Process for producing methionine

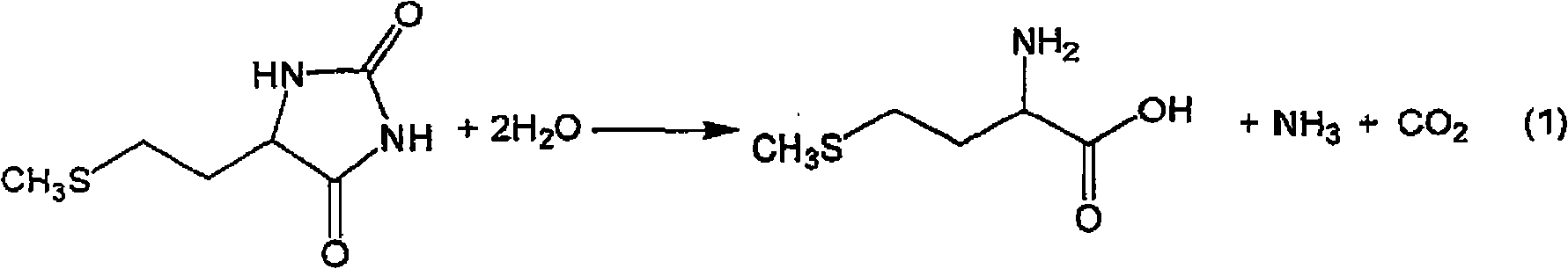

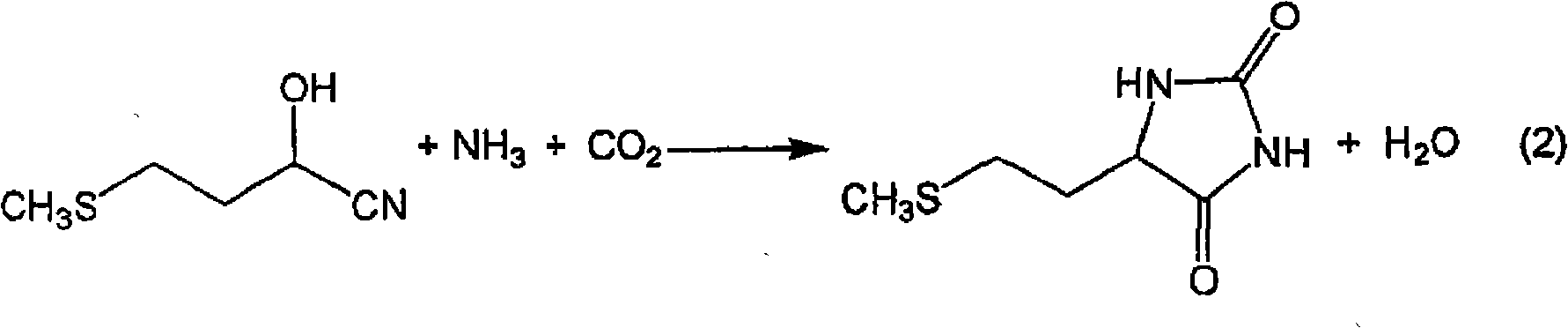

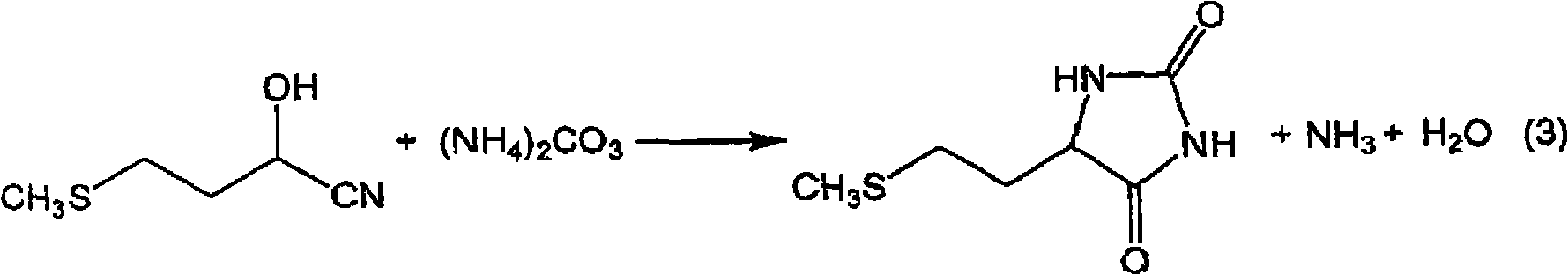

A technology for the production of methionine and reactors, applied in the field of methionine production, can solve the problems of low bulk density of methionine crystals, difficulty in stabilizing methionine crystals, and high equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A mixture of 5.4 parts / hour of a solution containing 5-[2-(methylthio)ethyl]imidazolidine-2,4-dione and an aqueous potassium hydroxide solution was continuously added to the non-stirring continuous first reaction tank. While carbon dioxide and ammonia produced as by-products are continuously distilled off together with water, the reaction solution is continuously fed into a non-stirring continuous second reaction tank different from the first reaction tank. At this time, the temperature of the reactor was 177° C., and the gauge pressure was 0.88 MPa. The residence time in the first reactor was 30 minutes and the residence time in the second reactor was 6 minutes, for a total of 36 minutes. After the reaction, the hydrolyzed solution thus obtained contained 10.4% potassium, 13.1% methionine and 1.29% methionine dipeptide, the ratio of methionine dipeptide to methionine being 9.9%.

[0070] One part of the hydrolyzed solution was added to the reactor, and then polyvinyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| loose density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com