Degreasing agent for permanent magnet material

A technology of permanent magnet material and degreasing agent, which is applied in the field of degreasing agent and degreasing agent of permanent magnet material, can solve the problem of incomplete degreasing and degreasing of NdFeB permanent magnet material and affect the surface of NdFeB permanent magnet material. Treatment effect, can not achieve better results and other problems, to achieve the effect of superior washing performance, large oil load, reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

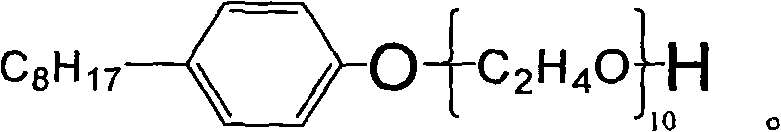

Method used

Image

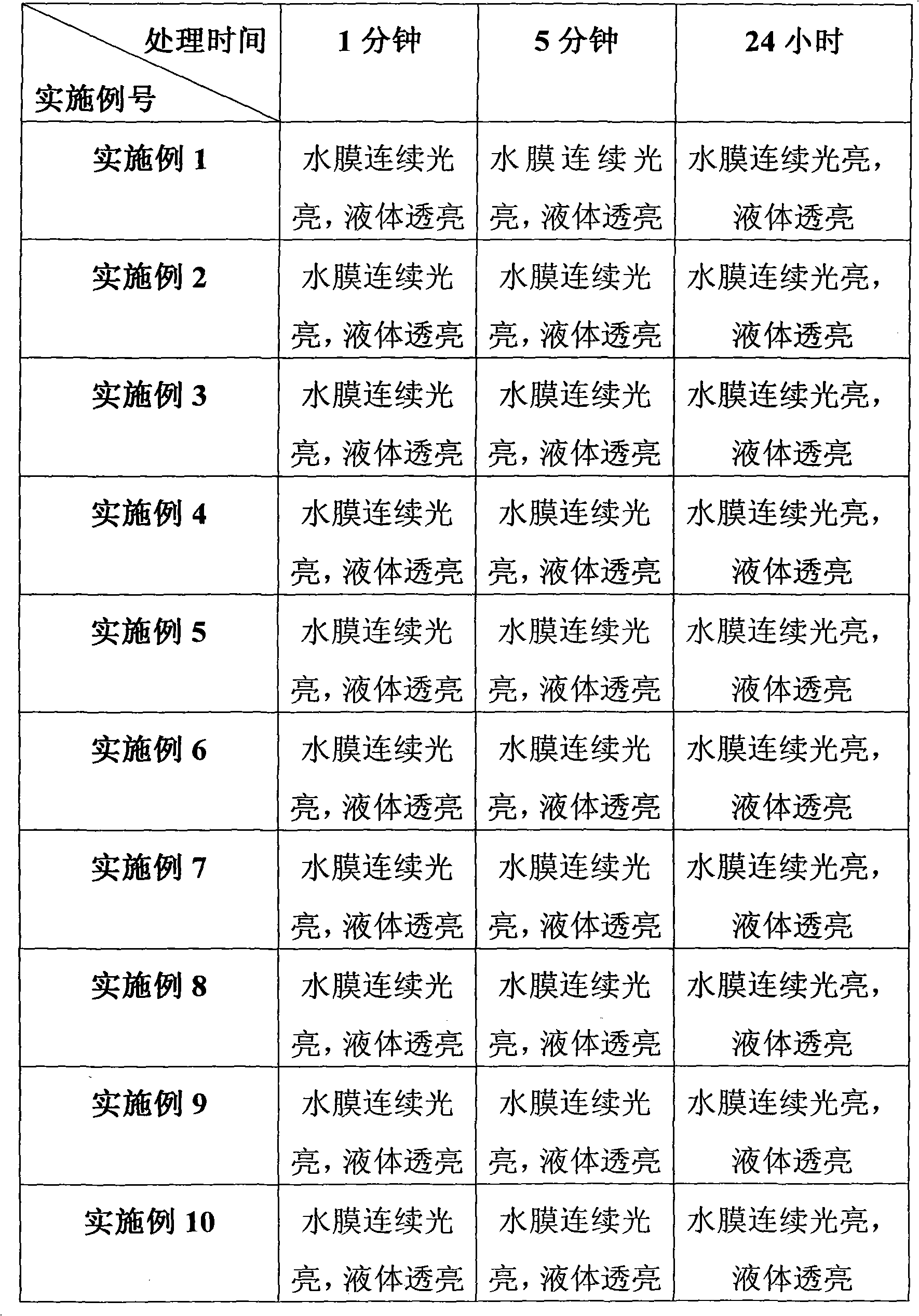

Examples

Embodiment 1

[0031] The degreasing agent is prepared in the following steps: respectively weigh 50g of sodium hydroxide, 150g of sodium carbonate, 50g of methylidene diphosphonic acid (MDP), and 50g of triton, and add them to 5L of water successively, and keep stirring to make it evenly mixed. Add water to make up to 10L. At this time, the concentration of each substance in the degreasing agent is respectively:

[0032] Sodium hydroxide 5g / L Sodium carbonate 15g / L

[0033] Methylidene diphosphonic acid 5g / L Triton 5g / L

[0034] Use an acid-base regulator to adjust the pH of the degreasing agent to 7.5, and keep the temperature of the degreasing agent at about 80°C. Divide the same bonded NdFeB permanent magnet material sample into three parts, put them into the above diluent at the same time, and take one of the above three permanent magnet material samples at the first minute, the fifth minute and the 24th hour. out.

Embodiment 2

[0036] The degreasing agent is prepared in the following steps: respectively weigh 50 g of sodium hydroxide, 150 g of sodium carbonate, 200 g of trisodium phosphate, 1-hydroxyethylidene-1, 1-diphosphonic acid (HEDP) 100 g, and 30 g of triton, Add it to 5L of water in turn, stir continuously to make it evenly mixed, then add water to make the volume to 10L. At this time, the concentration of each substance in the degreasing agent is respectively:

[0037] Sodium hydroxide 5g / L Sodium carbonate 15g / L

[0038] Trisodium Phosphate 20g / L 1-Hydroxyethylidene-1,1-Diphosphonic Acid 10g / L

[0039] Triton 3g / L

[0040] Use an acid-base regulator to adjust the pH of the degreasing agent to 8.0, and keep the temperature of the degreasing agent at about 60°C. Divide the same sintered NdFeB permanent magnet material sample into three parts, put them into the above diluent at the same time, take out one of the above three permanent magnet material samples at the first minute, the fifth mi...

Embodiment 3

[0042] The degreasing agent is prepared by the following steps: respectively weigh 100g of sodium hydroxide, 150g of sodium carbonate, 50g of sodium tripolyphosphate, 100g of ethylenediaminetetramethylidenephosphonic acid (EDTMP), 40g of triton, and add them to 5L In water, stir constantly to make it evenly mixed, then add water to make up to 10L. At this time, the concentration of each substance in the degreasing agent is respectively:

[0043] Sodium hydroxide 10g / L Sodium carbonate 15g / L

[0044] Sodium tripolyphosphate 5g / L EDTA 10g / L

[0045] AEO 4g / L

[0046] Use an acid-base regulator to adjust the pH of the degreasing agent to 8.0, and keep the temperature of the degreasing agent at about 50°C. Divide the same bonded NdFeB permanent magnet material sample into three parts, put them into the above diluent at the same time, and take one of the above three permanent magnet material samples at the first minute, the fifth minute and the 24th hour. out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com