Environment-friendly universal rust remover

A kind of rust remover and environmental protection technology, applied in the direction of metal material coating process, etc., can solve the problems of low rust prevention efficiency, long rust removal time, pollution, etc., to achieve the effect of improved anti-corrosion performance, simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

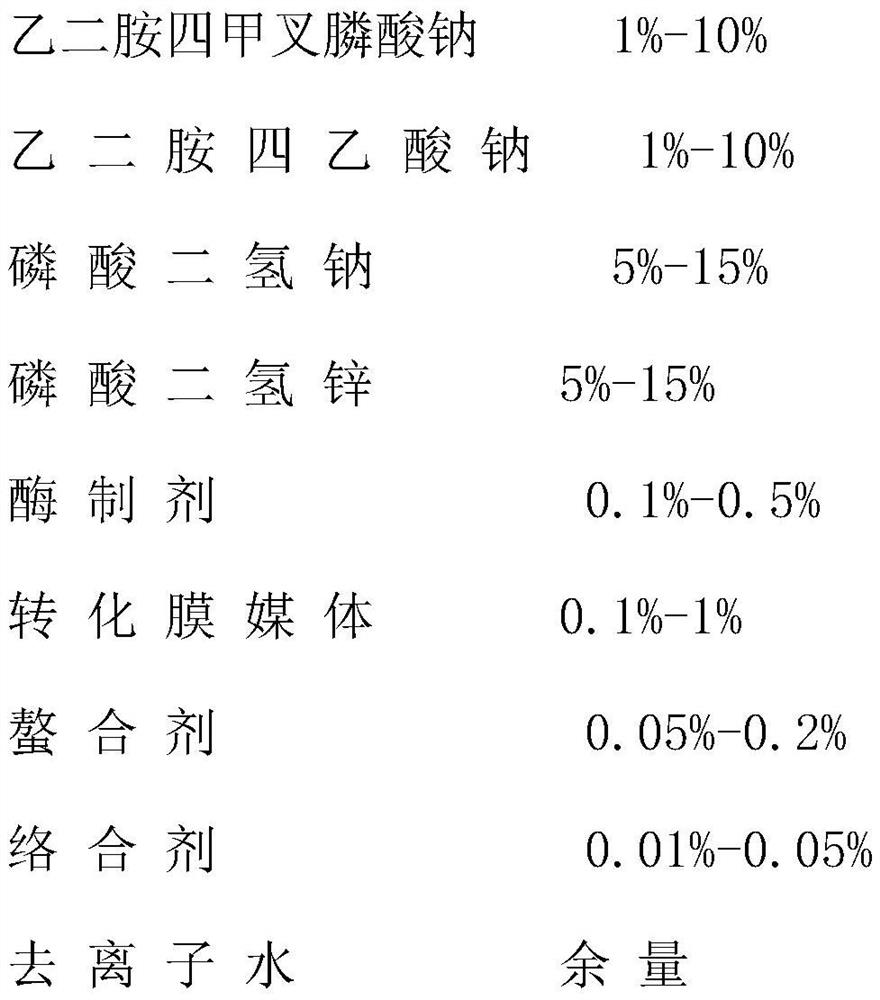

Method used

Image

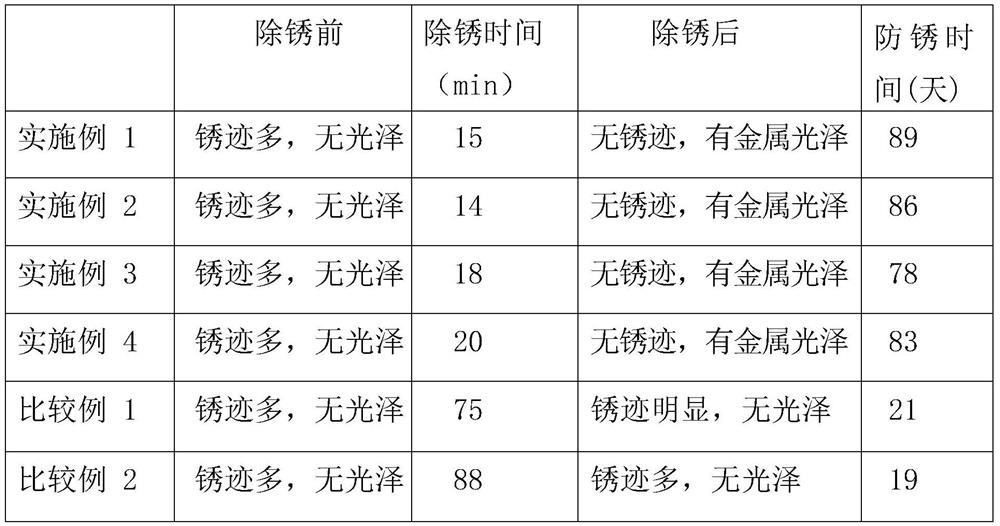

Examples

example 1

[0018] First select 1kg of sodium ethylenediamine tetramethylene phosphonate, 5 kg of sodium dihydrogen phosphate, 0.1 kg of urotropine, 0.05 kg of sodium gluconate, 0.01 kg of amine trimethylene phosphate, and then add 0.1 kg of enzyme preparation, and then add 8kg of deionized water until completely dissolved.

example 2

[0020] First select 10kg of sodium edetate, 15kg of zinc dihydrogen phosphate, 1kg of tartrate, 0.2kg of ammonium citrate, 0.05kg of diethylenetriaminepentamethylene phosphonate, add 0.5kg of enzyme preparation, and then add deionized 20kg of water until completely dissolved.

example 3

[0022] First select 10kg of sodium edetate, 5kg of sodium dihydrogen phosphate, 1kg of urotropine, 0.2kg of sodium gluconate, 0.05kg of amine trimethylene phosphate, add 0.3kg of enzyme preparation, and then add 15kg of deionized water to completely dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com