Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130 results about "Ethylenediaminetetra(methylenephosphonic)acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal surface oil and rust removal agent

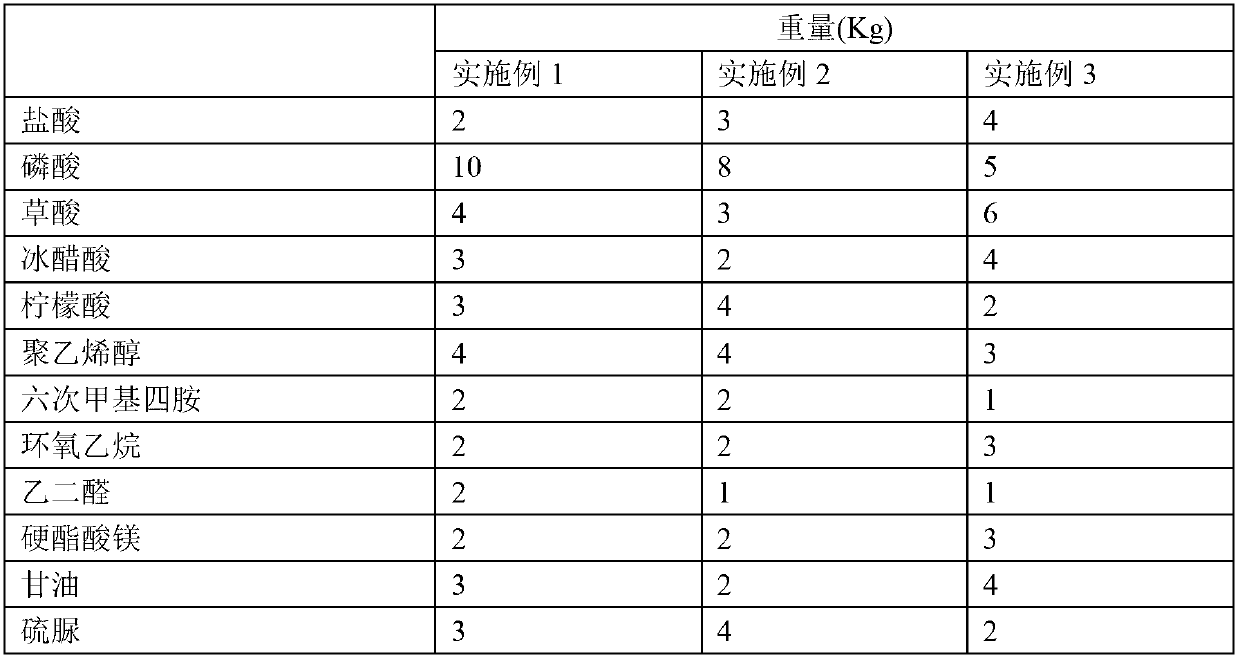

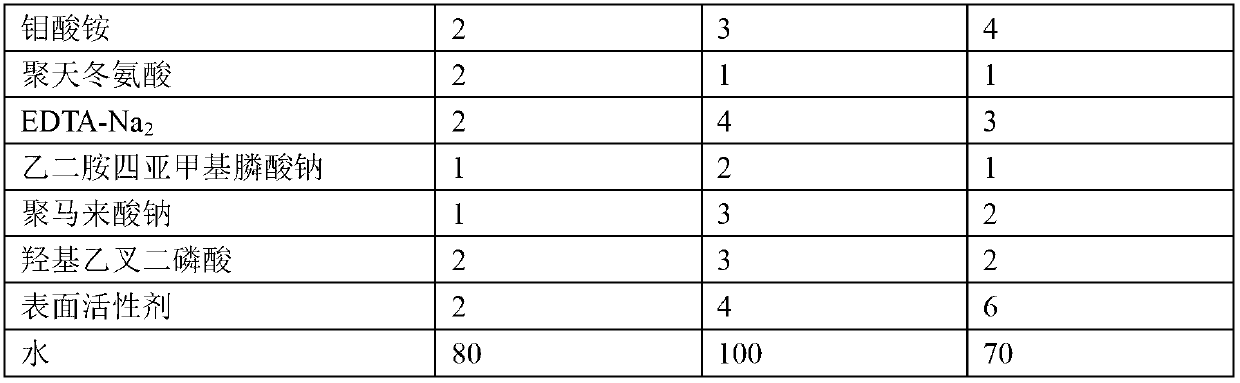

The invention provides a metal surface oil and rust removal agent, and belongs to the technical field of cleaning agents. The metal surface oil and rust removal agent comprises the following components by weight: 2 to 4 parts of hydrochloric acid, 5 to 10 parts of phosphoric acid, 3 to 6 parts of oxalic acid, 3 to 5 parts of glacial acetic acid, 2 to 4 parts of citric acid, 3 to 4 parts of polyvinyl alcohol, 1 to 2 parts of hexamethylene tetramine, 2 to 3 parts of ethylene oxide, 1 to 2 parts of glyoxal, 2 to 3 parts of magnesium stearate, 2 to 4 parts of glycerol, 2 to 4 parts of thiourea, 2 to 4 parts of ammonium molybdate, 1 to 2 parts of polyaspartic acid, 2 to 4 parts of EDTA-Na2, 1 to 2 parts of ethylene diamine tetra sodium, 1 to 3 parts of poly maleic acid sodium, 2 to 3 parts of HEDPA, 2 to 6 parts of surface active agent and 70 to 100 parts of water. The metal surface oil and rust removal agent is convenient to use, and removes light rust for about 2 minutes and heavy rust for 6 to 7 minutes, and the oil removal rate can reach more than 97%.

Owner:盐城创咏新能源投资有限公司

Short-process low-temperature dyeing aid and preparation method thereof

ActiveCN102619101AEliminate reduction cleaning processLower dyeing temperatureDyeing processYarnPolyester

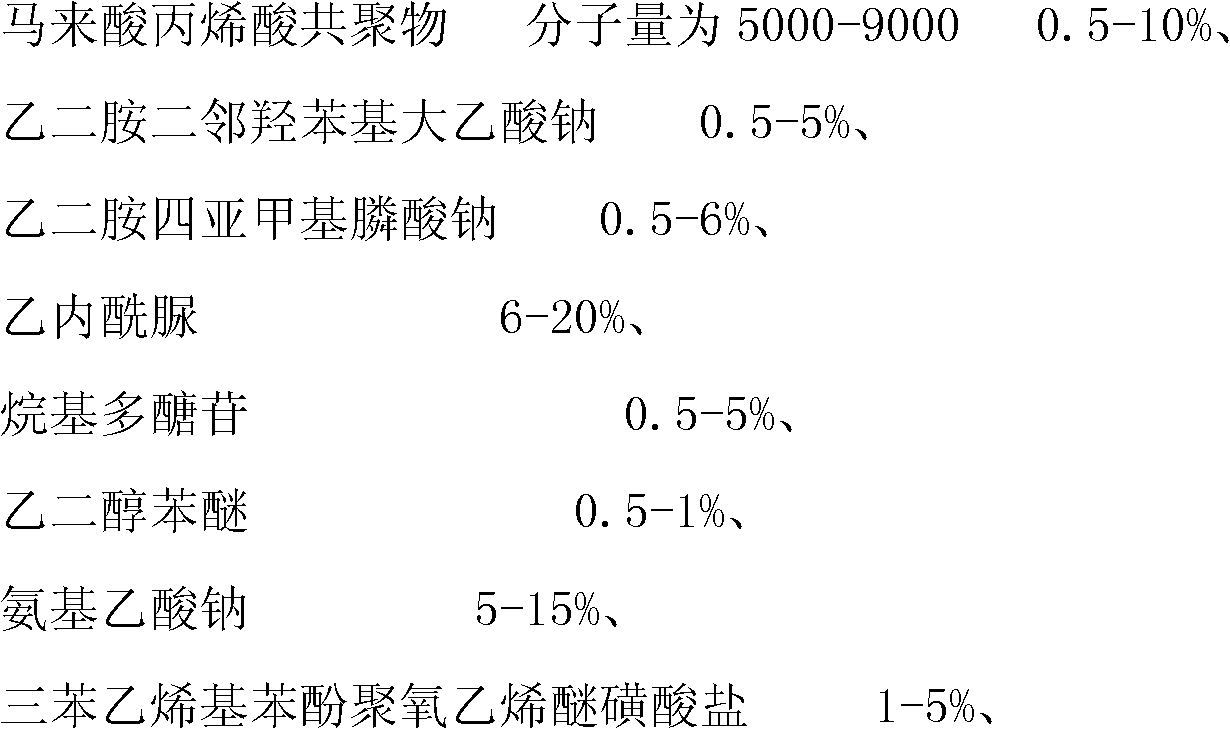

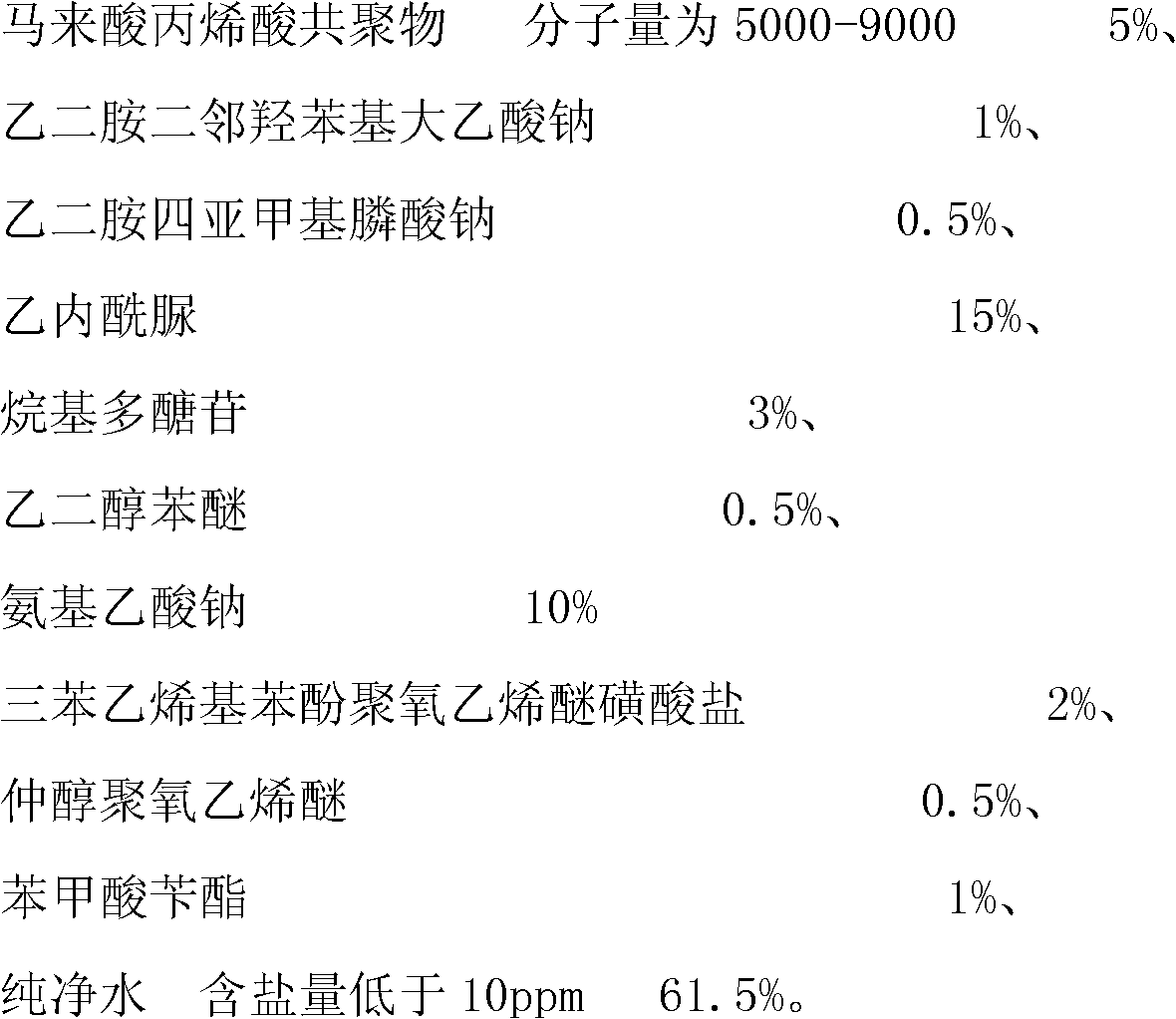

The invention relates to the field of dyeing, in particular to a short-process low-temperature dyeing aid and a preparation method thereof. The short-process low-temperature dyeing aid is characterized by mainly comprising the following components in percentage by weight: maleic acid acrylic copolymer, sodium ethylene diamine di-orthohydroxyphenyl aceticacid (EDDHA), ethylene diamine tetra sodium, hydantoin, alkyl polysaccharide, ethylene glycol phenylate, sodium glycinate, tristyrylphenol ethoxylates sulfonate, secondary alcohol polyoxyethylene ether, benzyl benzoate and the like. Compared with the prior art, the aid and the method have the advantages that the conventional pretreatment and dyeing processing mode of polyester and blended (yarns) fabrics is thoroughly changed, namely pretreatment processes of the yarns and the fabrics which comprise a yarn and knitwear oil removing process, a woven fabric desizing process, a slight decrement process, a polyester / cotton fabric bleaching treatment process and other processes are combined with a dyeing process to form a one bath treatment process; and the dyeing temperature of one bath dyeing is reduced, reduction clearing processes of most of dyed fabrics are eliminated, water is saved by more than 60 percent, and electricity is saved by more than 30 percent.

Owner:杭州彩润科技有限公司

Developing solution for photoresist

InactiveUS20050130082A1Good storage stabilityPrevent precipitationPhotoprinting processesSemiconductor/solid-state device manufacturingHexamethyldiamineTricarboxylic acid

A novel developing solution for photoresists which is suitable for use as a developing solution for a photoresist formed on an aluminum-containing base formed on a wafer. It comprises an alkali builder, a calcium compound, and a chelating agent, the chelating agent being selected from the group consisting of 1-hydroxyethylidene-1,1-diphosphonic acid, aminotrimethylenephosphonic acid, 2-phosphonobutane-1,2,4-tricarboxylic acid, ethylenediaminetetramethylenphosphonic acid, diethylencetriaminepentamethylenephosphonic acid, hexamethylenediaminetetraethylenephosphonic acid, and diethylenetriaminepenta(methylenephosphonic acid).

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Corrosion and scale inhibitor for oil well in high water cut stage

ActiveCN102321464AExtend the pump inspection cycleDrilling compositionBorehole/well accessoriesThioureaEthylenediaminetetra(methylenephosphonic)acid

The invention relates to a corrosion and scale inhibitor for an oil well in a high water cut stage, which is applicable to corrosion and scale inhibition of an oilfield. The corrosion and scale inhibitor comprises the following components in percentage by weight: 3.25-4.0% of o-dimethyl thiourea, 12.5-13.5% of ethylenediamine tetramethylene phosphonate, 8.0-8.5% of dodecyl butylamine methyl sulfide, 3.0-3.25% of tetradecyl tributyl phosphonium chloride, 15.0-16.2% of DN-3212 acrylic acid, organic phosphine and sulfonic acid copolymer, 5.25-5.75% of M-505A corrosion inhibitor, 6.85-7.25% of SL-2 corrosion and scale inhibitor, 5.0-7.5% of methanol, 3.4-3.75% of methenamine, 0.05-0.055% of vitamin A and the balance of water, wherein the sum of the weight percentage of each component is100%. The corrosion and scale inhibitor has the effects that: when the addition amount of the corrosion and scale inhibitor is 50-60 mg / L, the corrosion inhibition rate of the oil well reaches more than 85%, and the scale inhibition rate reaches more than 90%; and the average pump examination period is prolonged by more than one time.

Owner:PETROCHINA CO LTD

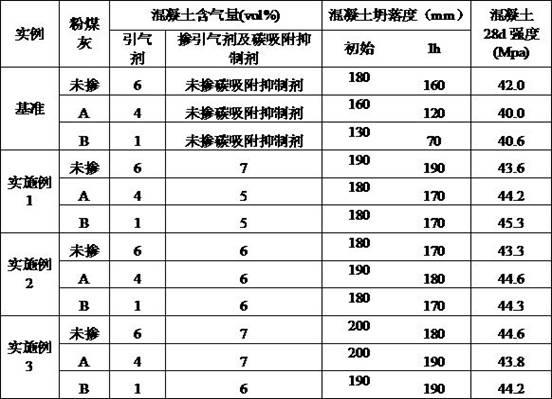

Fly ash concrete carbon adsorption inhibitor and application thereof

InactiveCN102674743AGood adsorption affinityIncrease late strengthEthylenediaminetetra(methylenephosphonic)acidCarbon particle

The invention discloses a fly ash concrete carbon adsorption inhibitor comprising the following components by weight: 5-10 parts of aromatic amino micromolecule, 12-26 parts of aromatic sodium sulfonate, 38-50 parts of alcohol derivative, 8-14 parts of neighboring hydroxybenzoic acid salt, 3-8 parts of crylic acid-2-acrylamide-2-methyl propanesulfonic acid copolymer, 3-10 parts of ethanediamine tetramethylene phosphonate and 6-10 parts of organosilan. The fly ash concrete carbon adsorption inhibitor inhibits adsorption of an additive by carbon particles in the fly ash, improves the performance stability and durability of concrete, is favorably adapted to various additives, has favorable inhibitive ability to the fly ash concrete carbon adsorption with various mixing amount and quality, and does not influence the performance of the concrete. The inhibitor is small in the mixing amount so that the strength of concrete is improved and the construction is convenient.

Owner:JIANGSU MINGHE GRP

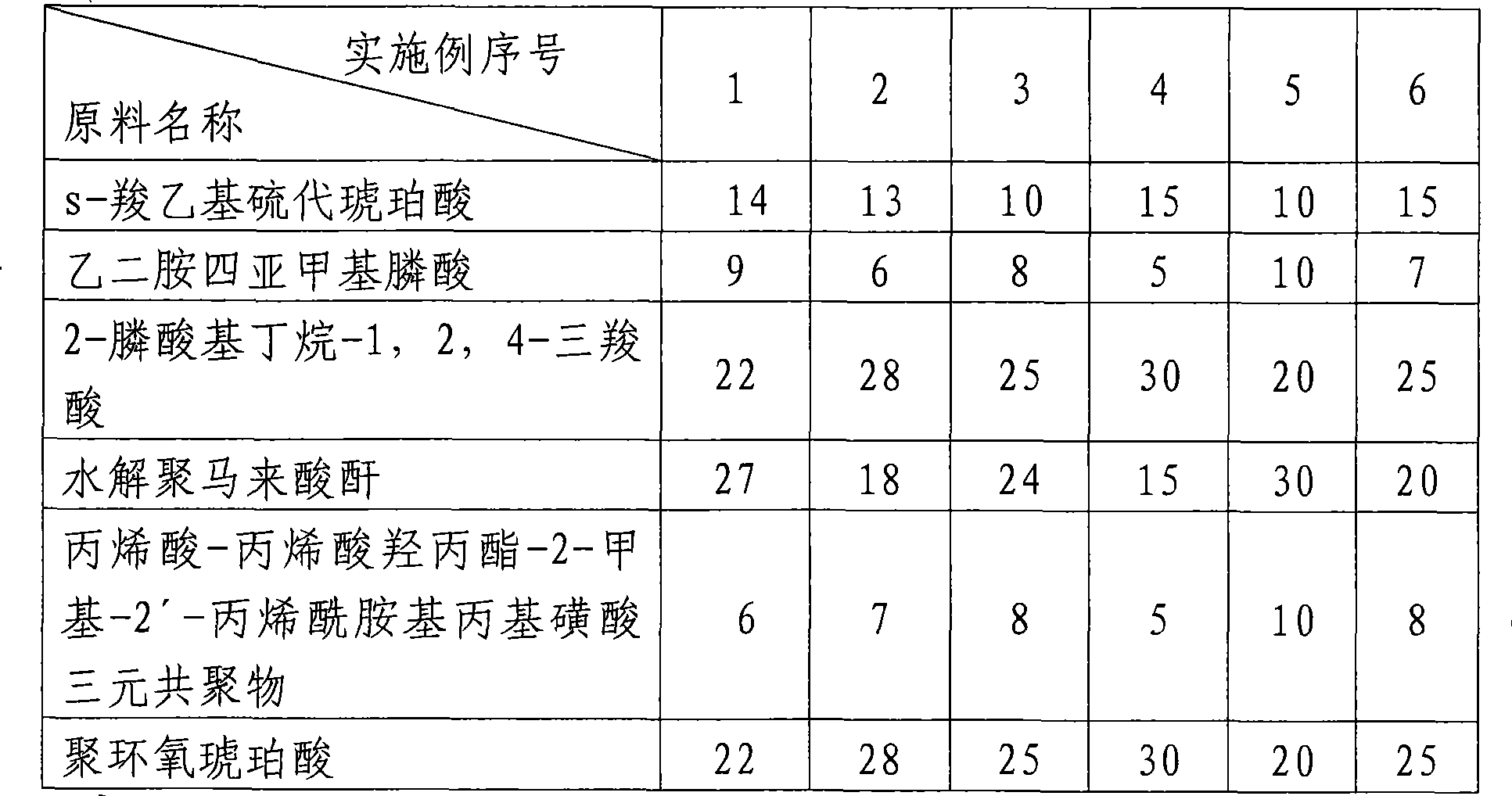

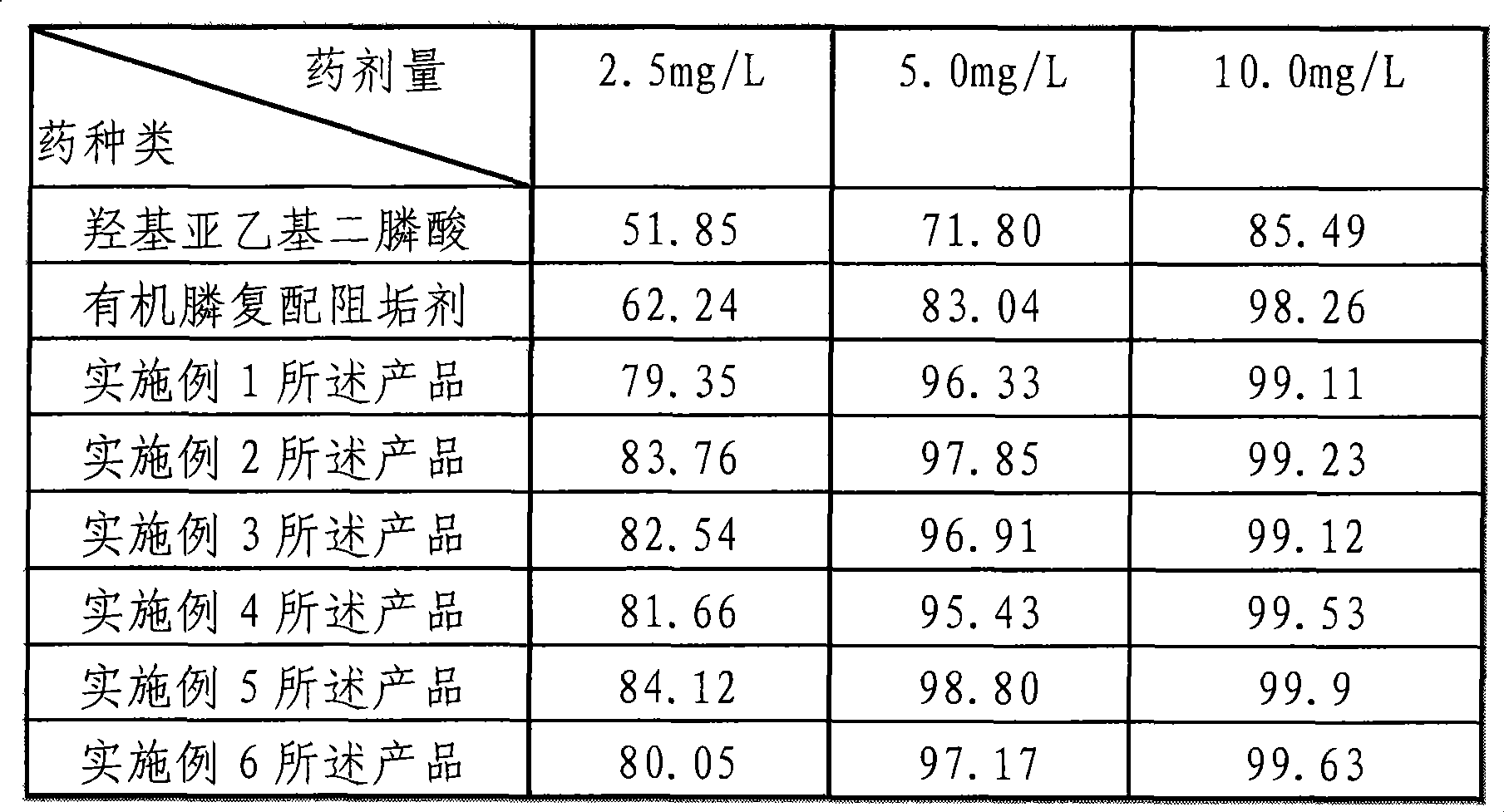

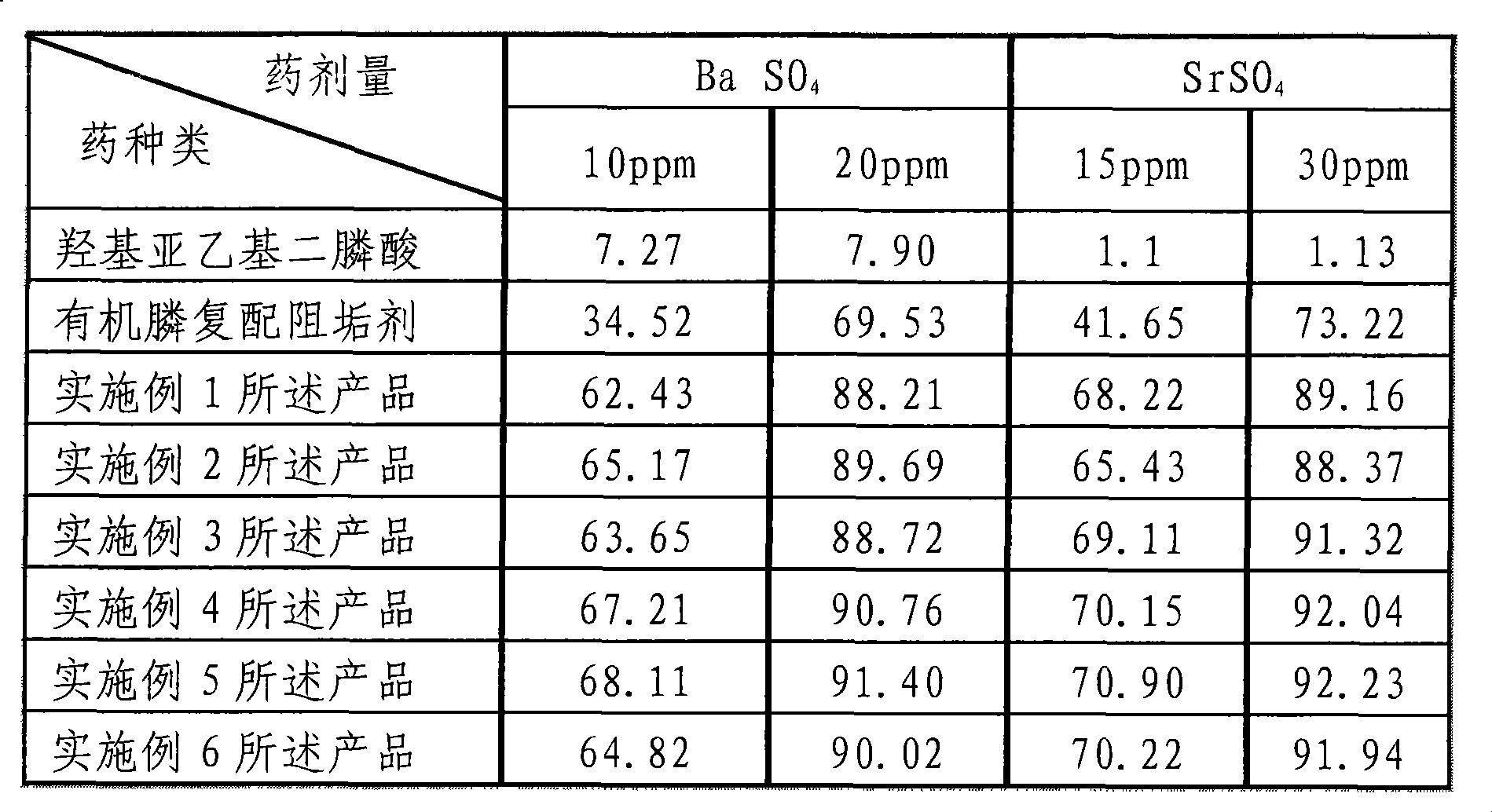

Composite multi-component scale inhibitor for treating oil-field water and preparation thereof

ActiveCN101412567ALattice distortionHas a critical effectScale removal and water softeningChemistryEthylenediaminetetra(methylenephosphonic)acid

The invention relates to a composite multi-component scale inhibitor for oil field water treatment and a preparation method thereof. The composite multi-component scale inhibitor comprises s-propyloic sulpho succinic acid, tetramethylenediamine phosphonic acid, 2-phosphonic butane-1, 2, 4-tricarboxylic acid, hydrolyzed polymaleic anhydride, propenoic-hydroxypropyl acrylate-2-methyl-2'-acrylamide propyl sulphonic acid terpolymer, and polyepoxy succinic acid, which are mixed in weight portion, wherein active substances must reach standardized contents of the experiment. The preparation method comprises the following steps: adding the polyepoxy succinic acid into the 2-phosphonic butane-1, 2, 4-tricarboxylic acid; adding the tetramethylenediamine phosphonic acid into the hydrolyzed polymaleic anhydride; and preparing solutions of the propenoic-hydroxypropyl acrylate-2- methyl-2' -acrylamide propyl sulphonic acid terpolymer and the s-propyloic sulpho succinic acid by steps and mixing the solutions, stirring the solution evenly for 50 to 90 minutes and keeping a temperature range from 12 to 48 DEG C, and obtaining the composite multi-component scale inhibitor for oil field water treatment which has little dosage, wide application range, and can play excellent efficiency under the conditions of high alkali, high hardness and high temperature.

Owner:XINJIANG DELAND

Oil removing and rust removing agent used for treating metal surface

The invention discloses an oil removing and rust removing agent used for treating a metal surface. The oil removing and rust removing agent comprises, by weight, 5-8 parts of hydrochloric acid, 8-12 parts of phosphoric acid, 3-6 parts of oxalic acid, 3-5 parts of tartaric acid, 2-4 parts of citric acid, 2-4 parts of nonionic surfactant, 2-4 parts of an anionic surfactant, 2-5 parts of ethylene diamine tetraacetic acid, 1-2 parts of sodium ethylenediamine tetramethylene phosphonate, 2-4 parts of thiourea, 1-2 parts of urotropine, 2-3 parts of polyester modified silicone oil, 2-4 parts of HEDP, 2-5 parts of polyethylene glycol oleate and 70-100 parts of water. The oil removing and rust removing agent can be used for conducting oil removing and rust removing on the metal surface at the same time, safety and environment friendliness are achieved, over etching and hydrogen brittleness phenomena are not generated on a metal matrix, irritant smells are avoided, the environment is not polluted, the property is stable, the preparing technology is simple, and the oil removing and rust removing agent can be widely used for oil removing and rust removing of paint sprayed workpieces, powder coated workpieces, electrophoresis workpieces, electroplated workpieces, zinc oxide workpieces and the like.

Owner:XUZHOU LIEQI COMMERCE & TRADE CO LTD

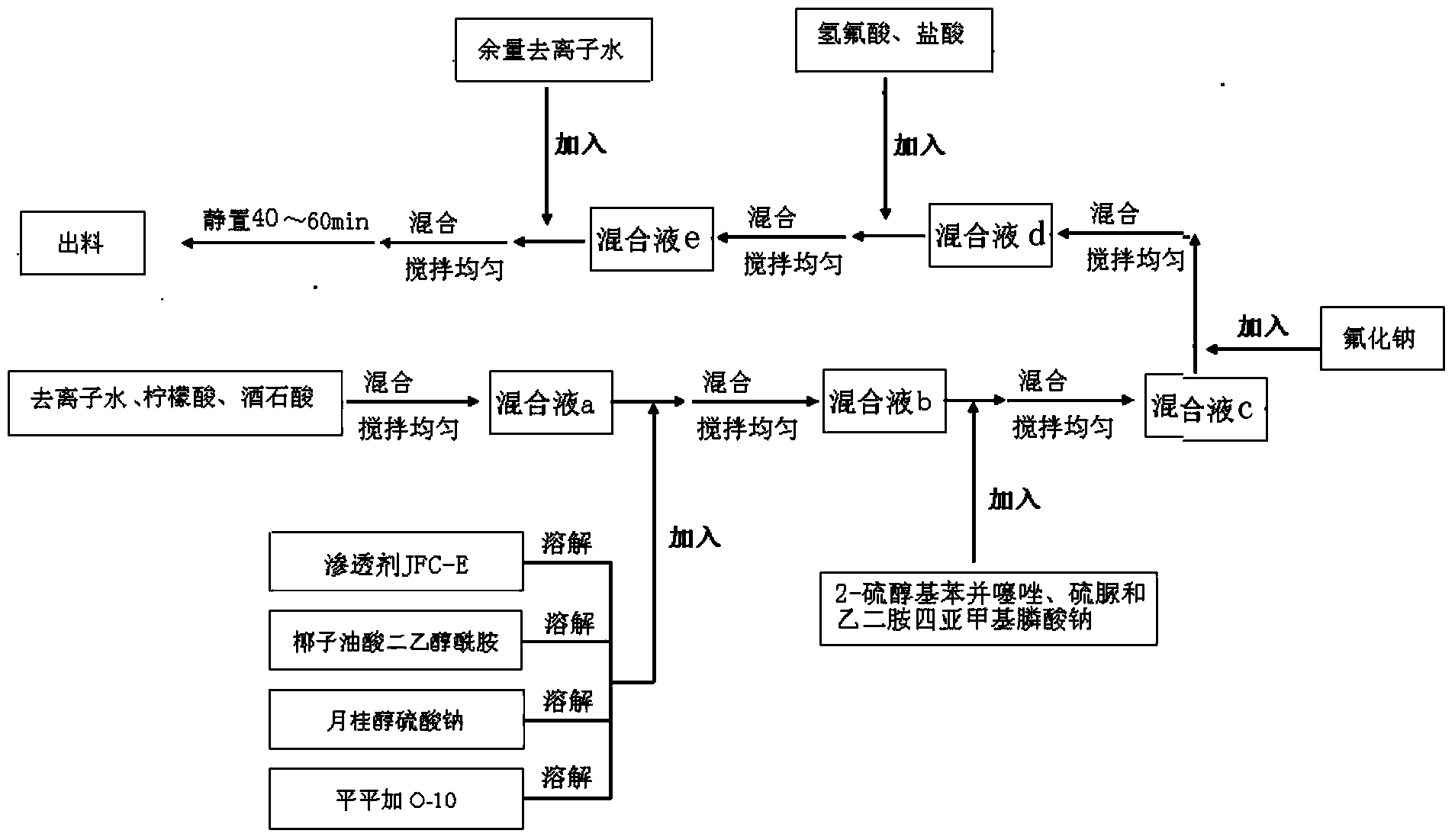

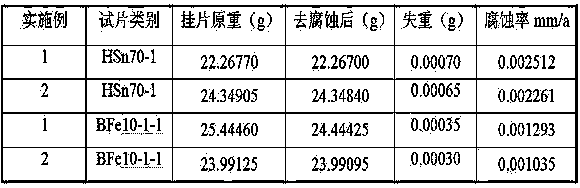

Detergent for stainless steel heat exchange coil pipe of industrial fermentation tank and preparation method thereof

The invention discloses a detergent for a stainless steel heat exchange coil pipe of an industrial fermentation tank and a preparation method thereof, and belongs to the technical field of chemical contaminant release. The detergent consists of citric acid, acetic acid, a penetrating agent JFC-E, coconut oil diethanoamine condensate, sodium laurylsulfate, peregal O-10, 2-thiol benzothiazole, thiourea, quadrol tetramethylene sodium ibandronate, sodium fluoride, hydrofluoric acid, hydrochloric acid and deionized water. All the components are mixed and uniformly stirred to obtain a product. The detergent is green, environment-friendly, good in contaminant release effect, strong in detergency, convenient to use and high in biodegradation rate; in addition, the detergent has extremely low corrosion rate to equipment.

Owner:江苏省轻工业科学研究设计院有限公司

Antisludging agent for hot method during sea water desalination

ActiveCN103896414AGeneral water supply conservationSeawater treatmentWater desalinationEthylenediaminetetra(methylenephosphonic)acid

The invention provides an antisludging agent for a hot method during sea water desalination. The antisludging agent for the hot method during sea water desalination contains deionized water, alcohols, imidazoles, hydrolytic polymaleic anhydride, ethylenediamine tetramethylene phosphonate, carboxyethylthiosuccinic acid and acryloyl morph copolymer in mass percent of (30-60):(2-8):(0.5-1.5):(5-35):(5-10):(2-15):(15-30). The antisludging agent for the hot method during sea water desalination can be applied to a multiple-effect distillation and multi-stage flash distillation system, has good inhibiting effect and dispersing effect on multiple dirts such as calcium carbonate and calcium sulphate, has a good copper corrosion inhibiting effect and does not influence smell and colour of a water product.

Owner:WEIHAI XIANGYU TECH

Scale and corrosion inhibitor

InactiveCN105600957APrevent or interfere with precipitationPrevent or interfere with foulingSpecific water treatment objectivesScale removal and water softeningEthylenediamineGluconic acid

The invention discloses a scale and corrosion inhibitor. The scale and corrosion inhibitor is prepared from the following raw materials in parts by weight: 20 to 25 parts of amino tri(methylene phosphonic acid), 30 to 35 parts of 1-hydroxyethane 1,1-diphosphonic acid, 15 to 20 parts of amino tri(methylene phosphonic acid), 3 to 5 parts of sodium ethylenediamine tetramethylene phosphonate, 2 to 5 parts of polyacrylic acid, 2 to 6 parts of lauric acid, 1 to 3 parts of polyaspartic acid, 1 to 3 parts of 2-hydroxyphosphonoacetic acid, 1 to 3 parts of methyl benzotriazole, 2 to 6 parts of sodium gluconate, 6 to 8 parts of zinc powder, 0.5 to 1 part of surfactant, and 60 to 70 parts of deionized water. The scale and corrosion inhibitor disclosed by the invention has a favorable restraining effect on calcium and calcium carbonate, and has the capabilities of dispersing slightly soluble inorganic salts in water and protecting metal against corrosion and rusting.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Galvanized steel sheet passivating agent and preparation method thereof

InactiveCN104451626AAccelerated corrosionImprove oxidation resistanceMetallic material coating processesPhosphatePhytic acid

The invention provides a galvanized steel sheet passivating agent and a preparation method thereof. The galvanized steel sheet passivating agent is prepared from the following components: phytic acid, 1-hydroxyl ethylidene bisphosphoric acid, nitrilotrimethylene phosphonic acid, ethanediamine tetramethylene phosphonic acid, sodium silicate, sodium formate, polyvinyl alcohol, sodium benzoate, triethanolamine, aluminum dihydrogen phosphate, sulfosalicylic acid, vanadiumoxy acetylacetonate, gamma-aminopropyltriethoxysilane, 2-acrylamido-2-methyl propane sulfonic acid, N, N-dimethyl acrylamide, silicon oxide filler, water-soluble film-forming resin and deionized water. The preparation method of the galvanized steel sheet passivating agent comprises the following steps: adding phytic acid, 1-hydroxyl ethylidene bisphosphoric acid, nitrilotrimethylene phosphonic acid, ethanediamine tetramethylene phosphonic acid, sodium silicate, sodium formate and polyvinyl alcohol into the deionized water, thereby forming a mixture I; then, mixing parts of the components with the deionized water, thereby forming a mixture II; and finally, mixing the mixture I with the mixture II, and then adding the residual components, thereby forming the galvanized steel sheet passivating agent. The galvanized steel sheet passivating agent does not contain chromium; and a galvanized steel sheet passivated by the galvanized steel sheet passivating agent has relatively high corrosion resistance and oxidization resistance.

Owner:WUXI EPIC TECH

Detergent for glass apparatus and preparation method thereof

InactiveCN103695202AGood removal effectOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsEthylenediaminetetra(methylenephosphonic)acidSodium phosphates

The present invention relates to a detergent for glass apparatus and a preparation method thereof. The detergent contains the following components by weight: 15-32 parts of dioctyl sulfosuccinate, sodium salt, 10-25 parts of dioctyl sodium sulfosuccinate, 5-15 parts of polyoxyethylene monococoate, 3-12 parts of betaine, 40-60 parts of sodium ethylenediamine tetramethylenephosphonate, 10-25 parts of sodium pyrophosphate, 5-15 parts of sodium phosphate and 780-880 parts of water. According to the detergent for glass apparatus and the preparation method thereof provided by the invention, the detergent has good removal ability on all the stains on surface of the glass apparatus, can easily remove residual acid, alkali and oil stains on the surface of the apparatus, and can kill the bacteria on the surface of the apparatus.

Owner:NANTONG JINGXIN OPTICAL GLASS

Corrosion and scale inhibitor for oil and gas fields and petrochemical industry

ActiveCN103819011AGood dispersionReduce dosageScale removal and water softeningMorpholineAlkylphenol

The invention relates to a corrosion and scale inhibitor for oil and gas fields and petrochemical industry, which is mainly used to inhibit scales and corrosion of oily water and effectively prevents generation of biological slimes of bacteria and algae in crude oil transportation pipelines and circulating cooling water systems in the petrochemical industry. The corrosion and scale inhibitor for oil and gas fields and petrochemical industry comprises at least one of maleic acid-acryloyl morpholine, polyepoxysuccinic acid, alkylphenol polyoxyethylenyl ether acrylate-acrylic acid, hydroxyl ethylidene diphosphonic acid, amino trimethylene phosphonic acid, ethylenediamine tetramethylenephosphonic acid, divinyl triamine pentamethylene phosphonic acid, 2-butane phosphonate-1, 2, 4-tricarboxylic acid and the like.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

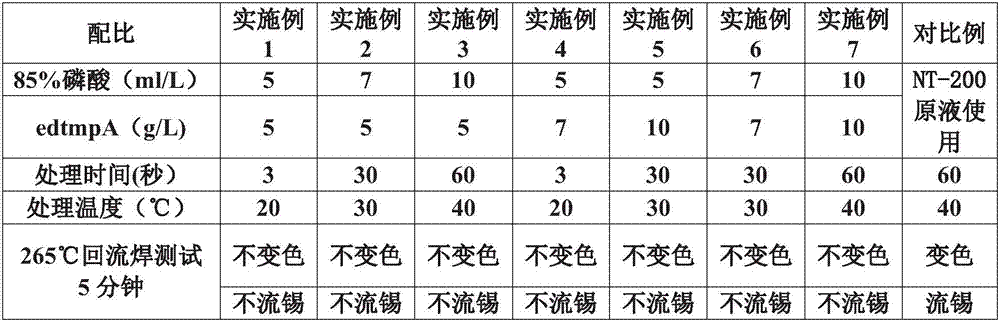

Electrotinning tarnishing prevention treating agent and using method thereof

The invention discloses an electrotinning tarnishing prevention treating agent and a using method thereof. The electrotinning tarnishing prevention treating agent is prepared from phosphoric acid, ethylenediamine tetramethylenephosphonic acid and deionized water. By means of the electrotinning tarnishing prevention treating agent and the using method thereof, an electrotinning layer can be effectively protected against oxidizing tarnishing and prevented from aging, and the product quality is improved.

Owner:DOWMORGEN ELECTRONICS TECH

Electrochemical corrosive process of anode aluminum foil

InactiveCN101029412AHigh mechanical strengthObservation uniformCapacitor electrodesAluminum IonPhosphate

An electrochemical corrosion technology for anode aluminum foils consists of two DC electrochemical corrosion processes. The first electrochemical corrosion process is carried out in mixed solution sulfuric acid, chlorine ion and aluminum ion; the second electrochemical corrosion process is carried out by adding into organic phosphonic acid or phosphate, ATMP, HEDP and EDTMP. It has homogenous appearance, large capacity ration, excellent mechanical strength and water-proof performance.

Owner:DONGGUAN HEC CONDENSER CO LTD

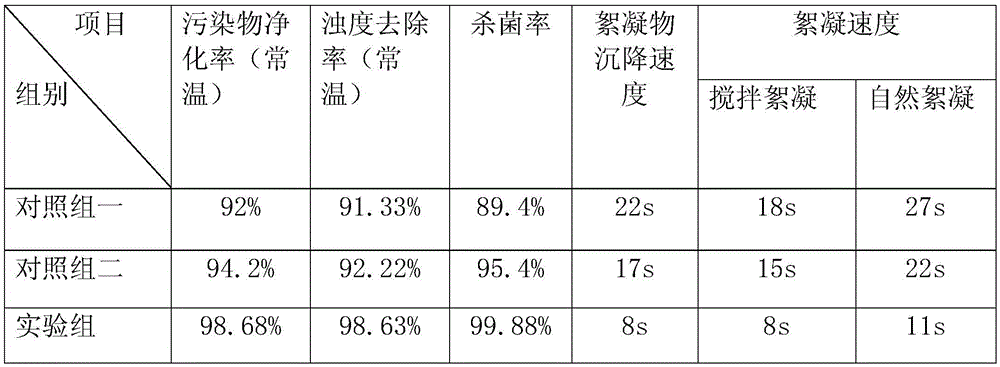

Water treatment agent for recovering reclaimed water and preparation method thereof

InactiveCN105585057AFunction increaseImprove the bactericidal effectBiocideSpecific water treatment objectivesSodium bicarbonateEthylenediaminetetra(methylenephosphonic)acid

The invention discloses a water treatment agent for recovering reclaimed water and a preparation method thereof. The water treatment agent comprises the following raw materials in parts by weight: 2-4 parts of dodecyldimethylbenzyl ammonium chloride, 1-3 parts of isothiazolinone, 2-4 parts of anhydrous citric acid, 2-4 parts of sodium hexametaphosphate, 5-7 parts of zinc sulfate, 12-14 parts of copper sulfate, 6-8 parts of quicklime, 6-8 parts of sulfur, 10-12 parts of ferrous sulfate, 5-7 parts of activated silica, 2-4 parts of isoleucine, 2-4 parts of polyepoxysuccinic acid, 1-3 parts of calcium hydroxide, 8-10 parts of polyacrylamide, 2-4 parts of sodium hypochlorite, 5-7 parts of ethylenediamine tetra(methylenephosphonic acid), 2-4 parts of poloxamer, 5-7 parts of polyvinylpyrrolidone, 3-5 parts of sodium bicarbonate and 1-3 parts of dipotassium glycyrrhetate. The water treatment agent for recovering reclaimed water has excellent purifying capacity and sterilization capacity.

Owner:张锐

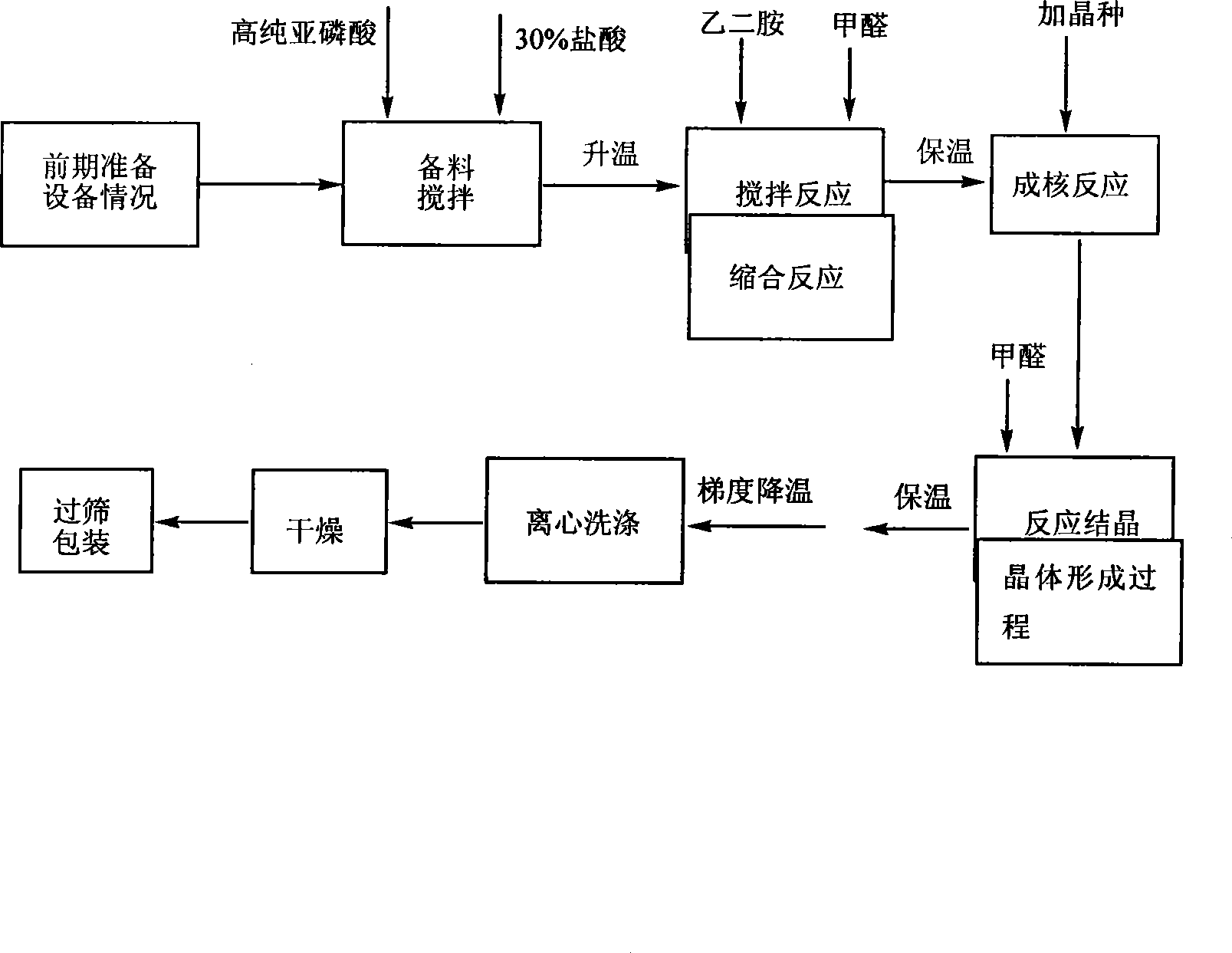

Preparation technology suitable for electronic grade solid ethylenediamine tetramethylene phosphonic acid

ActiveCN101381376AEasy to packEasy to storeGroup 5/15 element organic compoundsN-methylene phosphonic chitosanPhosphoric acid

The invention discloses a production process of high-purity solid ethylene diamine tetra (methylene phosphonic acid). The production process comprises the following steps: (1) first-phrase preparation which is to clean related equipment; (2) dissolving orthophosphorous acid crystals in high-purity water for recrystallization, and obtaining high purity orthophosphorous acid for later use; (3) placing the high-purity orthophosphorous acid and hydrochloric acid into a reaction kettle with stirring and temperate raising, and dripping ethylene diamine into the reaction kettle; (4) dripping methyl alcohol and keeping temperature; (5) dripping crystal nucleating agent till crystals are precipitated; (6) raising temperature and continuing to dripping methyl alcohol; (7) decreasing temperature step by step; (8) centrifugation, drying, screening and packaging. The white solid particles of EDTMPA has a content of active EDTMPA of more than 95 percent, a content of arsenic less than 0.5 mg / L. The high-purity solid ethylene diamine tetra (methylene phosphonic acid) can be used as metal-chelator for textile dyeing industry, a washing agent for electronic industry, a metal conditioner, etc., and has the advantages of simple package, convenient storage and transportation.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Sea water desalination scale inhibitor and preparation method thereof

InactiveCN106396145AWide variety of sourcesStrong chelating abilitySeawater treatmentSpecific water treatment objectivesEthylenediamineWater desalination

A sea water desalination scale inhibitor is prepared from high-purity water, polyamino polyether methylene phosphonic acid, hydroxyl methylene ammonium phosphate, ethylenediamine tetramethylene sodium phosphate, polyaspartic acid, hydrolytic polymaleic anhydride, butyl acrylate, polyacrylic acid, n-octyl acrylate, 2- phosphonobutane-1,2,4-tricarboxylic acid sodium salt and isothiazolinone. Calcium chelating ability is 240-260mg / g, the content of phosphorus in discharged water is 0.08-0.12mg / L, and a cleaning period of sea water desalination membranes is prolonged from 6 months to 8-10 months. Addition amount of the sea water desalination scale inhibitor in per liter of seawater is 2-6mg, the sea water desalination scale inhibitor is used for water high in alkalinity, hardness, pH value and concentration, synergistic effects of components are achieved, and the sea water desalination scale inhibitor is 0.0015-0.0035micron.a<-1> in carbon steel corrosion rate and 95.5-99.5% in calcium carbonate scale inhibition rate and makes seawater to replace fresh water to serve as industrial recycling cooling water.

Owner:JIANGSU JINGWEI TECH INNOVATION CONSULTING CO LTD

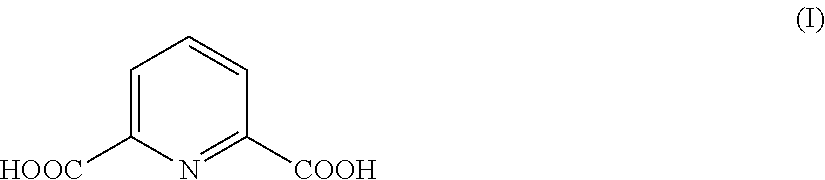

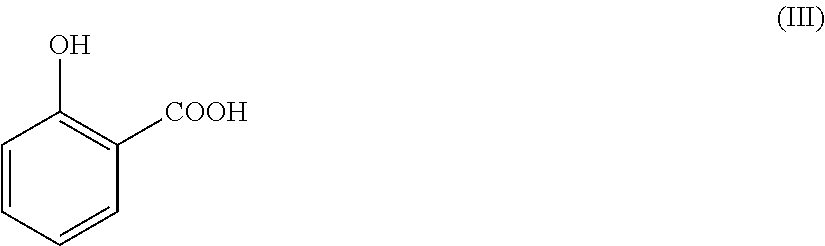

Stabilized hydrogen peroxide formulations in sachets made of barrier layer films

A cosmetic product for the oxidative color changing of keratinic fibers, in particular human hair, comprisinga preparation (A), which is packaged in a sachet (S), whereinpreparation (A) includes(A1) water and(A2) hydrogen peroxide and(A3) at least one stabilizer from the group comprising 2,6-dipicolinic acid, 1-hydroxyethane-1,1-diphosphonic acid (HEDP), benzoic acid, salicylic acid, ethylenediamine tetra(methylenephosphonic acid) (EDTMP), diethylenetriamine penta(methylenephosphonic acid) (DTPMP), amino tris(methylenephosphonic acid) (ATMP), N,N-bis[2-[bis(carboxymethyl)-amino]ethyl]glycine, ethylenediamine-N,N′-disuccinic acid (EDDS), 2-hydroxypropylenediamine-N,N′-disuccinic acid (HPDDS), ethylenediamine-N,N′-diglutaric acid (EDDG), ethylenediamine-N,N′-bis(orthohydroxyphenyl)acetic acid (EDDHA), diphosphoric acid, hydrated tin oxide,and / or the physiologically acceptable salts thereof,the wall of sachet (S) comprises(S1) a first layer made of a first polymeric material and(S2) a second layer made of a second polymeric material and(SBa) a barrier layer, which has a penetration barrier effect for gases and water vapor.

Owner:HENKEL KGAA

Dyeing technology of anti-static wool tops

The invention discloses a dyeing technology of anti-static wool tops. The dyeing technology comprises the following steps that 1, 0.7 part by weight of ethylene diamine tetramethylene phcsphonic acid sodium, 1.4 parts by weight of epoxy chloropropane, 2.6 parts by weight of tert-butyl peroxybenzoate, 1.4 parts by weight of methylene dinaphthyl sulfonate, 11 parts by weight of natural plant pigments, 0.5 part by weight of sodium hexametaphosphate, 1.7 parts by weight of nonyl phenol ethoxylate carboxylate and 32 parts by weight of water are added into a dye vat and stirred to be uniform; 2, wool tops are steeped in the dye vat for 60 min; 3, the steeped wool tops are dried at 85 DEG C; 4, the dried wool tops are immersed in clear water to be rinsed for 40 min; 5, the rinsed wool tops are taken out and naturally dried. According to the dyeing technology of the anti-static wool tops, the color fastness of the dyed wool tops is high, the uniformity of dyeing is good, and dyeing defects do not exist.

Owner:常熟市新华源有色毛条厂

Treating agent for papermaking sewage

InactiveCN106082369ANothing producedQuick responseWater/sewage treatmentWaste water treatment from plant processingSucrosePhosphate

Owner:虞永华

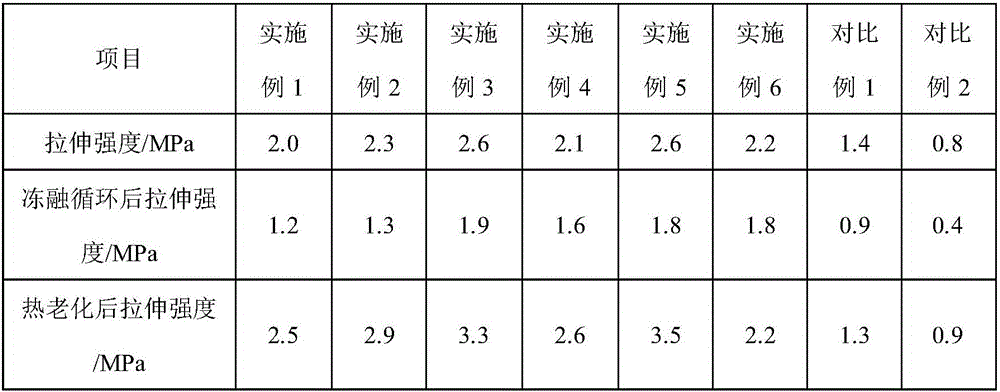

Ceramic tile adhesive for intelligent installation and decoration engineering of building

The invention relates to the technical field of building materials, and in particular relates to a ceramic tile adhesive for intelligent installation and decoration engineering of a building. The ceramic tile adhesive is prepared from the following substances in percentage by mass: 30 to 40 percent of cement. 15 to 20 percent of building garbage powder, 4 to 8 percent of dispersible latex powder, 0.1 to 0.3 percent of cellulose ether, 0.02 to 0.05 percent of ethylenediamine tetramethylene phosphonic acid, 0.02 to 0.05 percent of calcium saccharate, 0.2 to 1 percent of alkali lignin, 0.5 to 1 percent of a melamine water reducing agent, 0.5 to 0.8 percent of sticky rice starch, 0.2 to 0.5 percent of a viscous water retention agent, 0.2 to 1 percent of a reinforcer, 5 to 10 percent of zeolite powder and the balance of quartz sand. Compared with the conventional adhesive, the ceramic tile adhesive is high in anti-slipping property and has the advantages of high water resistance, heat resistance, freezing and thawing cycle resistance and the like.

Owner:SHENZHEN ZHONGZHUANG CONSTR GRP CO LTD

Soil heavy metal stabilizer functioning as nitrogen and phosphorus fertilizer, and preparation method and application thereof

ActiveCN111621304AHigh reactivityReduce reactivityAgriculture tools and machinesContaminated soil reclamationSoil heavy metalsEthylenediaminetetra(methylenephosphonic)acid

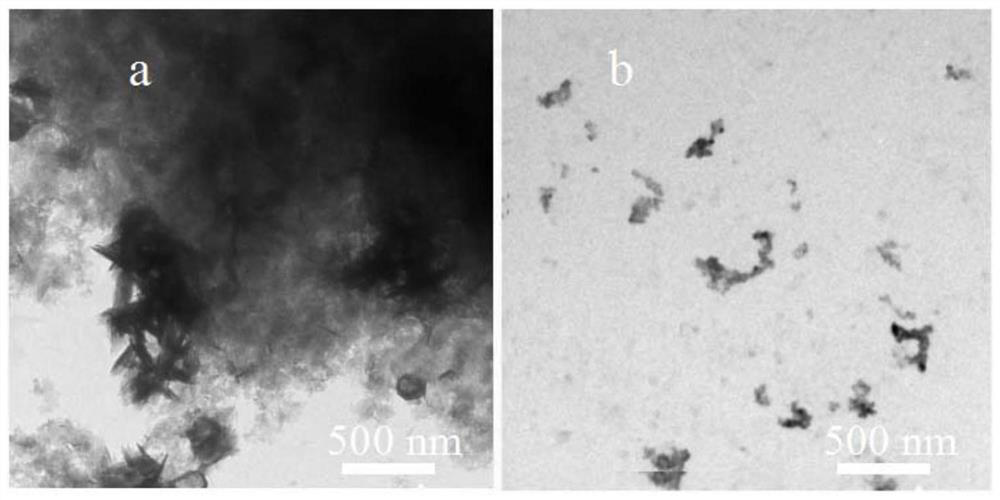

The invention discloses a soil heavy metal stabilizer functioning as a nitrogen and phosphorus fertilizer, and a preparation method and application thereof. The soil heavy metal stabilizer is an organic matter-ferrous sulfide nanoparticle suspension; the mass percentage concentration of the organic matter is 0.05-5%, and the organic matter is one or more selected from a group consisting of sodiumphytate, 1-hydroxyethylidene-1,1-diphosphonic acid tetrasodium salt, amino trimethylene phosphonate, ethylenediamine tetramethylene phosphonate and 1-hydroxymethylene phosphonate; and the particle sizes of ferrous sulfide nanoparticles are in a range of 250 to 500 nm. The soil heavy metal stabilizer can passivate and fix various heavy metal ions such as chromium, arsenic, lead and zinc in soil atthe same time, increases the content of organic matters in the soil, provide nutrient elements N and P needed by plant growth and improve soil fertility, and has potential application and popularization value.

Owner:NANJING NORMAL UNIVERSITY

Metal surface high-efficiency deoiling/derusting agent

InactiveCN104087925ANot affected by acid mistNot corroded and inhibited by acid mistMetallic material coating processesSodium lactateSodium acetate

The invention discloses a metal surface high-efficiency deoiling / derusting agent which is prepared from the following raw materials: 18-20 parts of phosphoric acid, 8-12 parts of hydrochloric acid, 5-8 parts of acetic acid, 3-5 parts of boric acid, 2-3 parts of ferric hydroxide, 2-4 parts of ammonium oxalate, 3-5 parts of diethyl ethanedioate, 4-6 parts of sodium acetate, 3-5 parts of potassium iodide, 2-3 parts of phenol, 4-5 parts of sodium lactate, 1-3 parts of citric acid, 3-6 parts of resorcinol, 4-5 parts of p-hydroxyanisole, 3-4 parts of sodium carbonate, 5-6 parts of ethylenediamine tetra(methylenephosphonic acid), 1-2 parts of ammonium bicarbonate and 25-30 parts of pure water. The metal surface high-efficiency deoiling / derusting agent can remove oil and rust at high speed at normal temperature, can prevent the metal base from being corroded, can inhibit acid mist, and has the excellent synergetic effect.

Owner:司徒建辉

Preparation method for environment-friendly stone deruster

ActiveCN105000909AWill not polluteImprove rust removal effectHexamethylenetetramineEthylenediaminetetra(methylenephosphonic)acid

The invention discloses a preparation method for an environment-friendly stone deruster. The preparation method comprises the following steps: placing hydrochloric acid, an emulsifier, triethavolamine, zinc stearate and thiourea dioxide into a stirring machine in parts by weight, and stirring at the temperature of 40-60 DEG C; adding hexamethylenetetramine, ammonium molybdate, benzotriazole, isobornyl acrylate, dibutyl phthalate and ethylene diamine tetramethylene phosphonic acid, heating to 60-80 DEG C within 3-6 min, performing ultrasonic treatment for 10-15 min, cooling to 40-60 DEG C, and continuously performing ultrasonic treatment for 10-15 min; placing the mixture into the stirring machine, and stirring at the ordinary temperature to obtain the environment-friendly stone deruster. The derusting performance of the deruster prepared by the method is improved, and the deruster has no impact on the surface of stone, meanwhile is simple in preparation process, avoids environment pollution, and has an excellent market prospect.

Owner:江苏凯信环保材料有限公司

Novel bleaching agent for textile pretreatment

InactiveCN104805678AAvoid damageImprove bleaching effectBleaching apparatusHexamethylenetetramineBleach

The invention discloses a novel bleaching agent for textile pretreatment. The novel bleaching agent is prepared by the following components in parts by weight: 20 to 40 parts of hydrogen peroxide, and 2 to 6 parts of potassium borate; 2 to 5 parts of ethylene diamine tetra sodium; 3 to 5 parts of sodium tripolyphosphate, 10 to 15 parts of acetic acid, 1 to 4 parts of magnesium chloride, 3 to 5 parts of tetraacetylethylenediamine, 2 to 6 parts of sodium silicate, 0.5 to 1.3 parts of sodium hydroxyethyl sulfonate, 10 to 18 parts of sodium percarbonate, 8 to 15 parts of sodium pyrophosphate, 10 to 20 parts of hexamethylenetetramine, and 100 to 120 parts of water. The novel bleaching agent has the advantages that the safety and non-toxic effects are realized, and the bleaching effect is good; at the premise of realizing good bleaching effect, the bleaching temperature is lowered, the damage to a fabric is reduced, the novel bleaching agent is suitable for bleaching the dirt of various fabrics, and the manufacturing cost is low.

Owner:HUZHOU LIHUA YUJIE UNION TEXTILE

Antifreezing glass cleaning liquid

InactiveCN104342293AImprove low temperature resistanceImprove performanceInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSalicylic acidGlycerol

The invention provides antifreezing glass cleaning liquid prepared from the following raw materials in parts by weight: 6-10 parts of ethylenediamine tetramethylenephosphonic acid sodium, 3-8 parts of tripropylene glycol monomethyl ether, 5-9 parts of monoethanolamine, 6-8 parts of glycerindiacetate, 5-9 parts of coconut oil fatty acid, 4-8 parts of salicylic acid, 5-8 parts of urea, 7-9 parts of sodium hydroxide, 5-10 parts of silicone emulsion, 2-6 parts of saponin glue, 7-11 parts of propylene glycol, 6-8 parts of kudzu glue, 3-6 parts of silicon dioxide, 1-5 parts of wax and 30 parts of water. The antifreezing glass cleaning liquid has the beneficial effects of being used normally at a low temperature and having good low-temperature resistance, a good antifreezing effect and excellent performance.

Owner:QINGDAO KELIKE INFORMATION TECH

Metal cleaning agent and preparation method thereof

The invention discloses a metal cleaning agent. The metal cleaning agent comprises the following raw materials by weight ratio: 10-15 parts of sodium polyacrylate, 4-6 parts of trifluoroethyl alcohol, 4-6 parts of polyoxyethylene nonyl phenyl ether, 4-6 parts of sodium citrate, 2-4 parts of EDTA tetrasodium, 2-4 parts of chitosan, 2-4 parts of sodium dodecanesulphonate, 3-5 parts of acetic acid, 3-5 parts of glycol, 3-5 parts of triethanolamine, 3-5 parts of di-o-tolyl-thiourea, 3-5 parts of sodium gluconate, 3-5 parts of carboxymethyl cellulose, 3-5 parts of sodium oleate, 3-5 parts of sodium pyrophosphate, 3-5 parts of silica, 3-5 parts of a nonionic surfactant, 2-4 parts of a anionic surfactant, 2-4 parts of an antifoaming agent, 2-4 parts of trisodium phosphate, and 2-4 parts of a stabilizing agent; wherein the stabilizing agent is selected from one or more of DPDP, PDDP, butyl epoxystearate, and dioctyl ethylenediamine tetramethylene sodium phosphate. The metal cleaning agent has good cleaning effect.

Owner:WUXI CITY SHANGXIN METAL PROD

Steel structure surface rust removing agent

The invention discloses a steel structure surface rust removing agent. The steel structure surface rust removing agent consists of the following raw materials in parts by weight: 45-50 parts of acrylic resin, 30-40 parts of organic silicon resin, 10-15 parts of fire retardant, 1-3 parts of corrosion inhibitor, 1-3 parts of penetrating agent, 4-8 parts of triethanolamine, 45-55 parts of de-ionized water, 4-6 parts of ethylene oxide, 3-6 parts of ammonium molybdate, 0.3-0.5 part of sodium ethylenediamine tetramethylene phosphonate, and 1-3 parts of fatty alcohol polyoxyethylene ether sodium sulfate, wherein the fire retardant is one or two of ammonium polyphosphate and pentaerythritol. The steel structure surface rust removing agent is different from a traditional acid rust removing agent, contains no strong acid and chloride ion component, and is free of corrosivity, low in cost, safe, environment-friendly and excellent in rust removing effect.

Owner:青岛唐鹏钢结构工程有限公司

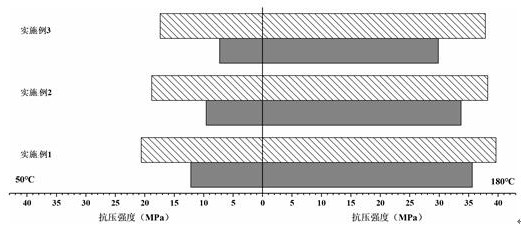

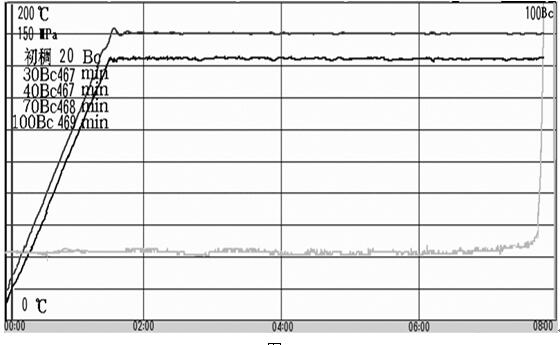

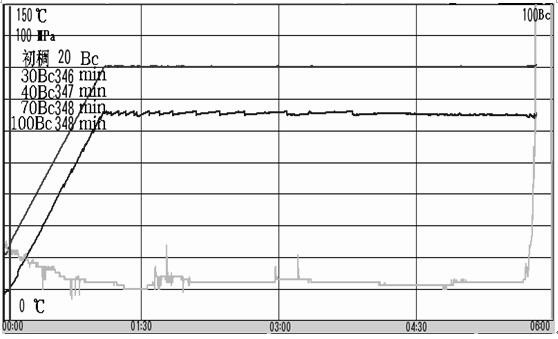

Cement paste system for long-cementing-section large-temperature-difference cementing

ActiveCN112961658ASatisfy retardationWide use temperature rangeDrilling compositionMeth-Ethylenediaminetetra(methylenephosphonic)acid

The invention discloses a cement slurry system for long-cementing-section large-temperature-difference cementing, and relates to the technical field of oil and gas field cementing materials. The cement paste consists of 74-88 wt% of oil well cement, 4-8 wt% of a fluid loss agent, 1-3 wt% of a suspension stabilizer, 10-20 wt% of a high-temperature strength stabilizer and 1-3 wt% of a retarder. The retarder is formed by mixing and compounding sodium ethylene diamine tetramethylene phosphonate, borax and a ternary polymer. The ternary polymer is prepared by taking sodium methallyl sulfonate, isopentenol polyvinyl ether and maleic anhydride as monomers and adopting a free radical solution copolymerization method. The cement paste provided by the invention has a wide use temperature interval, can meet the retarding effect on cement paste in the whole temperature interval that the temperatures of the upper end and the lower end of a cement paste injection well section in cementing construction are 50 DEG C and 180 DEG C respectively, the cement paste is ensured to have certain strength in a 50-DEG C high-temperature large-temperature-difference environment at the top, and the super retarding phenomenon of top cement is avoided.

Owner:JIAHUA SPECIAL CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com