Electrotinning tarnishing prevention treating agent and using method thereof

An anti-discoloration and treatment agent technology, which is applied in the field of surface treatment agents, can solve problems affecting the performance of components, unsatisfactory effects, and failure to meet environmental protection requirements, and achieve stable product performance and simple and convenient waste liquid treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

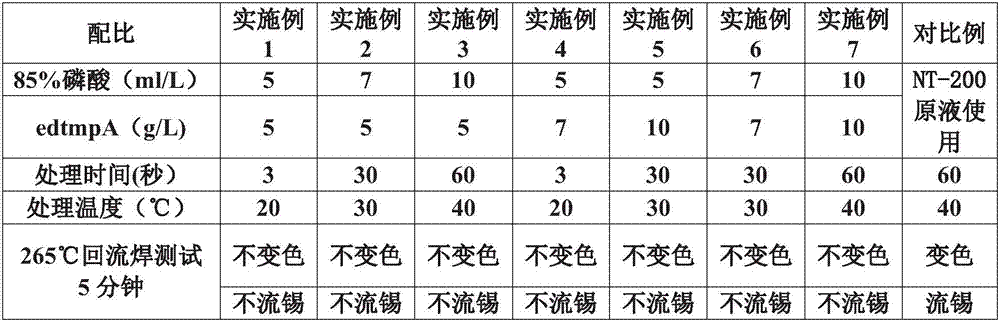

Examples

Embodiment 1

[0016] The electroplating tin anti-tarnish treatment agent is configured, and the components of the electrotin tin anti-tarnish treatment agent are: 5ml / L phosphoric acid, 5g / L ethylenediaminetetramethylenephosphonic acid (edtmpA), and deionized water. Phosphoric acid is commercially available phosphoric acid with a content of 85%.

[0017] The treatment method is: immerse the electroplated tin after washing in 20°C electroplated tin anti-tarnish agent for 3 seconds, wash the acidic residue on the surface with hot pure water and dry it. Use the reflow soldering test to test the anti-discoloration effect, after 5 minutes of reflow soldering test at 265°C, it will not change color or tin flow.

Embodiment 2

[0019] The electroplating tin anti-tarnish treatment agent is configured, and the components of the electrotin tin anti-tarnish treatment agent are: 7ml / L phosphoric acid, 5g / L ethylenediamine tetramethylene phosphonic acid, and deionized water. Phosphoric acid is commercially available phosphoric acid with a content of 85%.

[0020] The treatment method is: soak the electroplated tin after washing in 30°C electroplated tin anti-tarnish agent for 30 seconds, wash the acidic residue on the surface with hot pure water and dry it. Use the reflow soldering test to test the anti-discoloration effect, after 5 minutes of reflow soldering test at 265°C, it will not change color or tin flow.

Embodiment 3

[0022] The electroplating tin anti-tarnish treatment agent is configured, and the components of the electrotin tin anti-tarnish treatment agent are: 10ml / L phosphoric acid, 5g / L ethylenediamine tetramethylene phosphonic acid, and deionized water. Phosphoric acid is commercially available phosphoric acid with a content of 85%.

[0023] The treatment method is: soak the electroplated tin after washing in water for 60 seconds in the electroplated tin anti-tarnish agent at 40°C, wash the acidic residue on the surface with hot pure water and dry it. Use the reflow soldering test to test the anti-discoloration effect, after 5 minutes of reflow soldering test at 265°C, it will not change color or tin flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com