Composite multi-component scale inhibitor for treating oil-field water and preparation thereof

A scale inhibitor, oilfield water technology, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc. and other problems, to achieve the effect of good scale inhibition, good inhibition and elimination, and excellent scale inhibition and dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

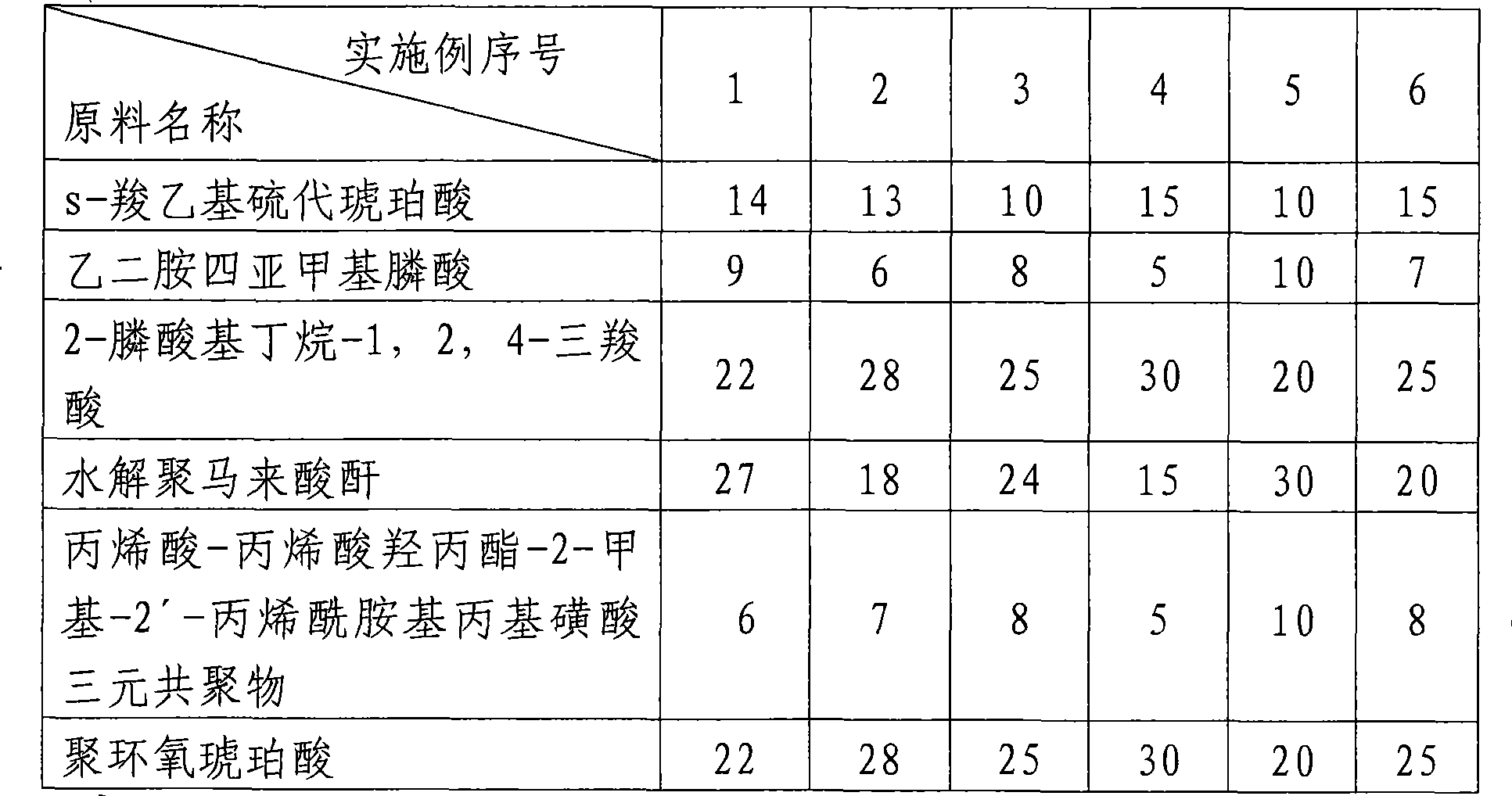

[0017] The present invention will be further described below in combination with embodiments. The antiscalant implementation plan of composite multi-element oilfield water treatment is as follows:

[0018] plan 1

[0019] Composite multi-element scale inhibitor for oilfield water treatment, the ratio of components by weight: 9-16 parts of s-carboxyethylsulfosuccinic acid, 4-11 parts of ethylenediamine tetramethylene phosphonic acid, 2- Phosphonobutane-1,2,4-tricarboxylic acid 19-31 parts, hydrolyzed polymaleic anhydride 14-31 parts, acrylic acid-hydroxypropyl acrylate-2-methyl-2'-acrylamidopropyl 4-11 parts of sulfonic acid terpolymer, 19-31 parts of polyepoxysuccinic acid.

[0020] Scenario 2

[0021] The scale inhibitor for composite multi-component water treatment, the preferred weight ratio is: 10-15 parts of s-carboxyethyl sulfosuccinic acid, 5-10 parts of ethylenediamine tetramethylene phosphonic acid, 2-phosphonobutyl Alkane-1,2,4-tricarboxylic acid 20-30 parts, hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com