Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131 results about "Methyl sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorption-biological treatment method for malodorous gas

The invention relates to an absorption and biological treatment method of malodorous waste gas. The malodorous waste gas enters a spray absorption tower to have an absorbing, humidifying and cooling function, and then enters into a biological dripping and filtrating device and contacts with a biological film attached to the surface of the filler in the process of rising to be degraded into odorless compounds, and then the purified gas is discharged. The residence time of a vacant bed is 11 to 45 seconds. Part of the waste water produced when spraying and absorbing can be used as biological circulating water, which can be reused again as spraying water after the biochemical treatment. The absorption and biological treatment method of the invention can effectively remove the odor polluting matters such as organic amine, ammonia gas, hydrogen sulfide, mercaptan type, dimethyl sulfide (DMS), dimethyl disulfide (DMDS), styrene, volatile organic compounds (VOC), dimethyl trisulfide, benzylamine, carbon disulfide, carbonyl sulfide, etc. and all kinds of malodorous smells, most of which are poisonous and a plurality of which are carcinogens. The deodorization effect can reach 99 percent, which can discharge by reaching the standard and can be applied to a deodorization and purification treatment of the large-capacity matters polluted by different malodorous gas with low concentration.

Owner:SUN YAT SEN UNIV

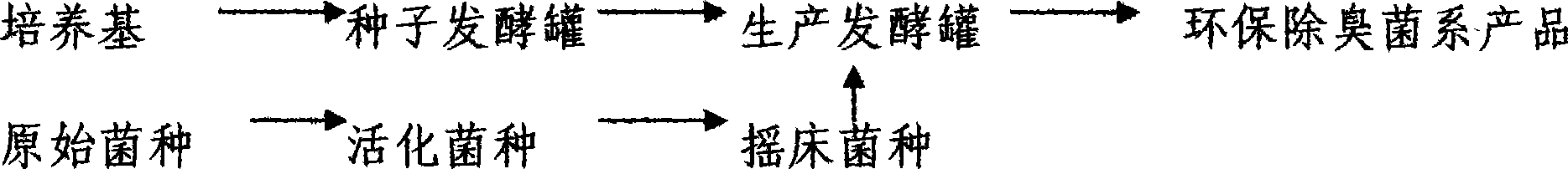

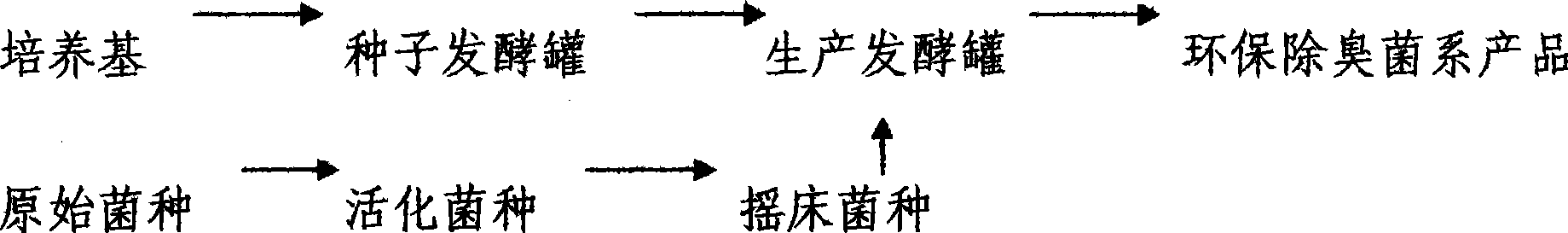

Antibacterial and environment-friendly deodorant of microorganism strains

The invention relates to an antibacterial and environment-friendly deodorant of microorganism strains and a preparation method thereof. The traditional method for removing odor generally uses essence to cover up the odor or pumping odor physically or uses ozone to oxidize and degrade the odor or uses a chemical method. The methods also can alleviate the odor to a certain extent, but finally the problem can not be solved really and fundamentally and the essence and chemical deodorization also have secondary pollution. The microbial deodorization technology utilizes the effects of high-efficient absorption, absorption and metabolism of particular microorganism strains which can convert or degrade odorant, to purify the odorous gases of amyl mercaptan, benzene methanethiol, methyl sulfide, ethanethiol, hydrogen sulfide, sulfur dioxide, p-benzyl mercaptan, ammonia, dimethylamine, trimethylamine and carbon disulfide and the like which are emitted from human life areas, domestic sewage and domestic garbage and the like and to convert the odorous components of amyl mercaptan, benzene methanethiol, methyl sulfide, ethanethiol, hydrogen sulfide, sulfur dioxide, p-benzyl mercaptan, ammonia, dimethylamine, trimethylamine and carbon disulfide and the like into matters without harm and odor, thus achieving the purpose of thoroughly improving air quality and protecting health of people. The preparation method utilizes a fermentation method of microorganism strains to prepare deodorant products.

Owner:王峰

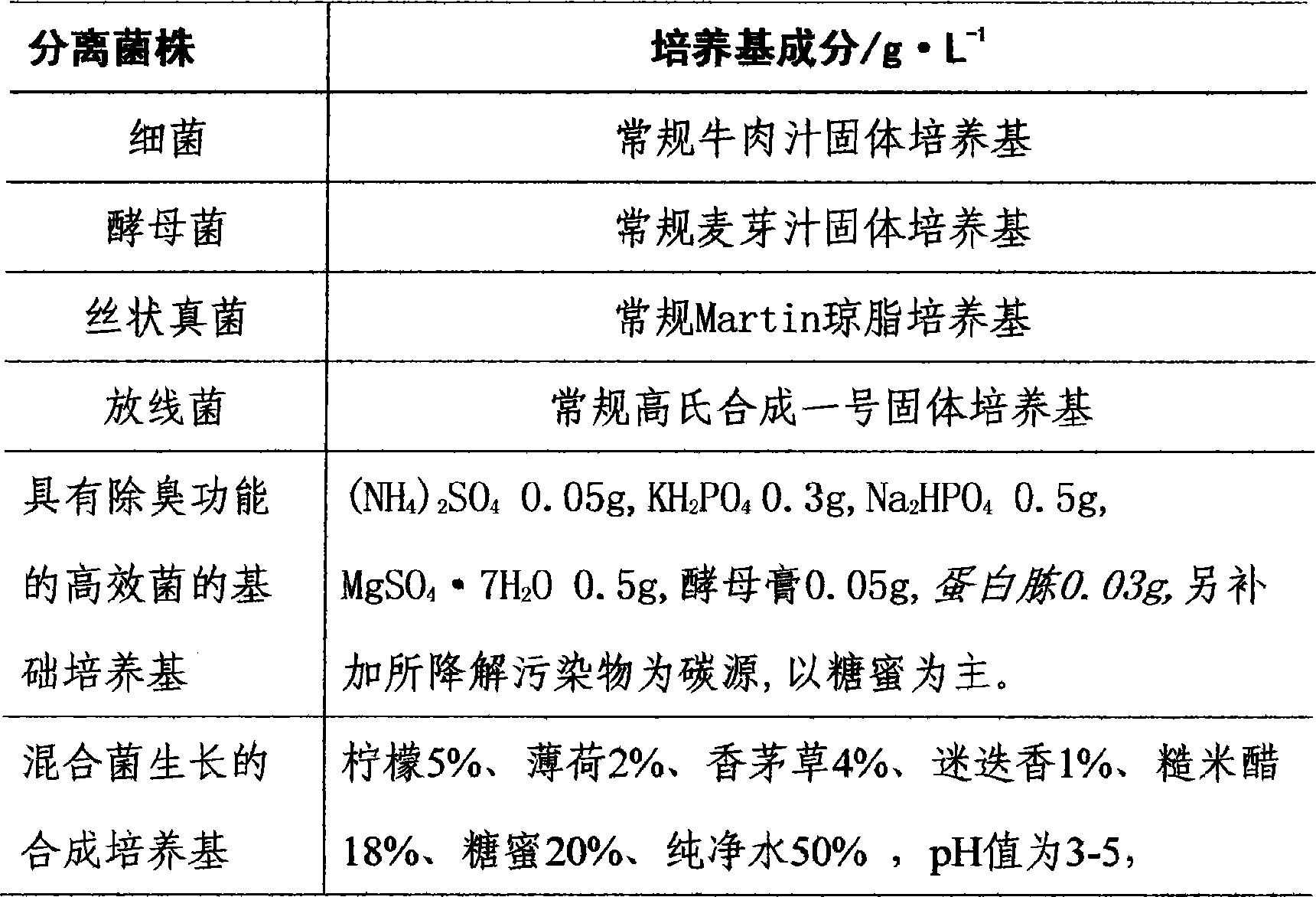

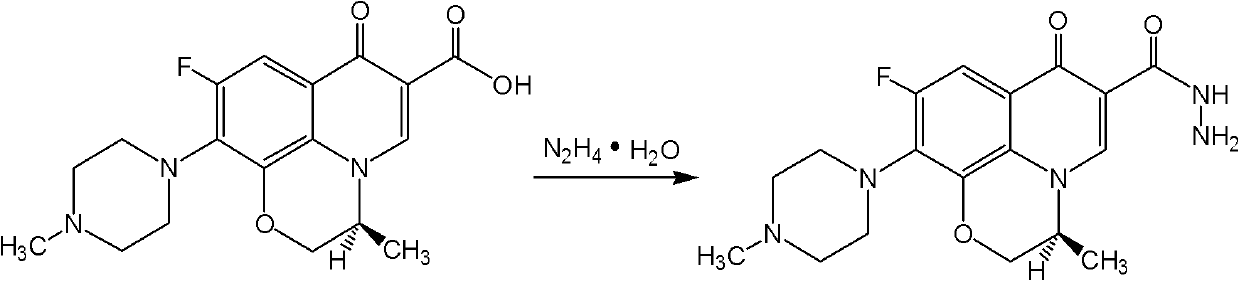

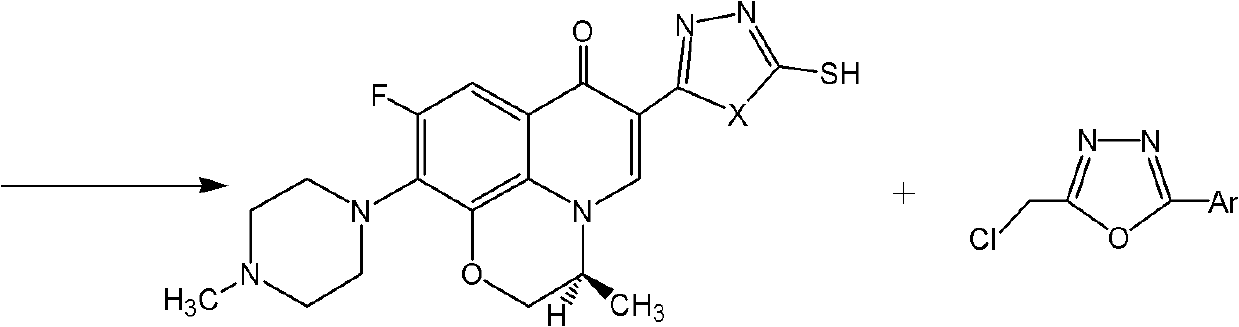

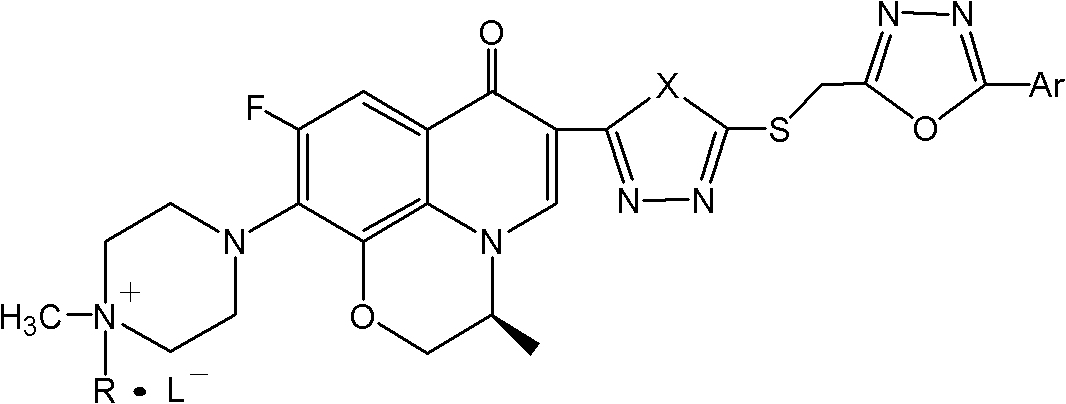

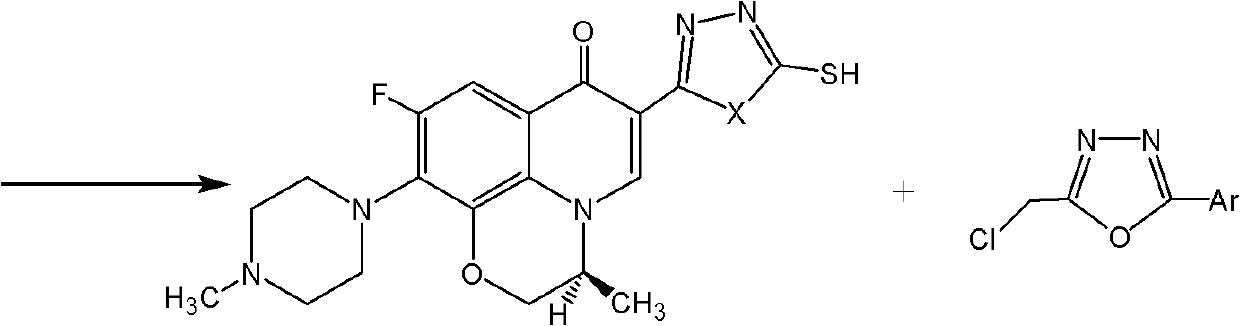

Levo-fluoroquinolone C3 bisazole methyl sulfide, preparation method and application thereof

InactiveCN102391287AStrong in vitro cytotoxicityGood antitumor activityOrganic active ingredientsOrganic chemistryCancer cellMethyl sulfide

The invention belongs to the technical field of medicine, and in particular discloses a levo-fluoroquinolone C3 bisazole methyl sulfide, a preparation method and application thereof in the field of pharmacy. The chemical structural formula of the levo-fluoroquinolone C3 bisazole methyl sulfide is shown as a general formula I, wherein in the general formula I, X is selected from any one of O, S and -NH; and Ar is selected from any one of phenyl, substituent-containing phenyl and heterocyclic aromatic hydrocarbon. The levo-fluoroquinolone C3 bisazole methyl sulfide has strong in vitro cytotoxin effect on experimental leukemia cancer cell strains, has strong anti-tumor activity, and can be mixed with a human acceptable acid salt or a medicinal carrier to prepare an anti-tumor medicament.

Owner:河南省健康伟业生物医药研究股份有限公司

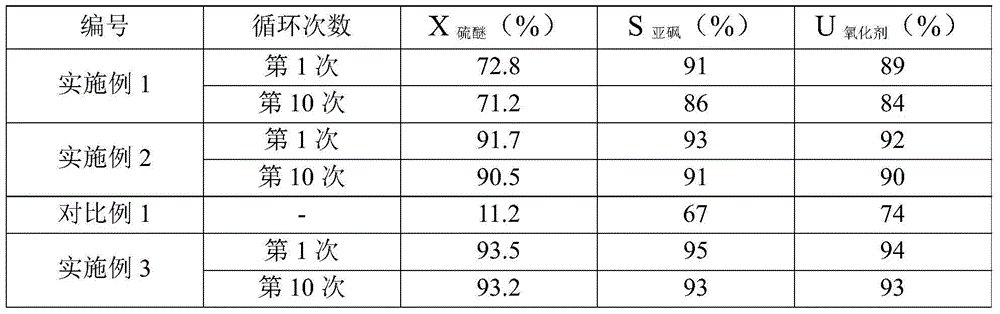

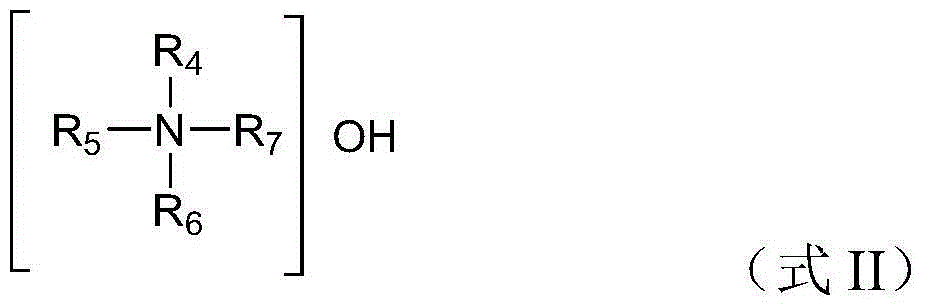

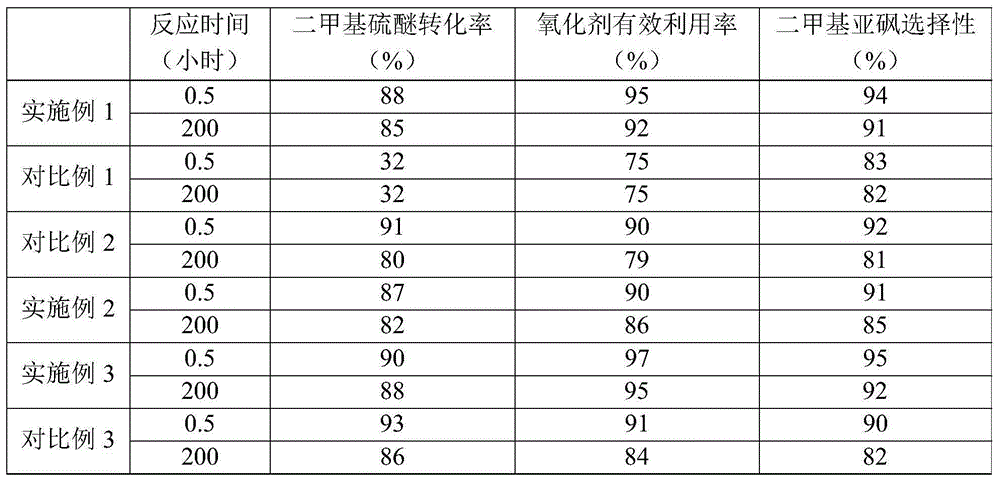

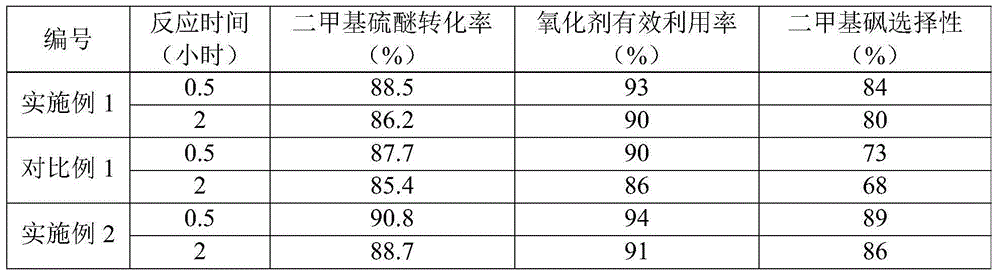

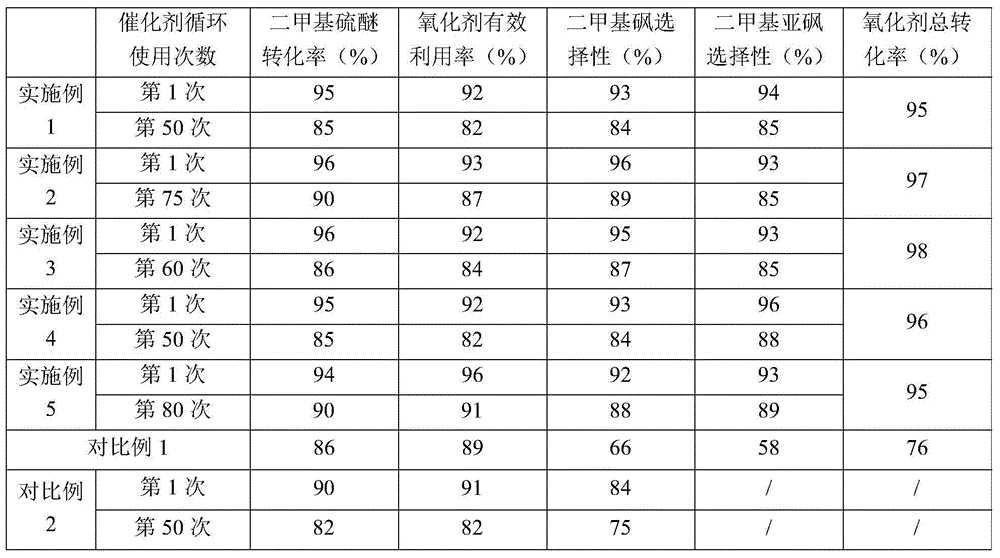

Method for preparing dimethyl sulfoxide

ActiveCN104557629AReduce usageImprove conversion rateOrganic chemistryMolecular sieve catalystsMolecular sieveMethyl sulfide

The invention provides a method for preparing dimethyl sulfoxide. The method comprises the following step of contacting dimethyl sulfide and at least one oxidant with at least one tin silicate molecular sieve under an oxidation condition. According to the method, especially when peroxide is used as an oxidant, the conversion rate of dimethyl sulfide and the effective utilization rate of the oxidant are high, the selectivity of dimethyl sulfoxide is good, the using amount of dimethyl sulfide and the oxidant can be effectively reduced, and the production cost of dimethyl sulfoxide can be reduced. Furthermore, by adopting the method, the catalyst has good activity stability, and high dimethyl sulfide conversion rate, oxidant effective utilization rate and dimethyl sulfoxide selectivity can stilled be obtained even the catalyst runs continuously for a long time or is recycled for multiple times. Furthermore, the method is mild in reacting condition and easy to control, and is suitable for large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Corrosion and scale inhibitor for oil well in high water cut stage

ActiveCN102321464AExtend the pump inspection cycleDrilling compositionBorehole/well accessoriesThioureaEthylenediaminetetra(methylenephosphonic)acid

The invention relates to a corrosion and scale inhibitor for an oil well in a high water cut stage, which is applicable to corrosion and scale inhibition of an oilfield. The corrosion and scale inhibitor comprises the following components in percentage by weight: 3.25-4.0% of o-dimethyl thiourea, 12.5-13.5% of ethylenediamine tetramethylene phosphonate, 8.0-8.5% of dodecyl butylamine methyl sulfide, 3.0-3.25% of tetradecyl tributyl phosphonium chloride, 15.0-16.2% of DN-3212 acrylic acid, organic phosphine and sulfonic acid copolymer, 5.25-5.75% of M-505A corrosion inhibitor, 6.85-7.25% of SL-2 corrosion and scale inhibitor, 5.0-7.5% of methanol, 3.4-3.75% of methenamine, 0.05-0.055% of vitamin A and the balance of water, wherein the sum of the weight percentage of each component is100%. The corrosion and scale inhibitor has the effects that: when the addition amount of the corrosion and scale inhibitor is 50-60 mg / L, the corrosion inhibition rate of the oil well reaches more than 85%, and the scale inhibition rate reaches more than 90%; and the average pump examination period is prolonged by more than one time.

Owner:PETROCHINA CO LTD

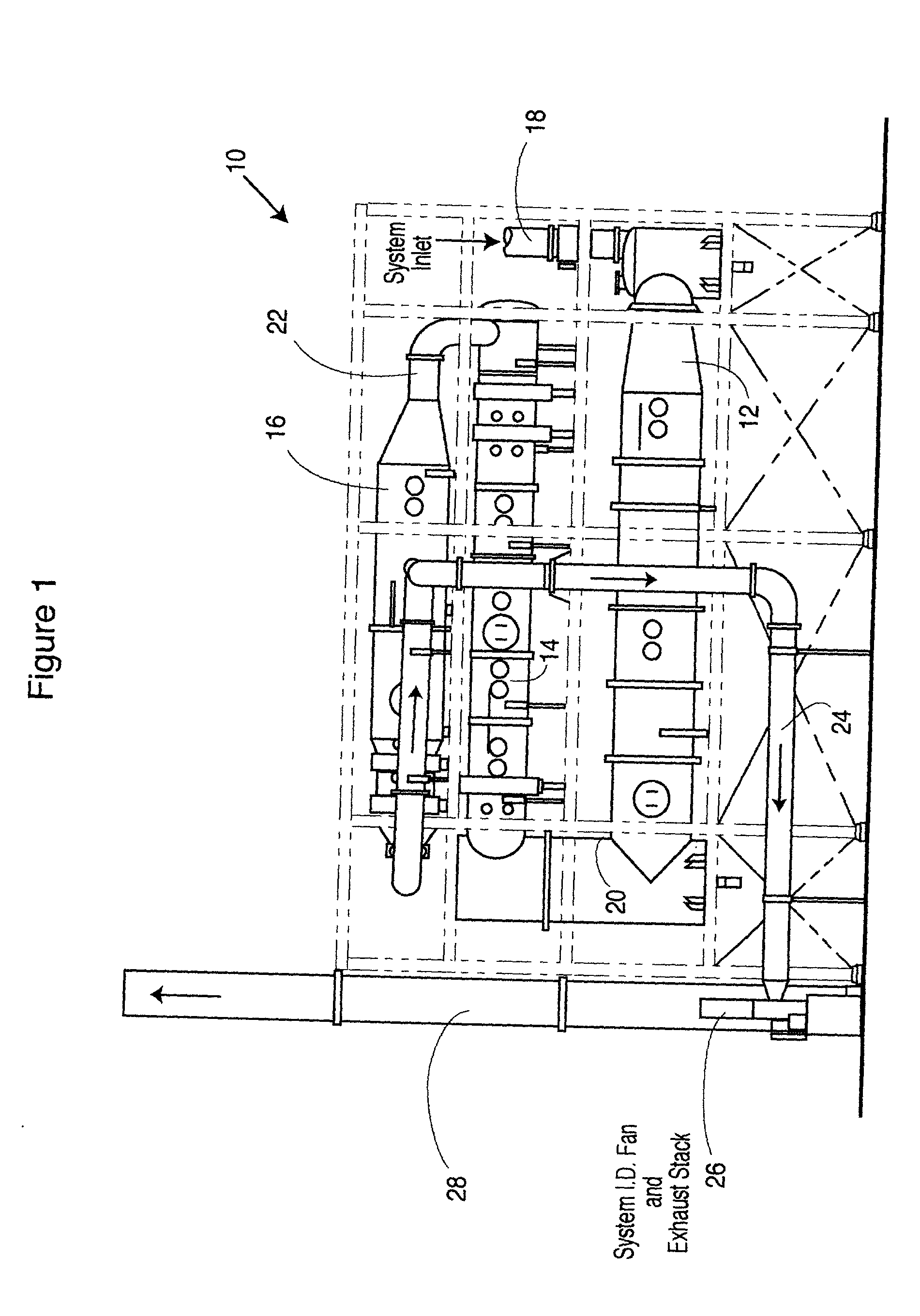

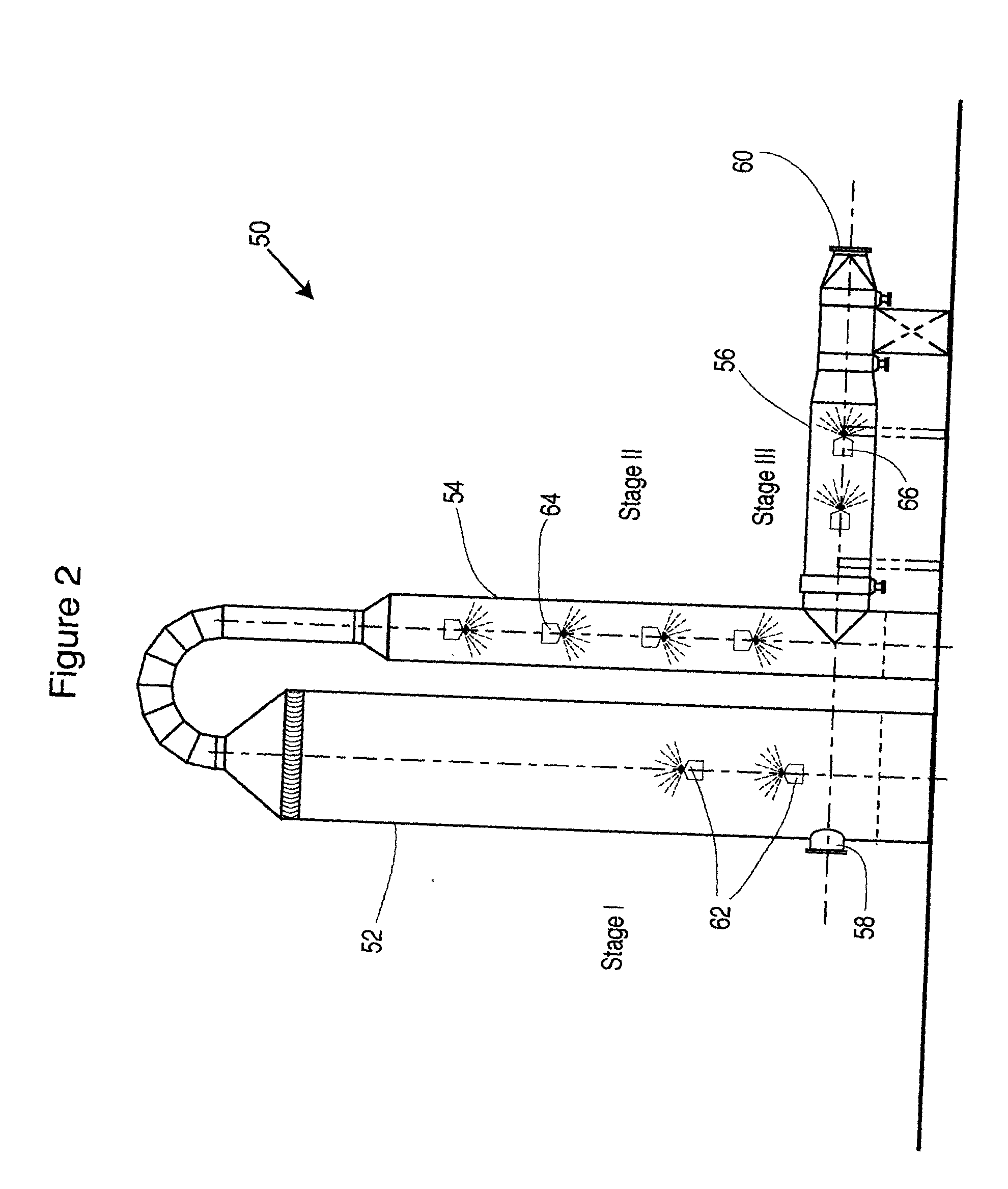

Treatment of gas streams containing reduced sulfur compounds

InactiveUS20020034468A1Efficient removalReduce solubilityDispersed particle filtrationElectrostatic separationParticulatesChlorine dioxide

Gas streams containing non-condensible gases (NCG's) including reduced sulfur compounds, such as hydrogen sulfide, dimethyl sulfide, dimethyl disulfide and mercaptans, are treated to remove the NCG's from the gas stream. Following an optional initial gas-liquid contact to cool the gas stream to its adiabatic dewpoint and to remove particulates, the gas stream is subjected to an intimate gas-liquid contact with aqueous chlorine dioxide, in one or more contact stages, to oxidize the reduced sulfur compounds and other oxidizable compounds present in The gas stream and then the gas stream is passed through an entrainment separator to remove entrained liquid droplets. Acidic gases produced in the oxidization stage and residual chlorine dioxide generally are removed from the gas steam by intimate gas-liquid contact of the gas stream with an aqueous neutralizing and reducing solution, in one or more contact stages, and ten the gas stream is passed through an entrainment separator to remove entrained liquid droplets.

Owner:MEGTEC TURBOSONIC

Method of producing toltrazuril

A preparation method of the Toltrazuril is provided. The Toltrazuril is the 1-[3-methyl-4-(4- Trifluoromethylthiobenzoxy) benzyl]-3-methyl-1, 3, 5, -triazine-2, 4, 6(1H, 3H, 5H)-trione. The methyl sulfide chloro compounds, fluoro-compounds, amides, phenol, methyl nitrate chlorobenzene, benzene aether, ammonia benzene aether, isonitrile acid ester and methyl urea from the reactions of 4-nitrochlorobenzene, sulfur, sodium sulfide and dimethyl sulfate. The detailed preparation is that reaction 1: the methanol of 410g and 4-nitrochlorobenzene of 158g are mixed and heated until soluble and are added with sulfur, sodium sulfide and methanol mixed liquor by drops, and kept for 2h under temperature of 60 DEG C. to 65DEG C.; reduce the temperature, add water of 880g and add dimethyl sulfate of 192g; during the period, the pH value of the sodium hydroxide is adjusted over 9, and the methyl sulfide of 153.6 is gained by filtering after reaction with yield of 91.1 per cent.

Owner:PU LIKE BIO ENG +1

Method for preparing dimethyl sulfoxide

ActiveCN104557630AImprove effective utilizationImprove conversion rateOrganic chemistryMolecular sieve catalystsMolecular sieveFixed bed

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment protection type polyurethane non-particle spray coating material for play ground layer and manufacture method thereof

InactiveCN101245223AImprove mechanical propertiesOvercome injuryGround pavingsPolyurea/polyurethane coatingsEpoxyCalcium bicarbonate

The invention discloses an environmental-friendly type polyurethane non particle spraying material used in stadium ground layer, which is formed by the mixing of component A and component B; wherein, the weight proportion of component A and component B is 1:3; the component A is obtained by mixing diphenylmethane diisocyanate and polyether glycol according to certain proportion; the component B is obtained by mixing polyether-tribasic alcohol, polyether glycol, dry process montmorillonite clay, 3, 5-methyl-sulfide base tolylene diamine, trimethylolpropane, epoxy resin, two-octyl, silica dioxide powder, calcium bicarbonate, organobentonite, iron oxide red or tartrazine-phthalo green mixture and metal carbonyl carboxylate according to certain proportion. The invention also discloses a preparation method of the material, which includes the steps: first preparing the component A and the component B respectively in specific condition, and mixing and stirring the component A and the component B to obtain the material of the invention. As the material of the invention contains no TDI and MOCA, the polyurethane non particle spraying material has no toxicity and safety hidden danger, and is an environmental-friendly material.

Owner:SICHUAN AOHAI SPORTS ENG

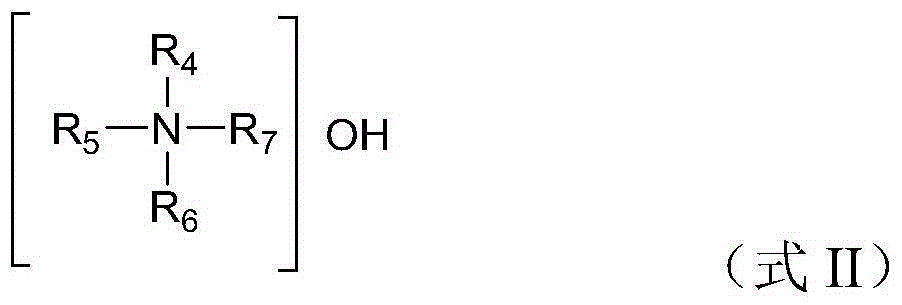

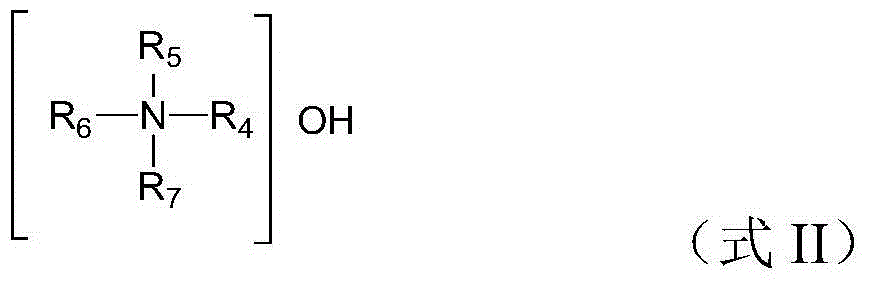

Levorotatory fluoroquinolone C3 diazole methyl sulfide quaternary ammonium salt, preparation method and application thereof

InactiveCN102443011AStrong in vitro cytotoxicityGood antitumor activityOrganic chemistryAntineoplastic agentsCancer cellMethyl sulfide

The invention relates to the technical field of medicines, in particular discloses a levorotatory fluoroquinolone C3 diazole methyl sulfide quaternary ammonium salt, and further discloses a preparation method and application of the levorotatory fluoroquinolone C3 diazole methyl sulfide quaternary ammonium salt in the pharmaceutical field simultaneously. The chemical structural formula of the levorotatory fluoroquinolone C3 diazole methyl sulfide quaternary ammonium salt is represented by a general formula I: the general formula I is described in the specification. The levorotatory fluoroquinolone C3 diazole methyl sulfide quaternary ammonium salt provided by the invention has stronger in-vitro cytotoxicity effect on experimental leukemia cancer cell strains and stronger anti-tumor activity, and can be mixedly prepared into anti-tumor medicines with human body acceptable acidic salts or pharmaceutical carriers.

Owner:HENAN UNIVERSITY

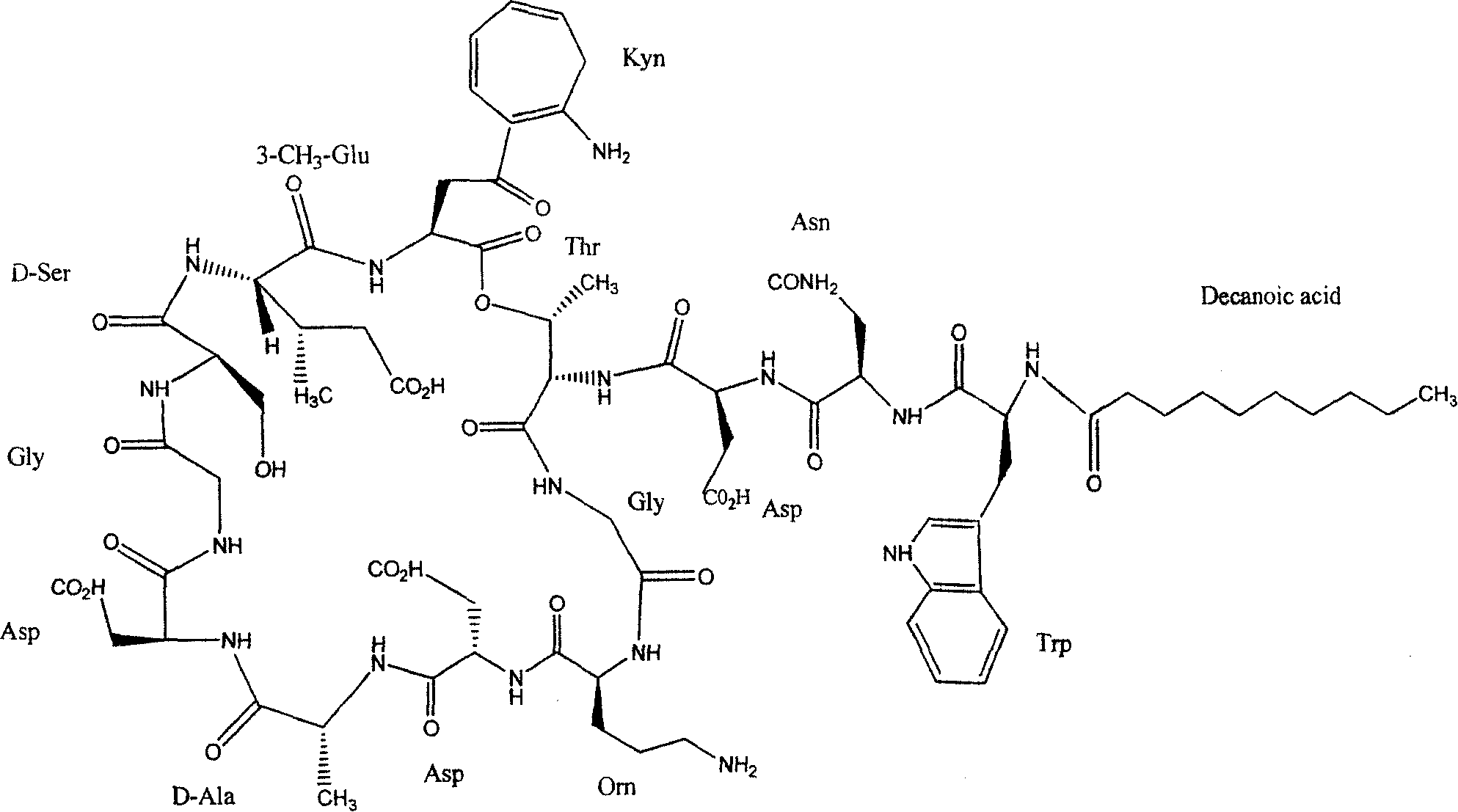

Synthesis method of daptomycin

ActiveCN101235080AAvoid it happening againGood effectPeptide preparation methodsBulk chemical productionSynthesis methodsSolid-phase synthesis

The invention relates to a daptomycin synthesis method for resolving the technical problem of prior art which uses rose spore streptomycete as raw material to cost high synthesis cost. The synthesis method comprises a, using 2-chlorine trityl chloride resin as carrier, via solid synthesis method to connect the amino acids with protective groups, to obtain protective decapeptide resin while the Fmoc-protective groups are removed in turn, B, connecting decanoic acid via same method, connecting next amino acid via esterification, removing Fmoc-protective groups, and connecting left two amino acids via normal solid method, removing Fmoc-protective groups, c, using trifluoroacetic acid or carrene solution to cut off total protective peptide from resin, drying and completing end-to-end liquid cyclisation in organic solvent, d, using the mixture of trifluoroacetic acid, water and benzene methyl sulfide to cut off peptide from resin to obtain crude product. The invention can synthesize daptomycin.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

Process for preparing hydrogen sulfide

The invention discloses a process for preparing hydrogen sulfide through the reaction between sulfuric-acid-containing exhausted liquid (by product of the production process for preparing chemical product and intermediate product by means of chemical reactions) and barium sulphide water soluble liquid phase (prepared from barium sulphide calcined member through water leaching), the produced hydrogen sulfide can be further used in preparing other chemical products, such as sodium hydroxide, sodium hydrogen sulfide, ammonium sulfide, ammonium hydrosulfide, sulfourea, methyl hydrosulfide, ethyl mercaptan and dimethyl sulfur ether.

Owner:唐培堃

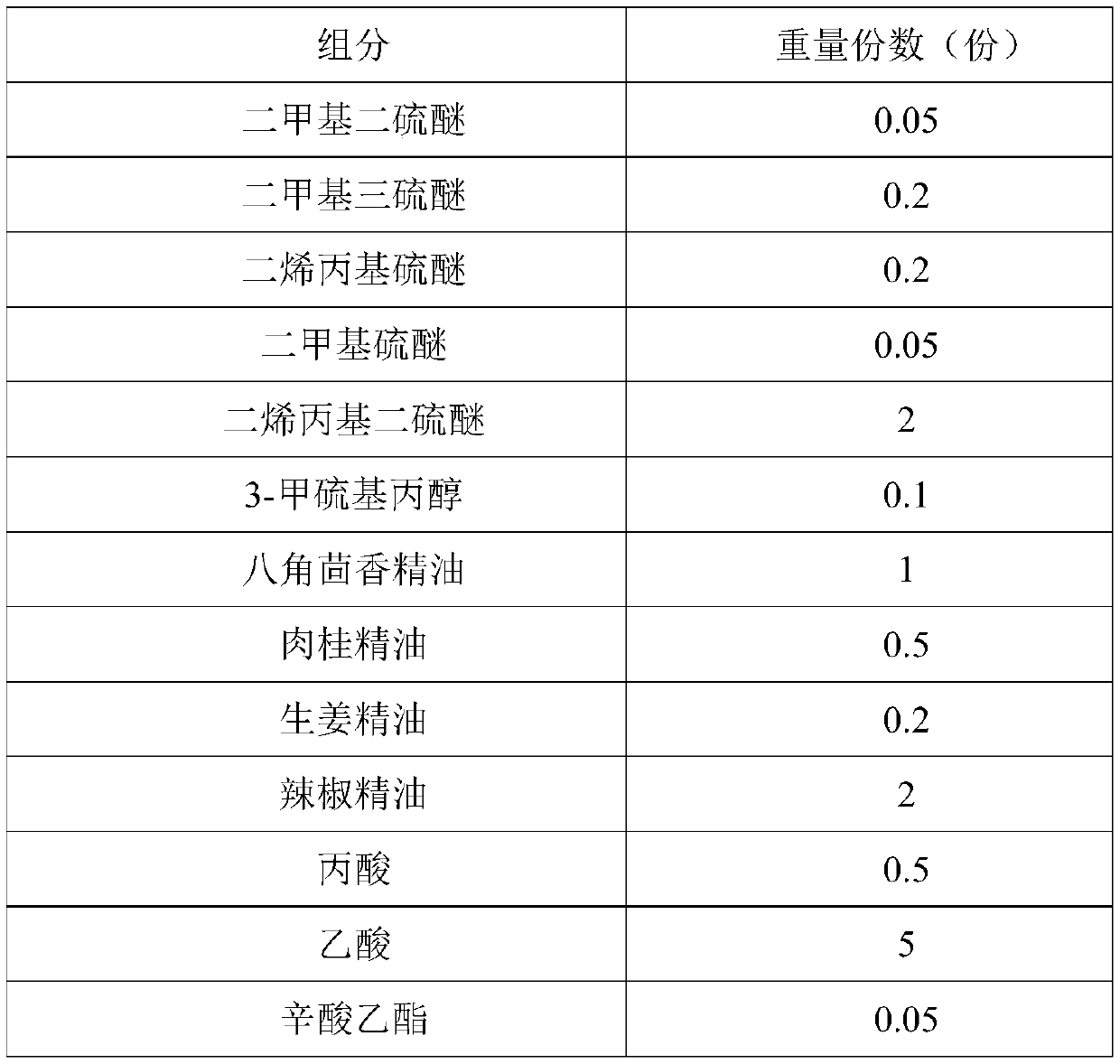

Preparation method of Korean pickled vegetable essence

ActiveCN110140935AFragrance aroma is pure and fullIncrease the fragranceClimate change adaptationAcidic food ingredientsPropanoic acidAllyl thiocyanate

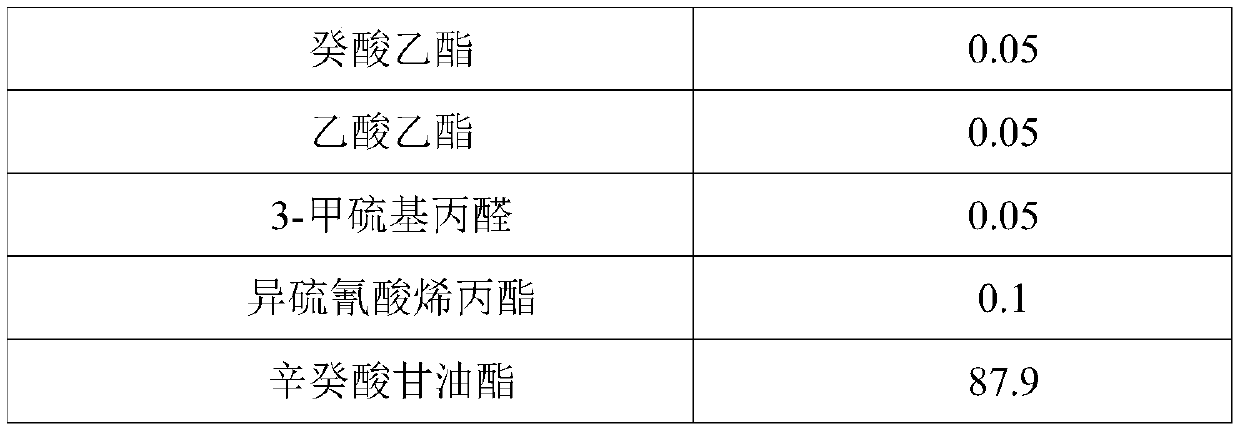

The invention provides a preparation method of Korean pickled vegetable essence. The disclosed Korean pickled vegetable essence comprises the ingredients of Caprylic capric triglycerride,, dimethyl disulfide, dimethyl trisulfide, diallyl sulfide, dimethyl sulfide, diallyl disulfide, 3-methylthiopropanol,, star anise essential oil, cinnamon essential oil, fresh ginger essential oil, chili pepper essential oil, propanoic acid, acetic acid, ethyl caprylate, ethyl caprate, ethyl acetate, 3-methylthiopropyl aldehyde and allyl isothiocyanate. The prepared pickled vegetable essence has the characteristics of being real and natural in fragrance, rich in mouth feel and stable in flavor, the appetence degree of a consumer is increased, and the Korean pickled vegetable essence can be well applied tothe field of foods of leisure puffed foods and the like.

Owner:江西省华宝孔雀食品科技发展有限公司

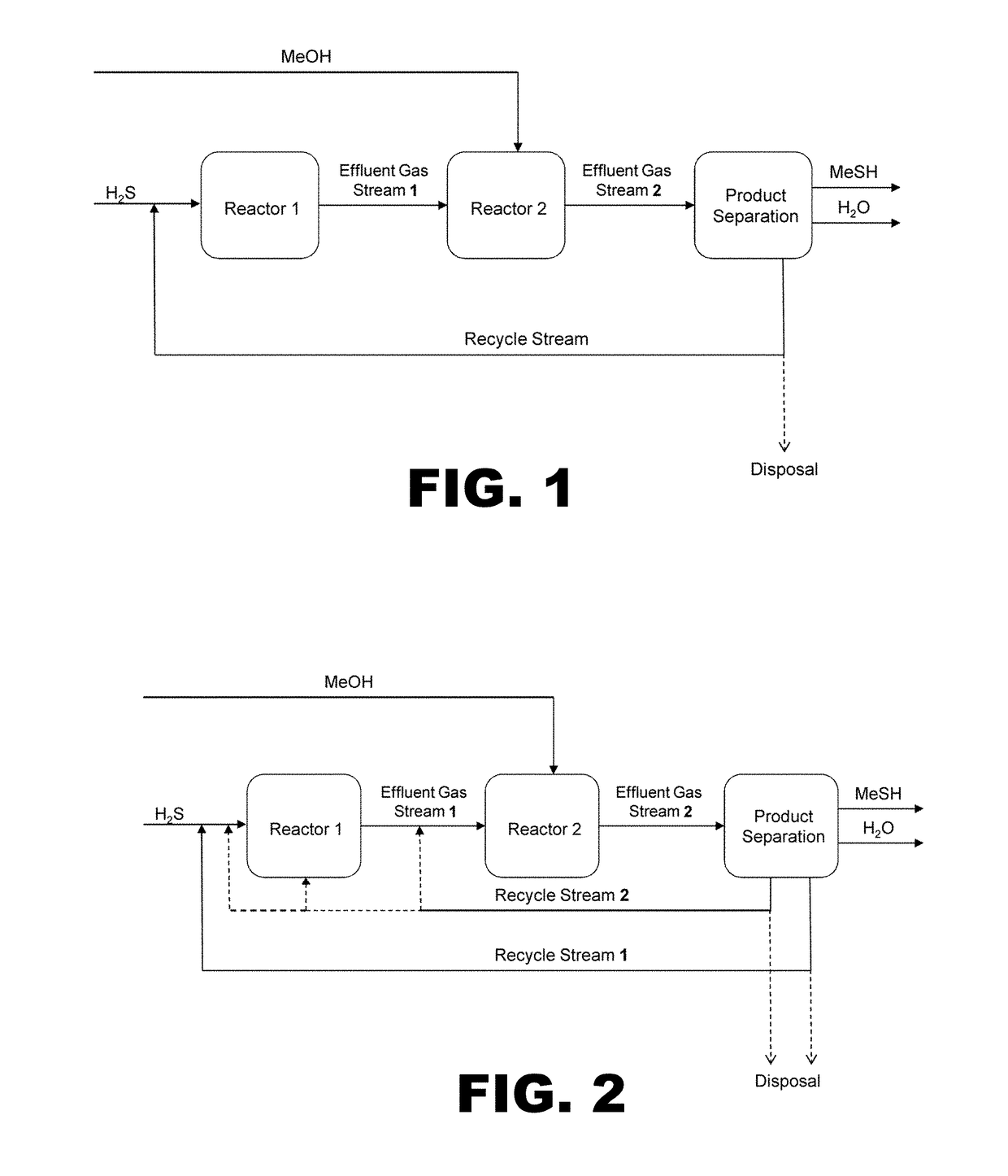

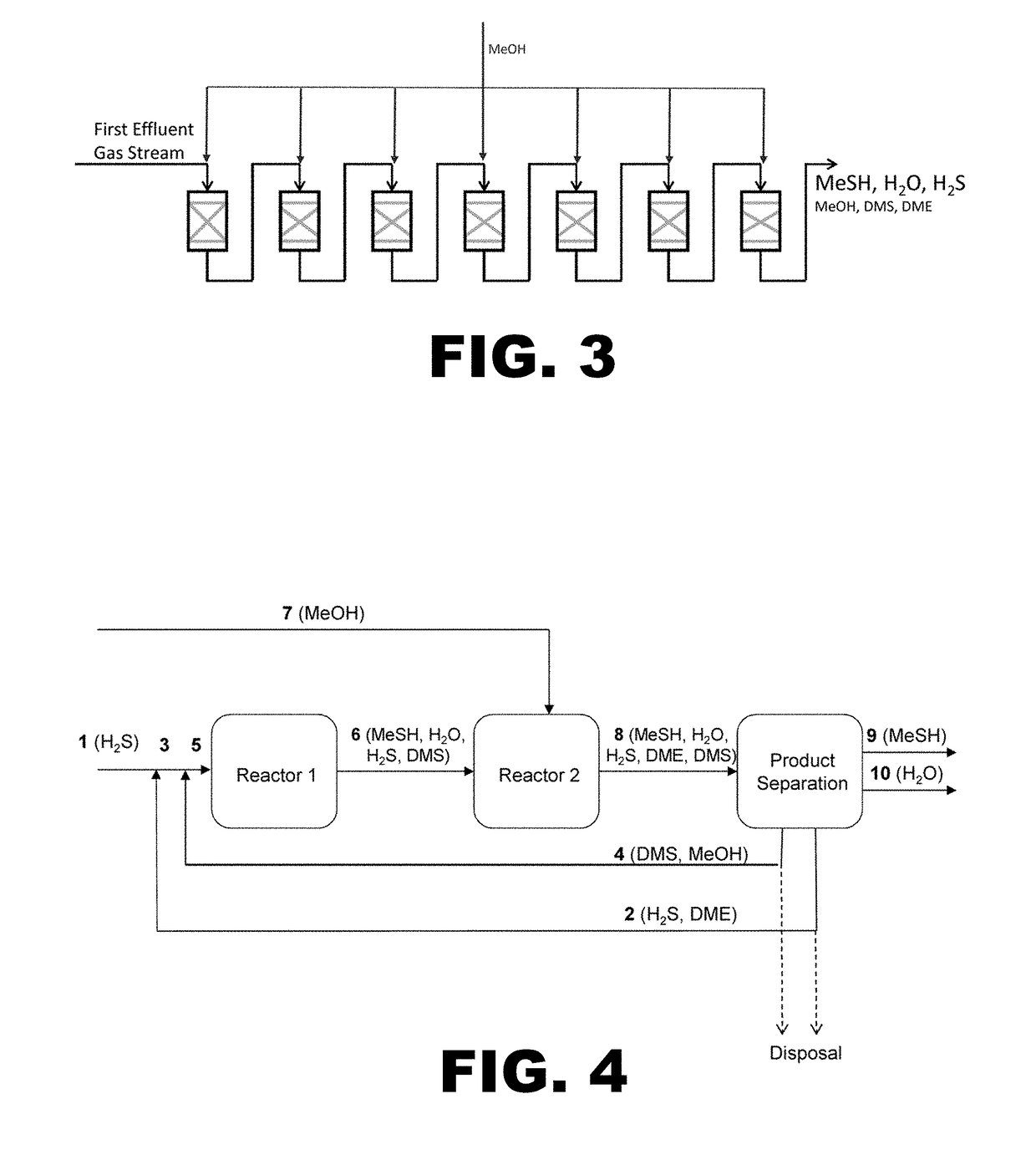

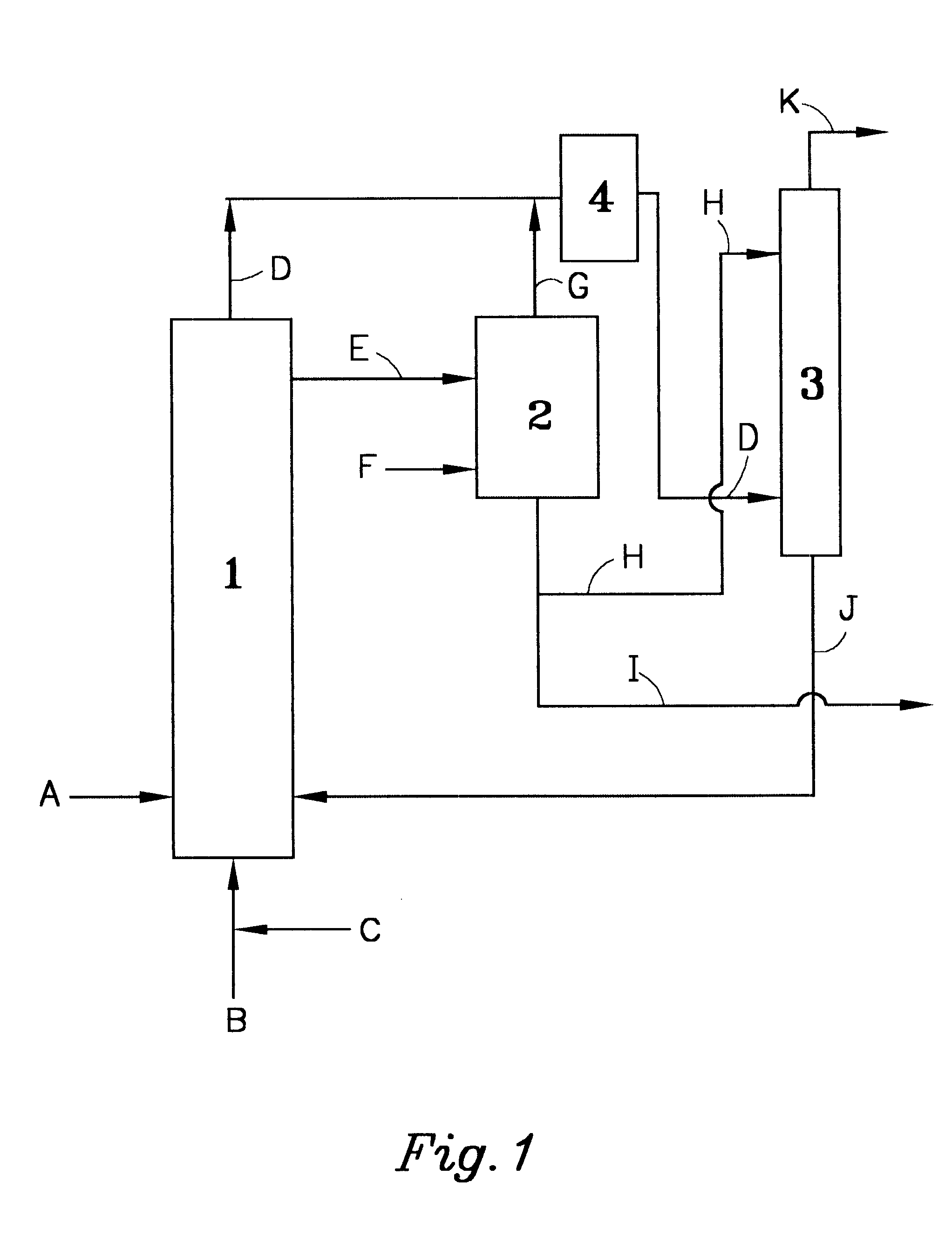

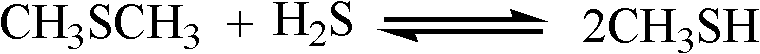

Process for producing methyl mercaptan from dimethyl sulfide

The present invention generally relates to the manufacture of methyl mercaptan using recycled dimethyl sulfide. In particular, the invention relates to a process for the continuous production of methyl mercaptan via the catalytic conversion of dimethyl sulfide using a non-promoted Al2O3 catalyst at low temperatures.

Owner:NOVUS INTERNATIONAL INC

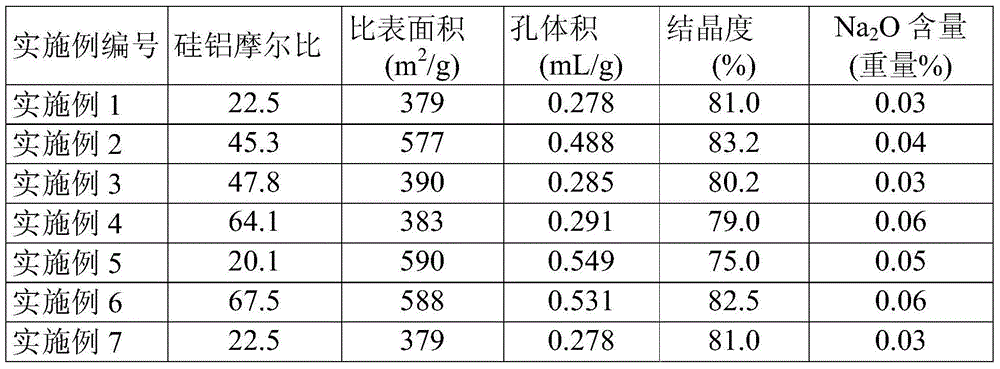

Process for producing dimethyl sulfoxide

InactiveUS6414193B1Efficient DMSO production processImprove disadvantagesPhysical/chemical process catalystsOrganic compound preparationMethyl sulfideAbsorption rate

The present invention provides an efficient dimethyl sulfoxide (DMSO) production process improved in the conversion from dimethyl sulfide (DMS) to DMSO by recycling the NOx used as a catalyst in the continuous oxidation reaction of DMS for producing DMSO, specifically providing a DMSO production process improved in the recovery rate and / or absorption rate of NOx by recovering NOx from the reaction off gas and / or the gas removed from the reaction product solution for re-utilization.

Owner:TORAY FINE CHEMICALS CO LTD

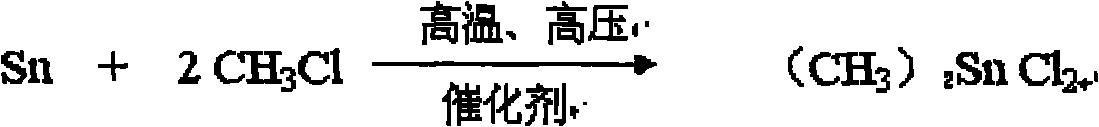

Process for synthesizing methyl tin chloride

The invention discloses a method for synthesizing methyl tin chloride. The invention adopts a synthesizing method by high pressure and one-step catalysis. The method comprises the following specific steps that: dimethyl thioether is used as a catalyst; tin powder and the methyl tin chloride are evenly mixed in a stainless steel high-pressure reaction kettle at a temperature of between 180 and 200 DEG C, passed through with methyl chloride and heated to a temperature of between 180 and 230 DEG C for carrying out a first reaction; after the methyl chloride is consumed, tin tetrachloride is added and methyl chloride is passed through to the mixture for carrying out a second reaction for 3 to 6 hours; and the mixture is subjected to decompression and distillation to prepare the methyl tin chloride. The method changes the prior synthesizing method which uses a grignard reagent to synthesize the methyl tin chloride; as the adopted catalyst is low molecular thioether, the catalyst has cheap price, shortens the process of synthesizing a methyl tin intermediate product; and the synthesized methyl tin intermediate product has high purity, contains no other impurities and has a yield reaching over 99 percent.

Owner:湖北犇星新能源材料有限公司

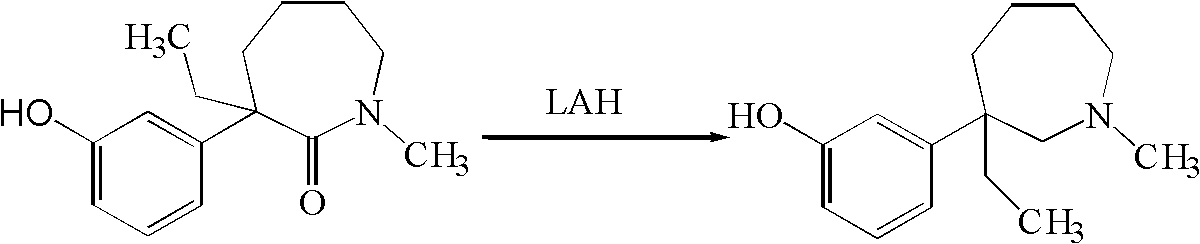

Method for preparing meptazinol and analogs thereof

The invention relates to a method for preparing meptazinol and analogs thereof, in particular to a method for preparing a compound shown in the general formula (1) from a compound shown in the general formula (2). Reducing agents are selected from one kind of or several kinds of materials in dihydro (2-methoxyethoxy) sodium aluminate (vitride solution), sodium borohydride, boron triflouride-aether, boron triflouride aether-sodium borohydride, boron triflouride and borane-methyl sulfide and is preferably the vitride solution. The reducing agents used in the method are stable in the air, in addition, the material addition is easy, and the quenching process can be completed in a shorter time, so the operation requirement is low, and the defect that the fire catching and the explosion are easy to occur in the traditional tetrahydro aluminum lithium reduction method is overcome.

Owner:CHINA RESOURCES DOUBLE CRANE PHARMA COMPANY

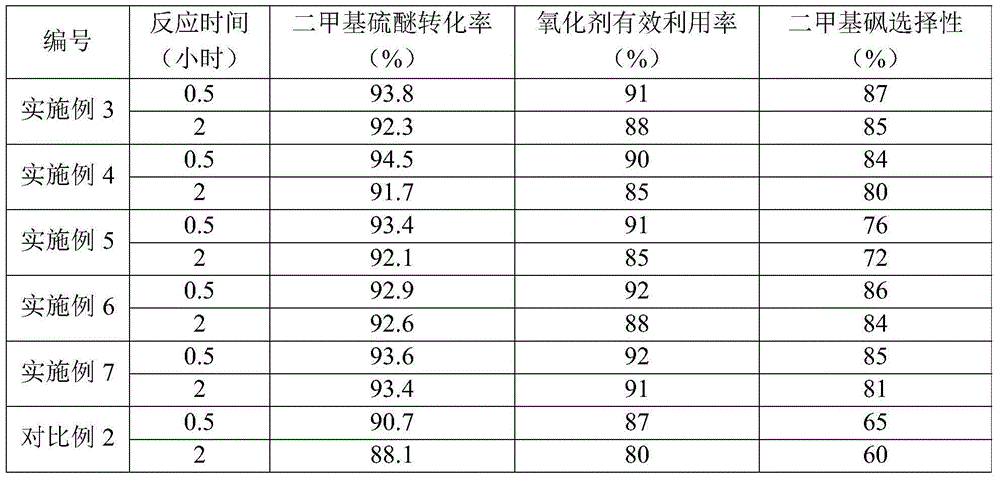

Method for oxidizing dimethyl sulfide

ActiveCN104557635AHigh selectivityImprove conversion rateOrganic chemistryOrganic compound preparationMolecular sieveMethyl sulfide

The invention provides a method for oxidizing dimethyl sulfide. The method comprises the step of contacting a liquid mixture with a least one titanium silicate molecular sieve serving as a catalyst under the condition of an oxidation reaction, wherein the liquid mixture contains dimethyl sulfide and at least one oxidant, and the pH value of the liquid mixture is 0.5-5.5. Compared with the method for directly contacting a liquid mixture of dimethyl sulfide and the oxidant with a titanium silicate molecular sieve, the method can be used for remarkably improving the selectivity of dimethyl sulfone and receiving high dimethyl sulfide conversion rate and high oxidant effective utilization rate. Furthermore, under a situation that other conditions are the same, a basically same dimethyl sulfide conversion rate, a higher oxidant effective utilization rate and dimethyl sulfone selectivity can be obtained by the method even at a lower temperature. Furthermore, the method is easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP +1

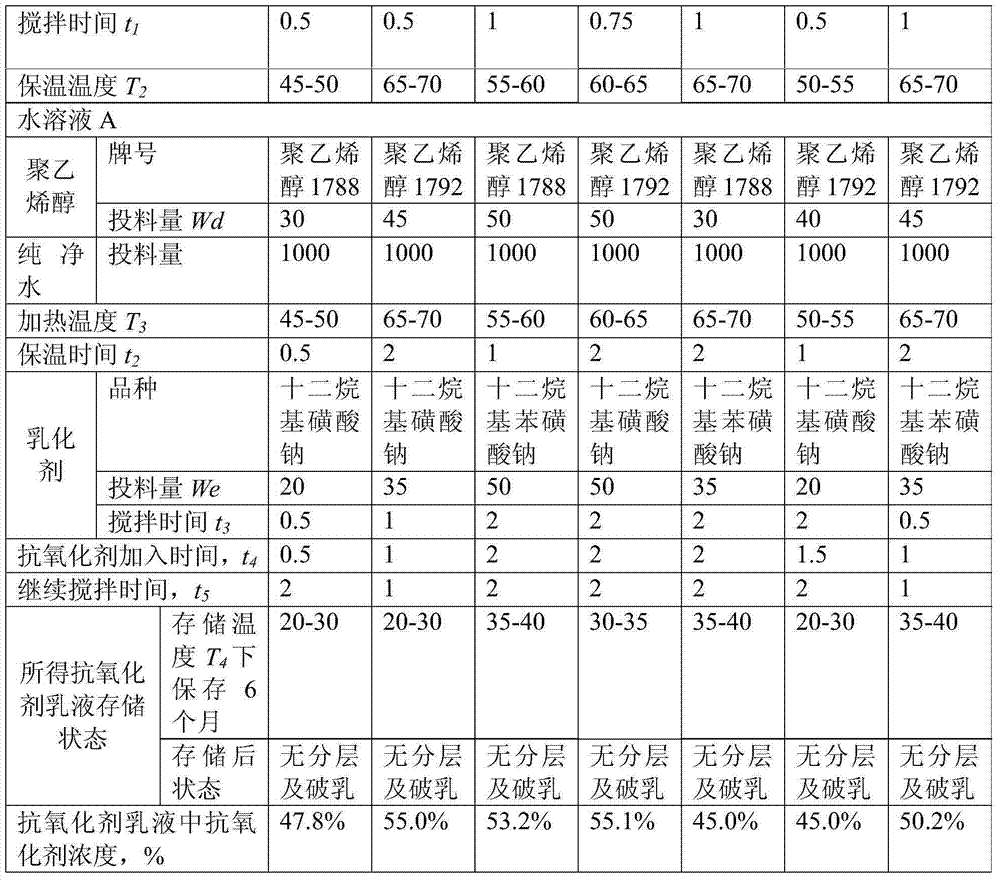

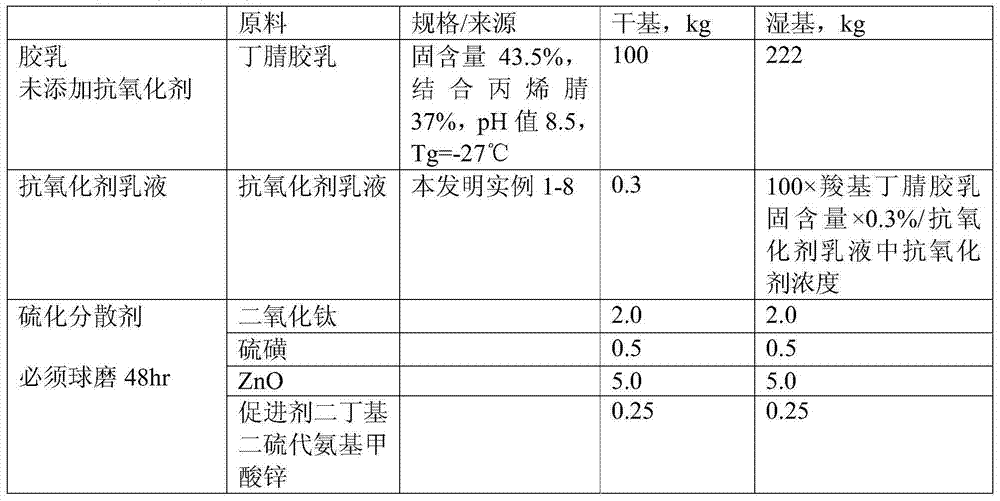

Antioxidant applied to acrylonitrile-butadiene rubber latex and carboxylic acrylonitrile butadiene rubber latex and preparation method

The invention relates to an antioxidant applied to acrylonitrile-butadiene rubber latex and carboxylic acrylonitrile butadiene rubber latex and a preparation method. The antioxidant comprises the following components: (a) component, i.e., one or combination of two of 4,6-bis(octylsulfanyl methyl) orthocresol (a1) or 4,6-bis(n-dodecyl methyl sulfide) orthocresol (a2); (b) component, i.e., one or combination of two of 3,5-di-tert-butyl-4-isooctyl hydroxyphenyl propionate (b1) or 3,5-di-tert-butyl-4-hydroxybenzene propanoic acid C7-C9 mixed alcohol ester (b2), and (c) component, i.e., ditridecyl thiodipropionate. After the antioxidant is prepared into emulsion and is applied to the acrylonitrile-butadiene rubber latex and the carboxylic acrylonitrile butadiene rubber latex to be prepared into a finished product, the antioxidant emulsion system has an ideal anti-oxidation effect; the application performance of the product is measured after long-term aging under a thermal oxidation condition; the superior long-term thermal oxidation stability of the antioxidant emulsion on the product is also displayed.

Owner:RIANLON

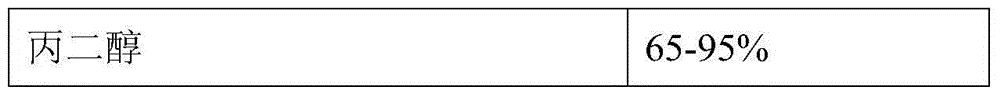

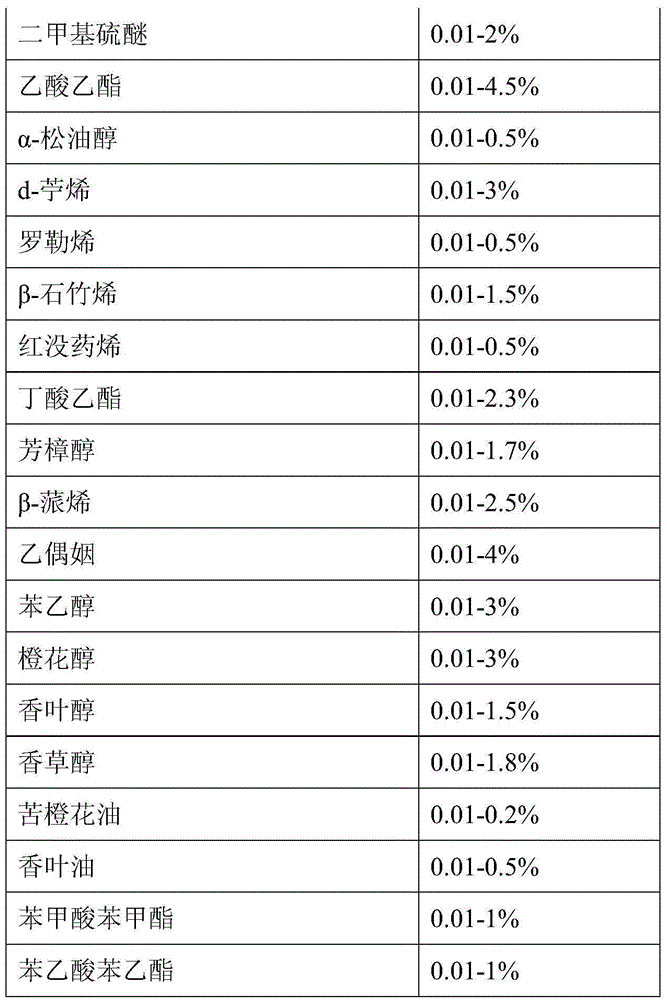

Litchi essence

ActiveCN104611134AHuge sales marketReduce dosageEssential-oils/perfumesFood preparationEthyl butyratePhenethyl alcohol

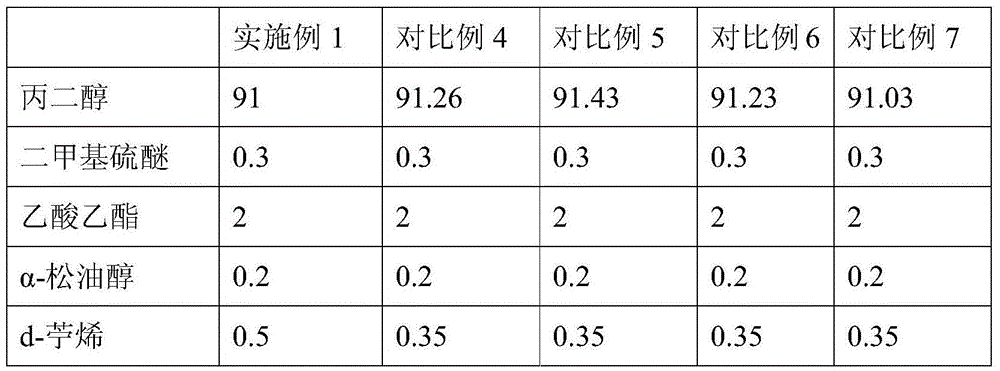

The invention discloses litchi essence which comprises the following components in percentage by weight: 65-95% of propylene glycol, 0.01-2% of dimethyl sulfide, 0.01-4.5% of ethyl acetate, 0.01-0.5% of alpha-terpilenol, 0.01-3% of d-limonene, 0.01-0.5% of ocimene, 0.01-1.5% of beta-caryophyllene, 0.01-0.5% of bisabolene, 0.01-2.3% of ethyl butyrate, 0.01-1.7% of linalool, 0.01-2.5% of beta-pinene, 0.01-4% of acetoin, 0.01-3% of phenethyl alcohol, 0.01-3% of nerol, 0.01-1.5% of geraniol, 0.01-1.8% of vanillyl alcohol, 0.01-0.2% of bitter orange flower oil, 0.01-0.5% of geranium oil, 0.01-1% of benzyl benzoate and 0.01-1% of 2-phenethyl phenylacetate.

Owner:阳江喜之郎果冻制造有限公司

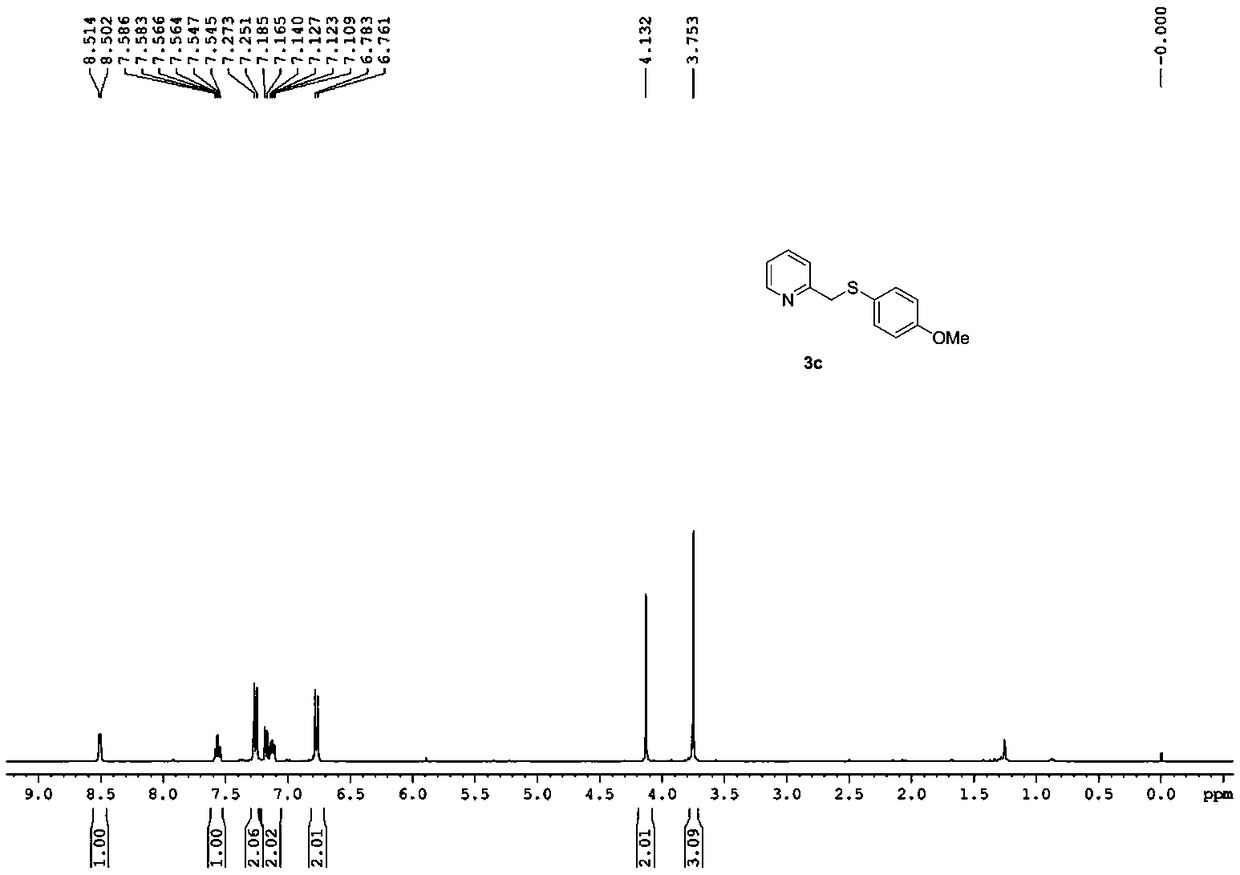

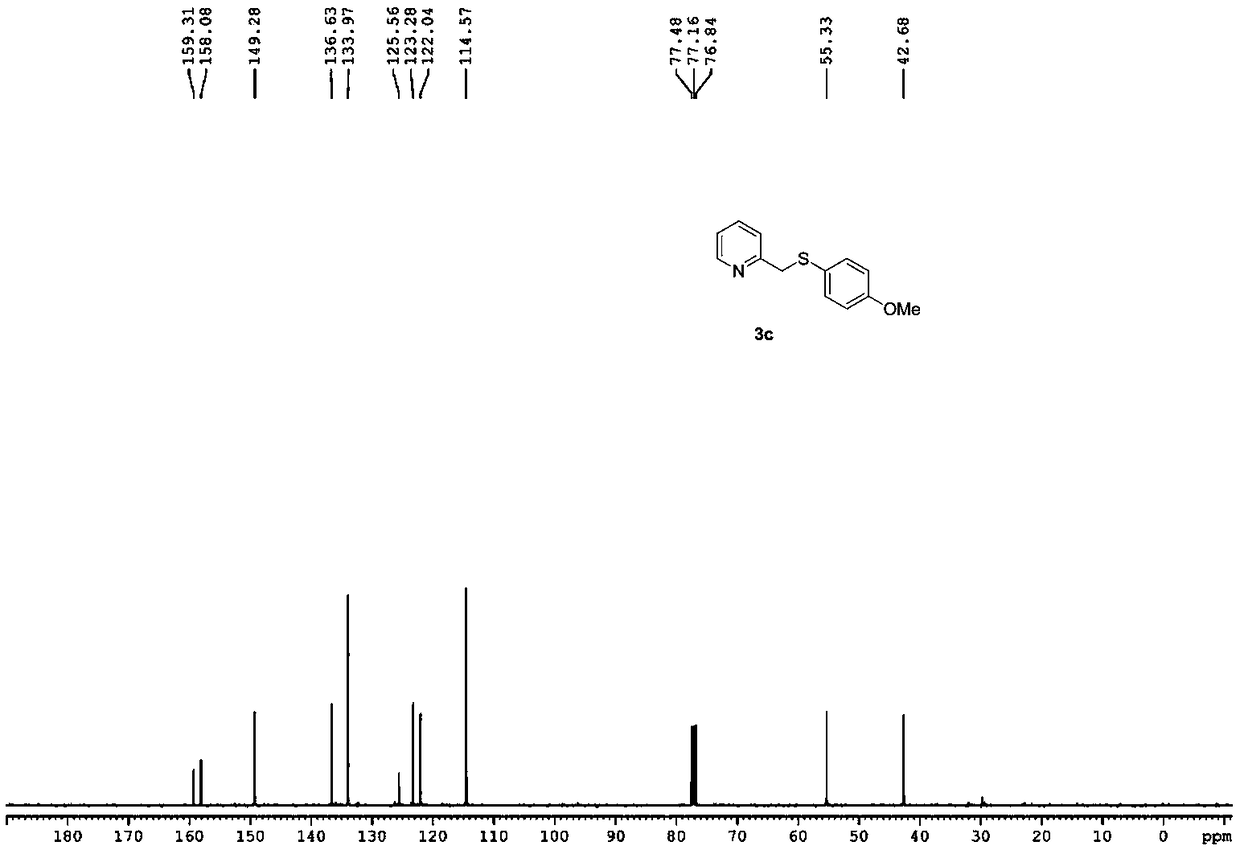

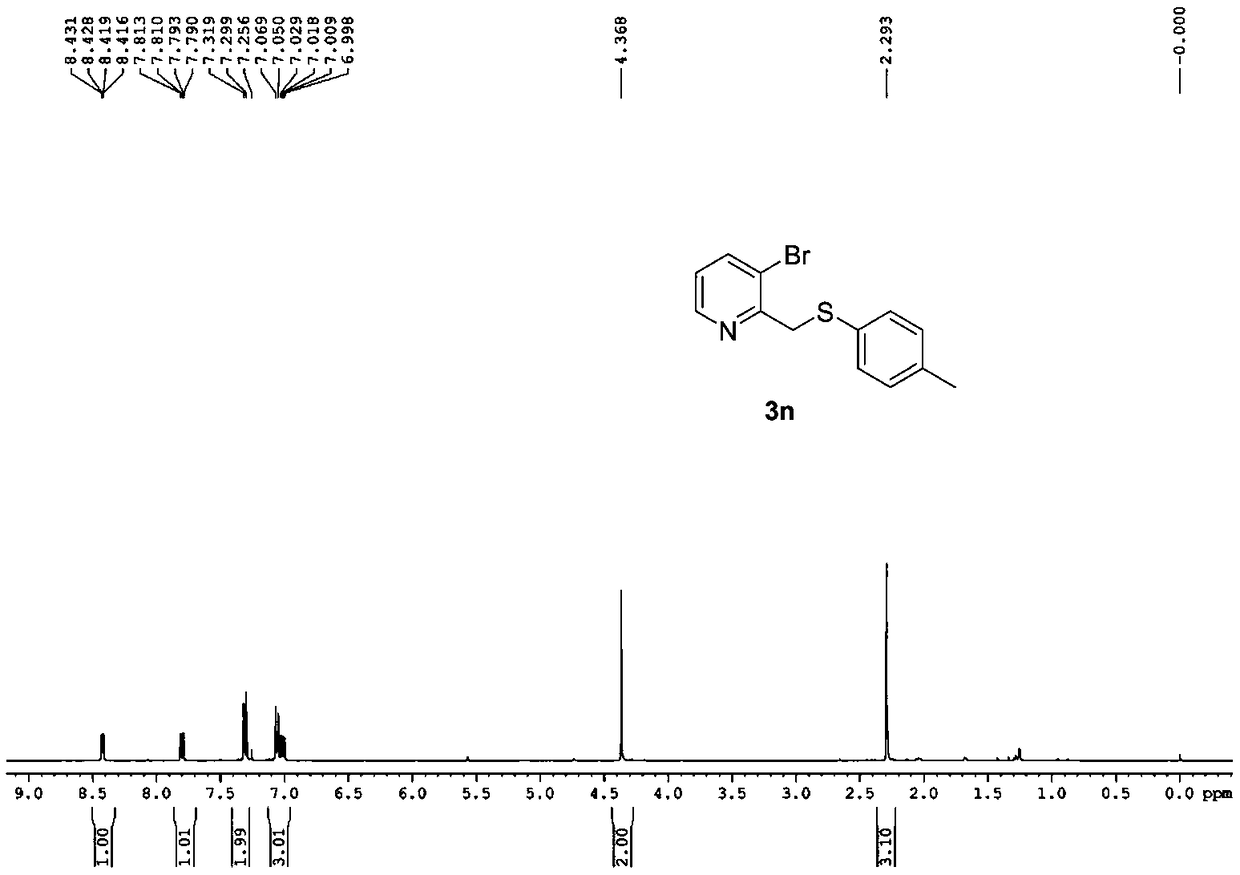

Synthesizing method of 2-pyridine methyl sulfide and synthesizing process of related drugs

ActiveCN109134354AStrong position selectivityHigh yieldOrganic chemistryLithium bromidePyridine-N-oxide

The invention relates to a simple synthesizing method of 2-pyridine methyl sulfide and related drugs. The method is characterized in that 2-methyl pyridine n-oxide is used as the raw material and pyridine n-oxide or dichloromethane is used as the solvent to have reaction with trifluoroacetic anhydride to obtain a trifluoroacetate intermediate, purification is not needed, the trifluoroacetate intermediate is allowed to have reaction with thiophenol under the catalysis of lithium bromide or tetrabutyl ammonium bromide and by using toluene or ethyl acetate as the solvent to generate the 2-pyridine methyl sulfide. The method is simple to operate, cheap in reagents, easy in reagent obtaining, mild in reaction conditions, wide in substrate applicability, good in position selectivity, high in yield and the like. In addition, the method is successfully applied to the synthesizing of omeprazole sulfide and rabeprazole sulfide, and the synthesizing method does not need catalysts.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

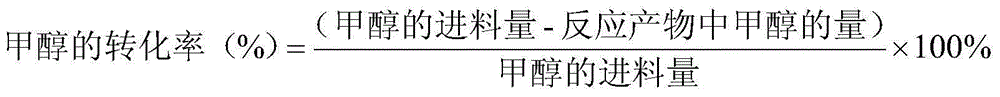

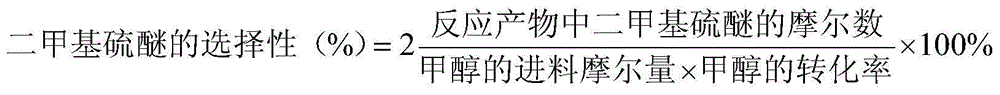

Preparation method of dimethyl sulfide

ActiveCN104974066AImprove conversion rateHigh selectivityMolecular sieve catalystsSulfide preparationMolecular sieveAlkaline water

The invention discloses a preparation method of dimethyl sulfide. The method comprises the step of reacting hydrogen sulfide with methanol in the presence of a modified molecular sieve catalyst to generate dimethyl sulphide, and is characterized by preparing the modified molecular sieve catalyst by firstly processing a molecular sieve catalyst with an alkaline water solution and then washing the molecular sieve catalyst with an acid solution. By adopting the method, reaction between hydrogen sulfide and methanol can be effectively catalyzed, and methanol can have a higher conversion rate while higher selectivity of dimethyl sulfide can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

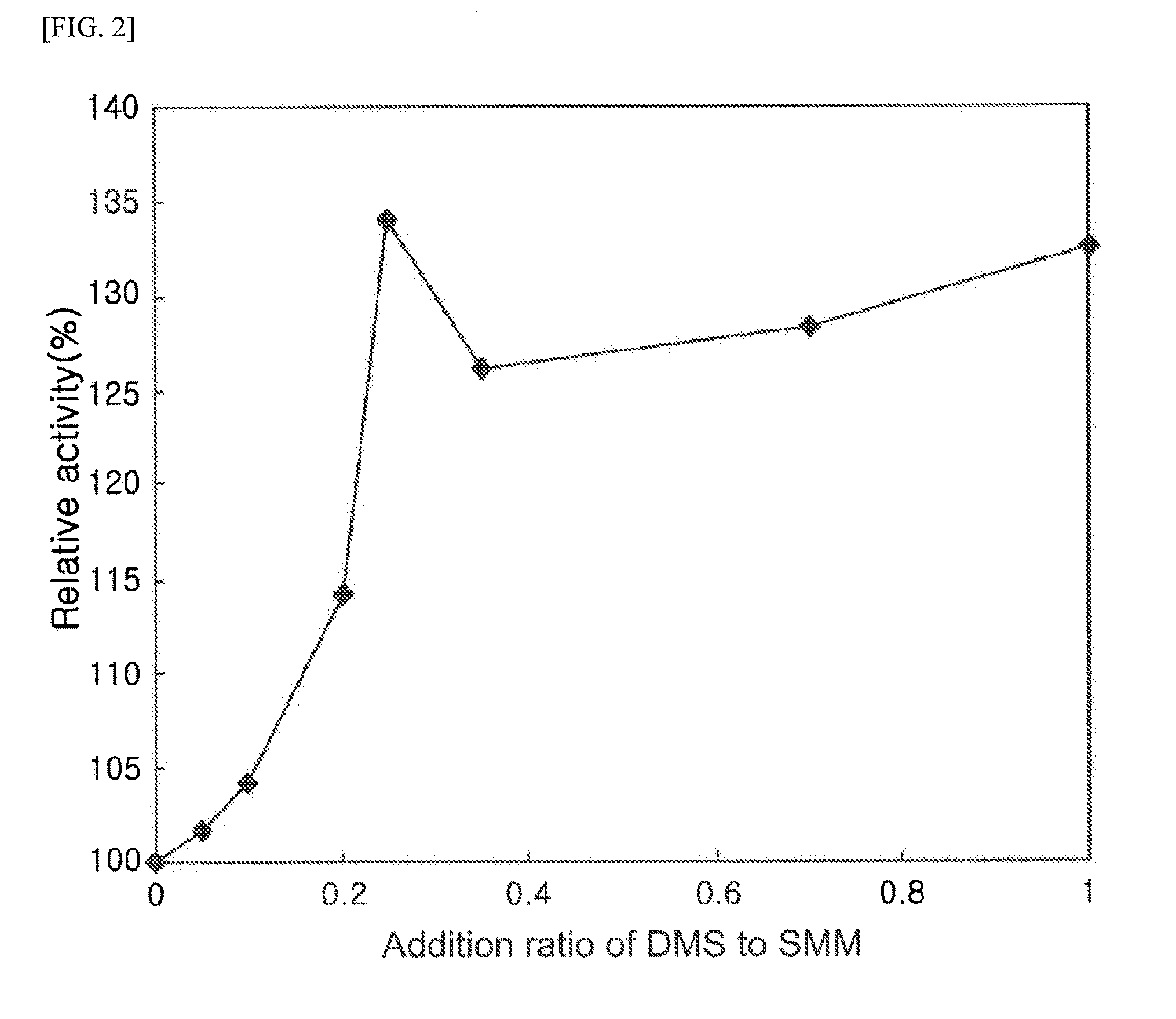

Method for Increasing Methionine Productivity Using a Mixture of Methyl Mercaptan and Dimethyl Sulfide

ActiveUS20120123158A1Low costImprove productivityOrganic chemistryFermentationHomoserineProduction rate

The present invention relates to a method for increasing L-methionine productivity and organic acid productivity. More particularly, the present invention relates to a method which involves adding a mixture containing methyl mercaptan and dimethyl sulfide at a appropriate ratio to O-acetyl homoserine or O-succinyl homoserine and to an enzyme having an activity of converting methionine precursor into L-methionine, so as to perform an enzyme reaction, to thereby improve the conversion rate of L-methionine and organic acid from the L-methionine precursor, and thus increasing L-methionine yield as compared to conventional method.

Owner:CJ CHEILJEDANG CORP

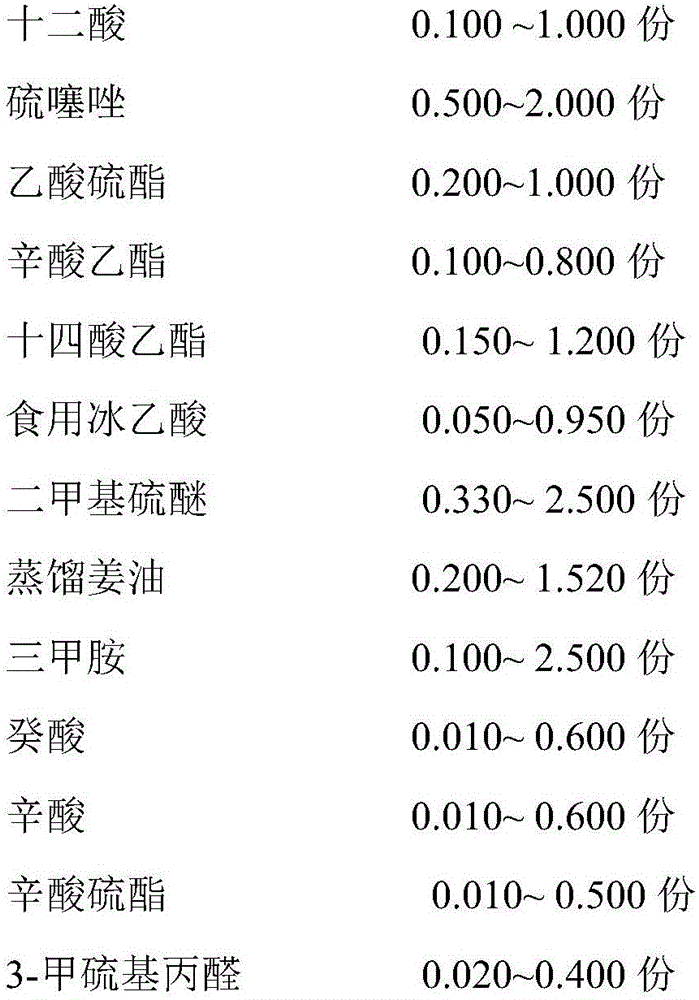

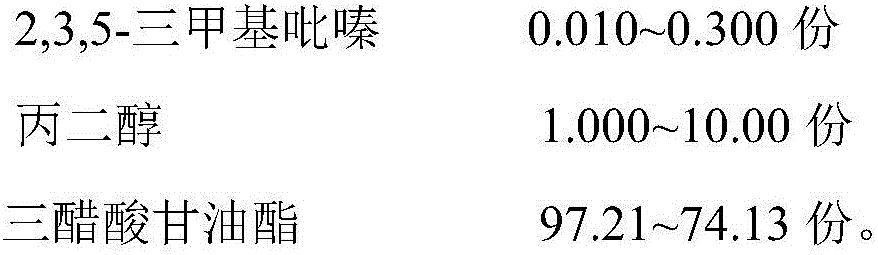

Crab-flavored essence, as well as preparation method and application thereof

The invention discloses a crab essence and its preparation method and application. The crab essence contains dodecanoic acid, thiothiazole, thioacetate, ethyl octanoate, ethyl myristate, edible glacial acetic acid, dimethyl sulfide, Distilled ginger oil, trimethylamine, capric acid, caprylic acid, caprylic acid thioester, 3-methylthiopropanal, 2,3,5-trimethylpyrazine, propylene glycol and glyceryl triacetate, the present invention has developed a specific formula Crab flavor, just a small amount, has the effect of strong crab meat, good fresh and sweet taste, and high fidelity, and is loved by a wide range of consumers; and even after high-temperature roasting, frying, and steaming, it will not affect the effect of crab flavor. It shows that the crab essence of the present invention has the properties of high temperature resistance and stable flavor. The crab essence of the invention can well supplement the flavor loss of the recombined crab meat due to thermal processing, enhance the sweetness and authenticity of the crab meat-flavored meatballs, and improve consumers' liking.

Owner:江西省华宝孔雀食品科技发展有限公司

Phosphorous catalyst for synthesizing methyl mercaptan and preparation method thereof

InactiveCN102247873APolyacid centerImprove pore structurePhysical/chemical process catalystsThiol preparationMethyl sulfideChemistry

The invention relates to a catalyst and provides a phosphorous catalyst with higher methyl sulfide transformation rate and methyl mercaptan selectivity for synthesizing the methyl mercaptan, and a preparation method thereof. The phosphorous catalyst is phosphorus modified alumina, the content of phosphorus contained in the phosphorous catalyst is 1-10 percent and preferably 3-5 percent, and the balance is alumina. The preparation method comprises the following steps of: dissolving a metered aluminum precursor by using water to prepare an aluminum solution; heating the aluminum solution, and then adding a metered phosphorus precursor solution and a dispersing agent, stirring, and adding a precipitator to form a gel solution at the same time; regulating the pH value of the gel solution to 5-9, and then ageing; drying the aged gel to constant weight, and then calcining to obtain the phosphorous catalyst for synthesizing the methyl mercaptan.

Owner:XIAMEN UNIV +1

Method for simultaneously producing dimethyl sulfone and dimethyl sulfoxide

ActiveCN105367463AImprove conversion rateLow running costOrganic chemistryOrganic compound preparationDimethyl SulphoneMethyl sulfide

The invention discloses a method for simultaneously producing dimethyl sulfone and dimethyl sulfoxide. The method comprises the steps that firstly, methyl sulfide reacts under the condition that dimethyl sulfone can be formed, a mixture containing dimethyl sulfone is obtained, and after dimethyl sulfone is freely separated out of the mixture and is further in contact and reacts with the other part of methyl sulfide, an unreacted oxidizing agent is utilized for oxidizing methyl sulfide to form dimethyl sulfoxide. The conversion rate of the oxidizing agent is effectively improved, running cost is reduced, and the requirement for subsequent residual oxidizing agent treatment and other steps is lowered. According to the method, high target oxidation product selectivity can be achieved during the two-step oxidizing reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

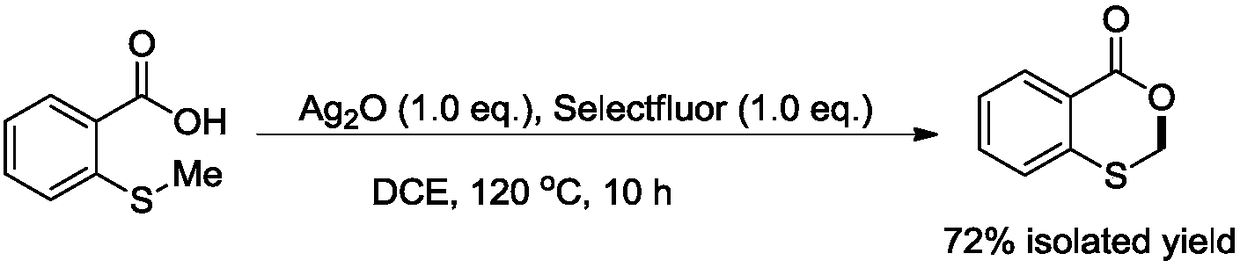

Novel method for preparing benzo 1,3-oxathiane-4-ketone

The invention relates to the technical field of fine chemical engineering and discloses a novel method for preparing benzo 1,3-oxathiane-4-ketone. The method includes steps: taking 2-carboxyphenyl dimethyl sulfide as a raw material, taking silver oxide and 1-chloromethyl-4-fluoro-1,4-diazabicyclo[2.2.2]octane di(tetrafluoroboric acid) salt as additives, and subjecting to reaction in 1,2-dichloroethane at 120 DEG C for 10 hours to obtain benzo 1,3-oxathiane-4-ketone. Compared with an existing method, the novel method has advantages that quickness and simplicity are realized, commercial 2-carboxyphenyl methyl sulfide is directly used as a reaction raw material to realize one-step direct construction of a target product, and novel reaction, simplicity in operation, high efficiency, potentialindustrial values and worthiness of popularization and application are realized.

Owner:CHANGZHOU UNIV

Technique for preparing middle raw material for producing methyl mercaptan and/or dimethyl sulfide by natural gas

InactiveCN107010606AAvoid problems that are not suitable for long-distance transportationReduce shipping costsCarbon disulfideThiol preparationHydrogenChemical reaction

The invention discloses a technique for preparing middle raw material for producing methyl mercaptan and / or dimethyl sulfide by natural gas. The technique includes steps of after preheating, mixing natural gas and sulphur in a device and heating to 600-700 DEG C, and preforming partial chemical reaction; reacting in a adiabatic reactor to obtain a mixed gas containing hydrogen sulfide and carbon disulfide; cooling the reacted mixed gas to 120-200 DEG C and performing gas and fluid separation, wherein the obtained gas is the middle raw material for producing methyl mercaptan and / or dimethyl sulfide. Through the natural gas sulfuration technique, the sulfuretted hydrogen, carbon disulfide and other middle raw materials for producing methyl mercaptan and / or dimethyl sulfide are obtained; thus the methyl mercaptan and dimethyl sulfide is further produced; the technique is featured by being low in raw material cost, convenient to convey and adaptable to domestic natural gas with high sulfur content.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Method for synthesizing and producing dimethyl disulfide from methyl mercaptan and dimethyl sulfoxide

InactiveCN103910662AReduce production processEasy to produceHydropoly/poly sulfide preparationPtru catalystMethyl sulfide

A method for synthesizing and producing dimethyl disulfide from methyl mercaptan and dimethyl sulfoxide comprises the following steps: introducing methyl mercaptan and dimethyl sulfoxide according to a molar ratio of 2:0.95-1.55 into a reactor, in the presence of an aluminium oxide catalyst, performing synthetic reaction to obtain reaction products dimethyl disulfide, dimethyl sulfide and water, performing condensation, cooling and standing separation on the reaction products to obtain a crude product dimethyl disulfide, and performing rectification to obtain a qualified dimethyl disulfide finished product. The methyl mercaptan synthetic process is employed for obtaining dimethyl disulfide, and the method is simple in production process, low in production cost, beneficial for large-scale industrialized production and less in produced ''three wastes (waste gas, waste water and industrial residue)'' discharge, and has substantial social benefic and economic benefit.

Owner:HUBEI XINGFA CHEM GRP CO LTD

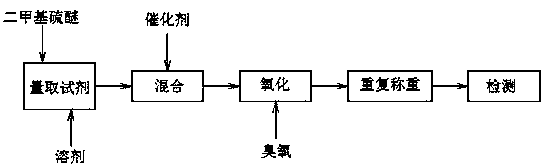

Method for preparing dimethyl sulfoxide from dimethyl sulfide

InactiveCN107698472AReduce riskOxidation reaction is rapidOrganic chemistryOrganic compound preparationHigh concentrationSolvent

The invention discloses a method for preparing dimethyl sulfoxide from dimethyl sulfide, and relates to methods for preparing dimethyl sulfoxide. Oxidization reaction is carried out under the pressures ranging from -0.1 Mpa to 0.5 Mpa at the temperatures ranging from 0 DEG C to 70 DEG C. The method has the advantages that the dimethyl sulfide is dissolved in solvents, the chance of forming explosive mixtures by dimethyl sulfide steam and oxygen can be prevented in the presence of the solvents, and uniform mixed solution can be formed; the mixed solution is filled with high-concentration ozoneunder the condition of the presence of catalysts; the ozone is used as an oxidizing agent, and bubble reaction is carried out in a vertical-pipe reactor with a large length-diameter ratio; oxidized dimethyl sulfide is converted into the dimethyl sulfoxide in the procedure, the pressures and the temperatures of reaction systems are controlled, the stage for oxidizing the dimethyl sulfide to obtainsulfoxide can be controlled by added selective catalysts, the reaction conversion rate is 95-98%, and the yield can reach 90-96%; efficient, complete, environment-friendly and high-selectivity technologies can be created for preparing the sulfoxide from the dimethyl sulfide by means of oxidization by the method.

Owner:辽宁省轻工设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com