Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "EDTMP" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

EDTMP or ethylenediamine tetra(methylene phosphonic acid) is a phosphonic acid. It has chelating and anti corrosion properties. EDTMP is the phosphonate analog of EDTA. It is classified as a nitrogenous organic polyphosphonic acid.

Special cleaning agent for three-way catalyst of vehicle

InactiveCN101982542AThe product is cost-effectiveSave cleaning oilOrganic detergent compounding agentsSurface-active detergent compositionsDodecylsulfonic acidCorrosion inhibitor

The invention relates to a cleaning agent, in particular to a special cleaning agent for a three-way catalyst of a vehicle. The cleaning agent is a mixed solution of one or combination of 3 to 10 percent of hydrochloric acid or sulfamic acid with inorganic acid concentration of 31 percent, 2 to 5 percent of surfactant sodium dodecyl sulfate and 1 to 5 percent of sodium triphosphate, one or combination of 1.5 to 5 percent of corrosion inhibitor isoquinoline quaternary ammonium salt and 1.5 to 5 percent of EDTMPS, 0.5 to 3 percent of chelating agent cetyl trimethyl ammonium bromide, and 50 to 60 percent of water. The cleaning agent can directly clean the three-way catalyst under any condition, especially under the condition that the vehicle engine cannot be started, so as to achieve the aim of effectively and quickly removing the gum deposited carbide of the three-way catalyst of the vehicle, and has the characteristics of high product cost performance, environment friendliness, multiple functions and the like, is convenient in use, and can reactivate the vehicle three-way catalyst and prolong the service life of the vehicle three-way catalyst.

Owner:吴龙生

Rare-earth multi-element plant nutrient fluid and preparing method thereof

InactiveCN1528716AFunctionalSolve the problem of coexistence and co-solutionBiocideAnimal repellantsVitamin CRare earth

The invention relates to a rare-earth multielement plant nutrient solution and preparing method, using light rare earth, multiple nitrates, urea, phosphoric acid as well as complexing agents such as EDTA, EDTMP, vitamin C, tartaric acid, citric acid and so on, to prepare it through the procedures of raw materials preparation, chelating medium body preparation, chain chelation reactions, compound preparation, etc. It has high content of light rare-earth and plant nutrient element, reasonable mixing proportion, good stability, etc, applied to spray multiple crops.

Owner:JUYUAN HIGH TECH DEV BEIJING

Chromate-free passivation agent for aluminum alloy

InactiveCN105779984AIncreasing the thicknessImprove compactnessMetallic material coating processesEpoxySilanes

The invention discloses a chromate-free passivation agent for an aluminum alloy. Per liter of chromate-free passivation agent is composed of, by mass, 10 mg to 300 mg of amino silane or / and epoxy silane, 1 mg-100 mg of dispersible nano particles, 10 mg-500 mg of a zirconium compound or / and a titanium compound, 1 mg-150 mg of metal ions, 10 mg-150 mg of fluoride, 1 mg-20 mg of a complexing agent, 75 mg-100 mg of organic phosphoric acid and the balance water; and the organic phosphoric acid is at least two of HEDP, HPMA, EDTMP, DTPMP, ATMP and PBTCA. According to the passivation agent, multiple kinds of organic phosphoric acid, multiple kinds of metal ions and multiple kinds of nano particles are chelated to the different degrees; on one aspect, the thickness and the compactness of a passivation film layer can be strengthened; and meanwhile, the passivation film layer (inorganic film layer) formed after chelation can show a color to a certain degree on the surface of the aluminum alloy.

Owner:NANJING KERUN LUBRICANTS

Treatment Fluids Comprising Vitrified Shale and Methods of Using Such Fluids in Subterranean Formations

Owner:HALLIBURTON ENERGY SERVICES INC

Aerated brick with anti-freezing function and preparation method thereof

InactiveCN103771894AImprove antifreeze effectImprove toughnessSolid waste managementCeramicwareBrickPhosphate

The invention discloses an aerated brick with an anti-freezing function. The aerated brick is characterized by being prepared from the following raw materials in parts by weight: 20-25 parts of lead-zinc tailing powder, 17-19 parts of household garbage, 11-14 parts of lime, 0.2-0.5 part of aluminum powder, 5-7 parts of phosphate cement, 10-13 parts of natural yellow sand, 2-4 parts of potassium sulfate, 1-4 parts of EDTMP.Na5, 2-5 parts of ammonium bicarbonate, 0.3-0.6 part of tara gum, 0.2-0.4 part of tamarind gum, 1-3 parts of soda ash, 3-5 parts of chestnut shells, 0.5-0.7 part of gelatin, 0.1-0.3 part of dried tangerine peel, 0.3-0.5 part of moxa leaves, 4-6 parts of auxiliaries and a proper volume of water. The prepared aerated brick disclosed by the invention has good anti-freezing property; through adding proper auxiliaries and foam stabilizer, the toughness of the aerated brick is improved, and the permeation resistance is improved; moreover, the processing process is simple and easy to implement, the production cost can be reduced, the cyclic economy effect of changing the waste into the valuable is realized, and the competitiveness of the product is improved.

Owner:ANHUI SHENGREN NEW BUILDING MATERIAL

Electrochemical corrosive process of anode aluminum foil

InactiveCN101029412AHigh mechanical strengthObservation uniformCapacitor electrodesAluminum IonPhosphate

An electrochemical corrosion technology for anode aluminum foils consists of two DC electrochemical corrosion processes. The first electrochemical corrosion process is carried out in mixed solution sulfuric acid, chlorine ion and aluminum ion; the second electrochemical corrosion process is carried out by adding into organic phosphonic acid or phosphate, ATMP, HEDP and EDTMP. It has homogenous appearance, large capacity ration, excellent mechanical strength and water-proof performance.

Owner:DONGGUAN HEC CONDENSER CO LTD

Scale-inhibition compositions and methods of making and using the same

ActiveUS9139799B1Organic detergent compounding agentsNon-surface-active detergent compositionsHexamethylenediamineDiethylenetriamine

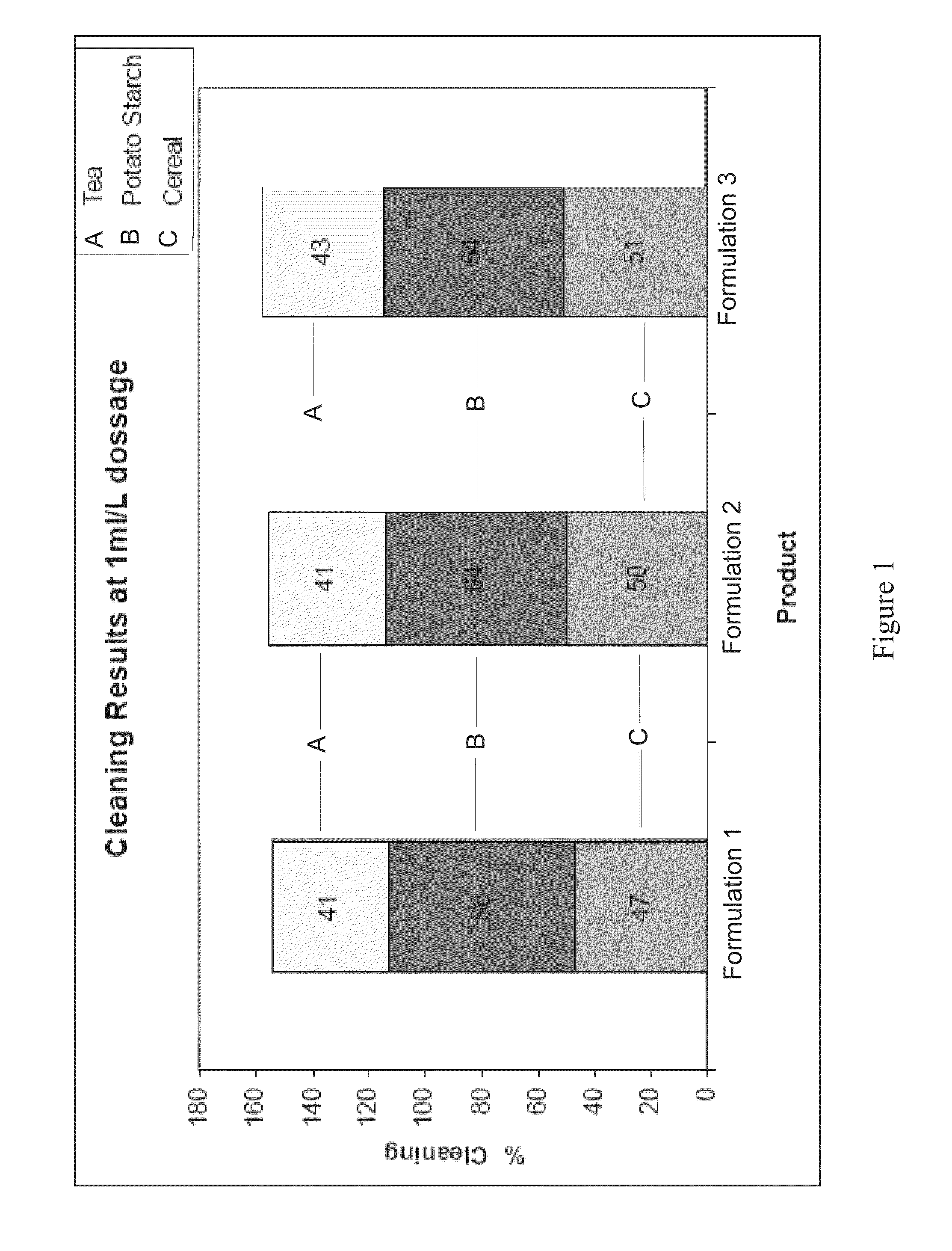

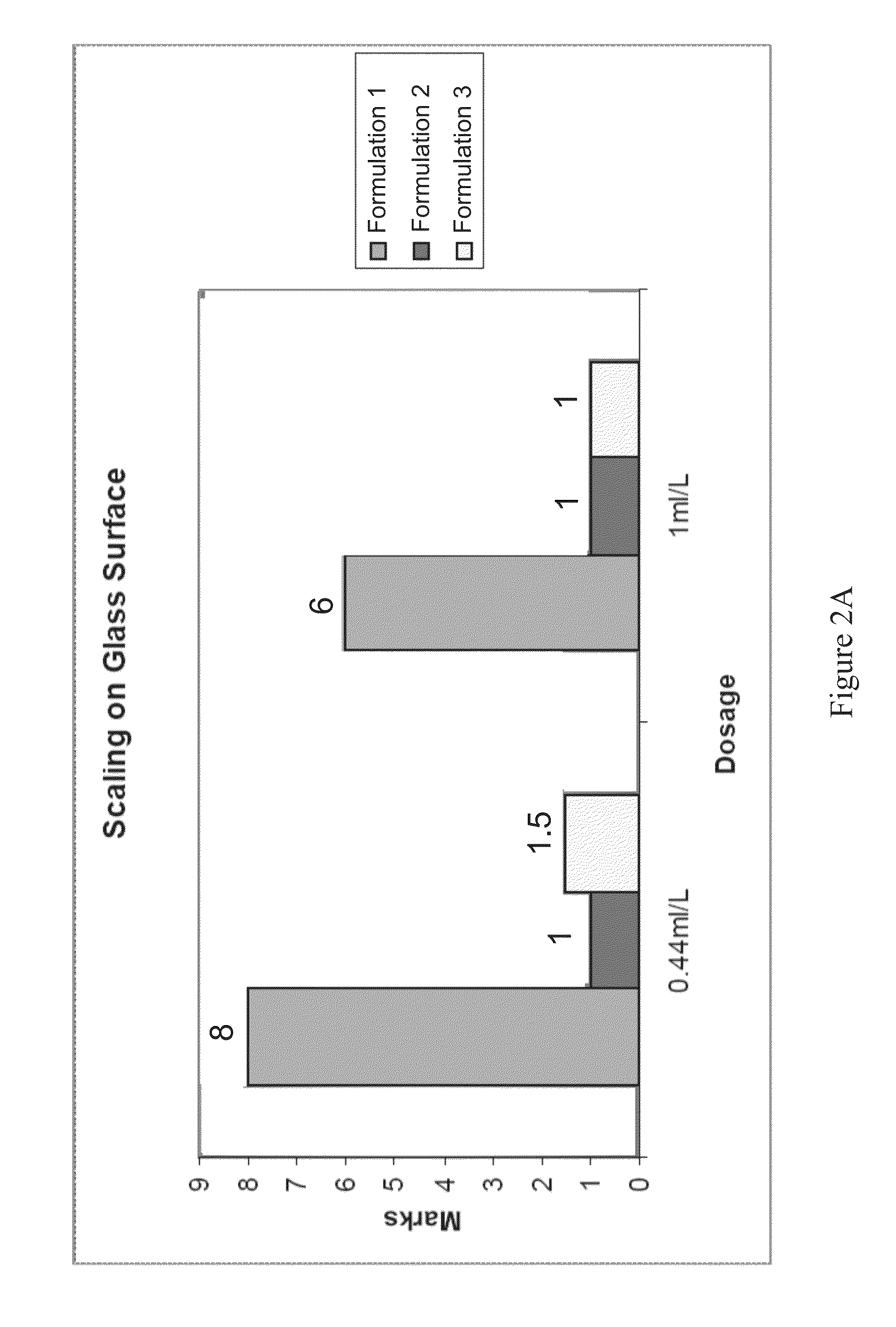

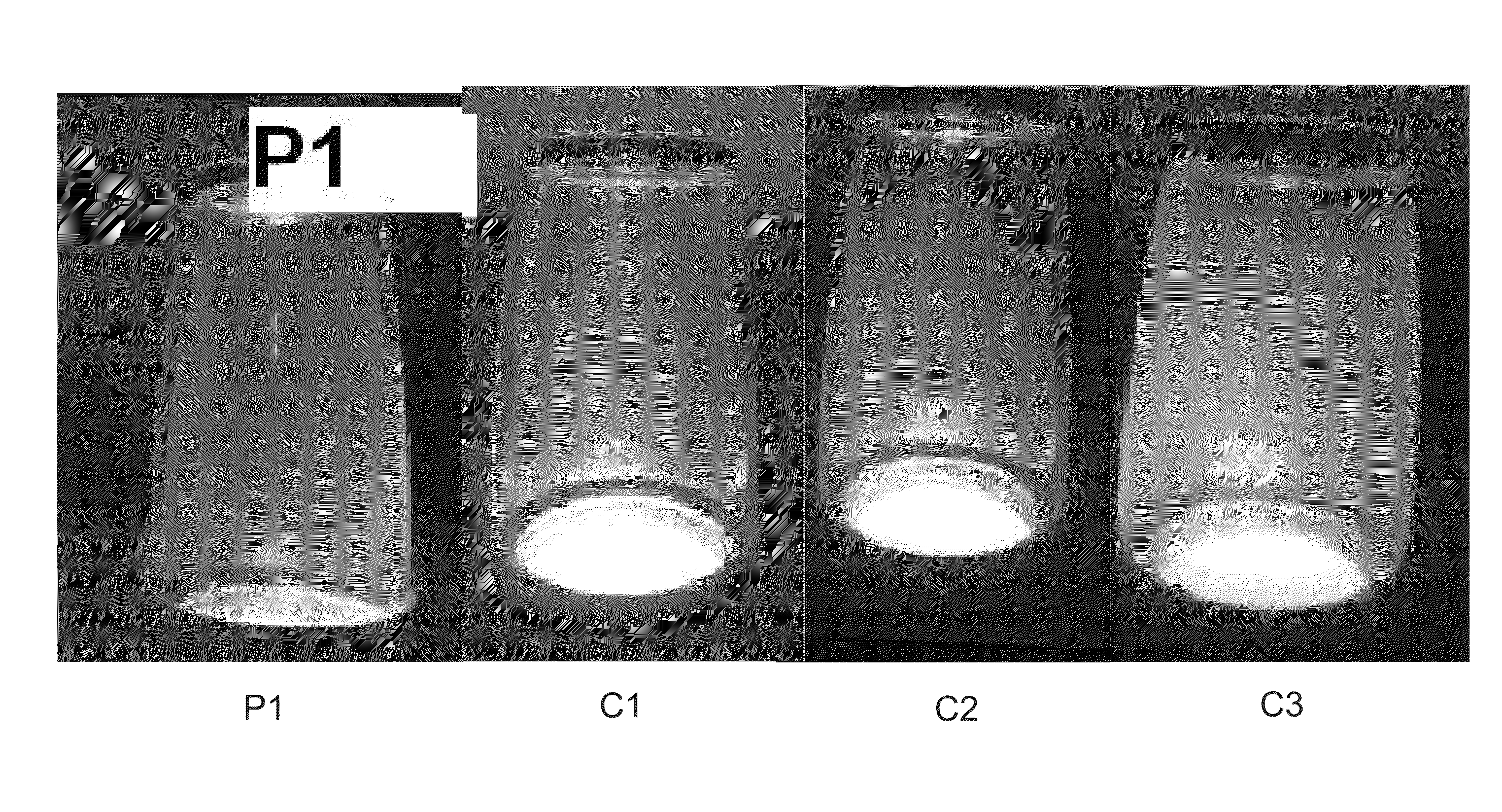

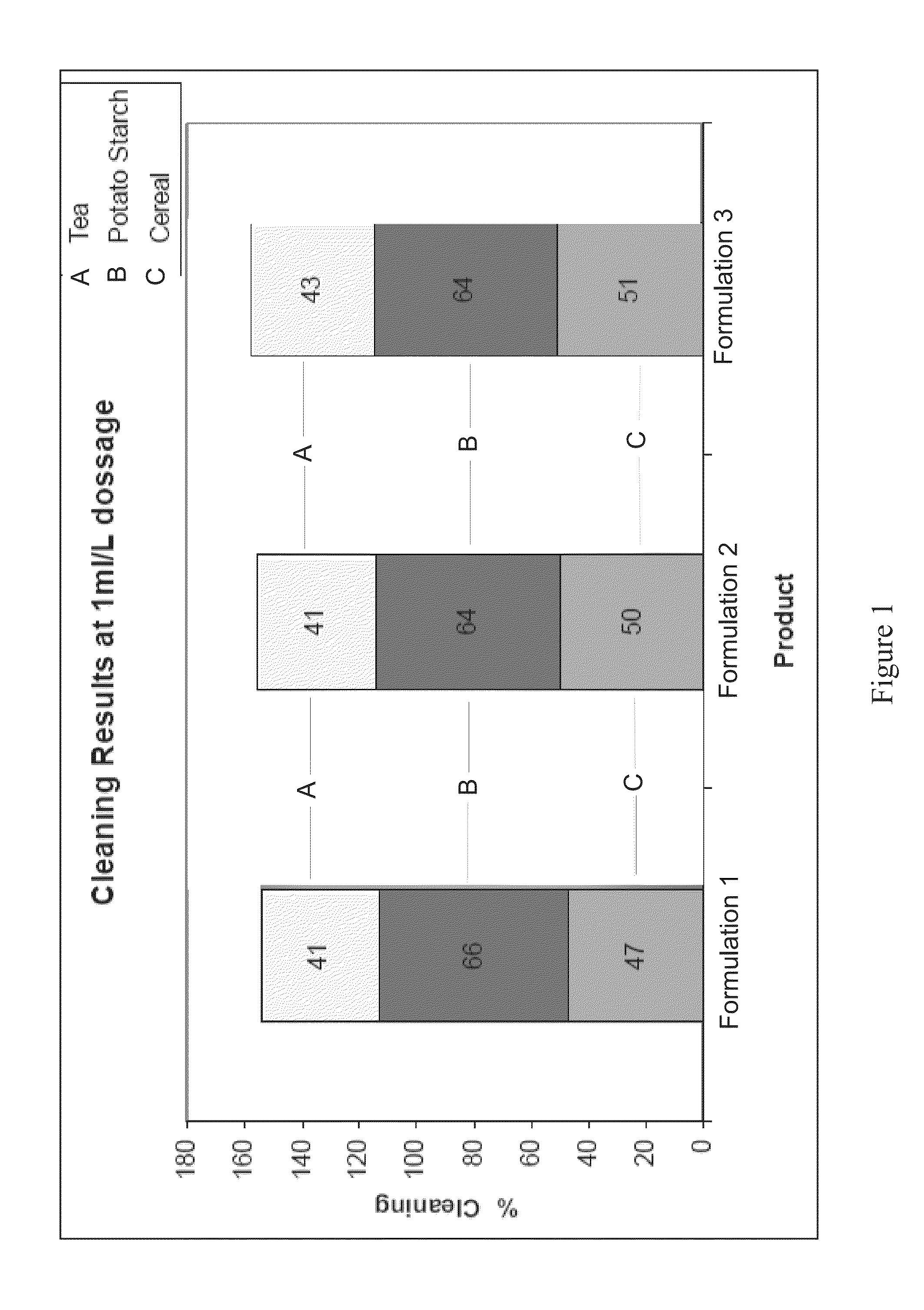

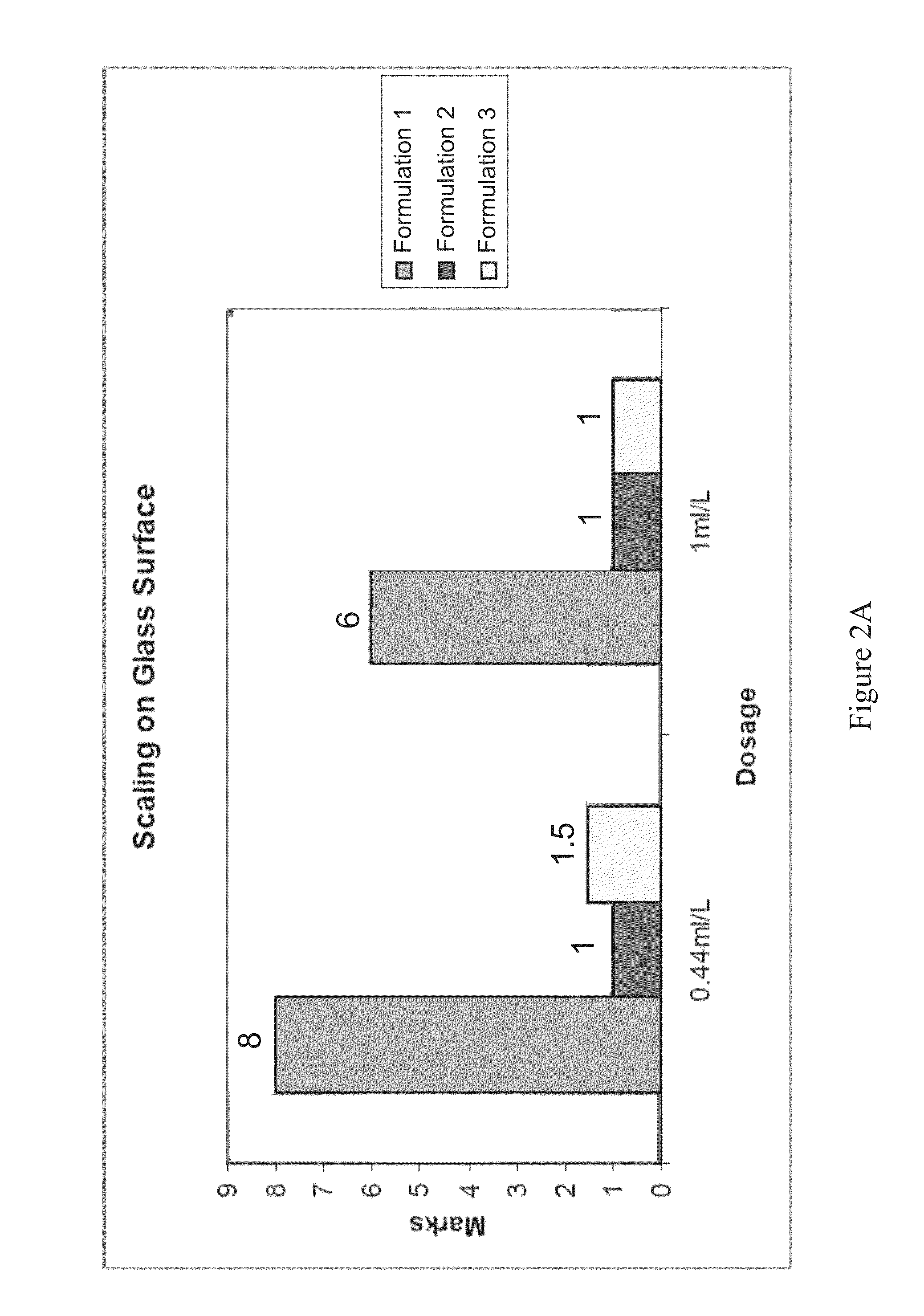

Provided are scale-inhibition compositions comprising (a) a first acrylic acid polymer having an average molecular weight of about 3000 to about 6000; (b) a second acrylic acid polymer having an average molecular weight of about 6000 to about 10000; (c) an aminocarboxylic acid selected from methylglycine diacetic acid (MGDA), glutamic acid diacetic acid (GLDA), diethylene triamine pentaacetic acid (DTPA), hydroxyethyl ethylene diamine triacetic acid (HEDTA), ethylenediaminetetraacetic acid (EDTA), and a combination thereof; and (d) a phosphonic acid selected from 1-hydroxyethane 1,1-diphosphonic acid (HEDP), amino tris(methylenephosphonic acid) (ATMP), ethylenediamine tetra(methylene phosphonic acid) (EDTMP), tetramethylenediamine tetra(methylene phosphonic acid) (TDTMP), hexamethylenediamine tetra(methylene phosphonic acid) (HDTMP), diethylenetriamine penta(methylene phosphonic acid) (DTPMP), and a combination thereof. The scale-inhibition compositions may be useful in machine ware washing detergents and formulations.

Owner:JOHNSONDIVERSEY INC

Scale-inhibition compositions and methods of making and using the same

ActiveUS20160010031A1Organic detergent compounding agentsNon-surface-active detergent compositionsHexamethylenediamineDiethylenetriamine

Provided are scale-inhibition compositions comprising (a) a first acrylic acid polymer having an average molecular weight of about 3000 to about 6000; (b) a second acrylic acid polymer having an average molecular weight of about 6000 to about 10000; (c) an aminocarboxylic acid selected from methylglycine diacetic acid (MGDA), glutamic acid diacetic acid (GLDA), diethylene triamine pentaacetic acid (DTPA), hydroxyethyl ethylene diamine triacetic acid (HEDTA), ethylenediaminetetraacetic acid (EDTA), and a combination thereof; and (d) a phosphonic acid selected from from 1-hydroxyethane 1,1-diphosphonic acid (HEDP), amino tris(methylenephosphonic acid) (ATMP), ethylenediamine tetra(methylene phosphonic acid) (EDTMP), tetramethylenediamine tetra(methylene phosphonic acid) (TDTMP), hexamethylenediamine tetra(methylene phosphonic acid) (HDTMP), diethylenetriamine penta(methylene phosphonic acid) (DTPMP), and a combination thereof. The scale-inhibition compositions may be useful in machine ware washing detergents and formulations.

Owner:JOHNSONDIVERSEY INC

Flocculant for sewage treatment

InactiveCN106044988ANothing producedQuick responseWater/sewage treatment by flocculation/precipitationPhosphatePolyethylene glycol

The invention relates to a flocculant for sewage treatment, which consists of the following components: polymaleic acid, acryloyloxyethyltrimethylammonium chloride, hydrolyzed polymaleic anhydride, sodium ethylenediamine tetramethylene phosphonate, Potassium chlorate, trichloroisocyanuric acid, triclosan, p-hydroxybenzoic acid, sodium percarbonate, zeolite powder, titanium dioxide powder, ammonium sulfate, zinc sulfate powder, magnesium sulfate, zinc sulfate, ammonium chloride, benzyl chloride, diphosphate Potassium Hydrogen, Tert-Butyl Cellosolve, Glyceryl Stearate, Coconut Oil, Capric Aldehyde, Epichlorohydrin, Butyl Acetate, Ethylene Oxide, Triethanolamine, Polymethyl Hydrogen Siloxane, Polyethylene Glycol Octyl phenyl ether, polydiallyldimethylammonium chloride, starch phosphate, deionized water. The product of the present invention has a fast reaction speed and no toxic and harmful gases are produced during the process; the product after the reaction is stable and will not be decomposed into toxic substances; it is highly efficient and non-toxic, safe for the human body before and after the reaction, and has no corrosion on objects; it is aimed at sewage treatment efficient.

Owner:李云海

Electroplating solution for composite organic phosphonic acid cyanide-free copper plating and electroplating method

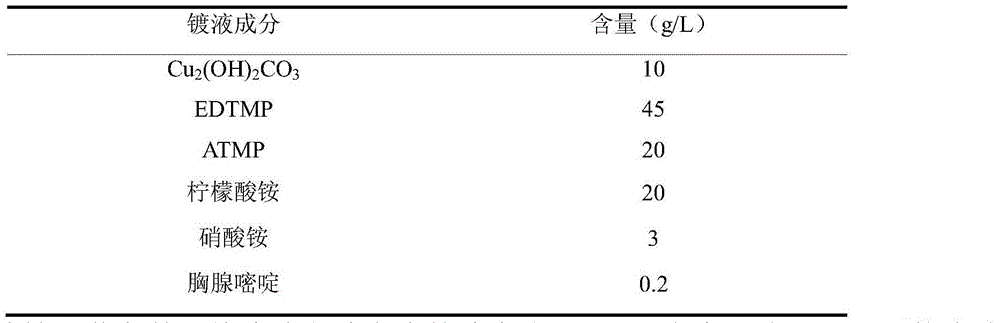

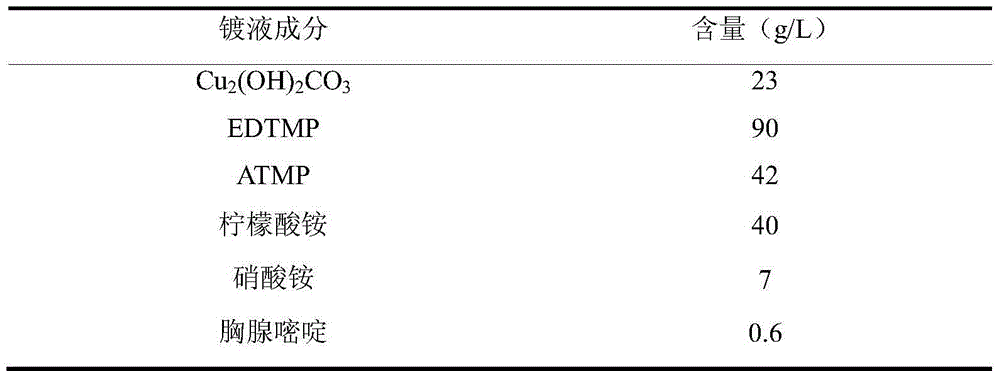

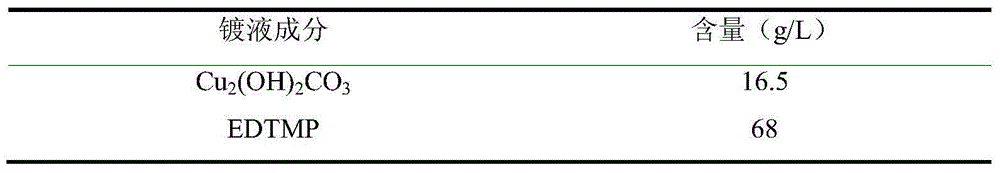

The invention discloses an electroplating solution for composite organic phosphonic acid cyanide-free copper plating and an electroplating method. The electroplating solution comprises: 10-23g / L Cu2(OH)2CO3, 45-90g / L EDTMP (ethylene diamine tetra(methylene phosphonic acid)), 20-42g / L ATMP (aminotri-(methylene phosphonic acid)), 20-40g / L citrate, 3-7g / L nitrate and 0.2-0.6g / L thymine. The electroplating solution provided by the invention adopts EDTMP and ATMP composite organic phosphonic acid as the coordination agent to improve the coordination ability of copper ions, and takes citrate as the auxiliary coordination agent, so that the electroplating solution has good dispersion force and deep plating ability, high cathode current efficiency, and excellent performance. The coating obtained by electroplating of the electroplating solution under an alkaline condition has low porosity and good quality.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

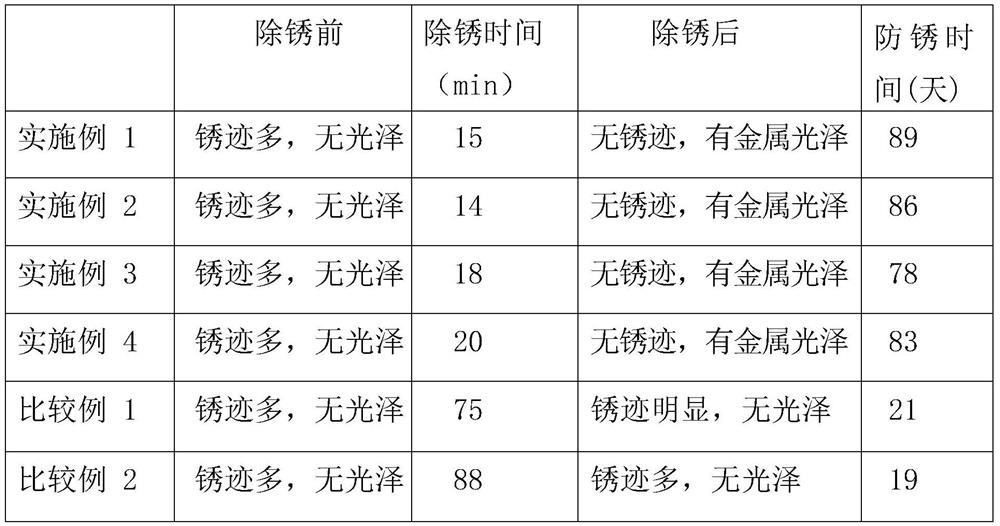

Environment-friendly universal rust remover

InactiveCN112301350AImprove bindingImprove anti-corrosion performanceMetallic material coating processesPhosphatePhosphoric acid

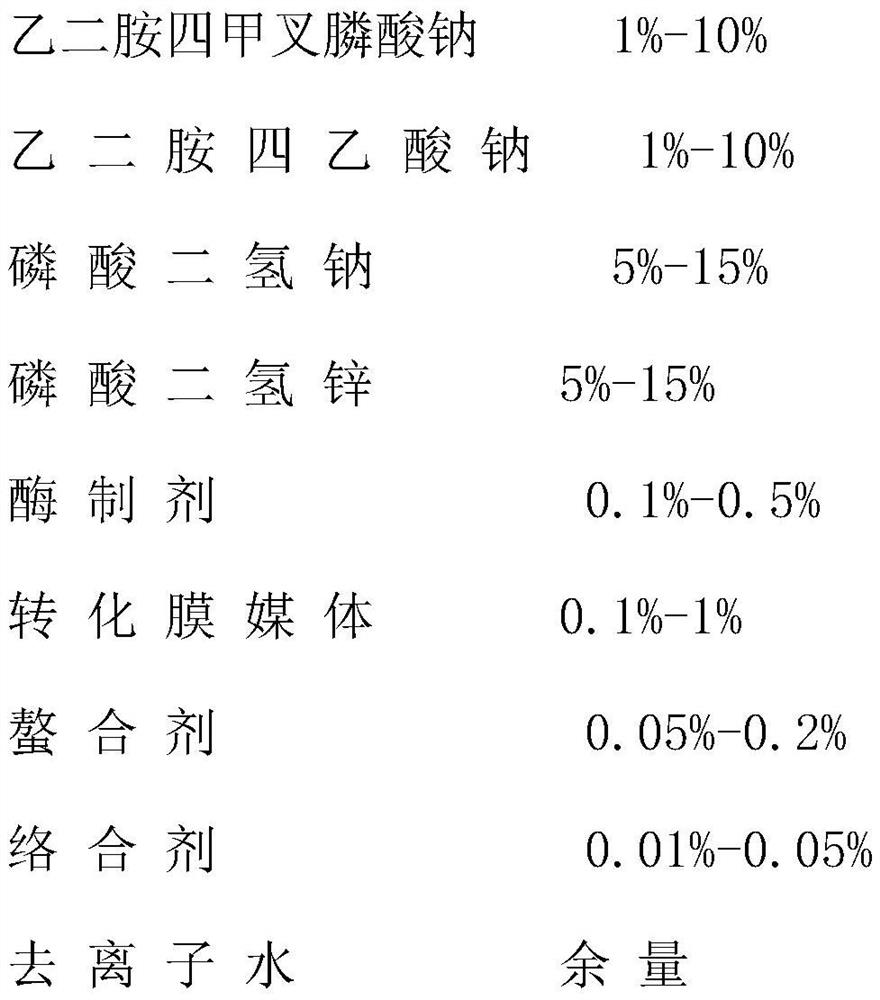

The invention discloses an environment-friendly universal rust remover. The environment-friendly universal rust remover is mainly prepared by mixing and dissolving the following raw materials including, by weight percent, 1%-10% of EDTMPS, 1%-10% of edetate disodium, 5%-15% of sodium dihydrogen phosphate, 5%-15% of zinc dihydrogen phosphate, 0.1%-0.5% of an enzyme preparation, 0.1%-1% of a conversion film medium, 0.05%-0.2% of a chelating agent, 0.01%-0.05% of a complexing agent and the balance deionized water. The environment-friendly universal rust remover has the advantages of improving thebinding force of paint, enhancing the corrosion resistance, and achieving the antirust effects of being quick in rust removal, free of pollution, healthy and environment-friendly.

Owner:杭州悦山科技有限公司

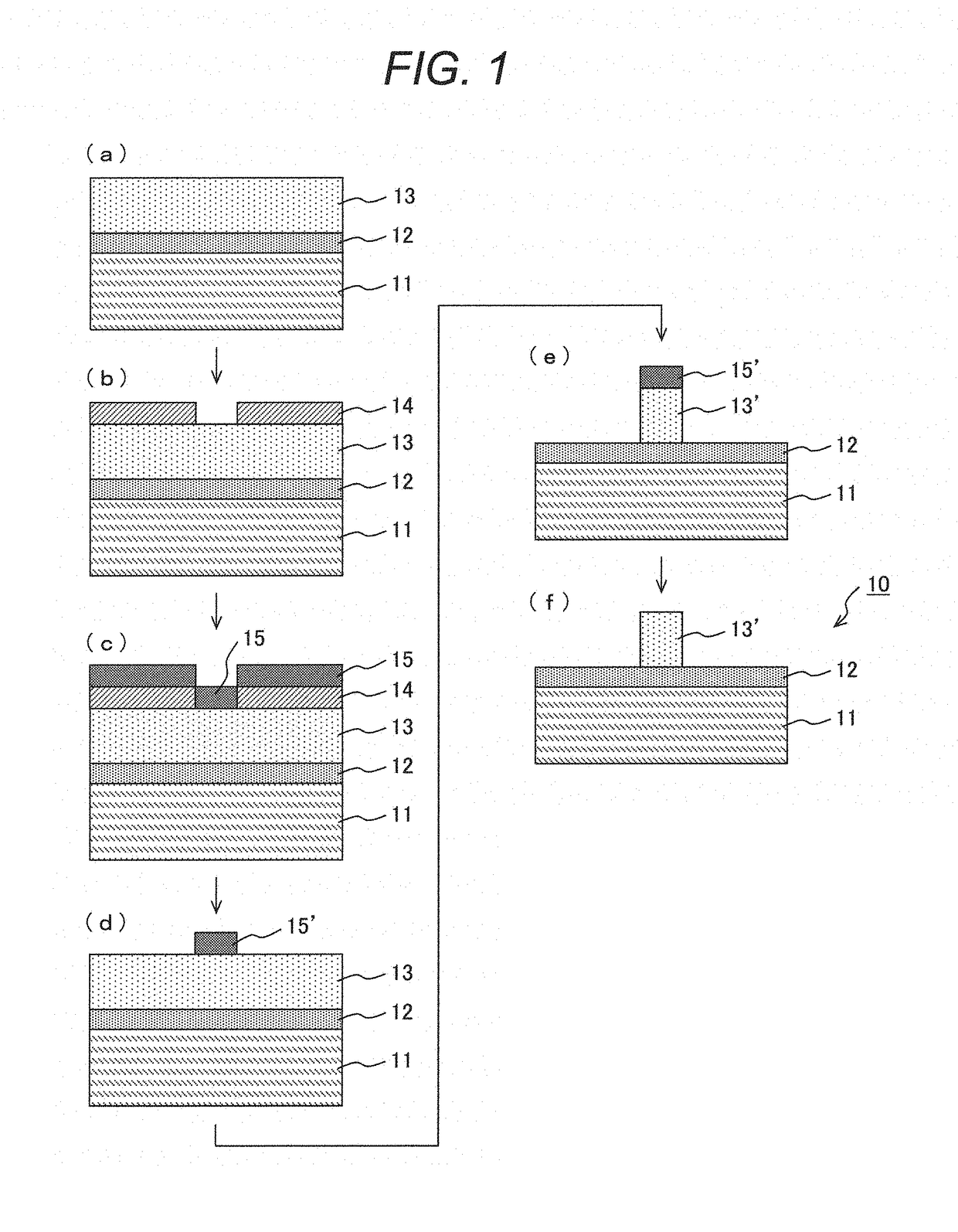

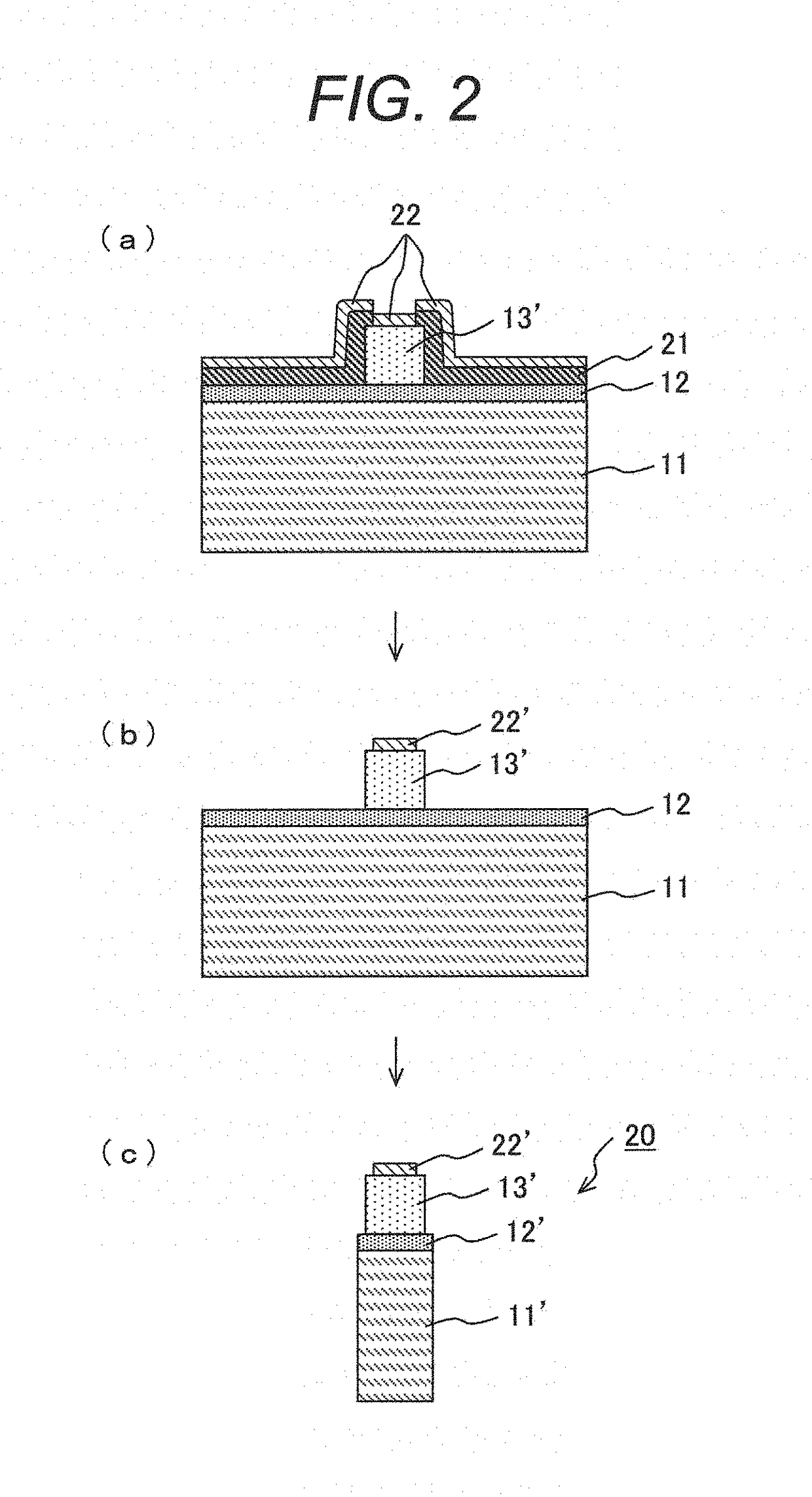

Method for manufacturing niobate-system ferroelectric thin-film device

ActiveUS10199564B2High dimensional accuracyLow costVacuum evaporation coatingSputtering coatingEtchingFerroelectric thin films

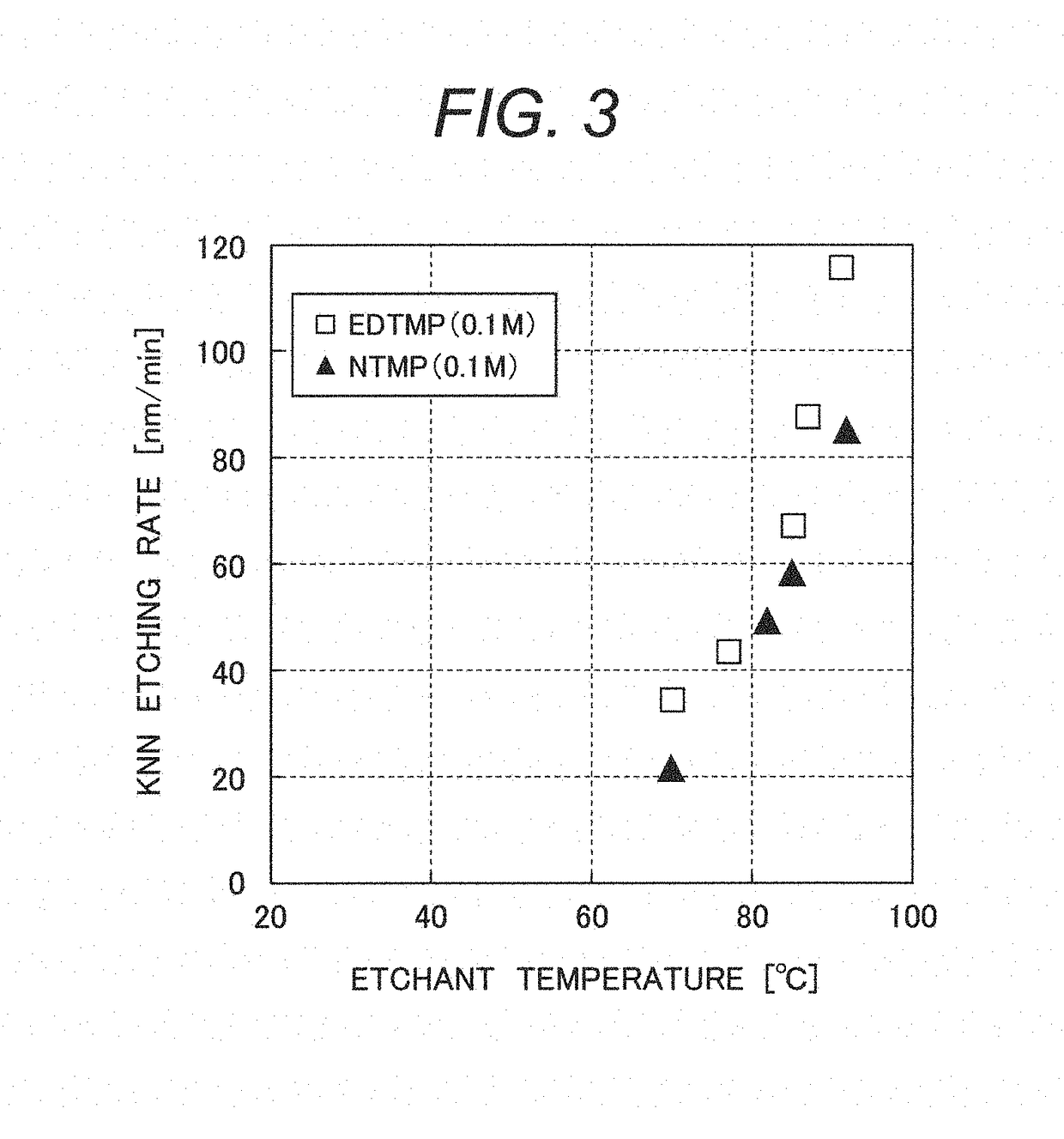

This method for manufacturing a lead-free niobate-system ferroelectric thin film device includes: a lower electrode film formation step of forming a lower electrode film on a substrate; a ferroelectric thin film formation step of forming a niobate-system ferroelectric thin film on the lower electrode film; an etch mask pattern formation step of forming an etch mask in a desired pattern on the niobate-system ferroelectric thin film; and a ferroelectric thin film etching step of shaping the niobate-system ferroelectric thin film into a desired fine pattern by wet etching using an etchant comprising: a predetermined chelating agent including at least one selected from EDTMP, NTMP, CyDTA, HEDP, GBMP, DTPMP, and citric acid; an aqueous alkaline solution containing an aqueous ammonia solution; and an aqueous hydrogen peroxide solution.

Owner:SUMITOMO CHEM CO LTD +1

Neutral deoiling derusting cleaning agent

InactiveCN1297646CNo peelingNo cloggingOrganic detergent compounding agentsSurface-active agentsCleansing Agents

The invention provides a neutral deoiling derusting cleaning agent which comprises polymeric compound, chelating agent, inorganic salt, surface active agent, sulfourea and water. Wherein the polymeric compound is polycarboxylic acid substance, which can be maleic anhydride, polyacrylic acid, sodium polyacrylate, the chelating agent is organo-phosphine acid or EDTA substance, the organo-phosphine acids can be ATMP, EDTMP, HEDP, the inorganic salt is Na2Co3, NaiHCo3, NaOH, the surface active agent is anionic surface active agent AS or LAS. The preparing process is also disclosed.

Owner:北京蓝星清洗有限公司

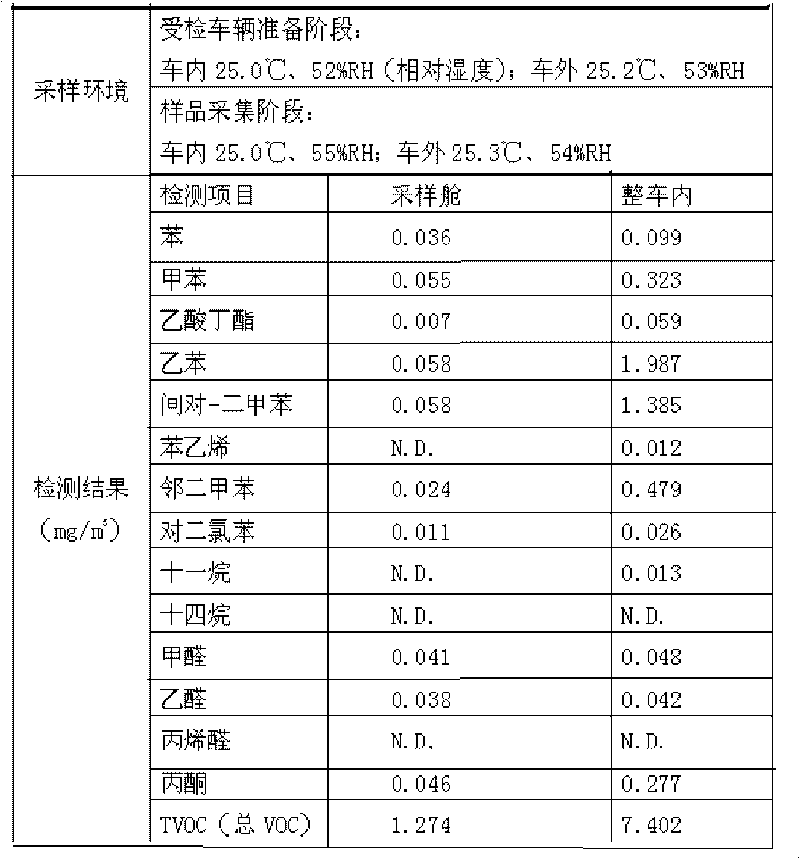

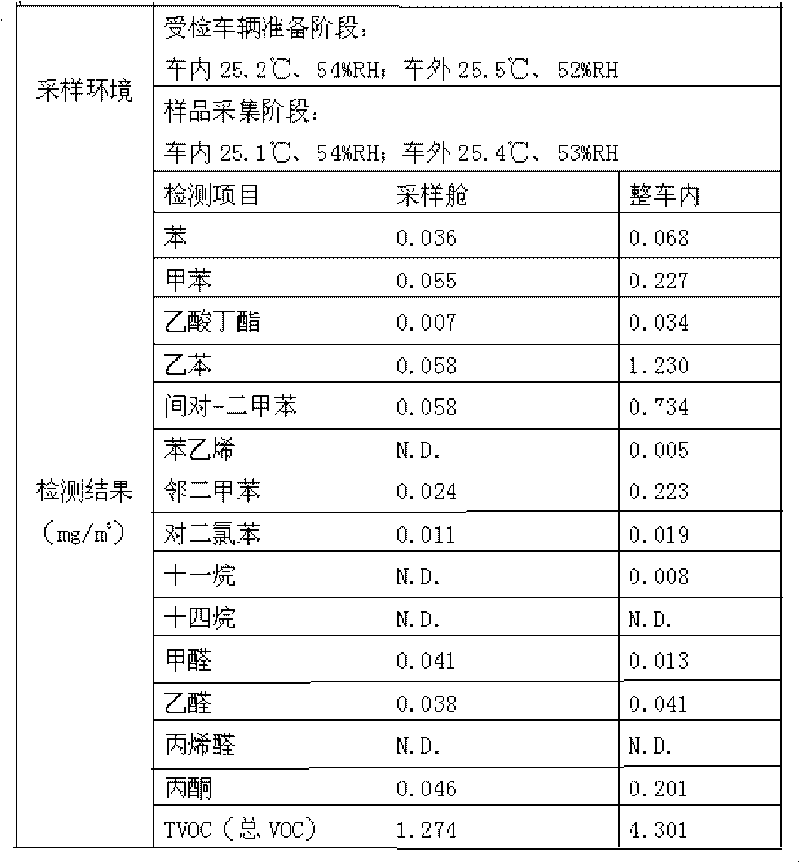

Purifying liquid, preparation method thereof and application of purifying liquid in in-vehicle air purification

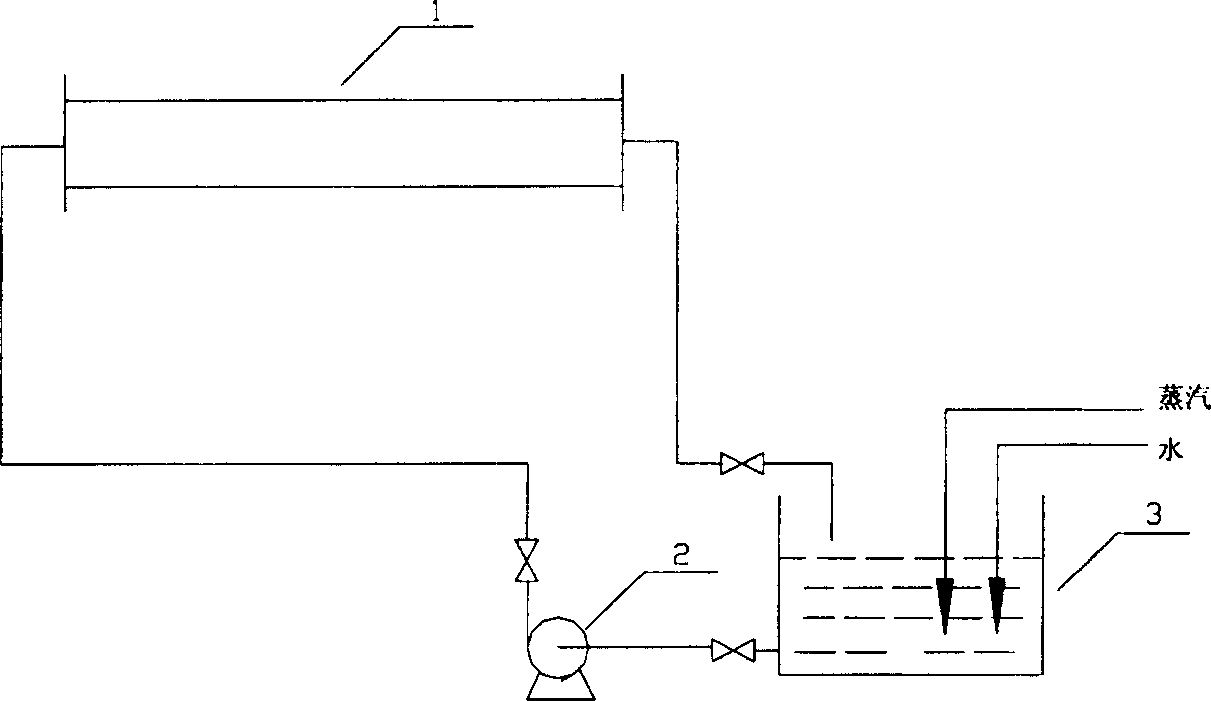

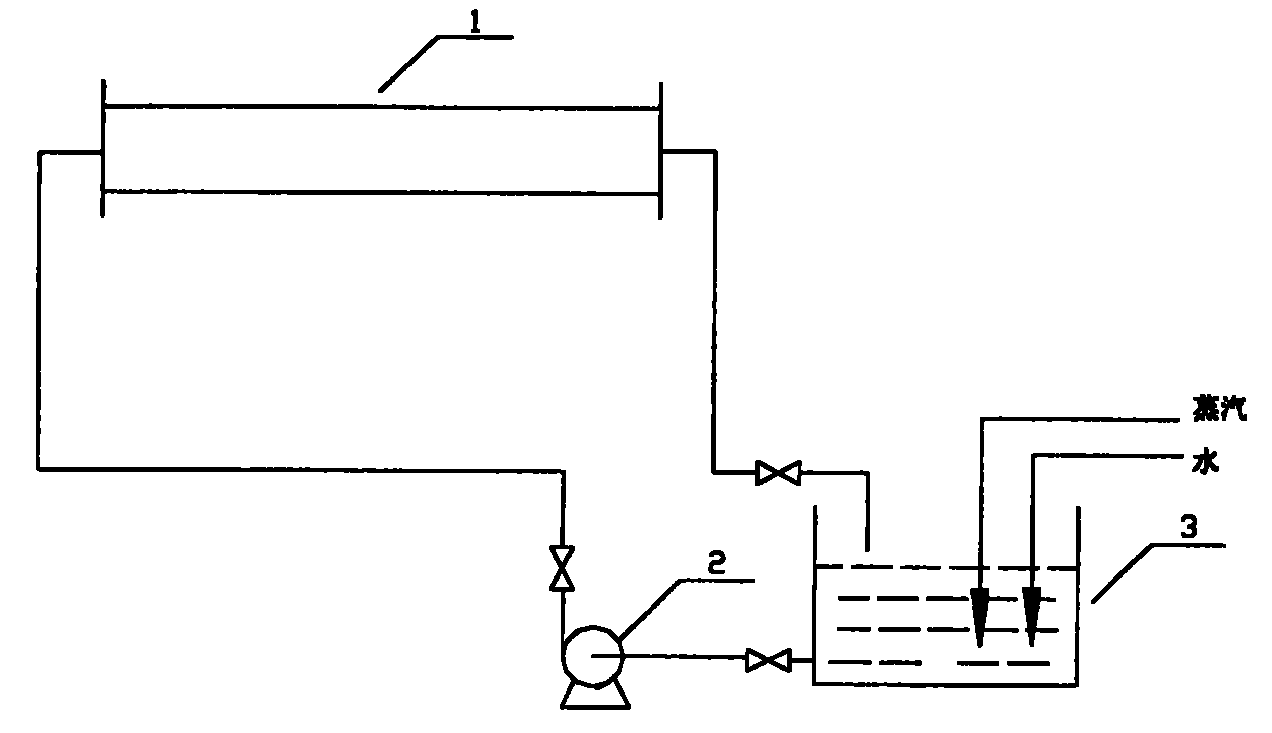

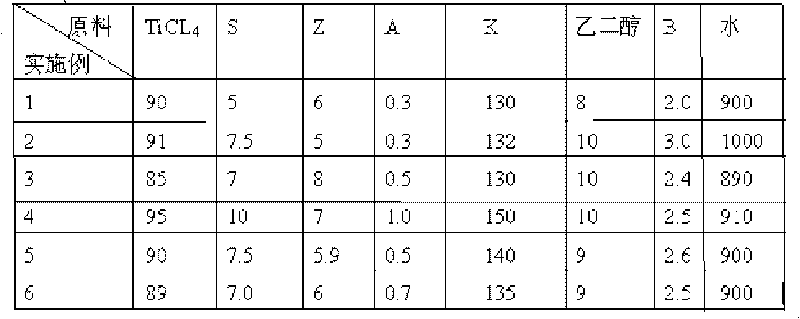

The invention discloses purifying liquid, which is prepared from the following raw materials by mass: 85 to 95 kilograms of TiCl4, 5 to 10 kilograms of nano platinum solution, 5 to 8 kilograms of chelating agent EDTMP, 0.3 to 1.0 kilogram of organic lanthanide series metal complex, 130 to 150 kilograms of alkali reagent, 8 to 10 kilograms of alcohol solution, 2.0 to 3.0 kilograms of silane coupling agent and 890 to 910 kilograms of water. The invention also provides a preparation method for the purifying liquid and application of the purifying liquid in in-vehicle air purification. The invention can effectively solve the problem of in-vehicle peculiar smell, and provides a healthy and environment-friendly in-vehicle air environment for passengers.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +2

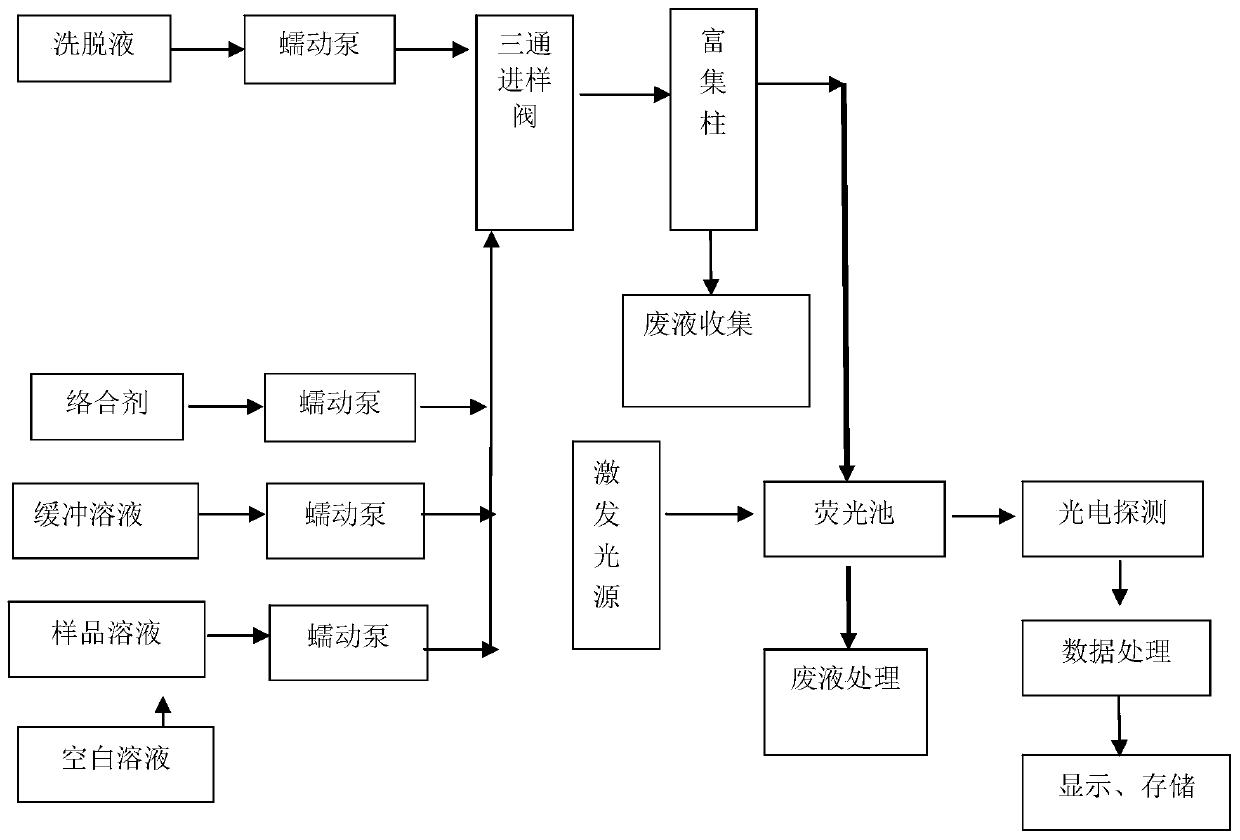

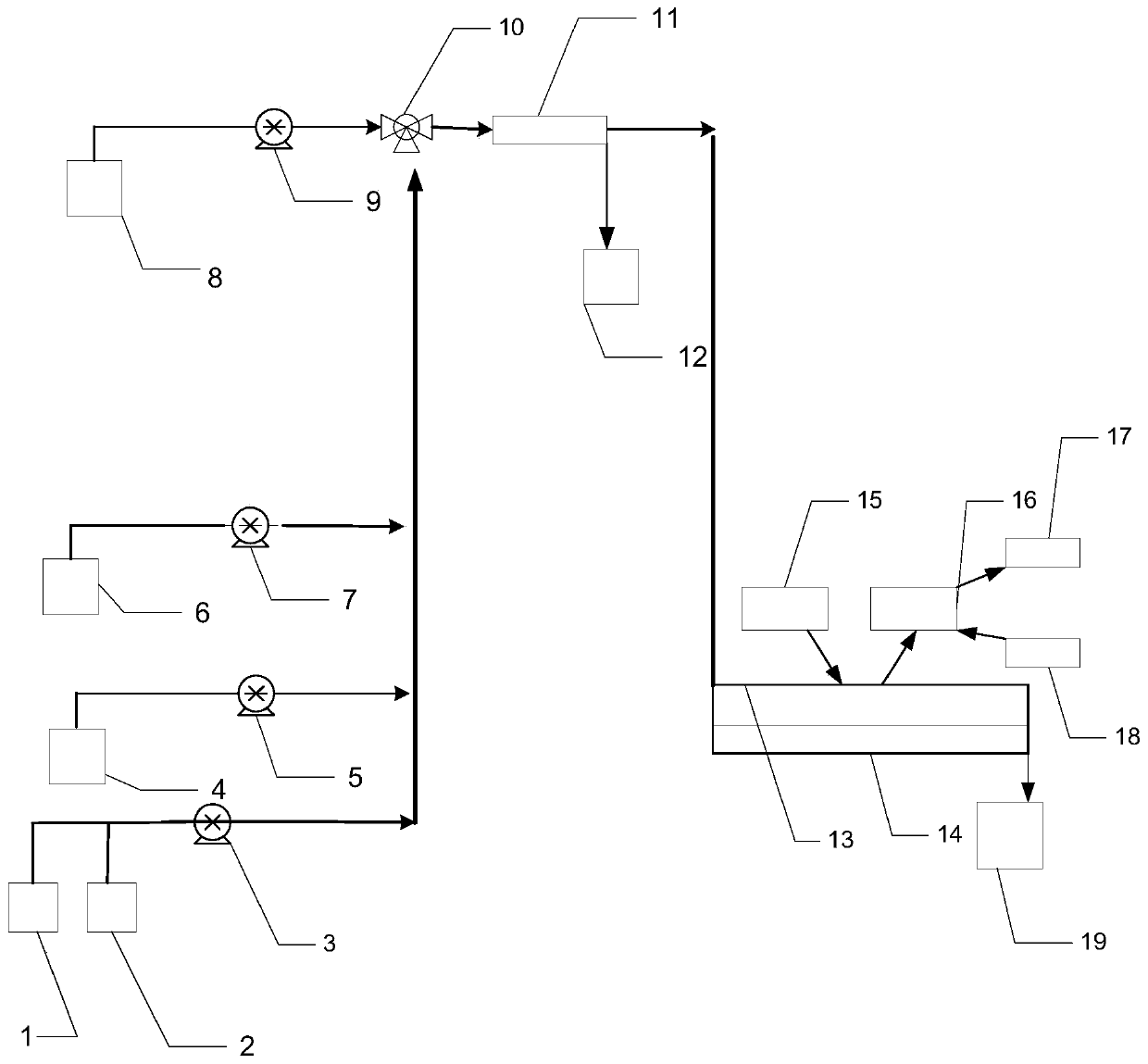

Method for measuring DDT in water by molecular imprinting selection fluorescence quenching

ActiveCN109900665AObvious quenching effectRapid AnalysisFluorescence/phosphorescenceFluorescenceLinear relationship

The invention discloses a method for measuring DDT in the water by molecular imprinting selection fluorescence quenching. The method comprises steps that firstly, the complex is formed through DDT inthe water sample and EDTMPS, secondly, the complex is then sequentially enriched and eluted, and lastly, the fluorescence technology is used for detection. The formed complex has the significant quenching effect on a fluorescent system, and the linear relationship between the fluorescence signal quenching degree and the concentration of DDT in the water is formed. The method is advantaged in thatthe method has on-site, fast, simple and sensitive characteristics, and problems that the existing technology can not work on site, the analysis duration is long, the analysis process is complicated,the conditions are harsh, the energy consumption is large, and especially secondary pollution occurs in the prior art are solved.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Scale inhibitor composition, scale inhibitor and preparation method of scale inhibitor

InactiveCN111217459AInhibition formationReduce foulingSpecific water treatment objectivesWater contaminantsSulfateAcid anhydride

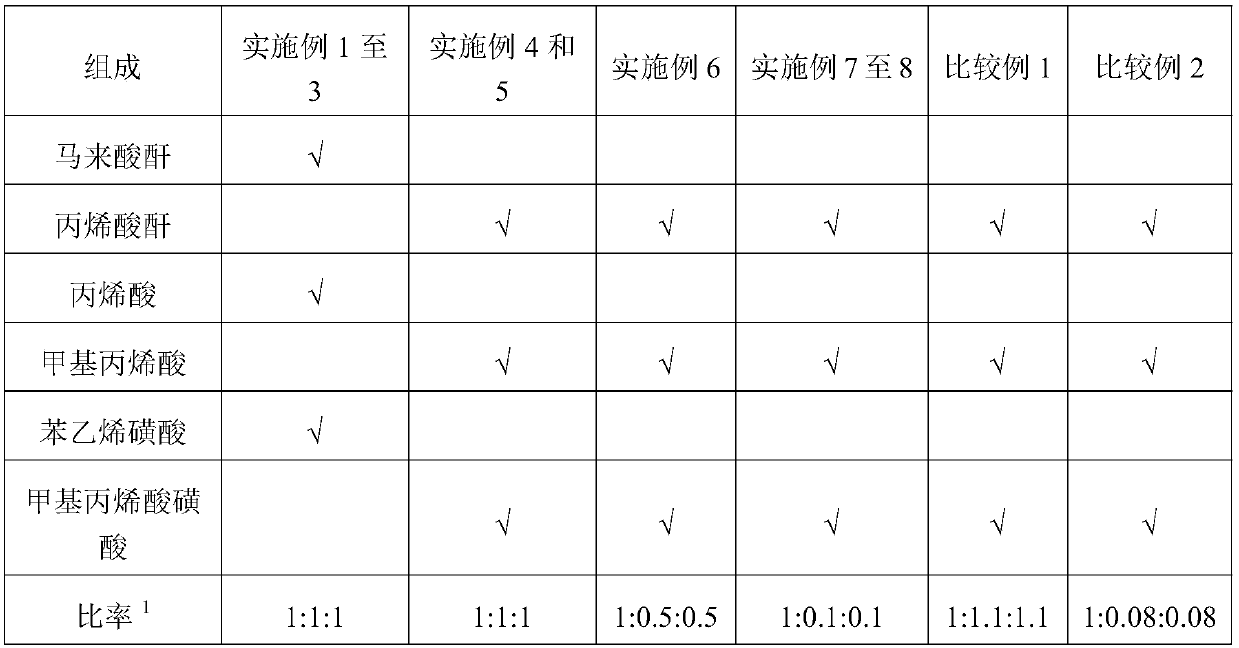

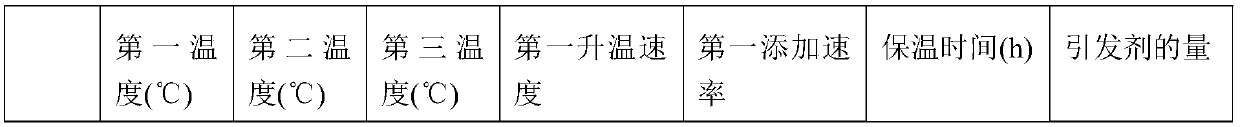

The invention provides a scale inhibitor composition, a scale inhibitor and a preparation method of the scale inhibitor. The scale inhibitor composition comprises aliphatic unsaturated acid anhydride,aliphatic unsaturated acid and a unsaturated sulfonic acid substance, wherein a molar ratio of the aliphatic unsaturated acid anhydride to the aliphatic unsaturated acid to the unsaturated sulfonic acid substance is 1:1:1 to 1:0.1:0.1. According to the invention, the scale inhibitor prepared from the scale inhibitor composition can effectively inhibit the formation of calcium carbonate, calcium sulfate, barium sulfate, silicate and other water scales, has good dispersity and certain zinc stability, greatly relieves the scaling phenomenon in an oil-gas development process, and saves the development cost; and the scale inhibitor provided by the invention does not contain phosphorus, can greatly reduce the emission of phosphorus, has good compatibility with HEDP, ATMP, EDTMP and other phosphorus scale inhibitors, and has the advantages of uncomplicated synthesis process and reliable and stable performance.

Owner:PETROCHINA CO LTD

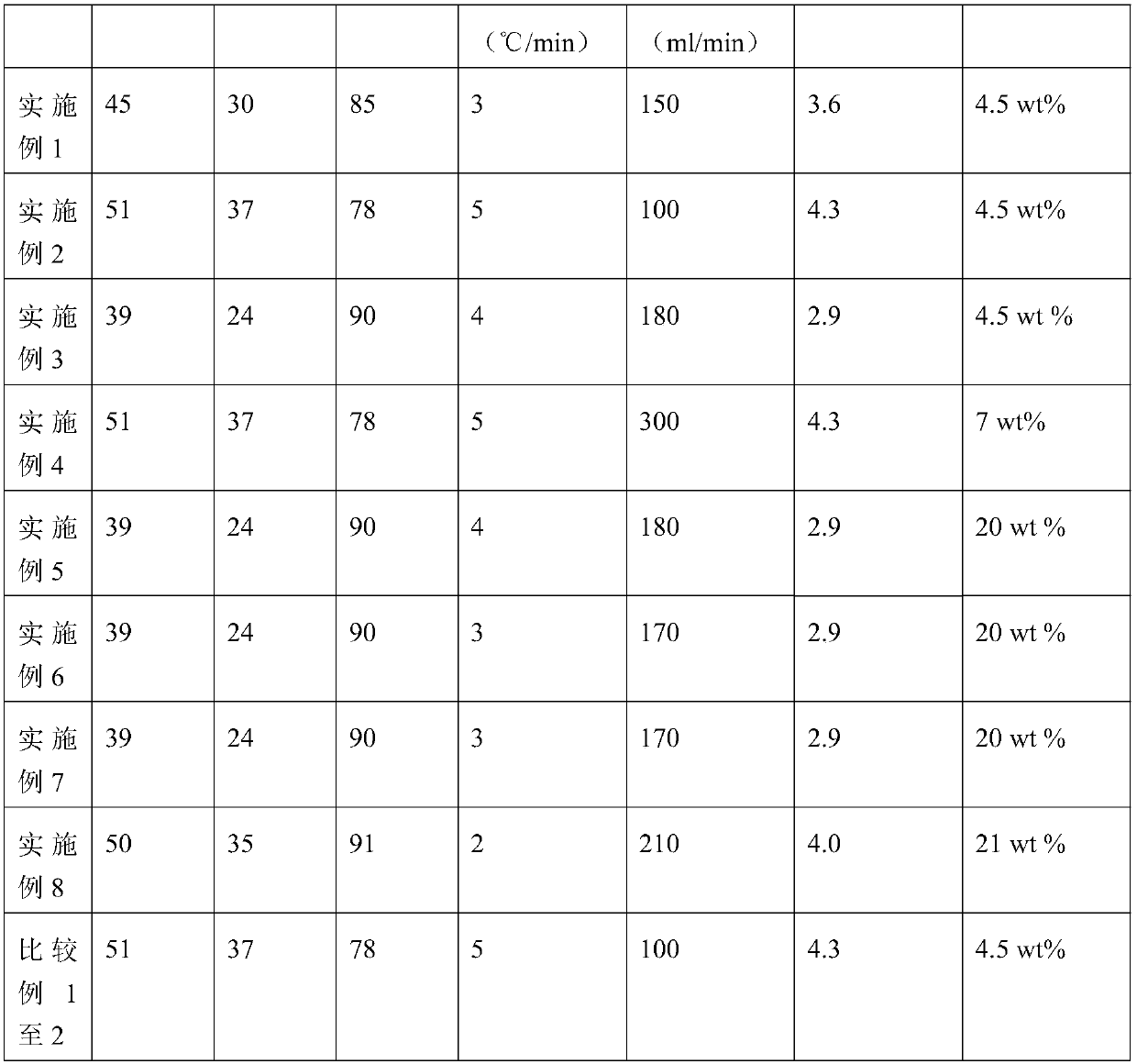

Processing technology of radix bupleuri traditional Chinese medicine decocotion pieces

InactiveCN109432149AImprove effectivenessHigh rate of side effectsInorganic non-active ingredientsPlant ingredientsEthylenediamineSide effect

The invention discloses a processing technology of radix bupleuri traditional Chinese medicine decocotion pieces. The processing technology comprises the following steps: (1) selecting and picking fresh radix bupleuri; (2) soaking the radix bupleuri in an EDTMPS (Ethylenediamine Tetramethylphosphonate Sodium) water solution for 2 to 3 hours; (3) slicing the radix bupleuri, and drying; (4) adding the dried radix bupleuri pieces in rice vinegar accounting for 0.2 time of the dried radix bupleuri in parts by mass, then adding an ethanol solution accounting for 0.1 time in parts by mass, and braising until completely absorbing the solution; (5) continuously adding yellow rice wine accounting for 0.1 time in parts by mass, then adding haw juice, ferment stoste and carbonic acid accounting for 0.2 time of the total amount in parts by mass, and continuously braising until completely absorbing the solution; wherein a mass ratio of the haw juice to the ferment stoste to the carbonic acid is (0.04 to 0.06):(0.01 to 0.02):(0.03 to 0.05); (6) drying and sorting, and packaging, thus obtaining a finished product-radix bupleuri decoction pieces. According to the processing technology disclosed bythe invention, by adopting the haw juice, the ferment stoste and the carbonic acid as a reinforcement system, the content and the side effect rate of effective components of the radix bupleuri traditional Chinese medicine decocotion pieces can be increased.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

Acrylic polyester ramie cotton mixed fabric pretreatment process

The invention discloses an acrylic polyester ramie cotton mixed fabric pretreatment process which comprises the following steps: turning cloth, sewing the end, singeing, desizing-scouring, bleaching, drying, mercerizing and drying, wherein the singeing step refers to one-step singeing, the four burners refer to two positive burners and two reverse burners, and the speed is 20m per minute; according to the desizing-scouring step, the caustic soda concentration in a working solution is 16g / L; according to the bleaching step, 6-8g / L of hydrogen peroxide (100 percent) is adopted, 2g / L of a stabilizer EDTMP is adopted, cold rolling is performed under the pH value of 10-10.5, and steaming is performed at the temperature between 90 DEG C and 95 DEG C for 60 minutes; and the concentration of alkali in a mercerizing solution in the mercerizing step is 140-160g / L. The singeing effect achieves a level 4; the desizing and scouring are combined into a process, the action time of acrylic fibers and strong base is reduced, and impurities on ramie cotton are effectively removed; and moreover, the acrylic polyester is not yellowed, and high strength is maintained.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

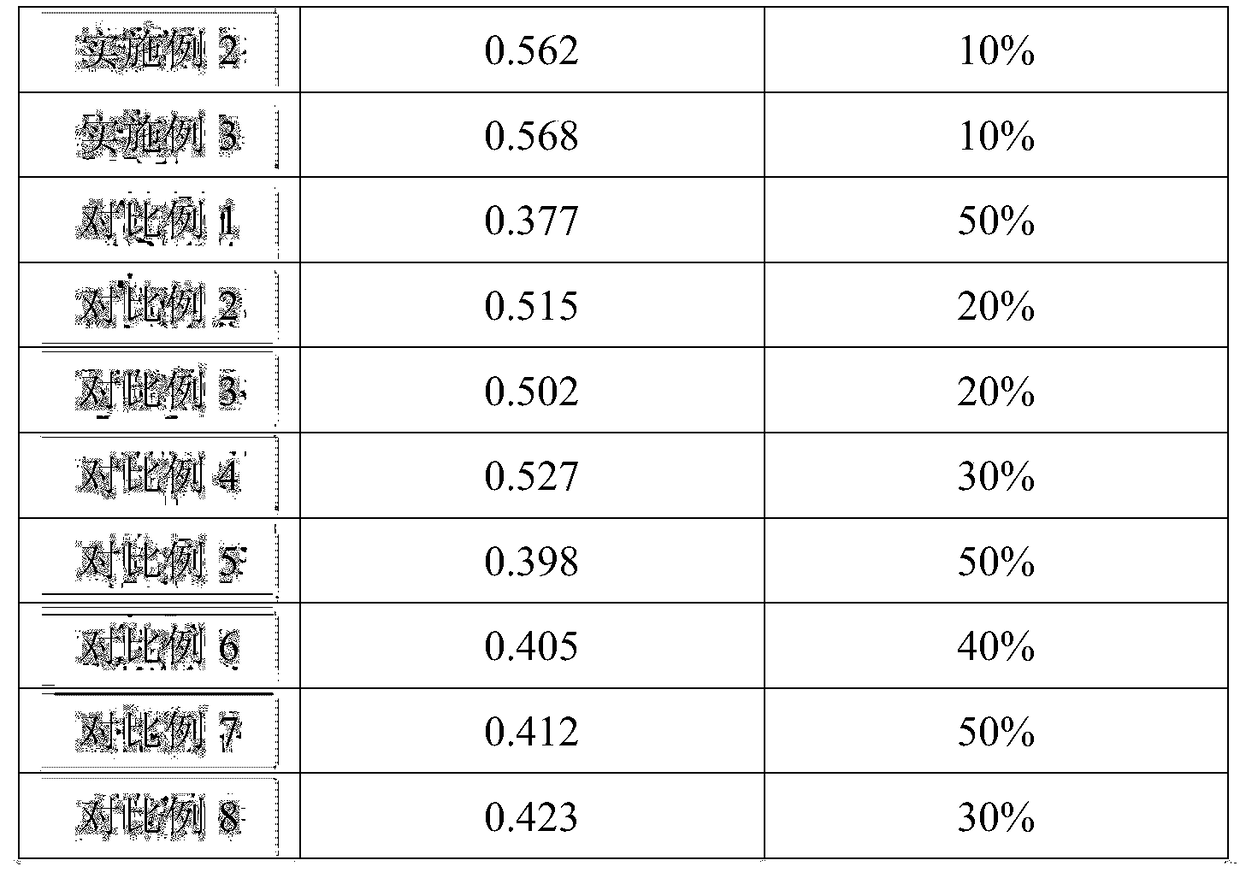

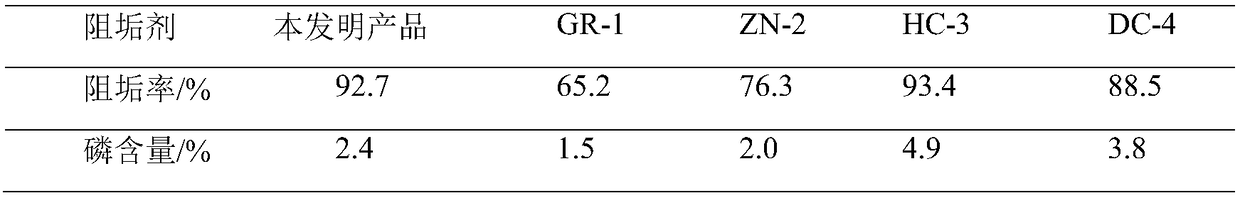

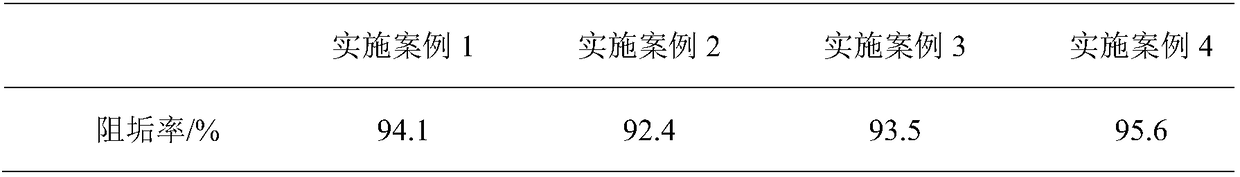

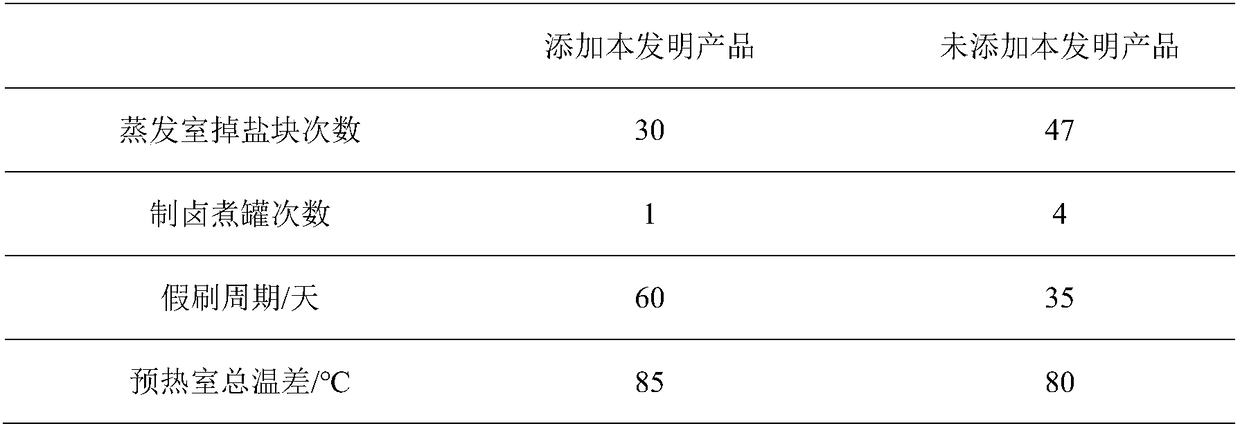

General scale inhibitor for salt and sodium sulfate co-production technology in salt-making industry

InactiveCN108640300AHigh standardAdding process is simpleScale removal and water softeningOrganic phosphorusEthylenediaminetetra(methylenephosphonic)acid

The invention discloses a general scale inhibitor for a salt and sodium sulfate co-production technology in a salt-making industry. The general scale inhibitor comprises organic phosphorus and a high-molecular polymer, the high-molecular polymer comprises hydrolytic polymaleic anhydride with a molecular weight being ten million to twenty million, a terpolymer T15, and Antiprex.A, and the organic phosphorus comprises ATMP and EDTMP. By aiming at the technical problem of the salt-making scale inhibitor, the high-efficiency general scale inhibitor is provided for solving the fouling problem of heat exchange equipment of a salt and sodium sulfate co-production system, the product uses the efficient chelating capability of organic phosphorus and excellent dispersion capability of the high-molecular polymer, and can be simultaneously effected on a salt system and a nitre system.

Owner:雪天盐业集团股份有限公司

Production method of targeted treatment medicinal pectin

The invention provides a production method of targeted treatment medicinal pectin and relates to the technical field of pectin extraction. The pectin product is mainly prepared by the following steps:boiling and filtering citrus pomace, soaking by using EDTMPS water bath, dividing filter residues into two parts, performing fermentation treatment by using composite enzyme a and composition enzymeb separately, and combining and extracting the pectin. The product increases the calcification degree of a composite formed by combining the pectin and calcium ions when the targeted medicine is prepared and enhances the treatment effect of the medicine.

Owner:ANHUI YUNING PECTIN CO LTD

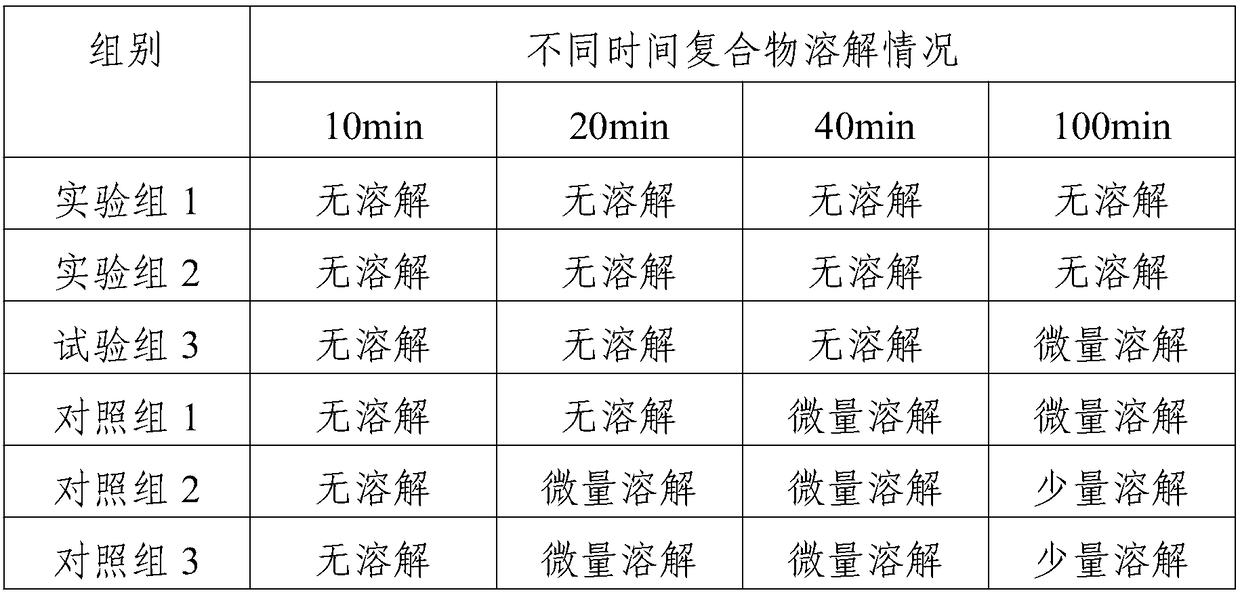

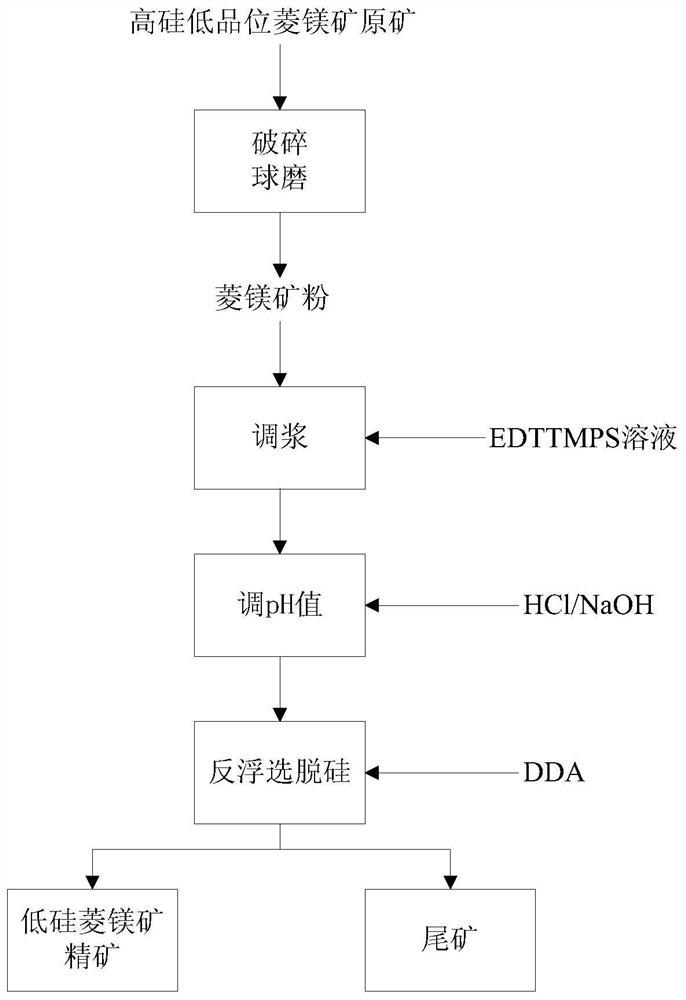

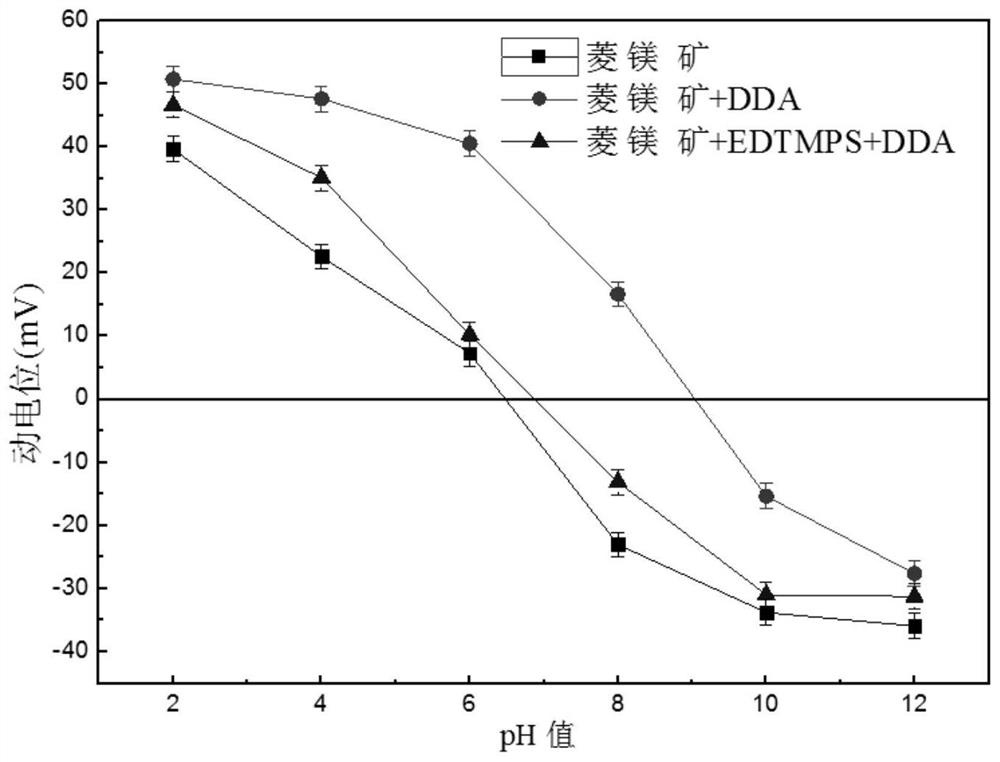

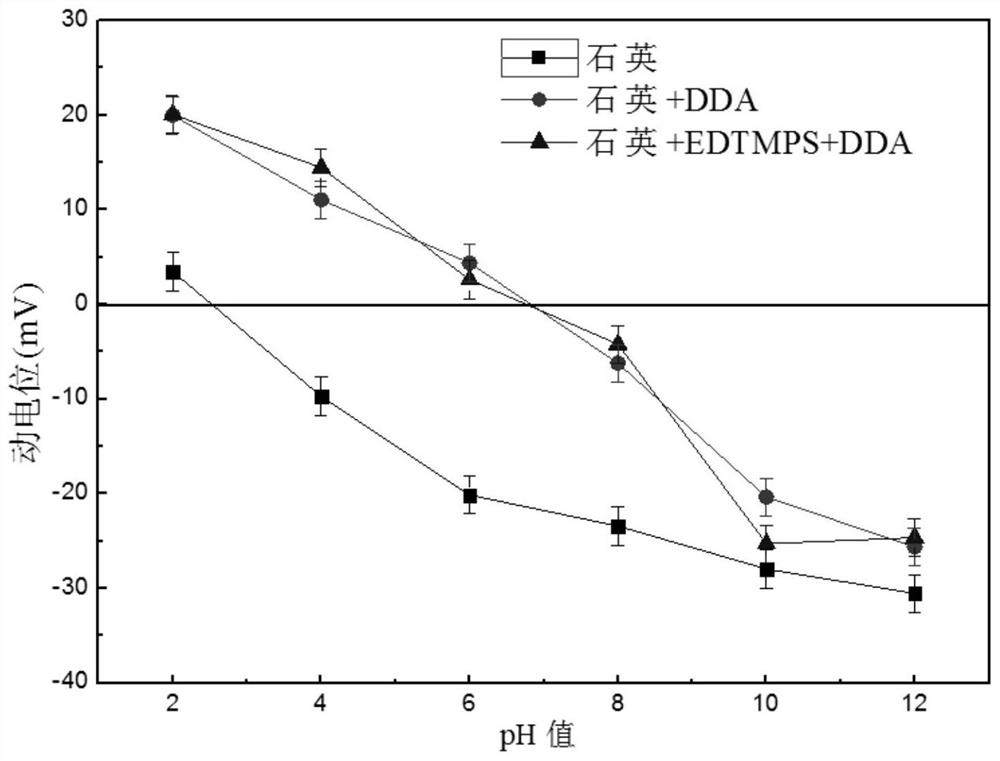

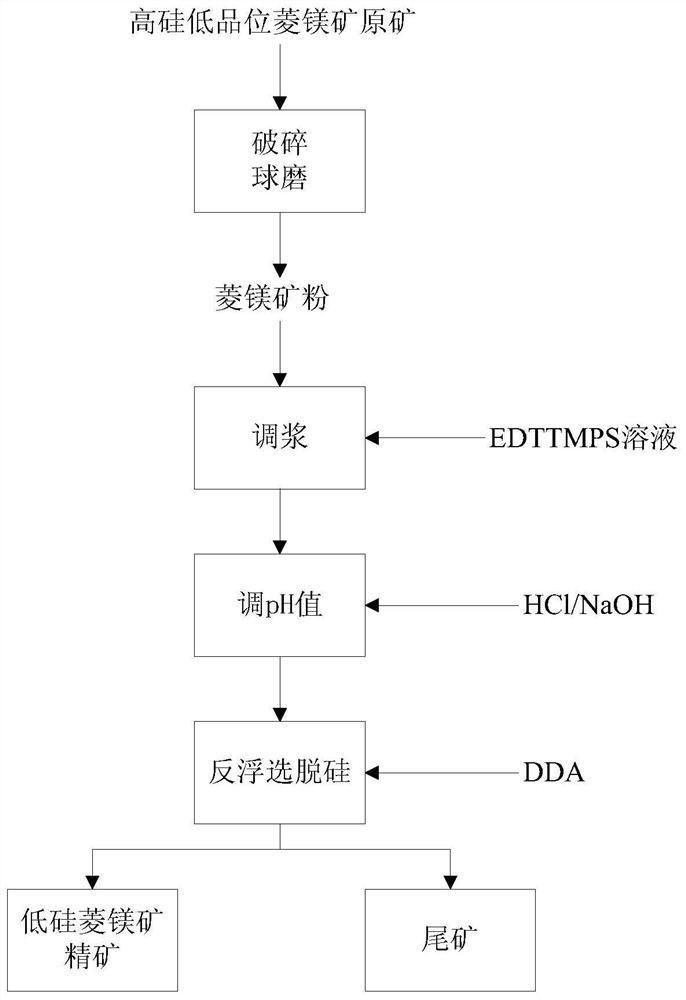

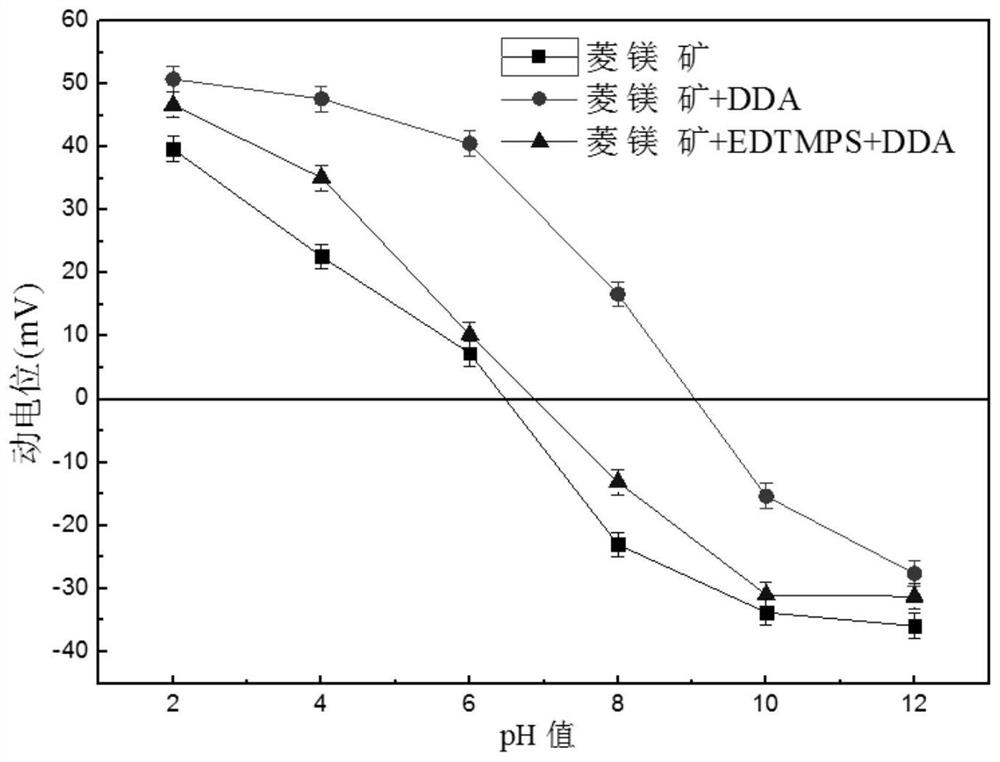

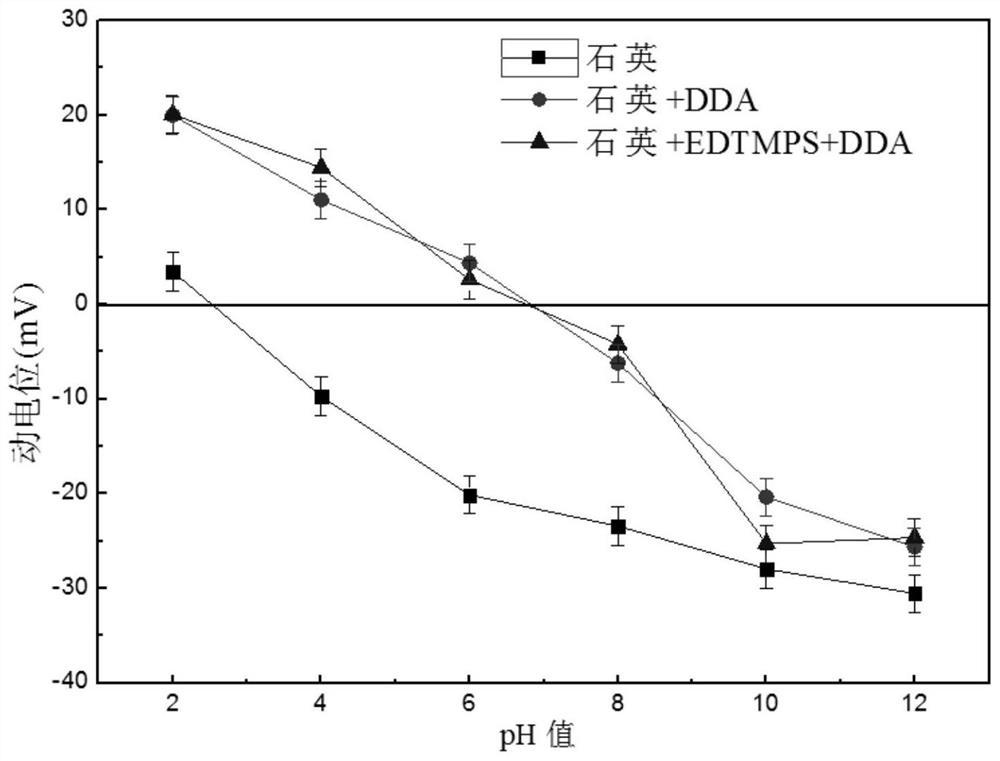

Application of selective inhibitor edtmps in flotation desilication of magnesite

The application of a selective inhibitor EDTMPS in magnesite flotation desiliconization belongs to the technical field of magnesite beneficiation and purification technology. The application of the selective inhibitor EDTMPS in magnesite flotation desiliconization is specifically adding the selective inhibitor EDTMPS in the magnesite flotation desilication process using dodecylamine (DDA) as a collector. According to mass ratio, dodecylamine (DDA):selective inhibitor EDTMPS=(8~12):(3~5). Under the dosage of different selective inhibitors EDTMPS (sodium ethylenediamine tetramethylene bisphosphonate), magnesite and silicon-containing gangue minerals in magnesite—the difference in buoyancy of quartz, the magnesite The removal of silicon-containing gangue minerals in magnesia improves the quality of magnesite and provides a new agent for beneficiation and desiliconization of high-silicon and low-grade magnesite.

Owner:NORTHEASTERN UNIV LIAONING

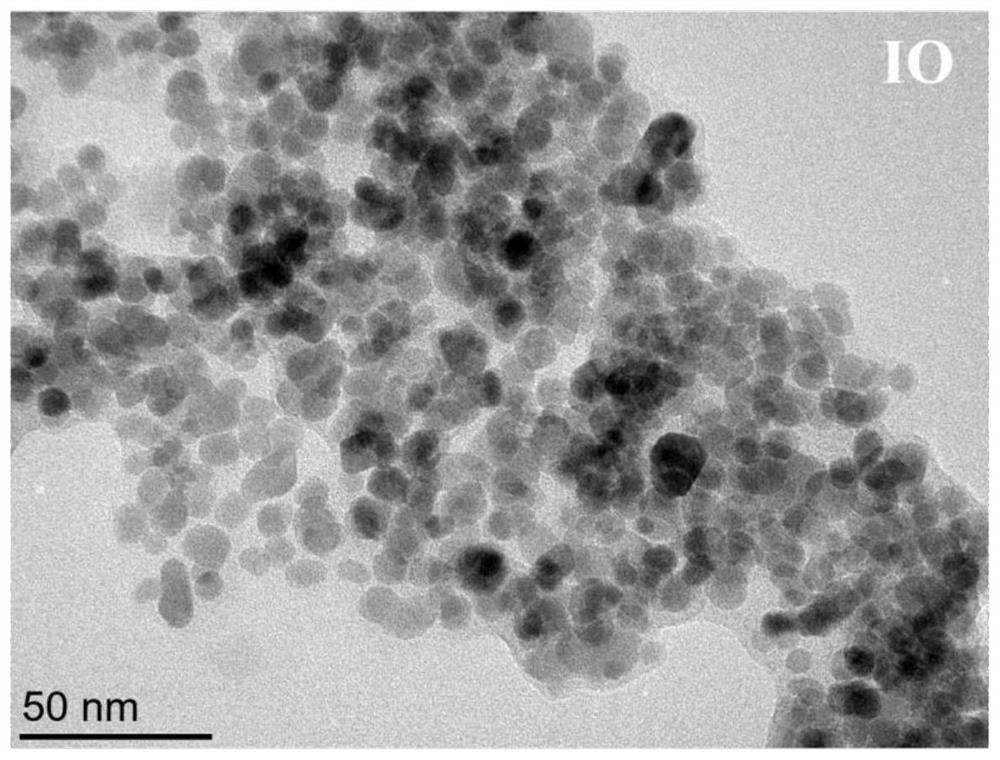

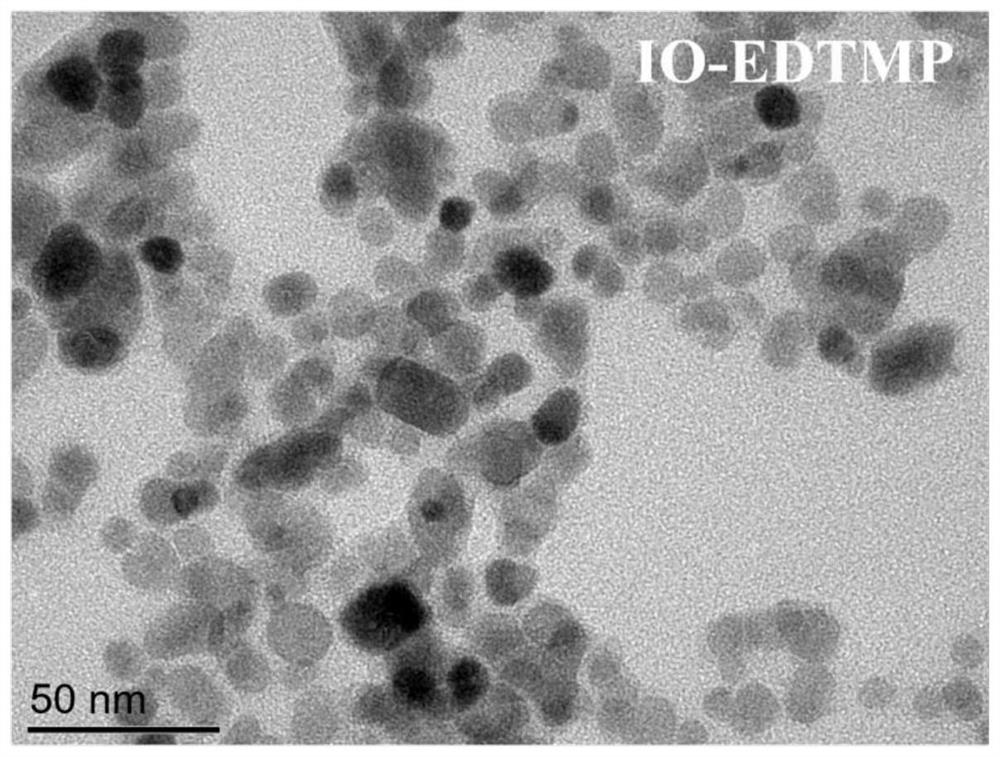

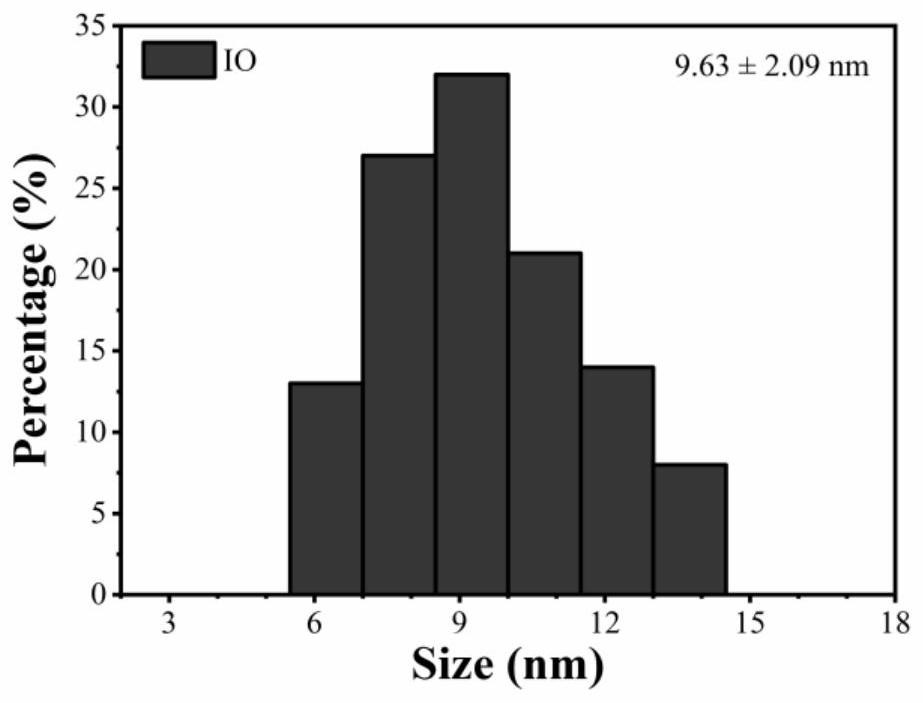

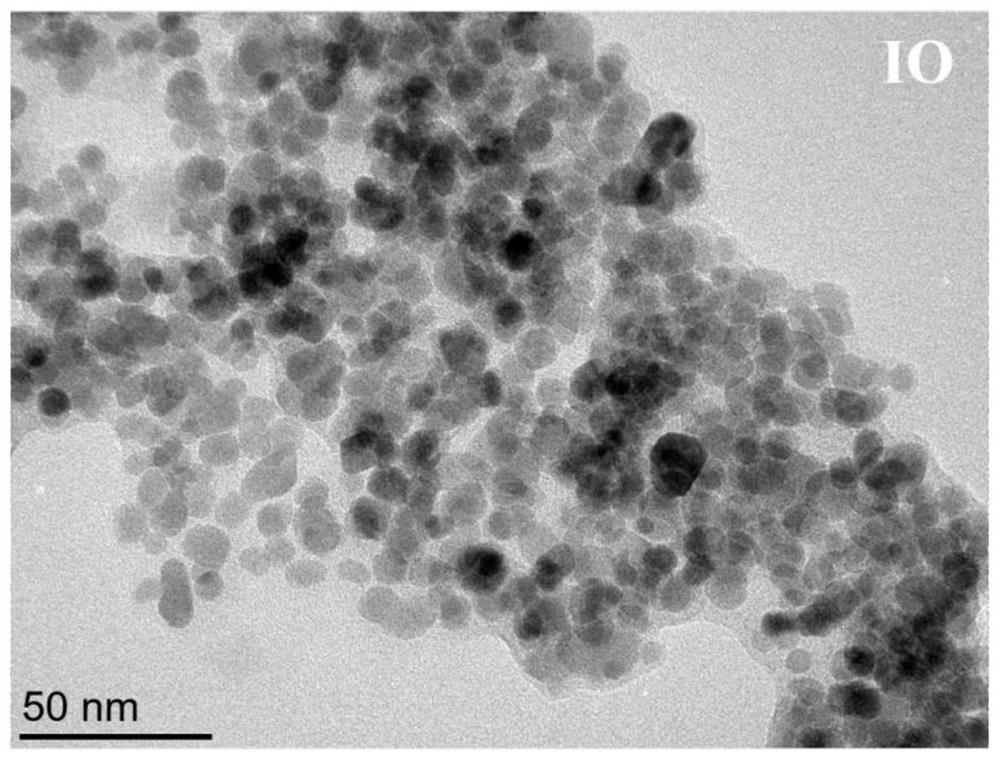

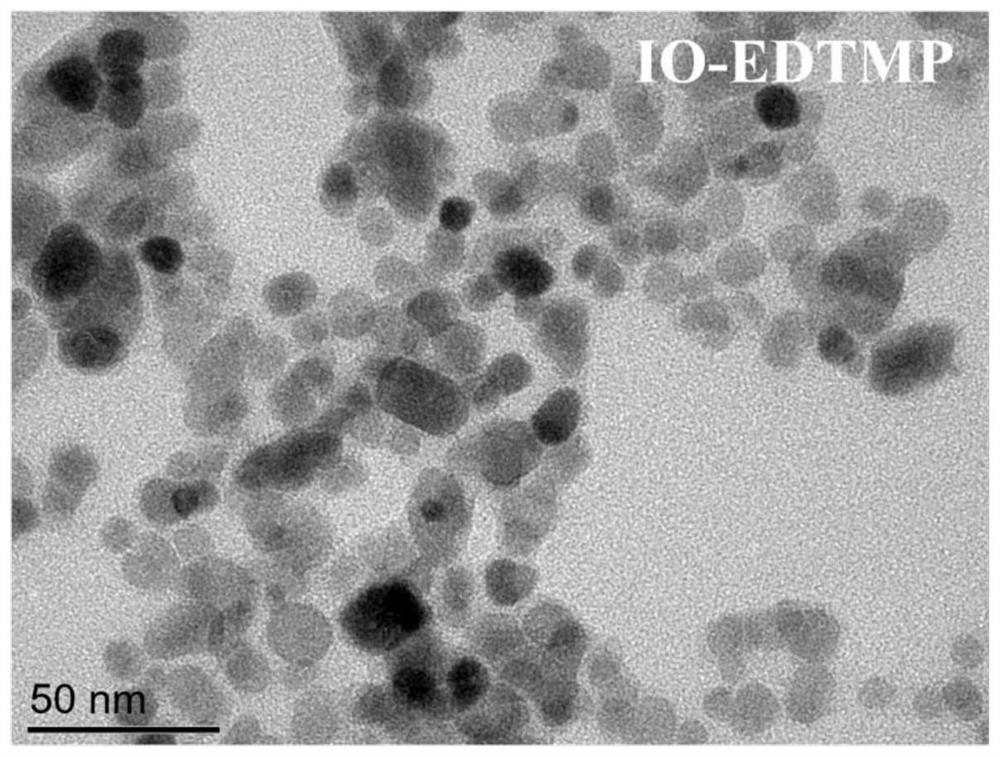

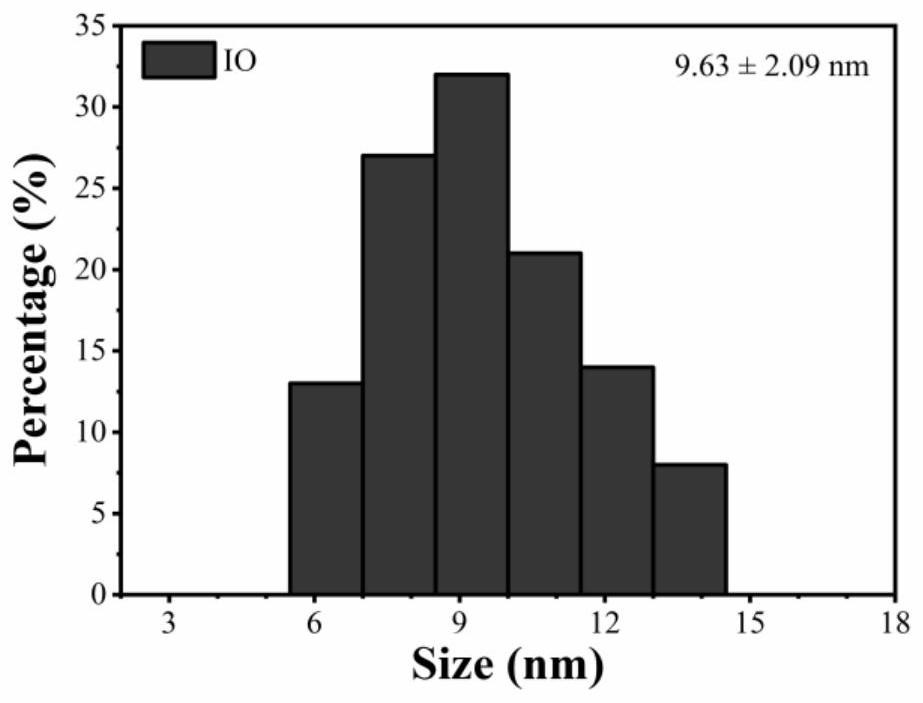

A kind of edtmp modified iron ferric oxide nanoparticles and its preparation method and application

ActiveCN112516334BGood biocompatibilityImprove biological activityNanomedicineEmulsion deliveryColloidBiocompatibility

The invention provides a method for preparing ferric oxide nanoparticles modified by EDTMP, comprising: FeCl 3 ·6H 2 O and FeCl 2 4H 2 O is mixed and dissolved in a hydrochloric acid solution to obtain a mixed solution; the mixed solution is mixed with an aqueous solution for reaction to obtain a reaction solution; the reaction solution is reacted with an EDTMP solution to obtain EDTMP-modified ferric oxide nanoparticles. The present invention synthesizes IO-EDTMP nanoparticles through a modified co-precipitation method, not only has good colloidal stability and biocompatibility, but also has good T1 and T2 relaxation effects, and can be used as a contrast agent in the field of clinical MRI imaging diagnosis have potential application value. The invention also provides an EDTMP modified ferric oxide nano particle and application thereof.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

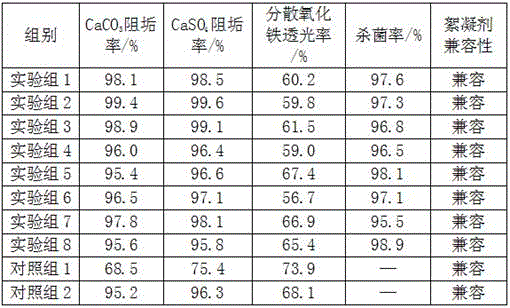

A kind of alkaline low phosphorus reverse osmosis membrane scale inhibitor and preparation method

ActiveCN104607052BPrevent scalingReduce pollutionSemi-permeable membranesReverse osmosisPhysical chemistry

The invention provides an alkaline low-phosphorous reverse osmosis membrane anti-scaling agent and a preparation method. The alkaline low-phosphorous reverse osmosis membrane anti-scaling agent comprises the following components in percentage by mass: 15-50% of EDTMPS, 10-40% of PAA with the molecular weight of 1800-2200, 5-20% of dimethyl fumarate, 2-8% of 0.5-2mg / ml graphene oxide aqueous dispersion, and 20-50% of a pH value adjusting agent. The alkaline low-phosphorous reverse osmosis membrane anti-scaling agent is simple in production process, free of waste emission, controllable in cost, appropriate in price, applicable to scale dispersion of various reverse osmosis membranes, capable of effectively achieving synergistic effects of physical adsorption and chemical adsorption on pollutants, and meanwhile is excellent in corrosion inhibition, sterilization and mold prevention.

Owner:山东应天环保能源有限公司

Circulating-water saving scale remover

InactiveCN107698045AIncrease the concentration factorReduce pollutionScale removal and water softeningPhosphateWater quality

Owner:张艳军

Method for producing compound fertilizer by using phosphorite tailings

PendingCN114736061ALow costGreat green featureClimate change adaptationFertilizer mixturesO-Phosphoric AcidAgricultural engineering

The invention provides a method for producing a compound fertilizer by using phosphorite tailings, which comprises the following steps: grinding phosphorite tailings raw materials into powder, putting the powder into a reaction container, adding a buffering agent, adding industrial waste phosphoric acid until the pH value is less than or equal to 4.5, and stirring for 2-3 hours at 65-85 DEG C; carrying out solid-liquid separation to remove insoluble solids, and slowly evaporating and crystallizing the residual solution at 50-60 DEG C; and carrying out solid-liquid separation again, washing the solid material with water, and then drying the solid material to obtain the compound fertilizer product. Industrial waste phosphoric acid is used as an acidolysis raw material, so that the method is low in cost and environment-friendly; according to the invention, EDTMPS, DTPMPA or EDDHA is used as a buffering agent, a stable chelate is formed through a chelation reaction between the chelating agent and calcium and magnesium ions, and the metal chelate is generally of a flocculent structure and can flow in a solution, so that further reaction between acid and internal raw materials cannot be blocked, and the reaction speed and the final reaction degree are improved.

Owner:湖北艾迪普生物科技有限公司

Method for preparing coal-based activated carbon with high adsorption capacity by using low temperature and low mesopore pore volume

InactiveCN109775709ASave energyOther chemical processesCarbon compoundsRoom temperatureCarbonization

The invention relates to a method for preparing coal-based activated carbon with high adsorption capacity by using low temperature and low mesopore pore volume. The method comprise the following concrete steps that (1) coal-based carbonized materials are put into a EDTMPS solution with the mass percent being 10 to 40 percent to be soaked for 8 to 10h; (2) materials obtained in the step (1) are putinto a carbonization furnace to be activated for 40 to 60 minutes at the temperature of 400 to 500 DEG C; (3) the activated materials are discharged out of the furnace and are cooled to room temperature; the cooled materials are put into an auxiliary agent solution with the mass percent being 5 percent to be soaked for 30 to 40 minutes; (4) the auxiliary agent solution is discharged; the activated materials are flushed by water until the PH value is neutral; (5) the activated materials are dried at 150 to 200 DEG C to reach the required moisture; a mesopore developed activated carbon finishedproduct is obtained. The method has the advantages that the activation temperature is reduced to 400 to 500 DEG C from the original 900 DEG C; energy sources are saved; under the condition that the total pore volume of the activated carbon is not reduced, the mesopore pore volume proportion is increased to 20 to 40 percent from the original 10 percent.

Owner:原东

Application of selective inhibitor EDTMPS in magnesite flotation desilicication

The invention discloses an application of a selective inhibitor EDTMPS in magnesite flotation desilicication, and belongs to the technical field of magnesite beneficiation and purification processes.The application of the selective inhibitor EDTMPS in magnesite flotation desilicication specifically comprises the step of adding the selective inhibitor EDTMPS in a magnesite flotation desilicicationprocess adopting dodecylamine (DDA) as a collecting agent. Wherein the mass ratio of the dodecylamine (DDA) to the selective inhibitor EDTMPS is (8-12): (3-5). The silicon-containing gangue mineral in the magnesite is removed through the floatability difference of the magnesite and the silicon-containing gangue mineral-quartz in the magnesite under the dosage of different selective inhibitors EDTMPS (Ethylene Diamine Tetramethylene Phosphonate Sodium), the quality of the magnesite is improved, and a new agent is provided for ore dressing and desilicication of the high-silicon low-grade magnesite.

Owner:NORTHEASTERN UNIV LIAONING

EDTMP-modified ferroferric oxide nanoparticles and preparation method and application thereof

ActiveCN112516334AGood biocompatibilityImprove biological activityNanomedicineEmulsion deliveryBiocompatibilityAqueous solution

The invention provides a preparation method of EDTMP-modified ferroferric oxide nanoparticles, and the preparation method comprises the following steps: mixing and dissolving FeCl3(subscript).6H2(subscript)O and FeCl2(subscript).4H2(subscript)O in a hydrochloric acid solution to obtain a mixed solution; mixing the mixed solution with an aqueous solution for reaction to obtain a reaction solution;and subjecting the reaction solution and an EDTMP solution to reaction to obtain the EDTMP-modified ferroferric oxide nanoparticles. The IO-EDTMP nanoparticles are synthesized by a modified coprecipitation method, so that the IO-EDTMP nanoparticles not only have good colloid stability and biocompatibility, but also have good T1 and T2 relaxation effects, and have potential application value in thefield of clinical MRI imaging diagnosis as a contrast agent. The invention also provides EDTMP-modified ferroferric oxide nanoparticles and application thereof.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Corrosion inhibitor composition for anticorrosion of high temperature oxygen-containing air foam flooding injection system

The invention discloses an anti-corrosion corrosion inhibitor composition for a high-temperature oxygen containing air foam flooding injection system. The anti-corrosion corrosion inhibitor composition comprises, by mass percent, 0.01%-0.02% of P-2, 0.8%-1.2% of NiSO4, 0.25%-0.35% of EDTMPS, 0.10%-0.20% of lactic acid, 0.06%-0.12% of citric acid and the balance water. After pre-filming treatment is conducted through the corrosion inhibitor composition, the average corrosion rate of a casing pipe in high-temperature and normal-pressure foam is reduced to 0.021 mm / a-0.030 mm / a from 12.592 mm / a,the average corrosion rate of the casing pipe in high-temperature and high-pressure foam is reduced to 0.054 mm / a-0.055 mm / a from 25.232 mm / a, and it is shown that the casing pipe subjected to pre-filming through the corrosion inhibitor composition has a good corrosion inhibition function in the high-temperature and normal-pressure foam and the high-temperature and high-pressure foam.

Owner:中国石油大港油田采油工艺研究院 +1

Antiscaling corrosion inhibitor of boiler and use thereof

The invention opened a method of boiler antiscale slow release agent and the employing method. The ingredient of the weight fraction was: EDTMP 2-5g, NaOH 80-120g, NaCO3 180-220, the method was: a. adding one portion of antiscale slow release agent due to the evaporating capacity per ton water, keep the water alkalinity, was 7-8 mgN / L, pH was 10-11.5; b. routinely pollution discharge while the boiler application. Its advantages include no need for factory building and equipment, saving the salt and treating water, no need for assay, low cost, save fuel, yield good ecnomic returns and social returens.

Owner:杜德明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com