Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

229 results about "Nitrochlorobenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrochlorobenzene may refer to: 2-Nitrochlorobenzene 3-Nitrochlorobenzene 4-Nitrochlorobenzene

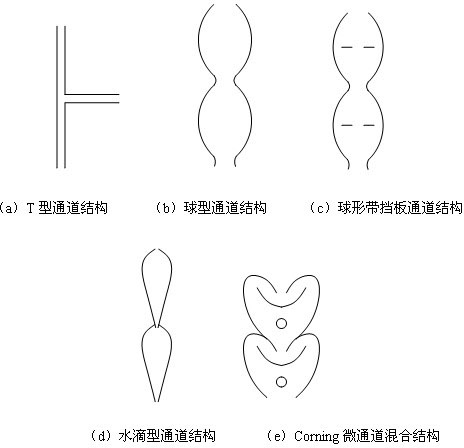

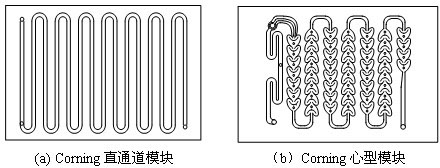

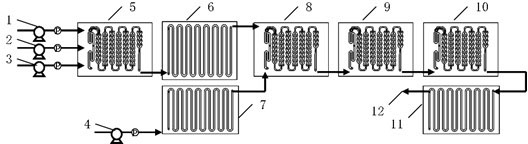

Method for undergoing chlorobenzene nitration reaction by using micro-channel reactor

ActiveCN102432471APrevent leakageAvoid dangerNitro compound preparationTemperature controlChlorobenzene

The invention relates to a method for undergoing a chlorobenzene nitration reaction by using a micro-channel reactor, belonging to the technical field of application of organic synthesis. In the method, nitric acid, sulfuric acid, water and chlorobenzene are taken as initial reaction raw materials, and processes such as mixed acid preparation, mixed acid and chlorobenzene preheating, mixed acid and chlorobenzene reacting and the like are completed in a micro-channel reactor system. In the reaction, nitro-sulfuric mixed acid is taken as a nitrating agent, the effective concentration of sulfuric acid in the mixed acid is 50-90 percent, the molar ratio of the nitric acid to the sulfuric acid in the mixed acid is 1:1-1:10, the molar ratio of the chlorobenzene to the nitric acid is 1:1.0-1:2.0, the reaction temperature is 50-100 DEG C, and the reaction time is 30-120 seconds. The chlorobenzene transformation ratio is up to 97 percent, the selectivity of nitrochlorobenzene serving as a product is over 96.5 percent, and the ratio of ortho-para nitrochlorobenzene is over 0.6. A strengthened mixed micro-channel reactor adopted in the invention is particularly suitable for undergoing a continuous nitration reaction, and has the characteristics of stable temperature control and safe process.

Owner:CHANGZHOU UNIV

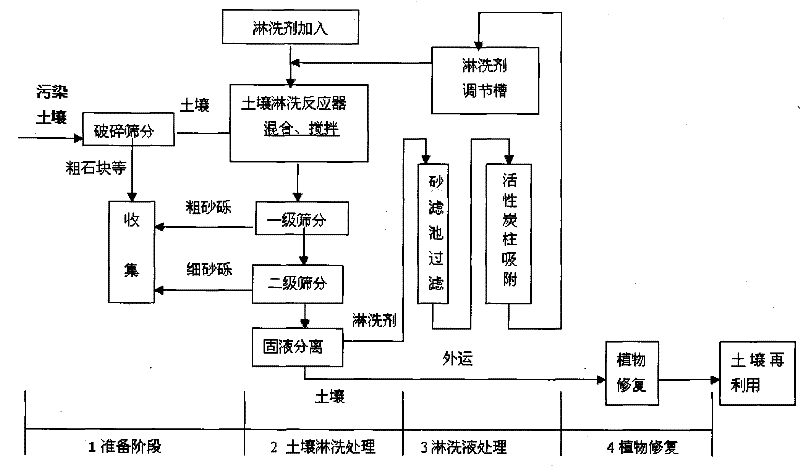

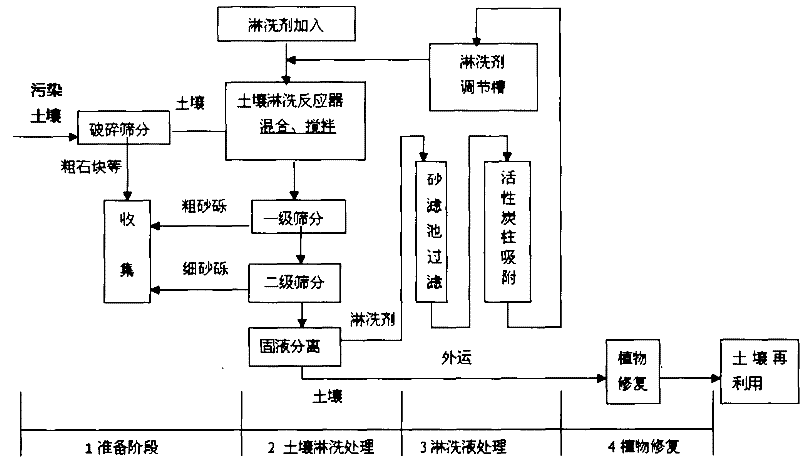

Ex-situ washing remediation method for nitrochlorobenzene-contaminated soil

InactiveCN102172614AThe process is easy to implementReduce labor inputContaminated soil reclamationEngineeringSlurry

The invention discloses an ex-situ washing remediation method for nitrochlorobenzene-contaminated soil, which comprises the following steps: crushing soil and sieving to remove stones and gravels; filling the soil into a washing reactor to fully mix the soil with a proper amount of washing solution, wherein the washing agent is ethanol; subjecting the washed mixture of slurry to two stages of sieving and filtering, wherein soil particles with large particle sizes are stopped by a screen; pumping the slurry mixture to soil-liquid separation equipment, recovering, filtering and purifying separated washing solution to regenerate the washing solution, regulating the concentration of the washing solution, and leaving the washing solution for washing at next time of washing. A sand filter column is used for filtering, active carbon is used for absorbing molecules of organic contaminants such as nitrochlorobenzene in the washing solution instead of molecules of ethanol serving as the washing agent, and thus, the washing solution is purified and can be recovered and recycling of resources is realized. The organic contaminant content of the washed soil reaches related standards. The soil particles which are sieved and filtered out can be used as building and road construction materials; and the soil particles obtained by solid-liquid separation can be used as raw materials for making concrete and fire bricks and also can be reclaimed. Thus, the whole soil remediation process is accomplished. In the invention, the process is easy to implement, small-scale industrial application can be realized, and an effective means is provided for scientific researchers for researching soil remediation.

Owner:南京市生态环境保护科学研究院

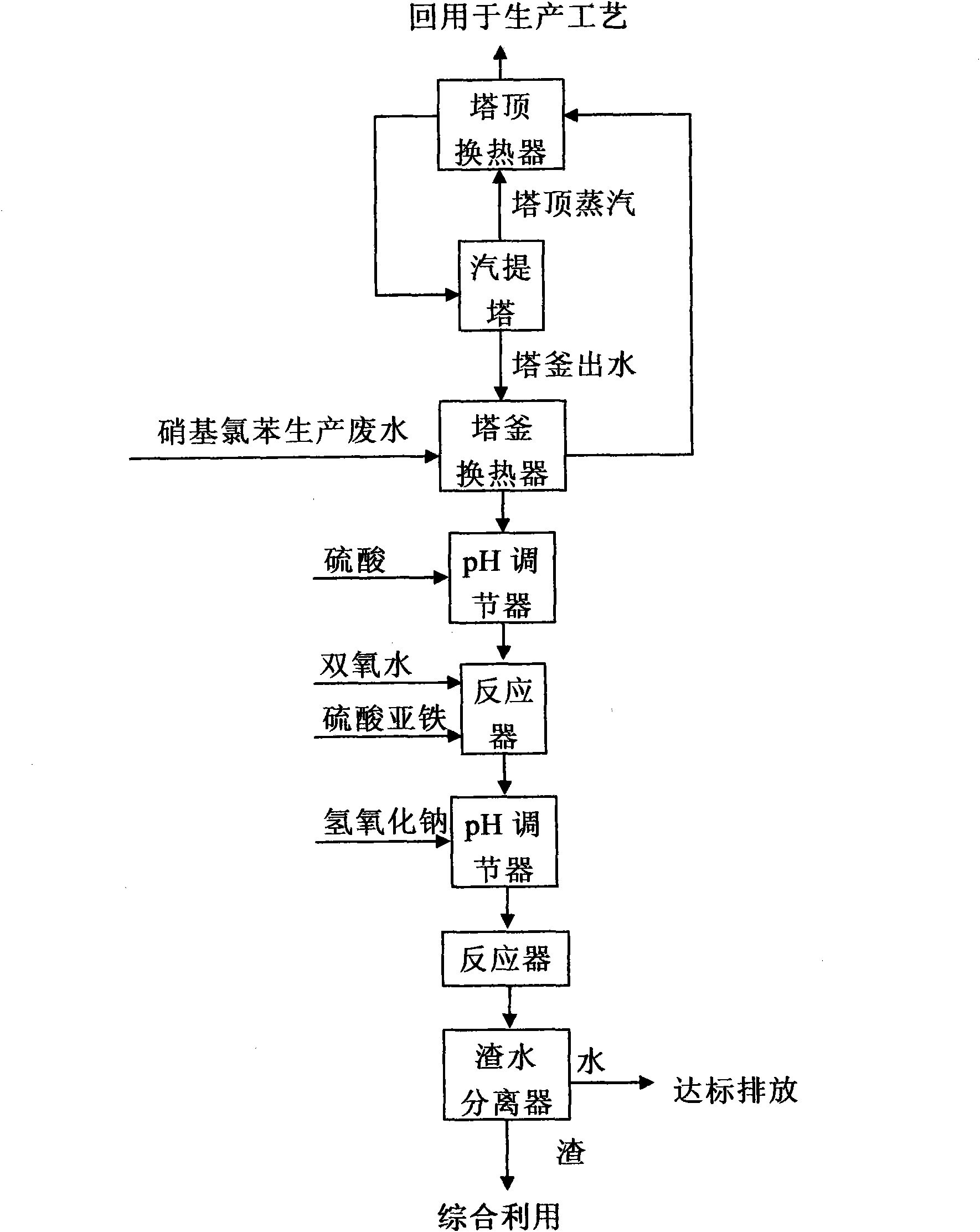

Treatment method of nitrochlorobenzene production wastewater

ActiveCN102040302AReduce chromaReduce CODMultistage water/sewage treatmentWater/sewage treatment by neutralisationChemical oxygen demandSlag

The invention relates to a treatment method of nitrochlorobenzene production wastewater, in particular to the treatment method of organic chemical wastewater. The treatment method comprises the following steps: 1. the waste water enters a stream stripping tower for stream stripping treatment after successively carrying out indirect heat-exchange temperature rise with effluent from the tower kettle of the steam stripping tower and the steam on the tower top of the steam stripping tower, and the steam on the tower top of the steam stripping tower and rich in nitrochlorobenzene is directly reused for the production technology after indirect heat-exchange cooling; 2. the pH value of the effluent from the tower kettle of the steam stripping tower is regulated to be acid, wherein the effluent from the tower kettle of the steam stripping tower is subjected to the indirect heat-exchange cooling by utilizing the nitrochlorobenzene production wastewater; 3. the catalytic oxidation treatment is carried out on the wastewater with the pH value of being acid, an oxidant is hydrogen peroxide, and a catalyst is ferrous sulphate; 4. the pH value of the effluent of the catalytic oxidation treatment is regulated to be close to neutrality and then the effluent of the catalytic oxidation treatment is precipitated and decomposed; and 5. the slag-water separation is carried out on the reaction effluent, the separated slag is comprehensively utilized, and the water reaches emission standard and can be discharged. The method has the advantages that the chromaticity and the COD (Chemical Oxygen Demand) of the wastewater, and the content of characteristic pollutants can be effectively reduced; the wastewater reaches emission standard and can be discharged.

Owner:CHINA PETROLEUM & CHEM CORP +1

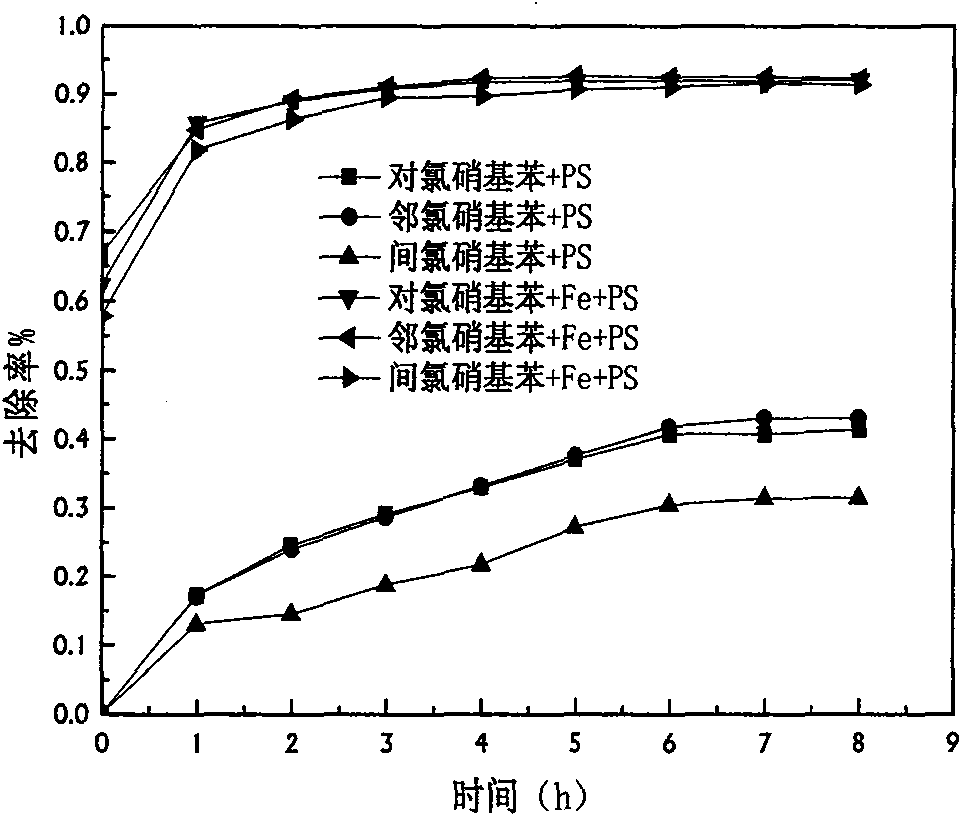

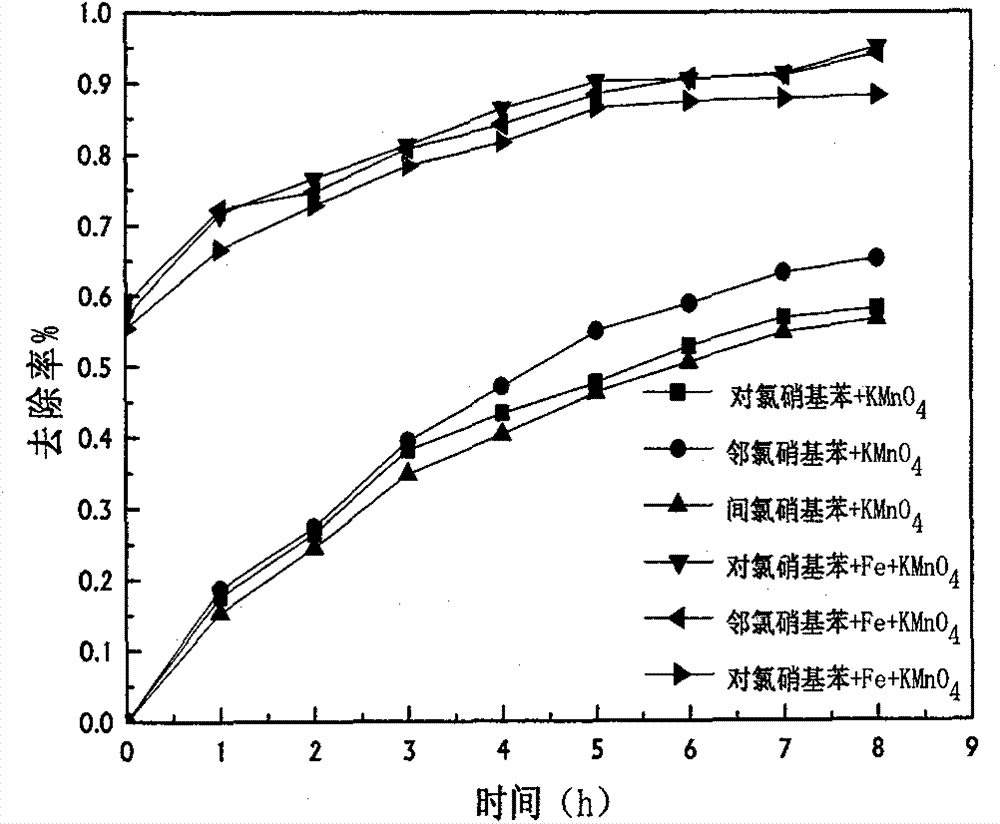

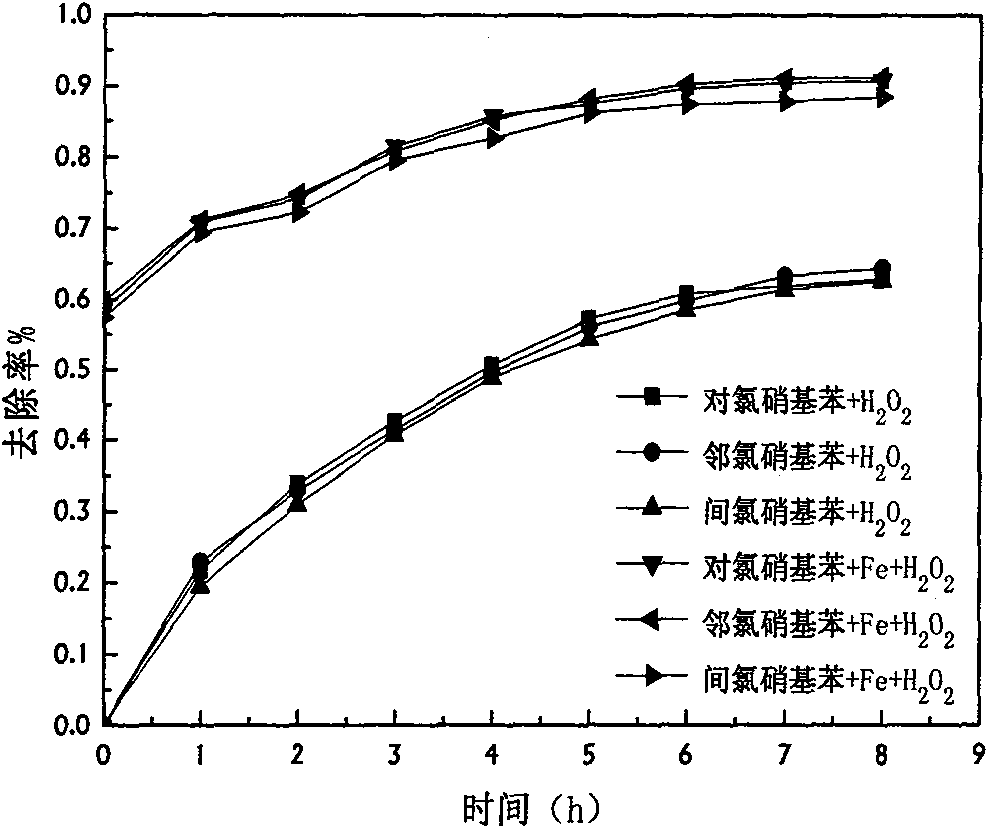

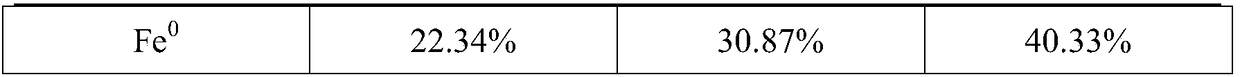

Method for increasing speed of oxidative degradation of organic pollutant in soil

ActiveCN104511476AShort repair timeImprove conversion rateContaminated soil reclamationPotassium persulfateFenton reagent

The invention relates to the technical field of pollution repairing and treatment of organic pollutants in soil, and especially discloses a chemically repairing method used in soil polluted by nitrobenzene, nitrochlorobenzene and the like. By means of the method in which the nitrobenzene, the nitrochlorobenzene and the like are firstly reduced into phenylamine which is easy to oxidatively degrade with zero-valent iron and finally the degraded product is oxidized to generate carbon dioxide and water, the soil, which is polluted by the organic pollutants including the nitrobenzene and the like, is completely repaired and removal efficiency of the organic pollutants is increased. The method can achieve a removal rate of the nitrochlorobenzene being 88.3-95.8%, wherein the nitrochlorobenzene is a difficultly-degraded organic substance. The method can overcome problems of low removal efficiency, high medicine cost and troublesome follow-up treatment during removal of the nitrobenzene-series organic pollutants in the soil with Fenton reagents, potassium persulfate, sodium permanganate and the like which are common in the prior art. By means of an indirectly oxidative degradation in which reduction is carried out firstly and oxidization is carried out after that, usage amount of an oxidizing agent can be reduced and the removal rate of the nitrobenzene-series organic pollutants can be increased. Meanwhile, the method is simple in operation and can avoid secondary pollution to environment by the oxidizing agent. The method can effectively achieve in-situ repairing of polluted soil and is especially suitable for complete repair of the soil severely polluted by the organic pollutants in local factory removal.

Owner:江苏迈克环境工程有限公司

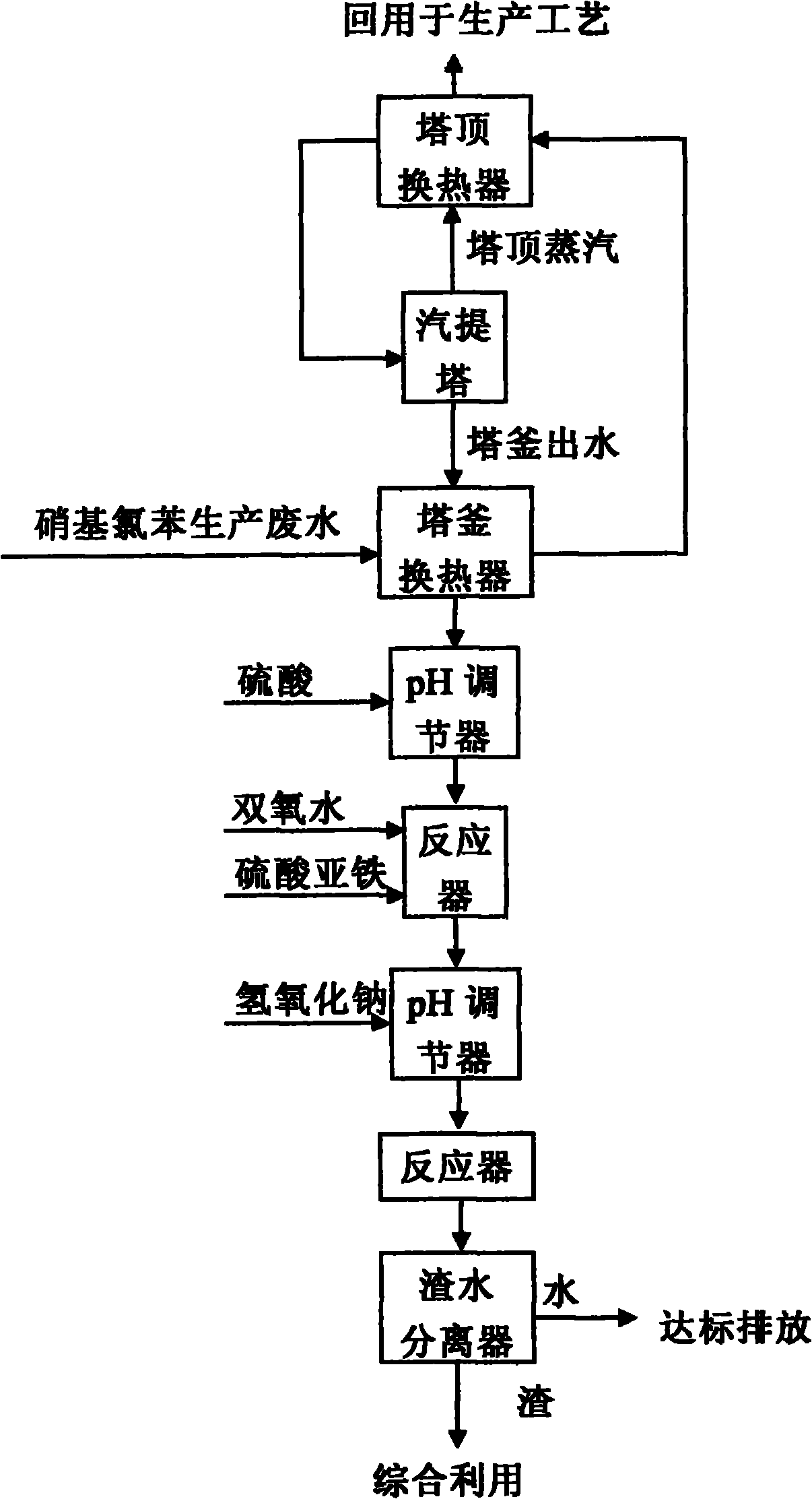

Method for processing wastewater from nitrochlorobenzene production

ActiveCN102417263ARelieve pressureHigh recovery rateMultistage water/sewage treatmentWater/sewage treatment by oxidationSlagCatalytic oxidation

The invention discloses a method for processing wastewater from nitrochlorobenzene production, comprising the following steps that: 1, wastewater is successively subject to treatment through a slag-water separator and a stripping tower and is discharged from the tower bottom of the stripping tower, then the discharged water is subject to indirect heat exchange and heating through the steam of thetower top of stripping tower, and then the heated product enters into the stripping tower for stripping; 2, the pH value of the output water from the stripping tower bottom, which is subject to indirect heat exchange and cooling through the wastewater from nitrochlorobenzene production, is regulated to acidity; 3, the acid wastewater is subject to catalytic oxidation, wherein, the oxidizing agentis hydrogen peroxide, and the catalyst is a composition of ferric salt and copper salt; 4, the pH value of the output water processed by catalytic oxidation is regulated to neutral or alkalescence to carry out precipitation reaction of dissolved copper and iron and decomposition reaction of residual H2O2 in the water; and 5, slag-water separation is carried out on the reaction effluent, the separated slag is subject to further disposal or comprehensive utilization, and the water reaches the standards of discharge after carrying out indirect heat exchange with the wastewater from nitrochlorobenzene production. The method disclosed herein can effectively reduce the chromaticity, COD and nitrochlorobenzene content of the wastewater, and realize the standard discharge of the wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of 2,4-dinitochloro benzene

InactiveCN1513830AImprove product qualityImprove efficiencyOrganic chemistryOrganic compound preparationBenzeneNitration

A process for preparing 2,4-benzene dinitrochloride from nitrochloro-benzene includes nitrifying reacting between said nitrochlorobenzene and the mixture of nitric acid and inorganic at 60-90 deg.C for 5-10 hr to generate 2,4-benzene dinitrochloride, separating out the waste acid at lower layer, and neutralizing to obtain high-purity product.

Owner:徐德军

Process for preparing aminoanisol and aniline by using mixture of nitroanisole and nitro chlorobenzene as raw materials

ActiveCN101307000AReduced conversion rate requirementsEasy to separateOrganic compound preparationAmino compound preparationDistillationOil phase

The invention relates to a process for preparing aminoanisole and aniline by taking a mixture of a nitroanisole and nitrochlorobenzene as a raw material. The process comprises the following: (1) a step of the catalytic hydrogenation reaction and the catalytic dechlorination reaction, during which, methanol is taken as a solvent, the mixture of the nitroanisole and the nitrochlorobenzene is taken as the raw material, catalyst is added, hydrogen is aerated; (2) a step of the solid-liquid separation, during which, solid and liquid in the material obtained from the step (1) after the catalytic hydrogenation reaction and the catalytic dechlorination reaction are separated, a liquid phase comprises aminoanisole, aniline, methanol, hydrochloride and water and is utilized in the next step; (3) a step of the liquid-liquid separation, during which, the oil phase-water phase liquid-liquid separation is performed in the material obtained in the step (2), the aminoanisole and aniline in the oil phase is utilized in the next step; (4) a step of distillation separation, during which, the distillation separation is performed in the oil phase to produce products of paraphenetidine, ortho-anisidine and aniline. The process for preparing the aminoanisole and the aniline has the advantages that: (1) the cost is low, the preliminary treatment step is saved, the process is simple; (2) the process is clean, the energy consumption is low, the 'three wastes' are little; (3) the purity of the product is high.

Owner:江苏仁欣化工股份有限公司

Pyrocatechin and hydroquinone production process

InactiveCN1962593AReduce pollutionSolve high salt contentOrganic chemistryOrganic compound preparationAnilinePhenol

The invention discloses a cleaning preparing technique to manufacture catechol and hydroquinone, which comprises the following steps: adopting o (p-)-nitrochlorobenzene as raw material; pressurizing the sodium hydroxide to obtain o (p-)-nitrophenol through hydrolyzing; hydrogenating under nickel catalyst; producing the product under acid catalyst in the water dielectric; avoiding high-salt and nitro waste water effectively as well as high-density hydrogen dioxide solution.

Owner:王在军

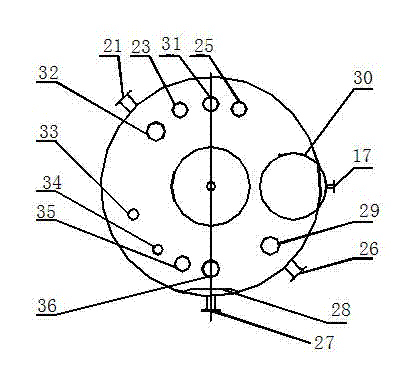

Method and device for co-production of o-phenylenediamine and p-phenylenediamine

ActiveCN102491905AIncrease exposureEasy to measureOrganic compound preparationChemical industryChlorobenzeneBiochemical engineering

The invention discloses a method and a device for co-production of o-phenylenediamine and p-phenylenediamine. The method for co-production of o-phenylenediamine and p-phenylenediamine is characterized in that a raw material of mixed nitrochlorobenzene obtained by chlorobenzene nitration undergoes an ammonolysis reaction to produce mixed nitroaniline; the mixed nitroaniline undergoes a hydrogenation reduction to produce mixed phenylenediamine; and the mixed phenylenediamine is subjected to rectification separation so that o-phenylenediamine and p-phenylenediamine are obtained. The method and a device for co-production of o-phenylenediamine and p-phenylenediamine have the advantages that production efficiency is high; operation is simple; technological parameters are stable; and safety hidden troubles existing in nitro-compound rectification separation are eliminated.

Owner:JIANGSU KESHENG CHEM EQUIP ENG

Method for effectively removing organic matters in wastewater from nitrochlorobenzene production

ActiveCN102417265ARelieve pressureHigh yieldMultistage water/sewage treatmentNature of treatment waterCatalytic oxidationWastewater

A method for effectively removing organic matters in wastewater from nitrochlorobenzene production relates to a method for processing organic chemical wastewater and comprises the following steps of: 1, respectively carrying out indirect heat exchange between wastewater and effluent at the bottom of a stripper and between wastewater and steam at the top of the stripper for heating, allowing the wastewater to enter into the stripper for stripping processing, and directly reusing the cooled nitrochlorobenzene-rich stream which has undergone indirect heat exchange at the top of the stripper for the production technology; 2, adjusting pH of the cooled effluent, which has undergone indirect heat exchange with the nitrochlorobenzene production wastewater at the bottom of the stripper, to acidity; 3, carrying out catalytic oxidation processing on the wastewater, pH of which is acidic, wherein the oxidizing agent is hydrogen peroxide and the catalyst is copper sulphate. The method provided by the invention can be used to effectively reduce chroma, TOC and nitrochlorobenzene content of the wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of paranitroaniline

ActiveCN102617361APromote safe productionIncrease production capacityOrganic compound preparationAmino compound preparationP-NitroanilineReaction temperature

Owner:苏州市罗森助剂有限公司

Rapid material cooling and waste acid recycling process after chlorobenzene thermal insulation nitration

InactiveCN101607909AReduce consumptionReduce heatOrganic compound preparationNitro compound preparationThermal insulationNitrochlorobenzene

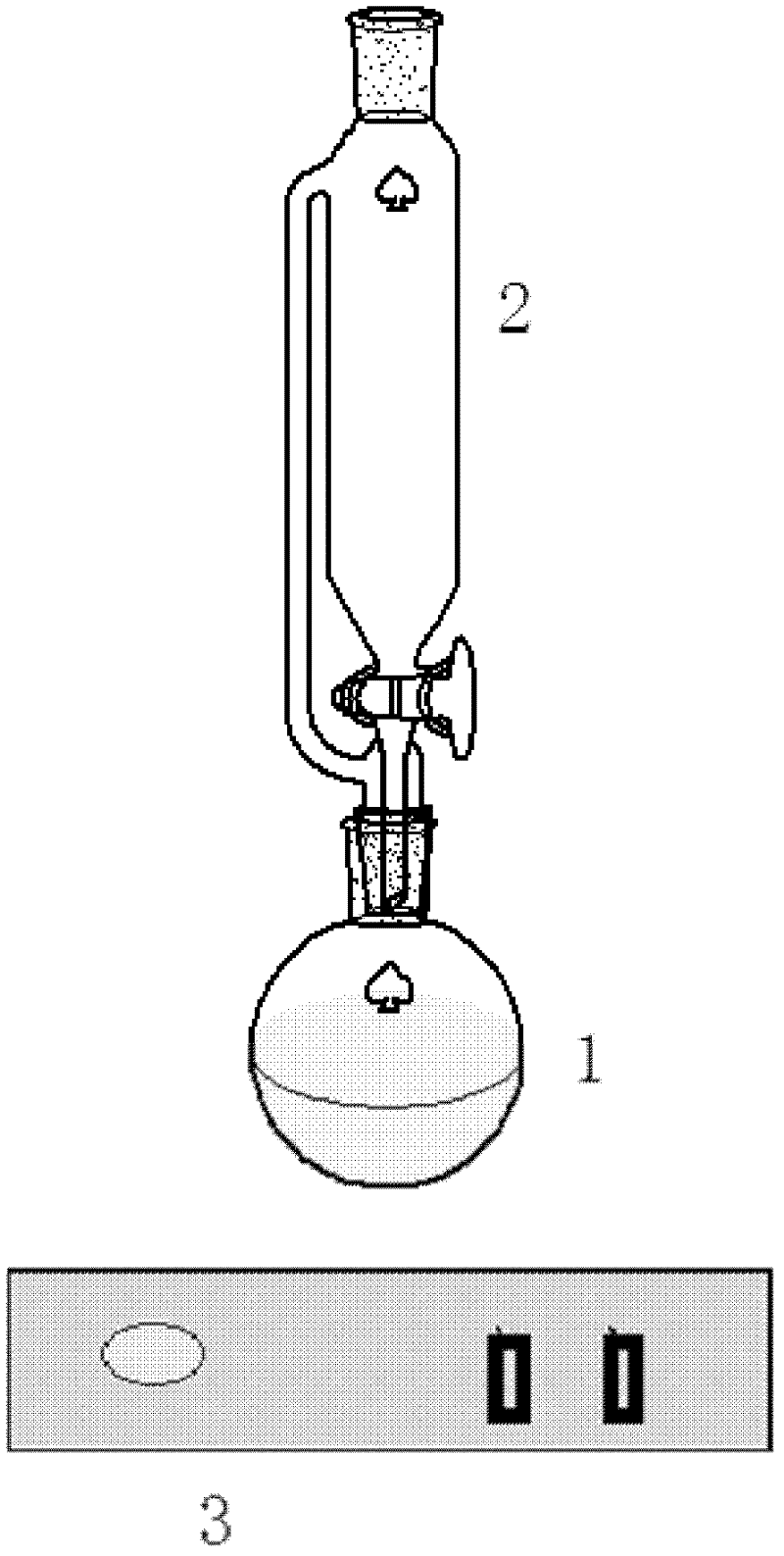

The invention discloses a rapid material cooling and waste acid recycling process after chlorobenzene thermal insulation nitration, comprising the following steps of: (1) chlorobenzene nitration; (2) vacuum flashing of material after the reaction; (3) gas-liquid separation; (4) gas-phase material cooling and condensation; (5) gas-liquid separation and gas-phase material treatment; (6) liquid-liquid separation of gas-phase materials from the previous step and treatment of oil-phase materials, and the use of water-phase materials as washing water of nitrochlorobenzene crude products in the eighth step; (7) liquid-liquid separation to the liquid-phase materials obtained from gas-liquid separation in the third step, utilization of water phase for mixed acid ingredients and treatment of the oil-phase materials in a next step; (8) mixed washing of the nitrochlorobenzene crude products and the water-phase materials obtained from the liquid-liquid separation in the sixth step; and (9) further treatment of the water-phase materials obtained from the liquid-liquid separation, and further separation and refining of the oil-phase nitrochlorobenzene for obtaining the products. The rapid material cooling and waste acid recycling process after chlorobenzene thermal insulation nitration has the advantages of less three wastes, cost conservation and convenient industrial implementation.

Owner:YANGZHOU UNIV

Method for preparing o-chloroaniline by adopting microchannel reaction device

ActiveCN103664642AFully contactedWell mixedOrganic compound preparationAmino compound preparationChlorobenzenePtru catalyst

The invention belongs to the technical field of fine chemical engineering, and relates to a method for preparing o-chloroaniline by adopting liquid-phase catalytic hydrogenation of o-nitrochlorobenzene. A microchannel reaction device is adopted in reaction, and ortho-nitrochlorobenzene, a solvent and a catalyst react with hydrogen by adopting a slurry feeding mode at 50-150 DEGC under the pressure of 0.5-1.2MPa, so as to obtain the o-chloroaniline. The preparation technology of the o-chloroaniline has the advantages that feed is continuous, the reaction condition is flexible to change, mass transfer effect is good, a reactant fully contacts with a catalyst, the side reaction is reduced, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing rubber peptizing agent, namely 2,2'-dibenzamido diphenyl disulfide compound

InactiveCN102304074AReduce acidityReduce viscosityHydropoly/poly sulfide preparationRoom temperatureBenzoyl chloride

The invention relates to a method for preparing a rubber peptizing agent, namely a 2,2'-dibenzamido diphenyl disulfide compound. The method comprises the following steps of: putting diphenyl disulfide, a deacid reagent, namely triethylamine, and a solvent in a reactor, stirring at room temperature, and slowly dropping benzoyl chloride, wherein the reaction time is 15-30 min; and obtaining the product by filtering, washing and drying after reacting. The mol ratio of the diphenyl disulfide to the deacid reagent to the benzoyl chloride to diethyl ether is (1.0-1.2):(2.0-2.2):(2.0-2.4):(50-70). According to the method disclosed by the invention, the nitrochlorobenzene is used as a raw material; the diphenyl disulfide is synthesized; the reaction speed is rapid; the reaction process is simple;and the purity of the obtained product is high.

Owner:LIAOCHENG UNIV

Method for preparing p-nitrochlorobenzene by nitrifying chlorobenzene by using nitrogen dioxide

InactiveCN103086892AHigh reaction yieldHigh selectivityNitro compound preparationChlorobenzeneNitrogen dioxide

The invention relates to a method for preparing p-nitrochlorobenzene by nitrifying chlorobenzene by using nitrogen dioxide. The p-nitrochlorobenzene is prepared by taking chlorobenzene as raw material and nitrogen dioxide as a nitration reagent. The nitrogen dioxide nitration reagent is used for replacing the traditional nitration reagent of nitric acid-sulphuric acid mixed acid, not only is utilization rate of reaction atoms improved, but also environmental economical efficiency of industrial preparation is improved, as well as the environment pollution is reduced. Simultaneously, the invention provides a nitration method of an acid sensitive compound, and the nitration method can be applied to the nitration of a plurality of aromatic compounds, and even applied to the nitration of aromatic compounds containing a plurality of deactivating groups.

Owner:ANHUI HUAIHUA

Method for preparing o-chloroaniline by virtue of solvent-free catalytic hydrogenation

ActiveCN103664641ASolve the problem of hydrogenolysis and dechlorinationReduce corrosionOrganic compound preparationAmino compound preparationPtru catalystSolvent free

The invention belongs to the technical field of fine chemical engineering, and relates to a method for preparing o-chloroaniline by virtue of solvent-free catalytic hydrogenation ortho-nitrochlorobenzene. The method is characterized in that ortho-nitrochlorobenzene is adopted as a raw material to be reacted with hydrogen in the presence of a catalyst at the temperature of 70-120 DEG C and the pressure of 0.5-5.0 MPa so as to obtain o-chloroaniline through the processing after the reaction. By adopting the method, no solvent is added, the defect for adding the solvent can be overcome, the environmental pollution problem and the solvent recycling problem can be avoided, the equipment investment is reduced, the production cost is reduced, the conversion rate of the ortho-nitrochlorobenzene can reach 100 percent, the selectivity of the o-chloroaniline is more than 99.2 percent, and the dechlorinating rate is less than 0.09 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

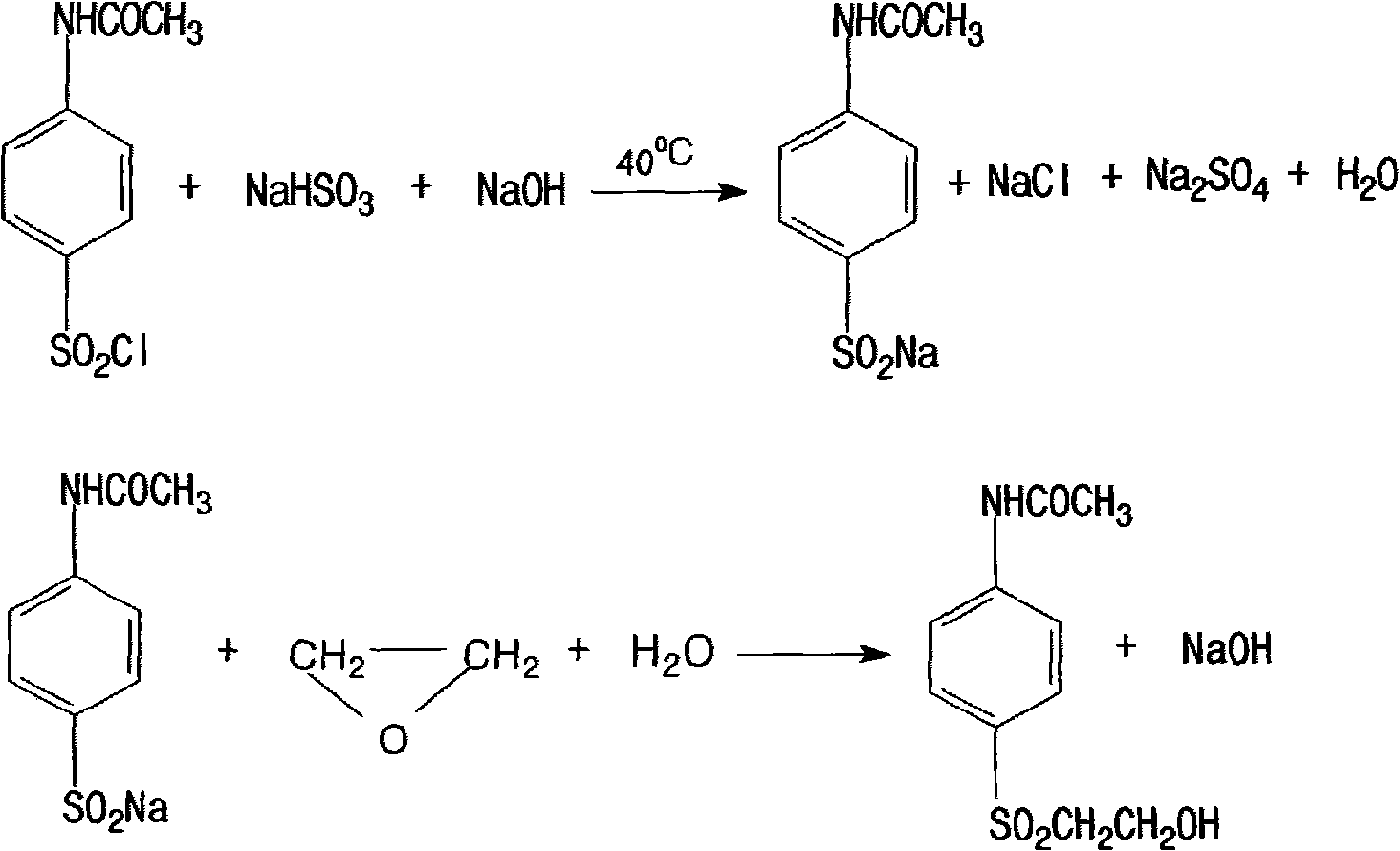

Method for producing amino-phenyl-beta-hydroxyethyl sulfone sulfate

ActiveCN101525309AIncrease profitReduce consumptionOrganic chemistryOrganic compound preparationDistillationTungstate

The invention relates to a method for producing amino-phenyl-beta-hydroxyethyl sulfone sulfate. The method comprises: nitrochlorobenzene and mercaptoethanol are added into DMF and then slowly added with sodium hydroxide, and the mol ratio among the nitrochlorobenzene, the mercaptoethanol, the DMF and the sodium hydroxide is 1:1-1.2:1.5-2:1; after the sodium hydroxide is added, the reaction lasts for 3-5h at the temperature of 50-80 DEG C; the preliminary product is obtained by reduced pressure distillation; the preliminary product, tungstate and hydrogen peroxide are added into an oxidation pot to react for 1-3h at the temperature of 95-100 DEG C, and oxidized crystallizing material is separated out by cooling, crystallizing and vacuum filtration; after that, the obtained oxidized crystallizing material is treated by hydrogenation reaction and esterification reaction, so that the amino-phenyl-beta-hydroxyethyl sulfone sulfate is obtained. The yield coefficient of the product reaches about 85%, and byproducts such as sodium chloride as well as three wastes which are waste acid, waste water and the like are less; as the quantity of the waste water is reduced to 1-2 t from 6-8 t produced by using the original product, the method reduces the production cost and is beneficial to promotion and application.

Owner:KAIFENG LONGXING CHEM

2-methyl-5-chloro-1,4-diaminobenzene and its prepn and application

InactiveCN1349974AHigh outputWide range of usesOrganic compound preparationElectrography/magnetographyAcetic anhydrideIron powder

The present invention discloses a compound 2-methyl-5-chloro-1,4-p-phenylenediamine, its preparation method and use. It is characterized by that under the acidic condition 2-methyl-5-chloro-phenylamine and acetic anhydride are reacted to obtain N-acetyl-2-methyl-5-chloro-phenylamine, then it uses a mixed acid to make said obtained material undergo the process of nitrate to obtain N-acetyl-2-methyl-4-nitro-5-chloro-phenylamine, and then makes said material undergo the hydrolysis to remove acetyl, and finally utilizes hydrochloric acid and adds the iron powder to make reduction to obtain the invented product. Said compound can be used for synthesizing paint, and synthesizing dyestuff, also can be used for preparing colour developing reagent.

Owner:WUHAN UNIV

Synthesizing method and application of 1,2,4,5-tetraamine benzene

InactiveCN108191669AAvoid pollutionRealize resource utilizationOrganic compound preparationAmino compound preparationFiberChlorobenzene

The invention discloses a synthesizing method and application of 1,2,4,5-tetraamine benzene. The synthesizing method comprises the following steps: preparing a chlorobenzene byproduct which is 1,2,3-trichlorobenzene as a raw material; nitrifying to obtain 4,6-binitro-1,2,3-trichlorobenzene; further performing ammonolysis in an organic solvent A to obtain 4,6-binitro-2-chlorine-1,3-phenylenediamine; dissolving an ammonolysis product into an organic solvent B; performing catalytic hydrogenolysis to obtain 1,2,4,5-tetraamine benzene. Compared with the prior art, the method has the advantages thatthe chlorobenzene byproduct which is 1,2,3-trichlorobenzene is utilized, and moreover, nitroreduction and halogen hydrogenolysis are integrated during the hydrogenolysis process, thereby facilitatingindustrial production, and providing raw material support to development of downstream products. The application is that 1,2,4,5-tetraamine benzene is used as the raw material and polymerized with 2,5-dihydroxy terephthalic acid to obtain PDBI resin which is an engineering fiber material being high in spinnability and high in modulus.

Owner:SOUTHEAST UNIV

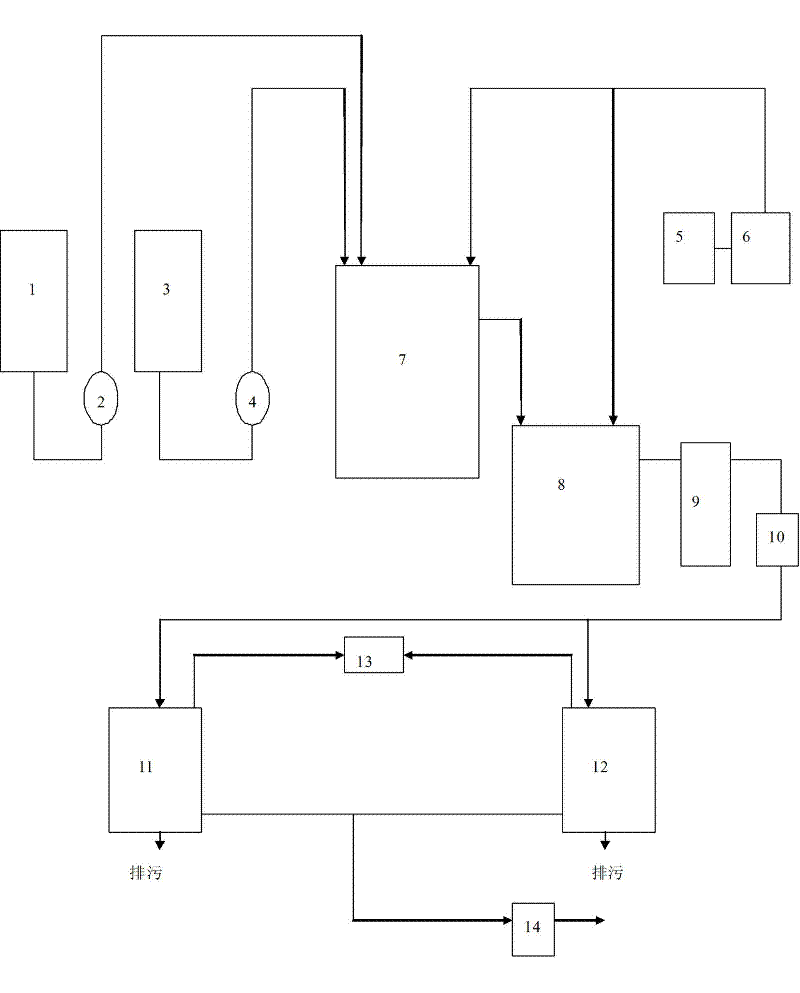

Treatment method and treatment system for nitrochlorobenzene production waste water

InactiveCN103951101AImprove processing efficiencyLow running costMultistage water/sewage treatmentSludgeFiltration

A treatment method and a treatment system for nitrochlorobenzene production waste water. The method comprises the following steps: pumping nitrochlorobenzene production waste water into an adjustment pool, adjusting the pH value to allow the waste water to be acidic, then allowing the waste water to enter an oxidation pool, adding oxidizing agents of sodium hypochlorite, calcium hypochlorite or hypochloric acid for chemical oxidation treatment, discharging the effluent from the oxidation pool into a neutralization pool, adjusting the pH value to allow the effluent to be neutral, discharging the effluent from the neutralization pool into a coagulation pool, adding coagulants of one or more than one of polyaluminium chloride, polyferric chloride, and polyacrylamide for a coagulation reaction, discharging the effluent from the coagulation pool into a sedimentation pool, allowing a supernatant obtained by sedimentation and separation in the sedimentation pool to overflow into a clean water pool, discharging the clean water that reaches the standard, concentrating and filtering sedimentated sludge at the bottom of the sedimentation pool for safety treatment, and discharging waste liquid generated during the concentration and filtration process into the adjustment pool for re-treatment. According to the invention, the removal rate of nitrochlorobenzene and other nitrobenzene compounds in effluent of the nitrochlorobenzene production waste water treated by the method of the invention is up to 99%, and the method of the invention has the advantages of high treatment efficiency, low operation cost, no secondary pollution, and the like.

Owner:LUOYANG INST OF SCI & TECH

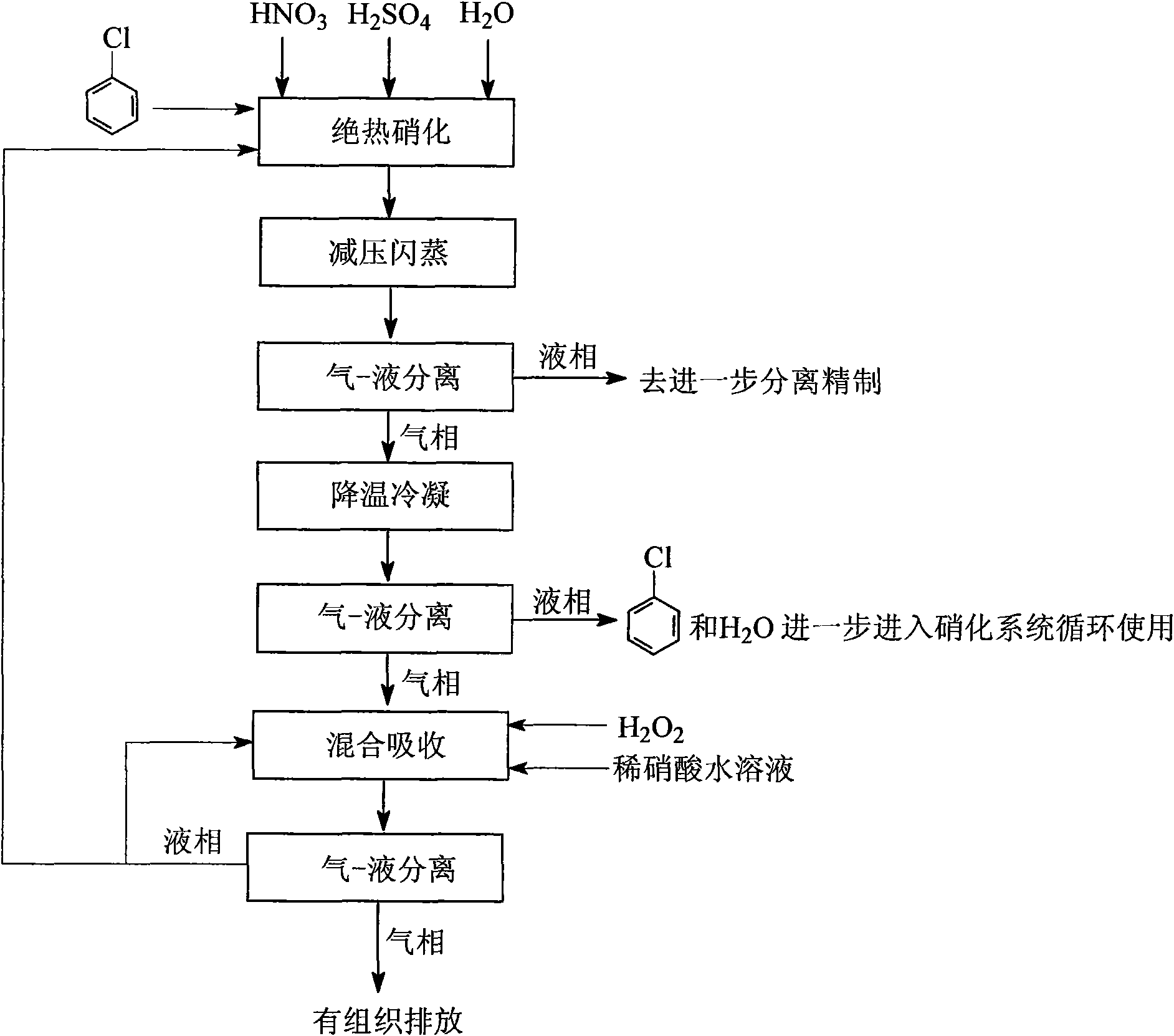

Removal technology of nitrogen oxides generated in chlorobenzene thermal insulation nitration

InactiveCN101607910AFull recoveryIncrease profitOrganic compound preparationDispersed particle separationChlorobenzeneThermal insulation

The invention relates to a removal technology of nitrogen oxides generated in chlorobenzene thermal insulation nitration, comprising the following steps of: (1) thermal insulation nitration; (2) vacuum flashing; (3) gas-liquid separation: nitrochlorobenzene crude products is further treated in liquid phase and gas-phase materials enters a next step; (4) cooling and condensation: condensed materials enter a next step; (5) gas-liquid separation: the nitrochlorobenzene and water are further treated and utilized in liquid phase, and gas-phase materials enter a next step; (6) mixed absorption: nitric acid aqueous solution and hydrogen peroxide aqueous solution absorb nitrogen oxides from exhaust gas; and (7) gas-liquid separation: the gas-phase materials are discharged after the nitrogen oxides therein achieve the standard in content, the batching of mixed acid and recycling of absorption liquid are conducted in liquid phase. The technology has the advantages of high utilization of materials, less three wastes and easy industrial implementation.

Owner:YANGZHOU UNIV

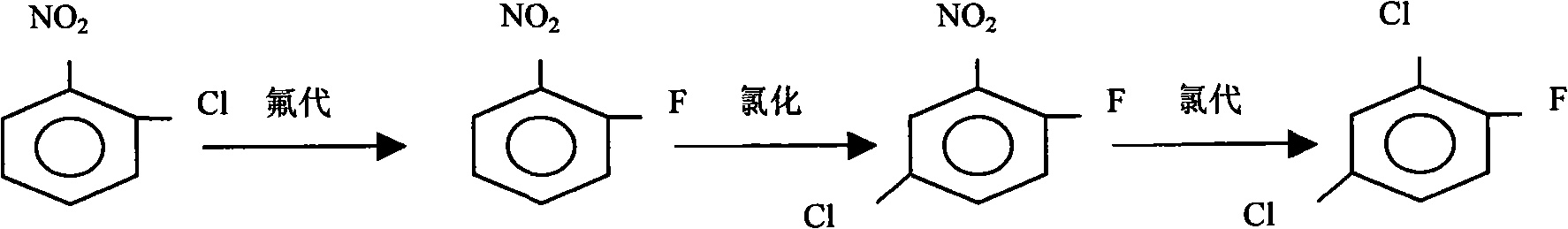

Method for separating and comprehensively utilizing nitrobenzene chlorides

InactiveCN101613286ASolve pollutionHigh economic valueOrganic compound preparationHalogenated hydrocarbon preparationChemical reactionEconomic benefits

The invention discloses a method for separating and comprehensively utilizing nitrobenzene chlorides, which comprises the separation and comprehensive utilization of monochloride and the comprehensive utilization of dichloride, wherein the monochloride is subjected to fluorine substituted reaction to separate m-nitrochlorobenzene, o-fluoronitrobenzene and dinitro-fluorobenzene, and the o-fluoronitrobenzene and the dinitro-fluorobenzene are taken as products for sale, or a mixture is subjected to chlorination to generate 2,4-dichlor fluorbenzene with higher economic value; and the dichloride is subjected to chlorination to generate the 2,4-dichlor fluorbenzene with higher economic value. The method improves the yield of the m-nitrochlorobenzene on the one hand, and utilizes the resources with low economic value to produce the product with higher economic value by steps of reasonable chemical reaction and separation, brings economic benefit to enterprises and solves environmental pollution problem on the other hand.

Owner:淮安嘉诚高新化工股份有限公司

Method for preparing nitroanisole from m-nitrochlorobenzene oil

ActiveCN104557557AShort reaction timeThe reaction cycle is shortenedOrganic chemistryOrganic compound preparationChlorobenzeneP-nitroanisole

The invention aims to provide a nitroanisole production method with low cost, low energy consumption, short production cycle and few three wastes (waste gas, wastewater and industrial residue), namely a method for preparing m-nitrochlorobenzene, p-nitroanisole and o-nitroanisole from m-nitrochlorobenzene oil under an anhydrous system by a high pressure method. To achieve the above purpose, the technical scheme of the invention is as follows: m-nitrochlorobenzene oil is added into an autoclave, and methanol and sodium hydroxide are respectively added, wherein the mole ratio of sodium hydroxide to m-nitrochlorobenzene oil is 0.01-2.00:1, the mole ratio of methanol to m-nitrochlorobenzene oil is 1-20:1, reaction temperature is 10-200 DEG C, reaction time is 1-20 h, and pressure is 0.1-4.0 MPa; and products obtained after the reaction undergo gas chromatography, and content changes with the composition change of the reaction raw material m-nitrochlorobenzene oil. In comparison with traditional technologies, the method provided by the invention has advantages of low production cost, short process, low energy consumption and little pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Washing impurity-removing technology of crude nitrochlorobenzene products after chlorobenzene thermal insulation nitration

InactiveCN101607911AHigh yieldReduce processingOrganic chemistryOrganic compound preparationThermal insulationNitration

The invention discloses a washing impurity-removing technology of crude nitrochlorobenzene products after a chlorobenzene thermal insulation nitration, comprising the following steps: (1) mixed washing of the crude nitrochlorobenzene products with condensation water obtained by vacuum flashing and water-phase materials obtained by secondary liquid-liquid separation is conducted; (2) wastewater in the water-phase materials is removed, and oil-phase materials enter the next step; (3) mixed washing of the oil-phase materials, the water-phase materials obtained by liquid-liquid separation of the third time and a neutralizer is conducted; (4) the water phase materials are used as primary mixed washing water, and the oil-phase materials enter the next step; (5) mixed washing of the oil-phase materials and water is conducted; and (6) the water-phase materials are used as secondary mixed washing water, and the oil-phase materials are separated and refined. The washing impurity-removing technology has the advantages of simpleness, easy operation, less energy consumption, washing water conservation, wastewater reduction, recyclable auxiliary products, saved cost and convenient realization of large-scale industrialization.

Owner:YANGZHOU UNIV

Method for degrading nitrochlorbenzenes pollution in soil

The invention discloses a method for degrading nitrochlorbenzenes pollution in soil and belongs to the field of soil restoration. According to the method, polluted soil and activated carbon supportednanometer zero-valent iron are mixed uniformly; then a persulfate solution is added in; then hydrogen peroxide is added in batches; and after uniform stirring, standing at a dark place is performed, and after a reaction ends, the nitrochlorbenzenes pollution in soil can be eliminated. By means of the method, nitrochlorobenzene, 3,5-dichloro-4-fluoronitrobenzene and the like can be effectively removed, and the beneficial effects that a reaction system generates free radicals high in oxidizing capacity, the reaction system is stable, the applicable pH range is wide and the oxidizing agent utilizing efficiency is high are achieved; and meanwhile, the procedure is simple, industrialization can be achieved easily, and the method is suitable for using and popularizing.

Owner:SOUTHEAST UNIV

Process for treating waste water of nitrobenzene, 2,4-dinitrophenol, p-nitro-chlorebenzene

ActiveCN1559933AShorten the migration pathElectrocatalytic Oxidative Degradation Speed ImprovementWater/sewage treatmentMultistage water/sewage treatmentIndustrial waste waterNitrobenzene

The invention is a method of processing the waste water containing nitrobenzene, 2, 4- dinitrophenol and para-nitrochlorobenzene, pumping the basic waste water in a water distributing tank or the neutral water produced by using 98% sulphuric acid to regulate the pH value up to 7-8, into an electro-catalyzing device with activated carbon particle group, the voltage and current of the device, staying for a short time and then making the outgoing water pass through a medium tank for buffering, adding in 98% sulphuric acid to regulate the pH value up to primary effluent standard in the list 4 of 'Sewage Synthetic Effluent Standard' of the national GB8978-1996 and discharging. It has characters of effective degrading the industrial waste water containing nondegradable basic or neutral organic pollutants like nitrobenzene, 2, 4- dinitrophenol, para-nitrochlorobenzene, etc.

Owner:江苏环保产业股份有限公司

Method and device used for processing nitrochlorobenzene production wastewater

InactiveCN103073139ARelieve pressureHigh yieldWater/sewage treatment by irradiationMultistage water/sewage treatmentNitrochlorobenzeneHydrogen peroxide

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing 2,2'-dichloro-hydrazobenzene

The invention discloses a process for preparing 2,2'-dichloro-hydrazobenzene by using ortho-nitrochlorobenzene as raw material, nickel system as catalyst, mixed solvent of alcohols and aromatic hydrocarbons as reaction medium for reaction under alkaline condition. The method can be used not only for intermittent hydrogenation reduction, but also for continuous hydrogenation preparation of 2, 2'-dichloro-hydrazobenzene.

Owner:JIANGSU YANGNONG CHEM GROUP

Chlorobenzene and nitrochlorobenzene production waste water microbial treatment method

InactiveCN101391850ANothing producedAvoid poor resultsFatty/oily/floating substances removal devicesTreatment using aerobic processesChlorobenzeneToxicant

The invention relates to a micro-organism treatment method of waste water of benzyl chloride and nitrochlorobenzene production, which belongs to the environmental protection technology field. The method, by mainly using H.S.B. patent microbial strains and combining the technique of a facultative oxygen system plus an oxic system plus a BAC system, successfully solves the technical problem of the waste water treated by the microorganism can also achieve national discharge standard of Class first, even though under the inhibition situations that the total salinity is up to 25000mg / l, chlorion concentration is up to 30000mg / l, with the existence of a plurality of toxic substances of benzyl chloride, nitrochlorobenzene, nitrobenzene and the like, moreover, the method does not generate any residue biological sludge, with the operation cost only 3.27 yuan / m<3> which is just 1 / 3-1 / 4 of materialization treatment for similar waste water.

Owner:SINOPEC NANJING CHEM IND CO LTD +1

Method for reducing generation of nitrophenol in preparation process of nitroanisole

InactiveCN105566121AHigh selectivityHigh yieldOrganic chemistryOrganic compound preparationSodium methoxideNitrobenzene

A special feeding mode is adopted in the invention to reduce generation of nitrophenol, and is characterized in that a sodium methoxide solution prepared from methanol and sodium hydroxide is added to an autoclave in t he production process of nitroanisole from m-oil (o-nitrochlorobenzene, p-nitrochlorobenzene and m-nitrochlorobenzene) in the autoclave, so generation of nitrophenol is reduced, thereby the reaction time is greatly shortened, the raw material conversion rate is improved, the reaction selectivity and the yield of the above product are improved, the cost is reduced, and three wastes are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com