78-82 DEG C to obtain the base stock of the glass fiber reinforced plastic paint. The production process provided by the invention is used for producing the glass fiber reinforced plastic paint.

Owner:HENAN DONGHAI COMPOUND MATERIALS

Water base type cation acrylic resin adhesive

InactiveCN1900199ASignificant positive effectImprove adhesionEster polymer adhesivesWater basedEmulsion

The present invention relates to actylic resin, and especially water base type cationic actylic resin adhesive and its preparation process. The water base type cationic actylic resin adhesive consists of water thinned cationic actylate resin in 75-90 weight portions and water thinned natural or synthetic cationic or non-ionic polymer solution. The cationic emulsifier is polynary copolymer emulsion including N, N'-dimethyl amino ethyl acrylate, butyl acrylate, styrene, 2-ethyl hexyl acrylate, etc. Compared with available technology, the present invention has the advantages of raised adhesion, raised waterproof performance, no toxicity and environment friendship, and is especially suitable for use in finishing household, office, etc.

Owner:天津鑫泰利科技发展有限公司

Water-based complex membrane sealing rubber and preparation method thereof

InactiveCN101974300AStrong initial adhesionStrong adhesionGraft polymer adhesivesPolymer sciencePlasticizer

The invention discloses a water-based complex membrane sealing rubber and a preparation method thereof. Styrene, ethyl hexyl acrylate, n-butyl acrylate, phenolic resin, VEA emulsion, anionic emulsifier, initiator, water-based chlorinated polypropylene, defoamer, thickener and deionized water are subject to free radical polymerization to obtain a yellowish milky water-based complex membrane sealing rubber. The water-based complex membrane sealing rubber of the invention is prepared from micro-emulsion phenolic resin modified acrylic acid emulsion as a main material and the water-based chlorinated polypropylene and the like as auxiliary materials, is safe and environment-friendly, does not contain benzene solvents, contains acrylic ester plasticizer, and completely can pass through the detection of residual quantity of heavy metals and VOC monomers in foods and drugs. The water-based complex membrane sealing rubber has good initial adhesion, good adhesive force and good mechanical properties such as high bonding strength, good heat resistance and good low temperature resistance, and has high drying speed.

Owner:苏州凯康化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com