Ultramicron three-proofing finishing agent and preparation method thereof

A technology of three-proof finishing agent and ultrafine particles, which is applied in fiber treatment, textiles and papermaking, etc., to achieve the effect of simple process, uniform texture and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

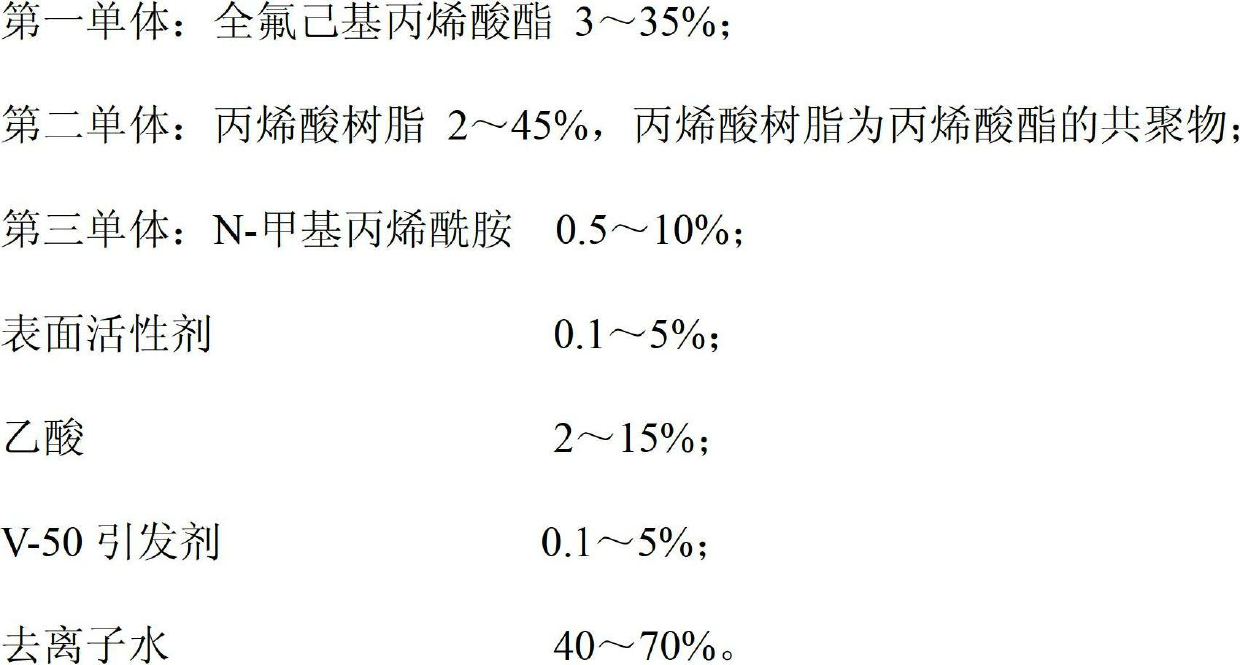

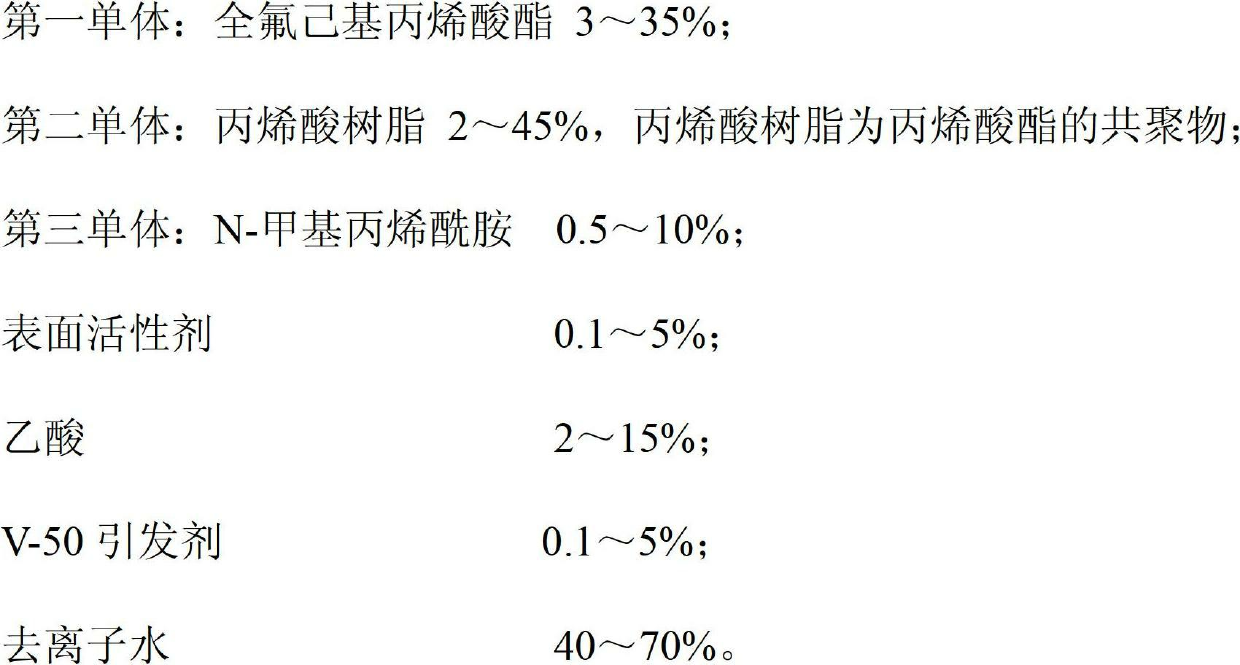

Method used

Image

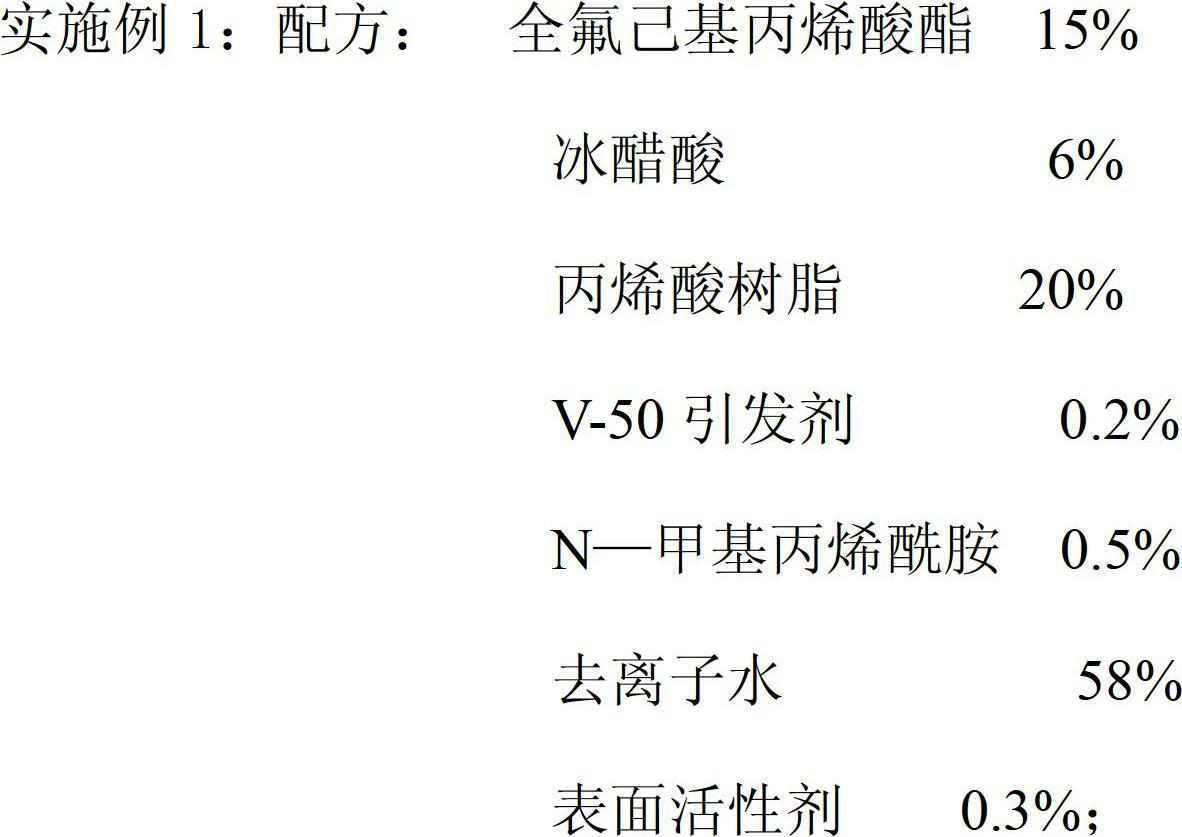

Examples

specific Embodiment approach

[0022]

[0023] Wherein, the above-mentioned acrylic resin is composed of the following monomers by weight: 40% methyl acrylate, and 60% butyl acrylate;

[0024] The above-mentioned surfactant is prepared from the following raw materials in parts by weight: 35% isomeric tridecyl alcohol ether, 30% octadecyltrimethylammonium chloride, and 35% fatty alcohol polyoxyethylene ether.

[0025] Preparation method: (1) Add the above-mentioned perfluorohexyl acrylate, acrylate copolymer, N-methacrylamide, surfactant, glacial acetic acid, and deionized water into the reaction tank at room temperature and stir evenly;

[0026] (2) Pour the above 1 / 3 weight of the above mixture into a temperature-controllable reactor and stir, and then add 1 / 3 of the weight of V-50 initiator when the temperature rises to 55°C, keep the temperature for 40 minutes, and then heat up to 75°C. ℃, and then pour the remaining 2 / 3 of the above mixed material and 2 / 3 of the V-50 initiator.

[0027] (3) Inject n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com