Method for oxidizing dimethyl sulfide

A technology for oxidizing dimethyl sulfide and dimethyl sulfide, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems that dimethyl sulfone application research has not yet been carried out well, and achieves Effects of high effective utilization rate of oxidant, ease of implementation, and high conversion rate of dimethyl sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Send dimethyl sulfide, titanium-silicon molecular sieve TS-1 as catalyst, hydrogen peroxide as oxidant, methanol and hydrochloric acid (36% aqueous solution) as solvent into a small slurry bed reactor for oxidation reaction, the catalyst is separated from the reaction mixture output from the slurry bed reactor to obtain a liquid phase mixture containing dimethyl sulfone, and the separated catalyst is recycled. Among them, the molar ratio of dimethyl sulfide to oxidant is 1:2.5, the mass ratio of dimethyl sulfide to catalyst is 25:1, the mass ratio of solvent to catalyst is 200:1, and the amount of hydrochloric acid makes the The pH value of the mixture formed by the base sulfide, the oxidizing agent and the solvent is 3.5; the reaction temperature is 30° C., the pressure in the reactor is 0.5 MPa, and the total feed rate of the reaction materials is 50 mL / min.

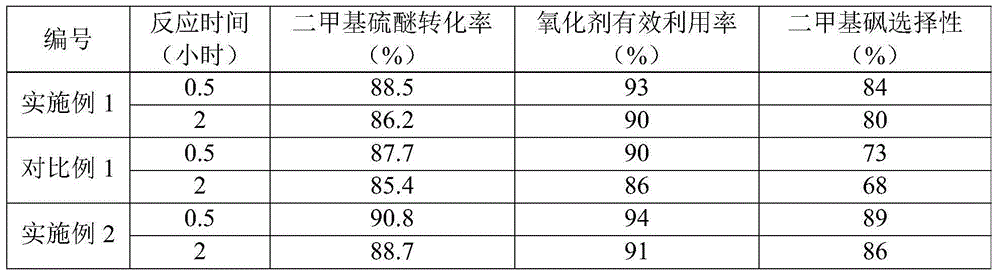

[0052] The liquid phase mixture obtained when the reaction was carried out to 0.5 hour and 2 hours was analyz...

Embodiment 2

[0057] Dimethyl sulfide was oxidized by the same method as in Example 1, except that an equal amount of hollow titanium-silicon molecular sieve was used instead of titanium-silicon molecular sieve TS-1.

[0058] The liquid phase mixture obtained when the reaction was carried out to 0.5 hour and 2 hours was analyzed by gas chromatography, and the conversion rate of dimethyl sulfide, the effective utilization rate of oxidant and the selectivity of dimethyl sulfone were calculated. The results obtained are shown in the table 1 listed.

[0059] Table 1

[0060]

[0061] Comparing Example 1 with Comparative Example 1, it can be seen that the method of the present invention can obtain higher conversion rate of dimethyl sulfide, effective utilization rate of oxidant and selectivity of dimethyl sulfone.

Embodiment 3

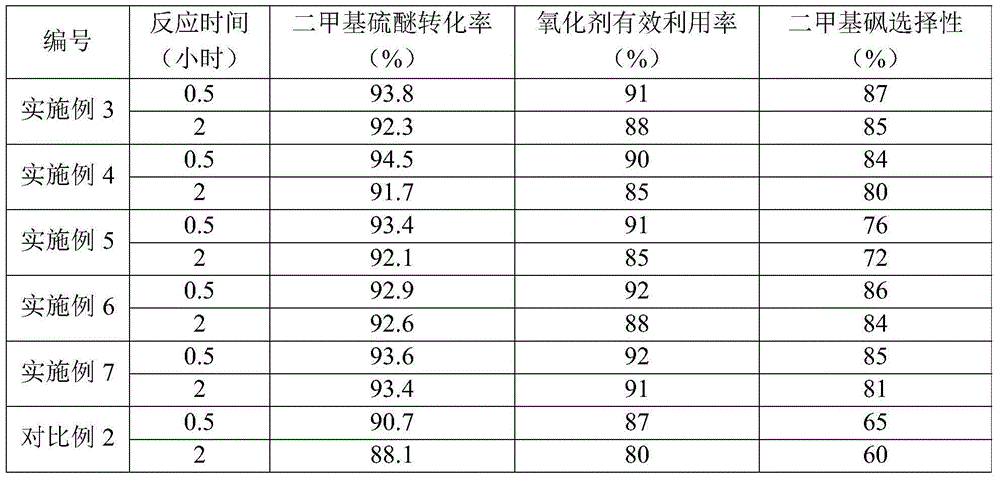

[0063] Send dimethyl sulfide, hollow titanium silicate molecular sieve as catalyst, hydrogen peroxide as oxidant, methanol and phosphoric acid as solvent (aqueous solution with a mass concentration of 36%) into a small slurry bed reactor for oxidation reaction, The catalyst is separated from the reaction mixture output from the slurry bed reactor to obtain a liquid phase mixture containing dimethyl sulfone, and the separated catalyst is recycled. Among them, the molar ratio of dimethyl sulfide to oxidant is 1:3, the mass ratio of dimethyl sulfide to catalyst is 10:1, the mass ratio of solvent to catalyst is 25:1, and the amount of phosphoric acid is such that the The pH value of the mixture formed by the base sulfide, the oxidizing agent and the solvent is 3.5; the reaction temperature is 90° C., the pressure in the reactor is 1.5 MPa, and the total feed rate of the reaction materials is 50 mL / min.

[0064] The liquid phase mixture obtained when the reaction was carried out to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com