Method for preparing dimethyl sulfoxide

A technology of dimethyl sulfoxide and dimethyl sulfide, which is applied in the field of preparation of dimethyl sulfoxide, can solve the problems of unsuitable large-scale production and high cost of anodization, and achieves easy control, good activity stability, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0076] The tin-silica molecular sieve Sn-β was prepared according to the method described in NATURE, 2001, Vol. 412, pages 423-425. The specific preparation process is as follows.

[0077] At 25°C, add 30g of ethyl orthosilicate (TEOS) to 32.99g of tetraethylammonium hydroxide (TEAOH, 35% by weight) aqueous solution, stir to mix and hydrolyze, add tin tetrachloride aqueous solution after 90 minutes (It is formed by dissolving 0.43 g of tin tetrachloride pentahydrate in 2.75 g of water), continue to stir until a clear solution is obtained. Add 3.2 g of hydrofluoric acid (48% by weight) to the above clear solution to obtain a paste-like mixture, and then add the seed suspension (formed by suspending 0.36 g of dealuminated β molecular sieve in 1.75 g of water) and stir well. The obtained mixture was transferred into a stainless steel reaction kettle lined with polytetrafluoroethylene and dynamically crystallized at 140°C for 480 hours. The crystallization product is subjected to s...

preparation example 2

[0080] According to Zeolites, 1992, Volume 12, page 943-950 described in the preparation of titanium silicate molecular sieve SnS-1, the difference is that the tetrabutyl titanate is replaced by tin tetrachloride pentahydrate , The specific preparation process is as follows.

[0081] At room temperature (20°C), 22.5g of tetraethylorthosilicate, 7.0g of tetrapropylammonium hydroxide and 59.8g of distilled water were stirred and reacted under normal pressure and 60°C for 1.0 hour to obtain a tetraethylorthosilicate Hydrolysis solution. With vigorous stirring, a tin tetrachloride solution (formed by dissolving 1.1 g of tin tetrachloride pentahydrate in 5.0 g of anhydrous isopropanol) was slowly added to the hydrolysis solution, and the resulting mixture was stirred at 75°C for 3 Hours, a clear transparent colloid is obtained. This colloid was placed in a stainless steel sealed reactor and placed at a constant temperature of 170°C for 72 hours. Then, the obtained crystallization m...

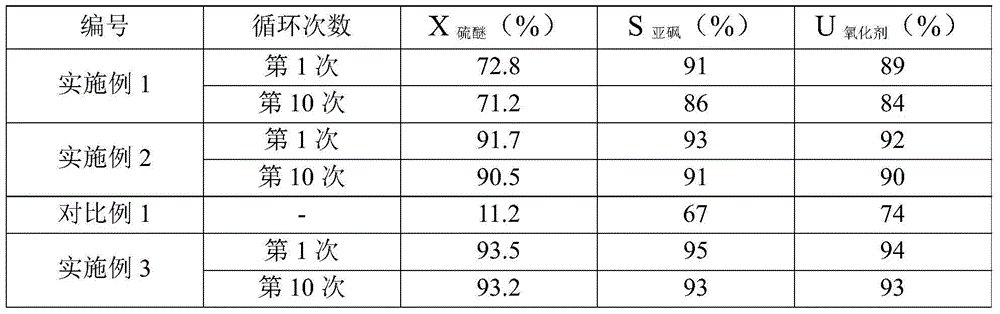

Embodiment 1

[0085] Put dimethyl sulfide, hydrogen peroxide, methanol and tin-silica molecular sieve Sn-β into the reaction kettle, with stirring, and react for 2 hours. The obtained mixture is filtered to obtain the recovered tin silicon molecular sieve and a liquid phase containing dimethyl sulfoxide. Among them, the reaction conditions include: the molar ratio of dimethyl sulfide to hydrogen peroxide is 1:1, the mass ratio of dimethyl sulfide to tin silicon molecular sieve is 25:1, the mass ratio of methanol to dimethyl sulfide It is 200:1, the reaction temperature is 30°C, and the pressure in the reactor is 0.5MPa.

[0086] The recovered tin-silicon molecular sieve is re-mixed with dimethyl sulfide, hydrogen peroxide and methanol according to the above method, and then sent to the reactor to continue the next reaction. Among them, tin-silica molecular sieve is recycled 10 times. During the reaction process, the composition of the mixture output from the reactor was detected each time, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com