Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3097results about "Sulfide preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

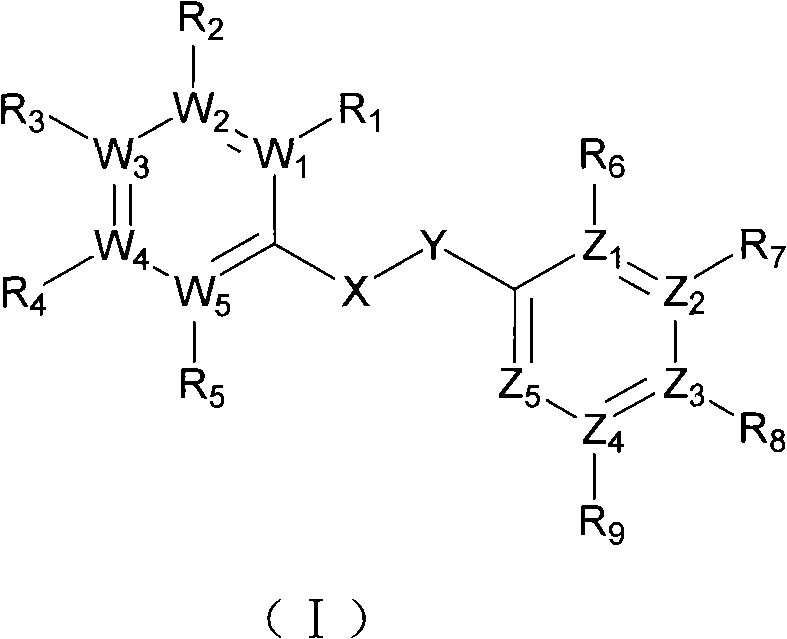

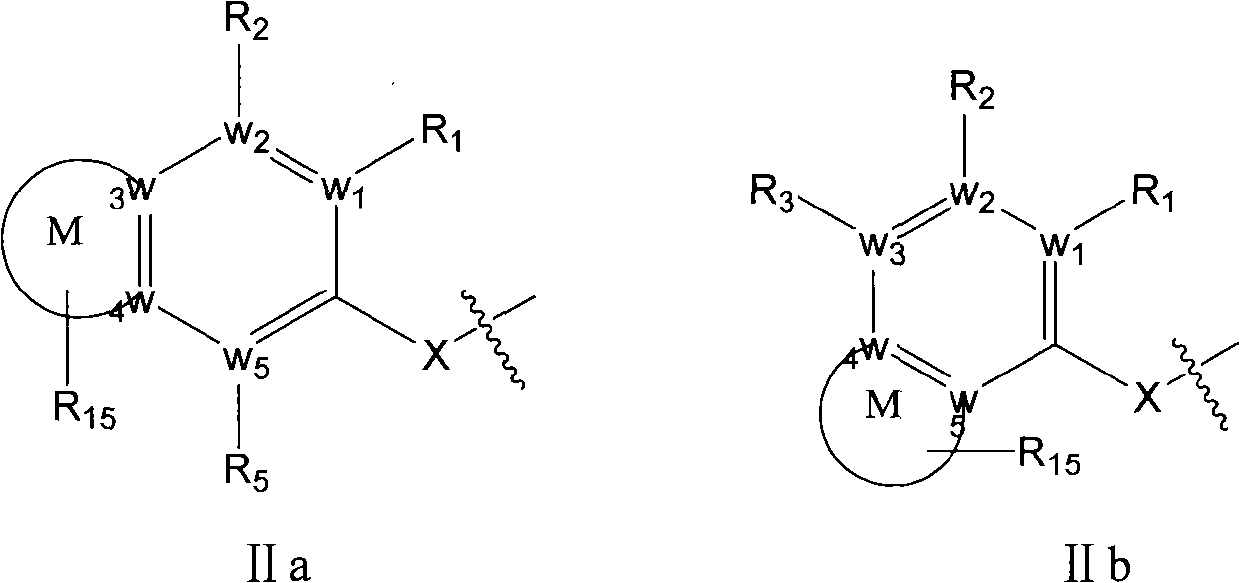

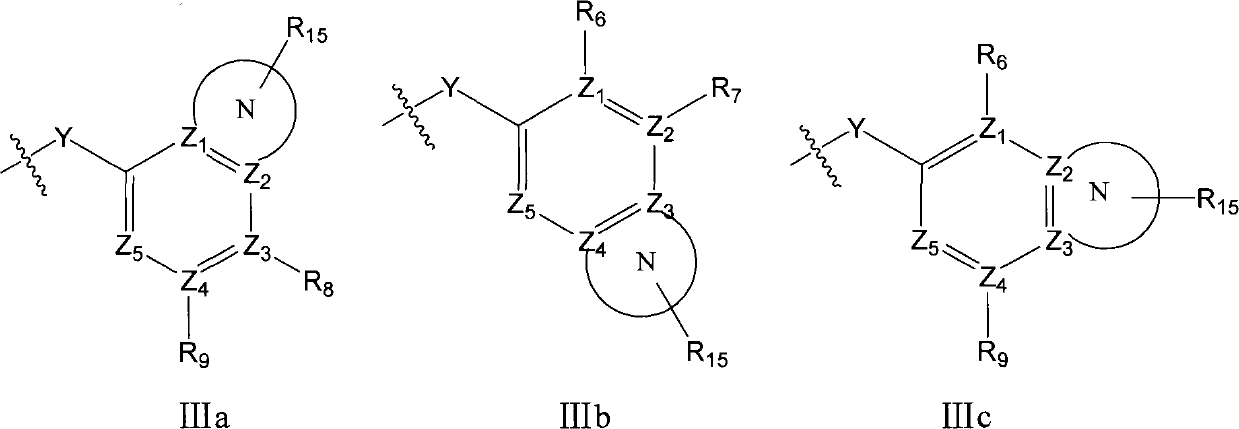

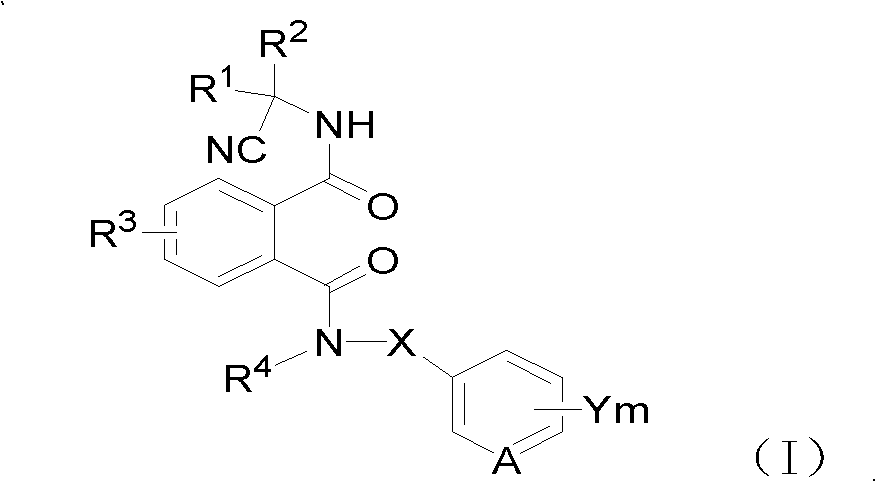

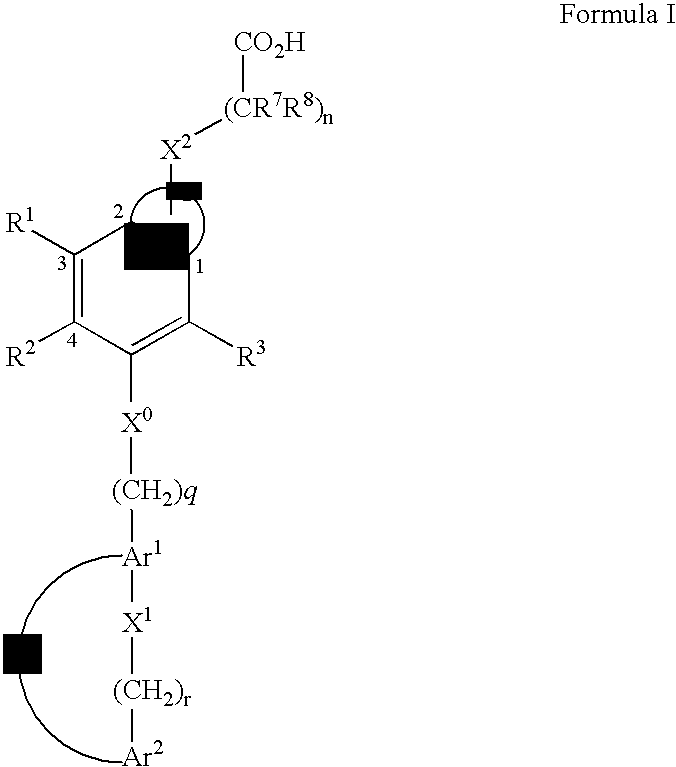

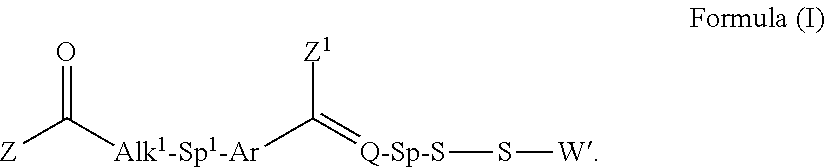

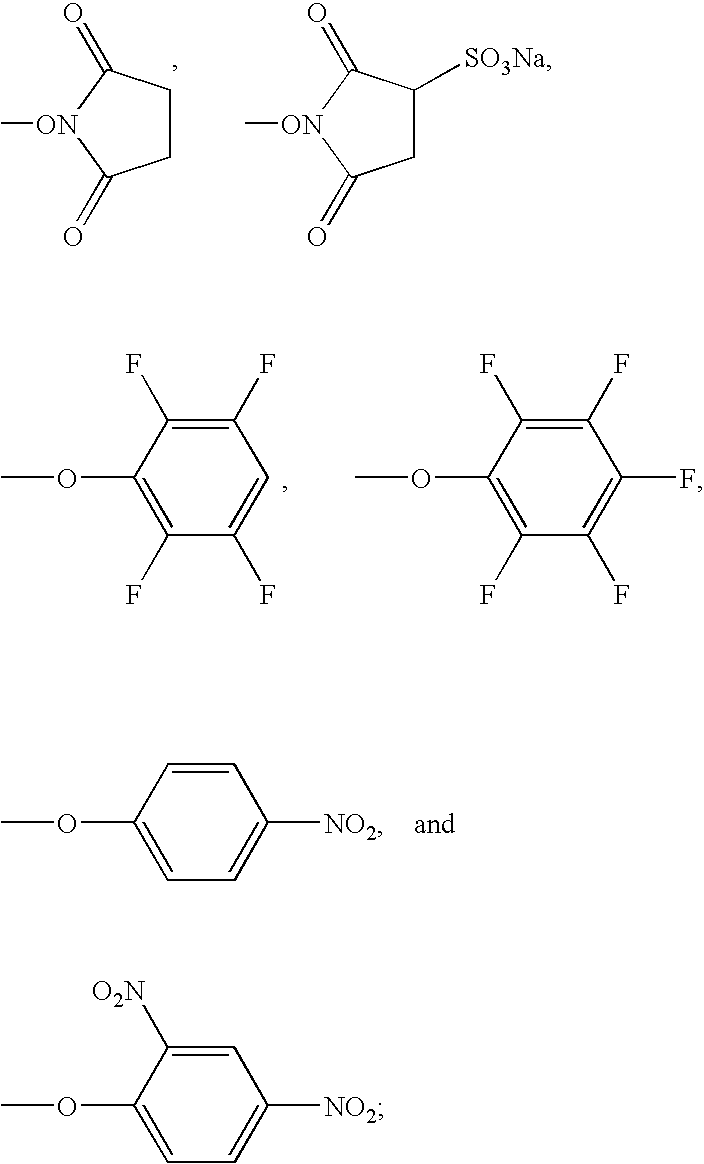

Substituted diaryl compound and preparation method and antiviral application thereof

ActiveCN102206172ALess likely to develop drug resistanceImprove securityCarbamic acid derivatives preparationSulfonic acid esters preparationMechanism of actionStructure–activity relationship

The invention provides substituted diaryl compounds as shown in general formula (I) or their pharmaceutically acceptable salts, and also provides a preparation method; a class of novel broad-spectrum antiviral compounds and pharmaceutical salts targeting cytokines are screened and obtained through studies on structure-activity relationship and action mechanism of active compounds; the compounds not only have significant broad-spectrum antiviral activity, but also have the advantages of low toxicity and good pharmaceutical properties.

Owner:MEDICINE & BIOENG INST OF CHINESE ACAD OF MEDICAL SCI

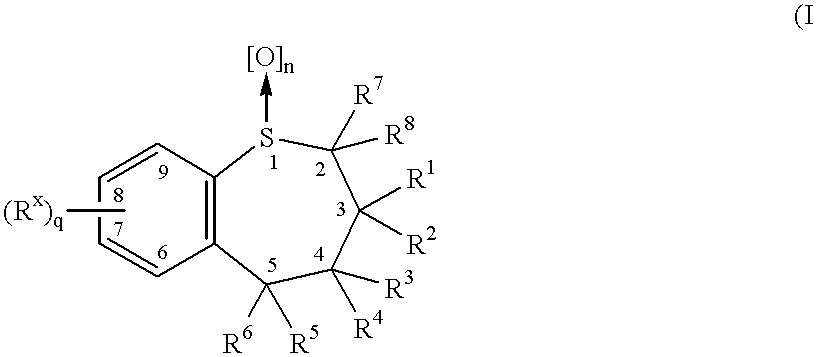

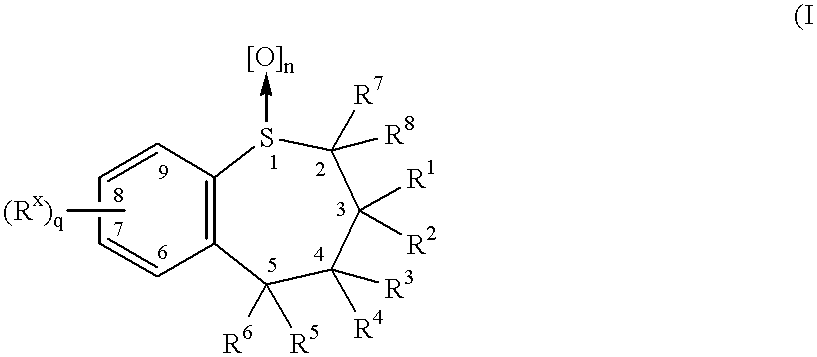

Benzothiepines having activity as inhibitors of ileal bile acid transport and taurocholate uptake

Provided are novel benzothiepines, derivatives, and analogs thereof; pharmaceutical compositions containing them; and methods of using these compounds and compositions in medicine, particularly in the prophylaxis and treatment of hyperlipidemic conditions such as those associated with atherosclerosis or hypercholesterolemia, in mammals.

Owner:GD SEARLE & CO

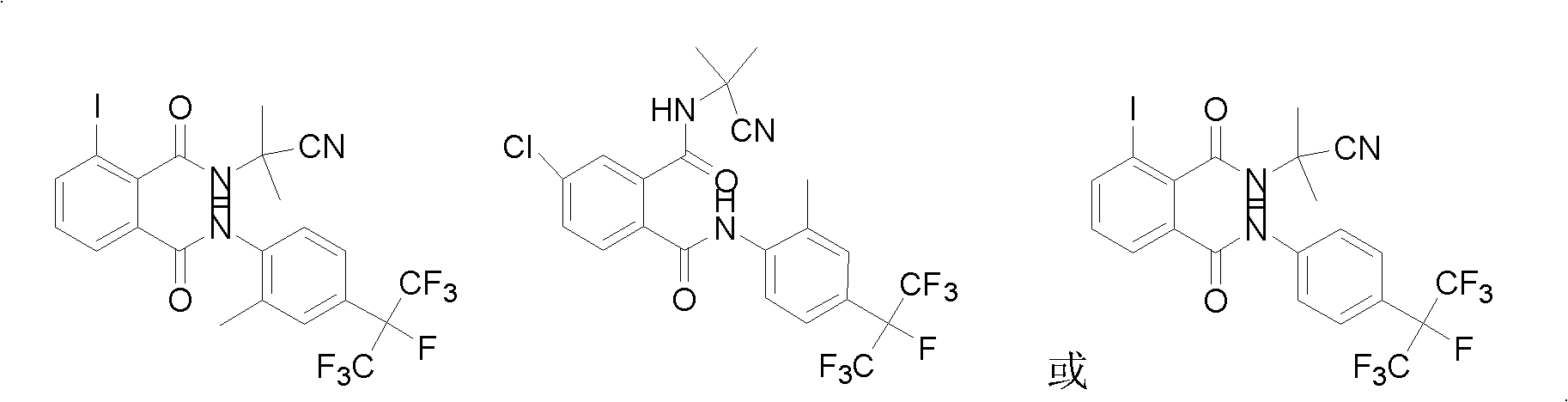

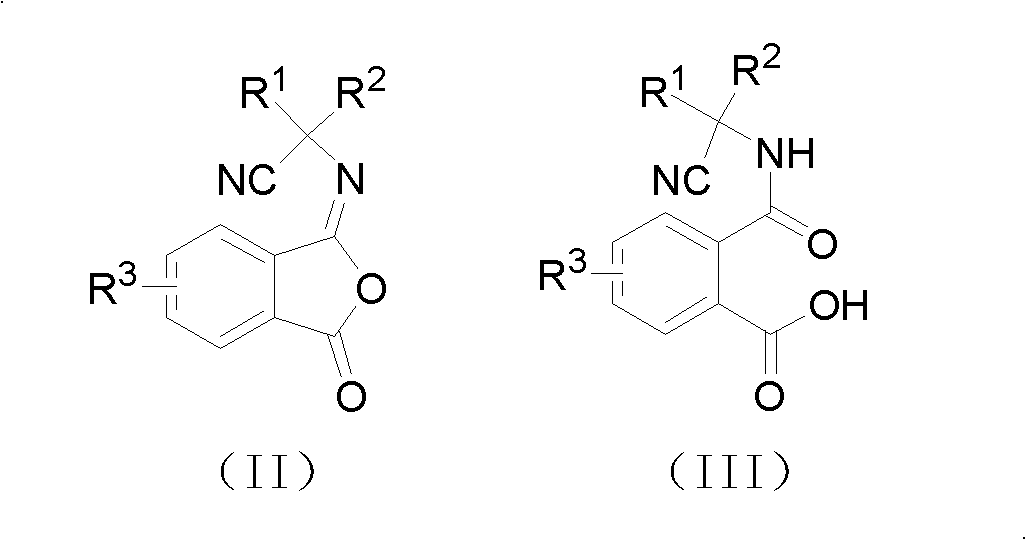

Cyano phthalic diamide compounds, preparation method thereof and use thereof as agricultural chemical pesticide

ActiveCN101935291AStrong noveltyHigh insecticidal activityBiocideCarboxylic acid nitrile preparationCotton bollwormStructural formula

The invention discloses cyano phthalic diamide compounds, a preparation method thereof and use thereof as an agricultural chemical pesticide. The compounds are represented by a structural formula (1), wherein the substituent groups are defined in the description. The phthalic diamide compounds of the invention have wide spectrum pesticidal activities and are effective for epidoptera; particularly, the compounds have high activities for plutella xylostella, cotton bollworm, prodenia litura and the like, and a better effect can be achieved with a small dose of the phthalic diamide compounds.

Owner:SINOCHEM LANTIAN +2

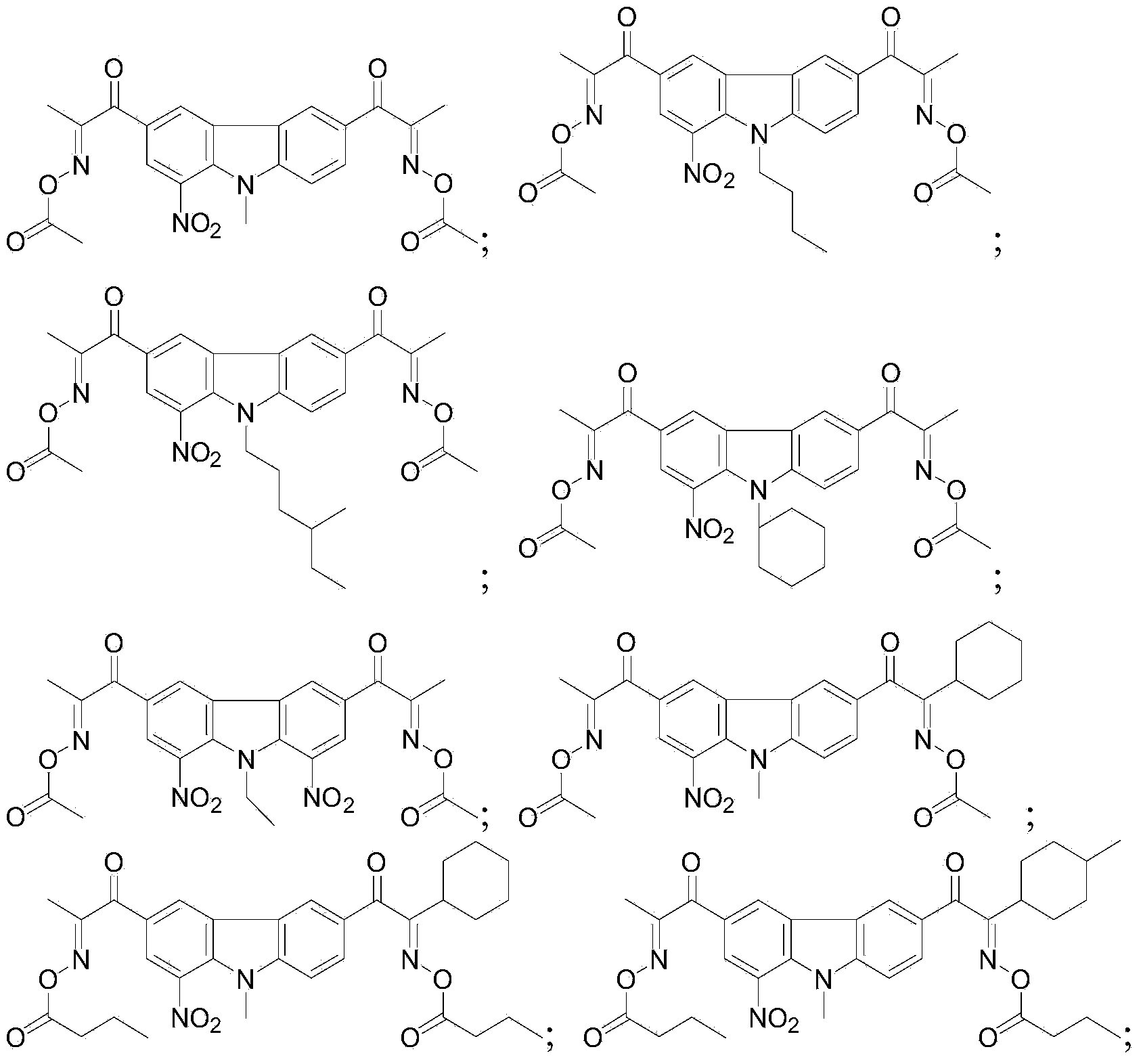

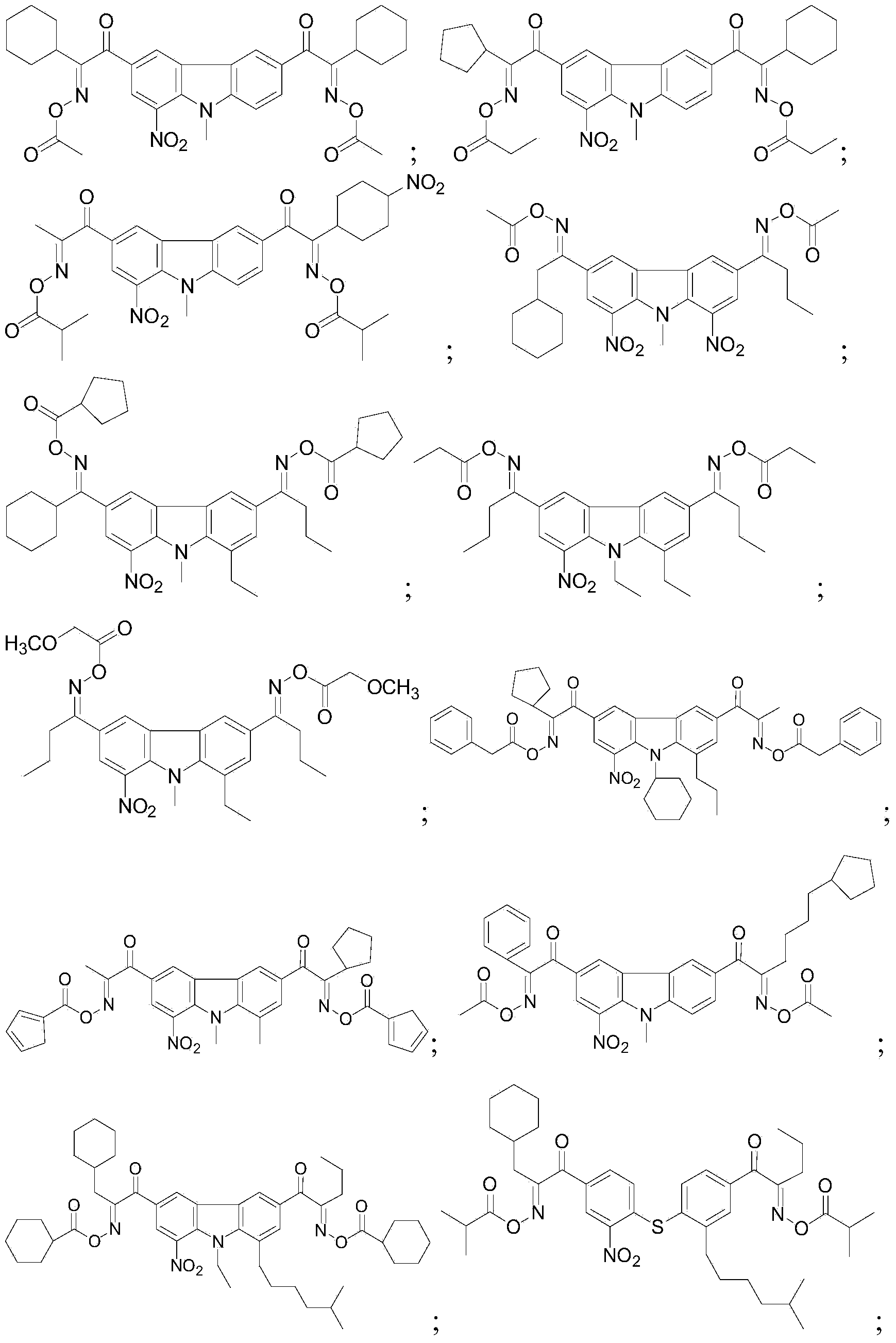

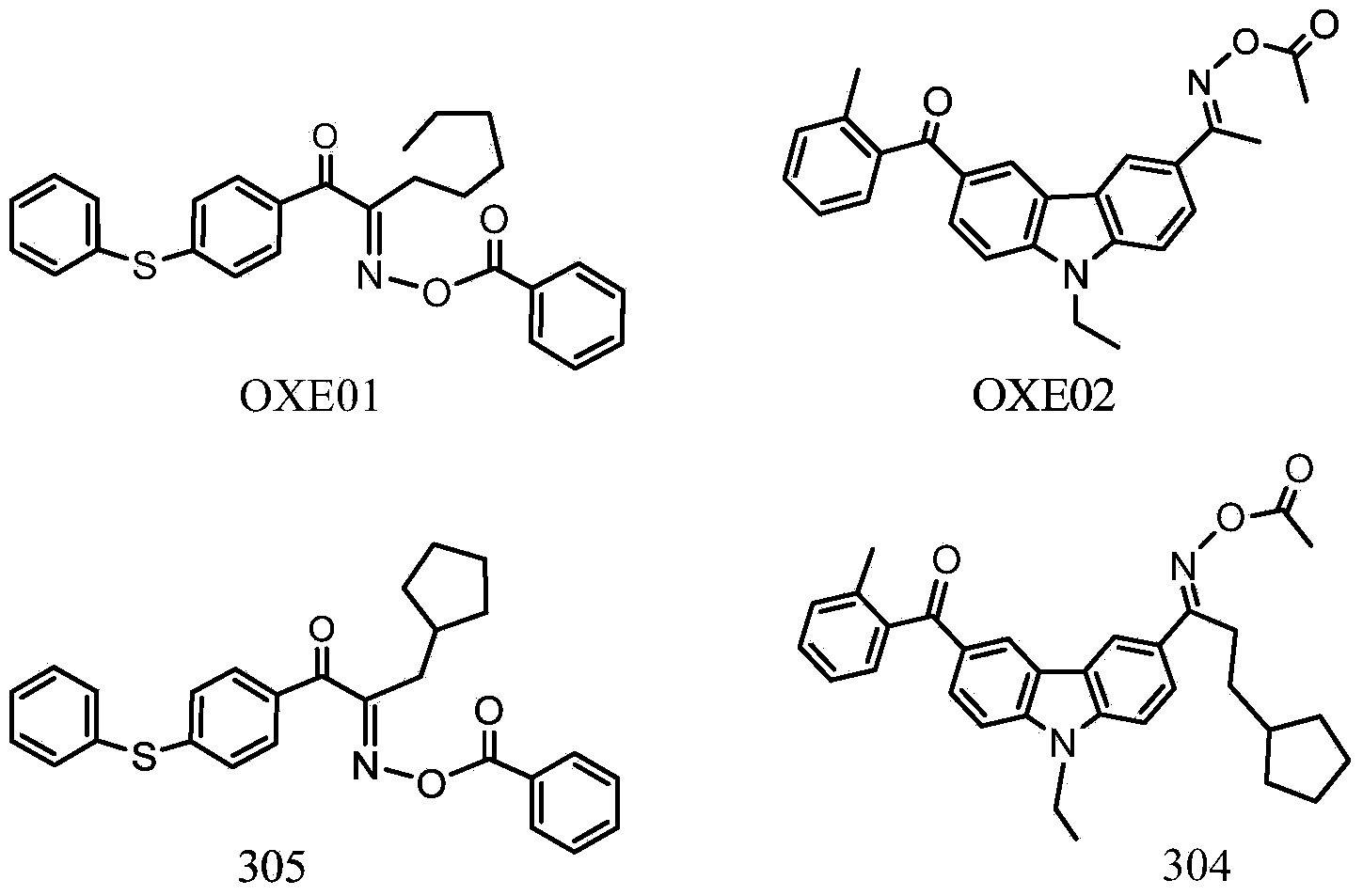

Ketoxime ester photoinitiator

ActiveCN101565472AImprove applicabilityApplication performance (good sensitivityOrganic compound preparationPhotomechanical apparatusCarbazoleMethyl benzene

The invention relates to a ketoxime ester photoinitiator, in particular to a ketoxime ester photoinitiator for a photo-curing material. The ketoxime ester photoinitiator has a chemical structural formula as the right, wherein in a R1 structure, n is an integer of between 0 and 5; m is an integer of between 1 and 6; R2 is methyl, phenyl, substituted phenyl, benzyl or substituted benzyl; and R3 is diphenyl sulfide group, substituted diphenyl sulfide group, carbazole group or substituted carbazole group. The ketoxime ester photoinitiator solves the problems of poor application performance and poor thermal stability of the prior OXE-1 ketoxime ester photoinitiator.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS

Compounds that modulate PPAR activity and methods for their preparation

InactiveUS6875780B2BiocideOxygen-containing compound preparationAcute hyperglycaemiaHypertriglyceridemia

This invention relates to compounds that alter PPAR activity. The invention also relates to pharmaceutically acceptable salts of the compounds, pharmaceutically acceptable compositions comprising the compounds or their salts, and methods of using them as therapeutic agents for treating or preventing dyslipidemia, hypercholesterolemia, obesity, hyperglycemia, atherosclerosis, hypertriglyceridemia and hyperinsulinemia in a mammal. The present invention also relates to methods for making the disclosed compounds.

Owner:WARNER-LAMBERT CO

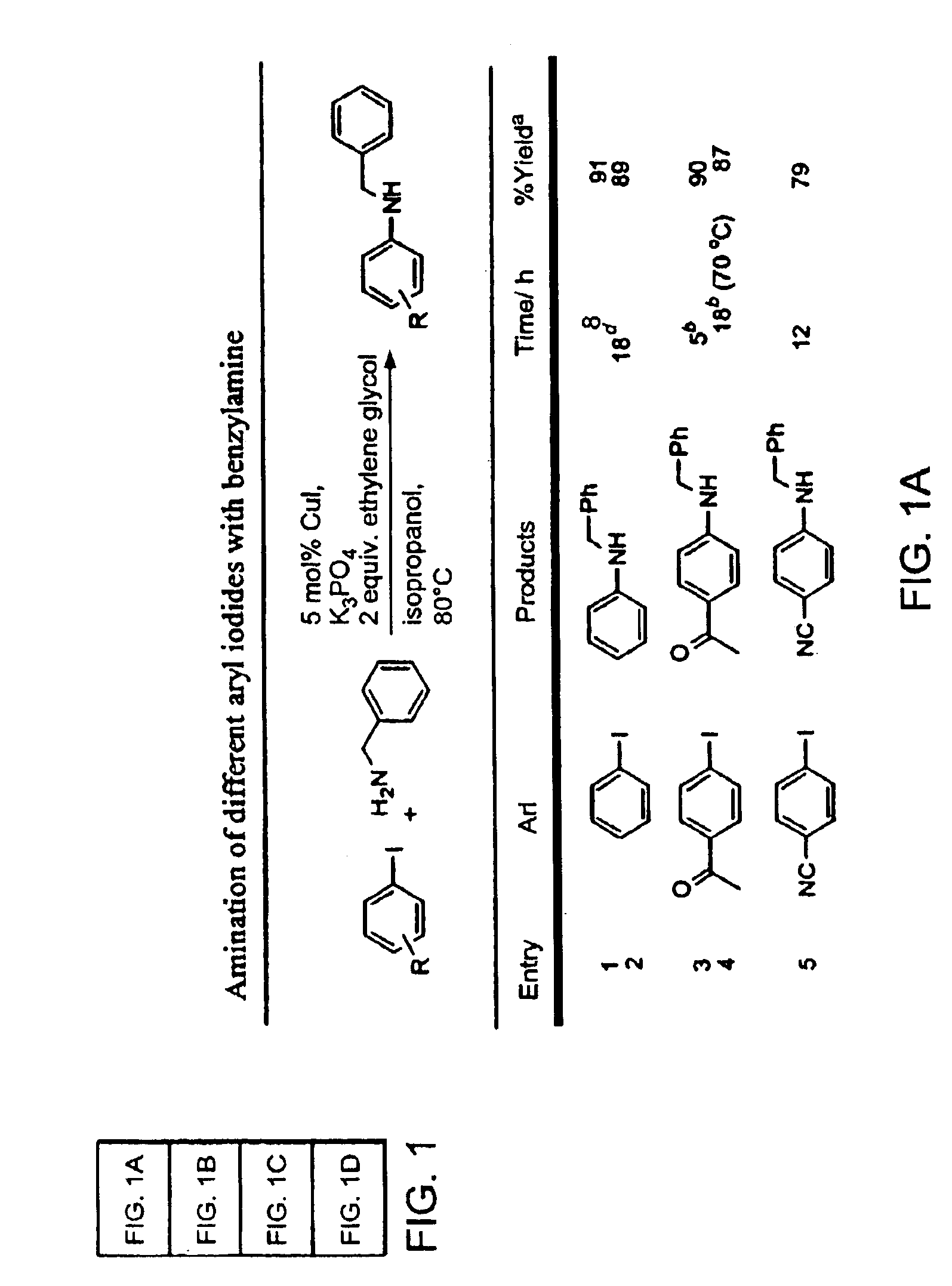

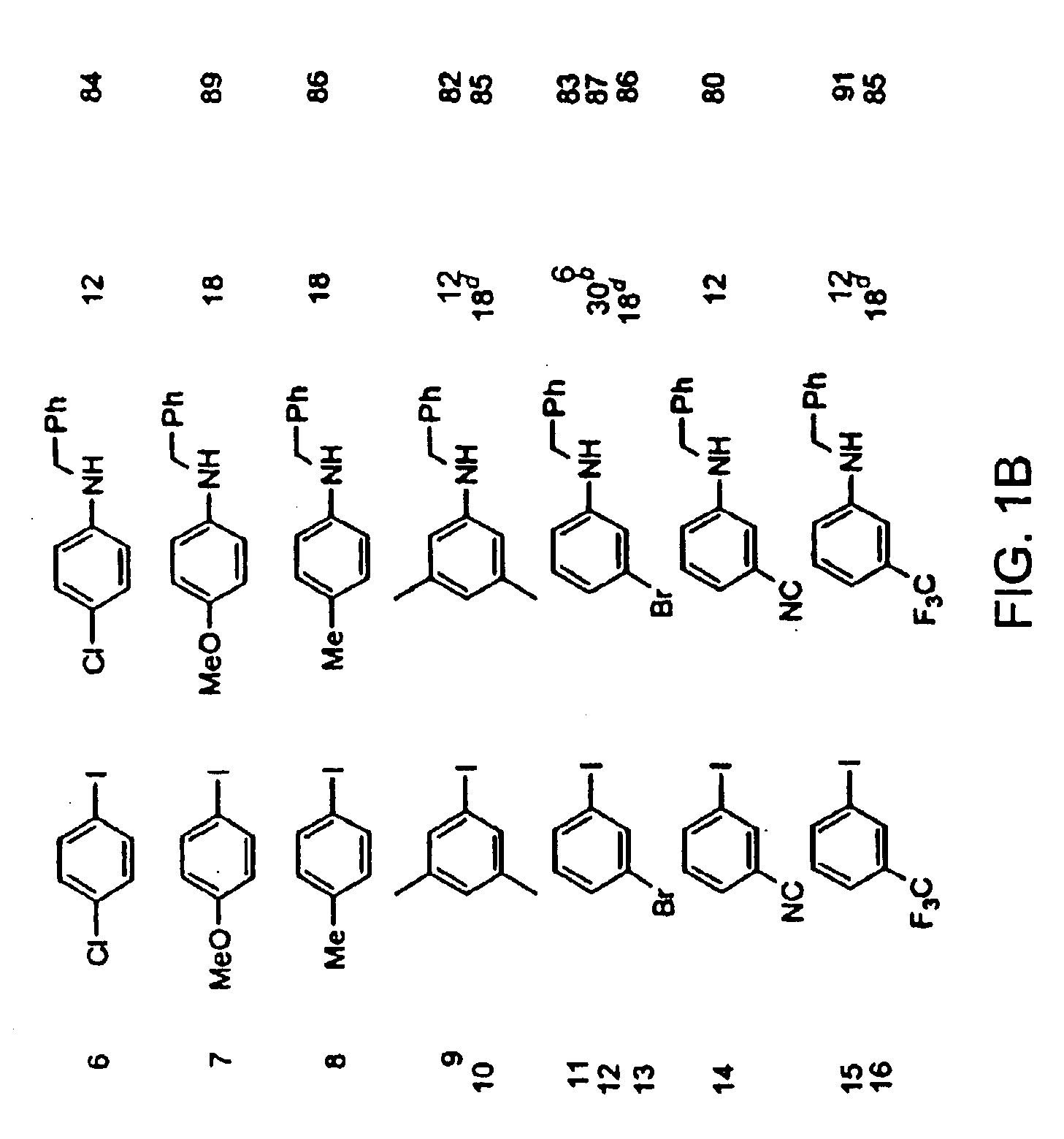

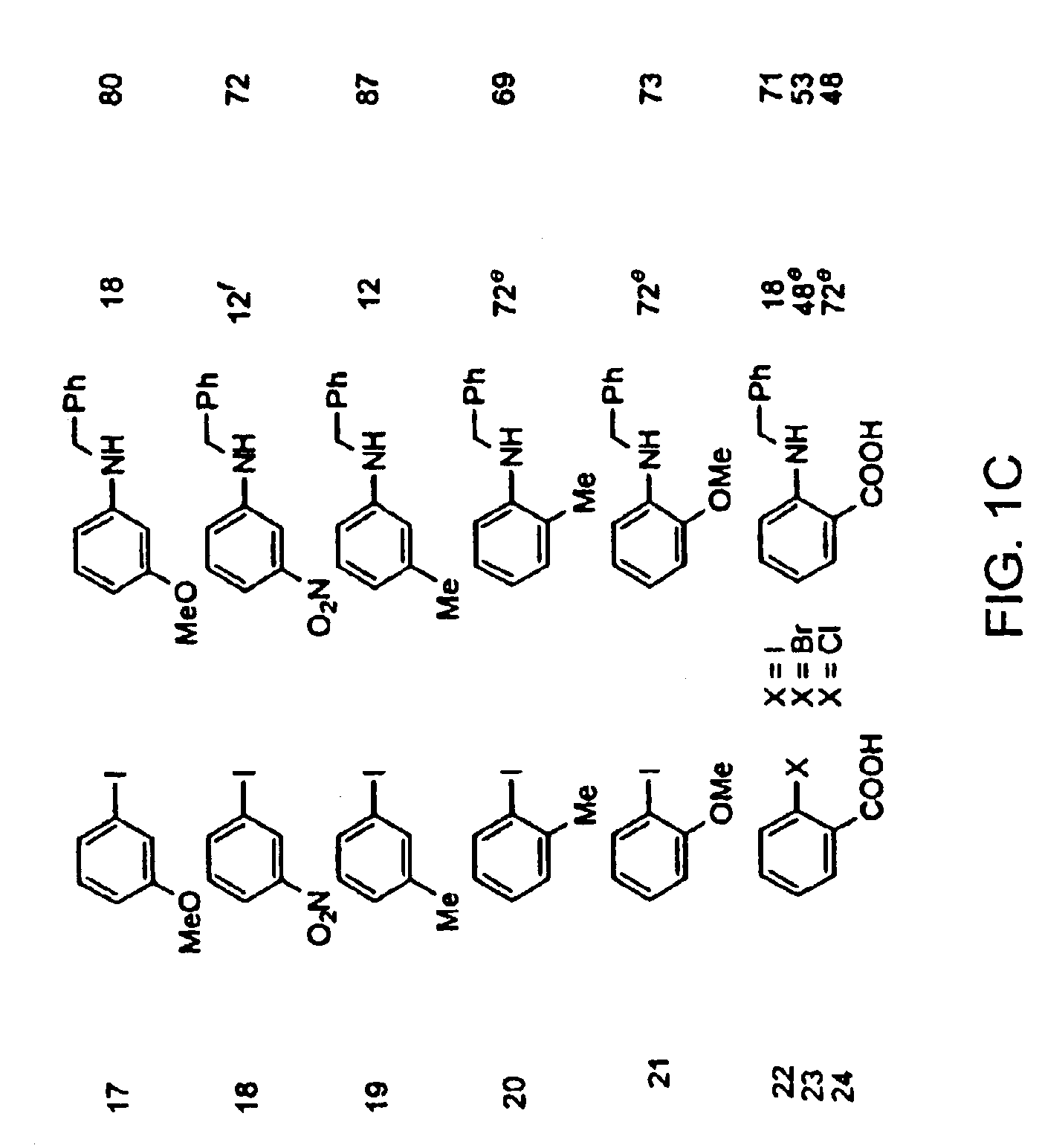

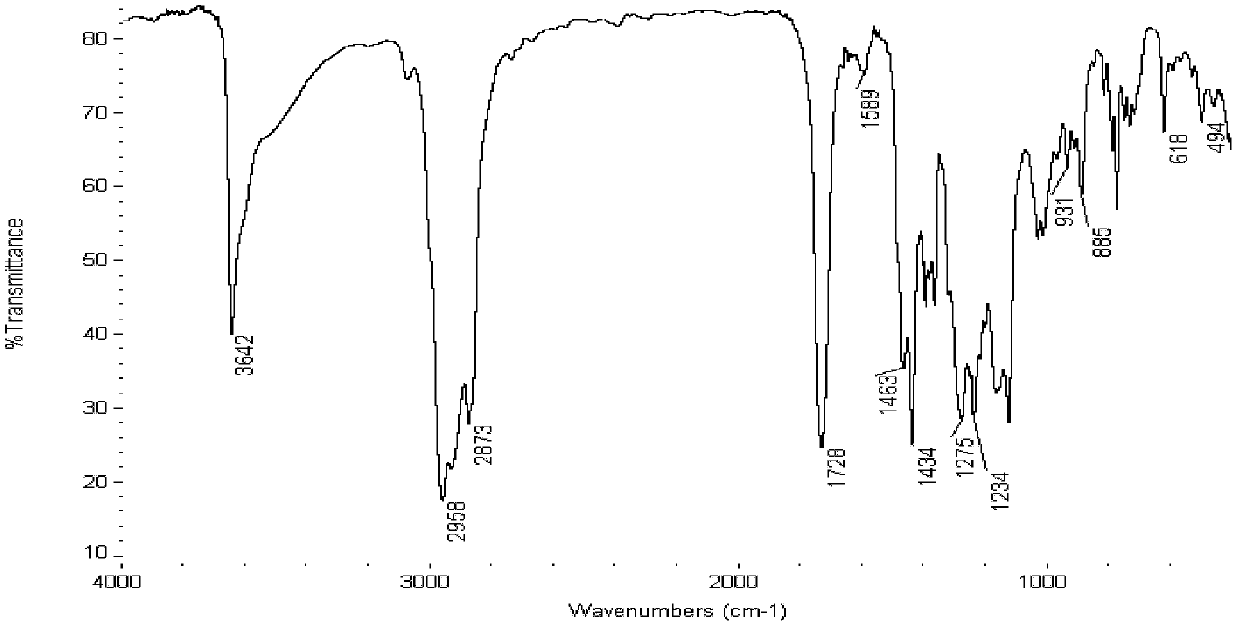

Copper-catalyzed formation of carbon-heteroatom and carbon-carbon bonds

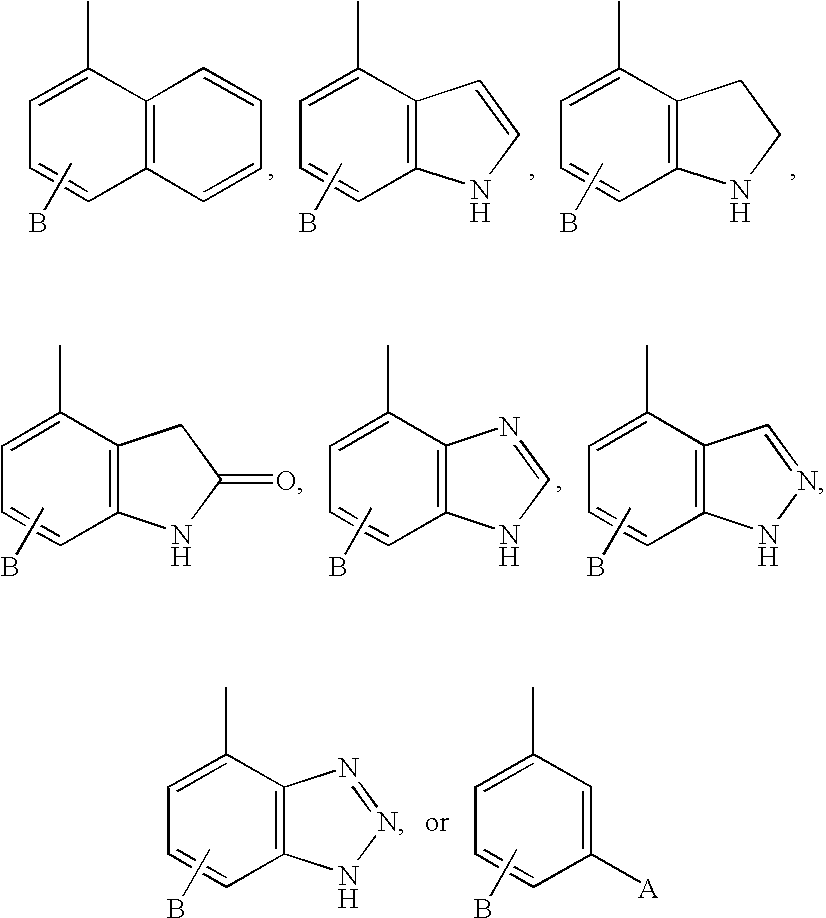

InactiveUS6867298B2Cheap and practicalLow costUrea derivatives preparationCarbamic acid derivatives preparationCarbon–oxygen bondHydrazine compound

The present invention relates to copper-catalyzed carbon-heteroatom and carbon-carbon bond-forming methods. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of an amide or amine moiety and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In additional embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between a nitrogen atom of an acyl hydrazine and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In other embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of a nitrogen-containing heteroaromatic, e.g., indole, pyrazole, and indazole, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-oxygen bond between the oxygen atom of an alcohol and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. The present invention also relates to copper-catalyzed methods of forming a carbon-carbon bond between a reactant comprising a nucleophilic carbon atom, e.g., an enolate or malonate anion, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. Importantly, all the methods of the present invention are relatively inexpensive to practice due to the low cost of the copper comprised by the catalysts.

Owner:MASSACHUSETTS INST OF TECH

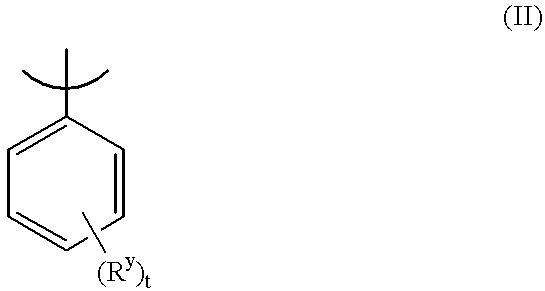

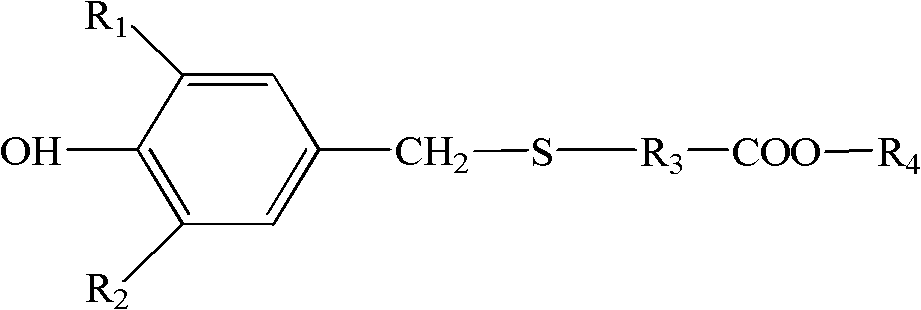

Thioether-containing hindered phenol antioxidant and preparation method thereof

InactiveCN103320198AImprove antioxidant capacityAchieve synergistic effectAdditivesSulfide preparationThioetherChemistry

The present invention provides a thioether bond structure-containing hindered phenol antioxidant and a preparation method thereof, wherein screen phenol, thiol ester and formaldehyde in a reaction medium are subjected to a reaction under a certain condition in the presence of a catalyst to obtain a thioether bond-containing hindered phenol antioxidant compound, wherein the compound has an excellent antioxidation performance in hydrogenation base oil, and can be adopted as a lubricating agent antioxidant to be separately used or is compounded with other additives to be used, and the antioxidant is applicable for internal combustion engine oils and industrial lubricating oils.

Owner:PETROCHINA CO LTD

Substituted 5-aryl-benzothiepines having activity as inhibitors of ileal bile acid transport and taurocholate uptake

Provided are novel benzothiepines, derivatives, and analogs thereof; pharmaceutical compositions containing them; and methods of using these compounds and compositions in medicine, particularly in the prophylaxis and treatment of hyperlipidemic conditions such as those associated with atherosclerosis or hypercholesterolemia, in mammals.

Owner:GD SEARLE & CO

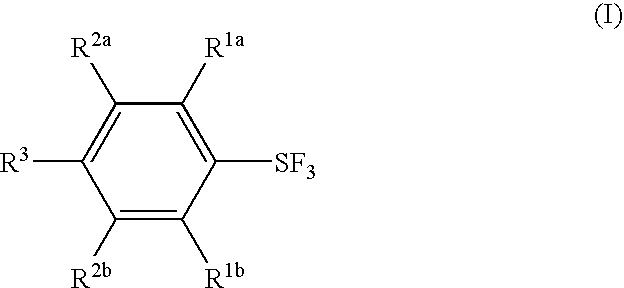

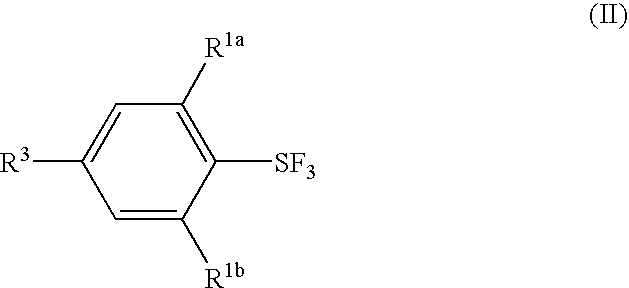

Substituted phenylsulfur trifluoride and other like fluorinating agents

ActiveUS7265247B1Significant comprehensive benefitsOrganic compound preparationOrganic halogenationTrifluorideCombinatorial chemistry

Novel substituted phenylsulfur trifluorides that act as fluorinating agents are disclosed. Also disclosed are methods for their preparation and methods for their use in introducing one or more fluorine atoms into target substrate compounds.

Owner:UBE CORP

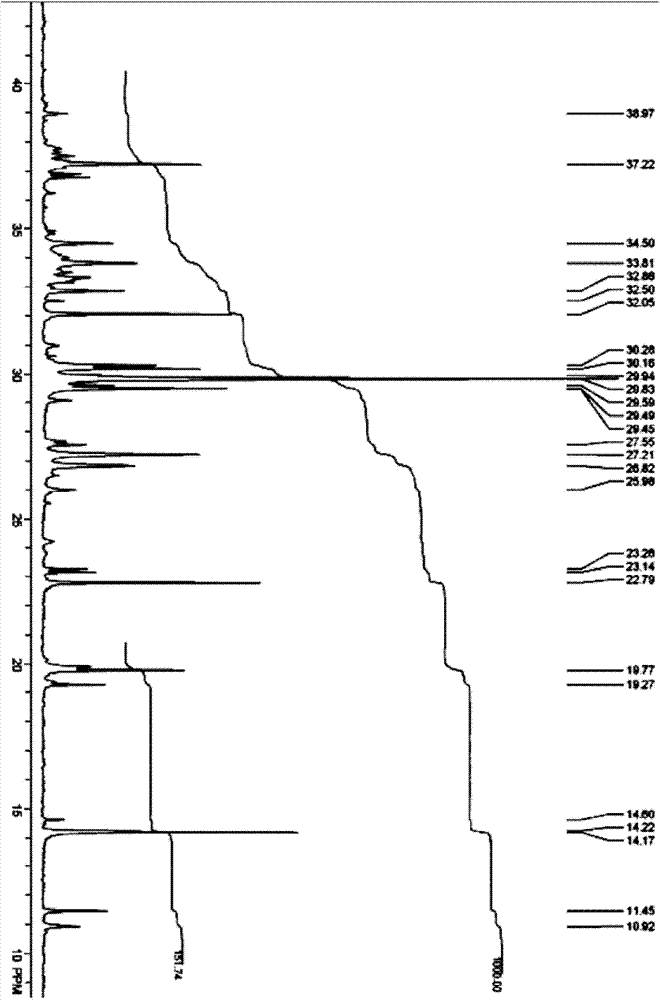

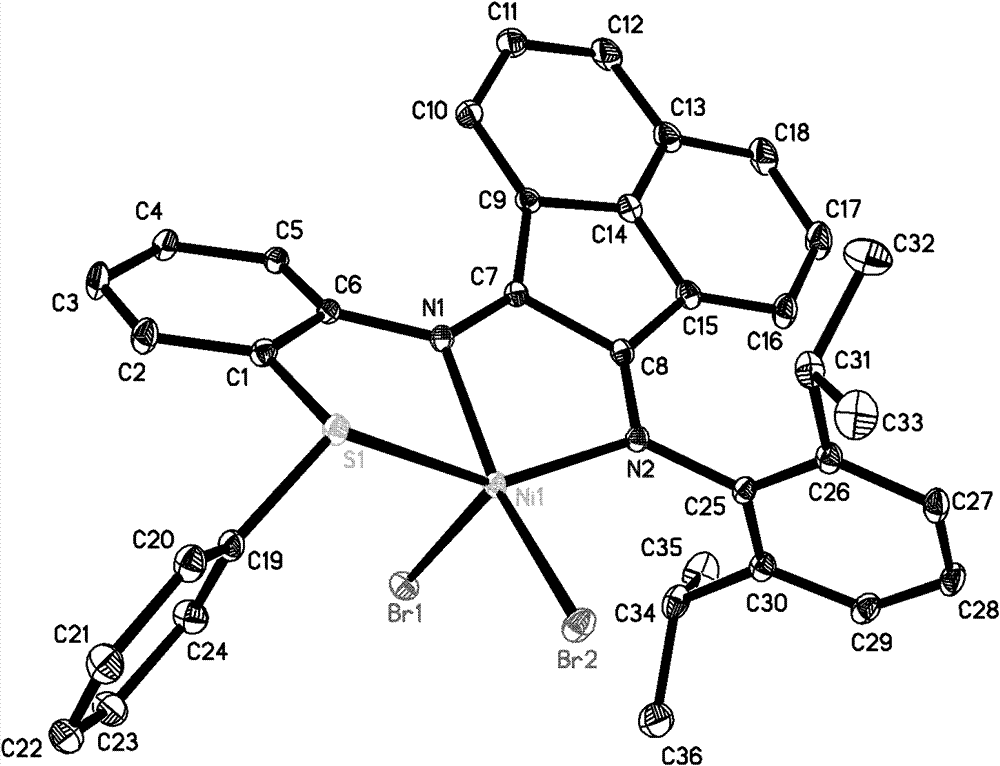

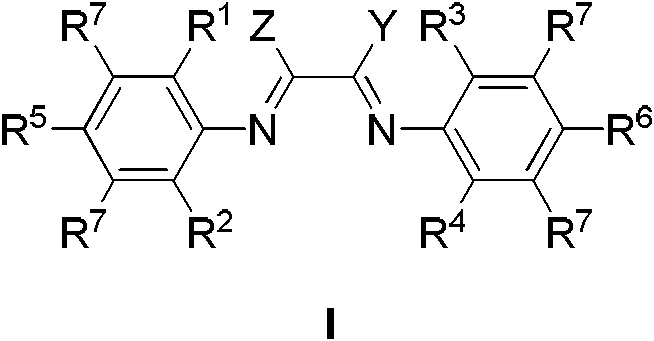

Catalysis systems for preparing highly branched alkane by using olefin

The present invention discloses a class of catalysis systems for preparing highly branched alkanes by using olefins. The catalysis systems comprise a class of novel nickel complexes and palladium complexes. With effects of the catalysis systems, only mild conditions are required to efficiently obtain oily highly branched alkane mixtures by using ethylene and other olefins, wherein the alkane mixtures have a low bromine value, and can be used for processing aids, and high-performance base oil of lubricants,. The present invention further provides a preparation method for catalysts, and a preparation method for oily olefin polymers.

Owner:NANJING CHEMRUN CO LTD +1

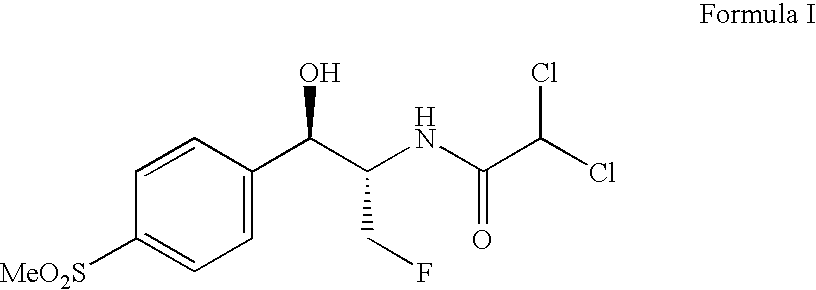

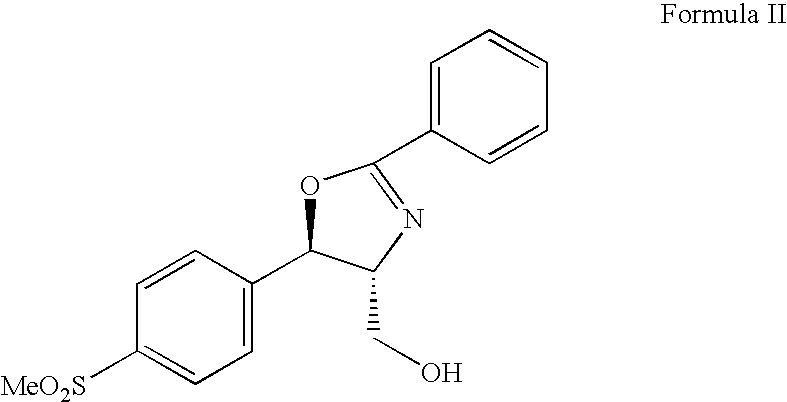

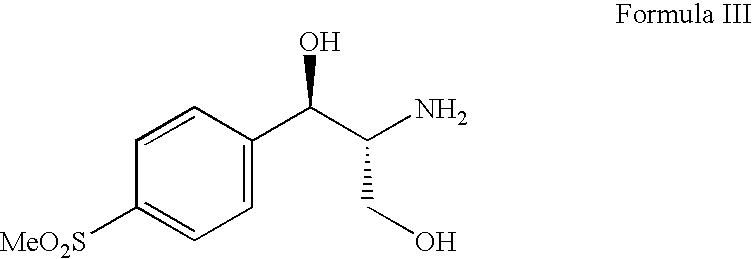

Process for preparing florfenicol

The present invention is directed to a new process of preparing highly pure Florfenicol. The invention is further directed to new oxazolidine derivatives useful in making Florfenicol and processes of making these derivatives. Examples of such intermediates include (4R,5R)-3-acetyl-2,2-dimethyl-4-hydroxymethyl-5-[4-(methylsulfonyl)phenyl]-1,3-oxazolidine; and (4S,5R)-3-acetyl-2,2-dimethyl-4-fluoromethyl-5-[4-(methylsulfonyl)phenyl]-1,3-oxazolidine.

Owner:AUROBINDO PHARMA LTD

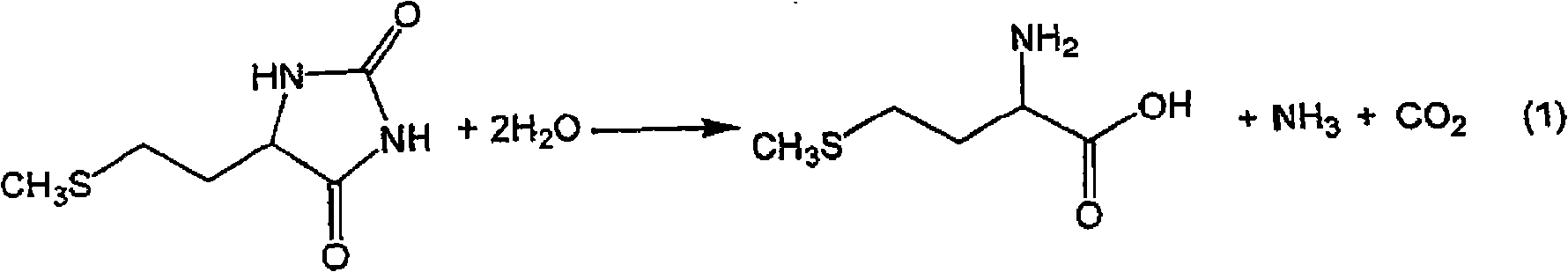

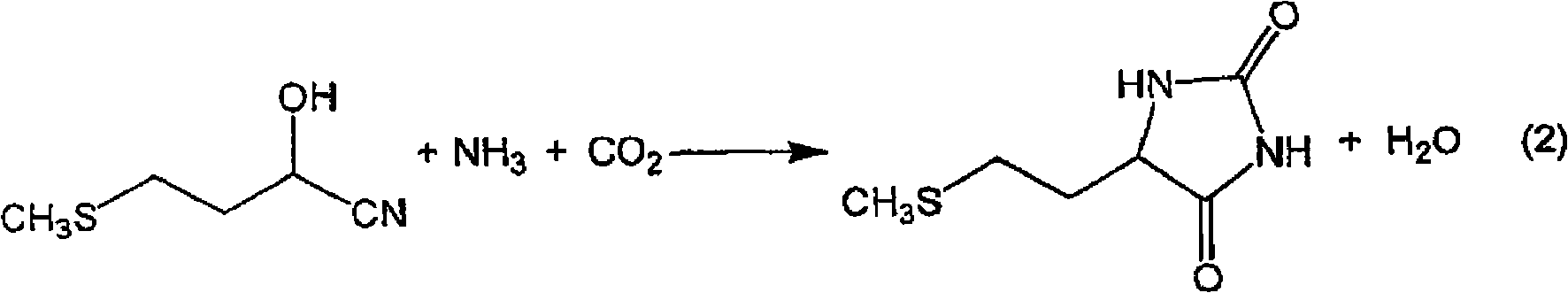

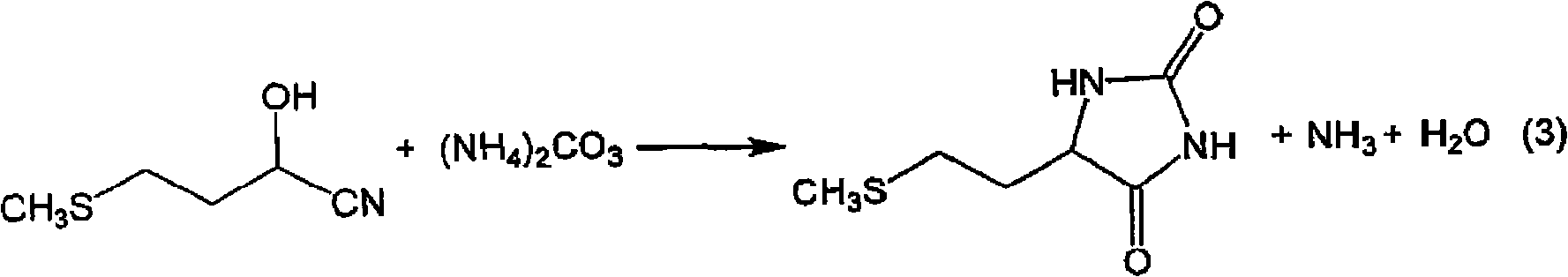

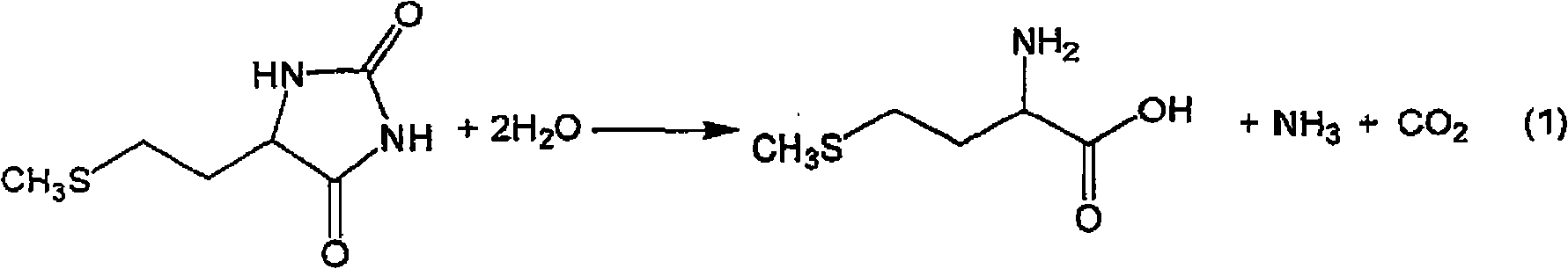

Process for producing methionine

InactiveCN101602700AEfficient recyclingEfficient productionOrganic compound preparationSulfide preparationPotassiumSlurry

The present invention provides a process for producing methionine which is advantageous from the viewpoints of cost and wastewater disposal, and which comprises the following steps (1) to (5): (1) a reaction step comprising hydrolysis of 5-[2-(methylthio)ethyl]imidazolidine-2,4-dione in the presence of a basic potassium compound; (2) a first crystallization step comprising introduction of carbon dioxide into the reaction solution obtained in step (1) to precipitate methionine, and separation of the resultant slurry into a precipitate and a mother liquor; (3) a second crystallization step comprising concentration of the mother liquor obtained in step (2), mixing with a lower alcohol, introduction of carbon dioxide into the mixture to precipitate methionine and potassium hydrogen carbonate, and separation of the resultant slurry into a precipitate and a mother liquor; (4) a heating step comprising concentration of the mother liquor obtained in step (3) followed by a heating treatment at 150 to 200 DEG C; and (5) a third crystallization step comprising introduction of carbon dioxide into the heated mother liquor obtained in step (4) to precipitate methionine and potassium hydrogen carbonate, and separation of the resultant slurry into a precipitate and a mother liquor.

Owner:SUMITOMO CHEM CO LTD

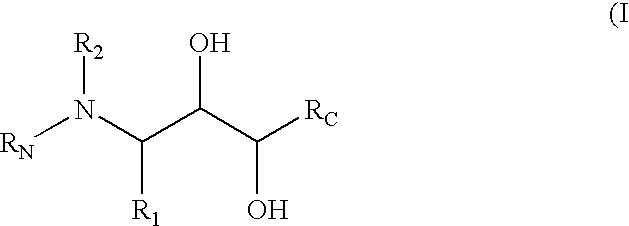

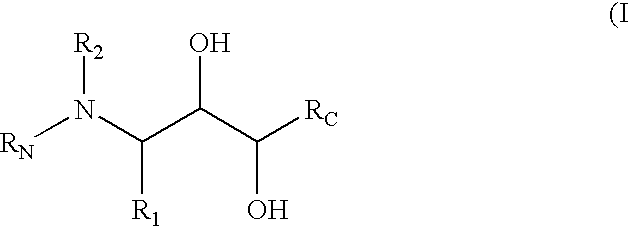

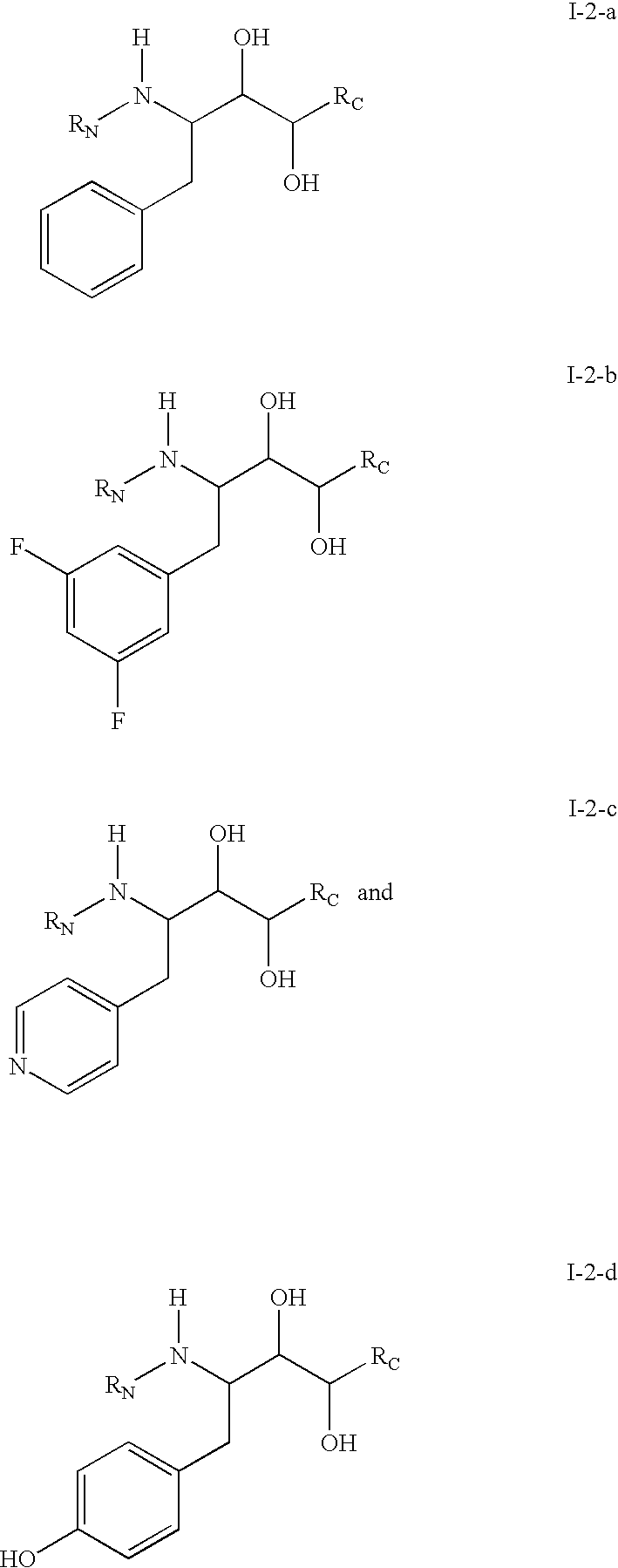

Aminediols for the treatment of Alzheimer's disease

The present invention relates to compounds of formula (I): useful in treating Alzheimer's disease and other similar diseases. These compounds include inhibitors of the beta-secretase enzyme that are useful in the treatment of Alzheimer's disease and other diseases characterized by deposition of A beta peptide in a mammal. The compounds of the invention are useful in pharmaceutical compositions and methods of treatment to reduce A beta peptide formation.

Owner:PHARMACIA & UPJOHN CO

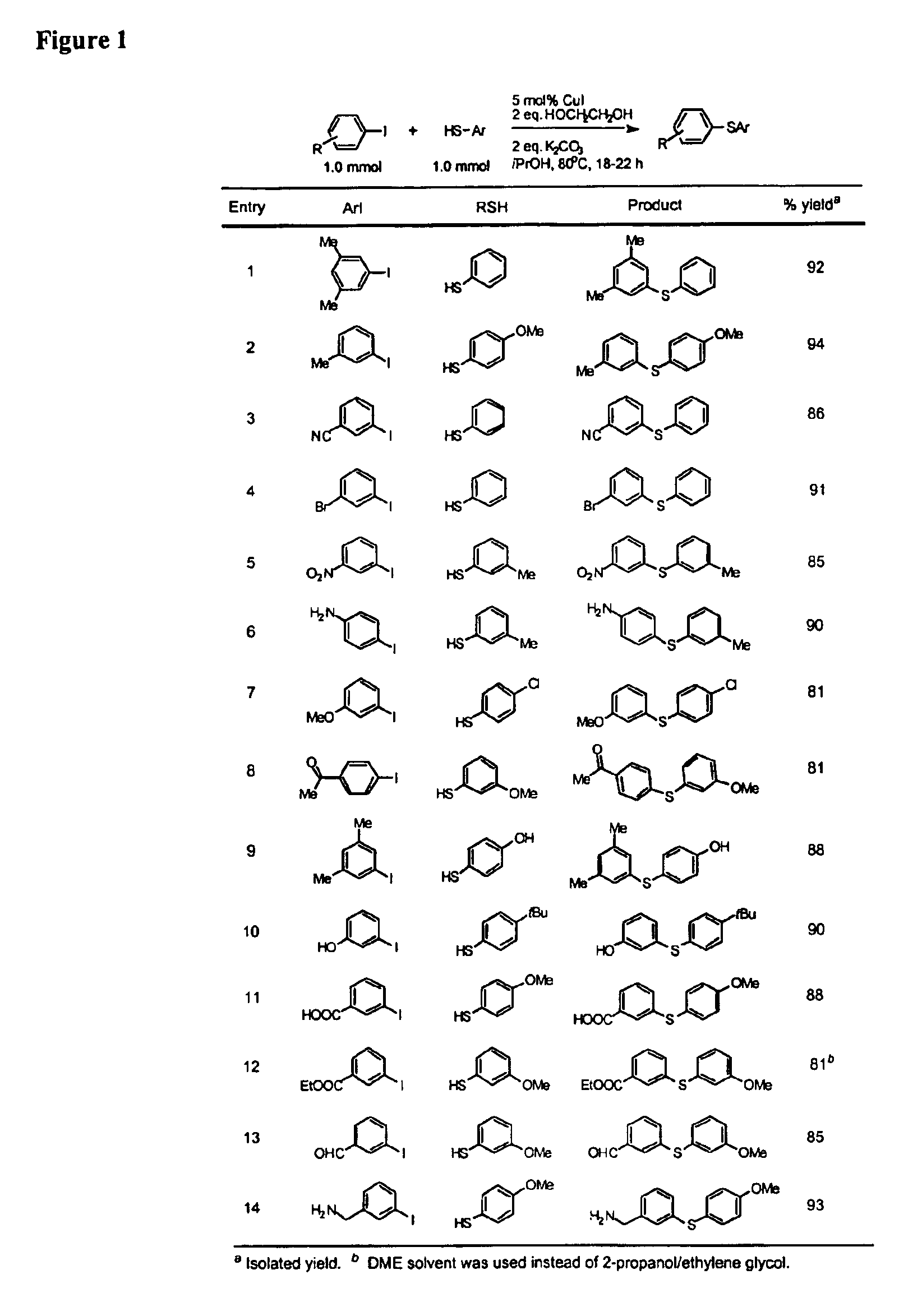

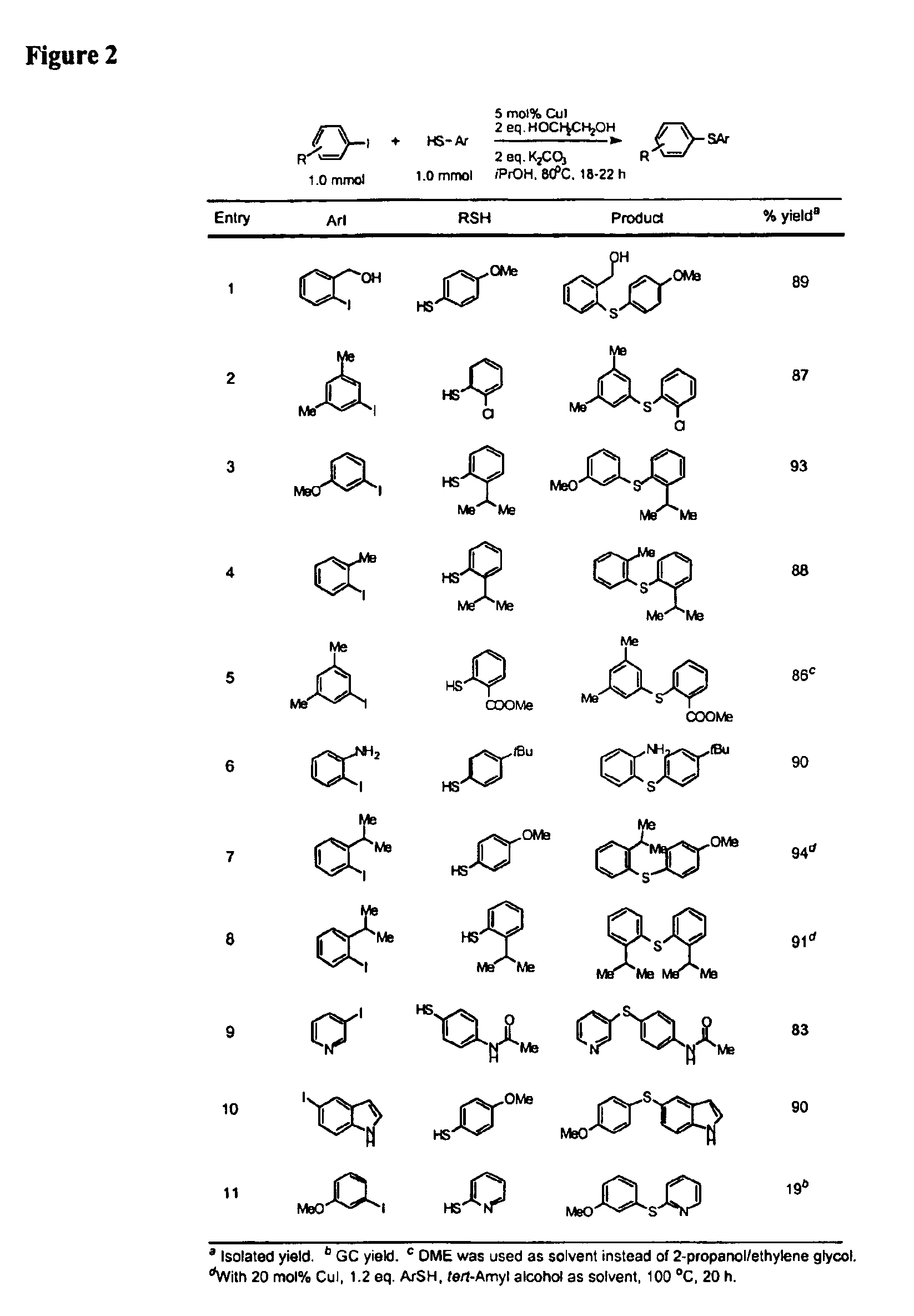

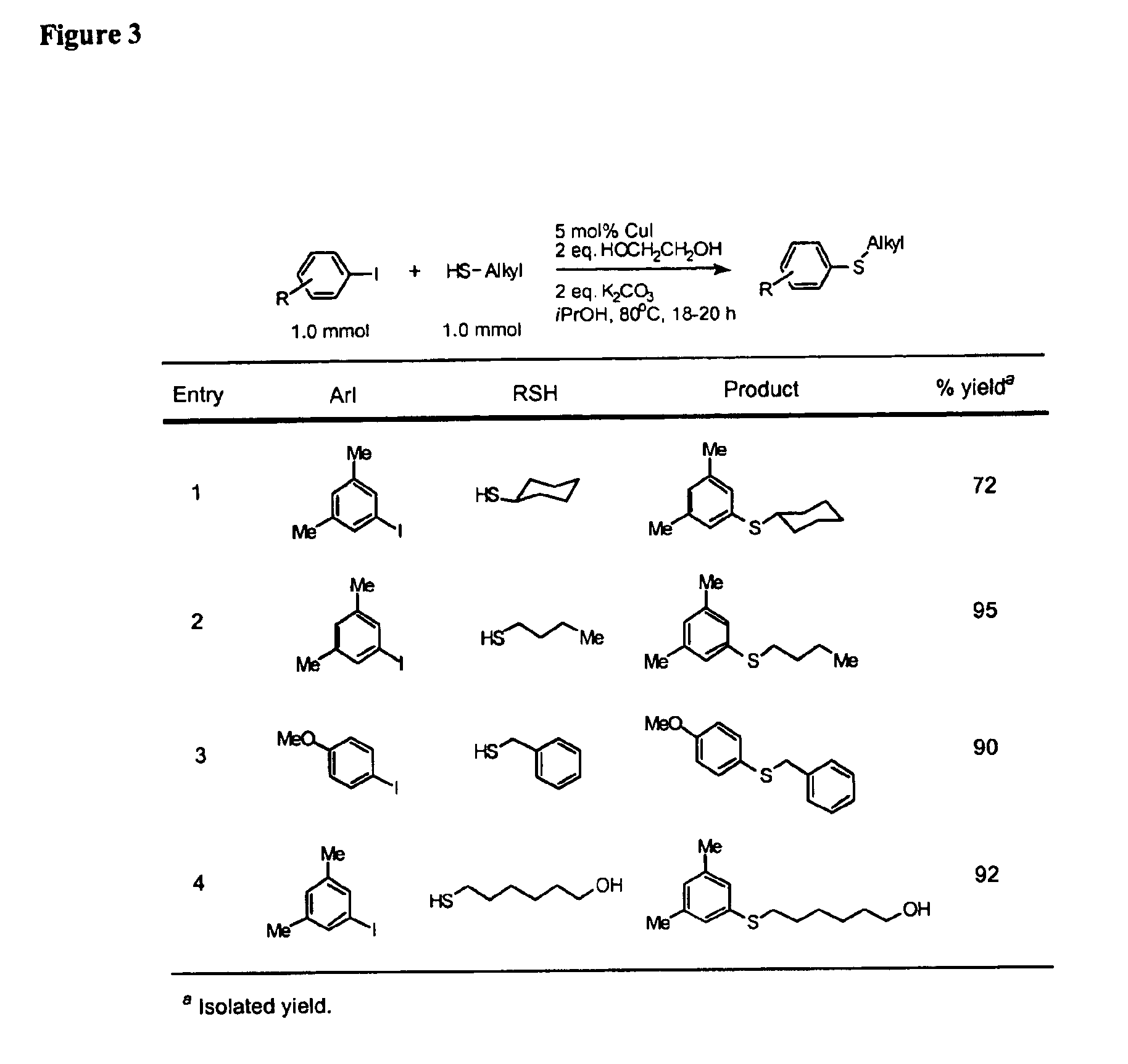

Copper-catalyzed formation of carbon-heteroatom and carbon-carbon bonds

InactiveUS6888032B2Cheap and practicalLow costOrganic compound preparationThiol preparationCarbon–carbon bondSulfide

One aspect of the present invention relates to copper-catalyzed carbon-heteroatom and carbon-carbon bond-forming methods. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-sulfur bond between the sulfur atom of a thiol moiety and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In other embodiments, the present invention relates to copper(II)-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of an amide and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-carbon bond between the carbon atom of cyanide ion and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In another embodiment, the present invention relates to a copper-catalyzed method of transforming an aryl, heteroaryl, or vinyl chloride or bromide into the corresponding aryl, heteroaryl, or vinyl iodide. Yet another embodient of the present invention relates to a tandem method, which may be practiced in a single reaction vessel, wherein the first step of the method involves the copper-catalyzed formation of an aryl, heteroaryl, or vinyl iodide from the corresponding aryl, heteroaryl, or vinyl chloride or bromide; and the second step of the method involves the copper-catalyzed formation of an aryl, heteroaryl, or vinyl nitrile, amide or sulfide from the aryl, heteroaryl, or vinyl iodide formed in the first step.

Owner:MASSACHUSETTS INST OF TECH

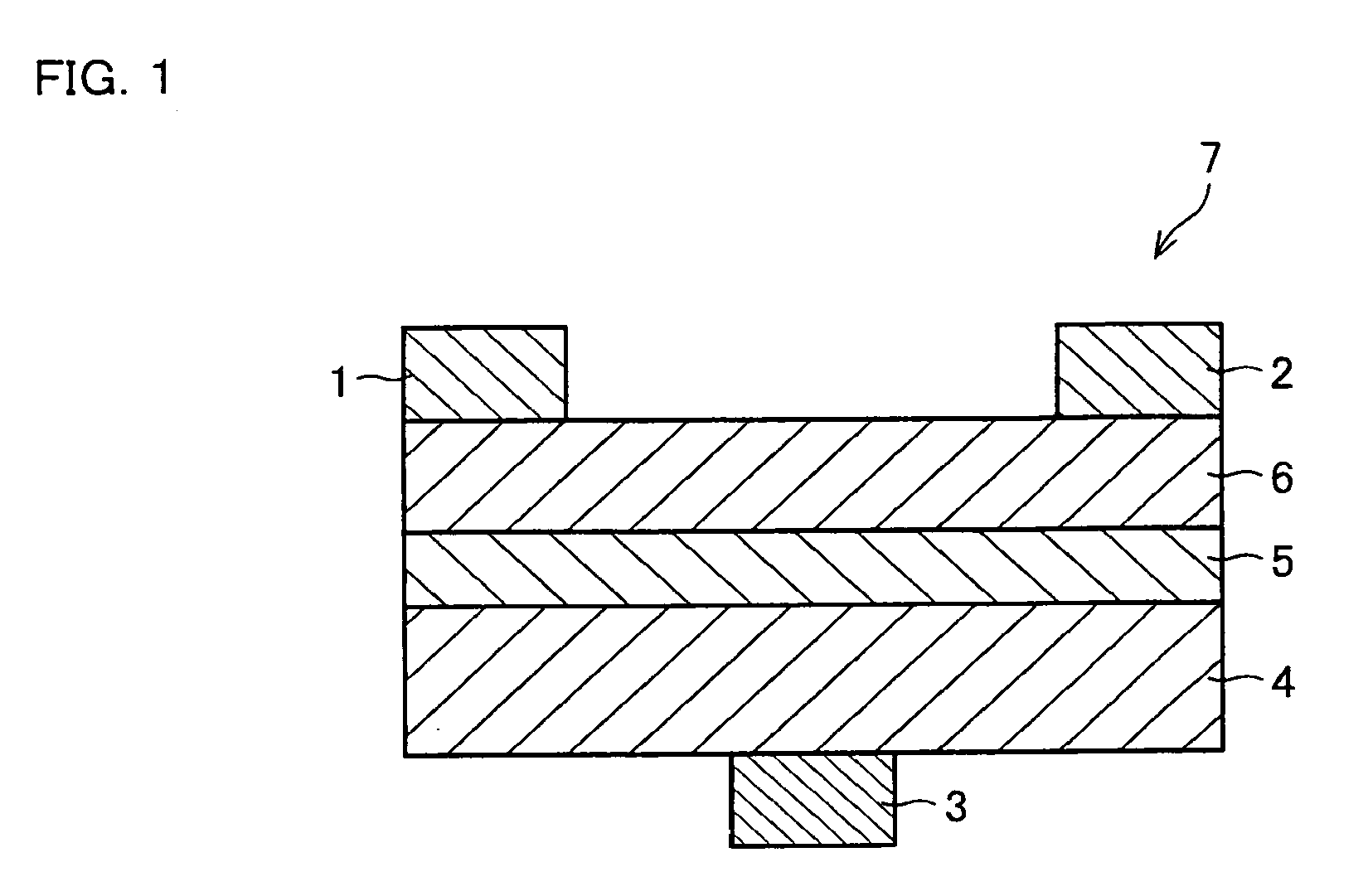

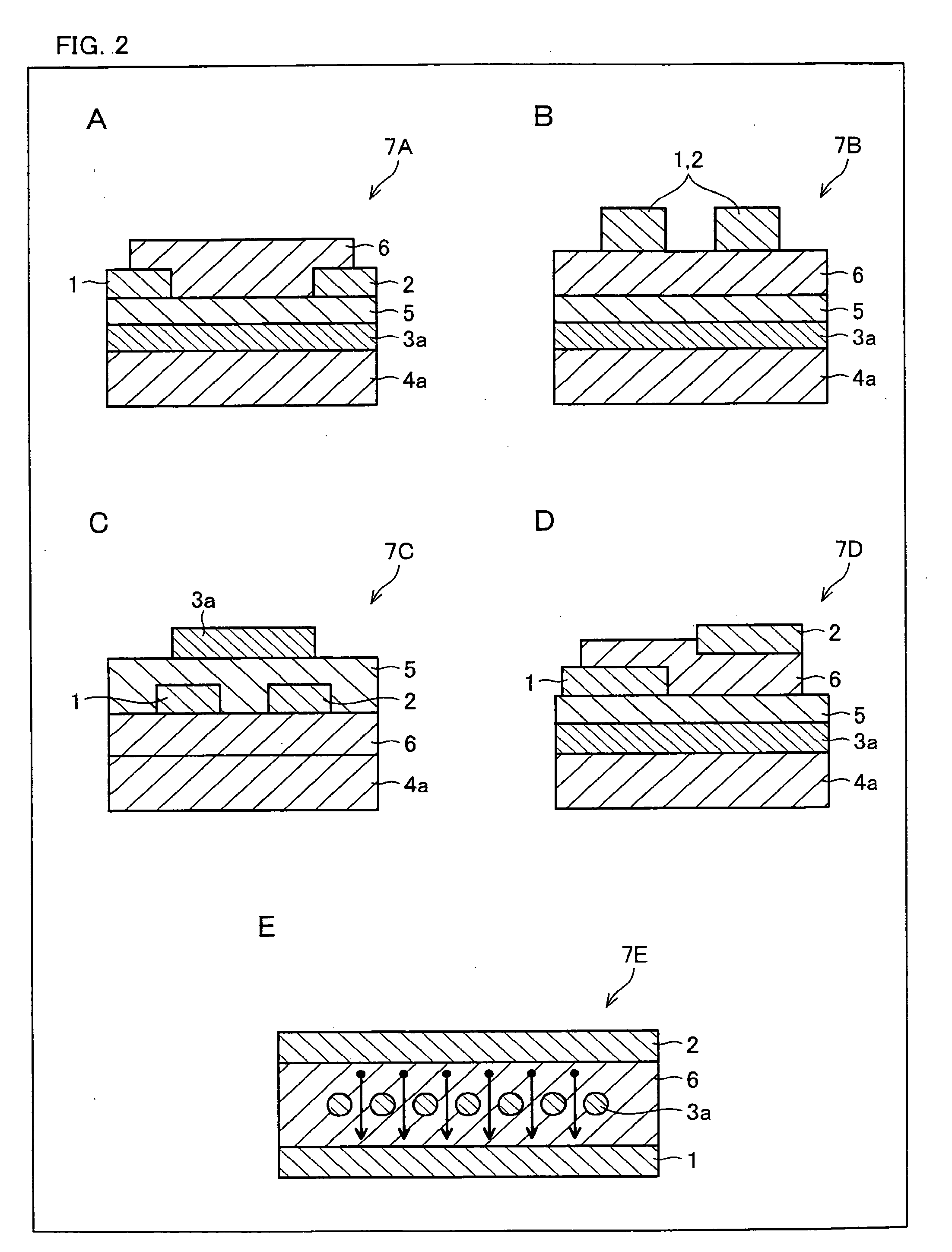

Novel fused polycyclic aromatic compound, process for producing the same, and use thereof

ActiveUS20100065826A1Improve accuracyEnhanced intermolecular interactionsSolid-state devicesSemiconductor/solid-state device manufacturingSolubilityPolycyclic compound

In one embodiment of the present invention, a novel fused polycyclic aromatic compound of the present invention is (a) a compound including a benzodichalcogenophenobenzodichalcogenophene (BXBX) skeleton further having an aromatic ring(s) located outside the BXBX skeleton, or (b) a compound including a BXBX skeleton in which a benzene ring is substituted with a heterocyclic ring. The compound can strengthen intermolecular interaction due to greater π electron orbits. This improves an electron field effect mobility of an organic semiconductor device that is manufactured by use of the compound as an organic semiconductor material. Further, since the number of fused rings included in the compound is small, the compound does not cause problems that generally occur in compounds having an extremely large number of fused rings, i.e., poor solubility in solvent and poor atmospheric stability due to high affinity to oxygen. As a result, the fused polycyclic aromatic compound of the present invention can be preferably used as an organic semiconductor material.

Owner:NIPPON KAYAKU CO LTD

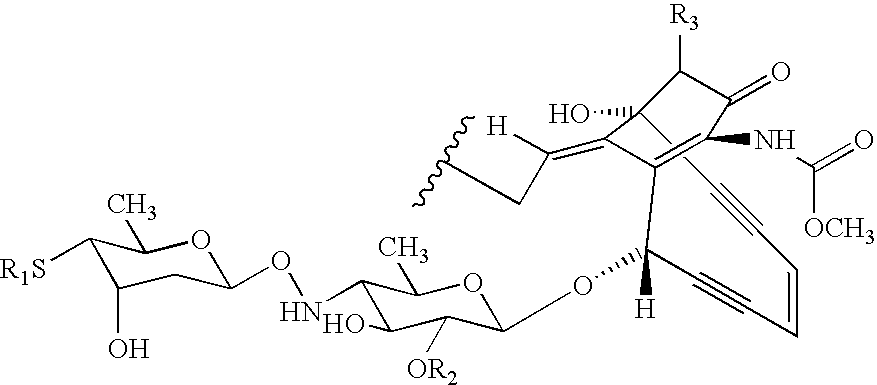

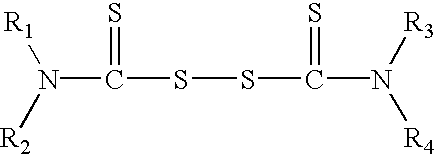

Processes for the convergent synthesis of calicheamicin derivatives

This invention describes processes for the convergent synthesis of calicheamicin derivatives, and similar analogs using bifunctional and trifunctional linker intermediates.

Owner:WYETH LLC

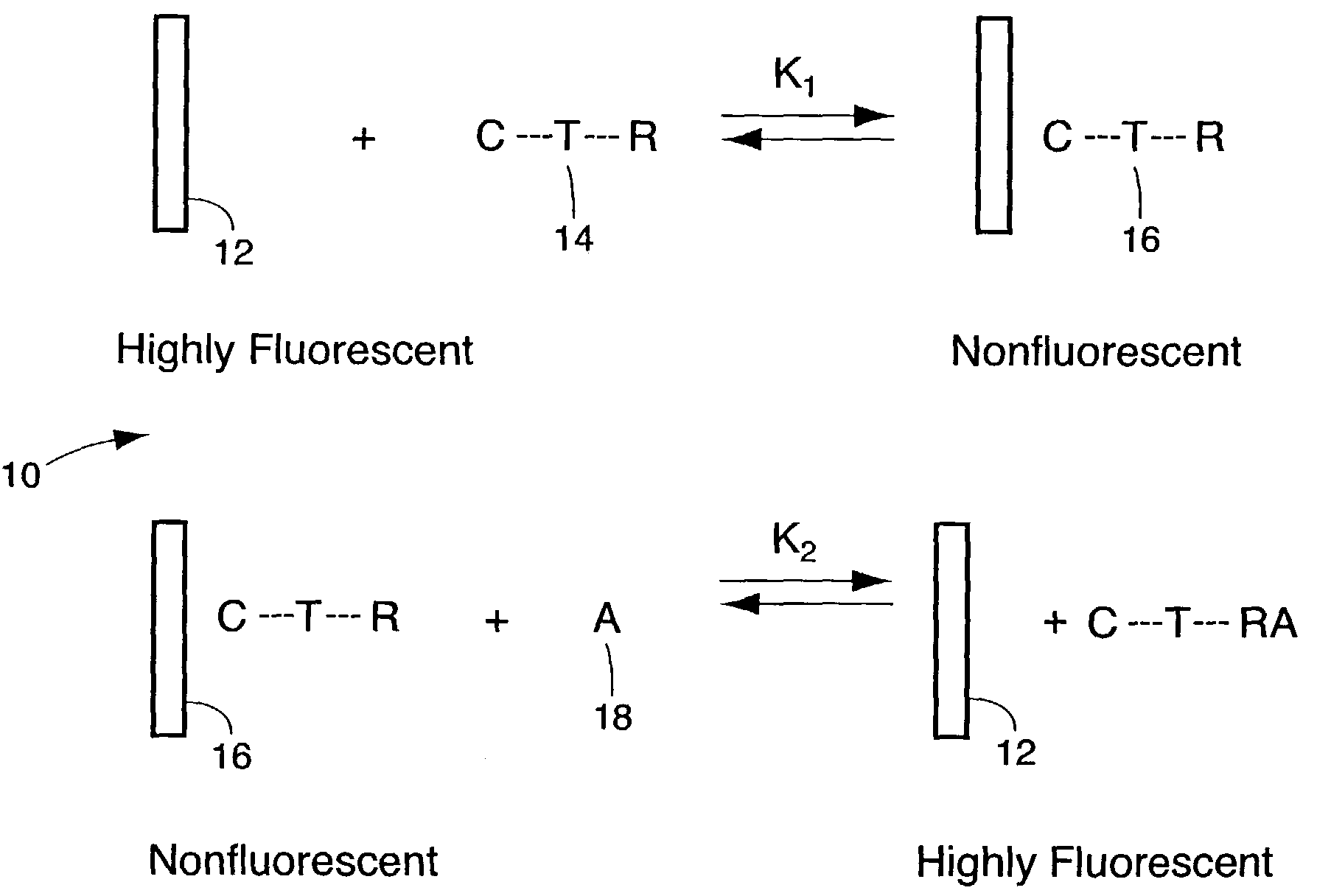

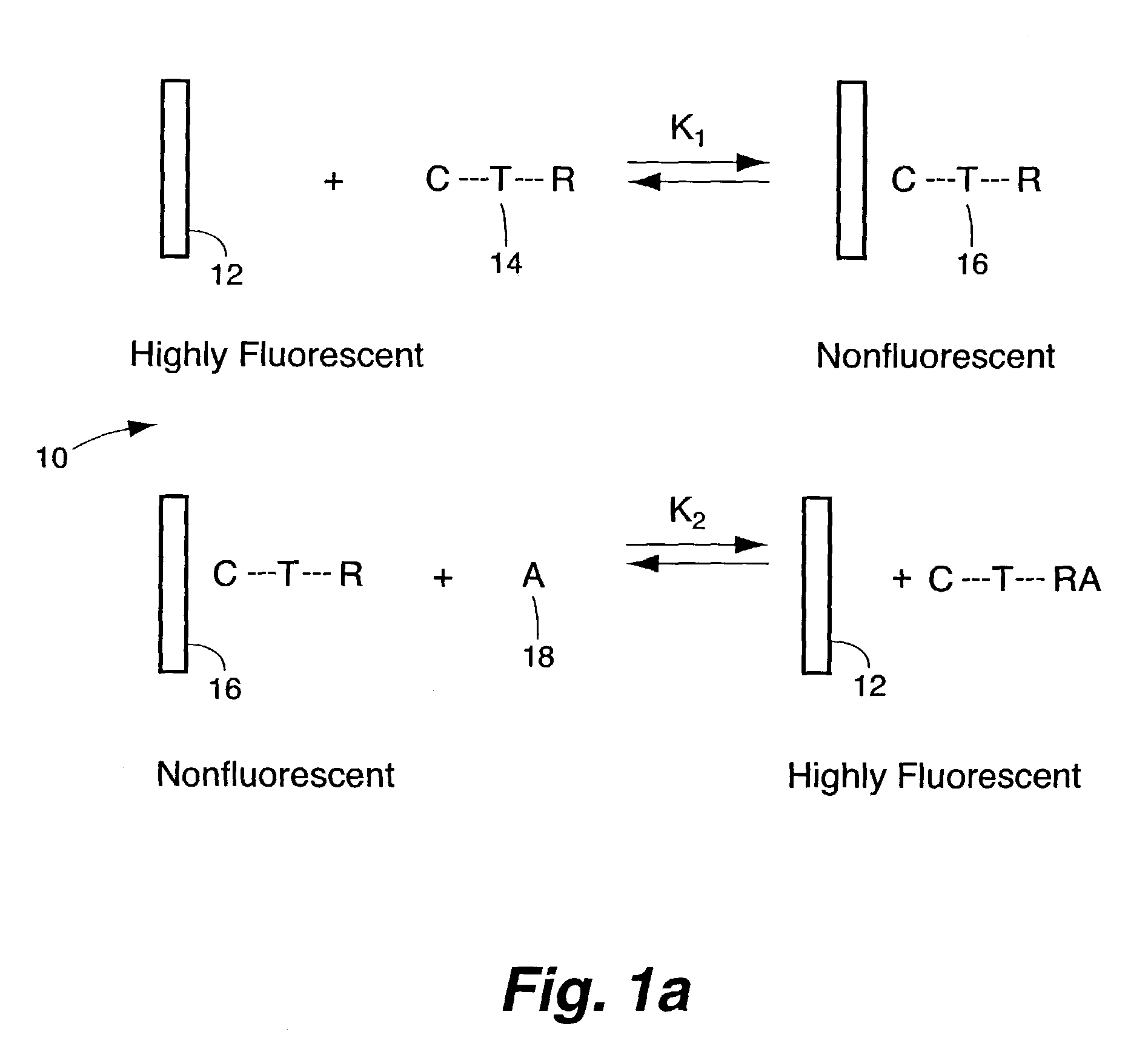

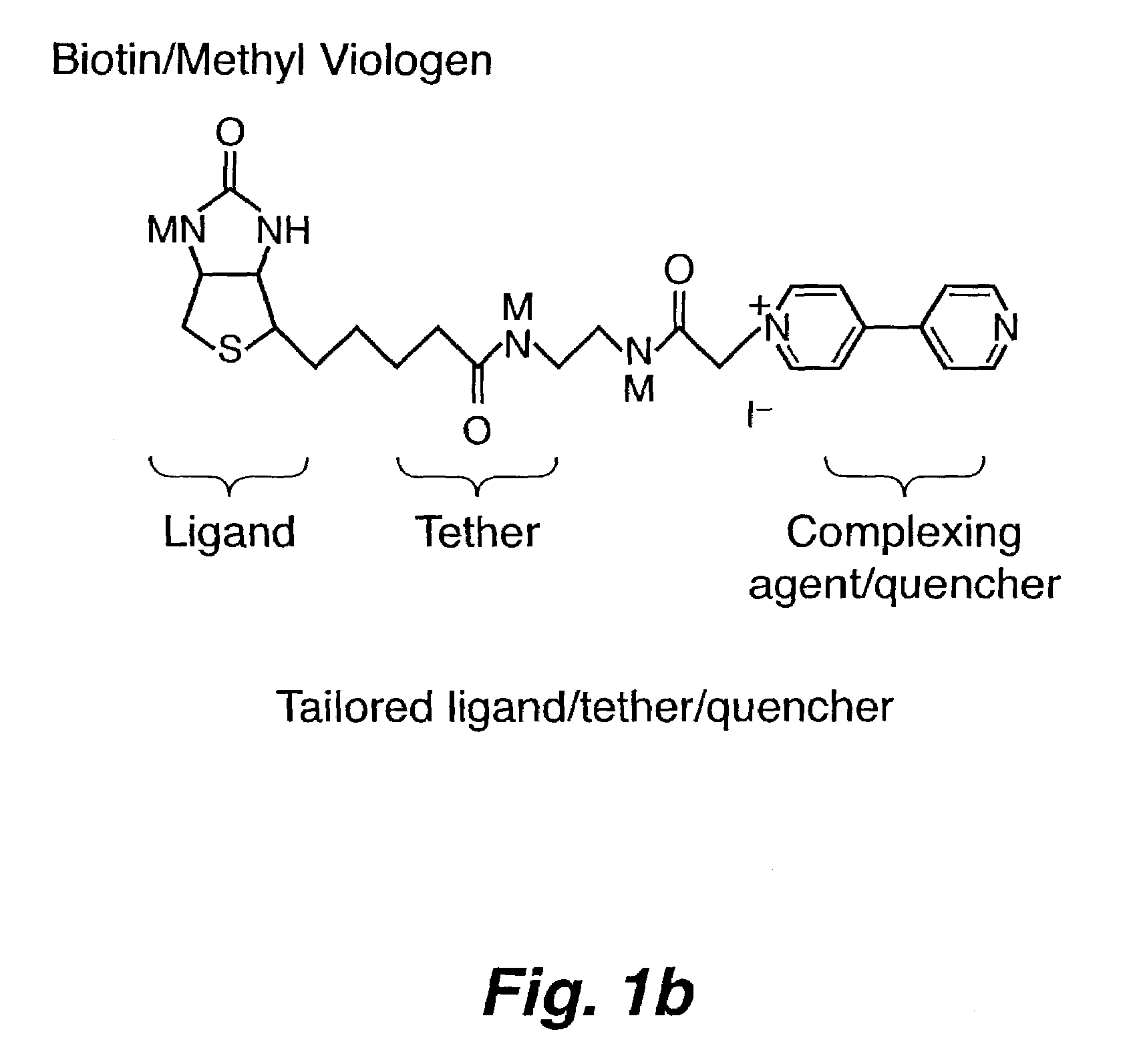

Method for detecting biological agents

A sensor is provided including a polymer capable of having an alterable measurable property from the group of luminescence and electrical conductivity, the polymer having an intermediate combination of a recognition element, a tethering element and a property-altering element bound thereto and capable of altering the measurable property, the intermediate combination adapted for subsequent separation from the polymer upon exposure to an agent having an affinity for binding to the recognition element whereupon the separation of the intermediate combination from the polymer results in a detectable change in the alterable measurable property, and, detecting said detectable change in the alterable measurable property.

Owner:LOS ALAMOS NATIONAL SECURITY

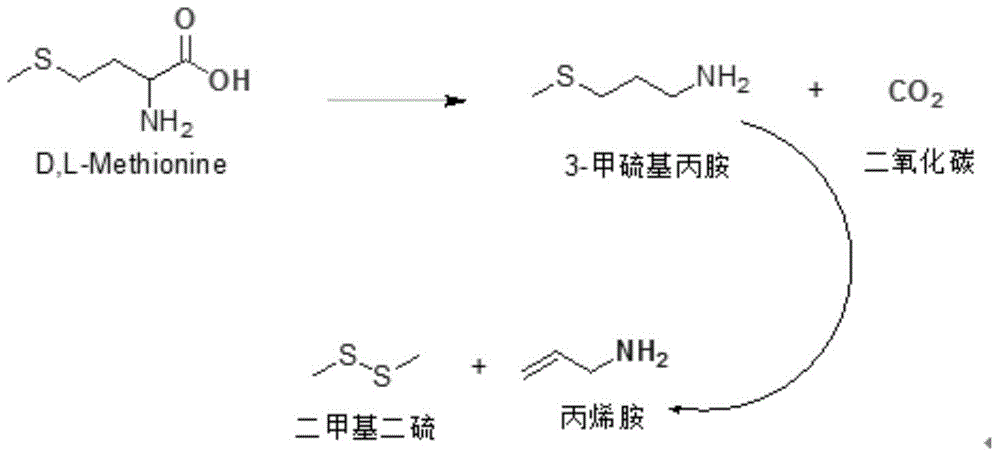

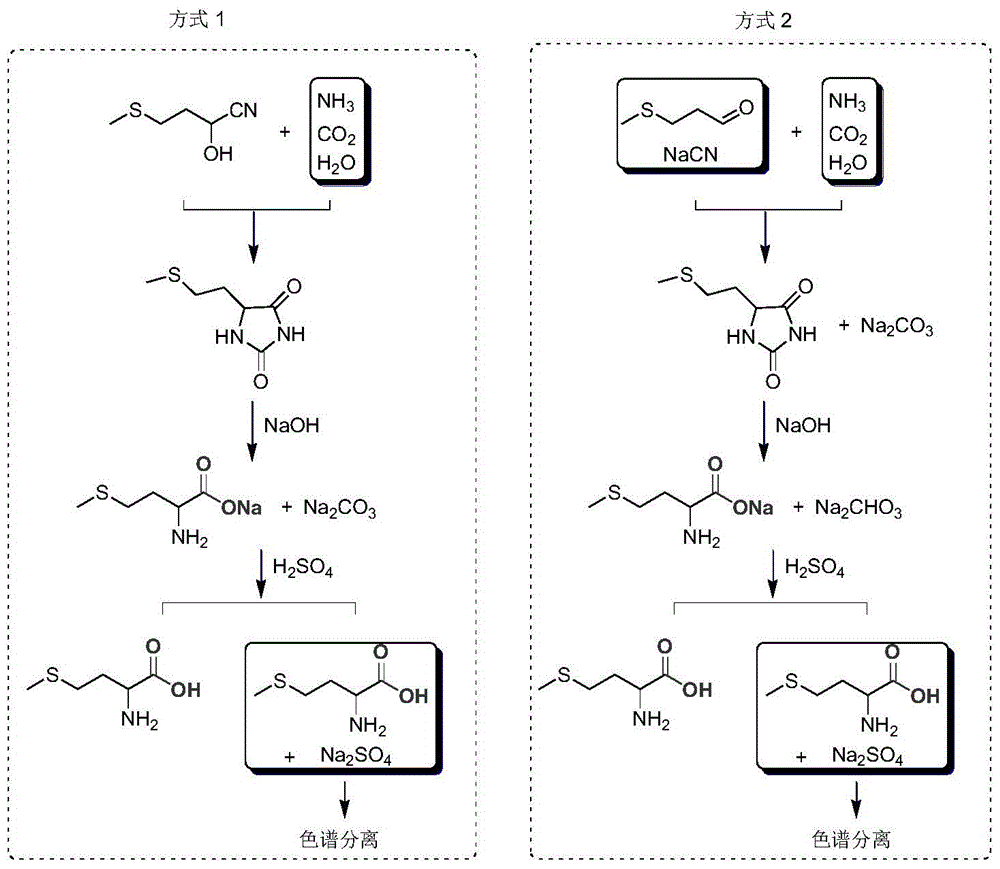

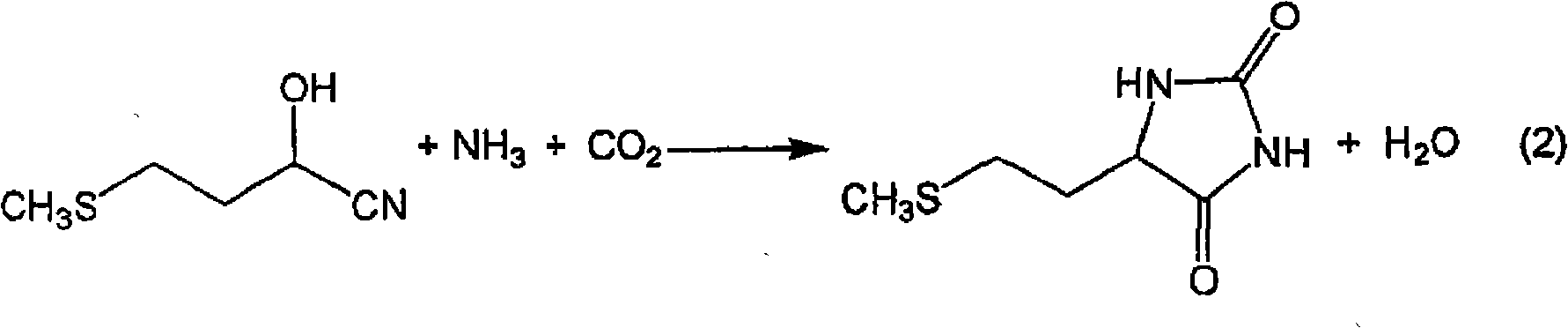

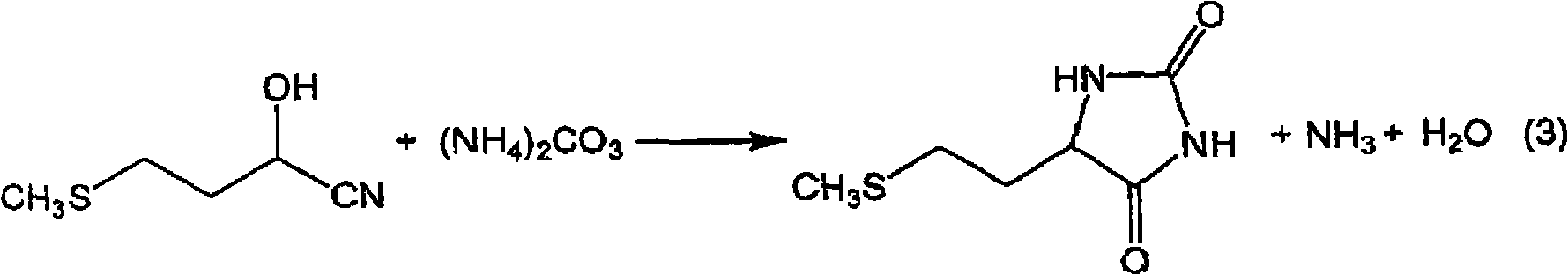

Method for preparing methionine

The invention discloses a method for preparing methionine. The method for preparing the methionine concretely comprises the steps that cyanohydrins, carbon dioxide and ammonia or sodium cyanide, 3-(Methylthio)propionaldehyde, carbon dioxide and ammonia serve as raw materials to prepare hydantoin; alkaline hydrolysis is conducted on the hydantoin and then the hydantoin is acidized to pH 3.0-6.0 to obtain a compound of the methionine and salts; crystallization is conducted under the condition of temperature ranges from 8 DEG C to 45 DEG C, then the compound is separated to obtain a methionine crystal and salt mother liquor, the methionine crystal is washed by water and dried, and washing liquor is standby; finally, the salt mother liquor is concentrated under the condition of temperature which is lower than 60 DEG C, and then the salt mother liquor passes through a chromatographic column to obtain an inorganic salt and the methionine; the preparation method can efficiently separate the methionine and the salts, the recovery rate of the methionine can reach 99%, and the method is green and protects the environment, no methionine is resolved, no large number of acid and stink wastewater is discharged, and the purity of the inorganic salt is high and can be sold as a commodity.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

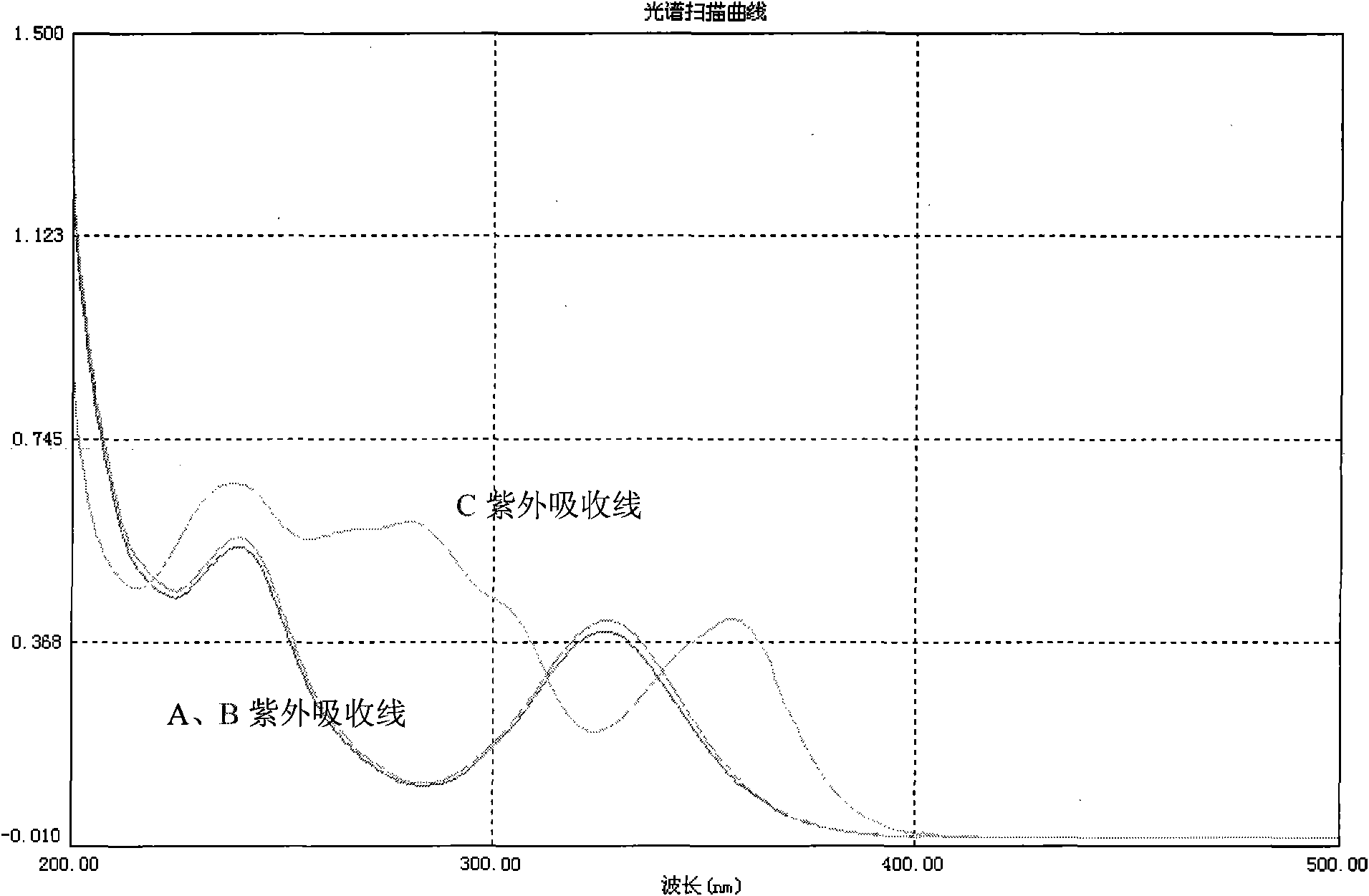

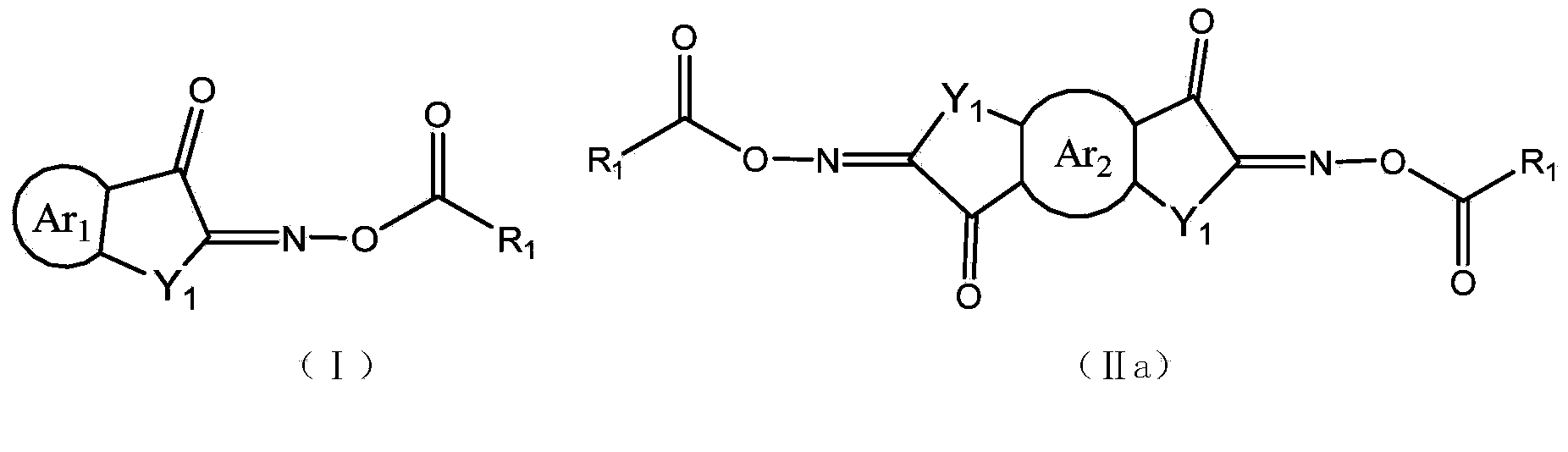

Photoinitiator containing nitro dioxime ester and preparation method and application thereof

ActiveCN103819583AOximes preparationPhotosensitive materials for photomechanical apparatusWavelengthUltraviolet light emitting diodes

The invention discloses a photoinitiator containing nitro dioxime ester. The structure of the photoinitiator is represented by a general formula I shown in the specification. The photoinitiator has excellent application properties on the aspects of storage stability, light sensitivity, developing performance, pattern integrity and the like, has good adaptability to single-wavelength UV-LED (Ultraviolet-Light Emitting Diode) light sources and shows light sensitization performance, which is obviously better than that of the existing photoinitiators, under the irradiation of UV-LED.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS +1

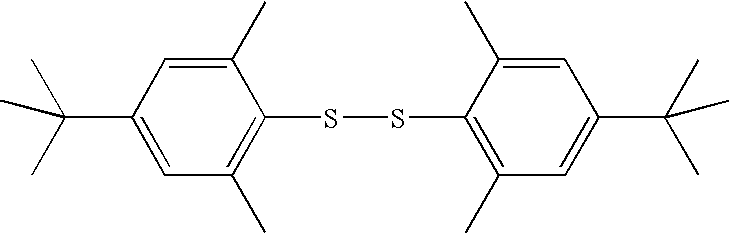

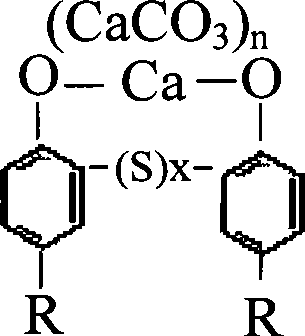

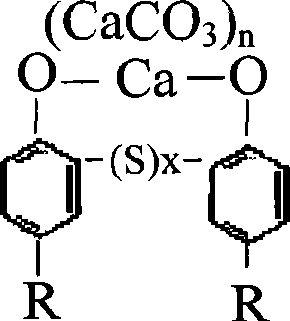

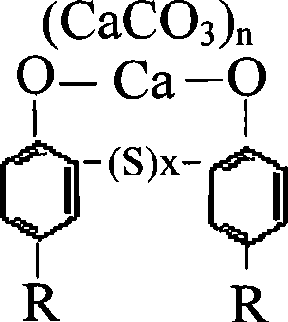

High basic value (TBN400) sulfurized calcium alkyl and preparation method thereof

ActiveCN101423483AWide range of usesImprove performanceAdditivesHydropoly/poly sulfide preparationChemical structureCarboxylic acid

The invention relates to high base number (TBN400) vulcanized alkyl phenol calcium and a preparation method thereof. The vulcanized alkyl phenol calcium has a chemical structure as right. The preparation method is as follows: in a system containing solvent and diluent oil, alkyl phenol compound, shielded phenol compound, calcium oxide and / or calcium hydroxide and sulfur are subjected to sulfonation / neutralization reaction at a temperature of between 60 and 180 DEG C to generate phenolate intermediate; balanced calcium oxide and / or calcium hydroxide are added into the mixture, carbon dioxide is introduced, and the mixture is subjected to carbonation reaction; and alkyl polylol is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, long-chain carboxylic acid is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, and products are obtained through refining. The vulcanized alkyl phenol calcium has the characteristics of high base number, low viscosity, low precipitation number, good heat storage stability, and the like, and has excellent combination property, does not cause environmental protection problem during use, and belongs to an environment-friendly product, and adopts a one-stage process, has mild reaction conditions, and is easy to filter.

Owner:JINZHOU DPF TH CHEM CO LTD

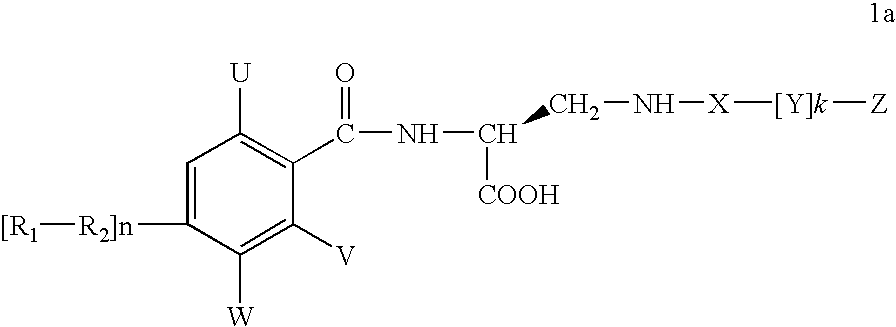

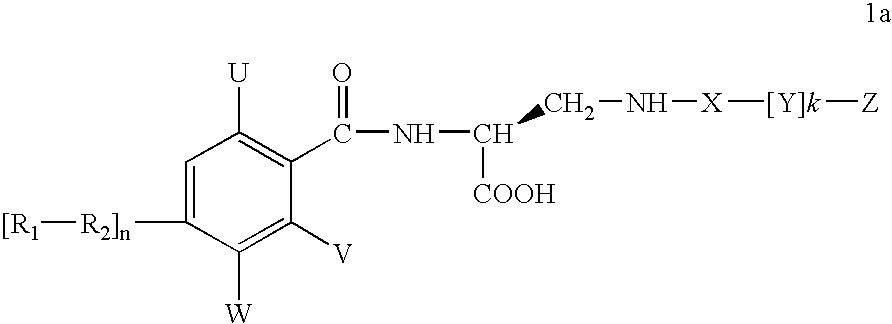

Diaminopropionic acid derivatives

A compound of formula 1a which is useful for treating reperfusion injury, and salts, prodrugs, and related compounds.

Owner:F HOFFMANN LA ROCHE INC

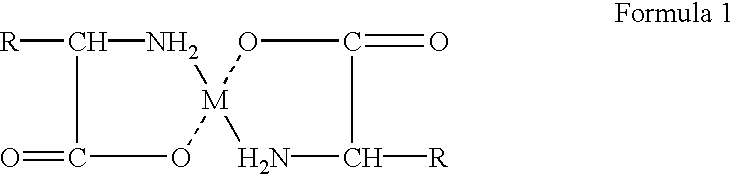

Composition and method for preparing amino acid chelates and complexes

Compositions and methods of preparing amino acid chelates and complexes are disclosed and described. Specifically, by (a) combining a hydrated metal sulfate salt with an amino acid ligand to form a particulate blend, (b) placing the particulate blend in an enclosed environment; and (c) applying heat to the particulate blend in the enclosed environment causing the waters of hydration of the metal sulfate salt to be released into the enclosed environment causing a reaction resulting in the formation of an amino acid chelate or complex by effecting the reaction between functional electron rich groups of the amino acid ligand and a metal ion of the metal sulfate salt. The waters of hydration serve to provide the water necessary to enable a bonding reaction to take place between the electron rich functional groups of the amino acid ligand and the metal ion of the hydrated metal sulfate salt.

Owner:ALBION LAB

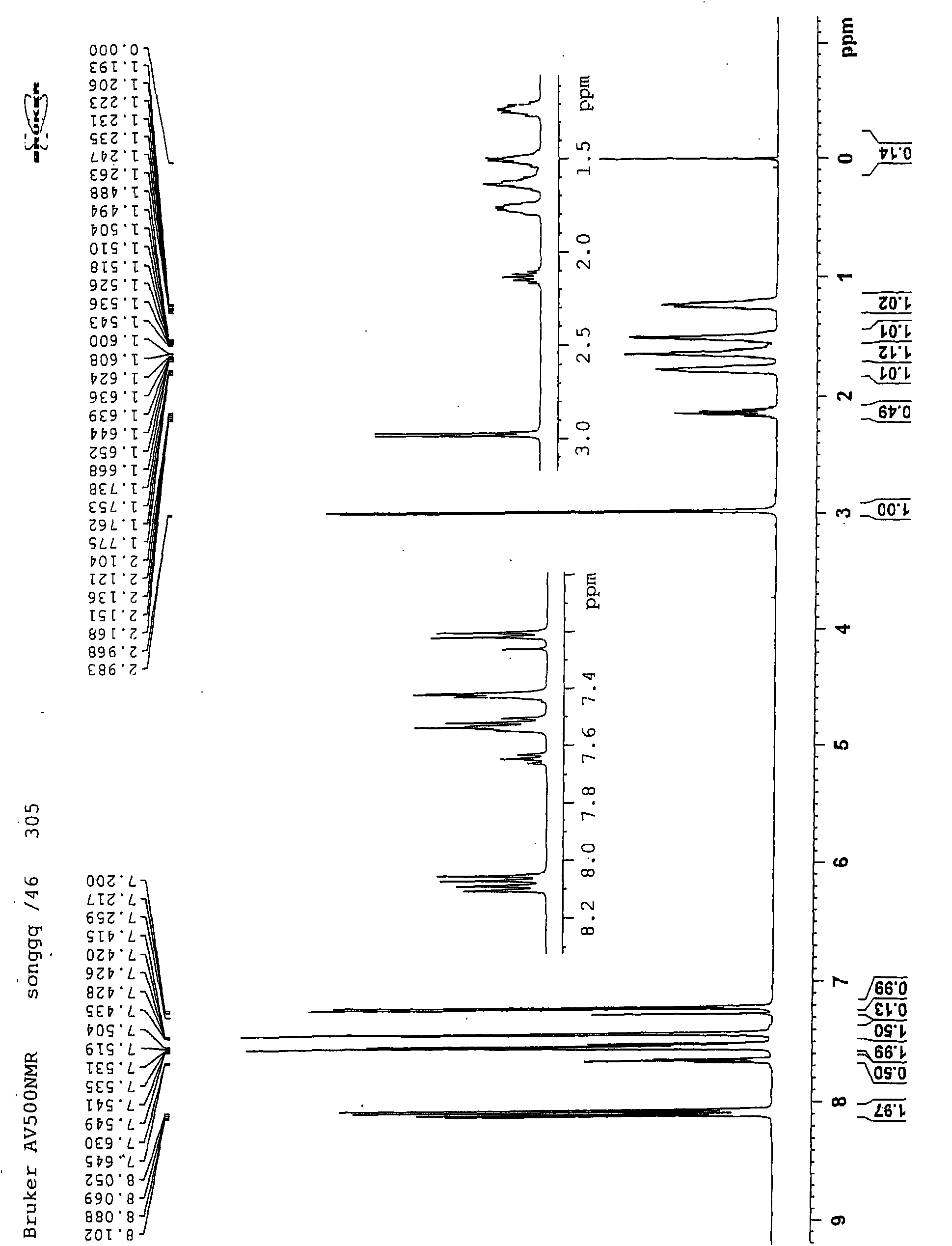

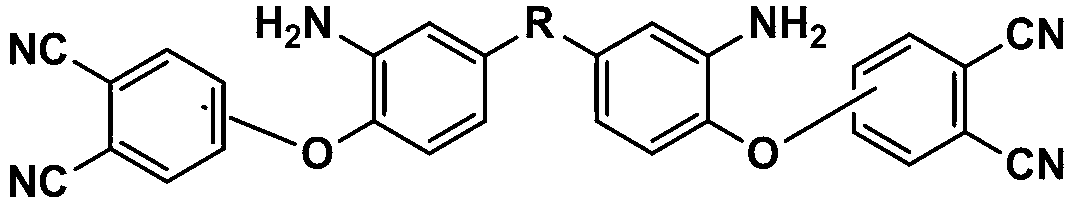

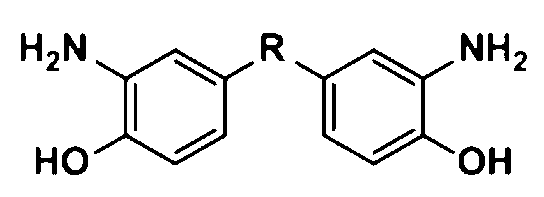

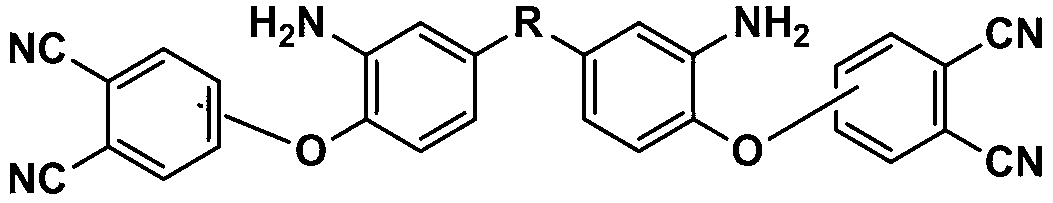

Aromatic diamine containing phthalonitrile side group and synthesis method and application thereof

InactiveCN102993070AIncrease typeBreak the rigid structureCarboxylic acid nitrile preparationOrganic compound preparationImidePolymer science

The invention discloses aromatic diamine containing phthalonitrile side group, which is characterized in that the structural formula is shown in the specification, wherein R is one of CF3CCF3, CH3CCH3, O, CO and S. A preparation method of the aromatic diamine containing phthalonitrile side group comprises the following steps of: adding 4-nitrophthalonitrile or 3-nitrophthalonitrile, a compound 1, potassium carbonate and a high-boiling point solvent into a reaction container; conducting reaction for 10-24 hours at room temperature under protection of nitrogen; and then precipitating, filtering and drying. The aromatic diamine containing phthalonitrile side group can be applied to the preparation of polyimide, polyamide and polyamide-imide.

Owner:SICHUAN UNIV

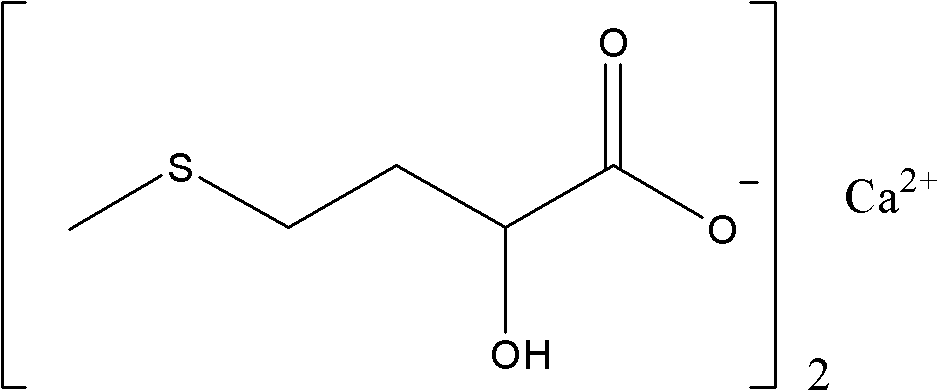

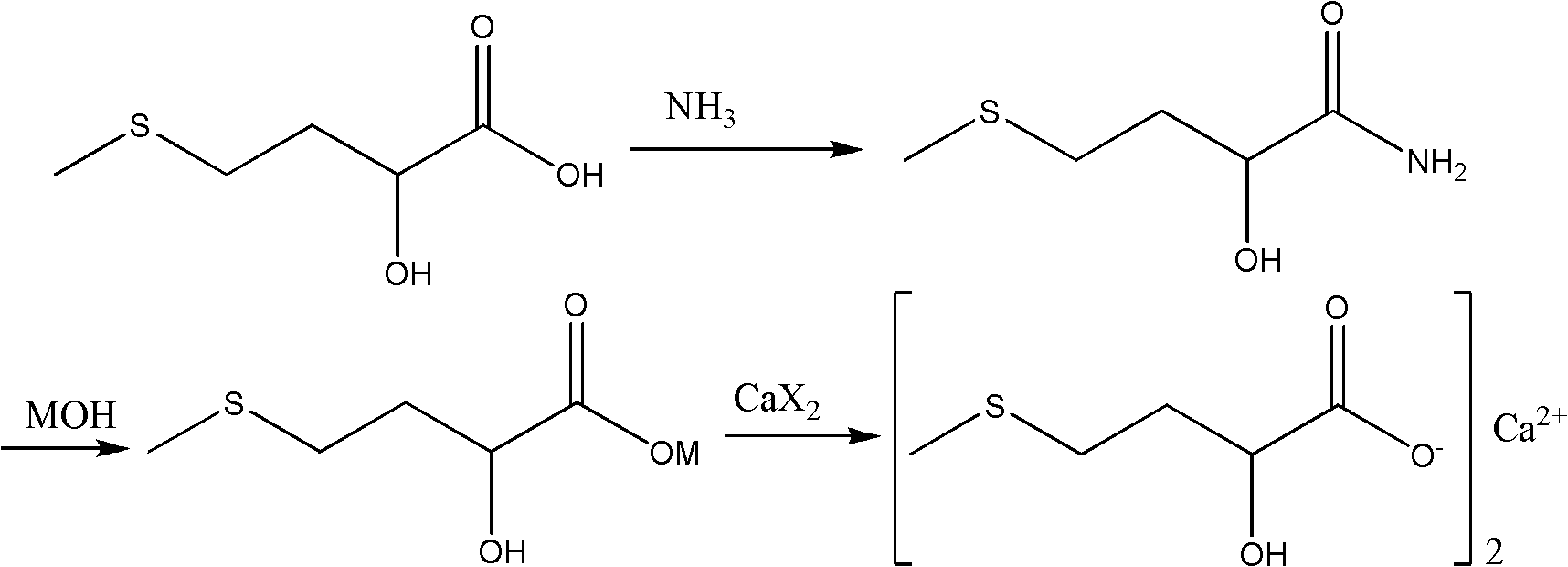

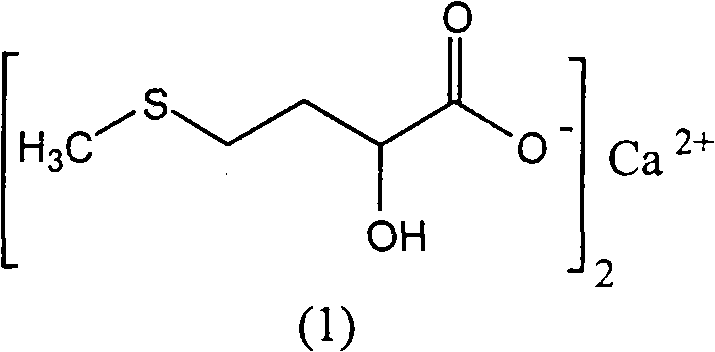

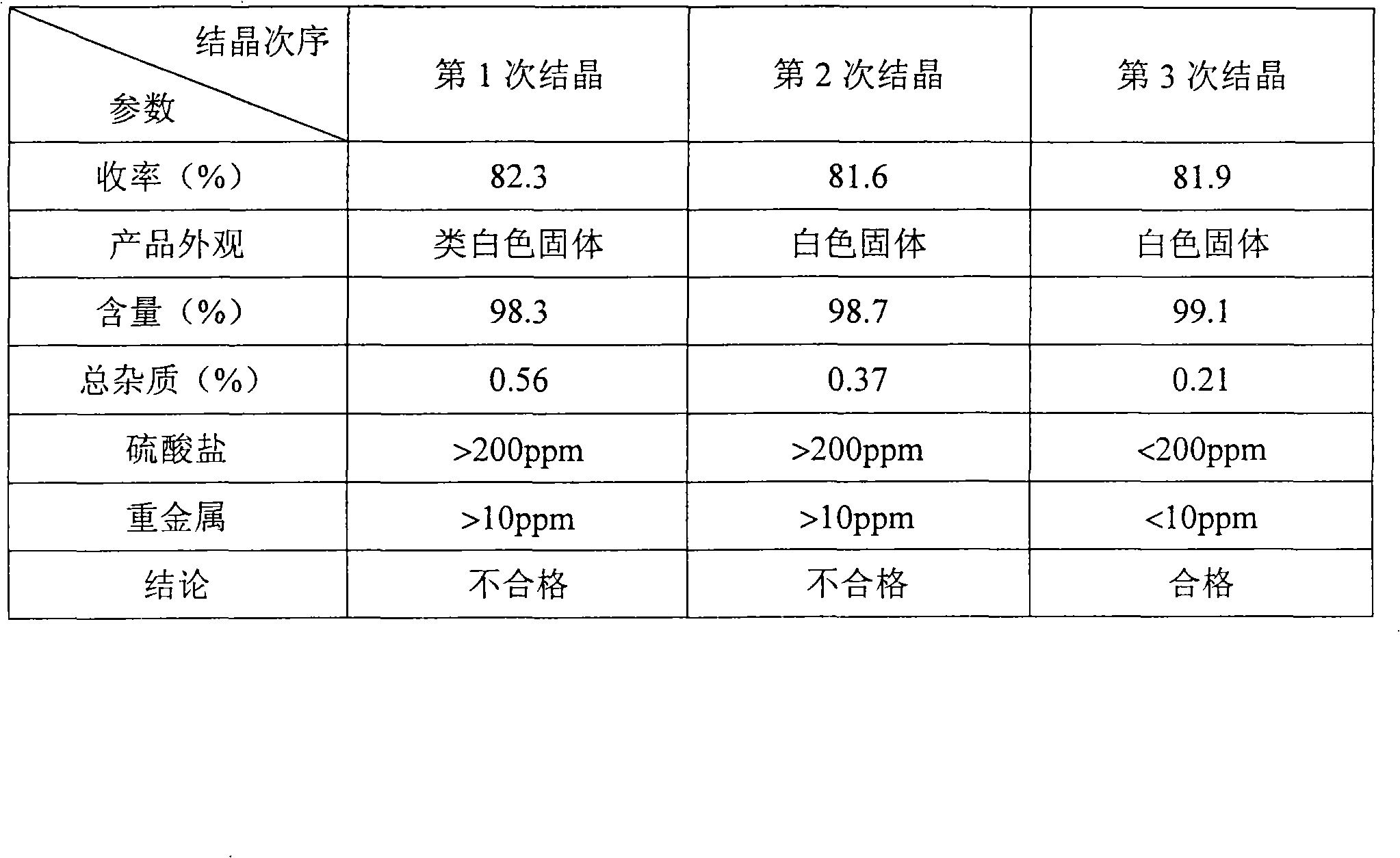

Synthesis method of medicinal calcium D,L-2-hydroxyl-4-(methylthio)butyrate

The invention discloses a synthesis method of medicinal calcium D,L-2-hydroxyl-4-(methylthio)butyrate. By adopting the existing methods, the product has more impurities and poor quality; and some methods have harsh conditions and low product yield and are not suitable for industrial production. The synthesis method comprises the following steps: using feed grade D,L-2-hydroxyl-4-methylthiobutyricacid of which the content is less than 90% or D,L-2-hydroxyl-4-methylthiobutyric acid of which the content is 75-90% as a starting raw material to react with ammonia and generate an ammonium salt, performing dehydration to obtain D,L-2-hydroxyl-4-methylthiobutyramide, extracting, concentrating, crystallizing and purifying to obtain D,L-2-hydroxyl-4-methylthiobutyramide of which the content is more than 98.5%; and hydrolyzing to generate D,L-2-hydroxyl-4-methylthiobutyrate, and performing the salt forming reaction with CaX2 to generate calcium D,L-2-hydroxyl-4-(methylthio)butyrate. The synthesis method in the invention has mild process conditions, less side reactions and high yield.

Owner:ZHEJIANG NHU CO LTD

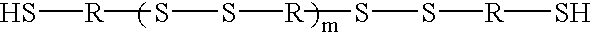

Preparation of polysulfide compositions

InactiveUS6939941B2High molecular weightReduce the amount requiredOrganic compound preparationOther chemical processesPolysulfidePolymer

A process is provided for the manufacture of liquid polysulfide polymers. In particular, the process allows for making the liquid form of the polysulfide polymer directly and eliminates the need to first make a solid polysulfide polymer and then convert it to a liquid.

Owner:TORAY FINE CHEMICALS CO LTD

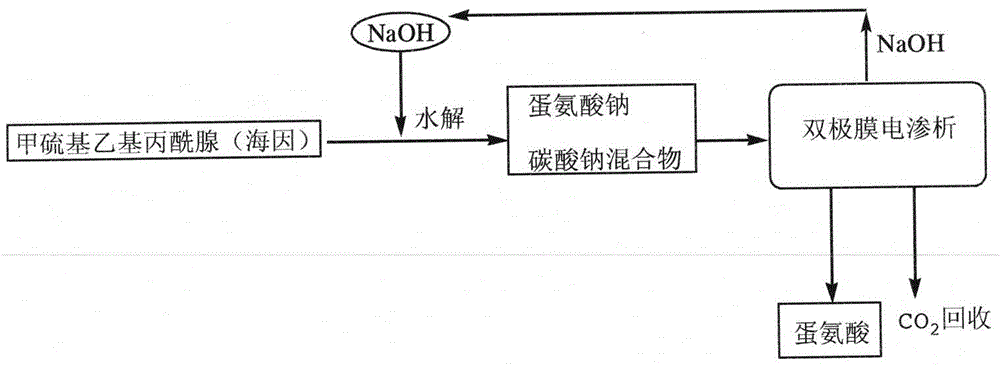

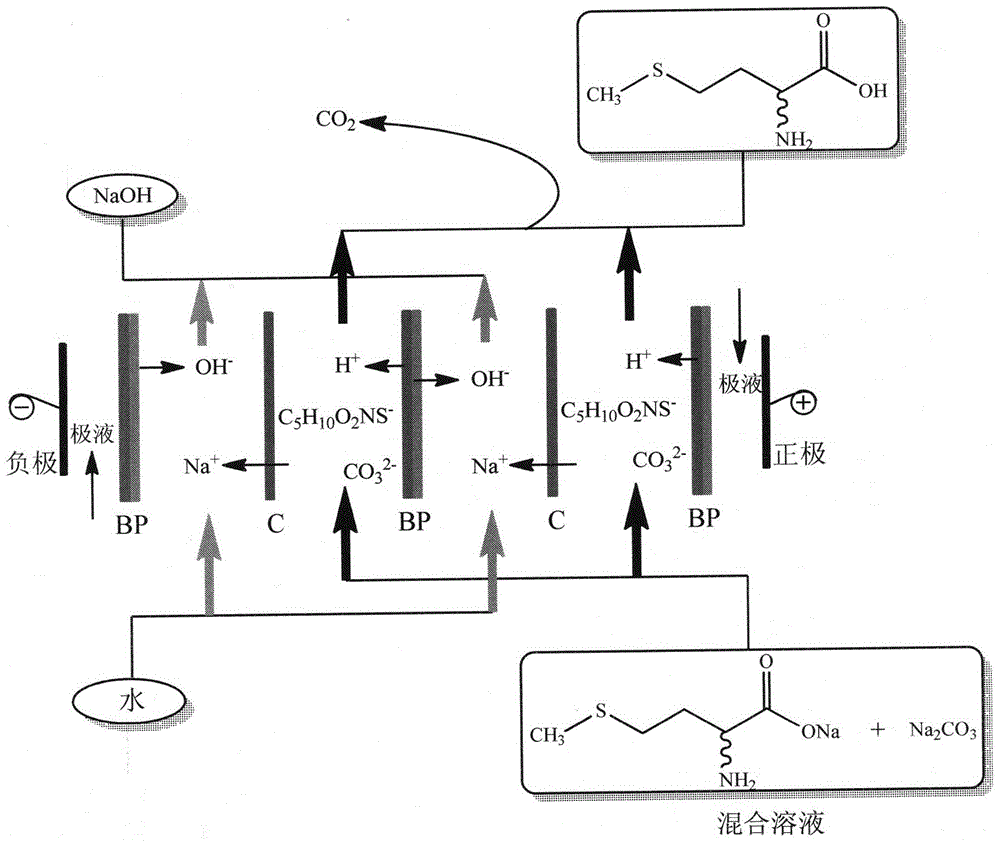

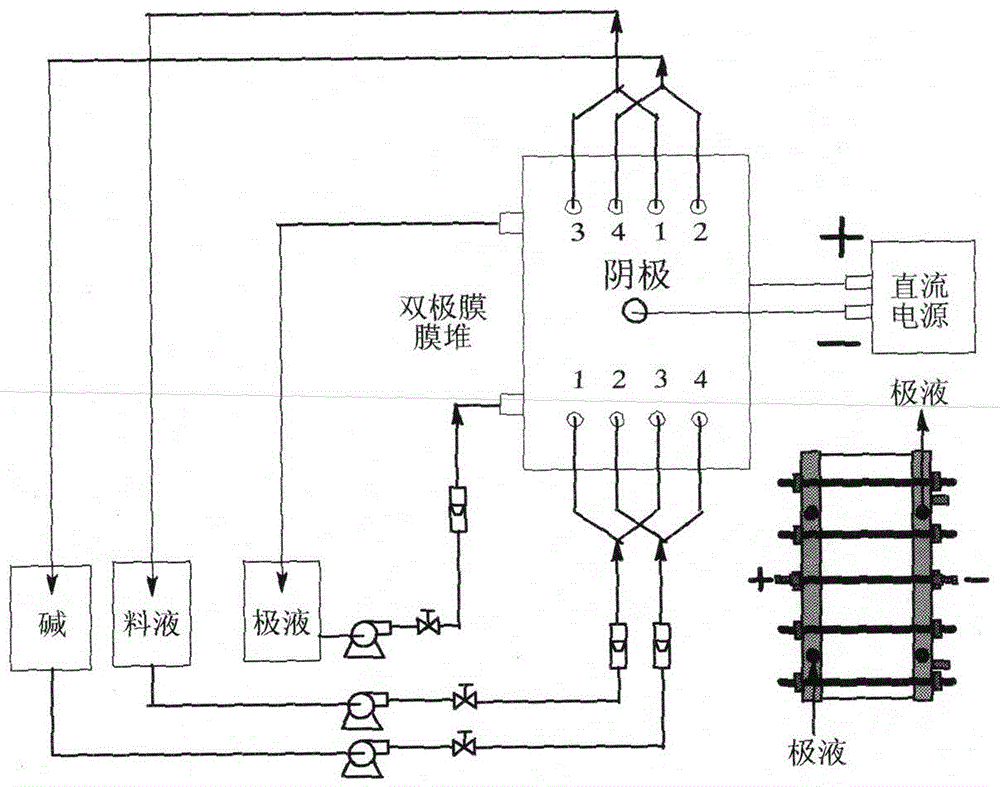

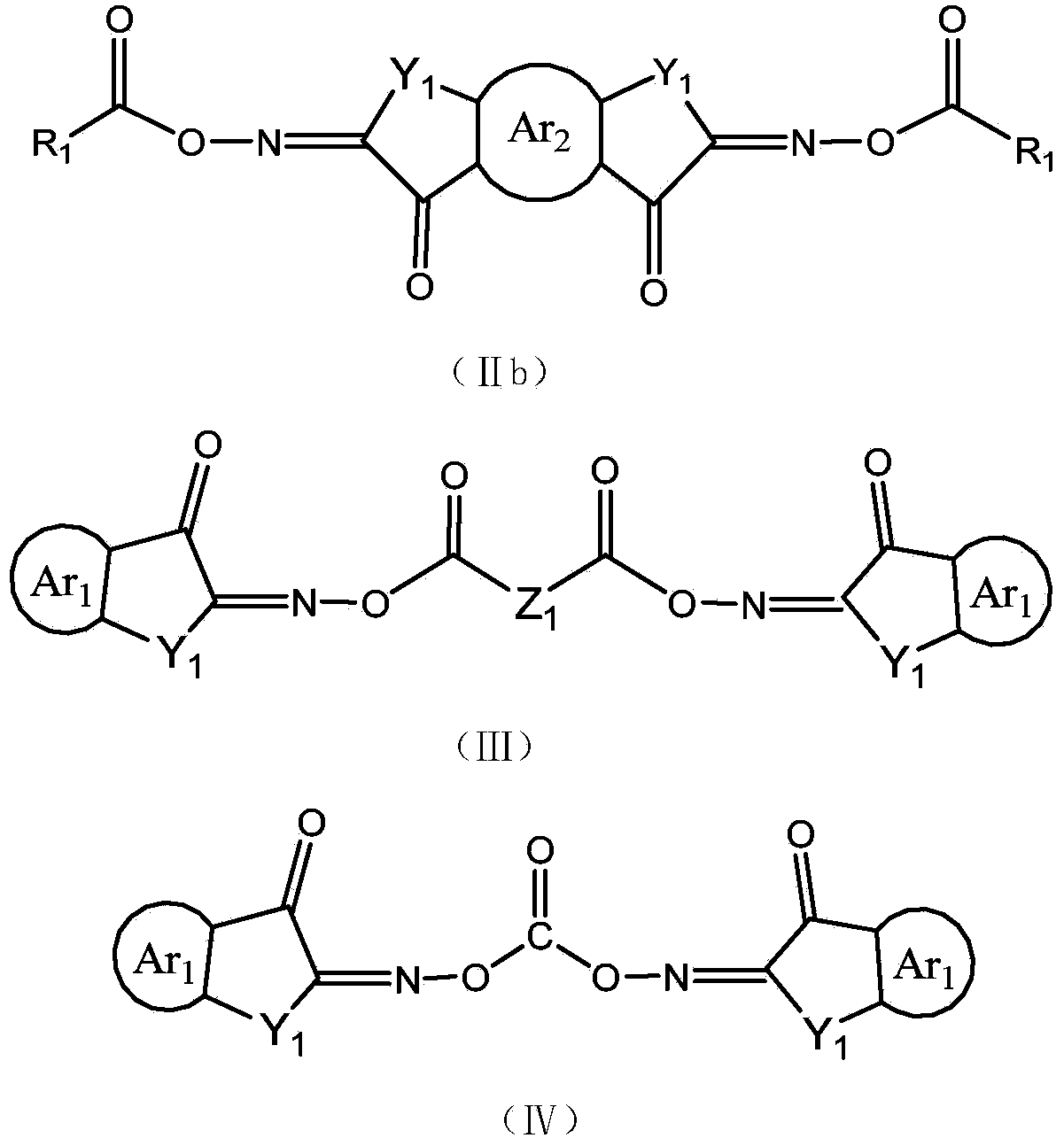

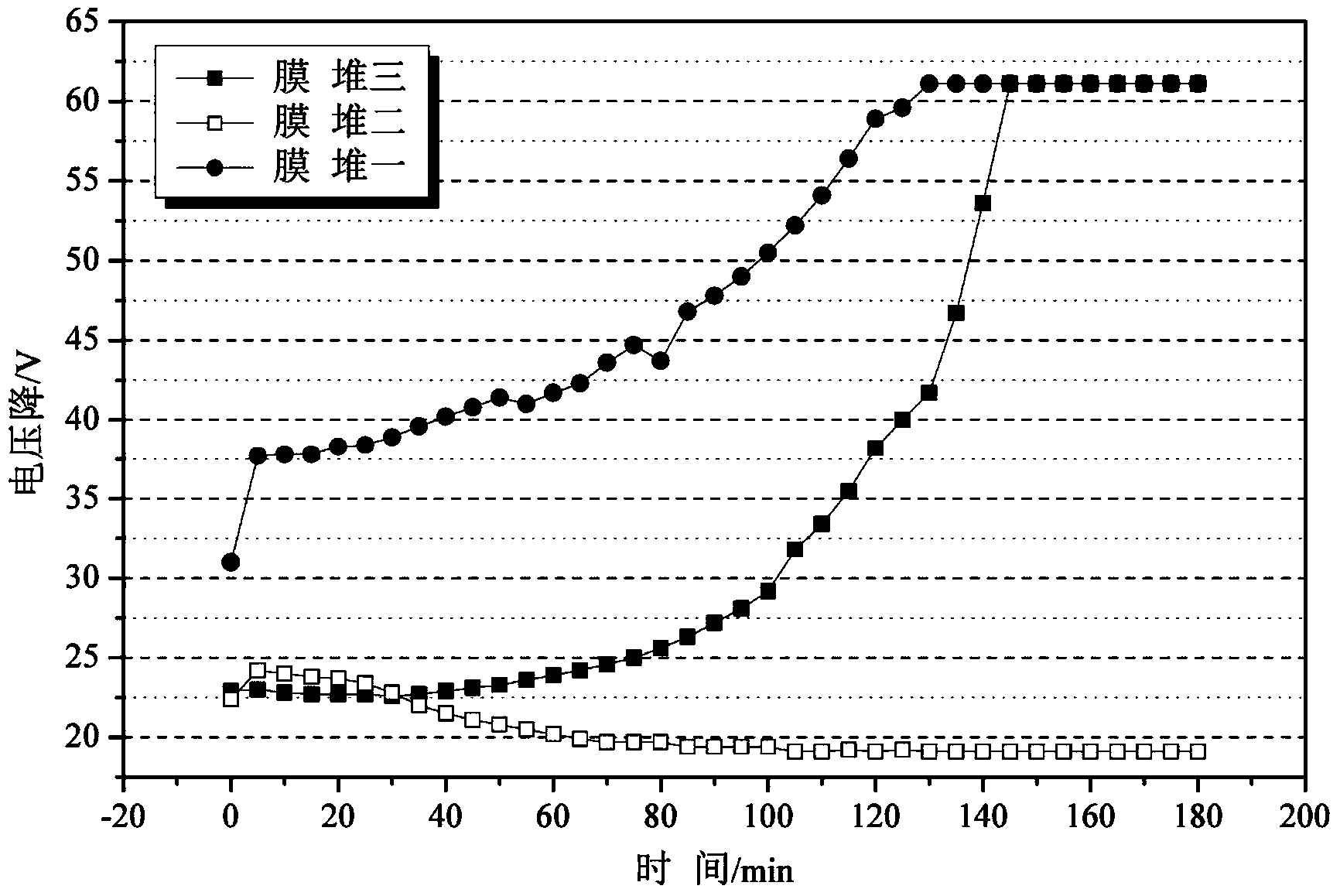

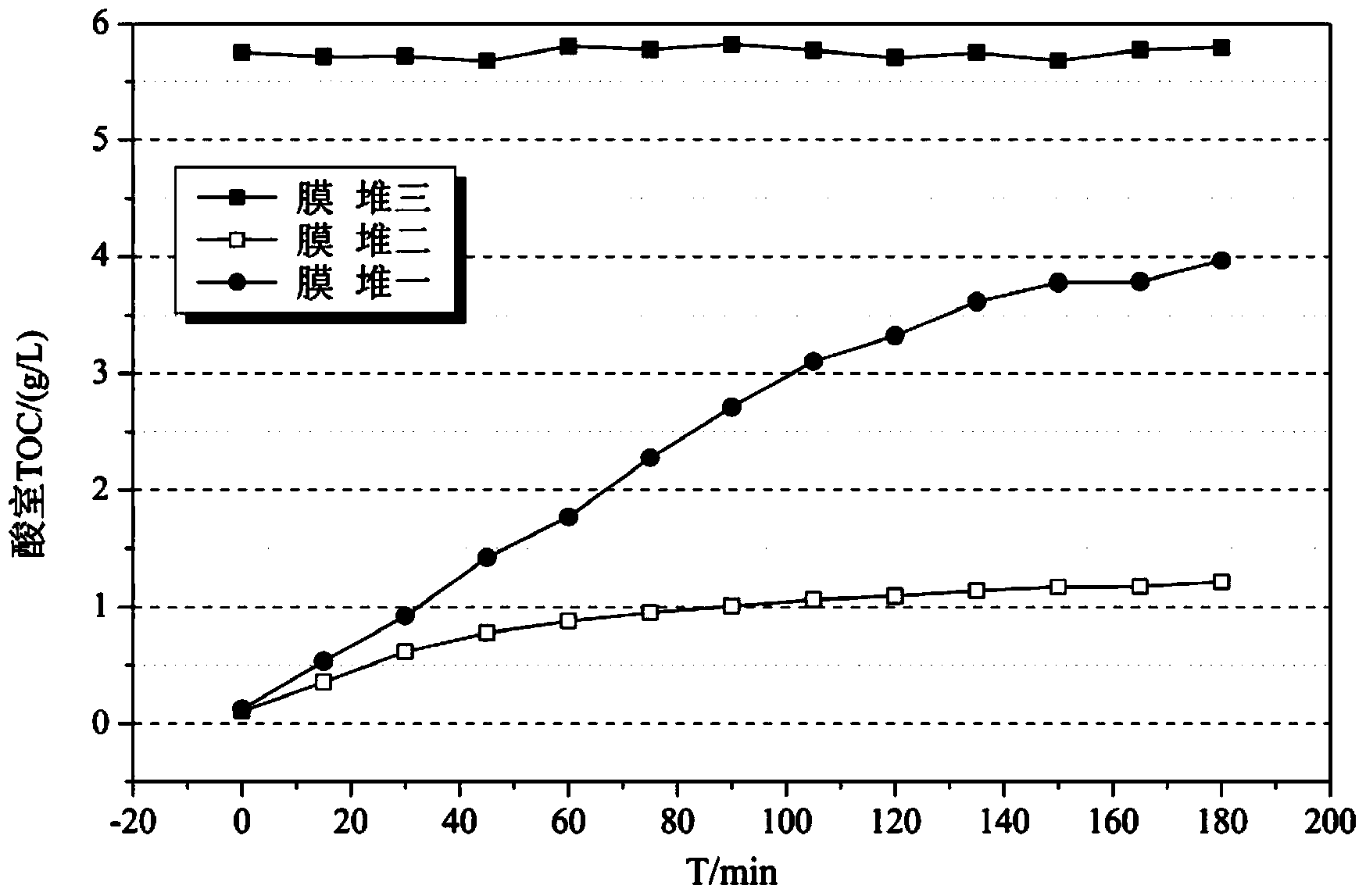

Method for preparing methionine and sodium hydroxide through bipolar membrane electrodialysis

InactiveCN103933861ARealize cleaner productionSignificant industrial application valueOrganic compound preparationAlkali metal hydroxidesMethionine recyclingHydrolysate

The invention discloses a method for preparing methionine and sodium hydroxide through applying a bipolar membrane electrodialysis technology. The method comprises the specific process: diluting a methylthioethyl hydantoin (hydantoin) hydrolysate to one-third to one-fifth of the original concentration, and filtering with a microporous filter; then pumping the hydrolysate into one of a salt chamber or a salt / acid chamber of a bipolar membrane electrodialysis device, and injecting a certain concentration of an electrolyte solution into other compartments; connecting a cathode and an anode of the bipolar membrane electrodialysis device respectively with a negative electrode and a positive electrode of a direct-current power source, starting the bipolar membrane electrodialysis device, controlling the current density of a direct-current electric field to be 50-150 mA / cm<2> and the temperature at 20-40 DEG C, and thus obtaining methionine with higher purity in an acid chamber, wherein the methionine recycling rate reaches more than 95% and the current efficiency reaches about 70%; and at the same time, collecting obtained carbon dioxide, and thus obtaining sodium hydroxide with the concentration of 4-6% in an alkali chamber. The method has the advantages of high yield, no pollution, less use of raw materials, and good application prospects.

Owner:ZHEJIANG CIRCLE TECH MEMBRANE TECH +1

Preparation of medicinal D,L-2-hydroxy-4-methylthio calcium butyrate

The invention discloses a method for preparing a D, L-2-hydroxyl-4-methylthio butanoic calcium salt for medicinal purpose. The method comprises following steps of: a. using a D,L-2-hydroxyl-4-methylthio butanoic acid and an alcohol with a general formula of ROH as the raw materials to carry out esterification to obtain a D, L-2-hydroxyl-4-methylthio butyrate, and; b. hydrolyzing the D, L-2-hydroxyl-4-methylthio butyrate in step a and calcium oxide in a solvent to produce the D, L-2-hydroxyl-4-methylthio butanoic calcium salt. The method provided by the invention for the production of the D, L-2-hydroxyl-4-methylthio butanoic calcium salt has the advantages of short course, readily available the raw materials, low cost, easy control over the quality of the product, and more importantly, the method can prepare high-purity D, L-2-hydroxyl-4-methylthio butanoic calcium salt for medicinal purpose, thereby satisfying the requirements of State Food and Drug Administration Bureau and Good Manufacturing Practice (GMP) for drug production, and facilitating the preparation of pharmaceutical preparations.

Owner:NANJING LIFENERGY R & D +1

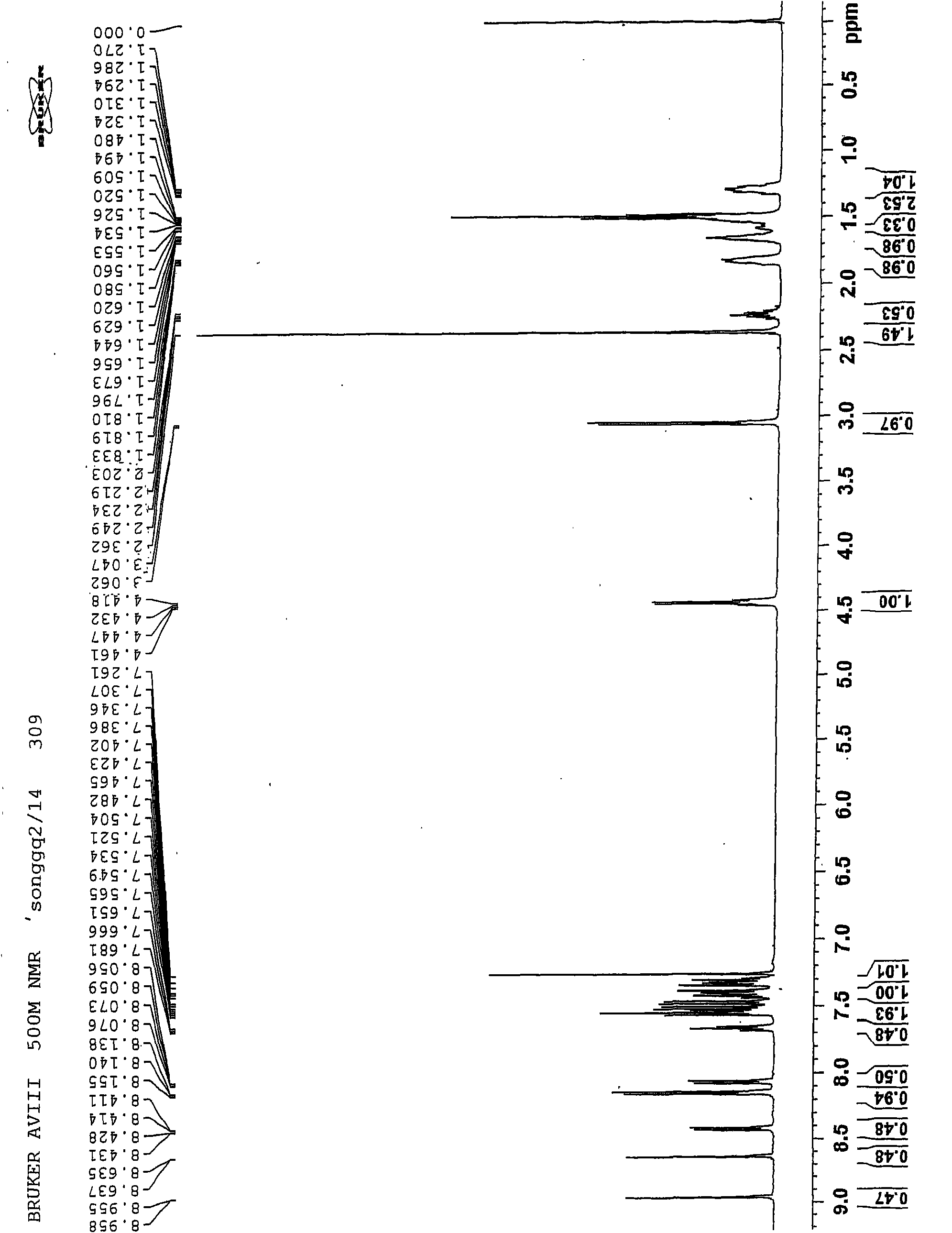

Cyclopentadiketoxime ester and applications thereof

ActiveCN103998422AHigh light sensitivityThe imaging effect is clearGroup 4/14 element organic compoundsNon-macromolecular adhesive additivesColor gelMedicinal chemistry

Owner:INSIGHT HIGH TECH (BEIJING) CO LTD

Method for separating methionine from mixed solution of methionine salt and carbonate by using bipolar membrane electrodialysis

The invention discloses a method for separating methionine from a mixed solution of methionine salt and carbonate by using bipolar membrane electrodialysis. The method is characterized by comprising the steps of arranging a bipolar membrane electrodialysis system, and separating methionine from a mixed solution of methionine salt and carbonate by using a bipolar membrane electrodialysis process, wherein a bipolar membrane is capable of simultaneously generating hydroxyl ions and hydrogen ions through hydrolytic dissociation, the hydrogen ions are capable of neutralizing methionine ions and carbanions in the mixed solution of methionine salt and carbonate to generate methionine, and the generated hydroxyl ions are capable of combining with positive ions to obtain inorganic base. According to the method, a large quantity of acid and alkaline are not required to be additionally introduced in the bipolar membrane electrodialysis process, the environment friendliness is achieved, the process cost is lowered, no inorganic salt waste residue is generated in the process, the recovery efficiency of methionine is high, and the purity is high, thus the generated wastewater is more easily treated.

Owner:UNIV OF SCI & TECH OF CHINA

Process for producing methionine

InactiveCN101602701AReduce the final amountOrganic compound preparationSulfide preparationPotassiumMethionine biosynthesis

The present invention provides a process for producing methionine, which comprises the steps of: hydrolyzing 5-[2-(methylthio)ethyl]imidazolidine-2,4-dione in the presence of a basic potassium compound in a non-stirred continuous first reaction tank, and heat-treating the reaction solution after hydrolysis in a second reaction tank. According to the process of the present invention, a methionine crystal with a higher bulk density can be produced.

Owner:SUMITOMO CHEM CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com