Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

768results about How to "Improve washing resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blumea oil microcapsule textile composite finishing agent and use thereof

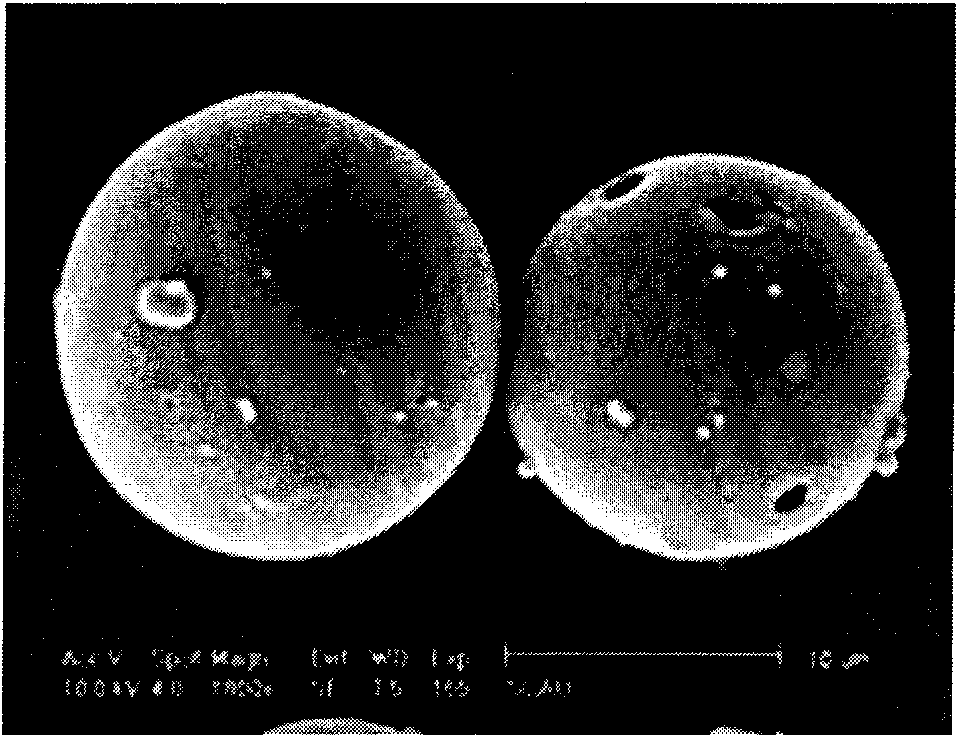

InactiveCN101591859AStir wellSmall particle sizeFibre treatmentMicroballoon preparationCross-linkChemical Linkage

The invention discloses a blumea oil microcapsule textile composite finishing agent and use thereof. Gelatin or acacia of natural polymers is used the main ingredient of a wall material, the blumea oil serving as a Chinese medicinal material is used as a core material, and complex coacervation is adopted to prepare an blumea oil microcapsule aqueous emulsion; a shrink-resistance crosslinker and a catalyst are added to be combined with the blumea oil microcapsule aqueous emulsion into a multifunctional blumea oil microcapsule textile composite finishing agent; researches on the use of blumea oil microcapsules in textile finishing are carried out; and a novel cross linked graft method is used to perform the microcapsule finishing of textiles to form chemical bonds between the microcapsules and the textiles though the shrink-resistance crosslinker and free formaldehyde molecules in 2D resin further participate in a cross-linking and curing reaction as a microcapsule curing agent, so the textiles achieve a long lasting antibacterial and health-care function, a shrink-resistance function and low formaldehyde release content performance.

Owner:SOUTH CHINA AGRI UNIV

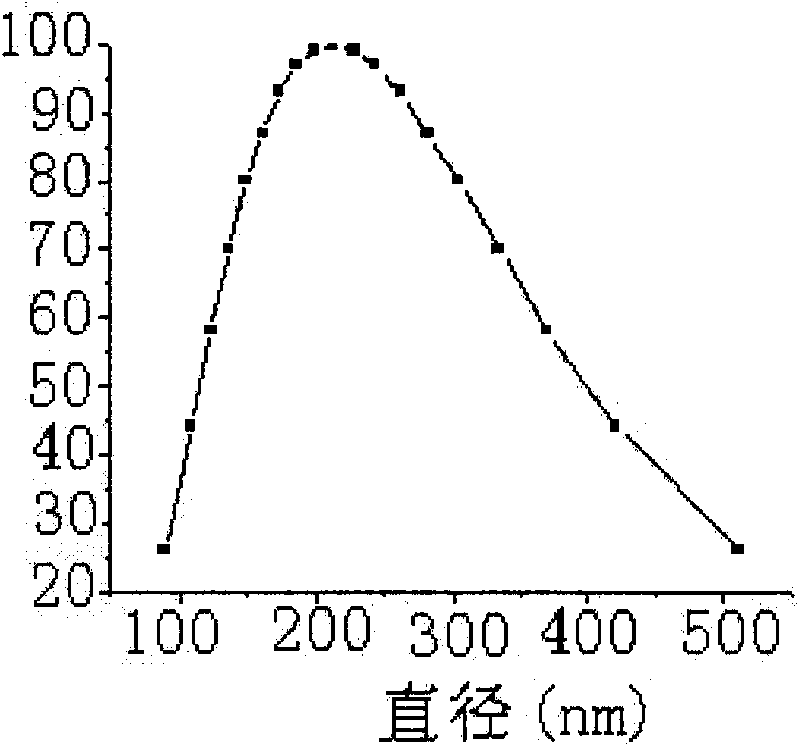

Reactive aqueous polyurethane fabric finishing agent, its preparation method and application

This invention relates to an aquosity polyurethane with end-closed or polyurethane structure preparing process and finishing method for preventing the fabric from winkle and distortion, which has a new application being used as finishing agent. The agent adopts prepolymer aggregating and end terminating technology to make out stable aquosity polyurethane with response type end group, whose emulsion particle diameter ranges from 50 to 500 nm and can be adjusted. The invention has functions of high adhesive strength, good impact resistance, hydrolytic resistance and shape memorization.

Owner:THE HONG KONG POLYTECHNIC UNIV

Expansion type flame-retardant coatings glue and use thereof in textile finishing

ActiveCN101498100AImprove washing resistanceResistance to Mechanical ImprovementVegetal fibresCross-linkPolymer science

The invention discloses an intumescent flame retardant coating gum and the application thereof on fabric finishing. When the traditional intumescent flame retardant is applied to fabric, the fabric is not resistant to water rinse, water immersion or transfer, the flame retardant can lose or degrade under the action of luminous rays, heat, moisture and mechanical external force, and the flame retardant properties are reduced. The intumescent flame retardant coating gum comprises a flame retardant coating base gum and a carbon source, and is characterized in that the flame retardant coating base gum is prepared by mixing ammonium polyphosphate, melamine and 4A zeolite, adding organic alcohol, coating the mixture by more than two silane coupling agents for modification, drying the mixture after removing the organic alcohol to obtain a composite flame retardant, adding water, a non-ionic surface active agent, a binding agent and a cross-linking agent to the composite flame retardant, and grinding and dispersing the mixture; the carbon source is aqueous polyacrylic ester containing hydroxyl groups or aqueous polyurethane containing hydroxyl groups or a modifier of the former two. The invention obviously improves the performance of the flame retardant coating gum on flame retardant fabric for resistance to water rinse, transfer, light, heat and friction.

Owner:传化智联股份有限公司 +2

Fabric finishing liquor for expelling and killing mosquitoes, method of use and products thereof

ActiveCN1664227AGood stabilityModerate viscosity of the systemBiocideBiochemical fibre treatmentEngineeringTextile

This invention refers to a fabric liquidate liquid used of killing mosquito and method of application and produce. The quality pencent direction of fabric liquidate liquid include pesticide and / or repellent 0.05-40.00%, bond 5.00-40.00%, crosslinking agent 0.025-1.50% and the rest is watetr, the sum of each elements is 100%. The pesticide and repellent is aqua repellent of effective content 1%-50%, the bond is aqua repellent of effective solid content 40%-50%. The use method of fabric liquidate liquid adopt printing liquidate fabric. After use the fabric liquidate liquid and dipping, adjust the roller press, enter in the drying machine with control contained liquid rate 30-150% and the drying temperature is 60-250oC.The textile which make use of fabric liquidate liquid or liquidate method is fiber fabric produce.

Owner:沧州永阔隆化工有限公司

Preparation method of essence microcapsules

InactiveCN102039108AGood chemical stabilityHigh mechanical strengthEssential-oils/perfumesMicroballoon preparationTextile fiberEthylic acid

The invention discloses a preparation method of essence microcapsules. The preparation method comprises the following steps: (1) dissolving chitosan in acetum; (2) adding emulsifier and essence into the chitosan acetum for high-speed emulsification and dispersion to obtain the chitosan essence emulsion; (3) adding the mixed solution of sodium alginate and sodium tripolyphosphate dropwise into the chitosan essence emulsion; (4) adjusting the pH value of the system to 5-7 with NaOH solution to obtain the condensed essence microcapsules; and (5) adding cross-linking agent into the condensed essence microcapsule system to perform chemical cross-linking process on the condensed essence microcapsules to obtain the essence microcapsules. For the essence microcapsules prepared according to the method disclosed by the invention, as chemical cross-linking process is implemented on the walls of the capsules, the density of the capsule walls and the resistance to the solution alkalinity / acidity are improved, and the application stability of the essence microcapsules is increased; moreover, with small size, the capsules can easily permeate into textile fiber, and the water-washing resistance of the textile fiber is greatly improved.

Owner:广州市戴文高分子材料科技有限公司 +1

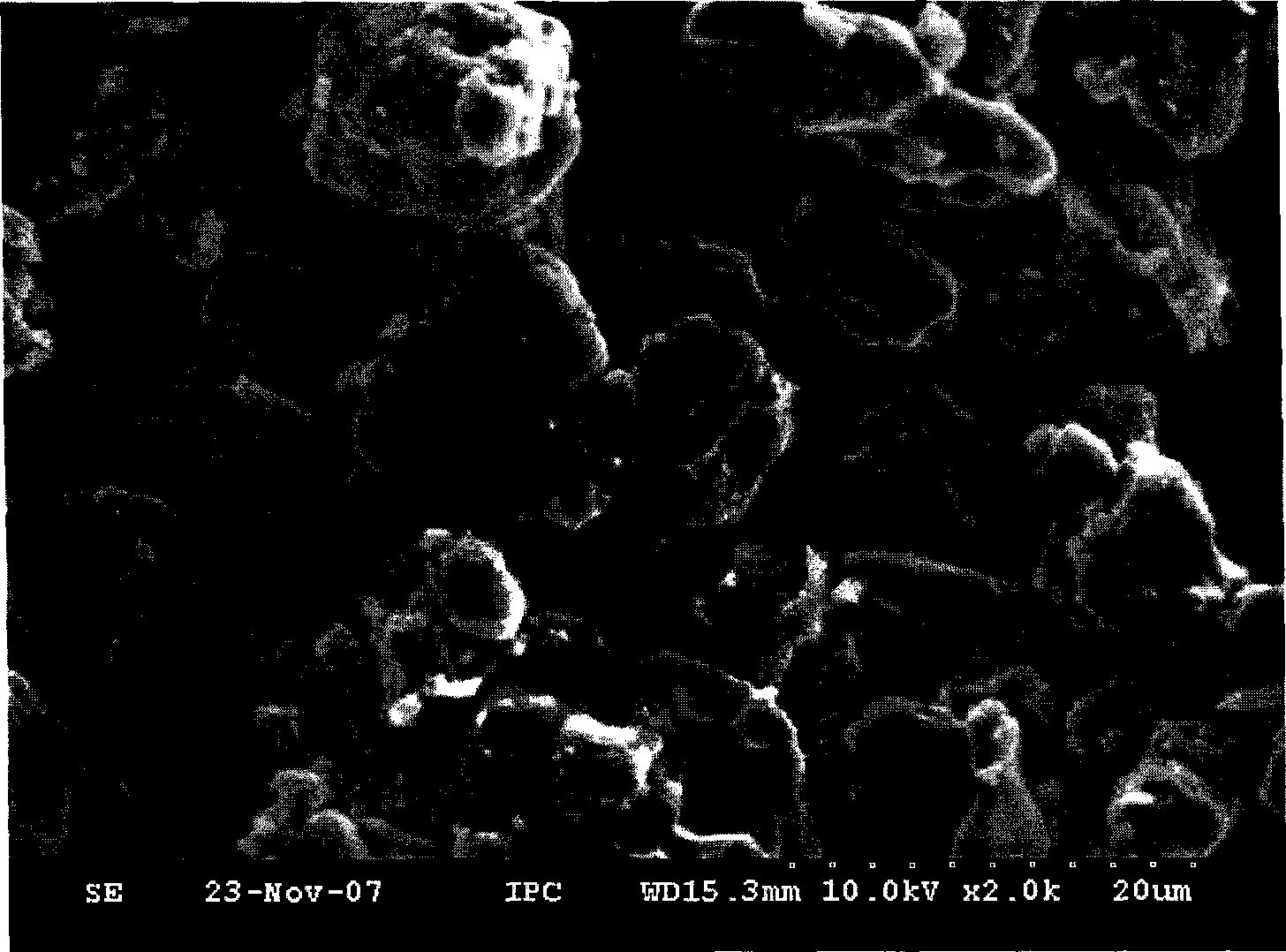

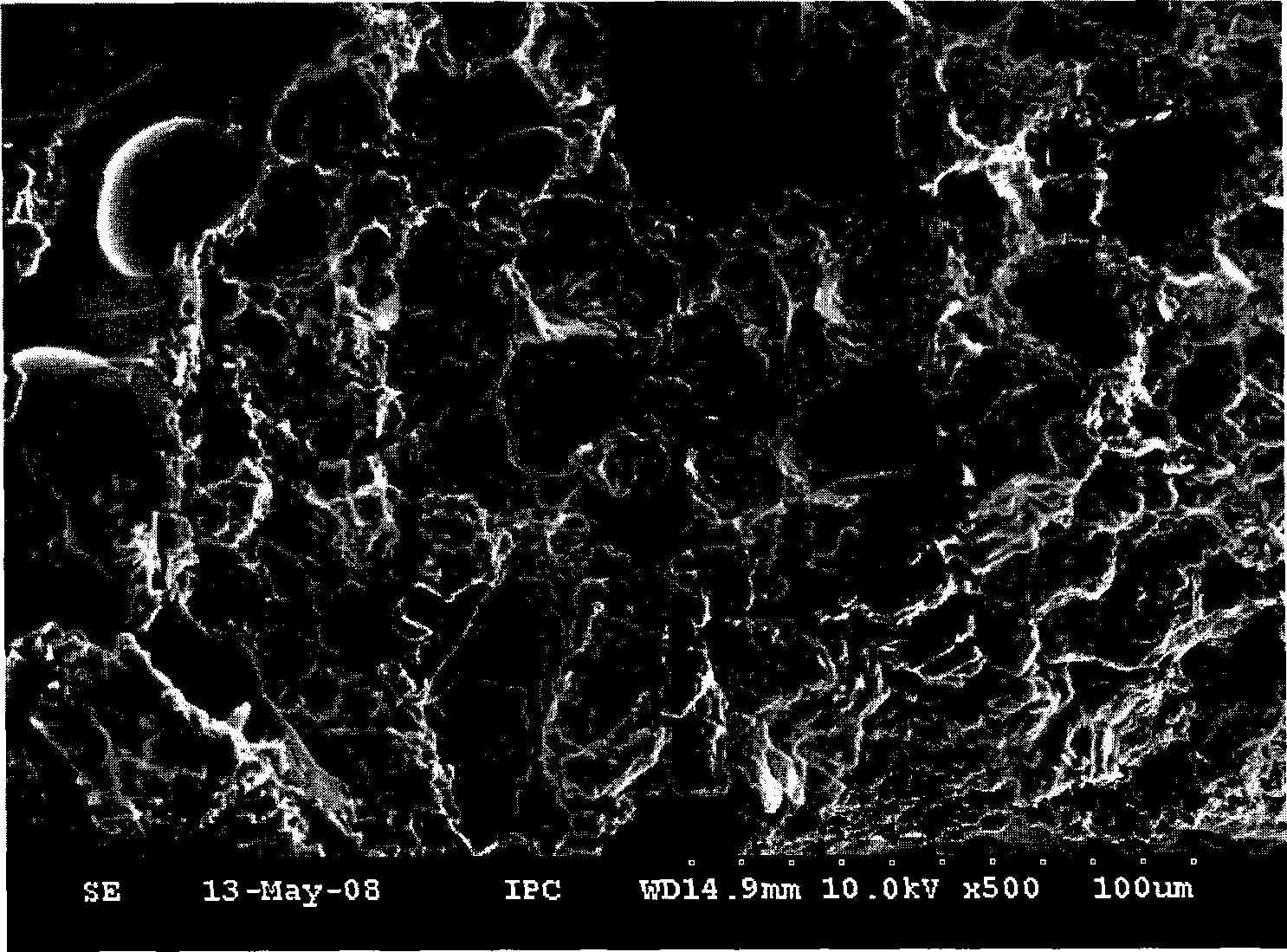

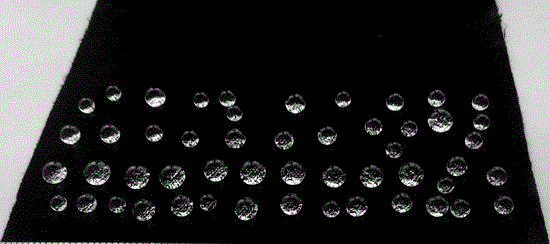

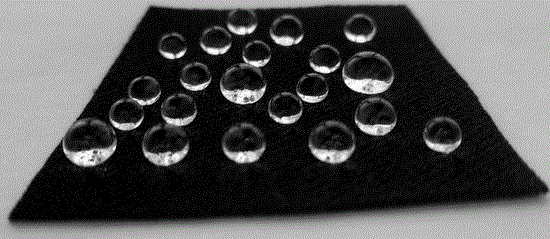

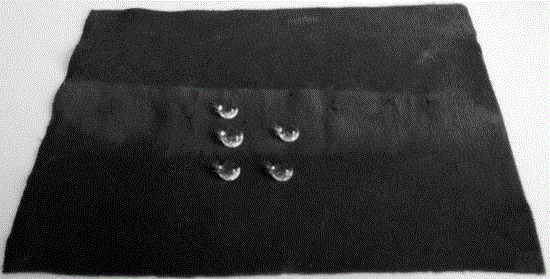

Preparation method of durable super-hydrophobic fabric

The invention provides a preparation method of a durable super-hydrophobic fabric. The preparation method comprises the following steps: firstly, depositing a polydopamine film on the surface of a common fabric; secondly, depositing silver oxide particles on the surface of the common fabric by using the chelating property of the common fabric to nano-particles; and finally, performing hydrophobic treatment on the fabric by using a low-surface-energy material, thereby obtaining the durable super-hydrophobic fabric. The preparation method provided by the invention has the positive progress effects that the static contact angle of water drops on the surface of the fabric prepared by the method is more than 150 degrees, and the water drops can roll easily on the surface of the fabric. After being washed or rubbed for a long time, the fabric still has excellent super-hydrophobic property; and the preparation method of the super-hydrophobic fabric does not need specific instruments and equipment, is simple to operate and is beneficial for popularization.

Owner:NANCHANG HANGKONG UNIVERSITY

Modified ABS antistatic material and preparation method thereof

The invention discloses a modified ABS antistatic material and a preparation method thereof. The antistatic material is formed by melting the mixture in an injection machine after mixing PEEA, maleic anhydride grafted ABS resin (or styrene maleic anhydride copolymer SMA), ABS resin, zlnc oxide whisker, coupler and other additives according to a given proportion. The antistatic ABS material has the advantages of low surface resistance, permanent static resistance, light color and good mechanics performance; and moreover, the antistatic ABS material has appropriate cost, no toxicity and pollution, simple formation processing technology, easy realization and promising application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Environment-friendly thixotropic antirust oil and manufacturing method thereof

ActiveCN101724499AImprove rust resistanceExcellent washabilityAdditivesOperating environmentBase oil

The invention discloses an environment-friendly thixotropic antirust oil which is composed of base oil, barium-free antirusting agent, thixotropic agent, accessory ingredient and antioxygen. The manufacturing method comprises the following steps: pouring the base oil with a weight of 73-96% into a reaction kettle to be heated and stirred; then pouring, heating and stirring barium-free antirusting agent with a weight of 2-20% to 100-120 DEG C before carrying out dehydration; adding thixotropic agent with a weight of 0.5-5.0%, antioxygen with a weight of 0.1-5.0% when cooling the mixture to below 80 DEG C; then carrying out 1 mu filtration to obtain the finished product. The antirust oil features excellent antirusting property and cleanable property and a certain degree of lubricity. A certain degree of calendering operation can be satisfied without the user adding lubricating agent. With excellent thixotropy, stable oil film can be formed on metal skin, flow can be reduced, oil comsumption can be saved, operating environment can be improved and environment-friendliness can be ensured.

Owner:QIDONG SYNTHESIZE CHEM

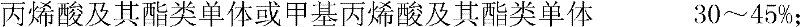

Adhesive for alkali resistant acrylate glass fiber mesh cloth shaping, and preparation method thereof

InactiveCN102533186AImprove sticking powerExcellent dry resistanceGraft polymer adhesivesPolymer adhesivePolymer science

The invention discloses an adhesive for alkali resistant acrylate glass fiber mesh cloth shaping, and a preparation method thereof, and belongs to the field of polymer adhesive preparation. The adhesive is prepared through the reaction of the following components, wherein the components comprise: a material selected from acrylic acid and an ester monomer thereof, or methacrylic acid and an ester monomer thereof; nano-silicon dioxide; a styrene monomer; an initiator; an emulsifier; a buffering agent; a molecular weight regulator; a pH value modulator; and deionized water. According to the adhesive, the nano-silicon dioxide is adopted as the core, a copolymer of the styrene monomer and the acrylic acid monomer is adopted as the shell layer, and the shell layer hard monomer is the acrylate copolymer emulsion with the significant core-shell structure, wherein the concentration of the shell layer hard monomer shows the gradient change. The glass fiber mesh cloth treated by the adhesive of the present invention has advantages of excellent positioning effect, strong adhesive force, bright mesh cloth, good elasticity, high alkali resistance, good water resistance, strong weathering resistance, no yellowing, and no after tack. The adhesive of the present invention is the single mass component glue, is easy to use, does not contain any organic solvents, and has advantages of aquosity and environmental protection.

Owner:BEIJING COMENS NEW MATERIALS

Environmentally-friendly water and oil repellent fluorinated acrylate emulsion and preparation method and application thereof

ActiveCN104418970AExcellent water and oil repellency and stain resistanceGood washing resistanceFibre treatmentEmulsionPolymer chemistry

The invention discloses environmentally-friendly water / oil-repellent fluorinated acrylate emulsion and a preparation method thereof. The fluorinated acrylate emulsion is mainly prepared from 3-chloro-2-hydroxy propyl methyl acrylate, a fluorine-containing alkyl acrylate monomer, an acrylate monomer, a crosslinking monomer, a non-ionic emulsifier, a cationic emulsifier, a modifier, an initiator and deionized water. The fluorinated acrylate emulsion prepared by using the method can be applied to a textile finishing agent; and the textile finished by the emulsion has excellent water and oil repellency and anti-pollution characteristic.

Owner:DYMATIC CHEM

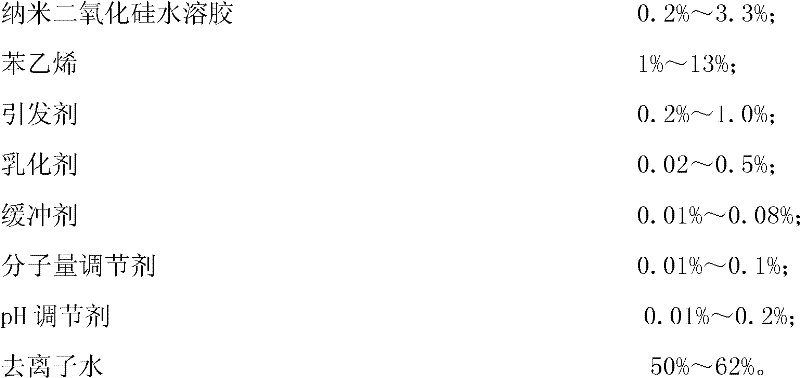

Conductive composition containing poly(3,4-ethylenedioxythiophene)/lignosulfonic acid and preparation method thereof

ActiveCN102516784AIncrease dosageImprove economyLignin material coatingsElectrically-conductive paintsDispersion stabilityAntistatic agent

The invention relates to a conductive composition containing poly(3,4-ethylenedioxythiophene) / lignosulfonic acid and a preparation method thereof. The method comprises the following steps of: chemically oxidizing and polymerizing 100 parts by weight of monomer (3,4-ethylenedioxythiophene) and 170-300 parts by weight of an oxidant in 100-1,000 parts by weight of an aqueous solution in which lignosulfonic acid is taken as a carrier; and adding 200-500 parts by weight of a non-aqueous solvent, 10-100 parts by weight of a polyhydroxy aromatic compound and 50-200 parts by weight of a bonding agent to obtain the conductive composition containing poly(3,4-ethylenedioxythiophene) / lignosulfonic acid. A product prepared with the method meets the requirements of low production cost, transparency, high conducting performance, high adhesion and high hardness in an efficient antistatic agent, and has the characteristics of high dispersion stability, heat stability, temperature stability and water washing resistance. The conductive composition has economic and environmental protection effects as well as a good industrial prospect.

Owner:SOUTH CHINA UNIV OF TECH

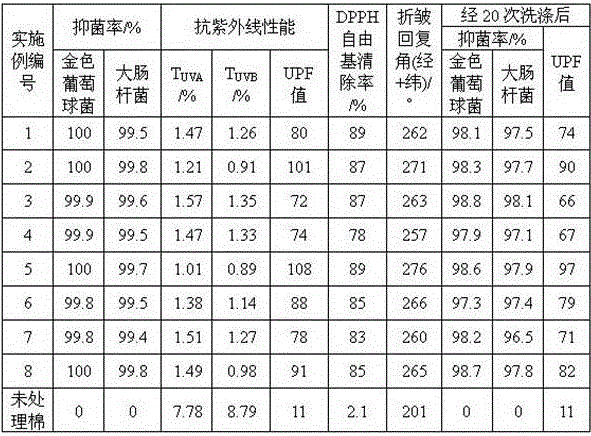

Treatment method for antibacterial and anti-ultraviolet cotton fabrics

ActiveCN106758216AImprove antibacterial propertiesImproves UV resistanceBiochemical fibre treatmentLight resistant fibresGrape seedUltraviolet

The invention discloses a treatment method for antibacterial and anti-ultraviolet cotton fabrics. The treatment method comprises the following steps: step 1, soaking the cotton fabrics with a nonionic surfactant; step 2, modifying the cotton fabrics with chitosan quaternary ammonium salt; step 3, dipping the cotton fabrics with antibacterial finishing liquid prepared by mixing 5-15 parts of a natural antibacterial agent composed of extracts of grape seeds, persimmon leaves, ginkgo leaves and licorice roots, 0.3-1 part of polyoxyethylene-40 hydrogenated castor oil and 1000 parts of water; step 4, soaking the cotton fabrics in a mixed aqueous solution containing 0.001-0.005mol / L of silver nitrate or silver sulfate or silver acetate and 1-3 g / L of soluble starch or hydroxyethyl cellulose to prepare the nano-silver attached antibacterial cotton fabrics. The prepared cotton fabrics not only have good antibacterial performance and anti-ultraviolet performance, but also have performance of resisting oxidation and scavenging free radicals, and have improved anti-wrinkle performance and good washing durability.

Owner:EASTERN LIAONING UNIV

Antibacterial polyester fibers and preparation method thereof

InactiveCN105040142ASimple methodImprove antibacterialMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterChemistry

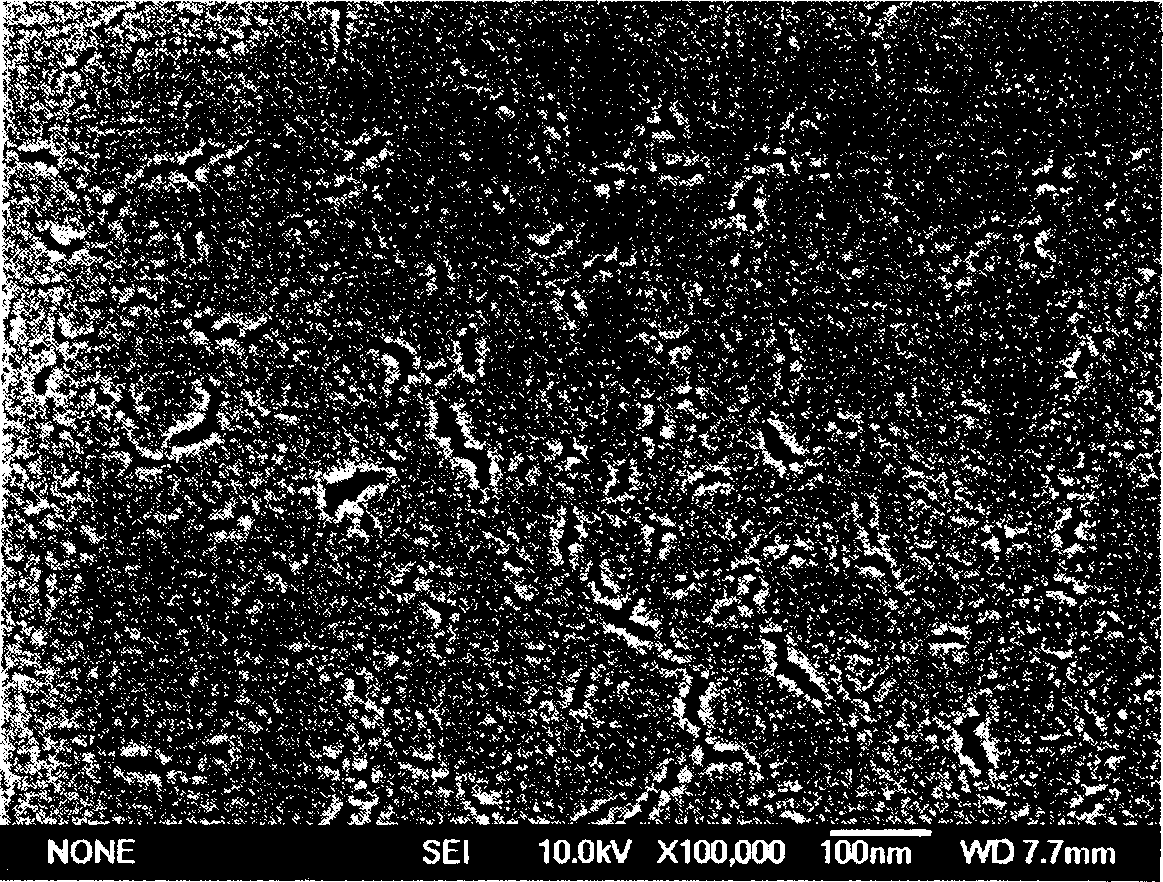

The invention belongs to the textile field and particularly relates to antibacterial polyester fibers. The antibacterial polyester fibers are prepared through melt spinning from the following materials in parts by weight: 100 parts of PET (polyester) chips and 2-5 parts of antibacterial polyester master batch, wherein the antibacterial polyester master batch is prepared from PET chips as well as a preprocessing nano-silver antibacterial agent with weight accounting for 2%-5% of that of the PET chips, an antioxidant with weight accounting for 2%-3% of that of the PET chips, a lubricant with weight accounting for 0.1%-2% of that of the PET chips and a dispersant with weight accounting for 1%-3% of that of the PET chips through melt blending and extruding, and the preprocessing nano-silver antibacterial agent is nano silver subjected to coating treatment through a hydroxypropyl-beta-cyclodextrin solution in a fluidized bed. According to the invention, uniform distribution with a small particle size of the nano-silver antibacterial agent in a PET base body is guaranteed, and the high-efficiency and long-acting antibacterial polyester fibers are prepared through melt spinning. A preparation method disclosed by the invention is simple and feasible, and is suitable for industrial popularization and application.

Owner:俞尧芳

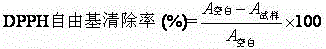

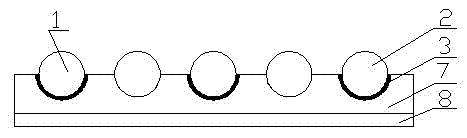

Vertical cotton breathable bra cup pad with silica gel net and preparation method thereof

The invention relates to the technical field of bra cup pad, and specifically relates to a vertical cotton breathable bra cup pad with a silica gel net and a preparation method thereof. The vertical cotton breathable bra cup pad comprises a vertical cotton outer layer and a vertical cotton inner layer; a vertical cotton interlayer is arranged between the vertical cotton outer layer and the vertical cotton inner layer; an adhesive layer is arranged between the vertical cotton interlayer and the vertical cotton inner layer; and a silica gel net layer is arranged between the vertical cotton outer layer and the vertical cotton interlayer. The vertical cotton breathable bra cup pad is prepared by a combined technology of hot pressing and cold pressing. The pad is made of vertical cotton, and is light, comfortable, and breathable. A silica gel layer is arranged between vertical cotton layers, the performance of the pad on resisting water washing is enhanced, the anti-collapse effect is good, three-dimensional effect of the cup pad is long-lasting and stable, and the deformation is difficult to happen.

Owner:HONGJI UNDERWEAR CO LTD

Nano grade polymer micro-emulsion for ink-jet printing and method for preparing the same

InactiveCN1803913ANarrow particle size distributionNatural fabric colorDyeing processButyl acrylateEmulsion

The disclosed preparation method for nano-polymer microemulsion in ink-jet printing comprises: using soft monomer butyl acrylate as main polymonomer for well film-forming flexible; adding comonomer with cross-linkging group to form three-dimensional space network structure and fix the color particle hard on textile fabric to prevent film tacky and endow the fabric with well resistance ability; adding polymerisable surfactant to let the polymer microemulsion have super stability even with much soft monomer and average size less than 100nm hard to agglomeration. This invention can obtain the product with small size and narrow distribution.

Owner:ZHEJIANG UNIV

Fabric post-finishing agent based on modified silk fibroin solution and preparation method of fabric post-finishing agent

ActiveCN105544210ASkin-friendlyHigh affinityBiochemical fibre treatmentGrip property fibresDissolutionSolvent

The invention provides a fabric post-finishing agent based on a modified silk fibroin solution and a preparation method of the fabric post-finishing agent. The preparation method comprises the following specific operational steps: (1) removing impurities from waste silk, putting the impurity-free waste silk in a sodium bicarbonate solution for boiling and degumming, taking out and wringing out the degummed waste silk, washing with clean water till the greasy feel is eliminated, putting the primarily treated waste silk in the sodium bicarbonate solution again for boiling and degumming, taking out and wringing out the degummed waste silk again, washing again with clean water till the greasy feel is eliminated, putting the secondarily treated waste silk in an oven for drying, so as to obtain degummed silk; (2) putting the degummed silk in a lithium bromide solution for standing and dissolution, taking out the treated silk, and performing cooling, dialysis and concentration to obtain a silk fibroin solution; and (3) adding glycerin and gelatin into the silk fibroin solution, uniformly stirring to form a membrane solution, adjusting the pH value of the membrane solution and then adding glutaraldehyde and chitosan, uniformly stirring, and finally mixing the treated membrane solution with a solvent containing additives, so as to obtain the fabric post-finishing agent. The fabric post-finishing agent obtained according to the preparation method covers the fabric surface in the form of a composite membrane; and the preparation method is beneficial to improvements in the membrane forming property, the ductility and the like of a silk fibroin finishing agent.

Owner:SUZHOU INSILK CO LTD

Preparation method for nano-silver antibacterial non-woven fabric and application of nano-silver antibacterial non-woven fabric to diapers

ActiveCN103194855AAvoid breedingLong-term physical sterilization functionConjugated synthetic polymer artificial filamentsNon-woven fabricsMasterbatchAdult diaper

The invention relates to a preparation method for nano-silver antibacterial non-woven fabric and application of the nano-silver antibacterial non-woven fabric to baby and adult diapers. The preparation method for the nano-silver antibacterial non-woven fabric comprises the steps of preparing antibacterial polyethylene (PE) masterbatch, preparing antibacterial ethylene-propylene side by side (ES) fiber, loosing cotton, shaping and the like. The preparation process is simple and cost is saved. In the nano-silver antibacterial non-woven fabric, nano-silver ions are modified and can be distributed into non-woven fiber uniformly to form an antibacterial high-tech material which can be stored for more than five years normally, can effectively inhibit bacterial growth for a long time and has a long-acting physical sterilization function and a unique self-cleaning function.

Owner:河南舒莱卫生用品有限公司

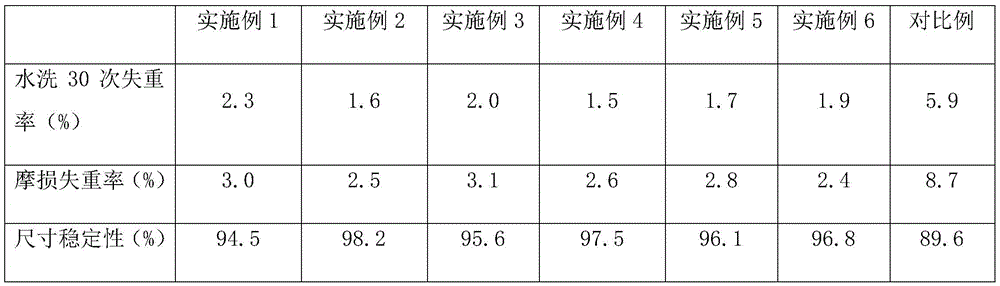

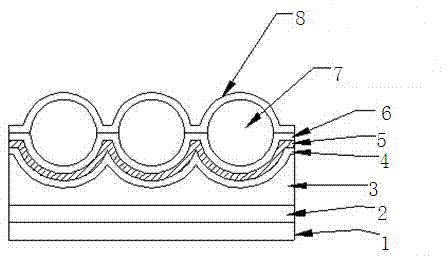

Preparation process of reflective fabric with heavy industry washing fastness

ActiveCN104275887AImprove washing resistanceImprove visibilitySynthetic resin layered productsLaminationMetal coatingProtection layer

The invention relates to a reflective fabric and in particular relates to a preparation process of a reflective fabric with the heavy industry washing fastness. The reflective fabric comprises a base cloth, a complex adhesive layer, a complex adhesive protection layer, an inert substance layer, a metal coating layer, a focusing layer, a glass microballoon layer and a transparent protection layer, wherein the complex adhesive layer is arranged on the base cloth; the complex adhesive protection layer is arranged on the complex adhesive layer; the inert substance layer is arranged on the complex adhesive protection layer; the metal coating layer is arranged on the inert substance layer; the focusing layer is arranged on the metal coating layer; the glass microballoon layer is arranged on the focusing layer; the transparent protection layer is arranged on the glass microballoon layer. The reflective fabric has the firm and washable cloth base; regression reflective glass microballoons are attached onto all durable fabric lining cushions; the washing fastness is improved; the reflective intensity is high; the reflective intensity typical value reaches more than 420CPL; when the reflective fabric is sewed onto other fabrics and linings, the reflective fabric has an extremely obvious effect of improving the visibility of wearers in night or in the environment with the bad visibility.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

Durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and preparation method

ActiveCN102108638AImprove washing resistanceGood film fastnessFibre treatmentGlycidyl methacrylateAdhesive

The invention provides a durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and a preparation method. The coating adhesive is prepared from methyl acrylate, n-butyl acrylate, glycidyl methacrylate, allyl methacrylate, 2,2,2-trifluoroethyl methacrylate, acryloyloxyethyl trimethyl ammonium chloride, fatty alcohol polyoxyethylene ether XL90, hexadecyl trimethyl ammonium chloride, 2,2-azobis(2-methylpropionamidine)hydrochloride, deionized water and an associative polyurethane levelling and rheological agent WT-203 through the processes of emulsification, initiated polymerization and thickening.

Owner:DANDONG UNIK TEXTILE

Multifunctional composite reflective cloth and manufacturing method thereof

ActiveCN103091746AHas retro-reflective functionImprove washing resistanceLaminationLamination apparatusAngle of incidenceFluorescence

The invention relates to a multifunctional composite reflective cloth which has not only a regression reflective effect but also a self-luminous function and a manufacturing method of the reflective cloth. A plurality of glass beads and a plurality of glass beads of which the mosaic surfaces are plated with metal reflective layers cover densely an adhesive layer in a stagger mode and are inlaid in the adhesive layer which has a fluorescent effect, and a cloth basic layer is composited on the adhesive layer. The multifunctional composite reflective cloth has the advantages that the cloth not only has the regression reflective function, but also has the self-luminous function, the high-brightness fluorescence lasts for more than 6h, the cloth is good in washing resistance, after the cloth is washed for 25 times, the even retroreflection factor still remains over 65 cd / lx*m<2> (the angle of incidence is 5 degrees, and the observing angle is 12 minutes).

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

Negative oxygen ion dry powder paint and preparation method thereof

InactiveCN106189393AHigh tensile strengthGood dispersionAntifouling/underwater paintsPaints with biocidesWollastoniteUltimate tensile strength

The invention discloses a negative oxygen ion dry powder paint, belonging to the technical field of paints. The paint comprises the following components in percentage by mass: 25-35% of ash calcium powder, 6.2-8.0% of diatomite, 4.5-6.5% of negative ion additive, 1.5-5.0% of antimicrobial agent, 0.15-0.80% of talcum powder, 0.15-0.80% of kaolin, 0.15-0.50% of wollastonite, 0.05-0.15% of surfactant, 0.55-1.5% of redispersible latex powder, 1.2-1.8% of light calcium carbonate powder, 0.15-0.50% of lithopone and the balance of heavy calcium carbonate powder. The paint is capable of efficiently absorbing formaldehyde and other harmful gases and naturally and enduringly releasing negative ions, has the characteristics of high mildew resistance, high bactericidal capacity and favorable air permeability, and can adjust the humidity of indoor air. The coating has the characteristics of favorable strength, favorable toughness, favorable scrubbing resistance and the like.

Owner:深圳锦家安科技有限公司

Antibacterial fabric/fiber finishing liquid for expelling and killing insect pollination and application method and fabric product/fiber product/paper product thereof

InactiveCN107761374AFix compatibility issuesSimple compositionBiochemical treatment with wool-protecting/anti-moth agentsPaper/cardboardFiberPollination

The invention relates to a fabric / fiber finishing solution for antibacterial and insecticide repelling, its use method and fabric / fiber product / paper product. The mass percentage formula of the fabric / fiber finishing solution is: 0.05-40% of insecticide / repellent; 0.05-20% of antibacterial agent; 5.00-35% of binder; and 0.025-5% of crosslinking agent. The method for using the fabric / fiber finishing liquid of the present invention can be selected according to the difference of the finishing fabric / fiber material, one of the padding method, the spraying method or the dipping method. The fabric / fiber product / paper product is obtained by finishing the fabric / fiber finishing liquid or / and the method of using the fabric / fiber finishing liquid of the present invention. The fabric / fiber finishing liquid and its products of the present invention have the advantages of high efficacy, strong adhesion, water washing resistance, can reach the WHO standard, low cost, good applicability, convenient use and popularization, and the like.

Owner:牛绍英

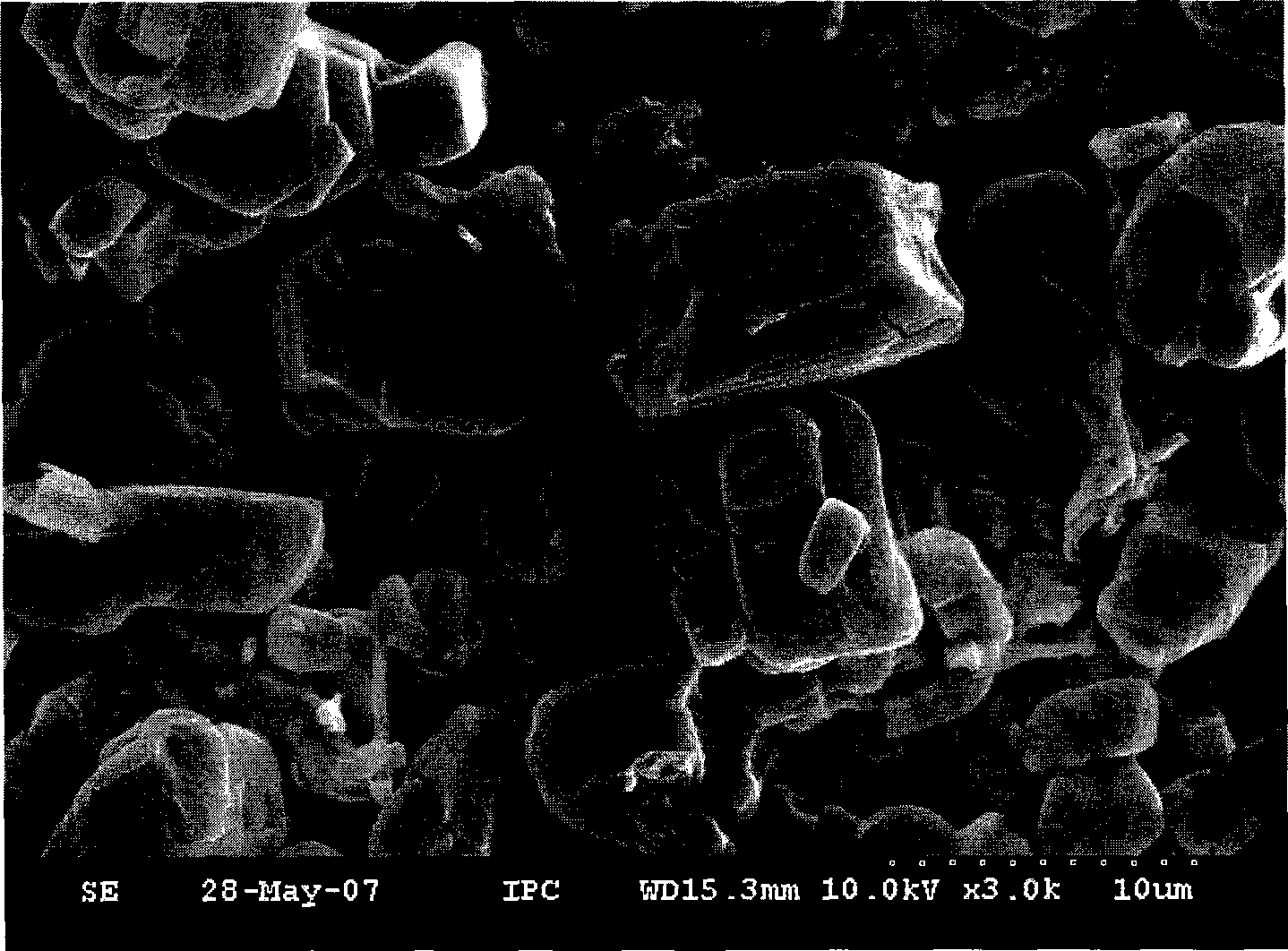

A method for manufacturing modified extra fine heavy calcium carbonate powder

ActiveCN101544852AImprove lipophilicityImprove wettabilityCoatingsPigment treatment with macromolecular organic compoundsShear viscosityChemistry

The invention relates to a method for manufacturing modified extra fine heavy calcium carbonate powder; polyglycol and water are evenly mixed according to a mass ratio of 1:1 to get fluid A which is added from an inlet orifice of a muller and enters the muller together with coarse fodder entering the muller; the coarse fodder is continuously grinded to be fine, ceaselessly mixed to be even with the fluid A, and evenly wrapped simultaneously; wrapped modified extra fine heavy calcium carbonate powder is separated after entering a grader through wind, thus obtaining modified extra fine heavy calcium carbonate powder. The modified extra fine heavy calcium carbonate of the invention not only ensures retaining of characteristics of modified extra fine heavy calcium carbonate powder, but can improve lipophilicity, wettability and disperse stability of powder body. After applied to a latex system, the modified extra fine heavy calcium carbonate powder obtained by the invention can improve hydrophobic mature of a dope system, rinse resistant times, high shear viscosity of a latex system, construction property, and reduce dosage of moistening dispersant and foam suppressor in the meanwhile.

Owner:广福建材(蕉岭)精化有限公司

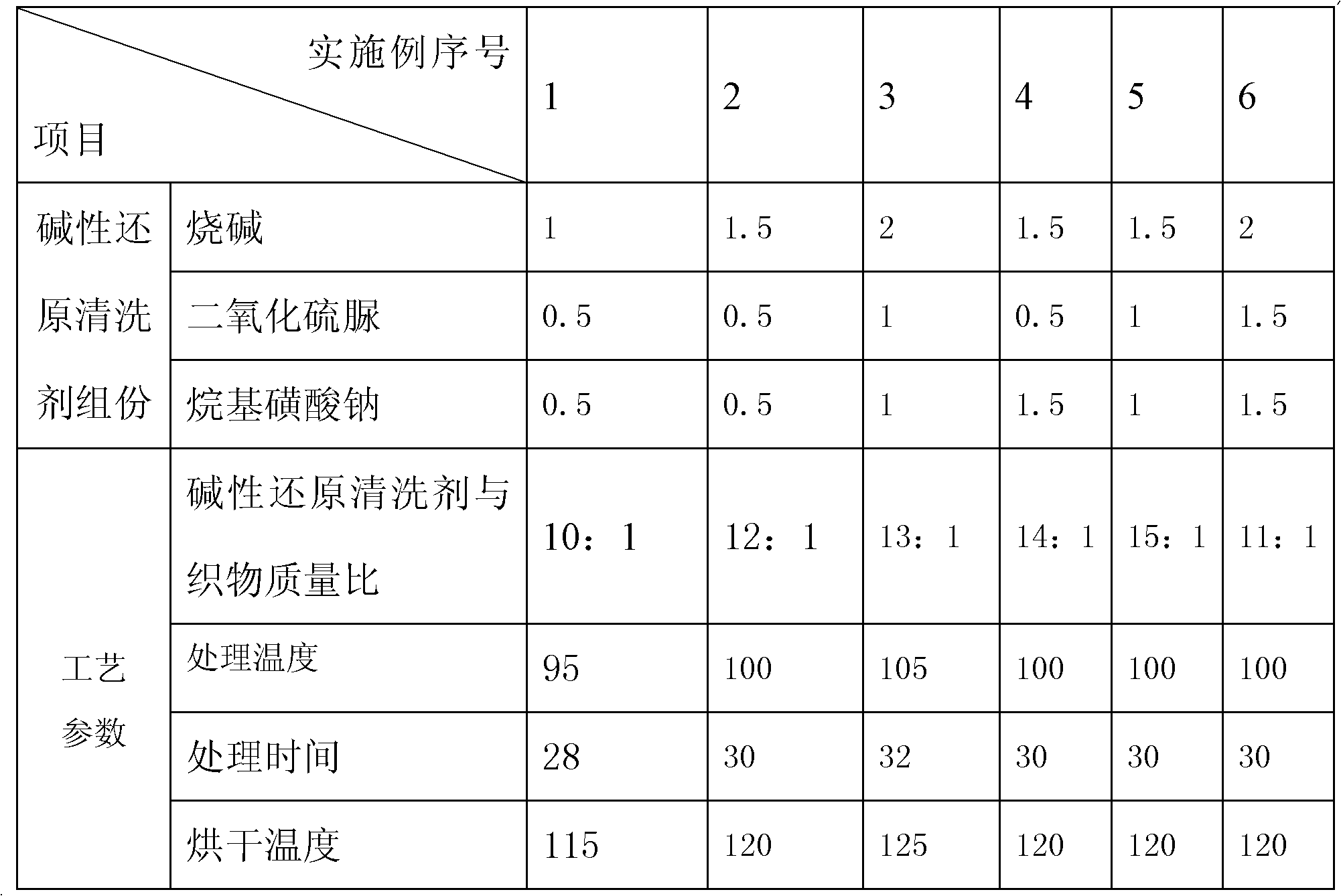

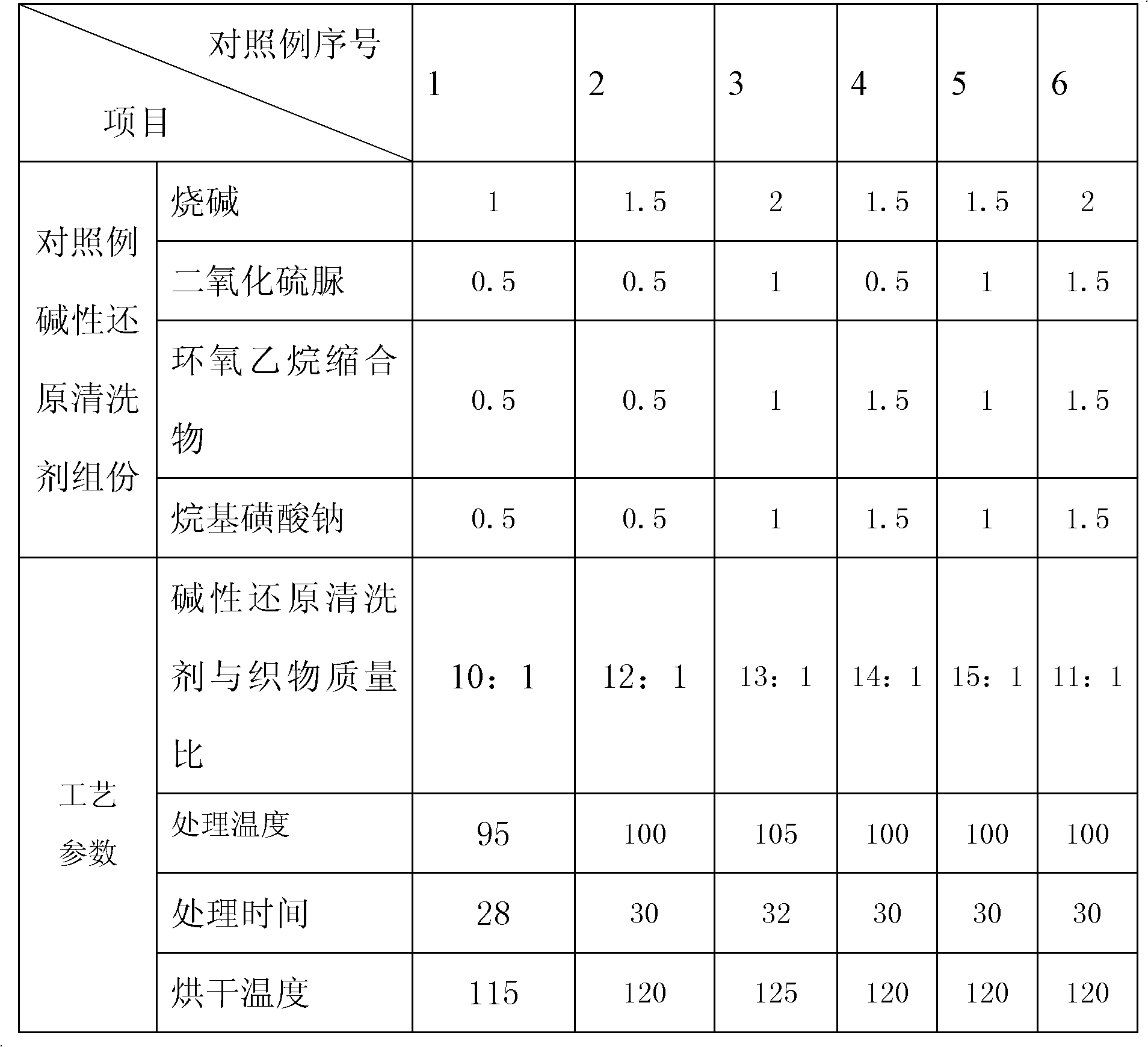

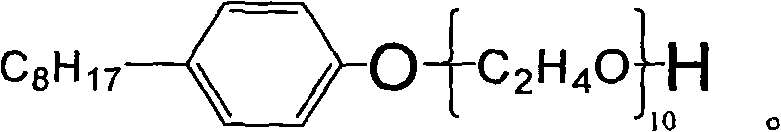

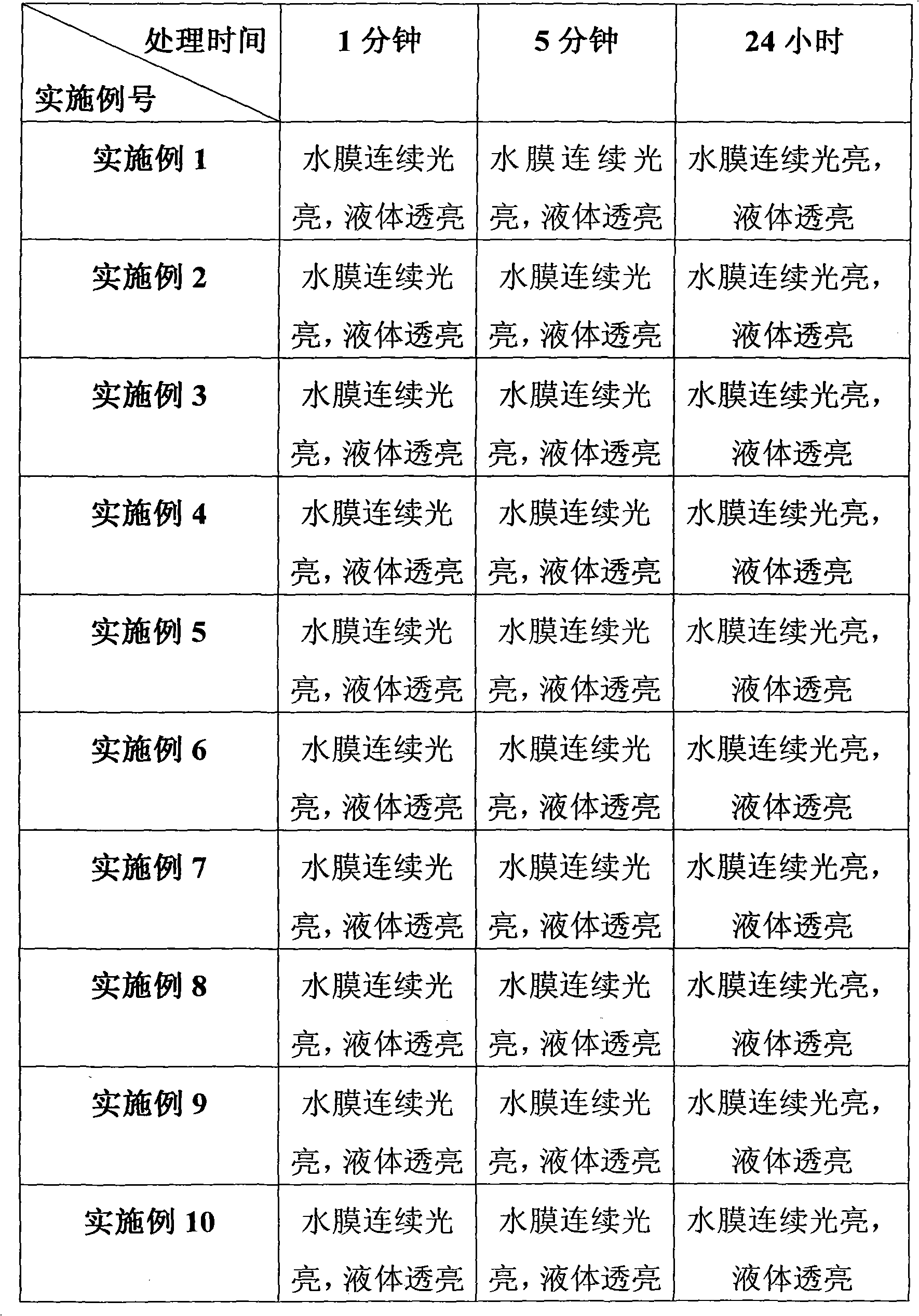

Fabric reductive cleaning agent with high soaping-resistant color fastness and high sublimation fastness, preparation method thereof and polyester fabric treatment method

ActiveCN102586038AHigh color fastnessConducive to three anti-heat setting finishingInorganic/elemental detergent compounding agentsSurface-active detergent compositionsPolyesterFiber

The invention provides a fabric reductive cleaning agent with high soaping-resistant color fastness and high sublimation fastness, a preparation method thereof and a polyester fabric treatment method specific to the defects of poor or instable soaping-resistant color fastness and sublimation fastness of a polyester fabric caused by unclean surface flooding of the cleaned fabric and instable three-proofing functional water resistance caused by the use of a reductive cleaning agent in the prior art. An alkaline reductive cleaning agent is an aqueous solution consisting of caustic soda, thioureadioxide, a soaping agent and a dispersant. The polyester fabric treatment method comprises the following steps of: dyeing a fabric, and adding the alkaline reductive cleaning agent into the fabric inthe weight ratio of (10-15):1 on a dyeing machine; performing reductive washing at the temperature of 100+ / -5 DEG C for 30+ / 2 minutes; washing with water; and drying at the temperature of 120+ / -5 DEGC. After a polyester fiber dyeing fabric is treated with the cleaning agent, flooding and low polymers are removed completely, and high color fastness of the fabric is realized.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Flame Retardant Bedding Product

InactiveUS20080254699A1Retain softnessRetains comfortablenessWarp knittingCircular knitting machinesPolyesterPolymer science

A bedding product, such as a pillow or cushion, that satisfactorily drawing out peculiar softness and comfort possessed by an internal filling material, realizes comfort and high flame retardance without detriment to the excellent drape and tactile sensation possessed by a fiber material of flame shielding cloth. There is provided a flame retardant bedding product comprising an internal filling material covered by a flame shielding cloth made of fibers containing 5 to 60 wt. % halogenous fiber (A), 5 to 60 wt. % flame retardant cellulose fiber (B), 0 to 75 wt. % cellulose fiber (C) and 0 to 50 wt. % polyester fiber (D).

Owner:KANEKA CORP

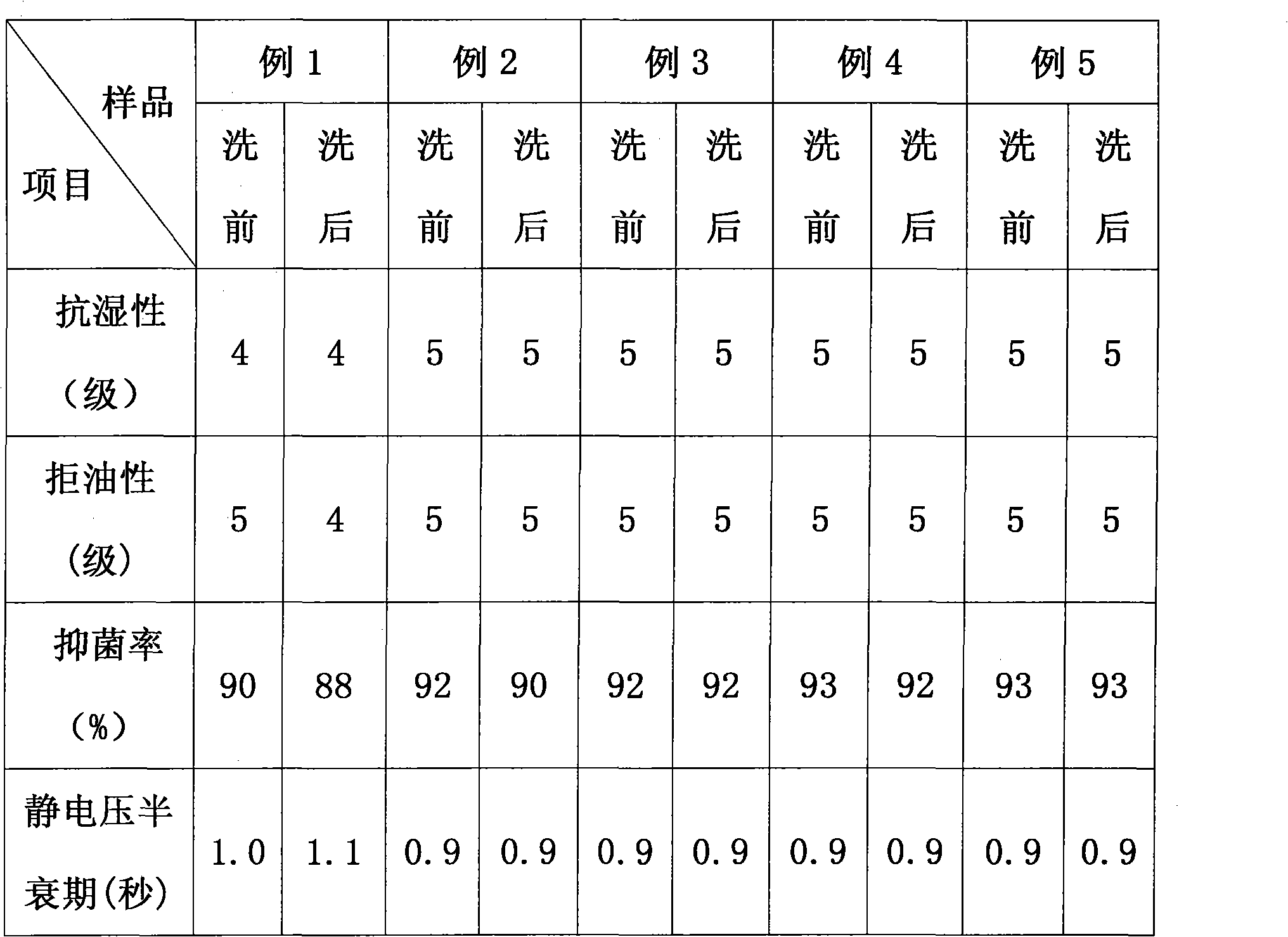

Preparation method of washable three-proofing and easy-decontamination antibacterial fabric

InactiveCN111535026AMeet environmental protection requirementsImprove washing resistanceStain/soil resistant fibresBiochemical fibre treatmentProcess engineeringCross linker

The invention discloses a preparation method of a washable three-proofing and easy-decontamination antibacterial fabric. The preparation method is characterized by comprising the following steps of: soaping, to be specific, after desizing, scouring, bleaching and mercerizing the fabric in advance, removing impurities on the cloth cover by a soaping process, and then drying; and performing one-bathprocess washable three-proofing and easy-decontamination antibacterial finishing, to be specific, shaping and processing the soaped and dried fabric on a shaping machine, drying, baking and finishing, thereby obtaining the washable three-proofing and easy-decontamination antibacterial fabric. A working solution which simultaneously contains a C6 durable three-proofing finishing agent, a purifiedcotton durable fluorine-free waterproof agent, a durable crosslinking agent, an antibacterial agent and a special waterproof penetrant is contained in a rolling groove of the shaping machine, and thefabric is subjected to padding, then is dried and baked to obtain the washable three-proofing and easy-decontamination antibacterial fabric. The preparation method solves the contradiction between thethree-proofing and the easy decontamination, and also solves the problems between the three-proofing and the bacteria prevention; and meanwhile the fabric is endowed with the function of washing resistance, and can meet the overall actual needs for functional fabrics in actual situations.

Owner:江苏康乃馨纺织科技有限公司

Degreasing agent for permanent magnet material

The invention relates to a degreasing agent for a permanent magnet material. The water-soluble degreasing agent comprises alkaline materials, a cleaning auxiliary agent and a surface active agent, wherein the alkaline materials are selected from at least two of sodium hydroxide, potassium hydroxide, sodium carbonate, sodium hydrogen carbonate, trisodium phosphate or sodium pyrophosphate; the cleaning auxiliary agent is selected from at least one of organic polybasic phosphonic cleaning auxiliary agents, or a mixture of at least one of the organic polybasic phosphonic cleaning auxiliary agents and at least one of inorganic phosphate cleaning auxiliary agents; and the surface active agent is a low-foam non-ionic surface active agent. According to the invention, the degreasing agent provided by the invention has good wettability, permeability and emulsibility, high degreasing speed, higher grease dirt capacity and long service life, and can prevent grease dirt from being adsorbed again; and meanwhile, by using the non-ionic surface active agent, the foam is little, the washing performance is superior, the water can be softened, and the corrosion of the permanent magnet material in the degreasing agent can be avoided.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Ready-made clothes after-finishing process

InactiveCN101265661AImprove waterproof performanceGood oil proofDry-cleaning apparatus for textilesNatural fibresEngineeringSoil resistance

The invention relates to a post-finishing process for ready-made clothes, which adopts the one-step method of one-bath in the following working procedures of desizing, unwatering, soaking in treatment fluid, re-drying, pressing and baking for setting, and cooling. In preparing the treatment fluid, resin 5-10%, OLEOPHOBOL 4-8%, penetrant 0.1-0.25%, and catalyst 1-2.5% are included. After finishing, the ready-made clothes with no ironing and washing for 30 times can achieve the crease shedding of level 4, water resistance of level 5, oil resistance of level 5, and soil resistance of level 5, thereby having excellent water-washing serviceability, durability and shrink resistance. The formaldehyde content is lower than 75ppm. The post-finishing process has the advantages of little pollution, obvious effects of water resistance, oil resistance, soil resistance, and no ironing, good durability and so on, thereby being applied to the ready-made clothes made of natural fibers such as cotton, hemp, tencel and so on.

Owner:翁卫东

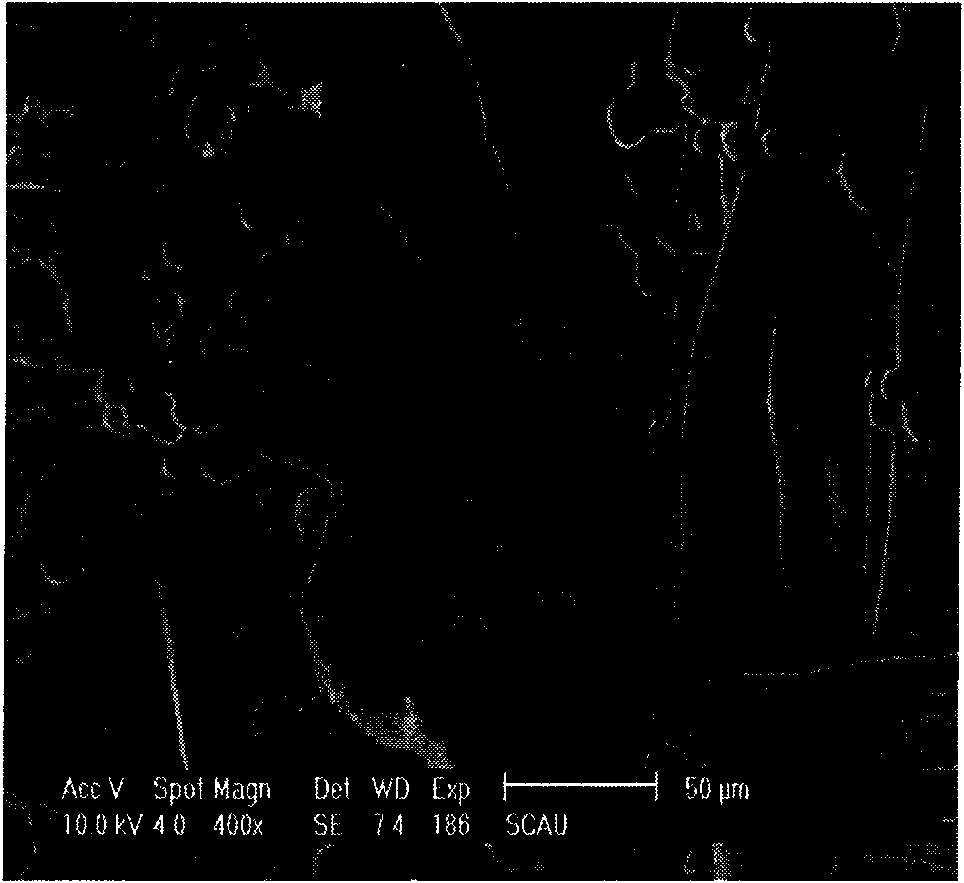

Antibacterial active carbon fiber coated by chitosan porous membrane and process for preparing same

The invention discloses an anti-bacterial activated carbon fibre covers with chitose porous membrane and preparing method, which comprises the following steps: dissolving chitose in alcaine or acetate water solution; preparing the 10-30g / L chitose acid solution; soaking the activated carbon fibre in chitose acid solution and draining; soaking with queous alkali and washing to neutral; draining; vacuum drying to constant weight; getting percent by weight of chitose of anti-bacterial activated carbon fibre is 5%-30%; Loading the 50nm-2 mum porous membrane on the activated carbon fibre surface. The invention solves the problems of durability, safety and re-use of the anti-bacterial activated carbon fibre; the invention can be used for personal protective device.

Owner:UNIV OF SCI & TECH OF CHINA

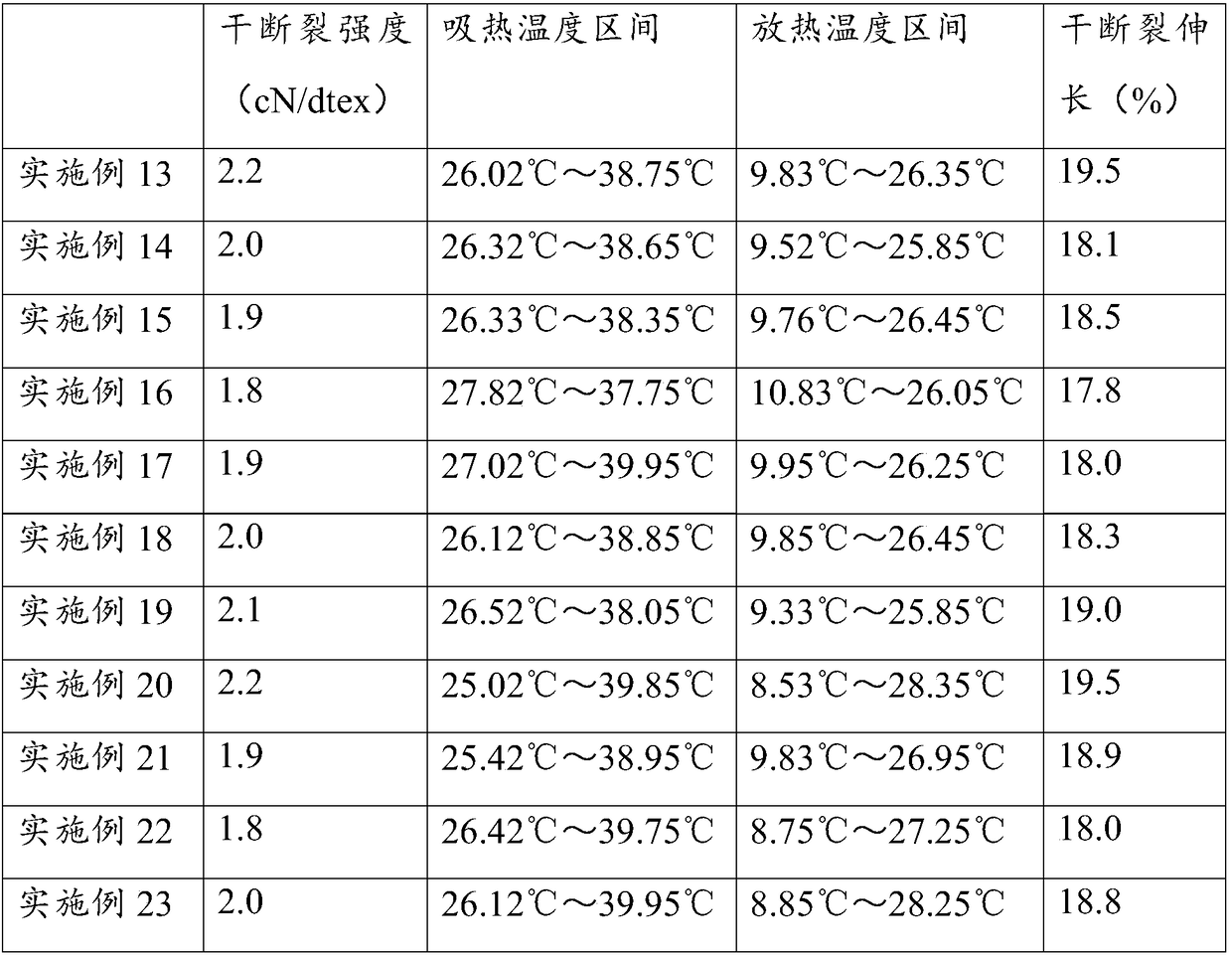

Graphene microcapsules, intelligent thermoregulation fibers and preparation methods thereof

InactiveCN108499497AAvoid complex process problemsGood dispersionArtificial filaments from viscoseMonocomponent synthetic polymer artificial filamentFiberDispersity

The invention provides graphene microcapsules, intelligent thermoregulation fibers and preparation methods thereof. The graphene microcapsules comprise a core material and a shell material, wherein the core material is a graphene material, and the shell material is a synthetic polymer or natural polymer material; the content of the core material is 15wt%-60wt% preferably. The preparation method ofthe graphene microcapsules comprises the following steps: an aqueous dispersion of the graphene material and a shell material raw material are mixed and emulsified, and a suspension is formed, the aqueous dispersion of the graphene material is prepared from deionized water, graphene and a surfactant; the shell material raw material is a prepolymer of a synthetic polymer or the natural polymer material; a curing agent or an initiator is added to the suspension, a curing reaction is performed, filtering and drying are performed, and the graphene microcapsules are obtained. By graphene microencapsulation, not only are dispersity and compatibility of graphene in a substrate improved, but also heat conduction and storage performance of the microcapsules is improved, a spinning process is optimized, and smoothness of surfaces of graphene modified fibers is improved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com