Preparation method of durable super-hydrophobic fabric

A super-hydrophobic and fabric technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of equipment and fabric type dependence, achieve good washing resistance, use promotion, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

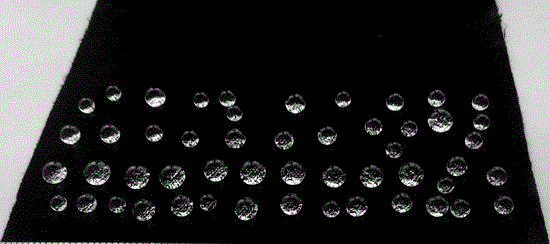

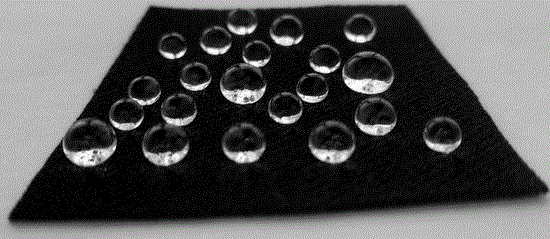

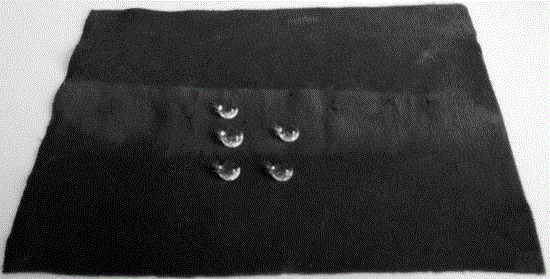

Image

Examples

Embodiment 1

[0021] Step 1: Deposition of polydopamine: Wash the polyester fabric with deionized water, immerse it in a tris-hydrochloric acid buffer solution (pH = 8.5) with a concentration of 2 mg / mL dopamine hydrochloride, and the deposition temperature is At room temperature, the deposition time was 12 h, and then the fabric was taken out, ultrasonically cleaned in deionized water for 10 min, and dried.

[0022] Step 2: Deposition of silver oxide: The polydopamine-deposited fabric was immersed in AgNO at a concentration of 5 mg / mL 3 In the aqueous solution for 1 min, take it out and rinse it in deionized water, and then immerse it in a 5 mg / mL NaOH solution for 1 min. Repeated sequential immersion in AgNO 3 / NaOH aqueous solution 3 times. The fabrics were ultrasonically cleaned in deionized water for 10 min and dried.

[0023] Step 3: Deposition of low surface energy substances: The polyester fabric treated by the above steps was immersed in a solution of dodecyl mercaptan methanol ...

Embodiment 2

[0026] Step 1: Deposition of polydopamine: Wash the polyester fabric with deionized water and immerse it in a tris-hydrochloric acid buffer solution (pH = 8.5) with a concentration of 5 mg / mL dopamine hydrochloride. The deposition temperature is At room temperature, the deposition time was 6 h, and then the fabric was taken out, ultrasonically cleaned in deionized water for 10 min, and dried.

[0027] Step 2: Deposition of silver oxide: The polydopamine-deposited fabric was immersed in AgNO at a concentration of 5 mg / mL 3 In the aqueous solution for 10 min, take it out and rinse it in deionized water, and then immerse it in a 5 mg / mL NaOH solution for 10 min. The fabrics were ultrasonically cleaned in deionized water for 10 min and dried.

[0028] Step 3: Deposition of low surface energy substances: The polyester fabric treated by the above steps was immersed in a solution of dodecyl mercaptan methanol with a concentration of 5 μL / mL, deposited at room temperature for 10 min,...

Embodiment 3

[0031] Step 1: Deposition of polydopamine: Wash the cotton fabric with deionized water and immerse it in a tris-hydrochloric acid buffer solution (pH = 8.5) with a concentration of 5 mg / mL dopamine hydrochloride, and the deposition temperature is At room temperature, the deposition time was 6 h, and then the fabric was taken out, ultrasonically cleaned in deionized water for 10 min, and dried.

[0032] Step 2: Deposition of silver oxide: The polydopamine-deposited fabric was immersed in AgNO at a concentration of 5 mg / mL 3 In the aqueous solution for 1 min, take it out and rinse it in deionized water, and then immerse it in a 5 mg / mL NaOH solution for 1 min. Repeated sequential immersion in AgNO 3 / NaOH aqueous solution 3 times. The fabrics were ultrasonically cleaned in deionized water for 10 min and dried.

[0033] Step 3: Deposition of low surface energy substances: immerse the polyester fabric treated in the above steps in a methanol solution of perfluorodecanethiol w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com