Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

776results about "Photoprinting processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

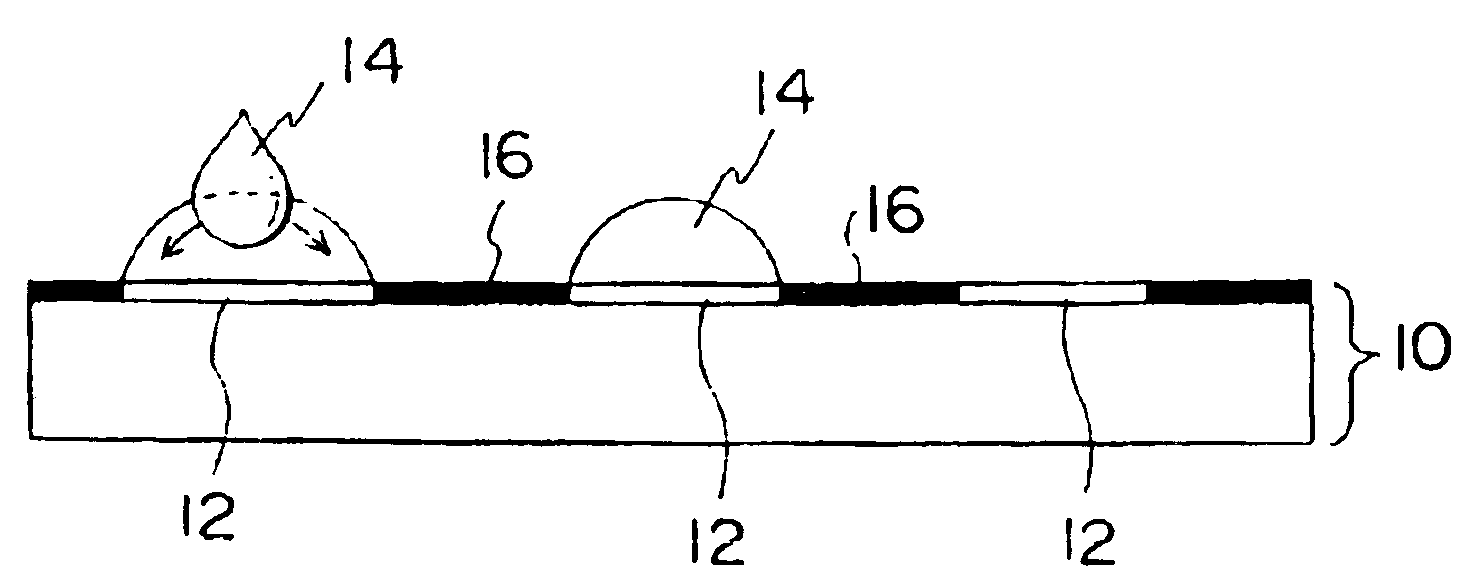

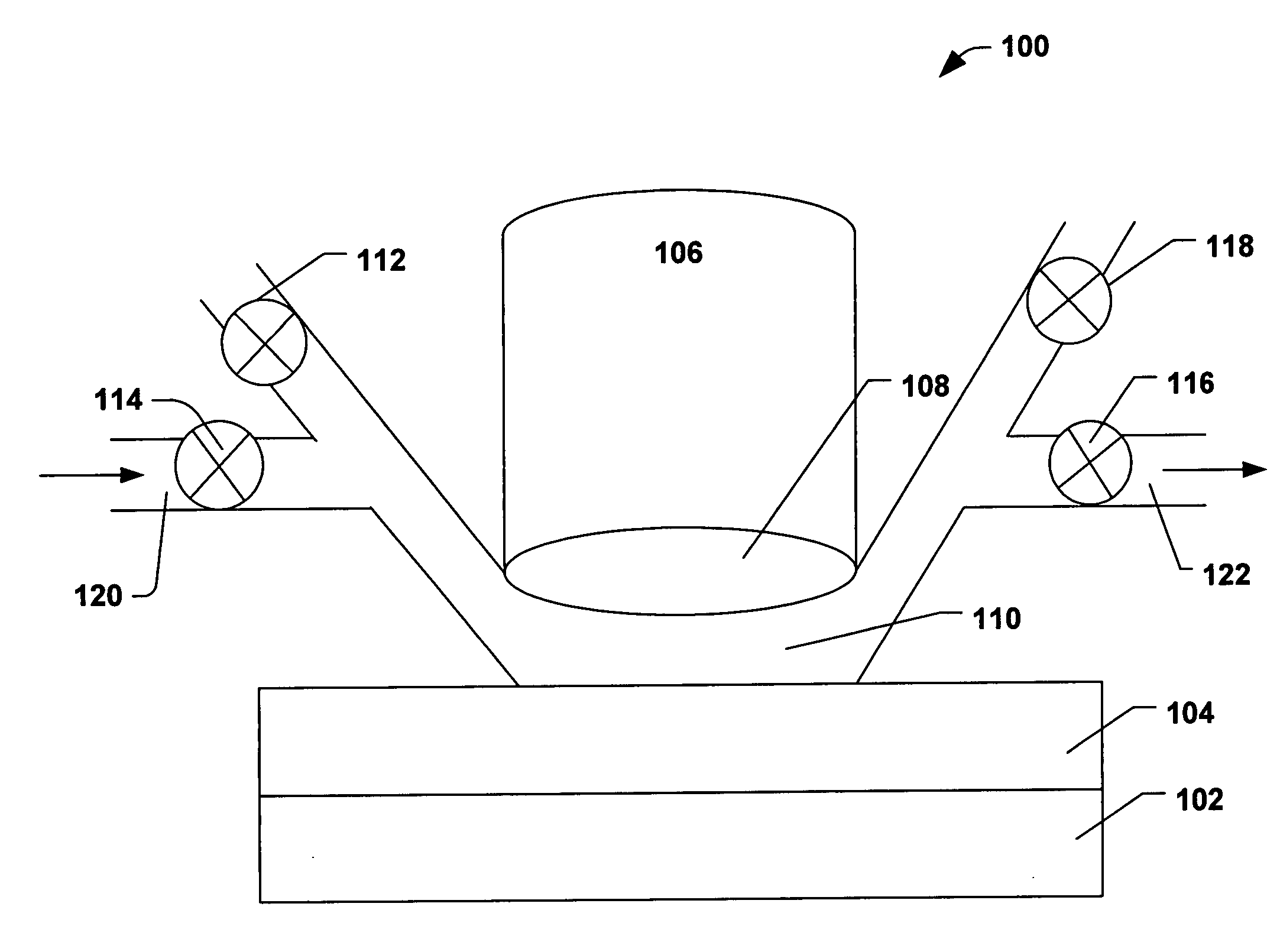

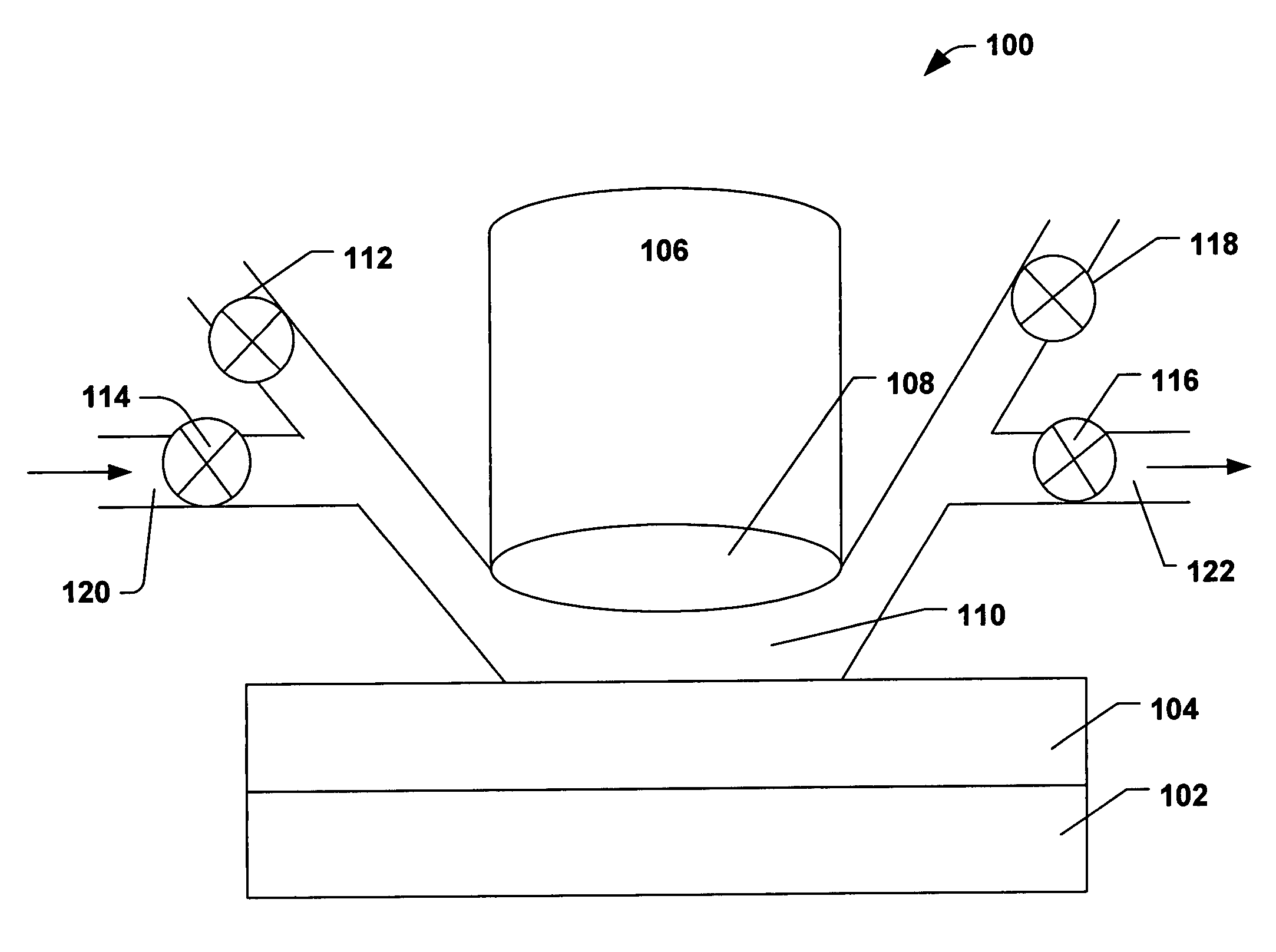

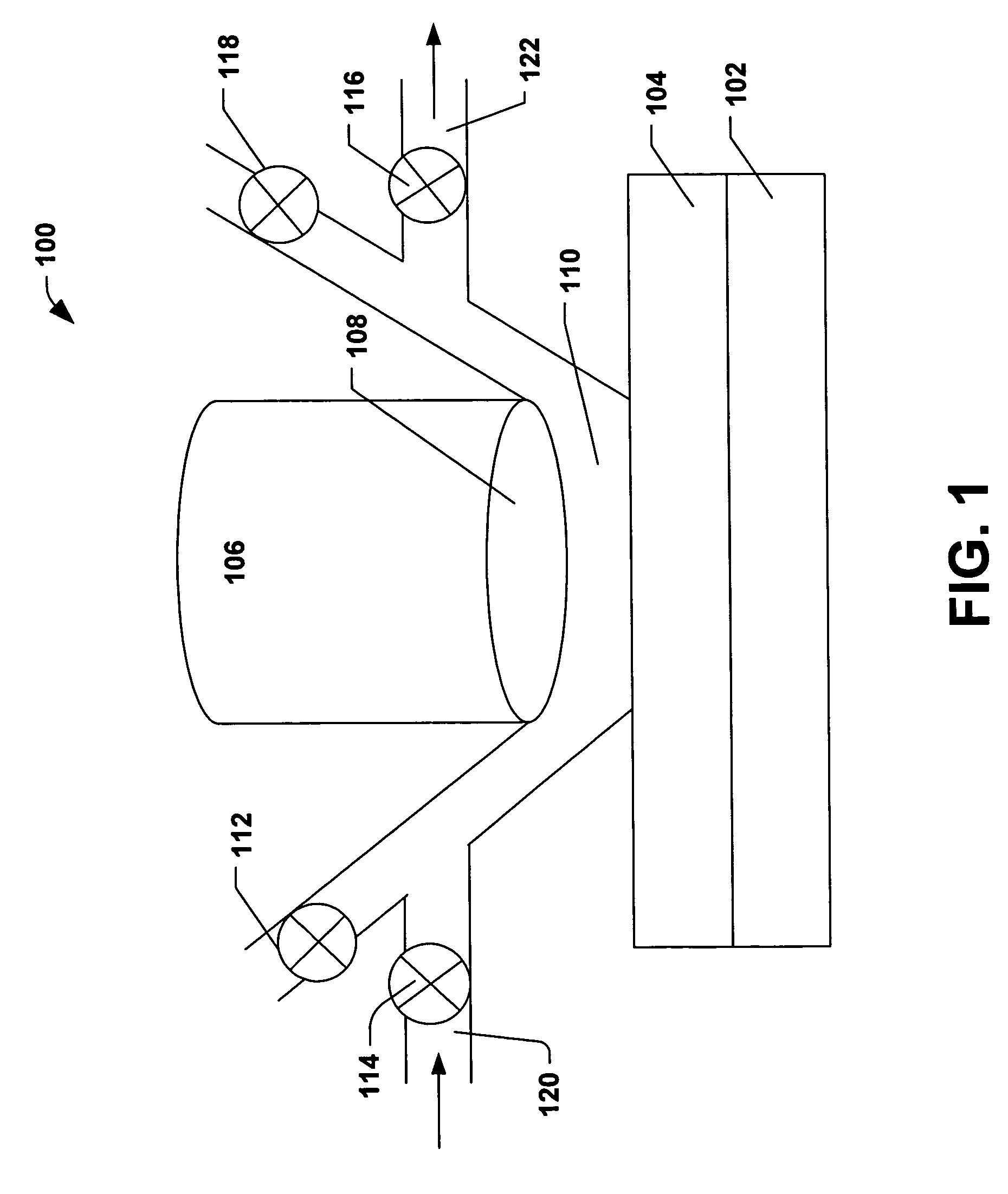

Liquid-filled balloons for immersion lithography

ActiveUS20050158673A1Suitable optical propertyPhotoprinting processesSemiconductor/solid-state device manufacturingOptical propertySemiconductor structure

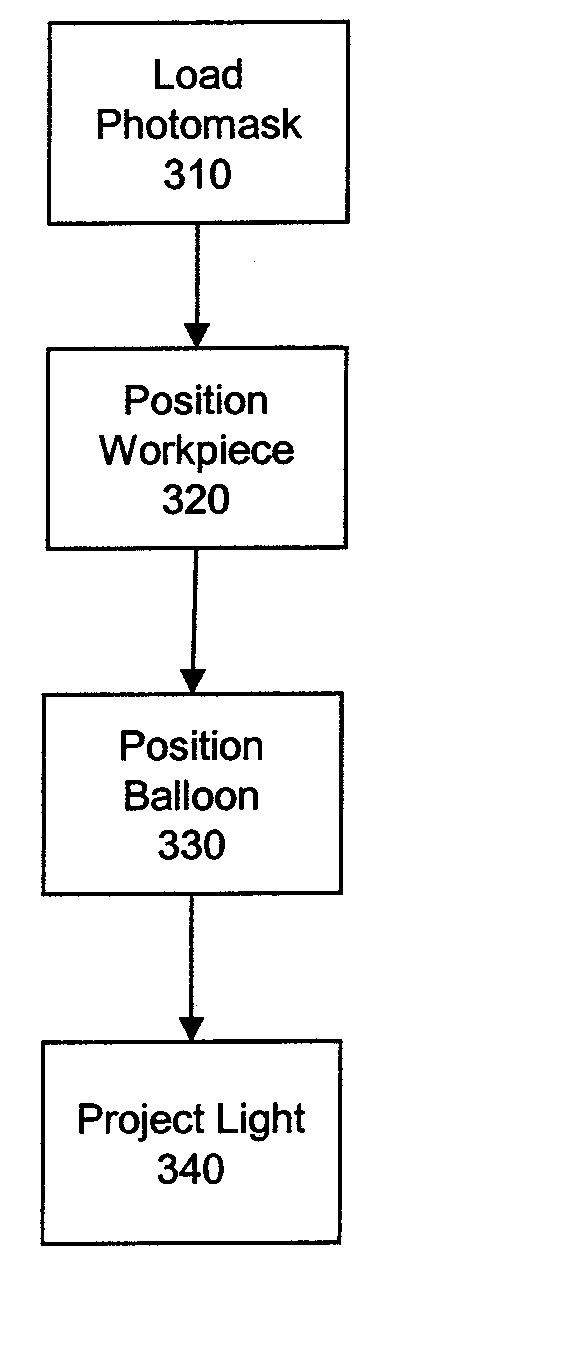

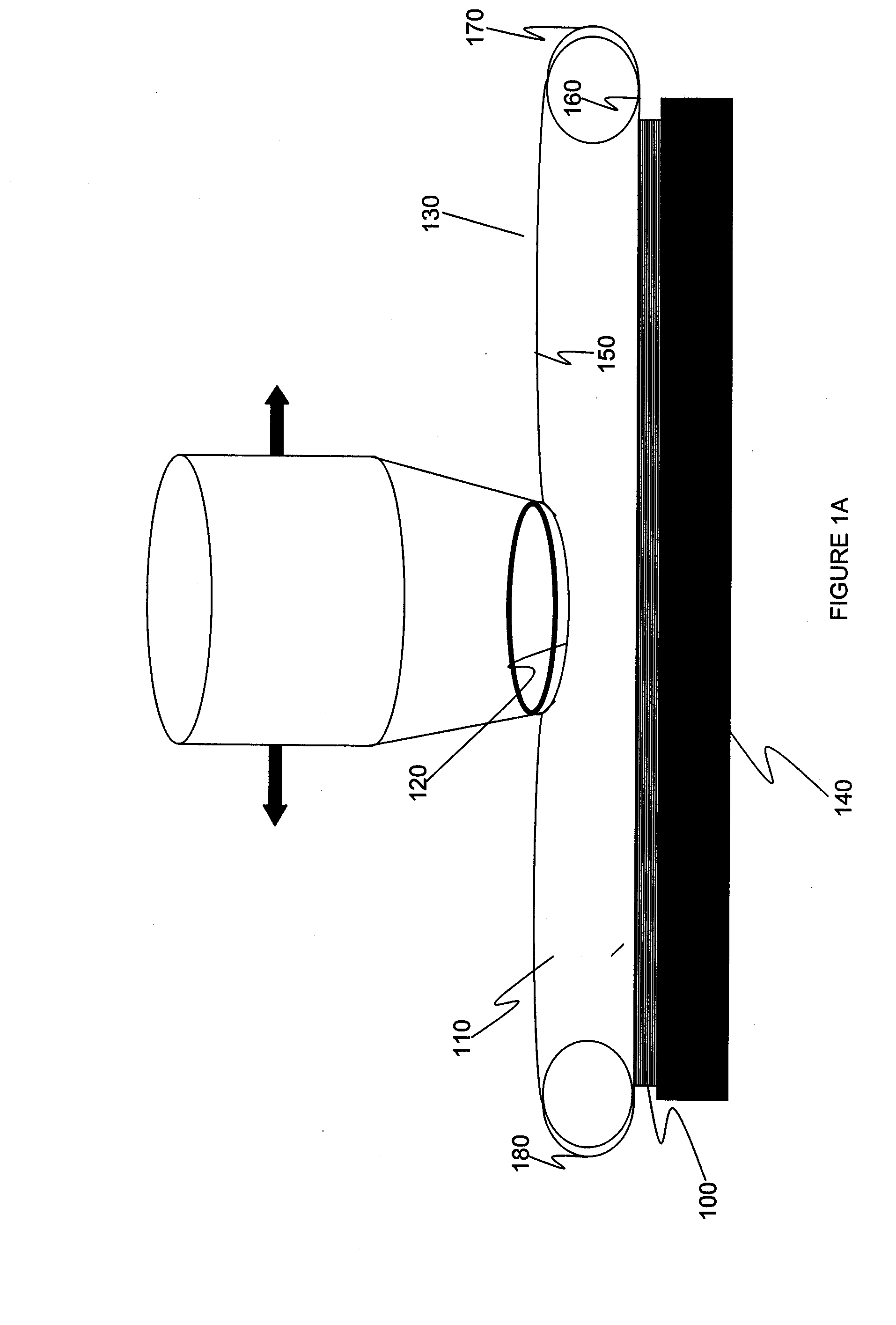

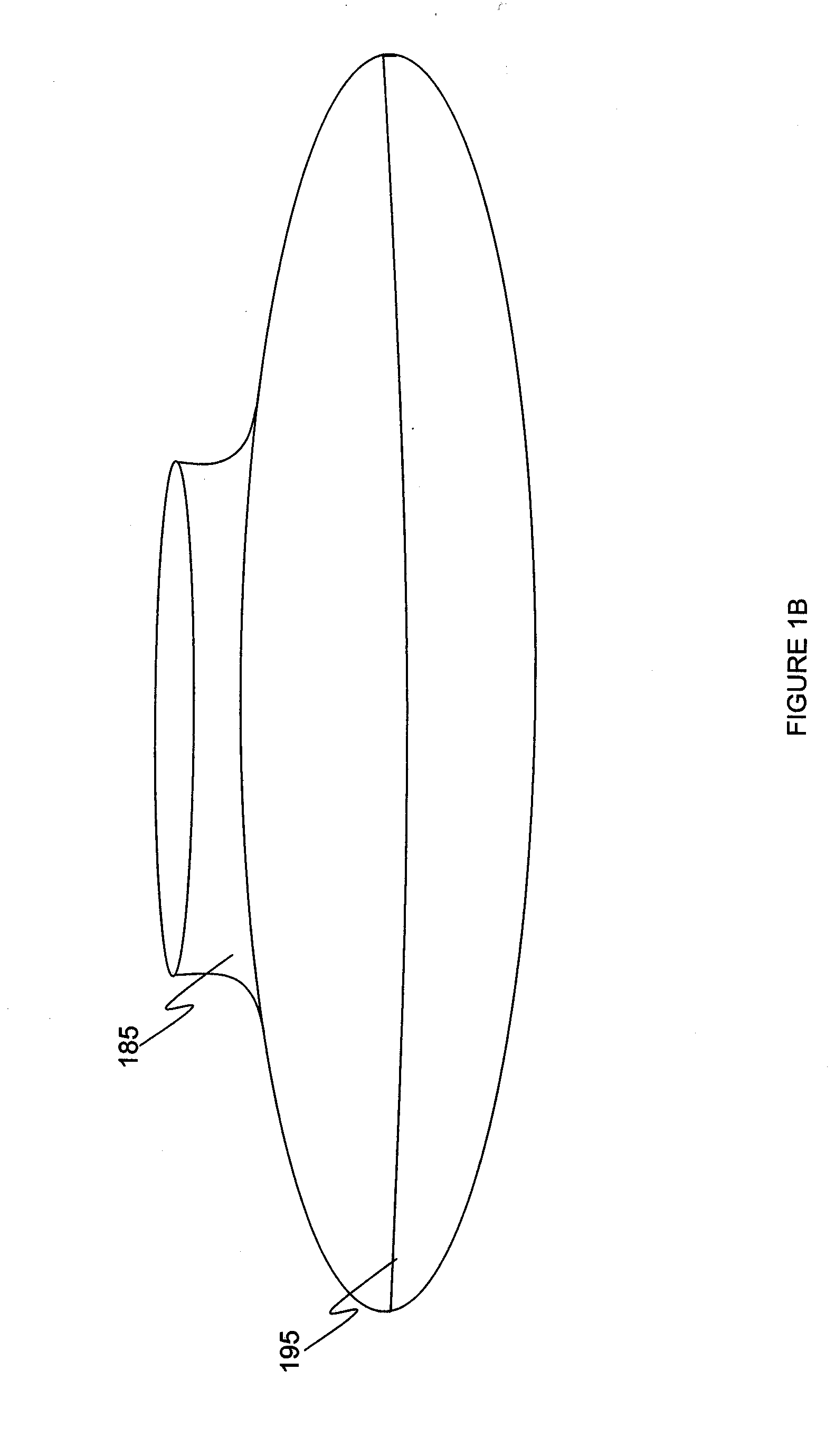

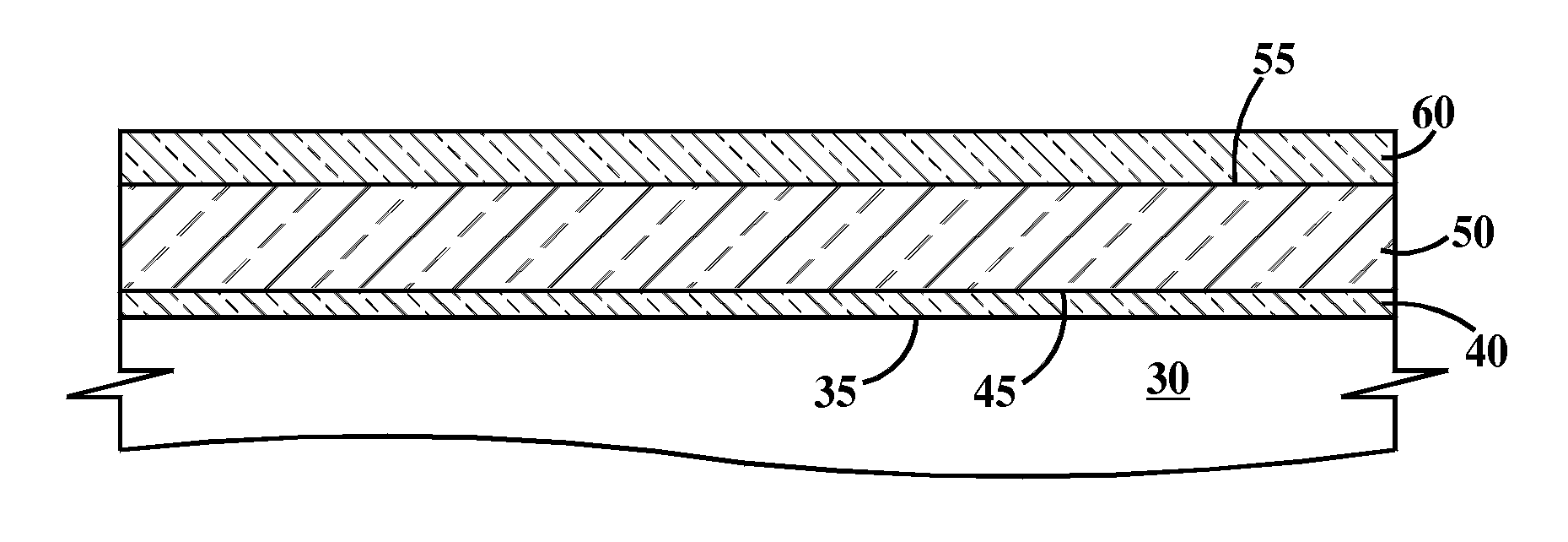

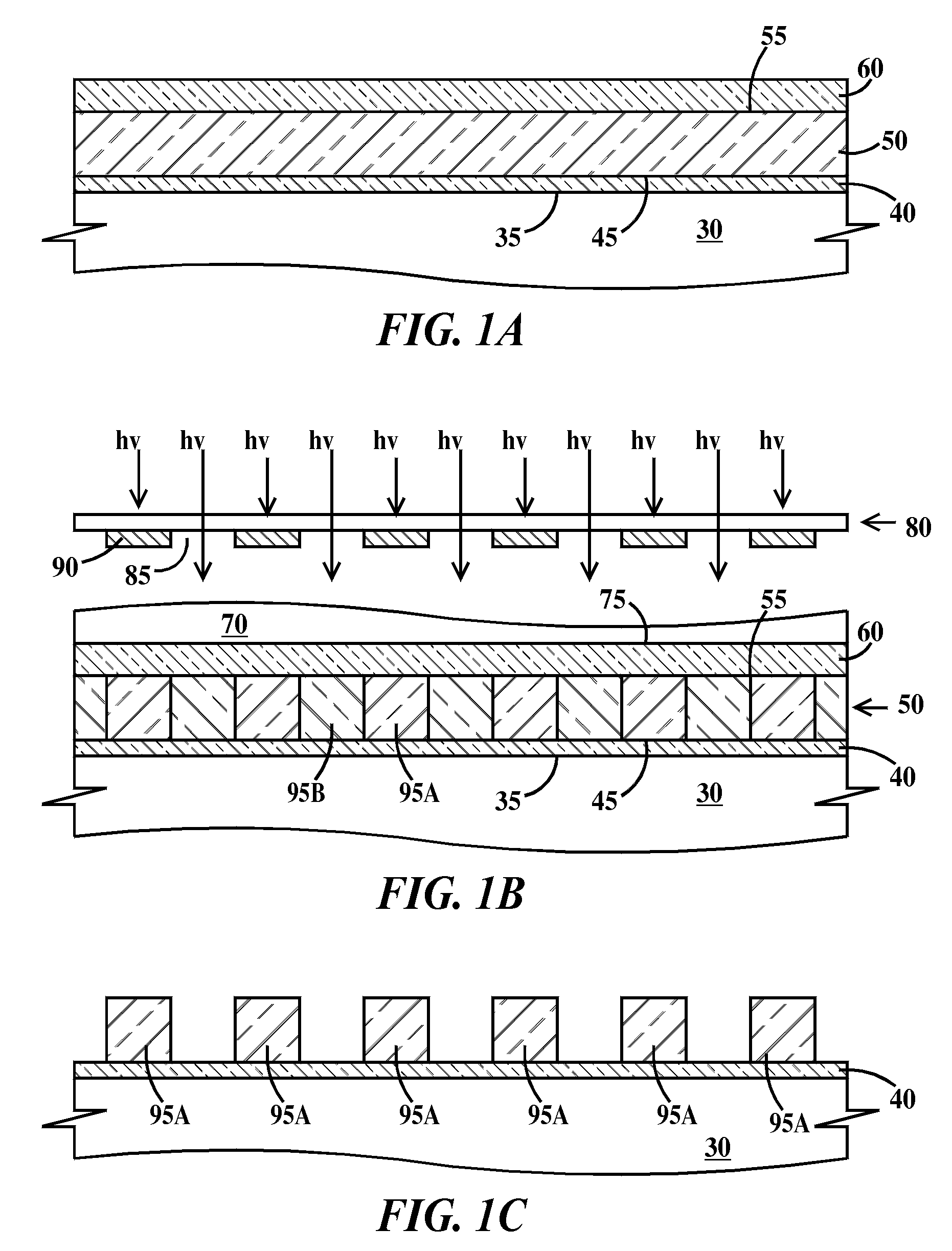

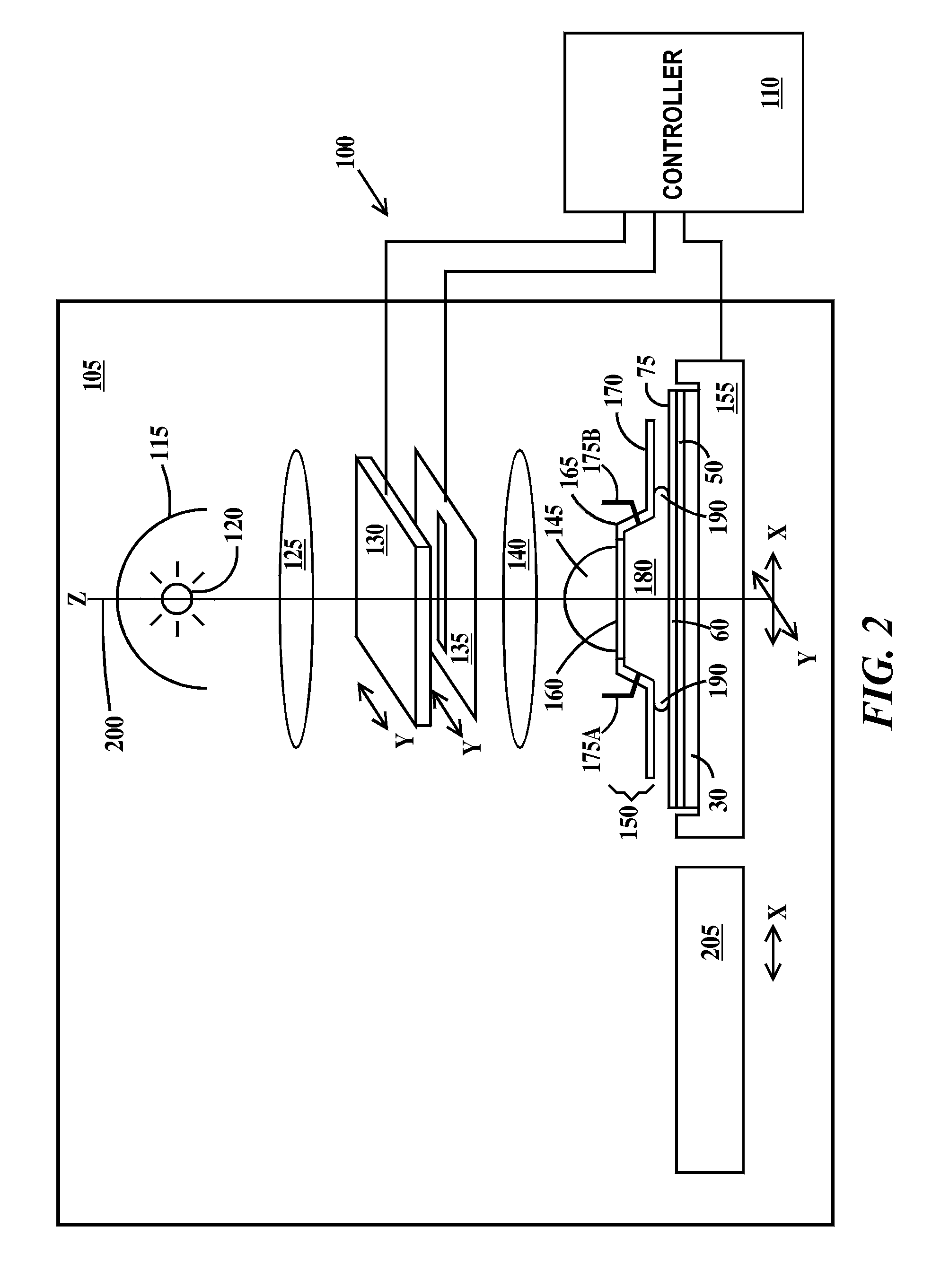

A liquid-filled balloon may be positioned between a workpiece, such as a semiconductor structure covered with a photoresist, and a lithography light source. The balloon includes a thin membrane that exhibits good optical and physical properties. Liquid contained in the balloon also exhibits good optical properties, including a refractive index higher than that of air. Light from the lithography light source passes through a mask, through a top layer of the balloon membrane, through the contained liquid, through a bottom layer of the balloon membrane, and onto the workpiece where it alters portions of the photoresist. As the liquid has a low absorption and a higher refractive index than air, the liquid-filled balloon system enhances resolution. Thus, the balloon provides optical benefits of liquid immersion without the complications of maintaining a liquid between (and in contact with) a lithographic light source mechanism and workpiece.

Owner:TWITTER INC

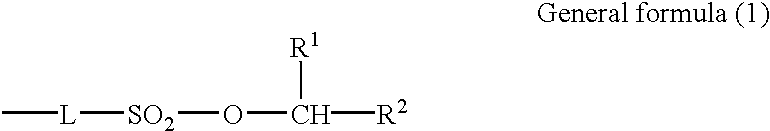

One component EUV photoresist

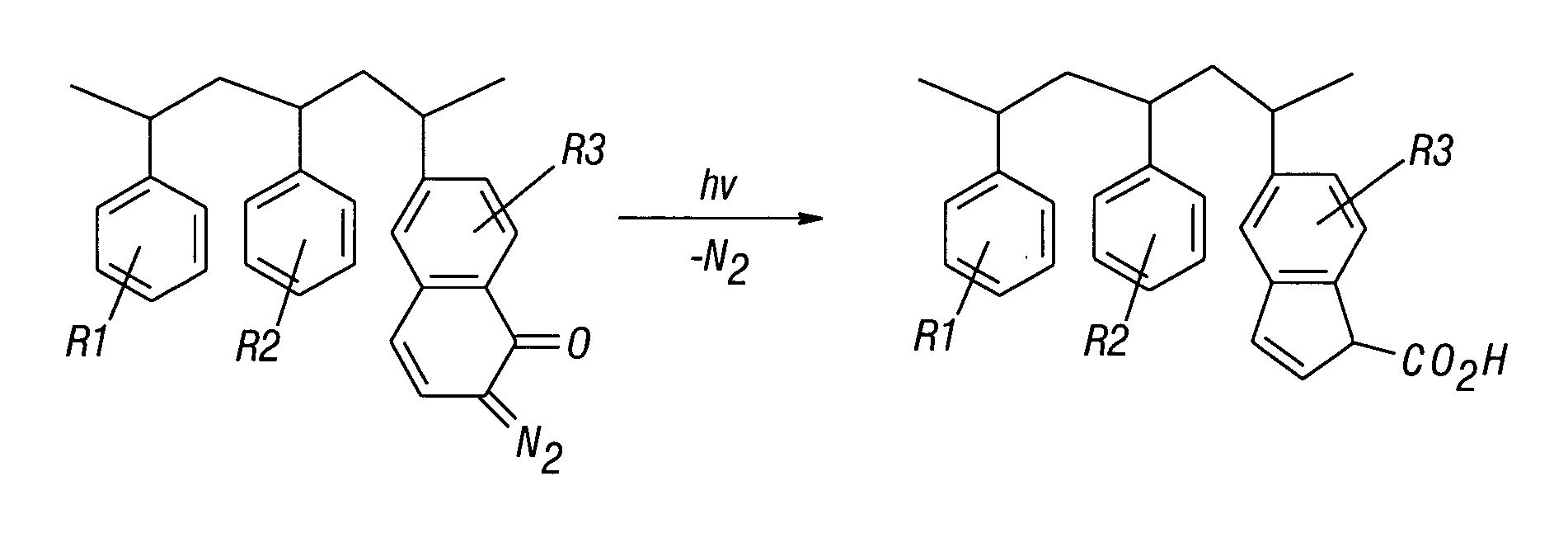

In one embodiment, a photoactive compound may be attached to a polymer backbone. This embodiment may be more resistant to the generation of reactive outgassing components and may exhibit better contrast.

Owner:INTEL CORP

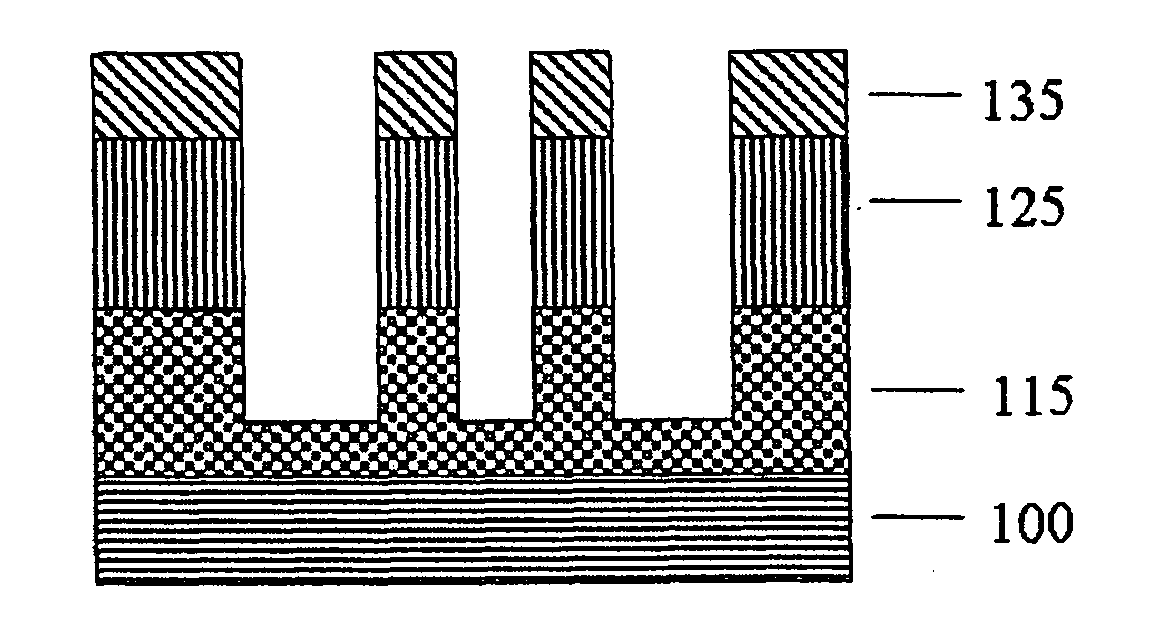

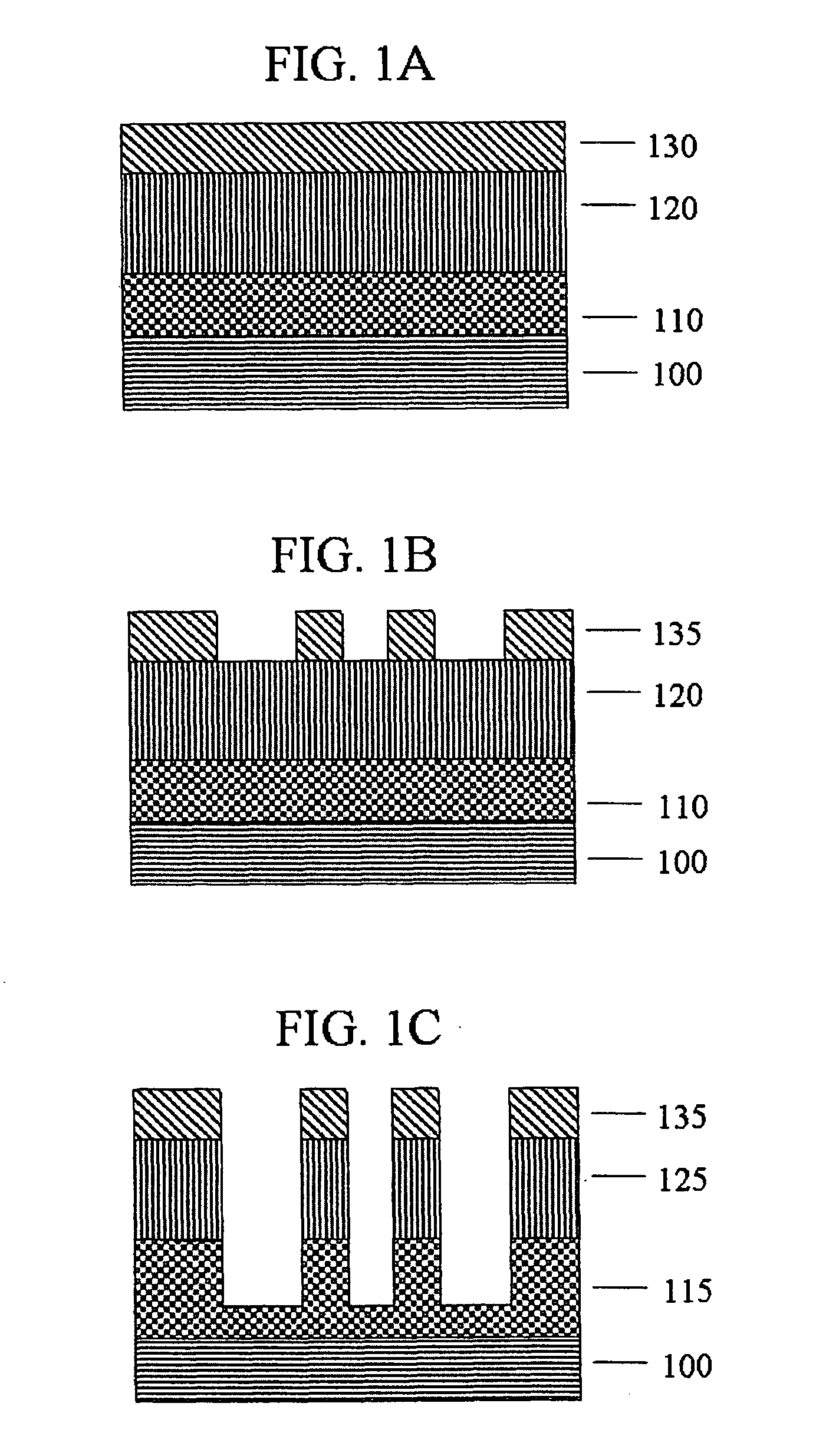

Immersion exposure process-use resist protection film forming material, composite film, and resist pattern forming method

InactiveUS20060141400A1High resolutionChange propertiesPhotoprinting processesPhotomechanical exposure apparatusHigh resolutionTectorial membrane

Provided are a material for forming a resist protecting film which is for use in a liquid immersion lithography process and which is formed on a resist film, wherein the material has the following properties of: being transparent with respect to exposure light; having substantially no compatibility with a liquid for liquid immersion lithography; and causing no mixing with the resist film, a composite film comprising a protective film formed from the material and a resist film, and a method for forming a resist pattern using them. These can prevent both the resist film and the liquid used from changing in properties during the liquid immersion lithography, so that a resist pattern with high resolution can be formed using the liquid immersion lithography.

Owner:TOKYO OHKA KOGYO CO LTD

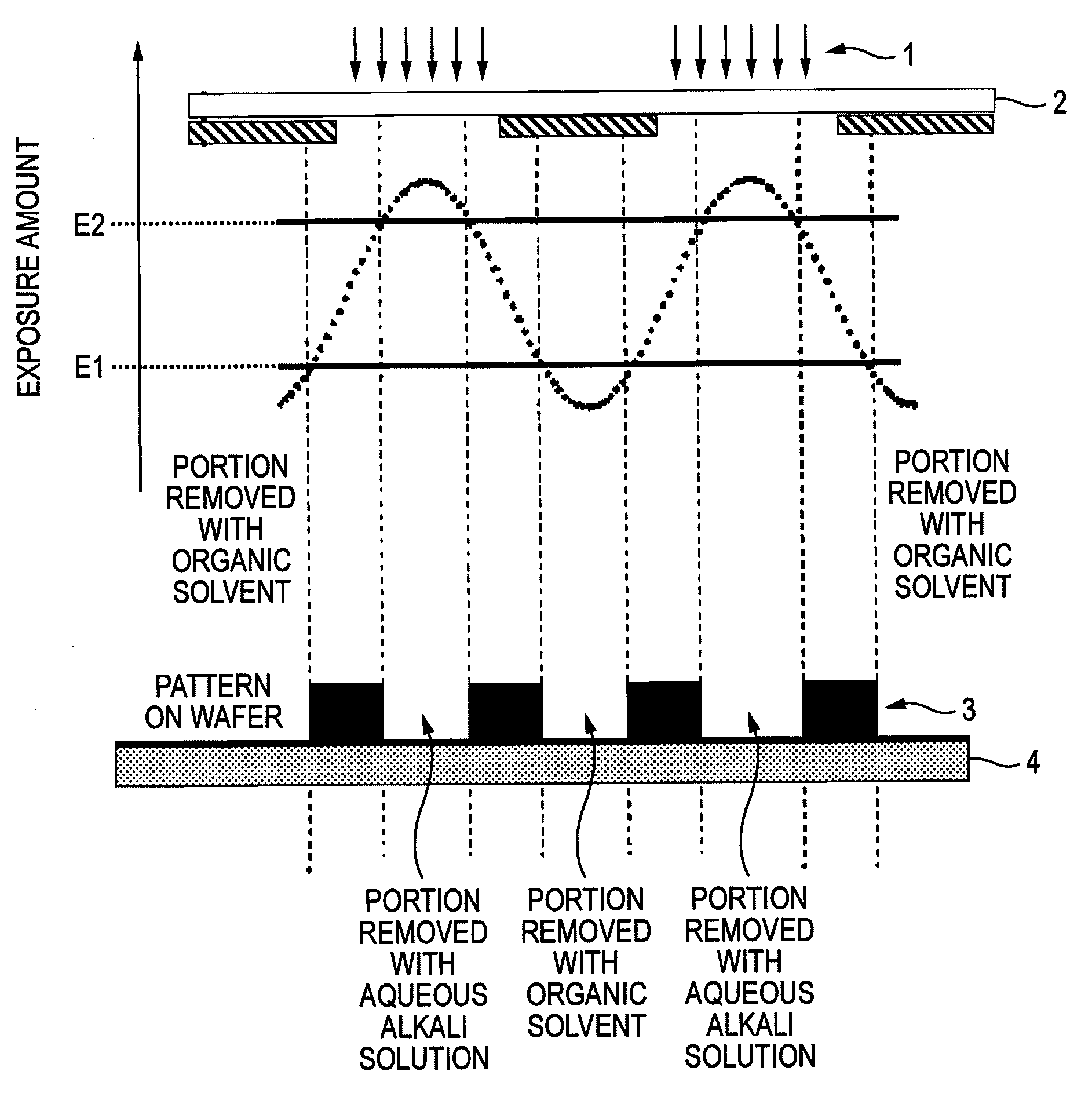

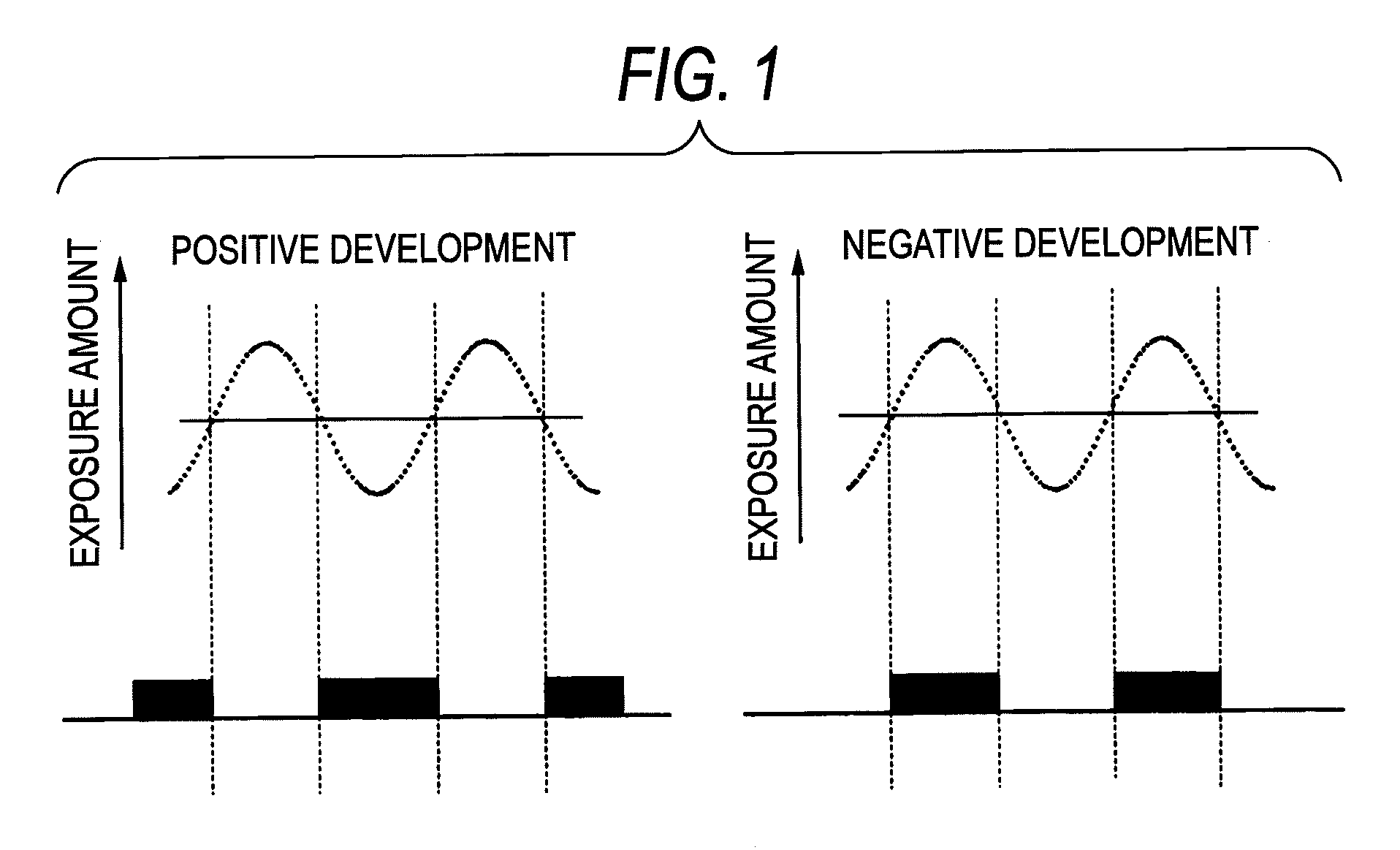

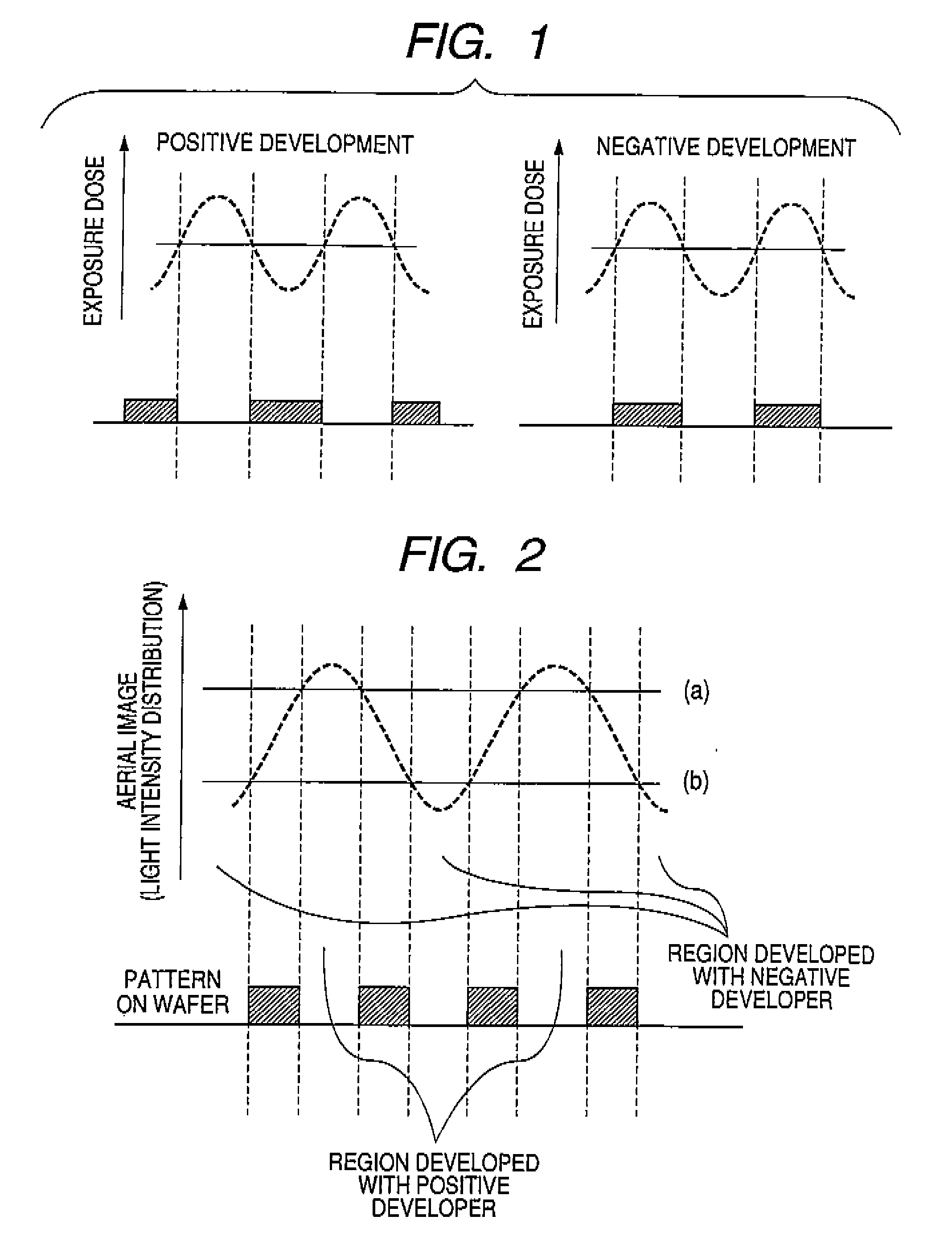

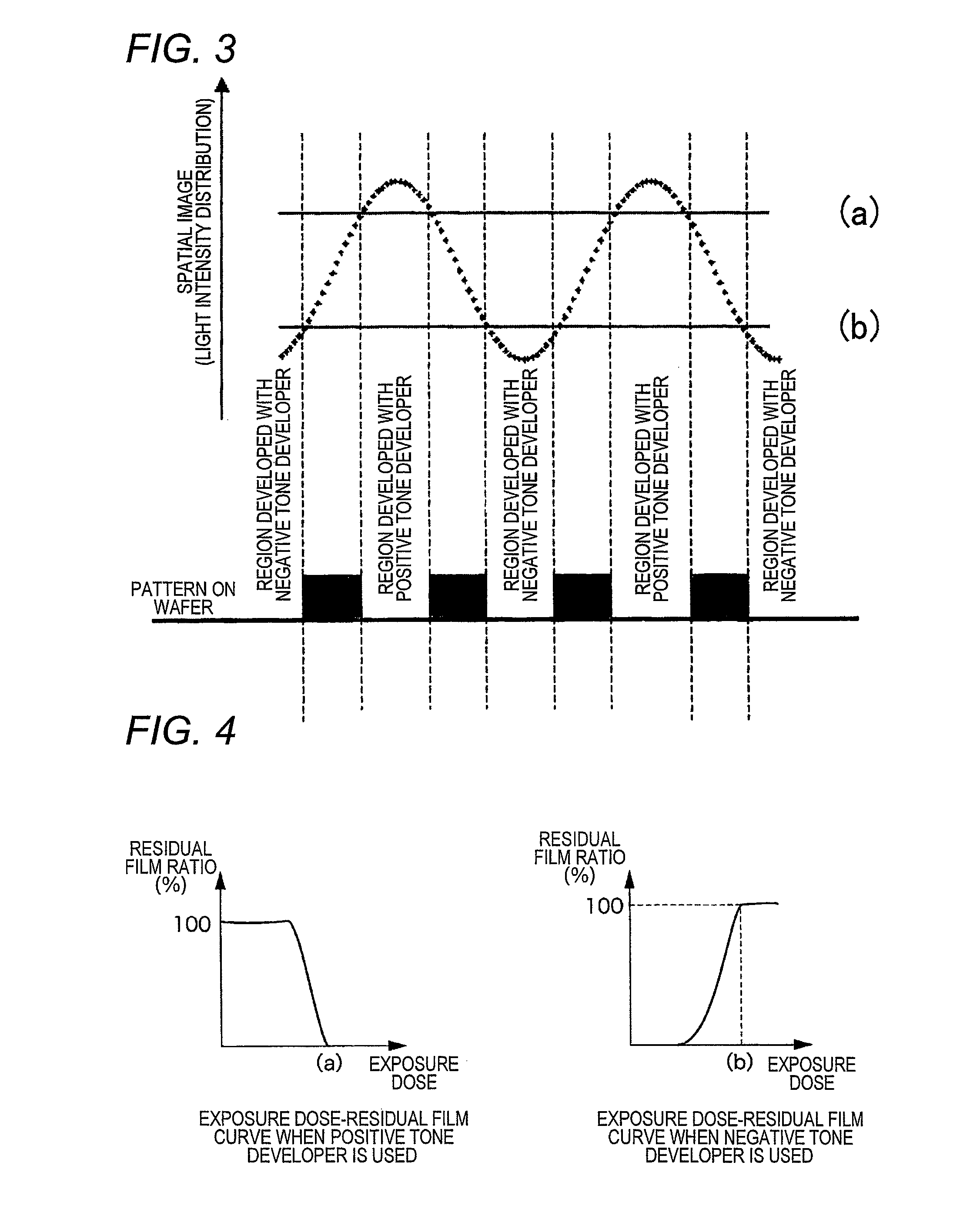

Method of forming patterns

ActiveUS20090042147A1Development defect can be reducedReduced line edge roughnessPhotosensitive materialsPhoto-taking processesActinic RaysChemistry

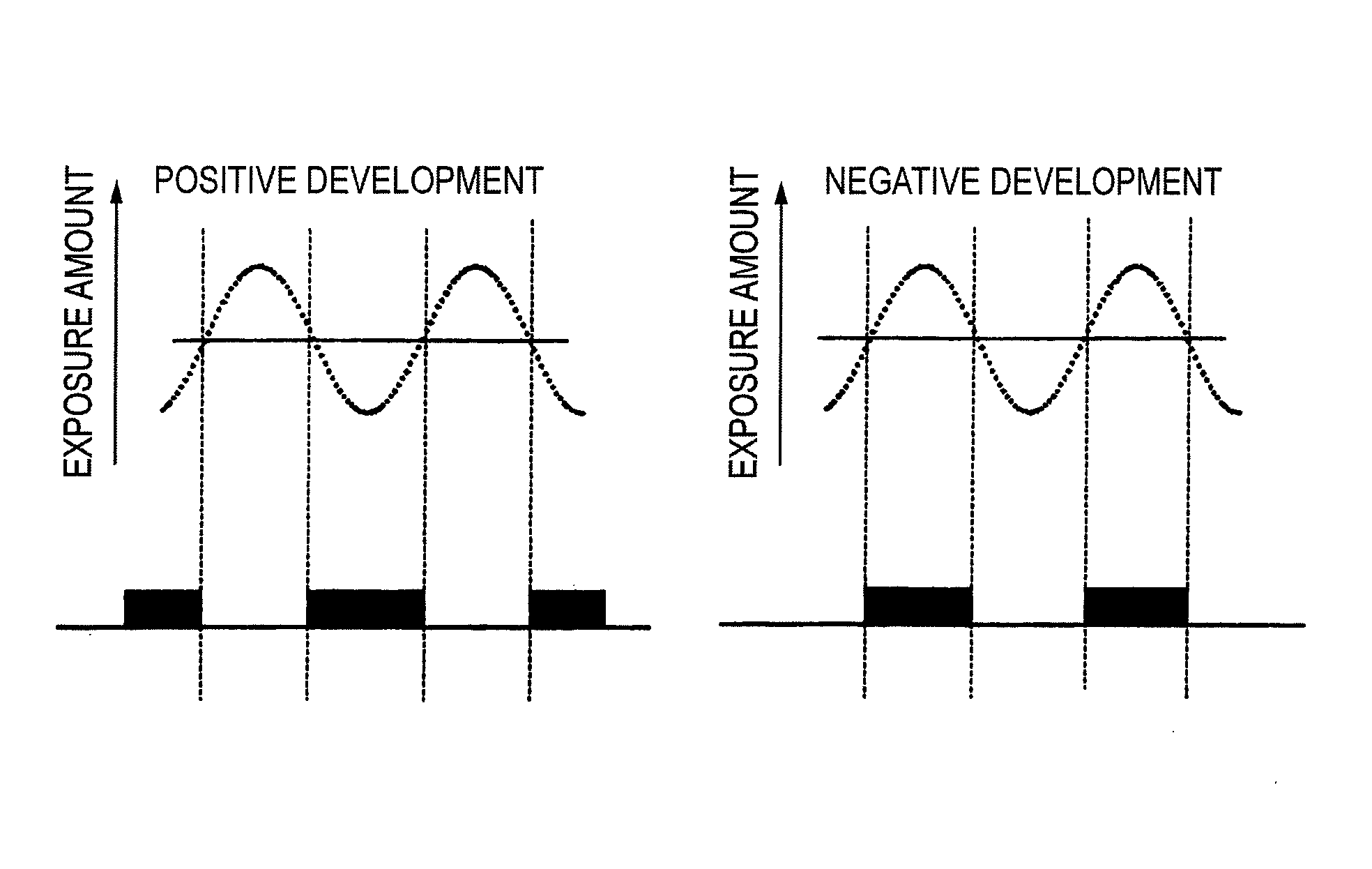

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film, wherein the resist composition contains a resin capable of increasing the polarity by the action of the acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) forming a protective film on the resist film with a protective film composition after forming the resist film and before exposing the resist film, (c) exposing the resist film via an immersion medium, and (d) performing development with a negative developer.

Owner:FUJIFILM CORP

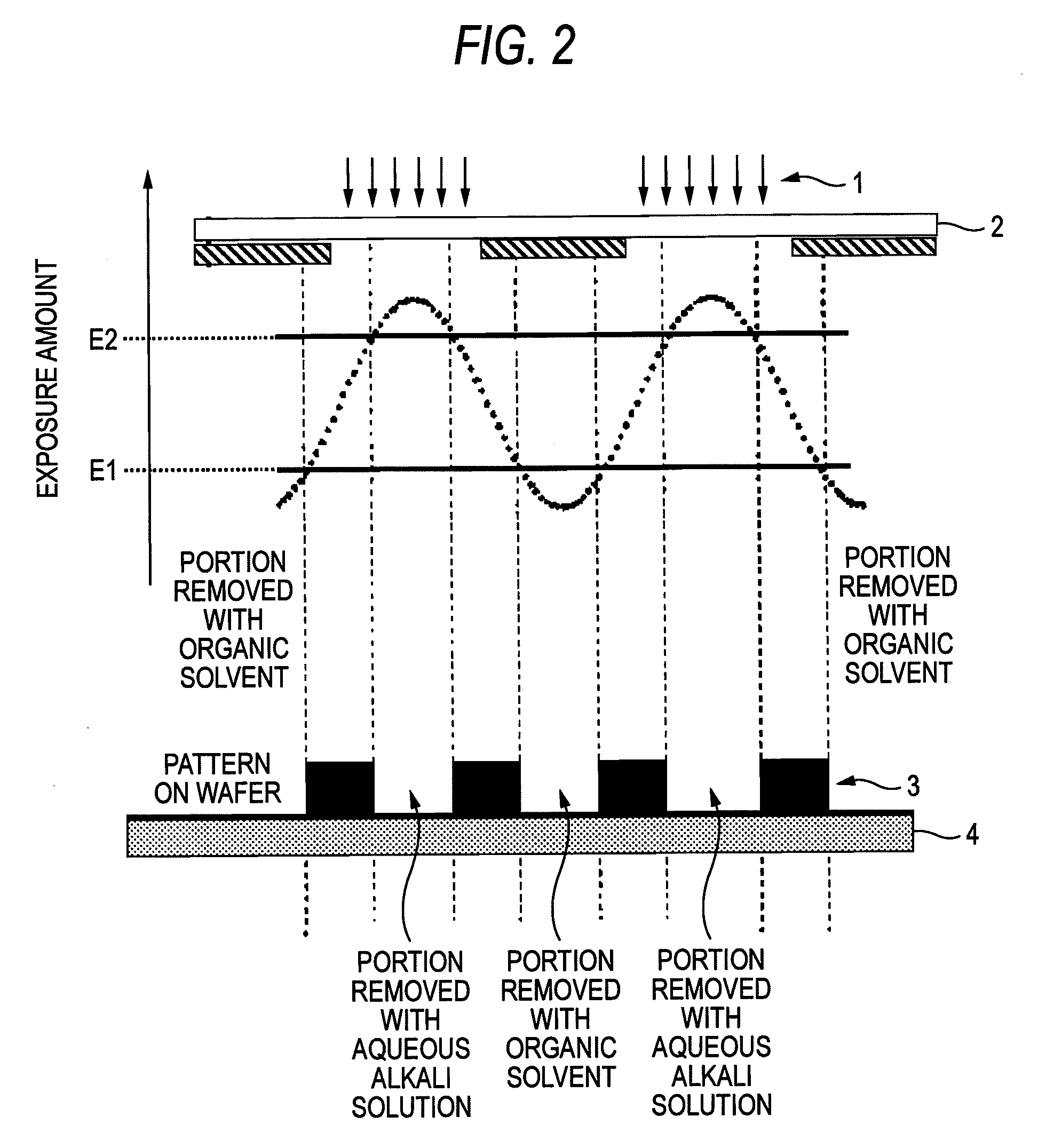

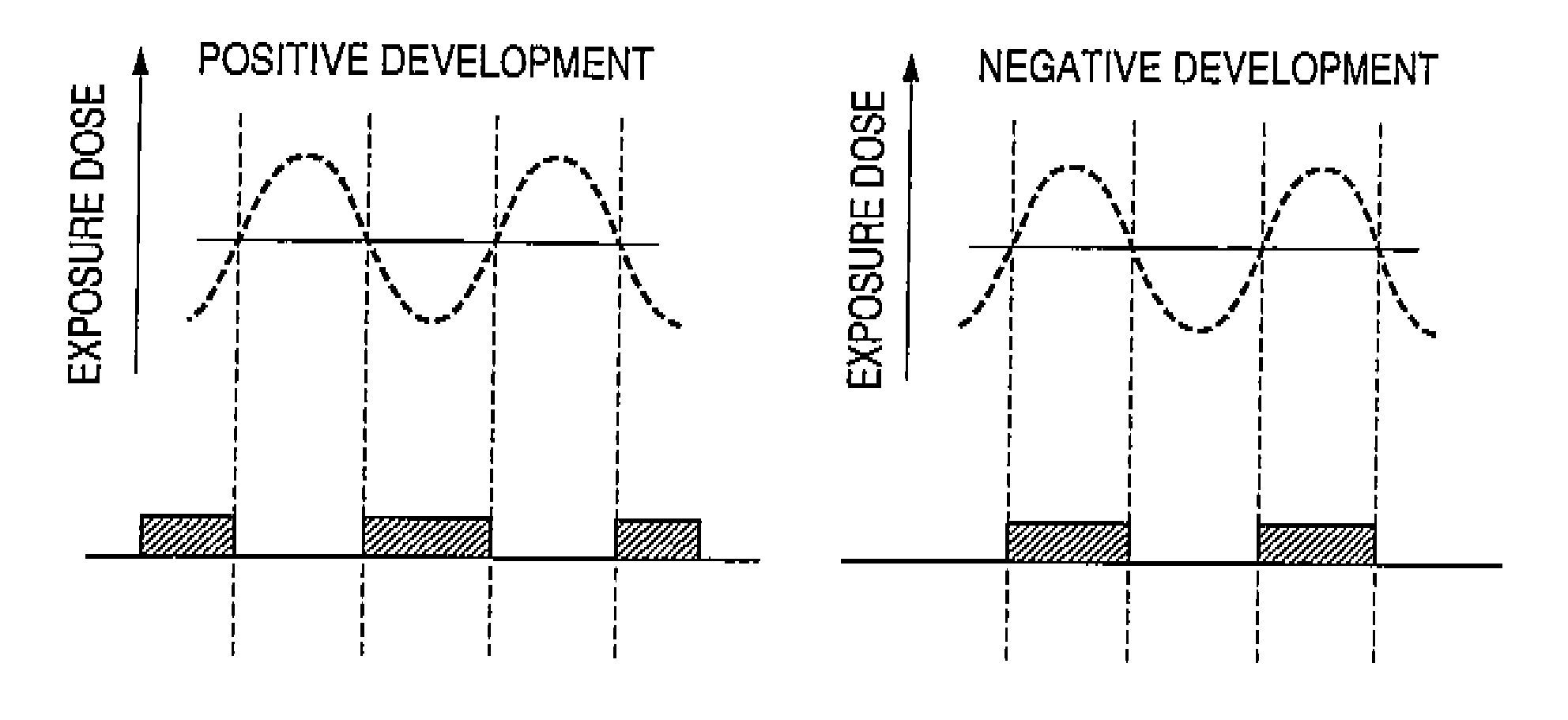

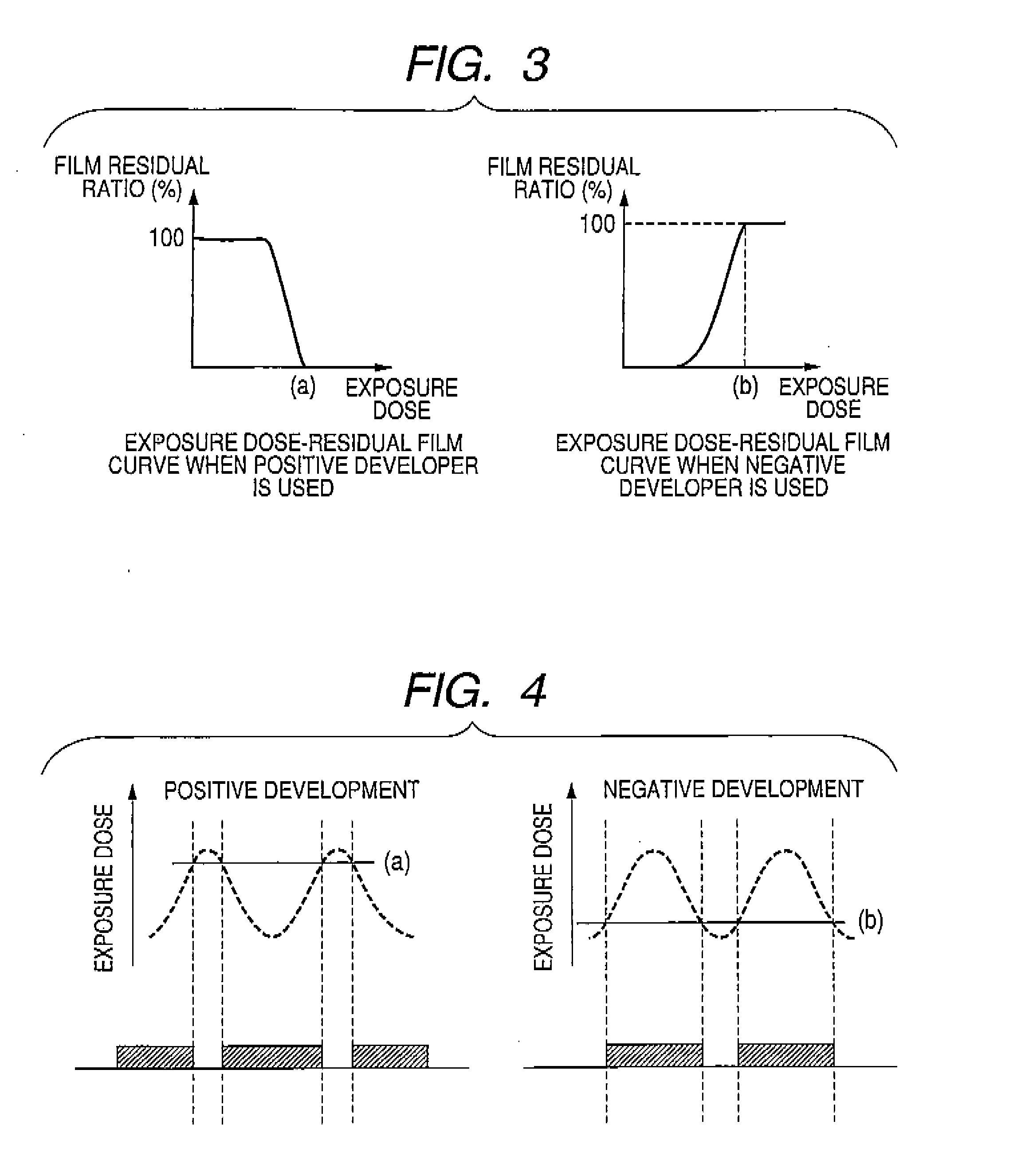

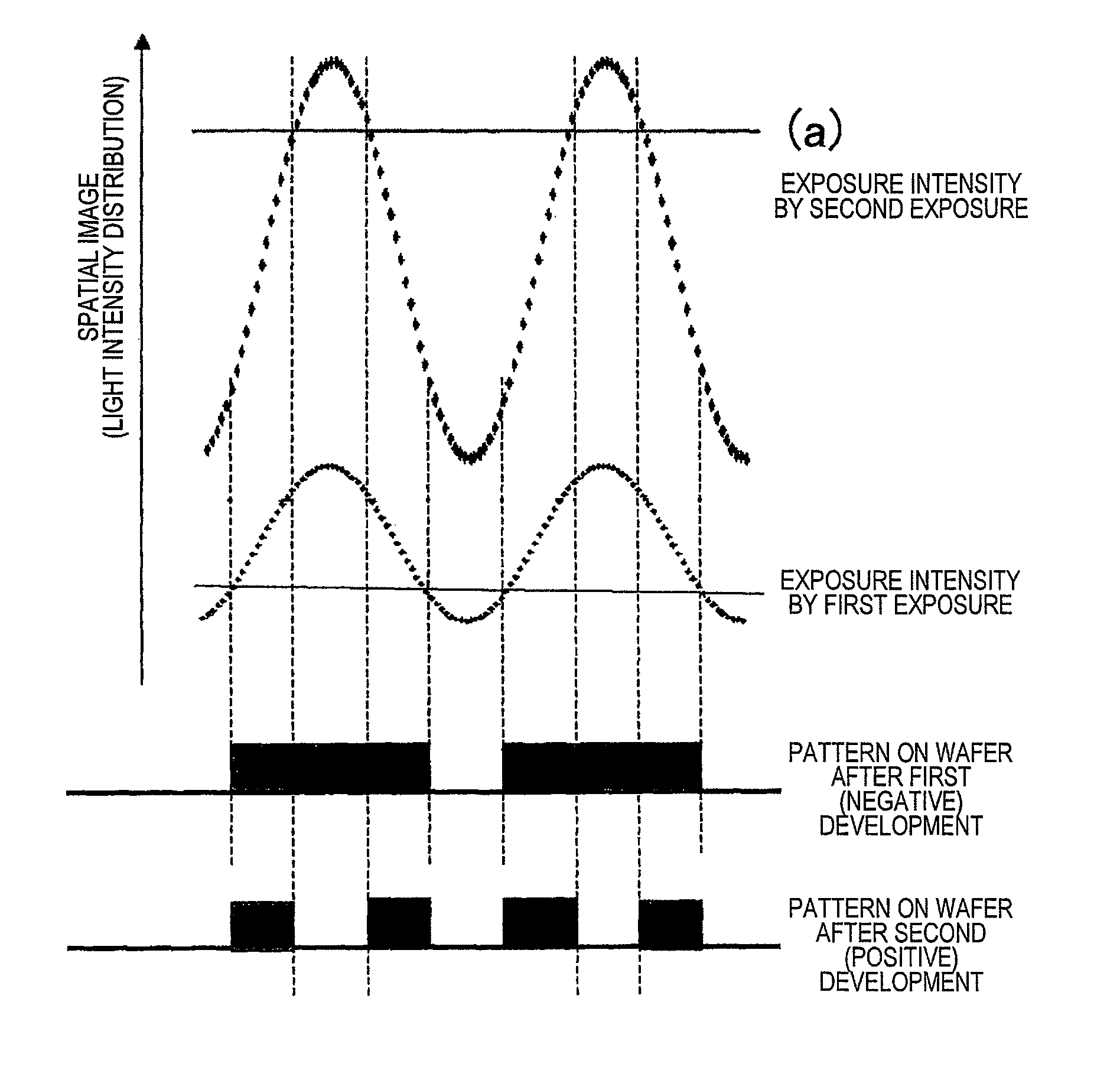

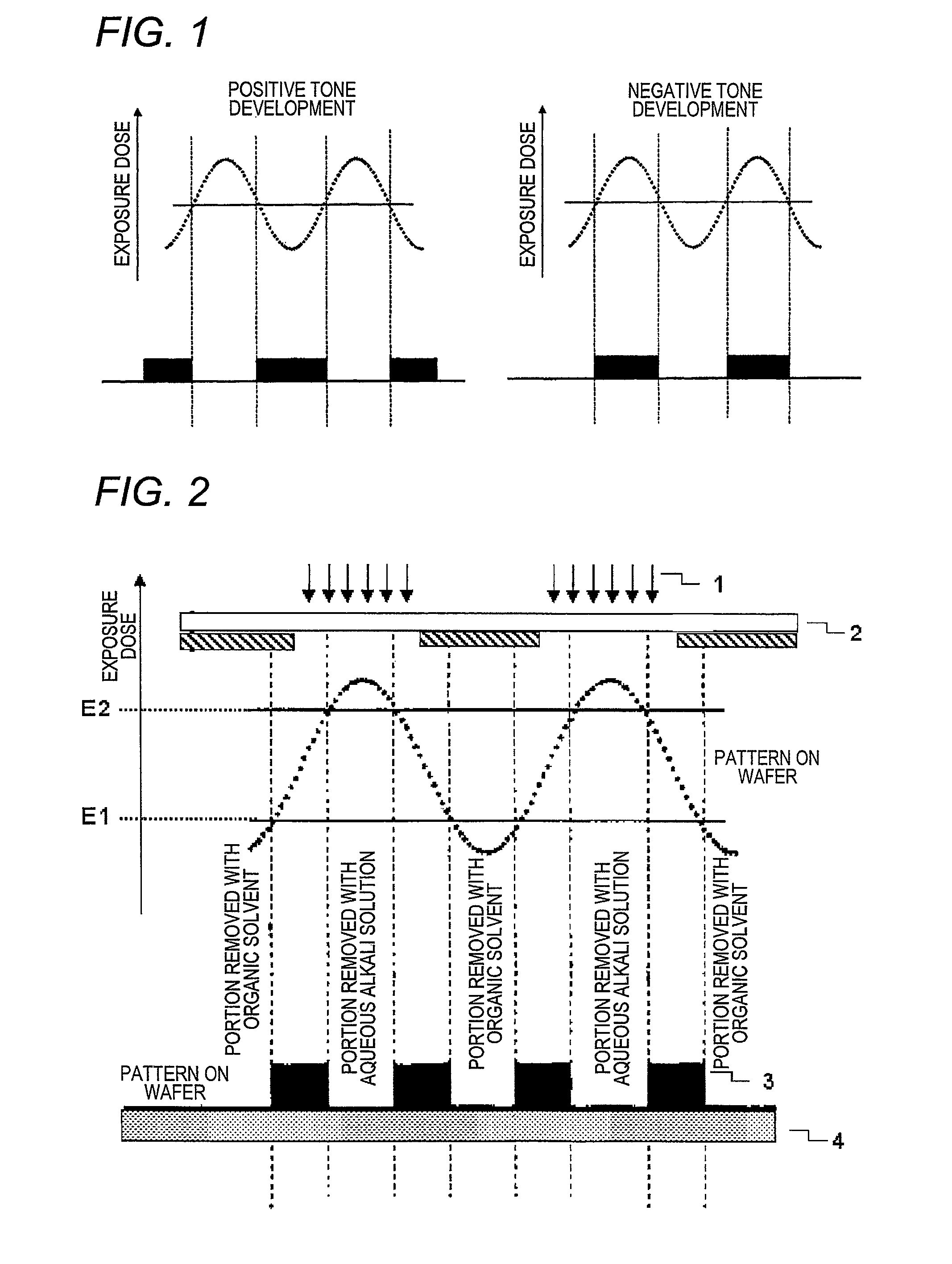

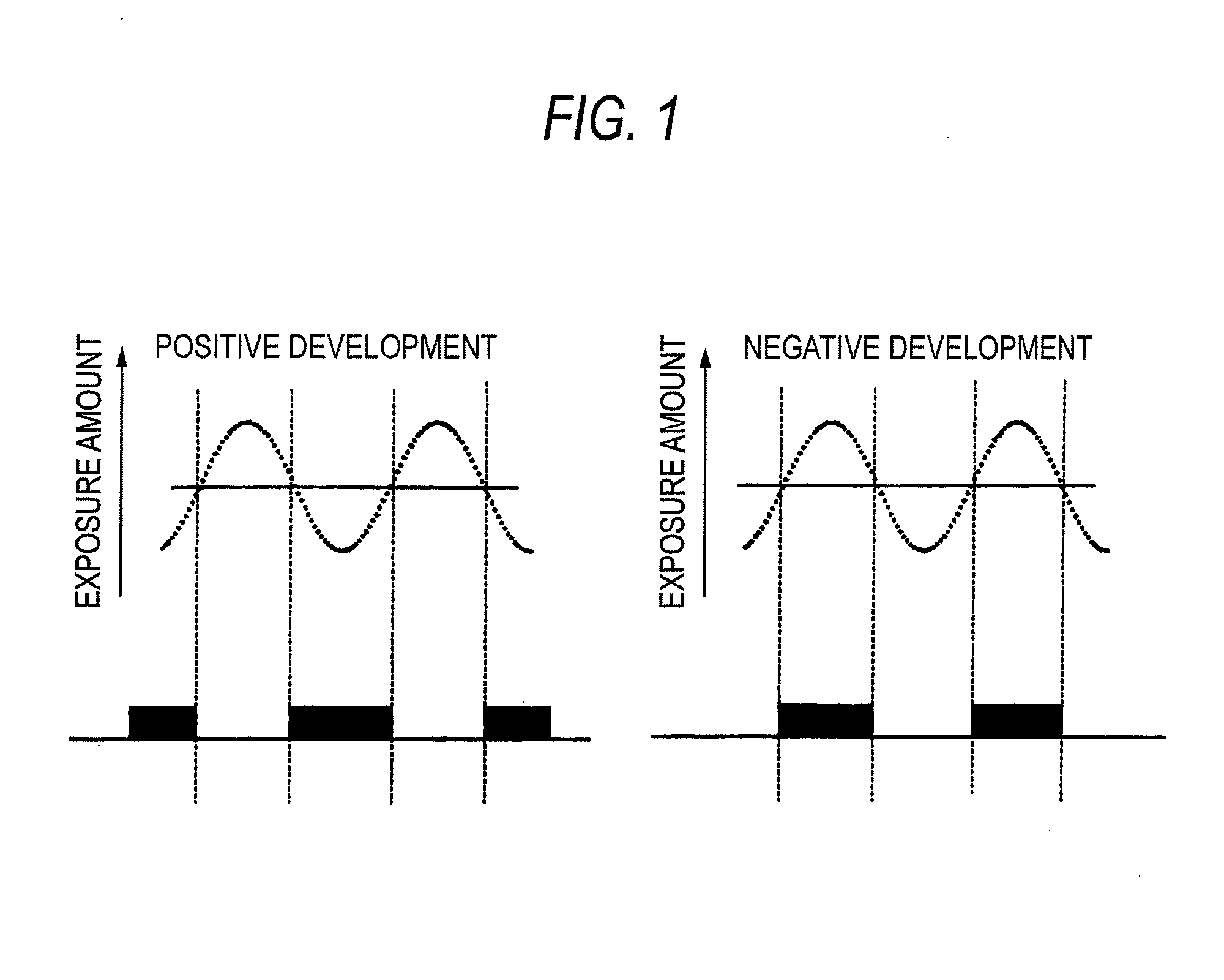

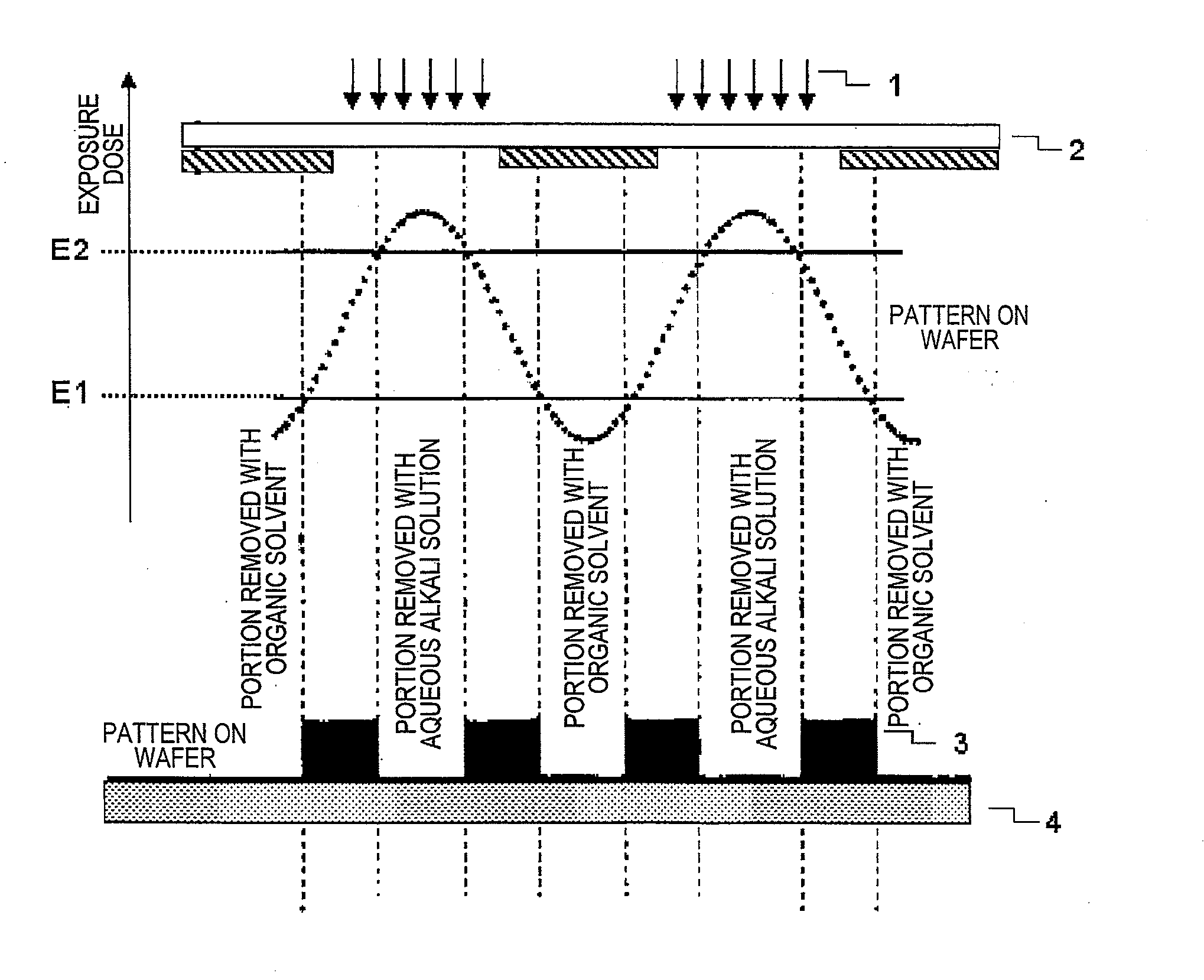

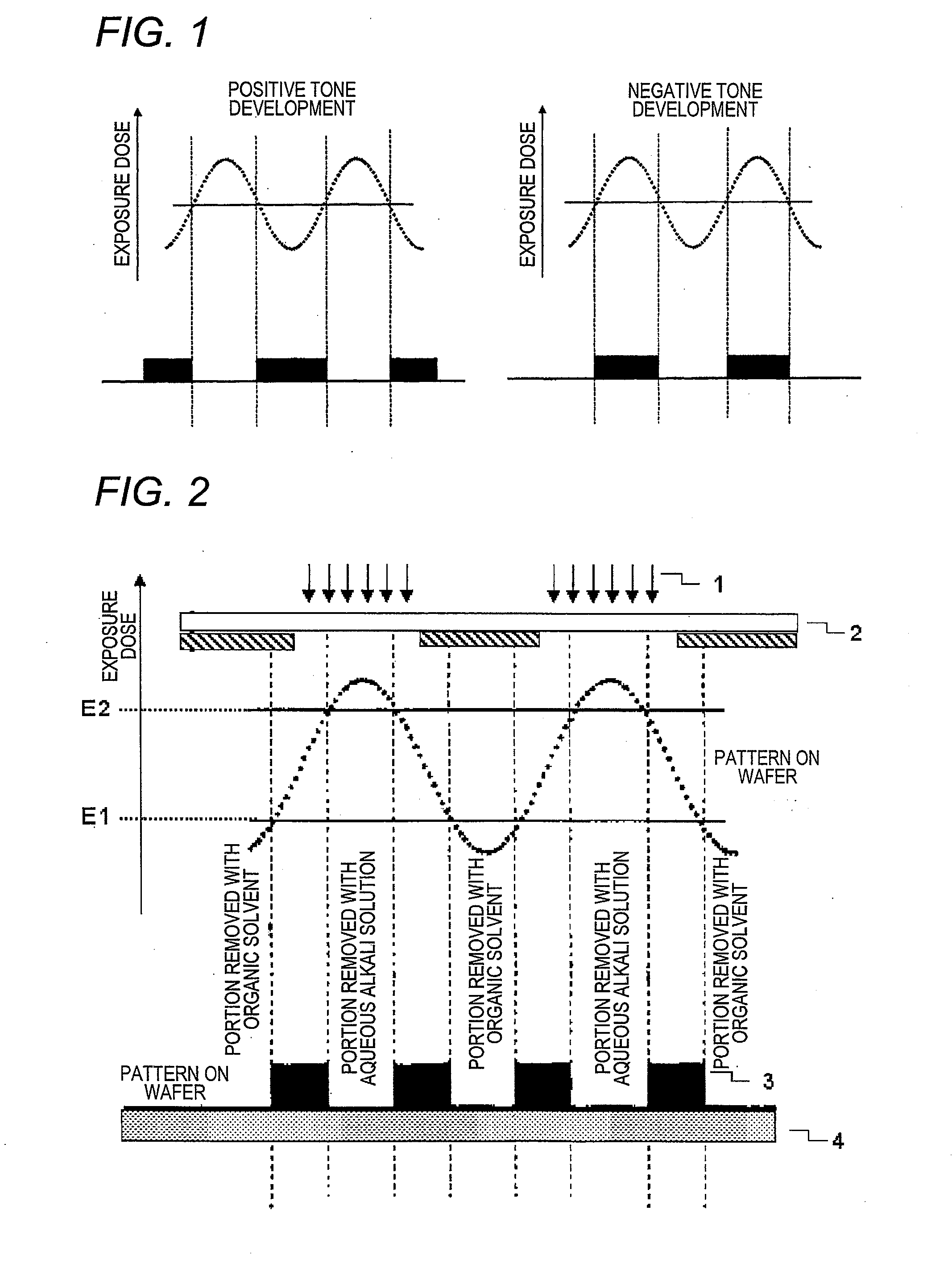

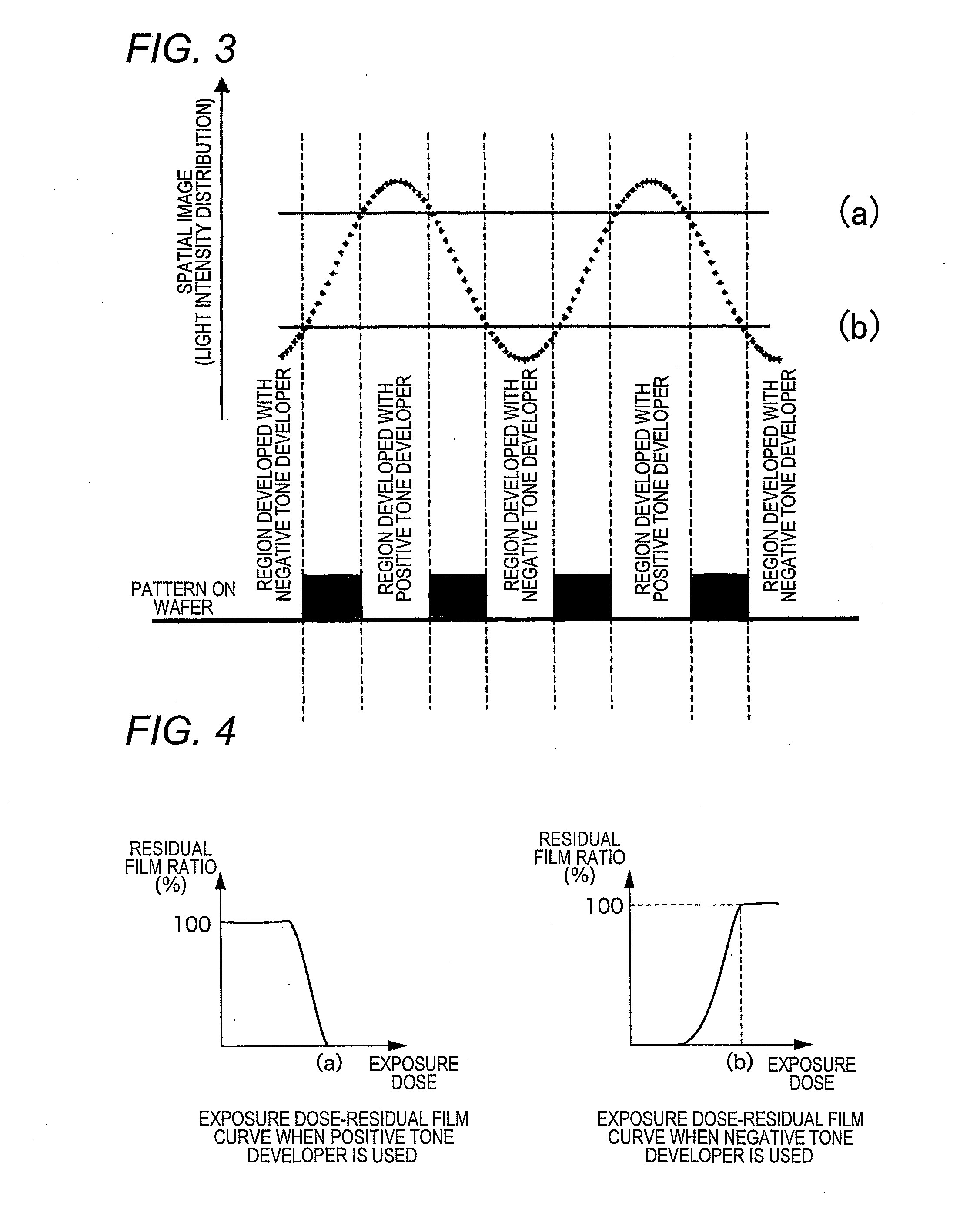

Pattern forming method, resist composition for multiple development used in the pattern forming method, developer for negative development used in the pattern forming method, and rinsing solution for negative development used in the pattern forming method

ActiveUS20080261150A1Improve accuracyMolding stabilityPhotosensitive materialsPhotoprinting processesActinic RaysPhotochemistry

A pattern forming method, including: (A) coating a substrate with a positive resist composition of which solubility in a positive developer increases and solubility in a negative developer decreases upon irradiation with actinic rays or radiation, so as to form a resist film; (B) exposing the resist film; and (D) developing the resist film with a negative developer; a positive resist composition for multiple development used in the method; a developer for use in the method; and a rinsing solution for negative development used in the method.

Owner:FUJIFILM CORP

Pattern forming method, and resist composition, developer and rinsing solution used in the pattern forming method

ActiveUS8017304B2Molding stabilityReduce roughnessPhotosensitive materialsPhotoprinting processesDispersityActinic Rays

A pattern forming method comprising a step of applying a resist composition whose solubility in a negative tone developer decreases upon irradiation with an actinic ray or radiation and which contains a resin having an alicyclic hydrocarbon structure and a dispersity of 1.7 or less and being capable of increasing the polarity by the action of an acid, an exposure step, and a development step using a negative tone developer; a resist composition for use in the method; and a developer and a rinsing solution for use in the method, are provided, whereby a pattern with reduced line edge roughness and high dimensional uniformity can be formed.

Owner:FUJIFILM CORP

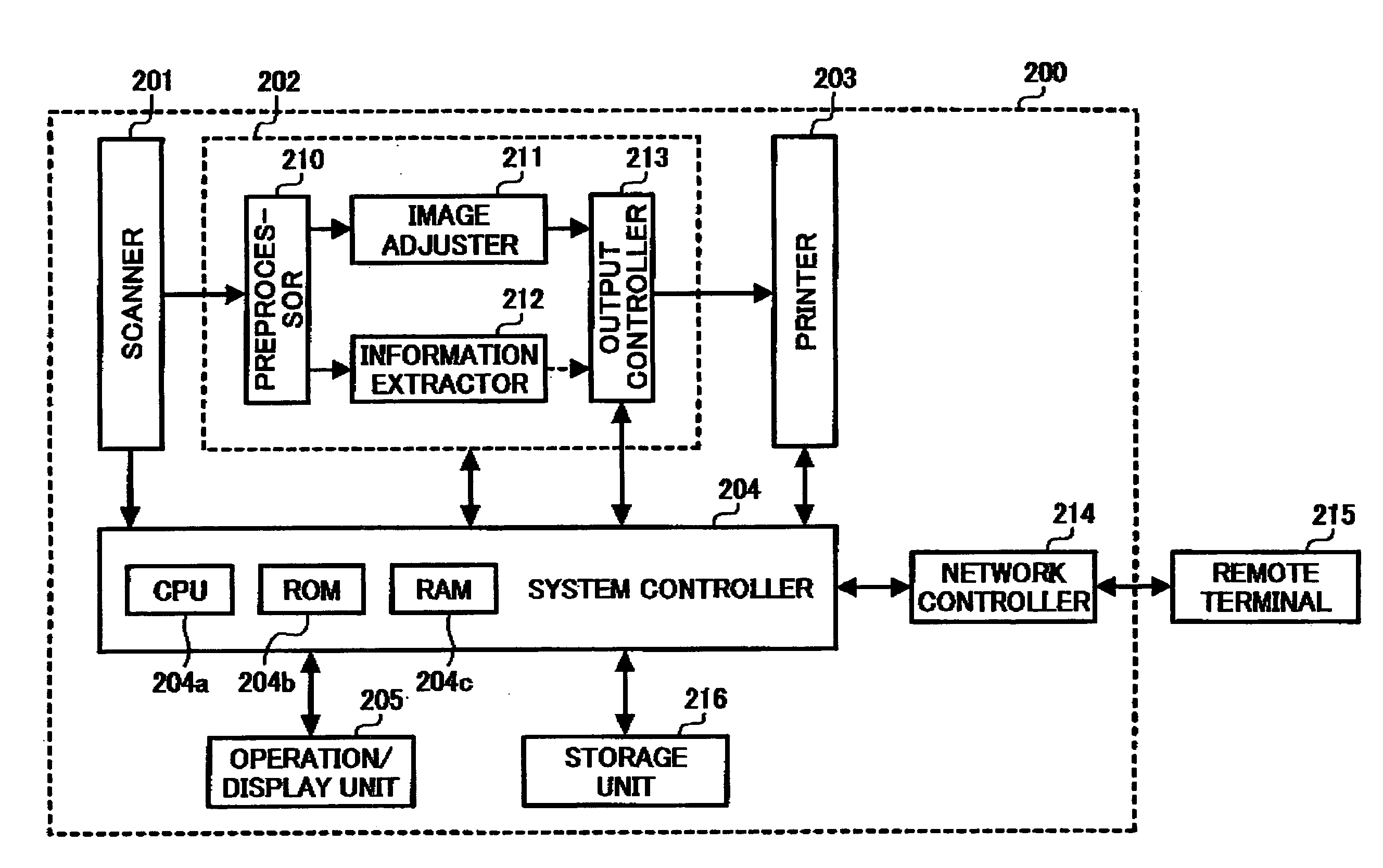

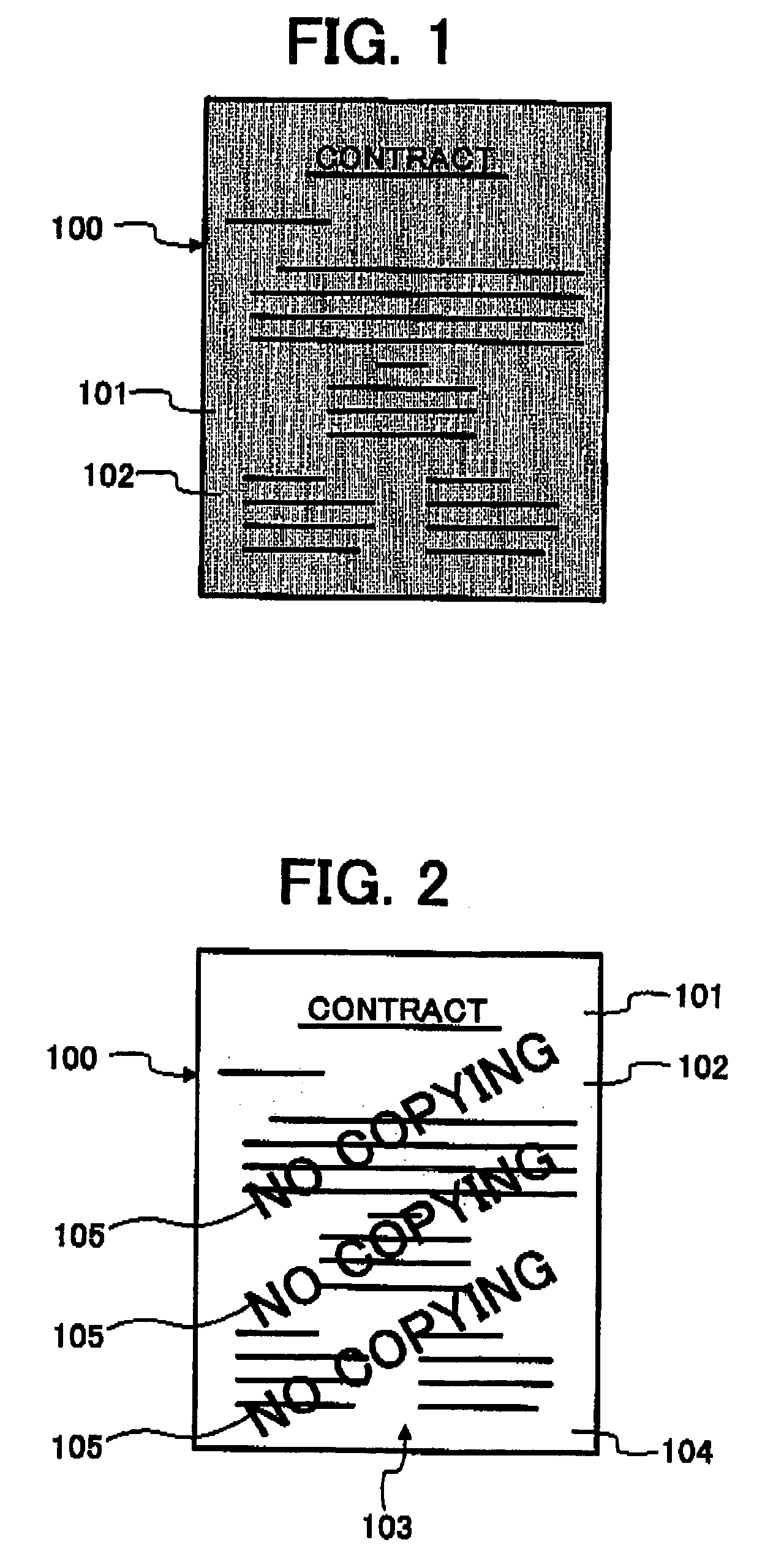

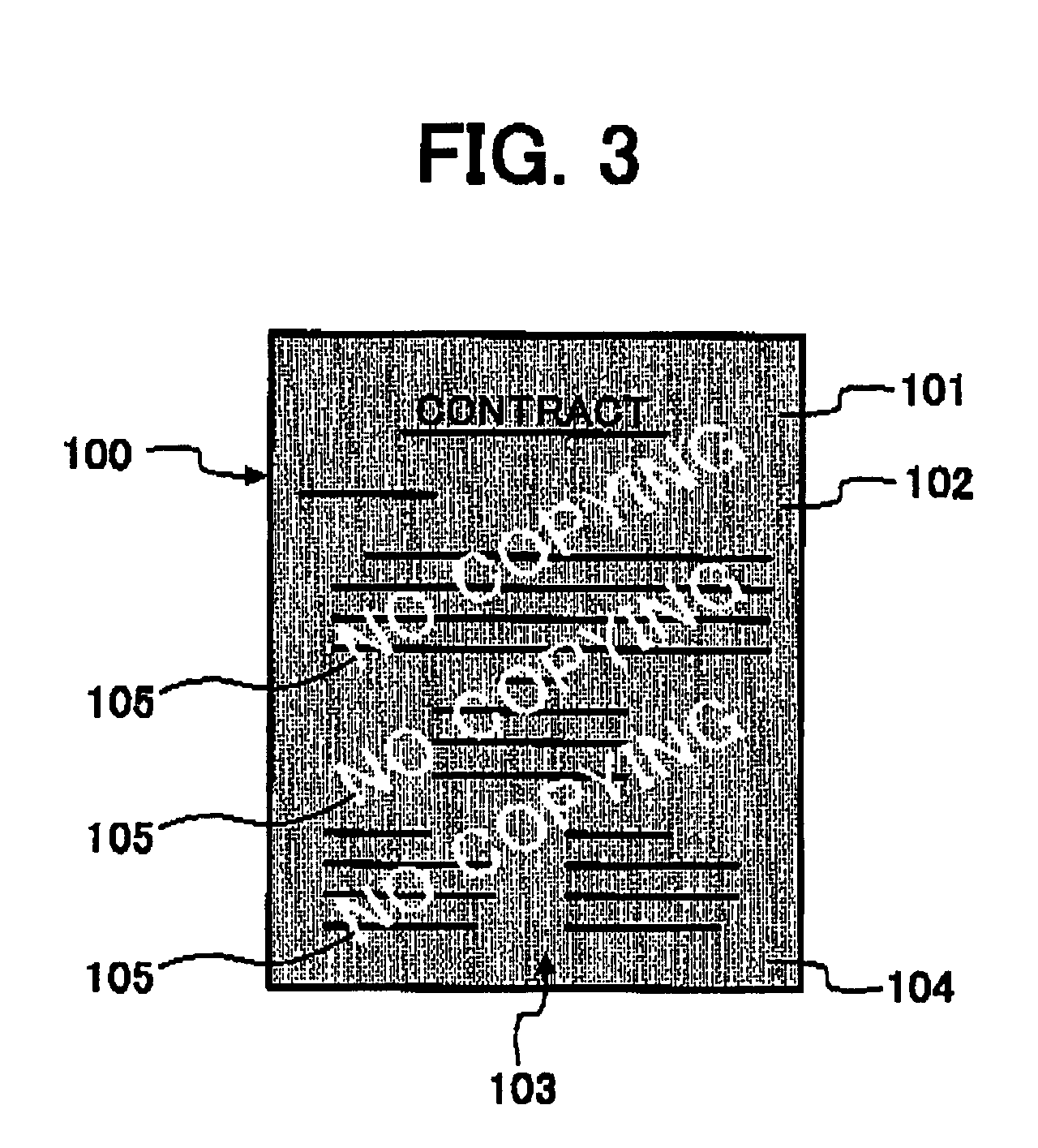

Method, computer program, and apparatus for detecting specific information included in image data of original image with accuracy, and computer readable storing medium storing the program

ActiveUS20050151990A1Efficient detectionOther printing matterPhotoprinting processesImaging processingImaging data

An image processing apparatus includes an image input device that reads an original image and obtains image data from the original image by selecting one of plural types of image reading modes of the image input device, an image pre-processing mechanism that performs at least one pre-processing relative to the image data obtained by the image input device, an image pre-processing selecting mechanism that selects at least one pre-processing according to the image reading mode selected by the image input device and causes the image pre-processing mechanism to perform the selected at least one pre-processing, and an information extracting mechanism that extracts specific information included in the image data subjected to the at least one pre-processing performed by the image pre-processing mechanism.

Owner:RICOH KK

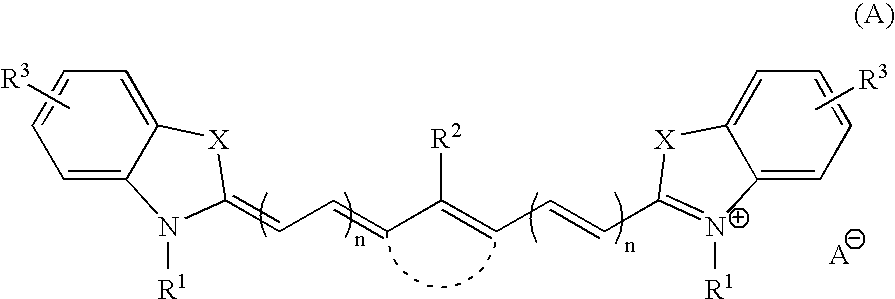

Top coat material and use thereof in lithography processes

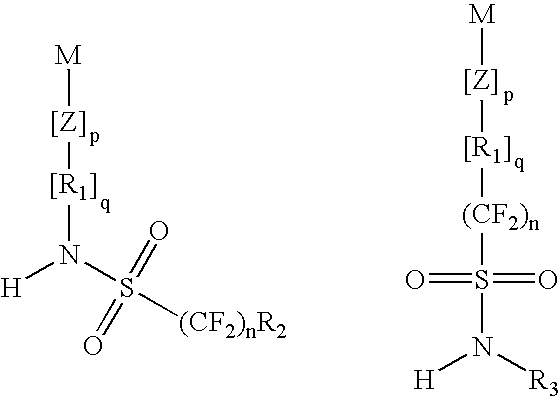

A top coat material for applying on top of a photoresist material is disclosed. The top coat material includes a polymer, which includes at least one fluorosulfonamide monomer unit having one of the following two structures: wherein: M is a polymerizable backbone moiety; Z is a linking moiety selected from the group consisting of —C(O)O—, —C(O)—, —OC(O)—, and —O—C(O)—C(O)—O—; R1 is selected from the group consisting of an alkylene, an arylene, a semi- or perfluorinated alkylene, and a semi- or perfluorinated arylene; p and q are 0 or 1; R2 is selected from the group consisting of hydrogen, fluorine, an alkyl group of 1 to 6 carbons, and a semi- or perfluorinated alkyl group of 1 to 6 carbons; n is an integer from 1 to 6; and R3 is selected from the group consisting of hydrogen, an alkyl, an aryl, a semi- or perfluorinated alkyl, and a semi- or perfluorinated aryl. The top coat material may be used in lithography processes, wherein the top coat material is applied on a photoresist layer. The top coat material is preferably soluble in aqueous alkaline developer. The top coat material is also preferably insoluble in water, and is therefore particularly useful in immersion lithography techniques using water as the imaging medium.

Owner:IBM CORP

Graded topcoat materials for immersion lithography

InactiveUS20080311530A1Photoprinting processesPhotosensitive material auxillary/base layersPhotoresistMaterials science

A topcoat material for immersion lithography and a method of performing immersion lithography using the topcoat material. The topcoat material includes a mixture of a first polymer and a second polymer. The first and second polymers of the topcoat material, when the topcoat material is formed into a topcoat layer between an immersion fluid and a photoresist layer, disperse non-homogenously throughout the topcoat layer.

Owner:IBM CORP

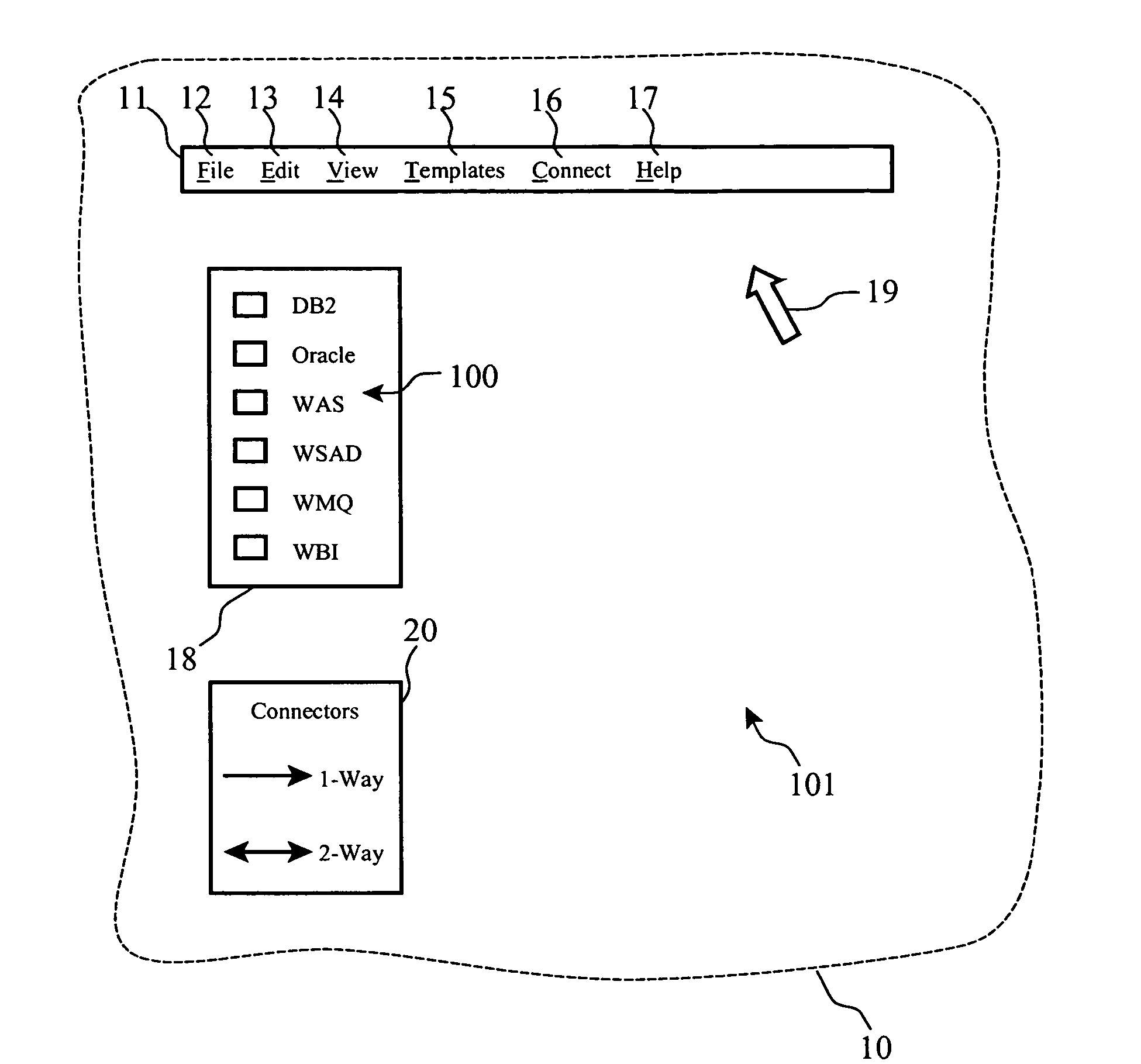

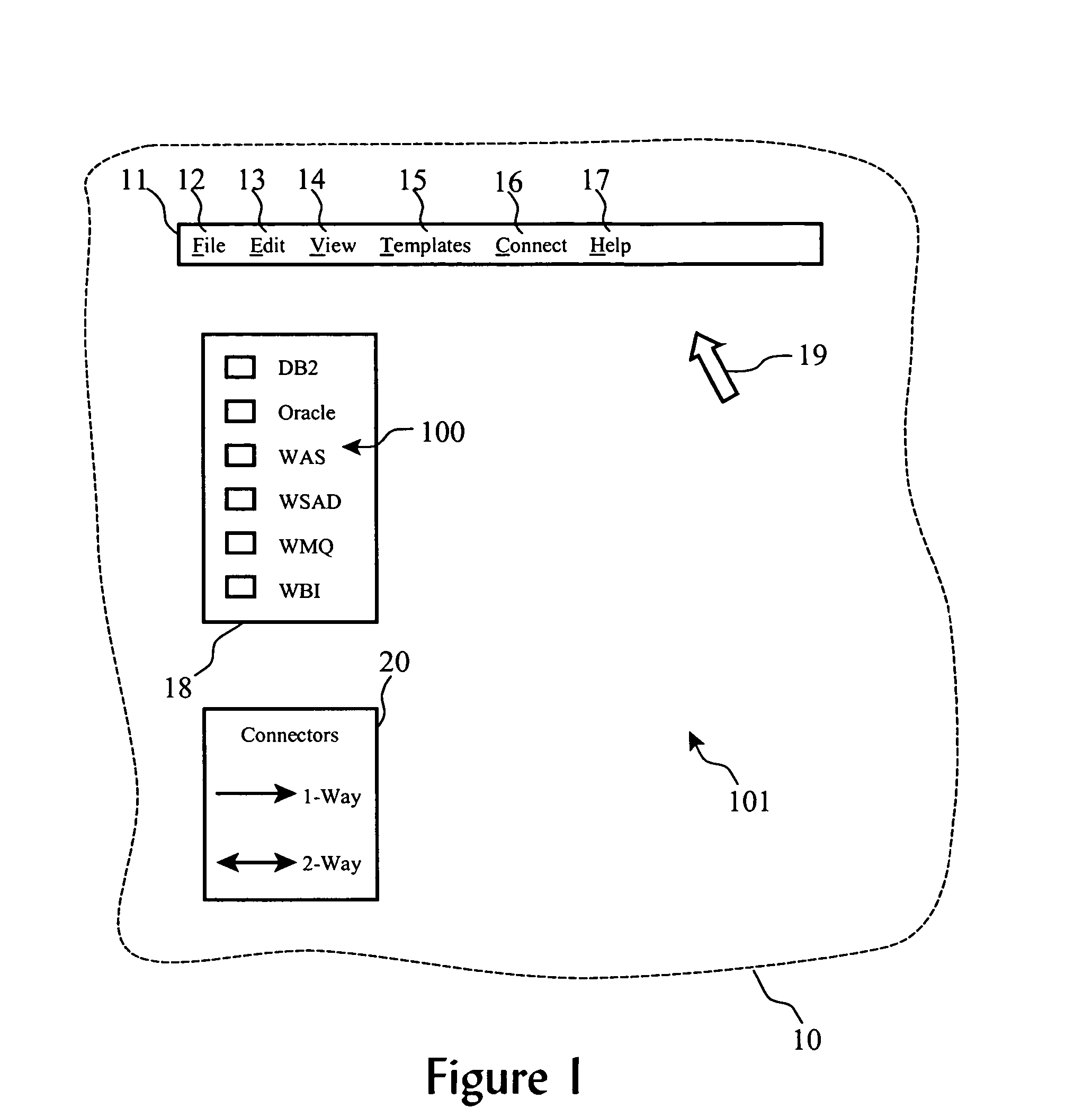

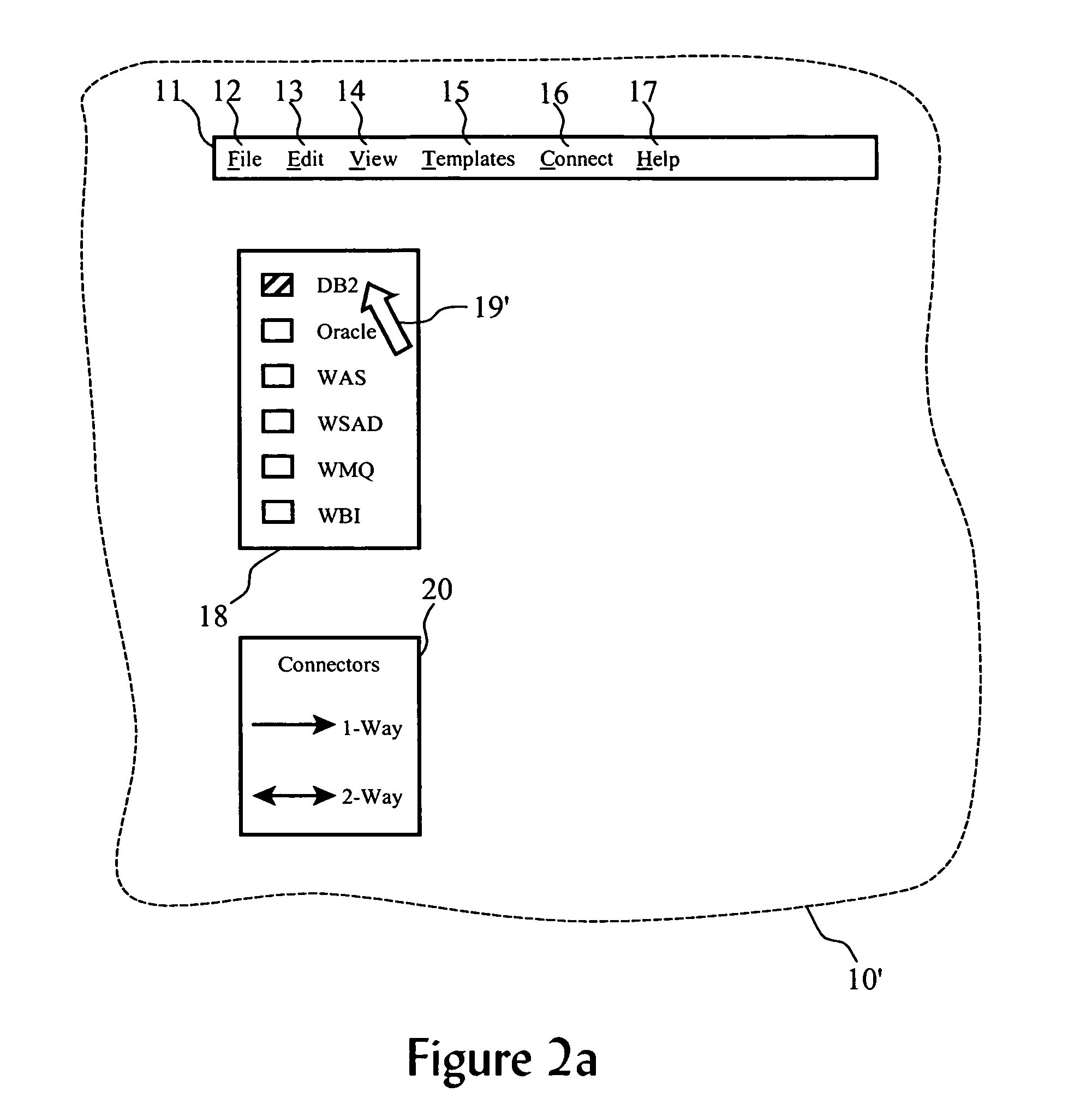

Solution builder wizard

InactiveUS20060228654A1Photoprinting processesVisual/graphical programmingGraphicsGraphical user interface

A computing solution is defined by displaying to a user in a graphical user interface a palette of icons representing available computing system components for potential use in a computing solution, each of which has an associated partially-defined behavioral model. The partially-defined behavioral models contain configurable behavioral and interface parameters. When the user selects one or more of the computing system components on the palette, an instance of each selected component is created, placed, arranged and displayed in a design area. The user can then define connections between each instance of component in the design area, which triggers predetermined logical processes to prompt the user for inputs to complete the partially-defined models for each instance of component. Finally, system solution behavioral model is created or saved comprising a collection of configured component instance behavioral models.

Owner:IBM CORP

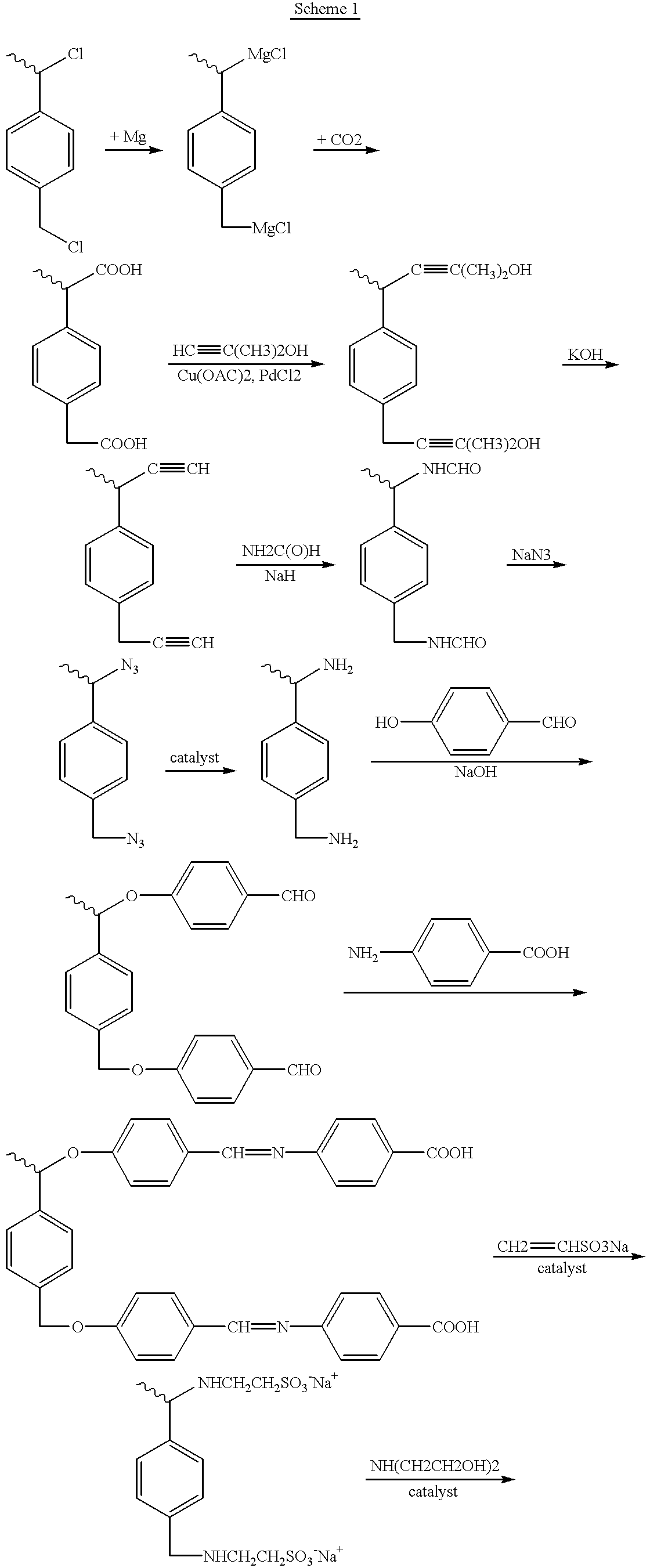

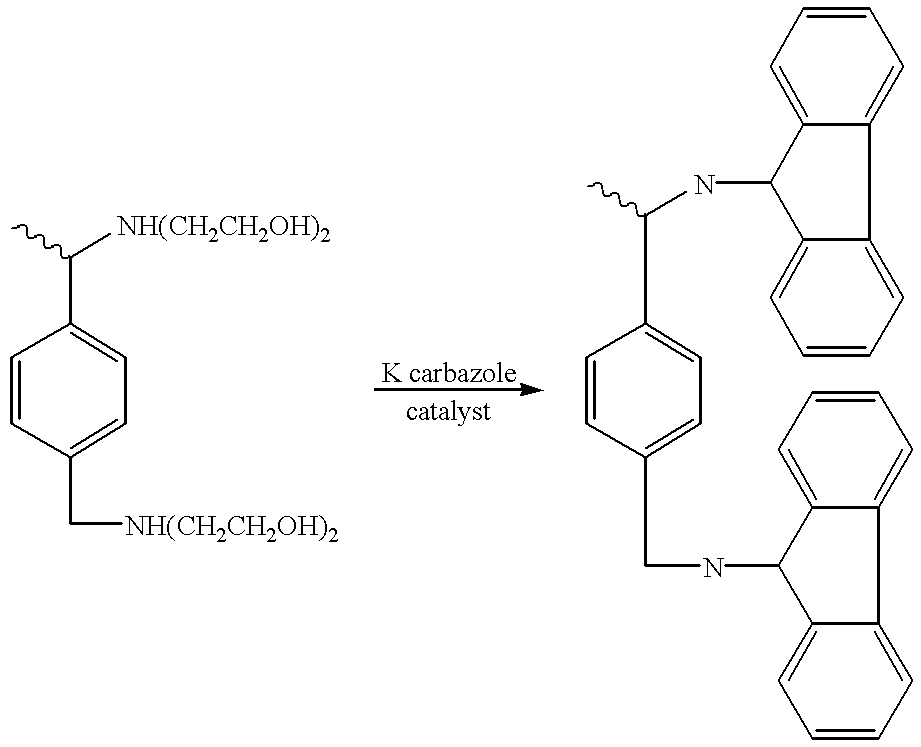

Vinyl hyperbranched polymer with photographically useful end groups

InactiveUS6252025B1Photoprinting processesMulticolor photographic processingDendrimerPolymer science

Photographically useful materials are disclosed comprising a hyperbranched polymer segment and multiple pendant photographically useful groups. Such materials may be prepared by forming an active hyperbranched polymer segment with multiple functionalized end group sites, and reacting the active hyperbranched polymer segment with an active compound comprising a photographically useful group to form a hyperbranched polymer ended with photographically useful groups. The hyperbranched segment may comprise any kind of polymer segment with hyperbranched architecture, and the active end groups may comprise any kind of reactive site. The active hyperbranched polymer may comprise any kind of other functional groups which are located in either backbone or the ends. The hyperbranched polymers containing photographically useful groups obtained in accordance with the invention are particularly advantageous in that they enable polymer structures comprising components exhibiting different photographically useful properties, while maintaining relatively low intrinsic viscosities compared to non-hyperbranched polymers containing photographically useful groups of similar chemical compositions. Additionally, the hyperbranched polymers are advantageous with respect to dendrimer type polymers in that a wide variety of hyperbranched polymer compositions may be synthesized in accordance with commercially acceptable processes.

Owner:EASTMAN KODAK CO

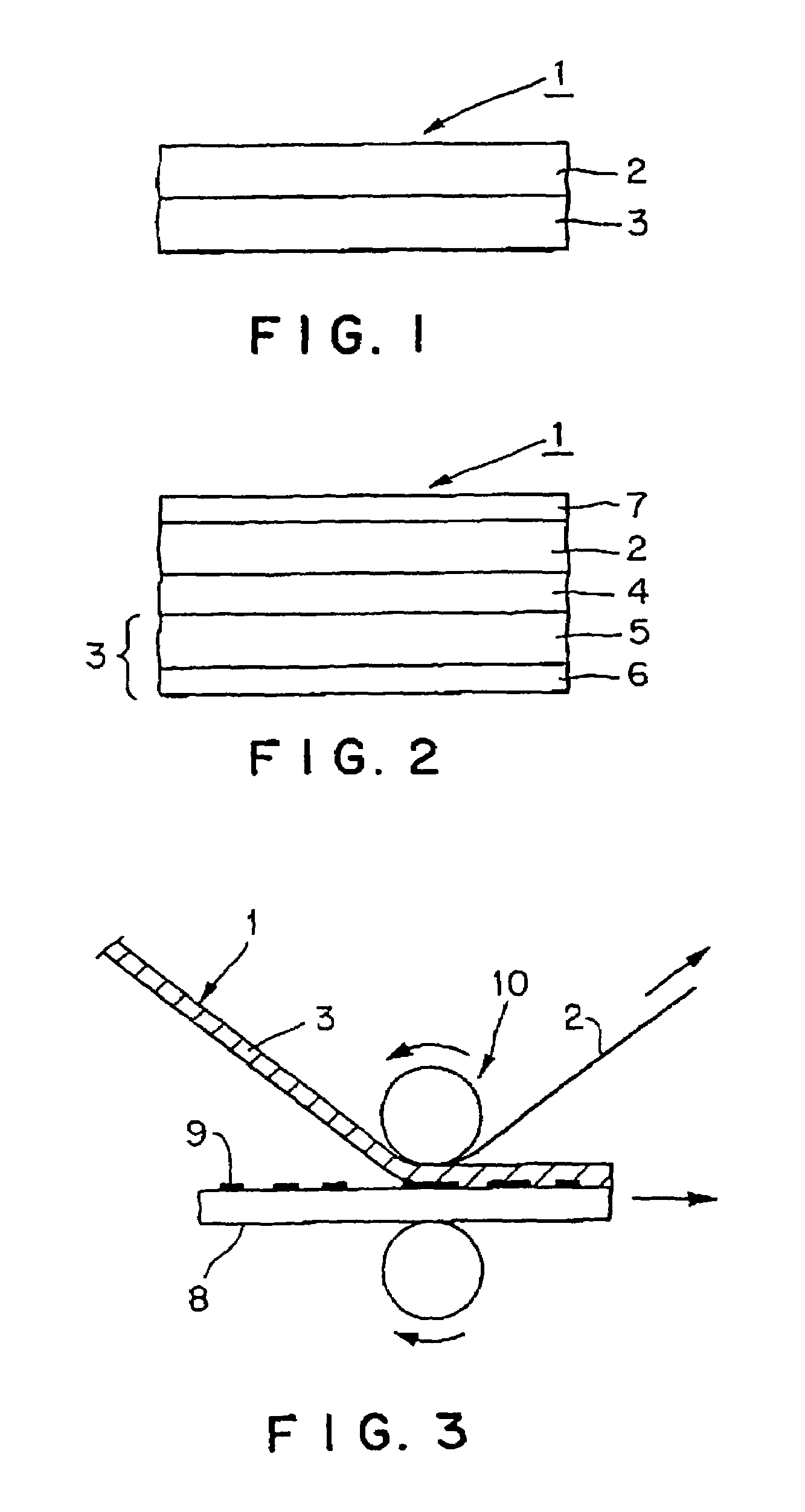

Thermally transferable image protective sheet, method for protective layer formation, and record produced by said method

InactiveUS7169546B2High fastnessIncrease resistancePhotography auxillary processesRadiation applicationsAngle of incidenceLightfastness

Disclosed are a thermally transferable image protective sheet and a method for protective layer formation that can provide a protective layer which can protect an image of a record produced by a nonsilver photographic color hard copy recording method, can impart lightfastness and other properties to the record, and can realize a record having a glossy impression comparable to silver salt photographs. The thermally transferable image protective sheet comprises a support and a thermally transferable resin layer having a single-layer or multilayer structure stacked on the support so as to be separable from the support. The thermally transferable image protective sheet has been constructed so that, when the thermally transferable image protective sheet is put on top of a print so as for the thermally transferable resin layer to be brought into contact with an image portion in the print and the thermally transferable resin layer is thermally transferred to cover at least the image portion of the print followed by the separation of the support from the thermally transferable image protective sheet to form a thermally transferred resin layer on the surface of the print, the surface of the thermally transferred resin layer on the print has a specular glossiness of not less than 60% as measured at an angle of incidence of 20 degrees according to JIS (Japanese Industrial Standards) Z 8741.

Owner:DAI NIPPON PRINTING CO LTD

Method of forming patterns

ActiveUS20080318171A1Enhanced in-plane uniformity of line widthReduced line edge roughnessPhotosensitive materialsPhoto-taking processesActinic RaysRadiation exposure

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film having a receding contact angle of 70 degrees or above with respect to water, wherein the resist composition for negative development contains a resin capable of increasing the polarity by the action of an acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) exposing the resist film via an immersion medium, and (c) performing development with a negative developer.

Owner:FUJIFILM CORP

Pattern forming method, and resist composition, developer and rinsing solution used in the pattern forming method

ActiveUS20100040972A1Reduced line edge roughnessGood size uniformityPhotosensitive materialsPhotoprinting processesDispersityActinic Rays

A pattern forming method comprising a step of applying a resist composition whose solubility in a negative tone developer decreases upon irradiation with an actinic ray or radiation and which contains a resin having an alicyclic hydrocarbon structure and a dispersity of 1.7 or less and being capable of increasing the polarity by the action of an acid, an exposure step, and a development step using a negative tone developer; a resist composition for use in the method; and a developer and a rinsing solution for use in the method, are provided, whereby a pattern with reduced line edge roughness and high dimensional uniformity can be formed.

Owner:FUJIFILM CORP

Conductive pattern material and method for forming conductive pattern

InactiveUS6919158B2Wide applicationHigh sensitivityPhotoprinting processesSolid-state devicesConductive materialsSupport surface

There are provided a conductive pattern material and a pattern-forming method by which a fine pattern having a high resolution and no wire breakage is obtained. The conductive pattern material is such that on a support surface a pattern-forming layer is formed which allows the formation of a hydrophilic / hydrophobic region directly bonded to the support surface due to energy imparted. Energy is imparted to the pattern-forming material in an imagewise manner to form the conductive material layer.

Owner:FUJIFILM CORP

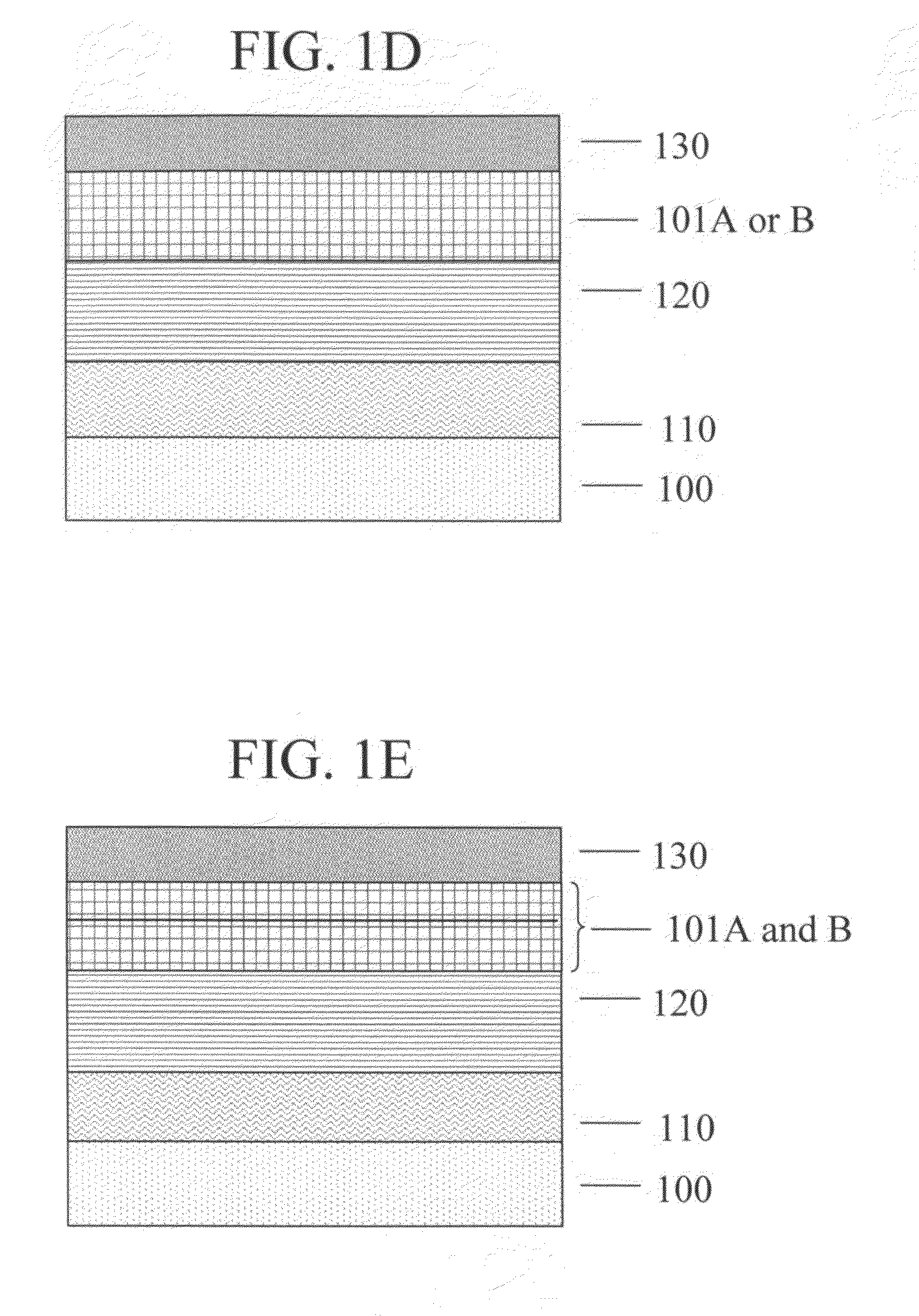

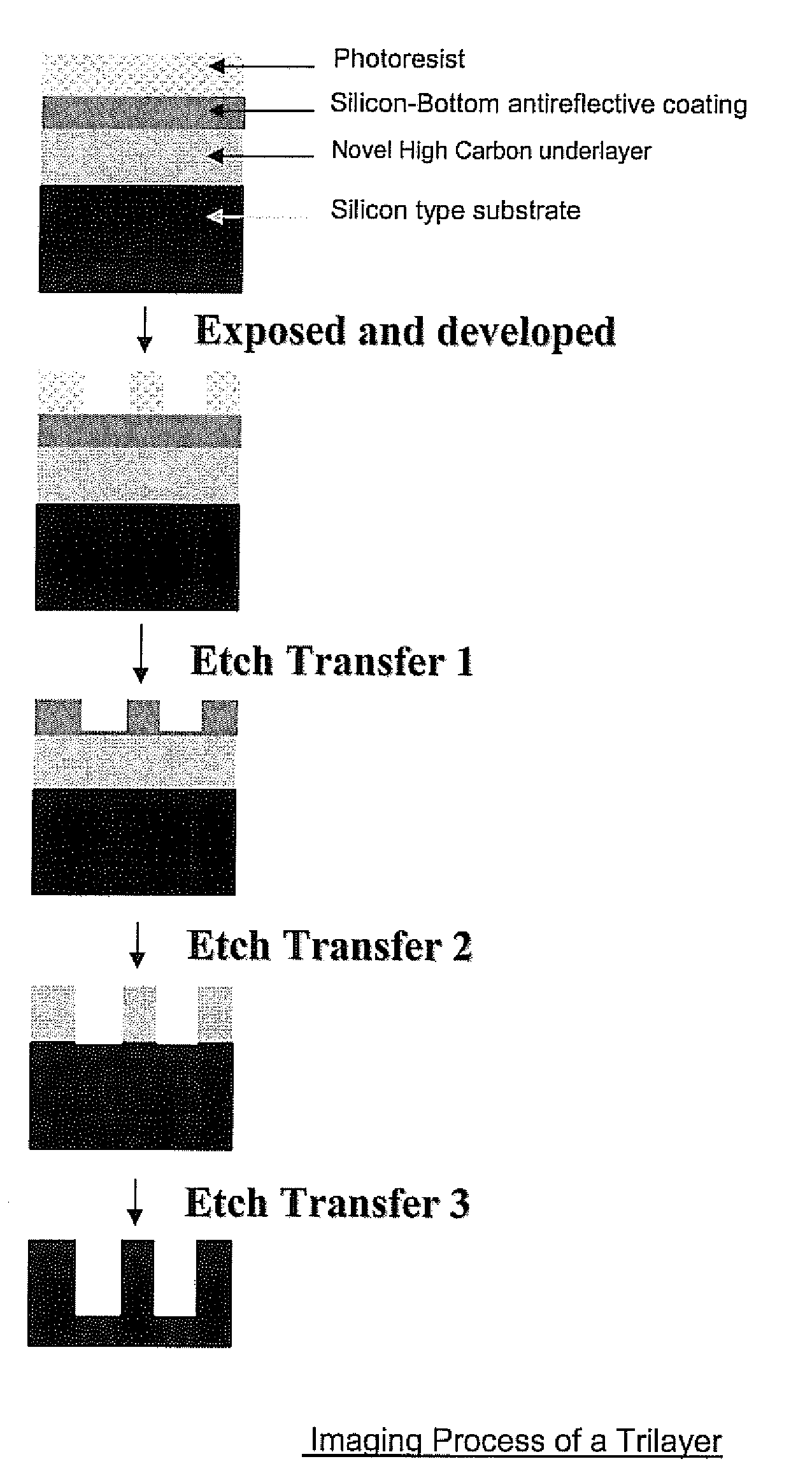

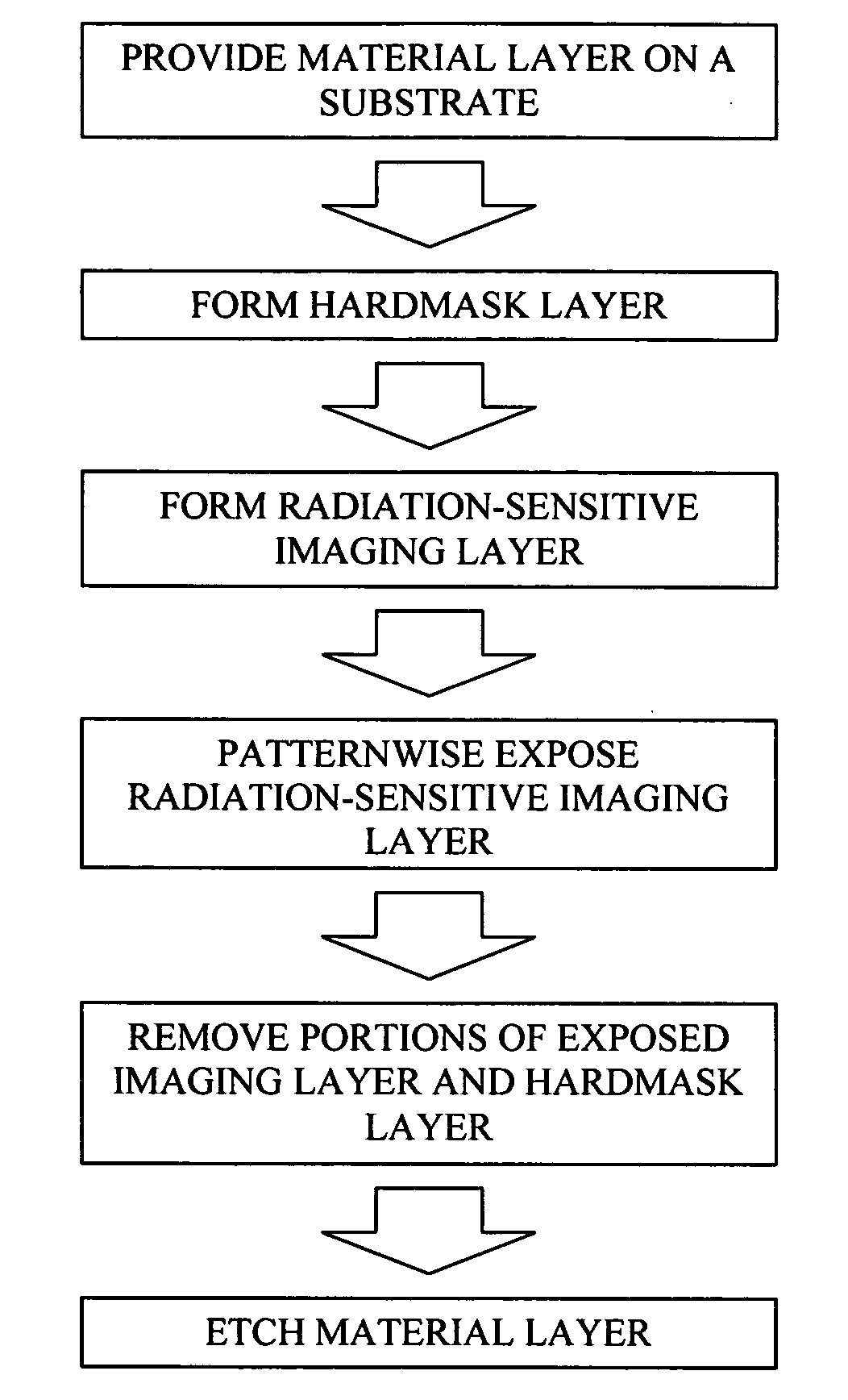

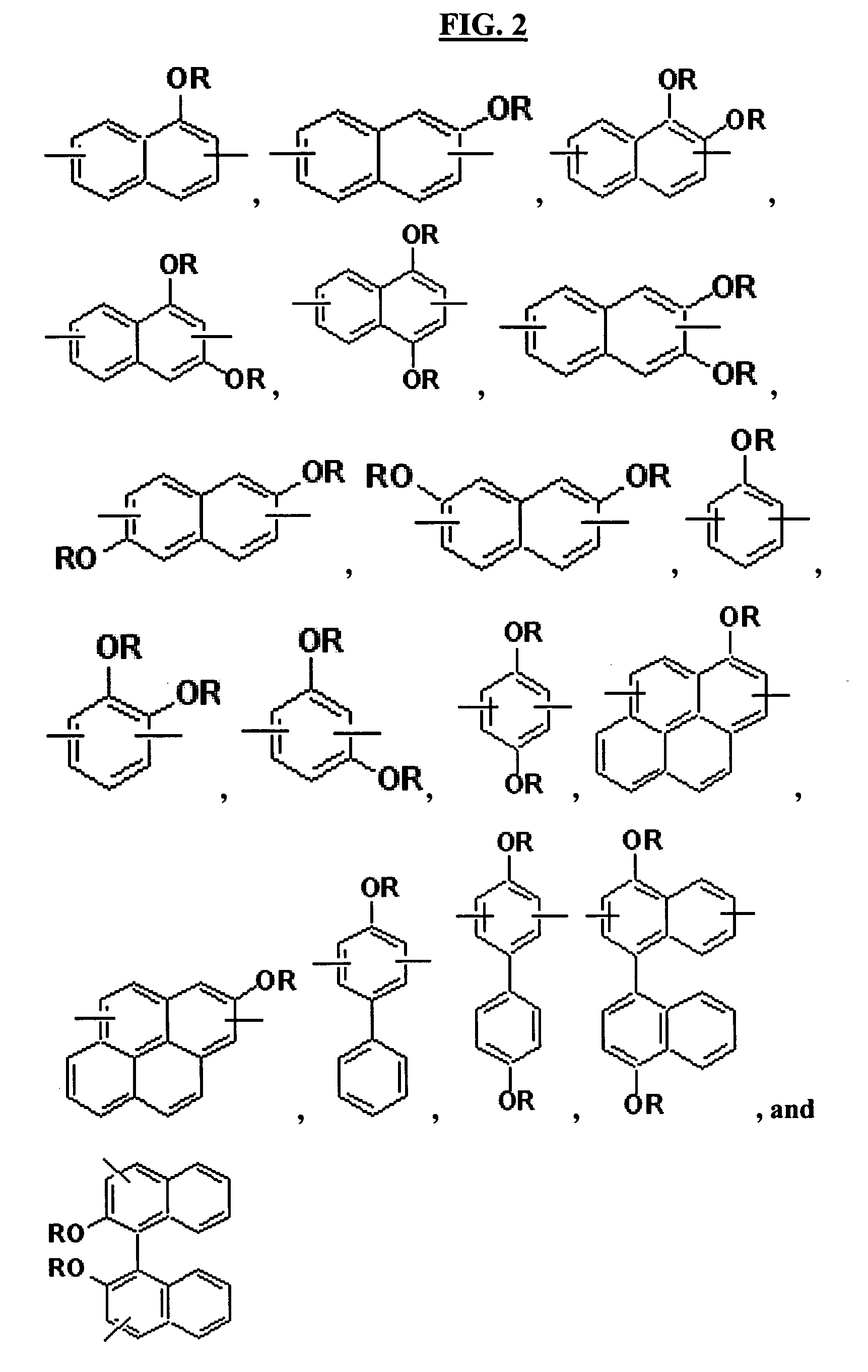

Polymer having antireflective properties and high carbon content, hardmask composition including the same, and process for forming a patterned material layer

ActiveUS20080160461A1High carbon contentPhotosensitive materialsPhotoprinting processesOrganic solventPolymer science

An antireflective hardmask composition includes an organic solvent, an initiator, and at least one polymer represented by Formulae A, B, or C:

Owner:CHEIL IND INC

Solution builder wizard

A palette is displayed containing icons representing available system components for use in a solution. Associated with the icons are partially defined behavioral models, implementation logic, and user-modifiable parameters and options in a markup language format. Instances of the configurable behavioral models are instantiated through selection by a user. A design area of the display shows icons for the instances, where they are placed and arranged by the user, including connection logic and user-input model interface and behavioral logic parameters. The models are configured according to the parameters by modifying the associated markup language. A system solution behavioral model is automatically created in a modeling language comprising a collection of the interconnected and fully defined component behavioral model instances, allowing simulation of operation of the system solution.

Owner:INT BUSINESS MASCH CORP

Antireflective Coating Composition Comprising Fused Aromatic Rings

The present invention relates to an organic spin coatable antireflective coating composition comprising a polymer comprising at least one unit with 3 or more fused aromatic rings in the backbone of the polymer and at least one unit with an aliphatic moeity in the backbone of the polymer. The invention further relates to a process for imaging the present composition.

Owner:MERCK PATENT GMBH

On-press developable IR sensitive printing plates

InactiveUS6846614B2Long shelf lifeHigh copy numberPhotosensitive materialsRadiation applicationsOligomerSide chain

The present invention relates to IR-sensitive compositions suitable for the manufacture of printing plates developable on-press. The IR-sensitive compositions comprise a first polymeric binder which does not comprise acidic groups having a pKa value≦8; a second polymeric binder comprising polyether groups; an initiator system; and a free radical polymerizable system comprising at least one member selected from unsaturated free radical polymerizable monomers, free radical polymerizable oligomers and polymers containing C═C bonds in the back bone and / or in the side chain groups. The initiator system includes (i) at least one compound capable of absorbing IR radiation; (ii) at least one compound capable of producing radicals selected from polyhaloalkyl-substituted compounds; and (iii) at least one polycarboxylic acid of formula R4—(CR5R6)r—Y—CH2COOH, wherein oxi<redii+1.6 eV, where oxi=oxidation potential of component (i) in eV, and redii=reduction potential of component (ii) in eV.

Owner:KODAK POLYCHROME GRAPHICS

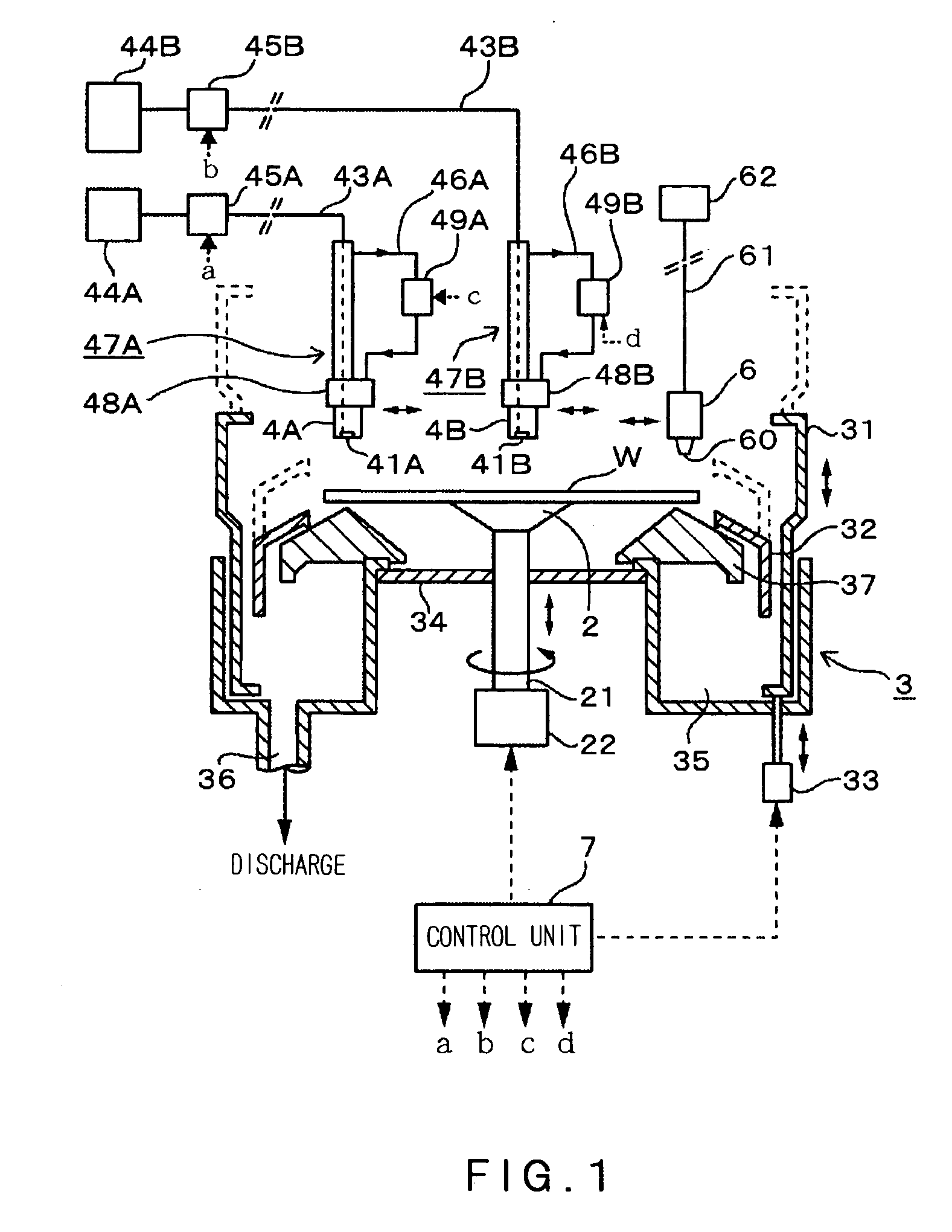

Use of supercritical fluid to dry wafer and clean lens in immersion lithography

InactiveUS20070026345A1Easy to replaceReduce downtimePhotoprinting processesSemiconductor/solid-state device manufacturingPhotoresistChemistry

Disclosed are immersion lithography methods and systems involving irradiating a photoresist through a lens and an immersion liquid of an immersion lithography tool, the immersion liquid in an immersion space contacting the lens and the photoresist; removing the immersion liquid from the immersion space; charging the immersion space with a supercritical fluid; removing the supercritical fluid from the immersion space; and charging the immersion space with immersion liquid.

Owner:SPANSION LLC +1

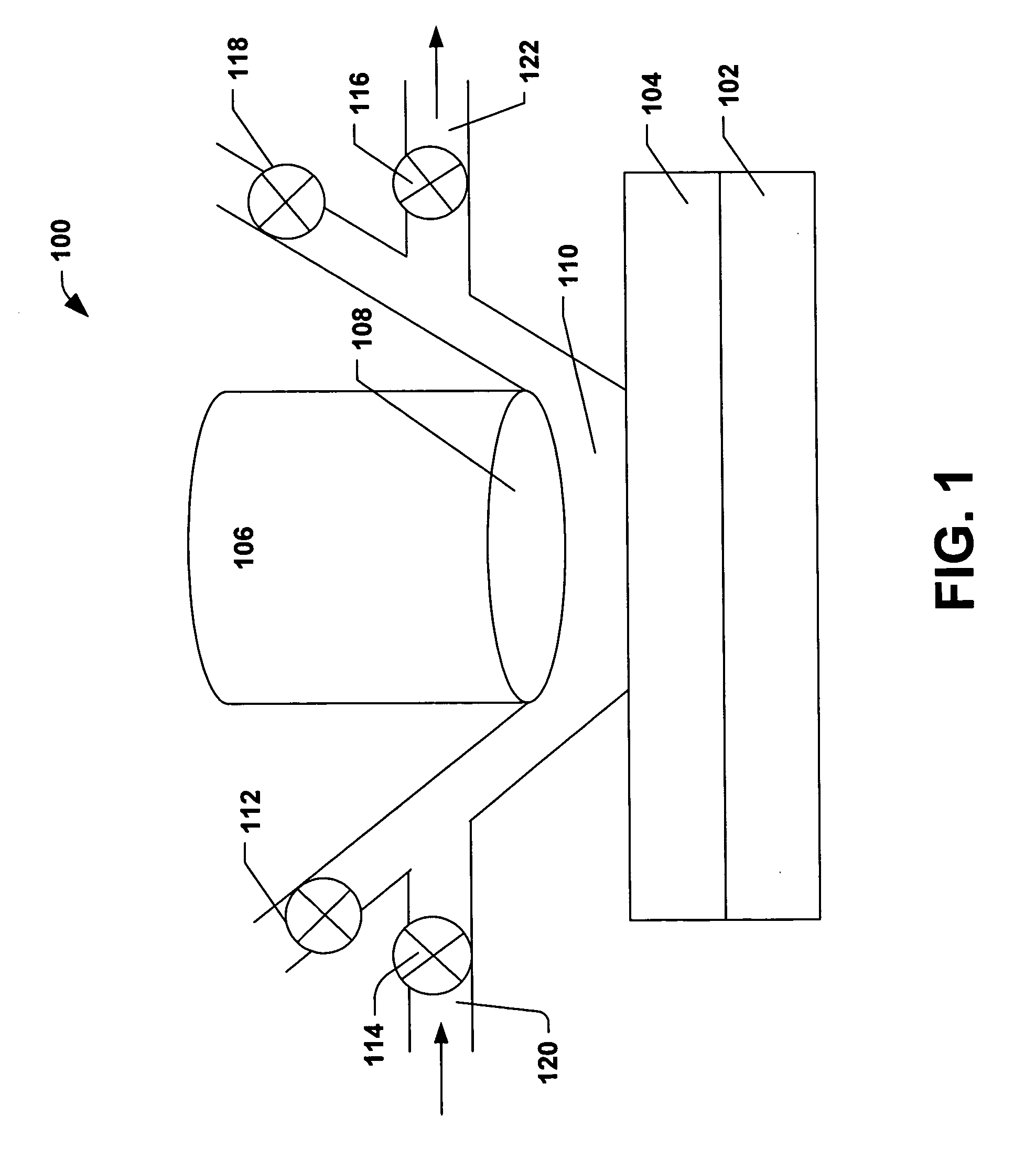

Development device and development method

ActiveUS20090130614A1Reduced amount of developing solutionShort timeLiquid surface applicatorsLiquid processingSpray nozzleMechanical engineering

A developer nozzle is moved from a periphery of a wafer toward the central portion while an exposed substrate held at a spin chuck is being rotated about a vertical axis and while a developing solution is being discharged from the developer nozzle, and this way the developing solution is supplied to the surface of the wafer, the developer nozzle having a slit-like ejection port whose longitudinal direction is oriented to the direction perpendicular to the radial direction of the wafer. The movement speed of the nozzle is higher than a case where a nozzle with a small-diameter circular nozzle is used, and this enables a development time to be reduced. Further, the thickness of a developing solution on a substrate can be reduced, so that the developing solution can be saved.

Owner:TOKYO ELECTRON LTD

Process for preparing a flexographic printing plate

InactiveUS7122295B2Easy to disassembleQuality improvementPhotosensitive materialsPhoto-taking processesPolymer sciencePolymer chemistry

Owner:DUPONT ELECTRONICS INC +1

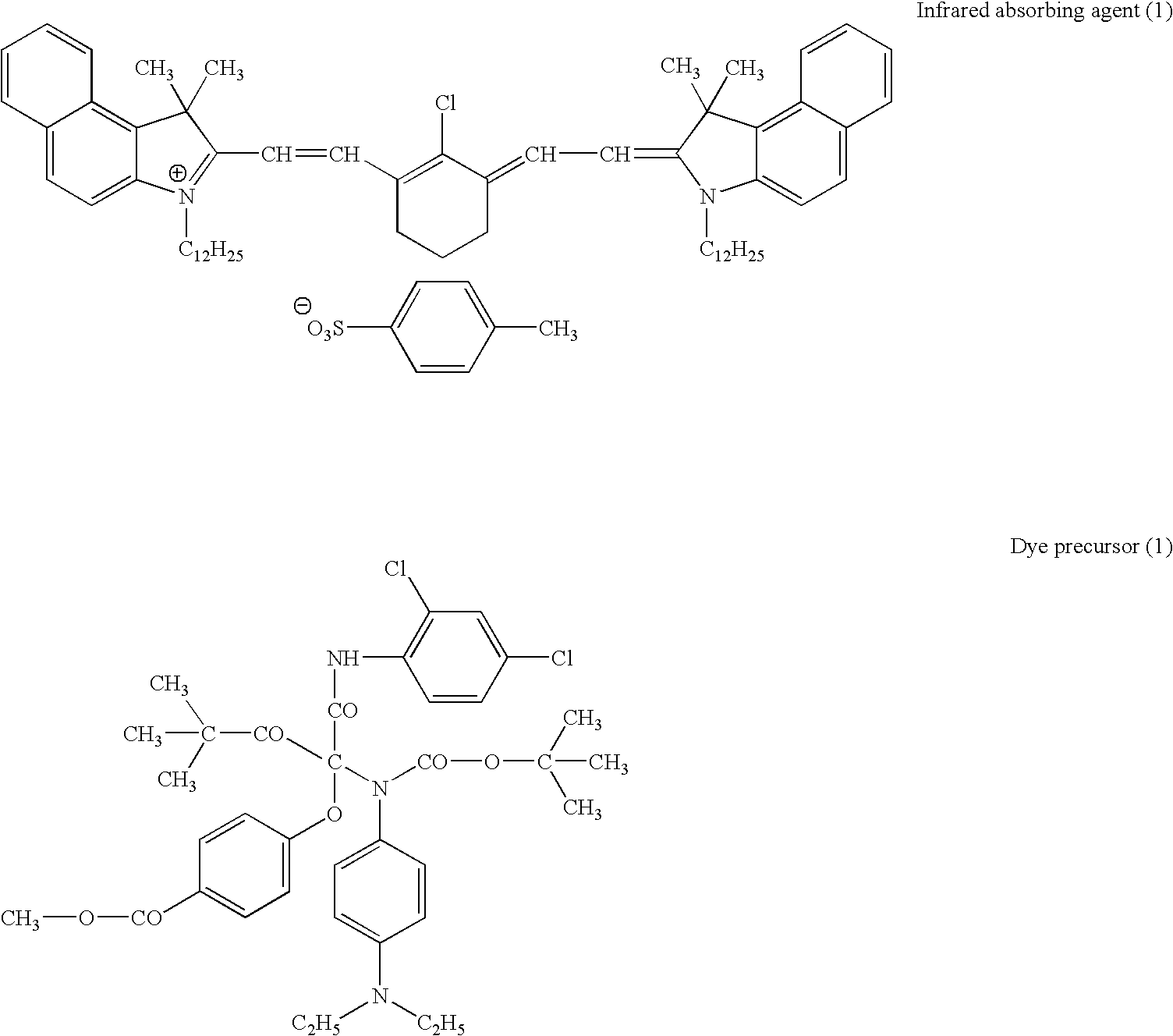

Lithographic printing process

A lithographic printing process which comprises the steps of: imagewise exposing to infrared light a presensitized lithographic plate which comprises a hydrophilic support and a removable image-forming layer containing an infrared absorbing agent having the absorption maximum within an infrared region and a dye precursor having substantially no absorption within a visible region to change the dye precursor to a visible dye having an absorption within a visible region within the exposed area, and to make the image-forming layer irremovable within the exposed area; removing the image-forming layer within the unexposed area of the lithographic plate mounted on a cylinder of a printing press; and then printing an image with the lithographic plate mounted on the cylinder of the printing press. The other processes are also disclosed.

Owner:FUJIFILM HLDG CORP +1

Use of supercritical fluid to dry wafer and clean lens in immersion lithography

InactiveUS7262422B2Easy to replaceReduce downtimePhotoprinting processesSemiconductor/solid-state device manufacturingPhotoresistChemistry

Disclosed are immersion lithography methods and systems involving irradiating a photoresist through a lens and an immersion liquid of an immersion lithography tool, the immersion liquid in an immersion space contacting the lens and the photoresist; removing the immersion liquid from the immersion space; charging the immersion space with a supercritical fluid; removing the supercritical fluid from the immersion space; and charging the immersion space with immersion liquid.

Owner:SPANSION LLC +1

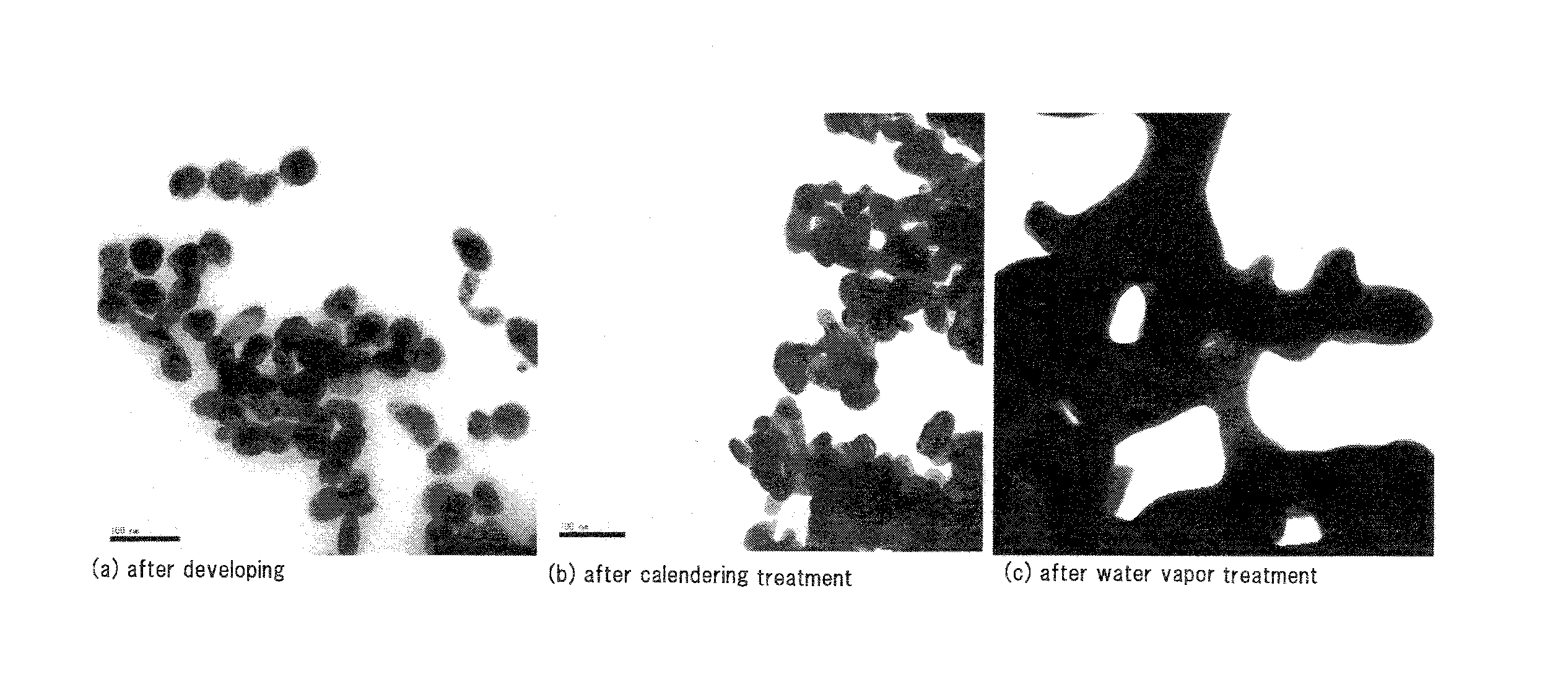

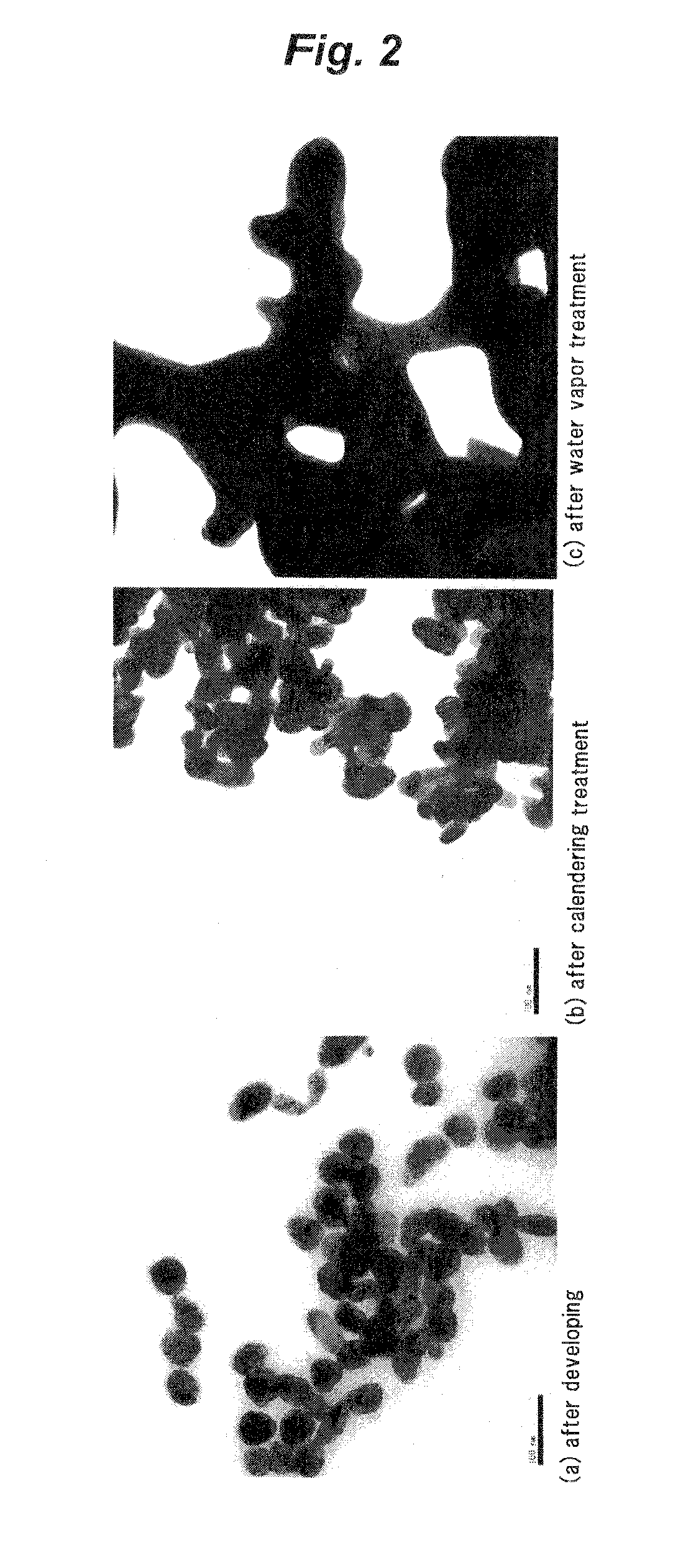

Conductive film and method of producing thereof

InactiveUS7985527B2Improve conductivityLow costConductive layers on insulating-supportsMagnetic/electric field screeningConductive materialsMetal

A method for producing a conductive film, having the steps: forming, on a support, a conductive metal portion containing a conductive material and a binder; bringing the conductive metal portion into contact with vapor or a hot water; and immersing the conductive metal portion into hot water having a temperature of 40° C. or higher.

Owner:FUJIFILM CORP

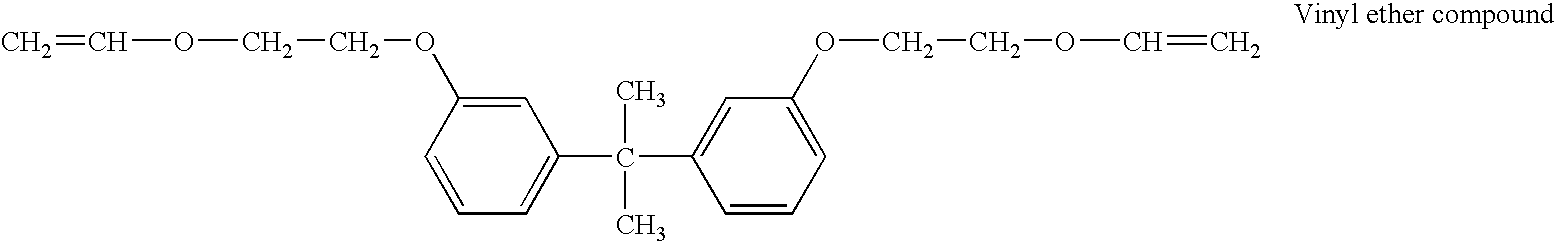

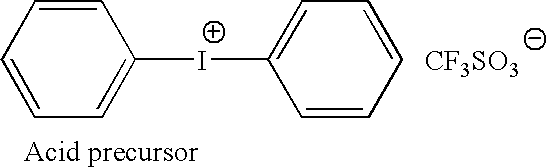

Anti-Reflective Coating Forming Composition Containing Vinyl Ether Compound

InactiveUS20080138744A1Photosensitive materialsPhotoprinting processesAnti-reflective coatingVinyl ether

There is provided an anti-reflective coating forming composition for use in a lithography of the manufacture of semiconductor devices and for forming an anti-reflective coating that can be developed with an alkaline developer for photoresist, and a method for forming photoresist pattern by use of the anti-reflective coating forming composition. The anti-reflective coating forming composition comprises a compound having at least two vinyl ether groups, an alkali-soluble compound having at least two phenolic hydroxy groups or carboxyl groups, a photoacid generator, and a solvent.

Owner:NISSAN CHEM IND LTD

Hardmask composition having antirelective properties and method of patterning material on susbstrate using the same

ActiveUS20080305441A1Improve etch selectivitySolve the lack of resistancePhotosensitive materialsPhotoprinting processesPolymer scienceOrganic solvent

A hardmask composition includes an organic solvent and one or more aromatic ring-containing polymers represented by Formulae 1, 2 and 3:

Owner:CHEIL IND INC

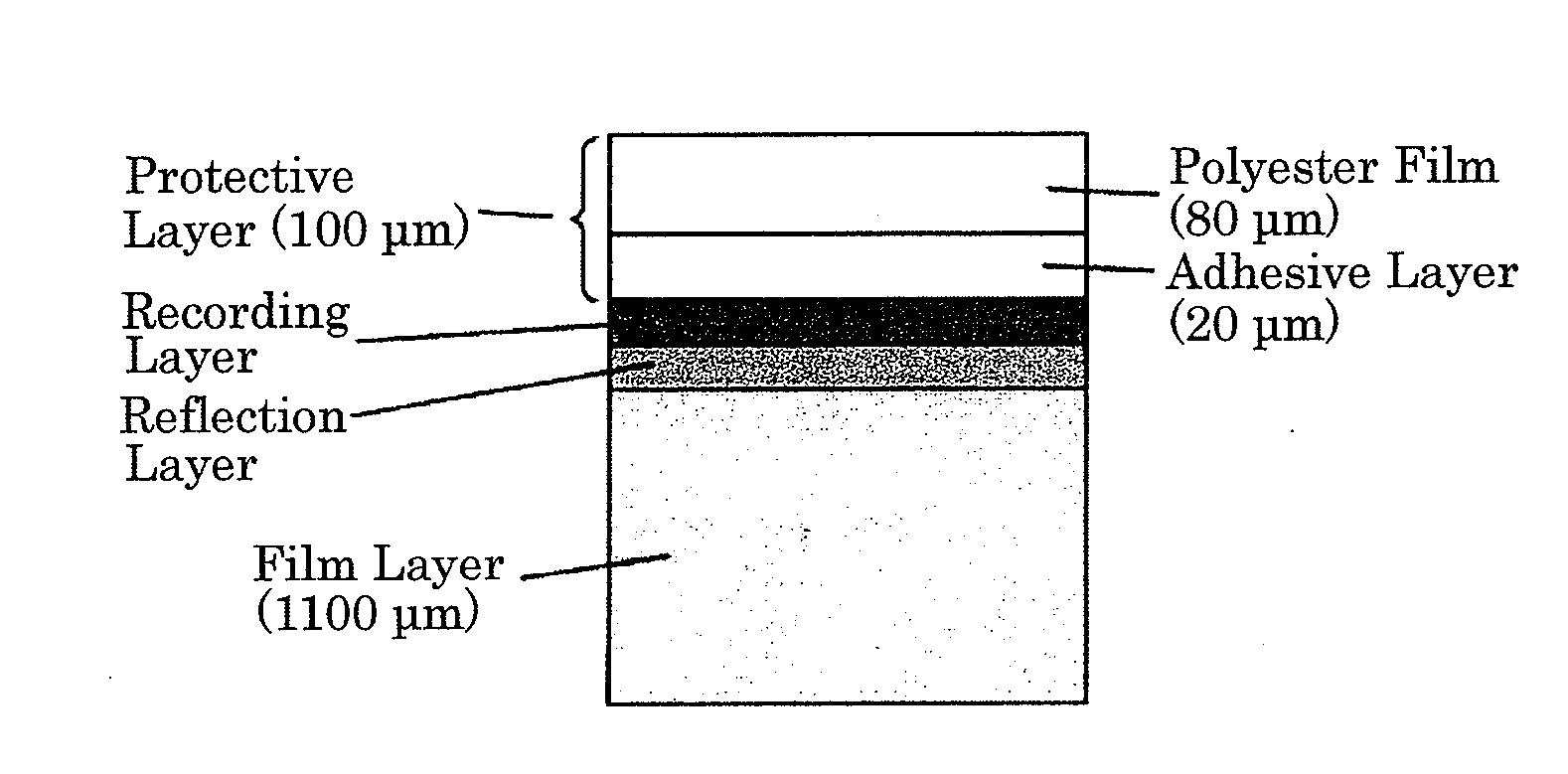

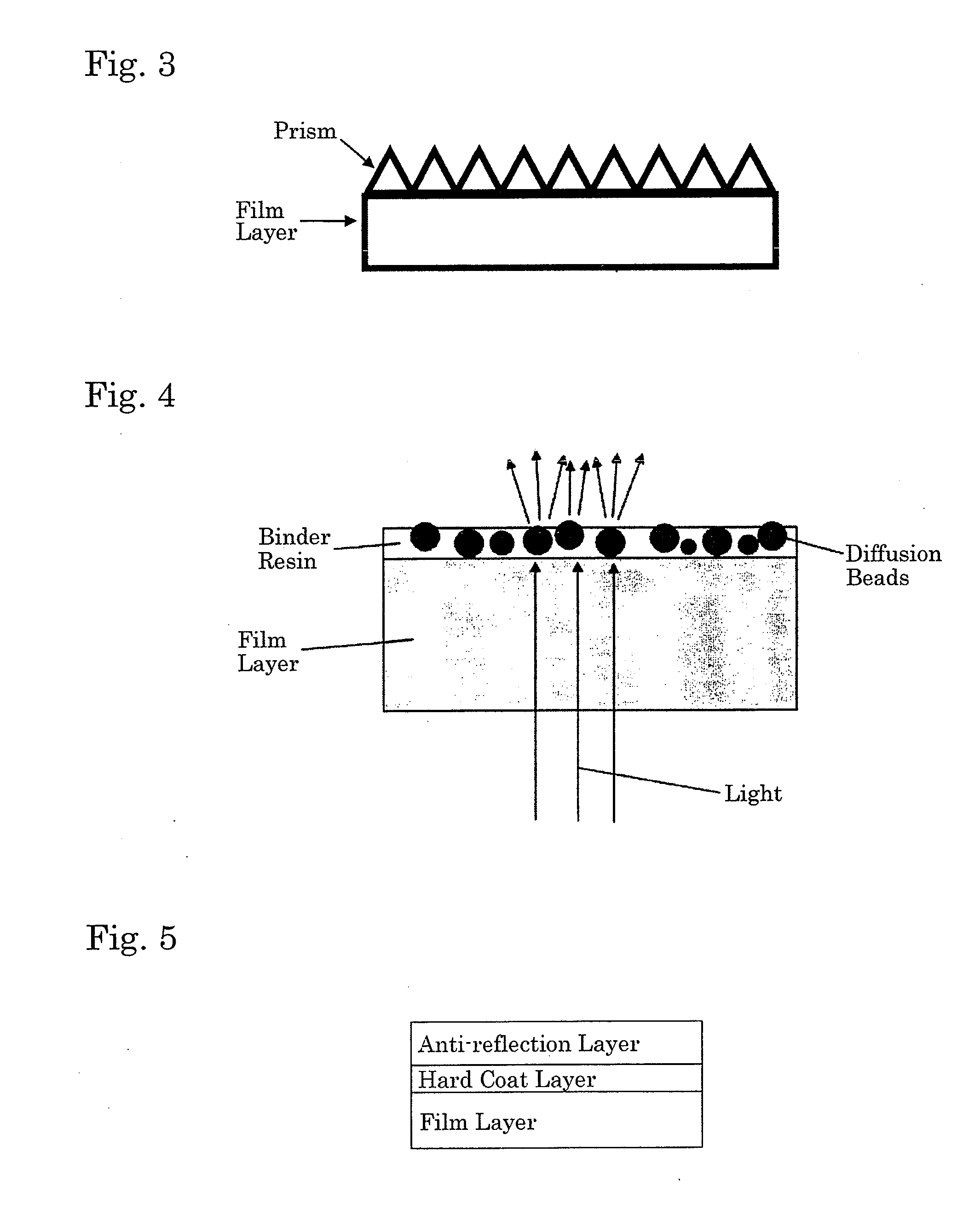

Polyester film, process for producing the same and use thereof

The present invention relates to a polyester film produced by melt-extruding a polyester composed of a dicarboxylic acid unit and a diol unit, wherein 1 to 80 mol % of the diol unit is a unit containing a cyclic acetal skeleton, and the polyester film has an in-plane retardation of 20 nm or less at a wavelength of 550 nm. The polyester film is an optically isotropic polyester film which is easily produced by an extrusion-molding method and has an economical advantage. The polyester film is useful for production of optical members or optical products such as phase difference films, protective films for polarizing plates, light diffusion films, lens sheets, anti-reflection films and optical information recording media.

Owner:MITSUBISHI GAS CHEM CO INC

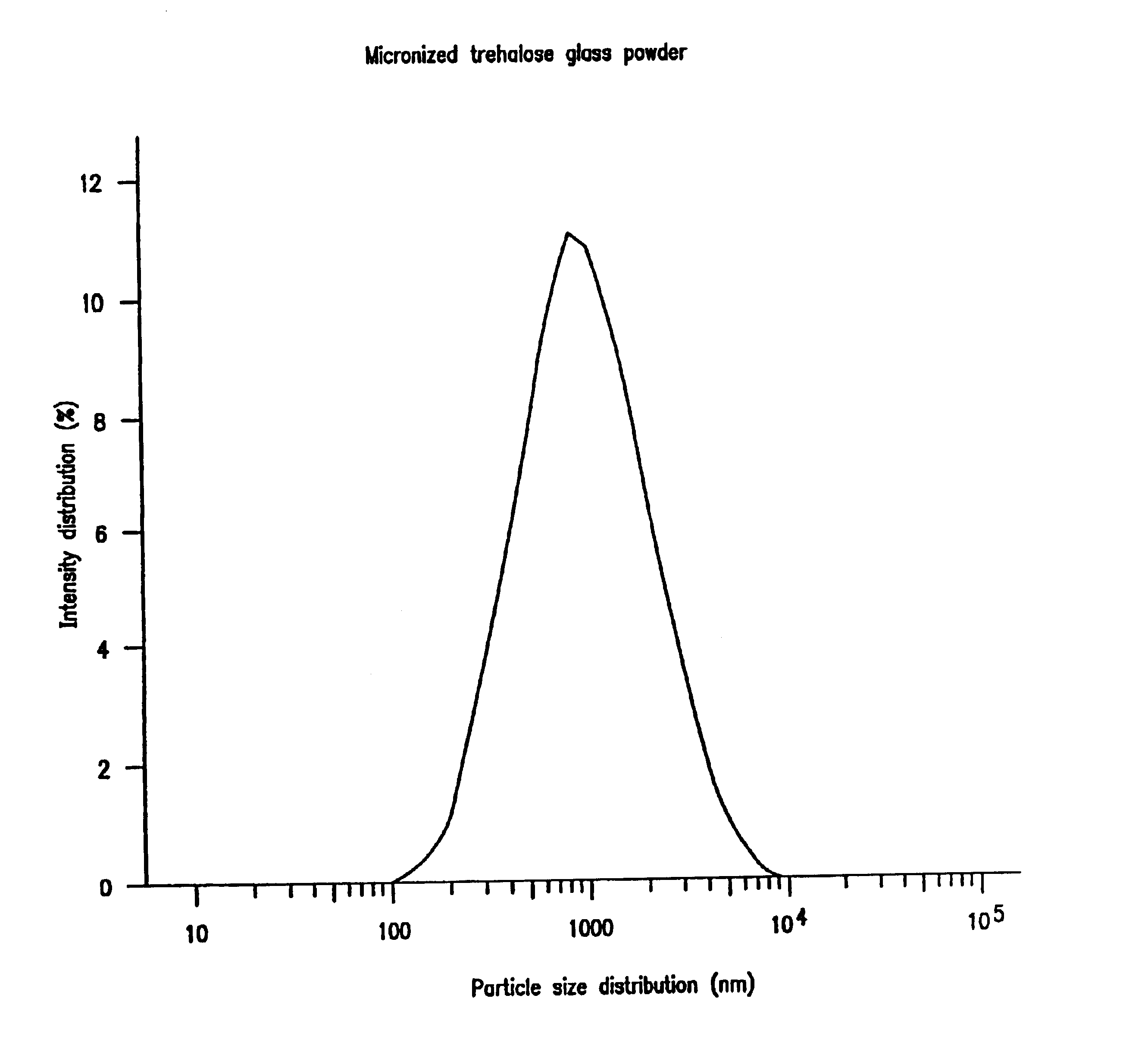

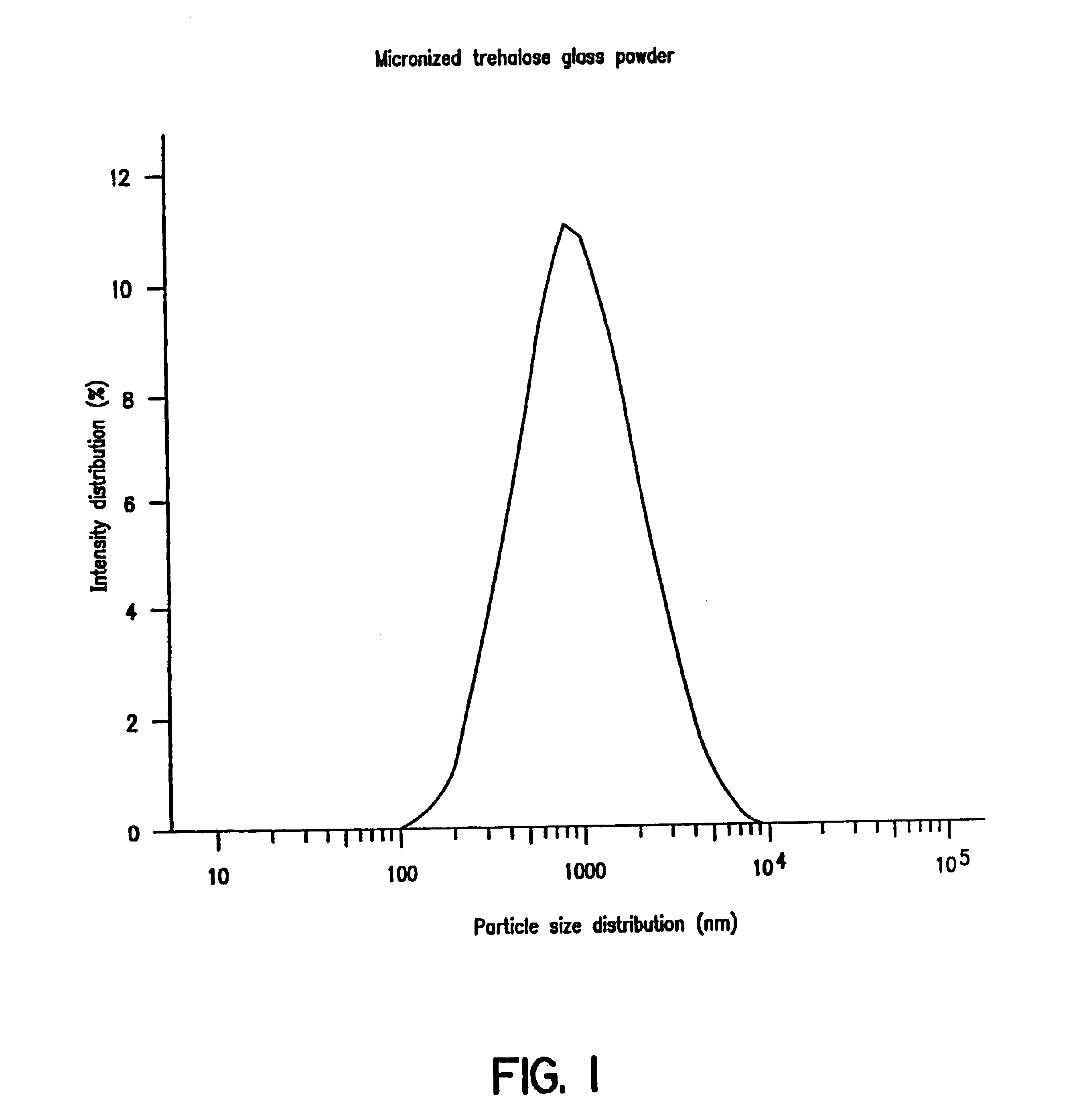

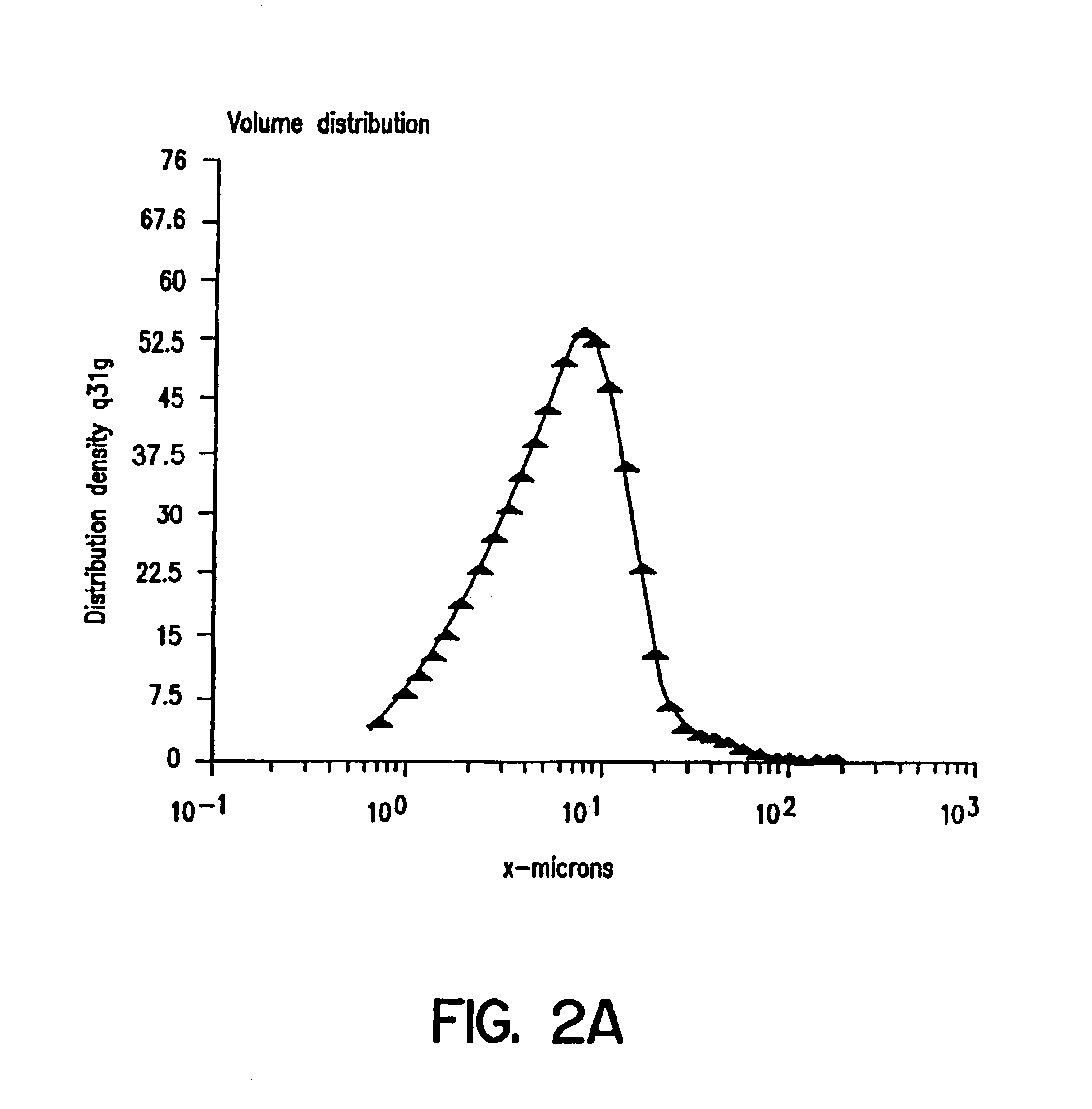

Solid dose delivery vehicle and methods of making same

The present invention encompasses a solid dose delivery vehicle for ballistic administration of a bioactive material to subcutaneous and intradermal tissue, the delivery vehicle being sized and shaped for penetrating the epidermis. The delivery vehicle further comprises a stabilizing polyol glass loaded with the bioactive material and capable of releasing the bioactive material in situ. The present invention further includes methods of making and using the solid dose delivery vehicle of the invention.

Owner:QUADRANT DRUG DELIVERY

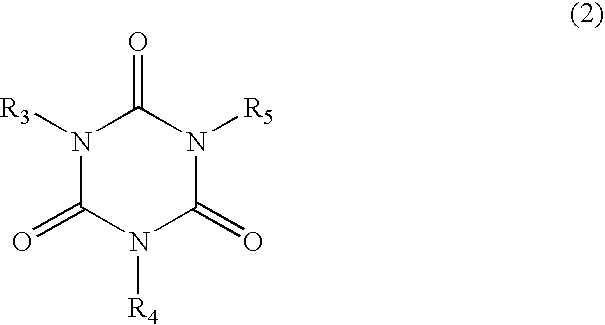

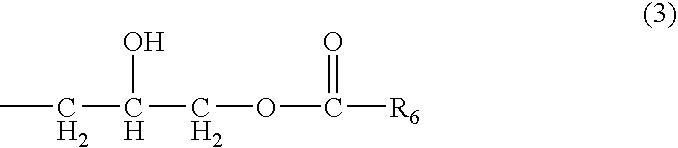

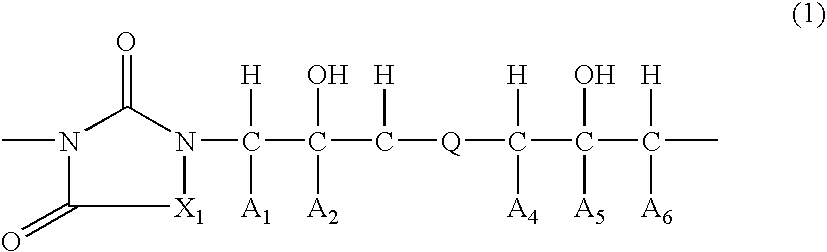

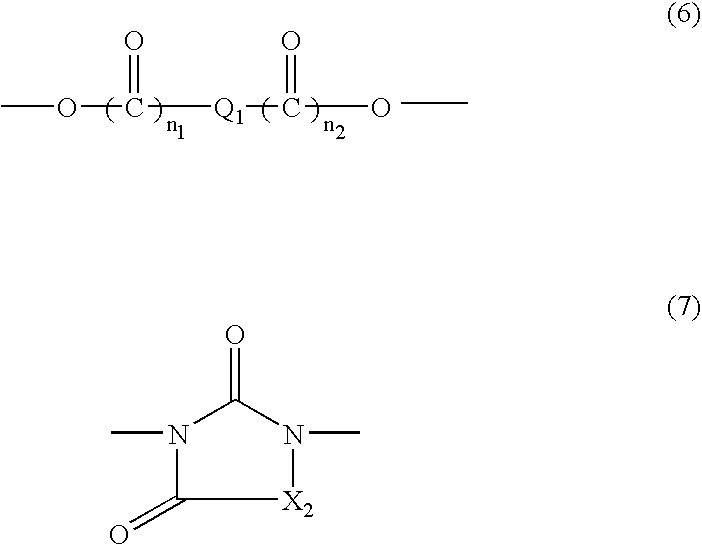

Condensation Type Polymer-Containing Anti-Reflective Coating For Semiconductor

ActiveUS20080038678A1Effective absorptionHigh ratePhotosensitive materialsPhotoprinting processesAnti-reflective coatingLithography process

There is provided an anti-reflective coating forming composition comprising a polymer having a pyrimidinetrione structure, imidazolidinedione structure, imidazolidinetrione structure or triazinetrione structure and a solvent. The anti-reflective coating obtained from the composition has a high preventive effect for reflected light, causes no intermixing with photoresists, and can use in lithography process by use of a light having a short wavelength such as ArF excimer laser beam (wavelength 193 nm) or F2 excimer laser beam (wavelength 157 nm), etc.

Owner:DYMAS FUNDING COMPANY LLC AS AGENT +1

Popular searches

Surgical instrument details Microlithography exposure apparatus Originals for photomechanical treatment Photographic printing Diazo-type processes Irradiation devices Semiconductor devices Photosensitive material processing Photosensitive materials for photomechanical apparatus Silver-salt material processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com