Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1244 results about "Nitrophenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

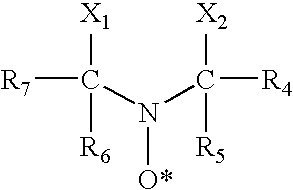

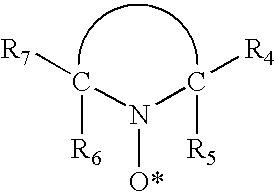

Nitrophenols are compounds of the formula HOC₆H₅₋ₓ(NO₂)ₓ. The conjugate bases are called nitrophenolates. Nitrophenols are more acidic than phenol itself.

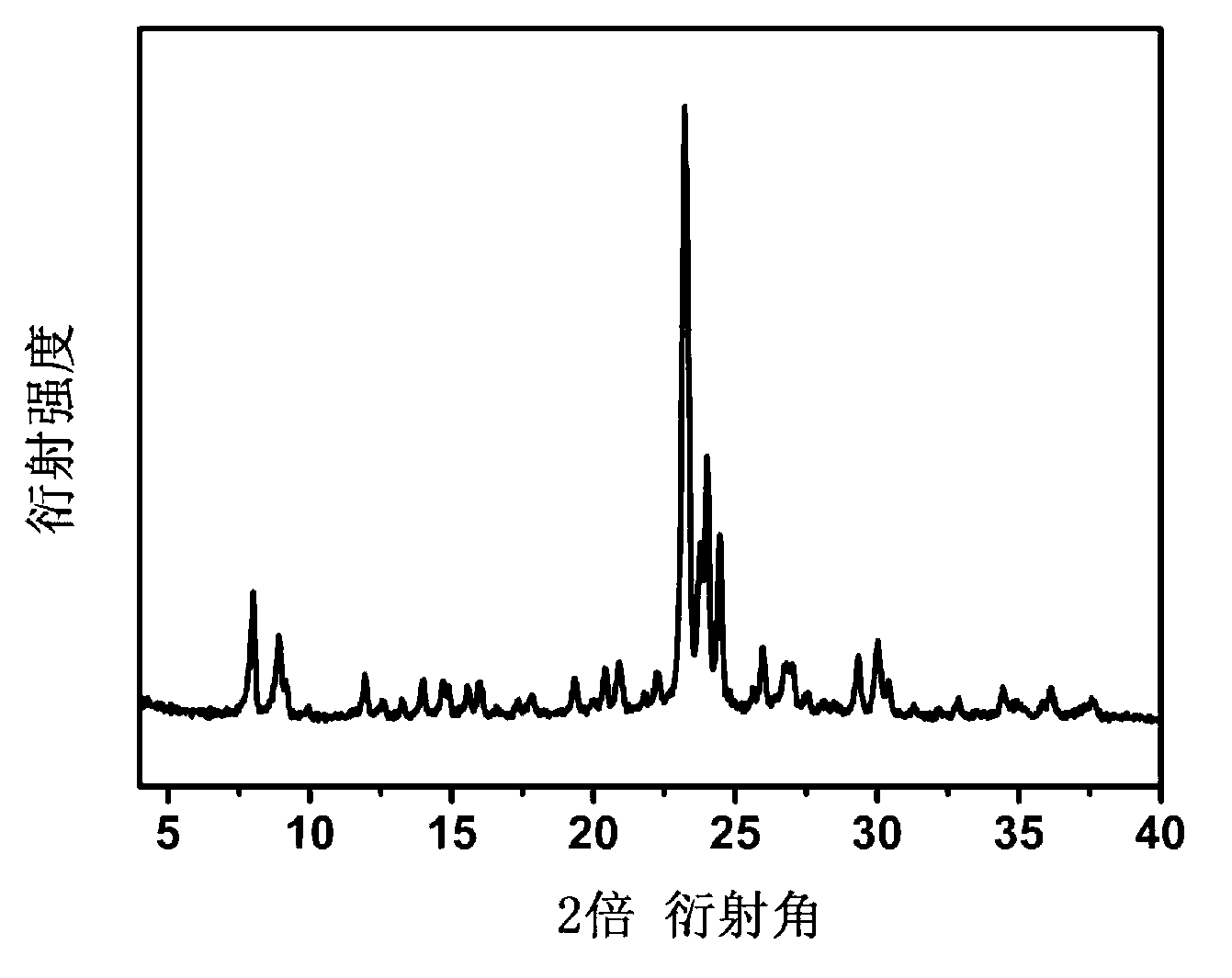

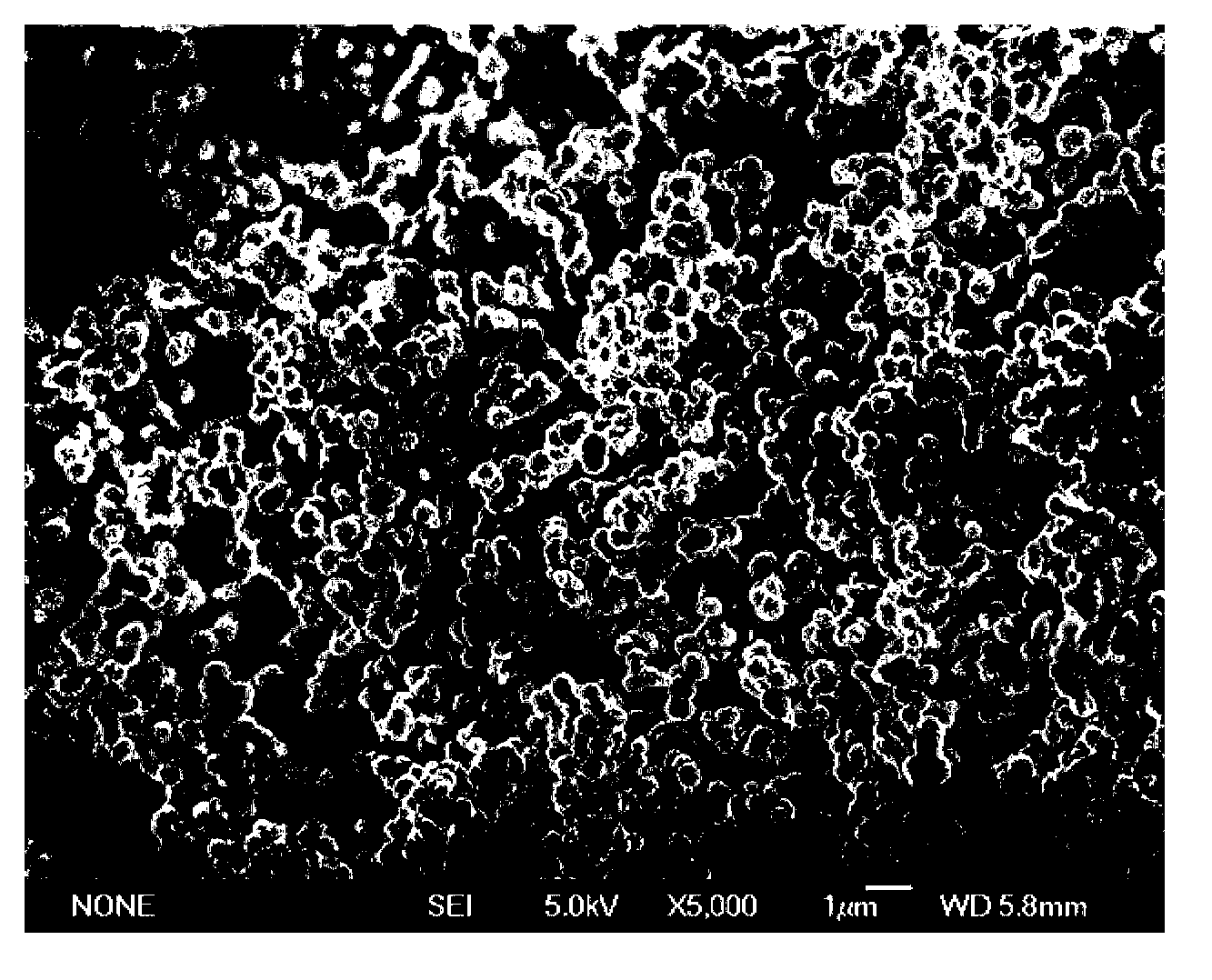

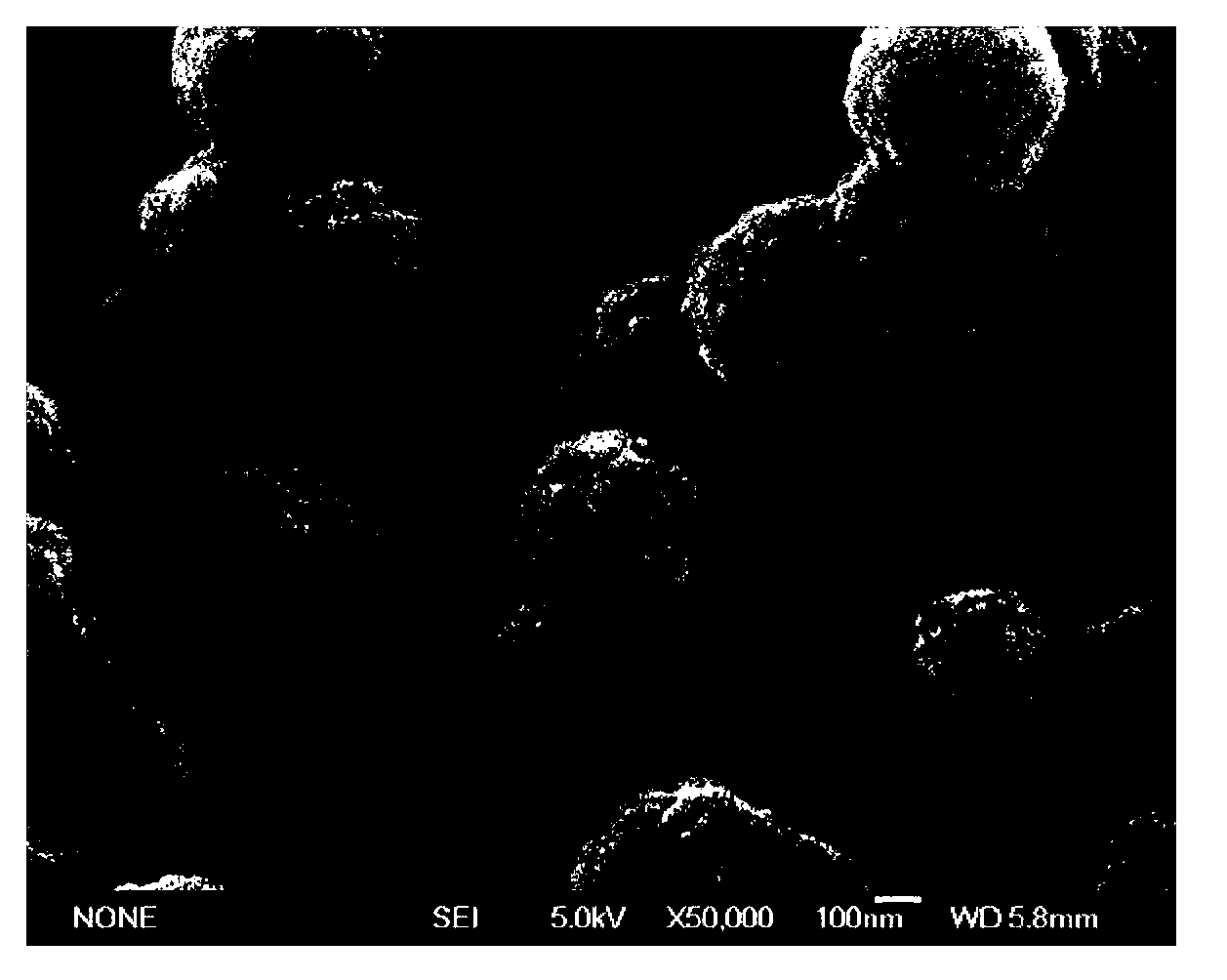

Microporous-mesoporous molecular sieve containing noble metal, preparation method and application to catalytic reduction of p-nitrophenol

InactiveCN103011189AReduce pollutionLow cost of industrializationMolecular sieve catalystsOrganic compound preparationWater bathsDispersity

The invention belongs to the technical field of molecular sieve preparation, and particularly relates to an in-situ preparation method for a microporous-mesoporous molecular sieve containing noble metal. The in-situ preparation method comprises the steps as follows: adding a coupling pore-forming agent, a silicon source, an aluminum source or a titanium source, and an alkali source into a water solution of noble metal nano particles in sequence under the water bath condition; and ageing, drying, crystallizing, drying and carrying out high-temperature calcination to obtain the microporous-mesoporous molecular sieve containing the noble metal. The prepared microporous-mesoporous molecular sieve is provided with a hierarchical pore structure; the noble metal nano particles with high dispersity are covered in situ while a mesoporous structure is generated; and a synthetic method is convenient and simple, saves energy and reduces emission. A multifunctional catalyst prepared with the method integrates the advantages of the microporous channels of the molecular sieve, the transgranular meso pores and the intergranular meso pores of the molecular sieve and the noble metal nano particles, and is more suitable for catalytic reactions of sulfur-containing large molecules such as hydrogen desulfurization and the like.

Owner:JILIN UNIV

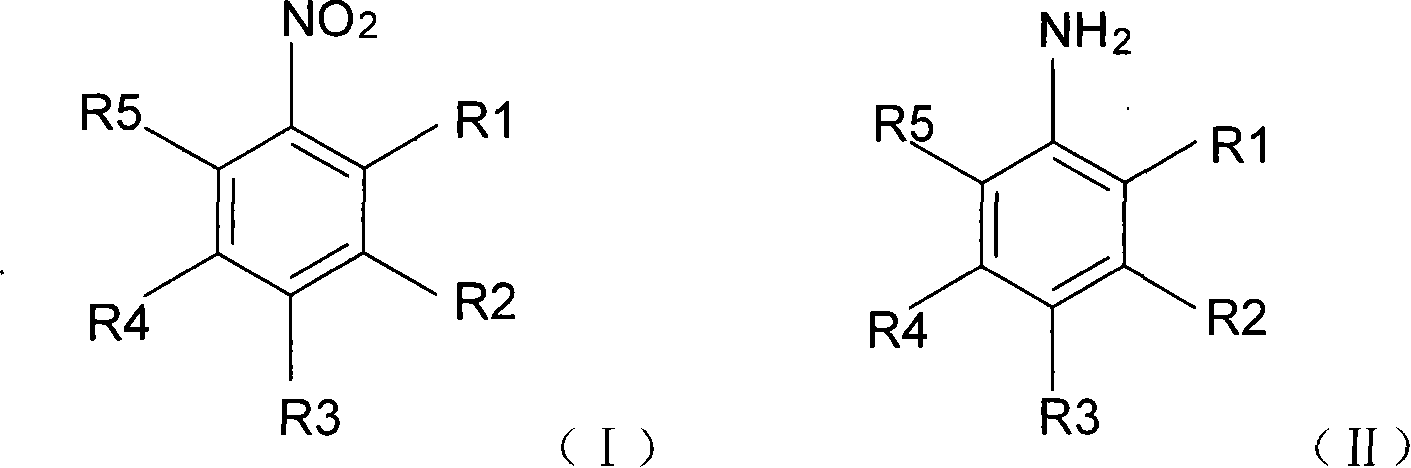

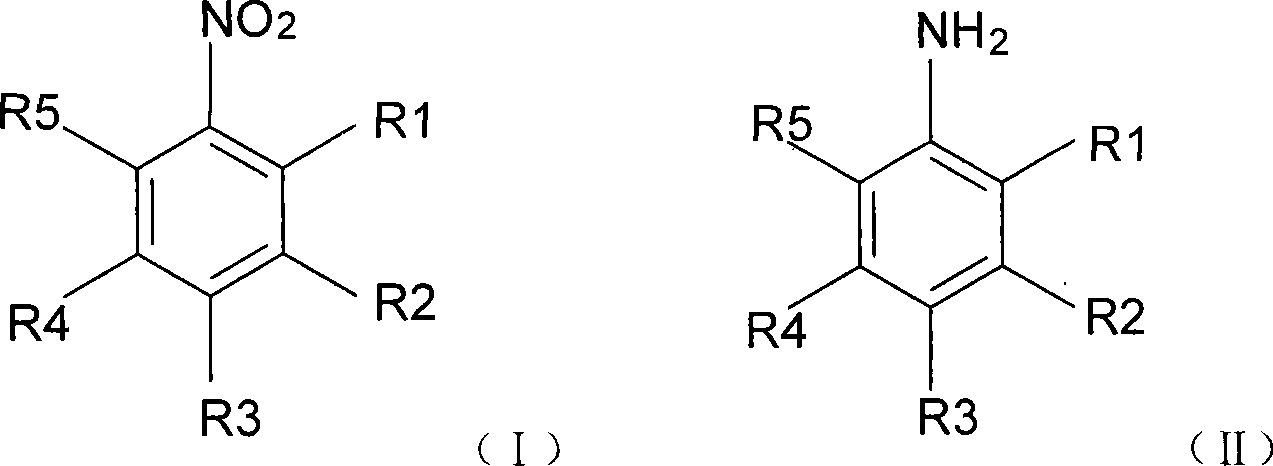

Method for preparation of (substituted radical containted) aminophenol by catalytic hydrogenation of (substituted radical containted) nitrophenol

ActiveCN101041623AOvercoming pollutionSolve problems such as recycling difficultiesMolecular sieve catalystsOrganic compound preparationMolecular sieveNitrophenol

The invention discloses a making method of aminophenol with substituted group through hydrogenating nitrophenol with substituted group, which adopts Ni-A / X typed loaded catalyst, wherein A is one of Co, Mn, Cu, Cr, Mo, Ca, Zn, Fe and W; the carrier X is one of their composition of zeolite molecular sieve, Al2O3, SiO2, TiO2, MgO, active charcoal or amorphic aluminium silicate; the mass percentage of Ni in the catalyst is 2-45% and the mass percentage of component A is 1-40%.

Owner:SHANGHAI HUAYI NEW MATERIAL

Chemical industrial waste salt refining process

ActiveCN104649495AImprove qualityRealize resource regenerationMultistage water/sewage treatmentAlkali metal chloridesTunnel kilnEvaporation

The invention relates to a chemical industrial waste salt refining process which comprises the following steps: pretreating high salt wastewater generated in the production process of aminobenzene ether and p-nitrophenol so as to adjust the pH value, adsorbing by using activated carbon, kieselguhr or macroporous resin, removing organisms and organic salts in the wastewater, reducing the COD of the wastewater, neutralizing the high salt wastewater, performing multi-effect evaporation or mechanical recompression so as to evaporate and crystallize, and centrifuging a solid salt; performing high-temperature calcination on the centrifuged solid salt in a rotary kiln or a tunnel kiln, thereby decomposing and oxidizing the organisms at a high temperature, further thoroughly combusting the tail gas generated through calcination in a heat accumulation type tail gas combustion furnace, preheating and recycling the tail gas, performing spraying absorption, dissolving the calcinated salt with water so as to prepare a saturated solution, filtering by using a precise filter, directly supplying the filtrate to ionic membrane caustic soda for use, or performing multi-effect evaporation or mechanical recompression on the filtered saturated salt water so as to evaporate, crystallize and purify, and performing centrifugation, thereby obtaining high-quality solid sodium chloride.

Owner:JIANGSU ZHONGDAN GROUP

Catalyst for catalytic hydrogenation of p-nitrophenol and preparation method thereof

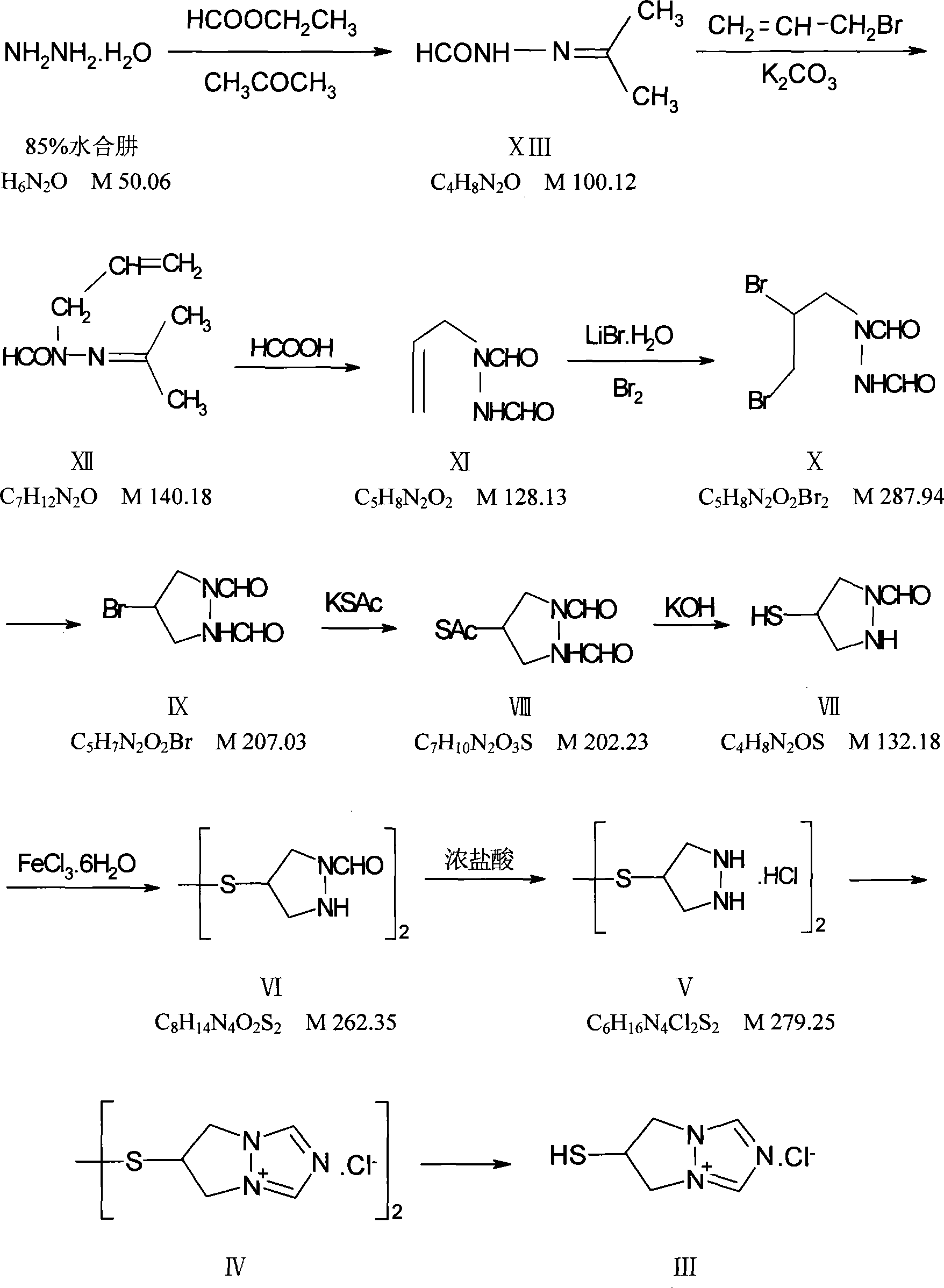

ActiveCN102091626AEasy to separateSimple production processCatalyst carriersOrganic compound preparationSilanesP-Aminophenol

The invention relates to a catalyst for preparing p-aminophenol through catalytic hydrogenation of p-nitrophenol, and a preparation method thereof, and belongs to the technical field of catalysis. The carrier of the catalyst is a ceramic membrane, and the preparation method comprises the following steps of: modifying the membrane surface by using aminosilane; immersing in salt solution of an active ingredient; and performing hydrazine hydrate reduction to prepare a catalytic membrane. The invention has the advantages that: nano-scale catalyst particles are supported on the surface of the ceramic membrane modified by silane, and the activity and stability of the catalyst are improved; moreover, a problem that the catalyst is hardly separated from the product subsequently is avoided. The catalyst is simple in preparation process and high in activity and stability and can be widely applied to preparing the p-aminophenol through catalytic hydrogenation of the p-nitrophenol.

Owner:NANJING UNIV OF TECH

Pseudomonas stutzeri JSD-008 and its degradation function for organophosphorus pesticide

InactiveCN101096644APromote degradationBacteriaMicroorganism based processesChlorpyrifosMethyl parathion

The invention discloses a Pseudomonas stutzeri JSD-008 and degradation for organophosphorus pesticide, which is preserved in the 'Chinese germ management committee center (CGMCC)' with preservation number at CGMCC No.1738, wherein the strain is separated from the soil at pollution discharge pore of pesticide processing plant polluted by organophosphorus pesticide; the thallus and ferment liquid with the thallus can be degradation agent of organophosphorus pesticide to degrade the chlorpyrifos into trichlopyridinenol and methyl parathion into nitrophenol; fitting for rapid in-situ rehabilitation polluted by field soil pesticide.

Owner:谢明

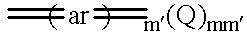

Synthesis method for biapenem

The invention is a synthesis method of the biapenem, with the MAP ((1R, 5R, 6R) 2-(drophenyl phosphate)-6-[(R)-1- hydroxyethyl]-1-methyl-1-1 - carbapenems-2-en-3-formic acid benzyl ester of p-nitrophenol)) and the 6, 7-dihydro-6-mercapto-5 H-pyrazol [1,2 - a] [1,2 , 4]-triazole chloride ( the intermediate III) as the starting materials; after the condensation, hydrolysis and the fine preparation reaction and synthesis, the biapenem is made.

Owner:严洁

Two-stroke cycle lubricant and method of using same

A lubricant composition suitable for fuel injected two-stroke cycle engines includes an oil of lubricating viscosity, an amount, sufficient to reduce or prevent piston scuffing, of a mixture of (A) at least one phenol selected from (A-1) an aminophenol and (A-2) a reaction product of a nitrophenol and an amino compound, and (B) at least one Mannich dispersant, amine dispersant, nitrogen-containing carboxylic dispersant, or ester dispersant. The composition further includes an amount, sufficient to reduce degradation of the lubricant composition upon exposure to oxygen or oxides of nitrogen, of a nitrogen-containing inhibitor, a hindered phenol inhibitor, or a sulfur-containing organic inhibitor.

Owner:THE LUBRIZOL CORP

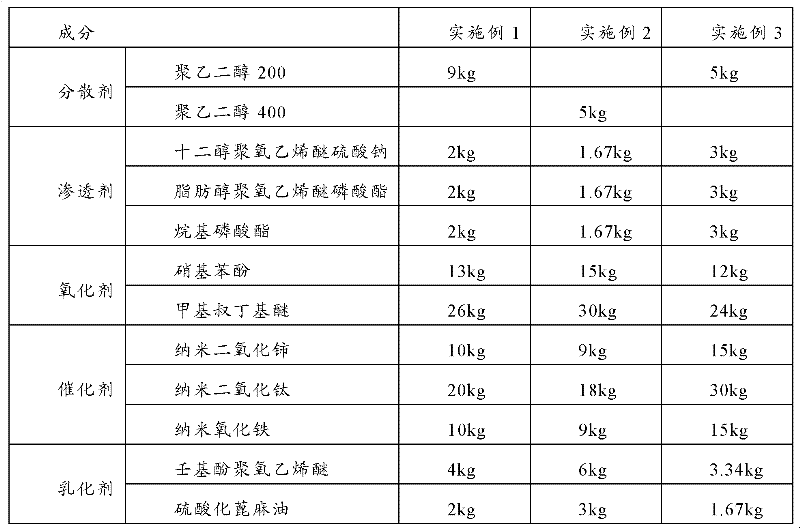

A kind of coal combustion accelerant

The invention provides a coal combustion improver which comprises 5 to 10 percent of dispersing agent, 5 to 10 percent of penetrant, 35 to 50 percent of oxidizing agent, 35 to 50 percent of catalyst and 5 to 10 percent of emulsifying agent, wherein the oxidizing agent is a mixture of nitrophenol and methyl tertiary butyl ether; and the catalyst is nano-scale metallic oxide. The coal combustion improver provided by the invention has high combustion improving efficiency and is safe and environmental-friendly. The invention also provides a method for preparing the coal combustion improver.

Owner:安徽海螺材料科技股份有限公司

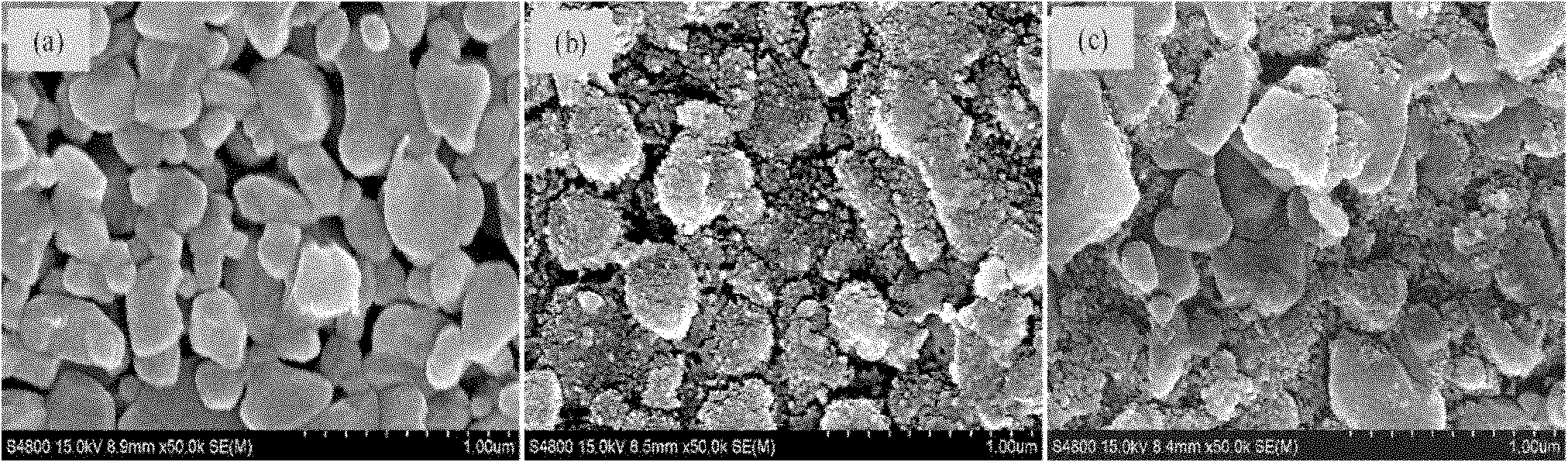

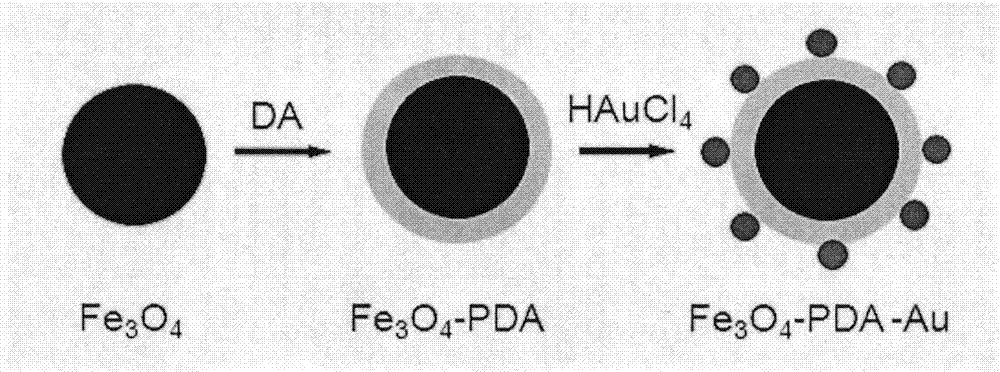

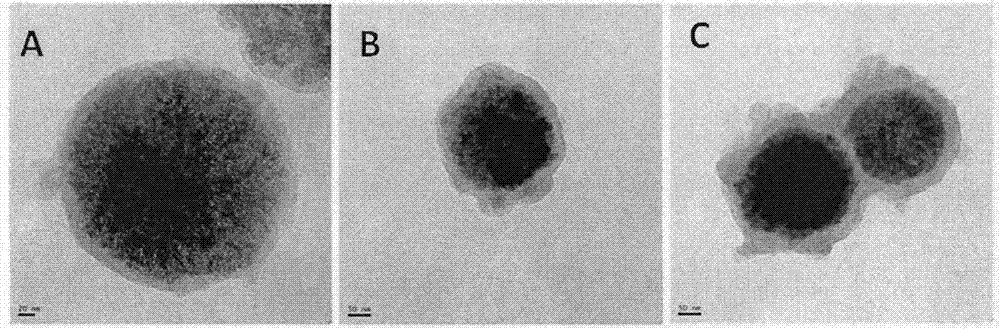

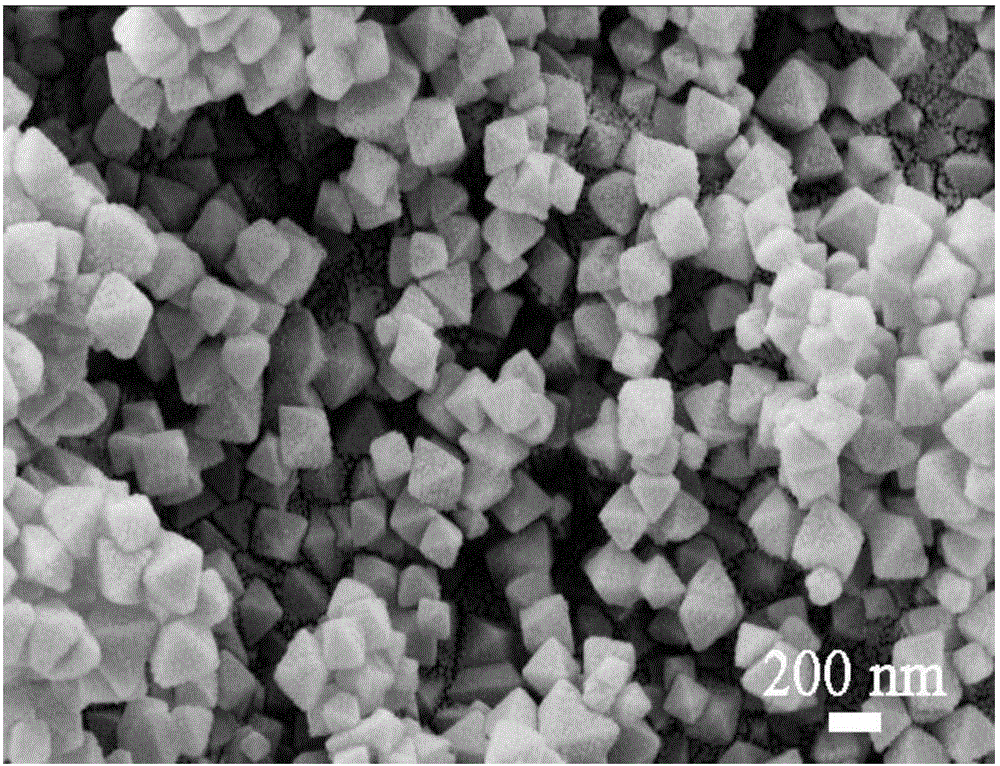

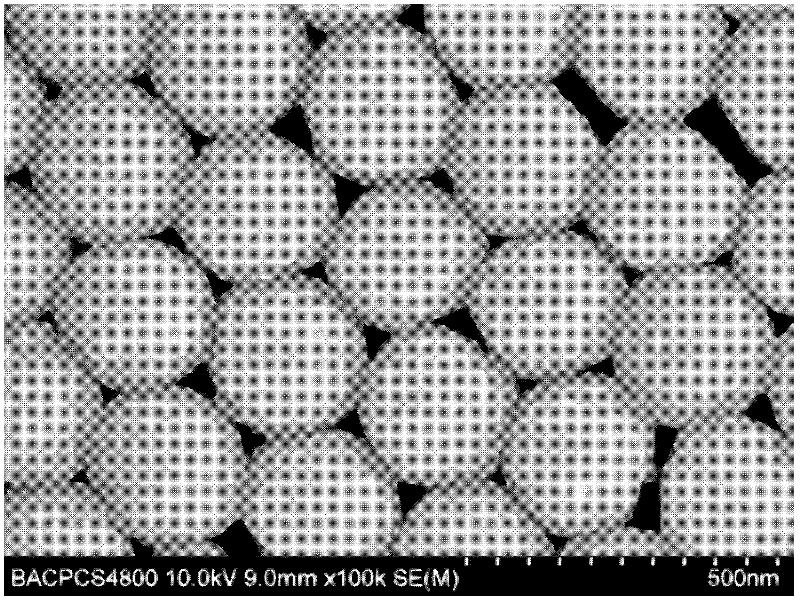

Fe3O4-poly-dopamine-Au nano-composite material as well as preparation method and application thereof

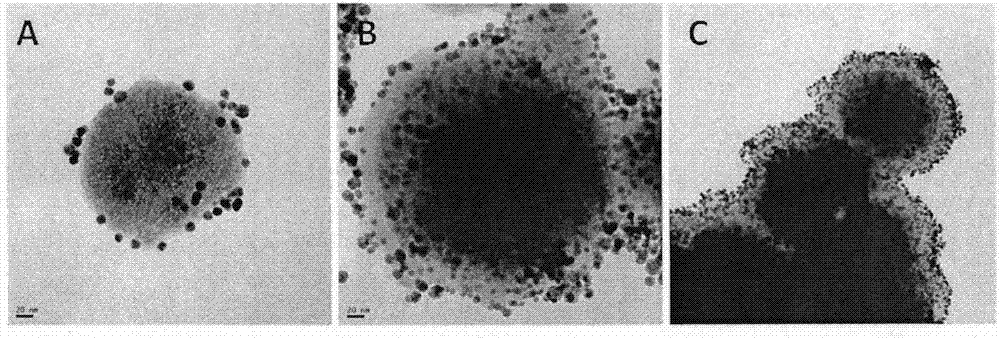

InactiveCN104258909AImprove distributionGood biocompatibilityOrganic-compounds/hydrides/coordination-complexes catalystsColor/spectral properties measurementsSurface layerMagnetic bead

The invention provides a Fe3O4-poly-dopamine-Au nano-composite material. Au nano-particles are deposited on the surfaces of Fe3O4 nano-magnetic beads covering poly-dopamine, wherein the diameter of the Au nano-particles is 10-30 nm; the thickness of poly-dopamine is 20-55 nm, and the diameter of Fe3O4 magnetic beads is 200-250 nm. The invention also provides a preparation method of the Fe3O4-poly-dopamine-Au nano-composite material and an application of the Fe3O4-poly-dopamine-Au nano-composite material in detection of catalysis of p-nitrophenol. According to the composite material, because nanogold is distributed on the surface layer of the Fe3O4-poly-dopamine-Au nano-composite material, the catalytic efficiency is improved; in addition, the Fe3O4 magnetic beads have the characteristics of high biocompatibility and environmental protection, and is convenient to synthesize and easy to separate, so that a nanogold catalyst can be repeatedly used.

Owner:QUFU NORMAL UNIV

Preparation method for photocatalyst for treating nitrophenol wastewater and treatment method for nitrophenol wastewater

InactiveCN104399516AEnlarging hole diameterImprove performanceMolecular sieve catalystsWater/sewage treatment by irradiationMolecular sieveSulfate radicals

The invention provides a preparation method for a photocatalyst for treating nitrophenol wastewater and a treatment method for the nitrophenol wastewater. Compared with the prior art, the preparation method and the treatment method have the advantages that by modification of ZSM-5, the hole diameter of a molecular sieve is enlarged, more mesoporouses are provided, and the specific surface area and the hole capacity are enlarged; a secondary mesoporous molecular sieve (ZSM5) is prepared; nano TiO2 is synthesized by a sol-gel method and is loaded on the ZSM5 to prepare a composite catalyst with high performance; meanwhile, peroxysulphate is added in order to solve the problem that independent UV / TiO2 is low in oxidization capacity, so that a sulfate radical anion is generated by peroxysulphate under UV excitation and can develop higher oxidization capacity under cooperation with -OH. According to the preparation method and the treatment method, the photocatalysis action of nano TiO2 / mesoporous ZSM-5 and the advanced oxidation action of the sulfate radical anion are combined, so that the photocatalysis treatment efficiency is improved, the treatment cost is reduced, and the characteristics of repeated use and green high efficiency are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

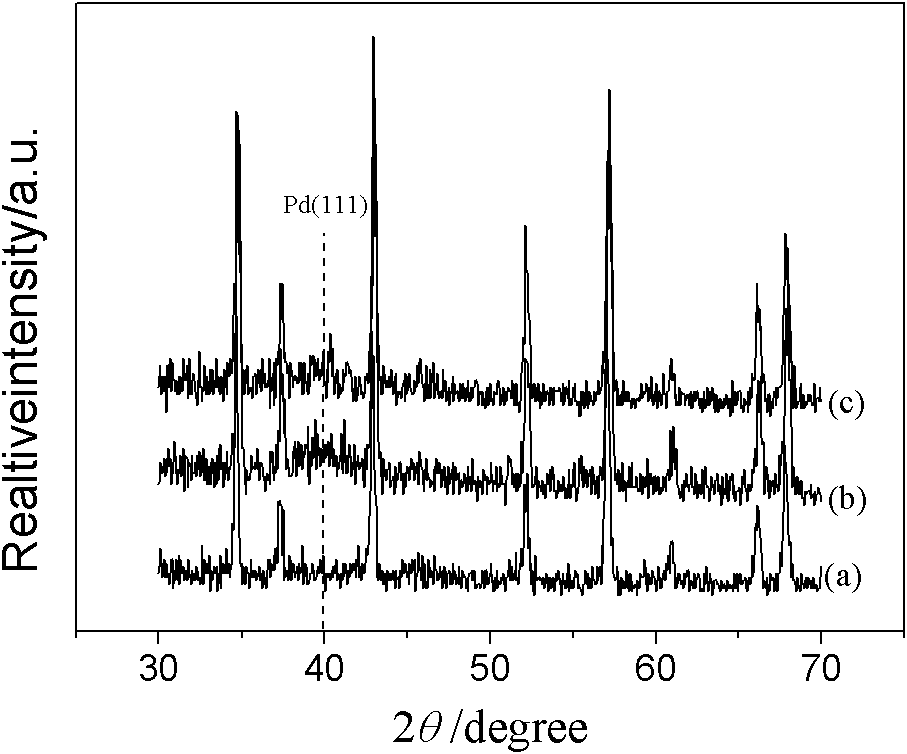

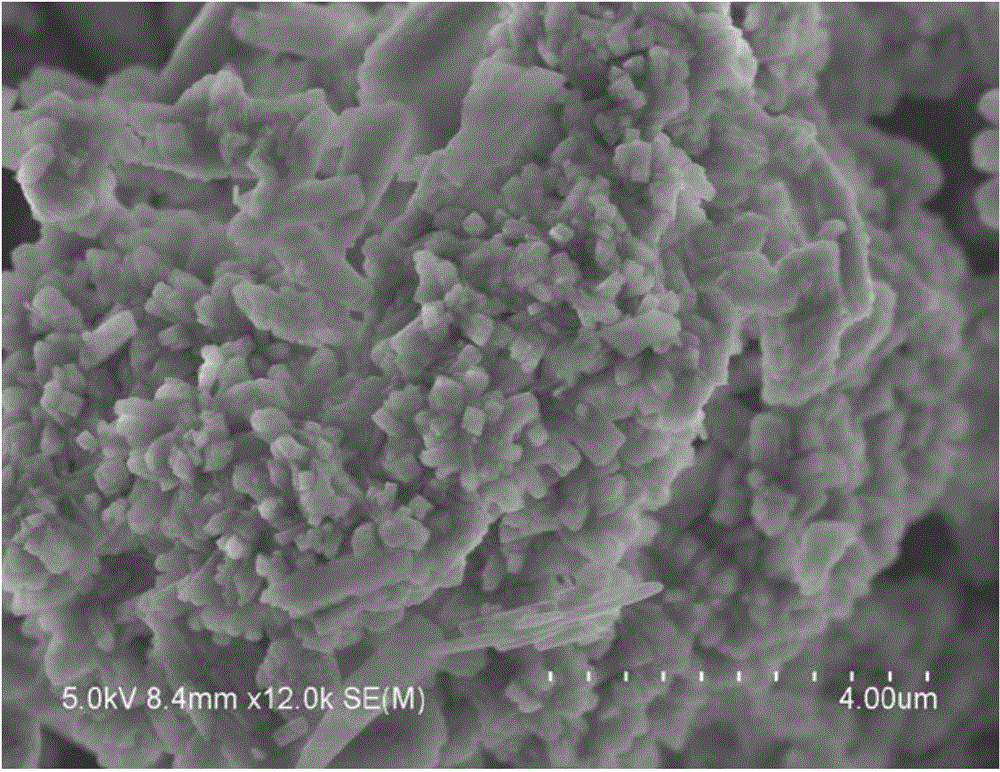

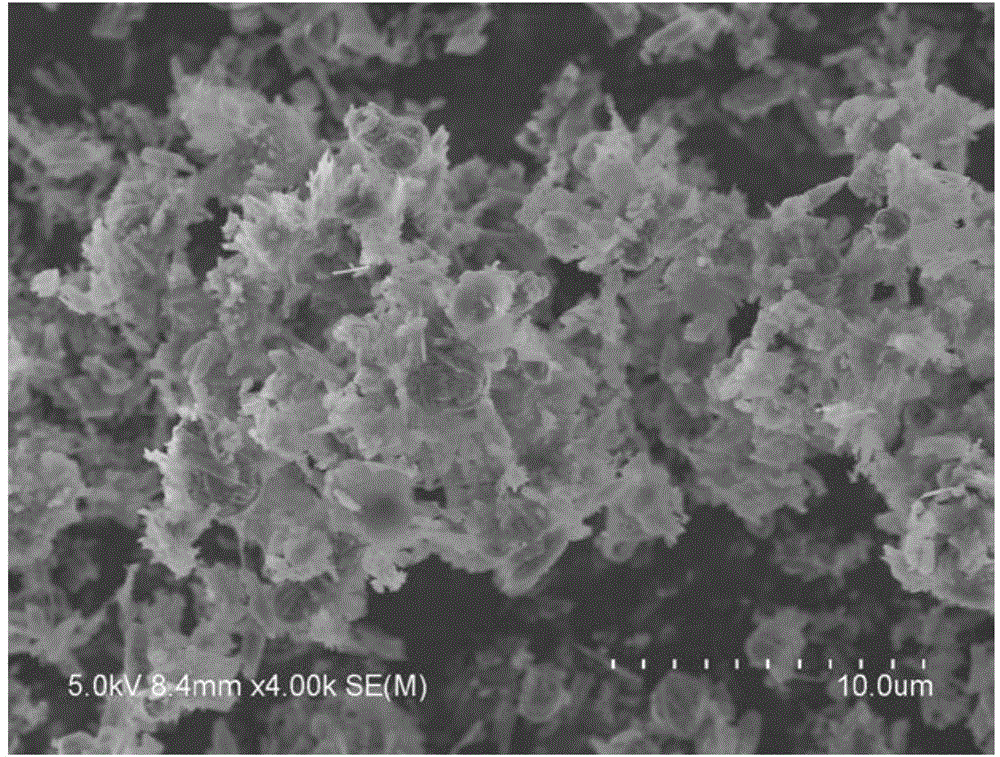

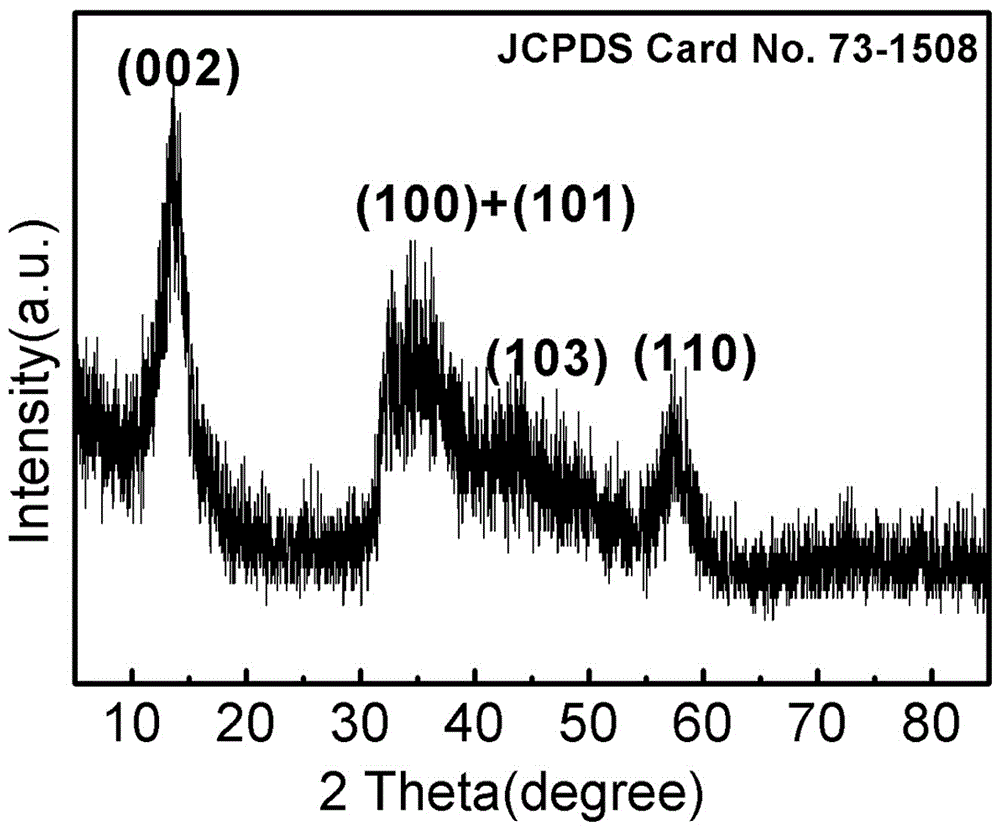

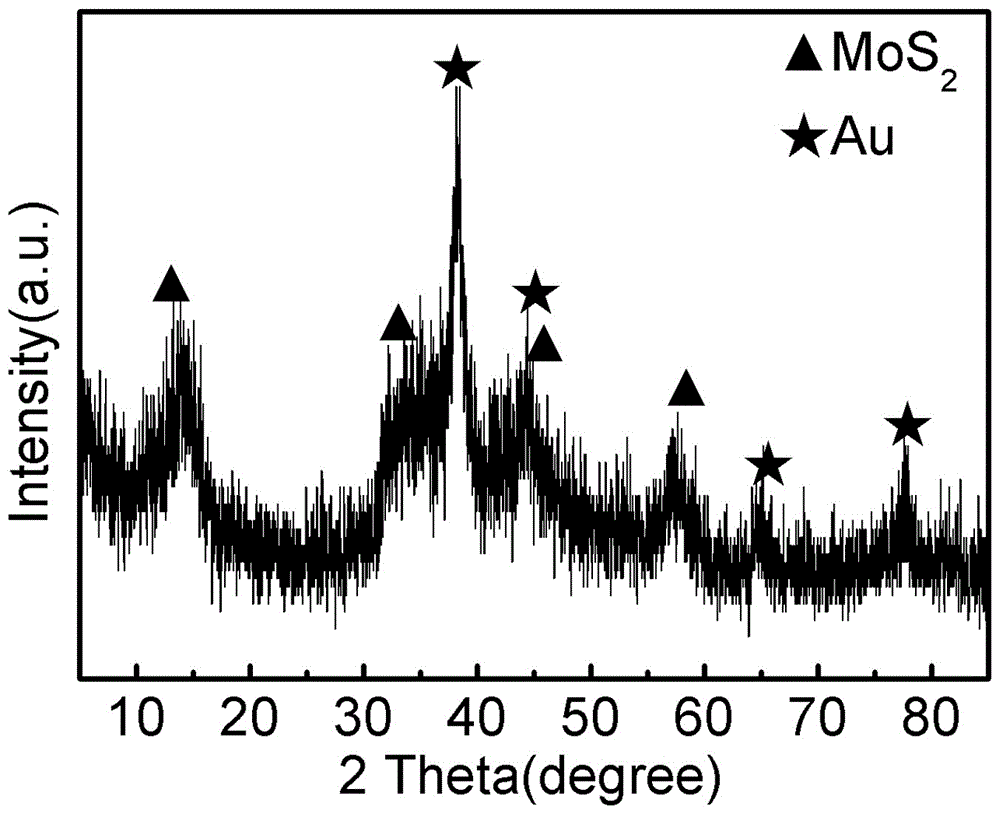

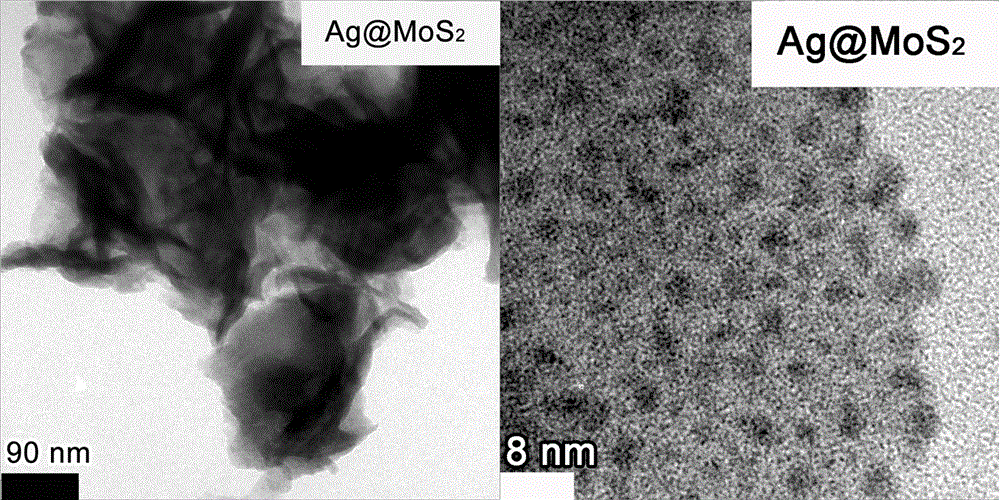

Supported two-dimensional layered molybdenum sulfide composite material and preparation method and application thereof

InactiveCN105664976AAvoid reunionHigh catalytic efficiencyPhysical/chemical process catalystsOrganic compound preparationChemical compoundNitrophenol

The invention belongs to a supported two-dimensional layered molybdenum sulfide composite material and discloses a noble metal (Ag, Au)-supported composite nano-catalytic material and its application in catalytic reduction of p-nitrophenol. The two-step synthetic technology is adopted in the invention. Firstly, molybdenum sulfide nanosheet with a porous ultrathin structure is synthesized by a hydrothermal method; then, by an ultraviolet reduction technology, noble metal nanoparticles are supported onto the surface of the two-dimensional layered compound molybdenum sulfide with a sandwich structure, and agglomeration phenomenon during the noble metal preparation process can be effectively avoided by the combination of nano confinement growth effects; and finally, noble metal nanoparticles with uniform size distribution are obtained. According to the supported catalyst system, the metal catalytic active center and a carrier together form a catalyst due to localized surface plasma resonance effect of noble metal active ingredients and synergistic effect between noble metal active ingredients and the carrier.

Owner:CHINA THREE GORGES UNIV

Preparation method of thermosensitive microgel asymmetric supported nano silver catalyst

InactiveCN103464203AHigh catalytic activityImprove adsorption capacityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsEmulsion polymerizationPickering emulsion

A preparation method of a thermosensitive microgel asymmetric supported nano silver catalyst comprises the steps of preparing poly-(N-isopropylacrylamide-styrene) / poly-(N-isopropylacrylamide-methacrylic acid) core-shell microgel by a soap-free emulsion polymerization method and a seed emulsion polymerization method, and then synthesizing the asymmetric supported nano silver catalyst taking the microgel as a template by a pickering emulsion template method. The thermosensitive microgel asymmetric supported nano silver catalyst prepared by the method shows good thermosensitivity, and good catalytic activity as the catalytic reaction efficiency is regulated and controlled by temperature and the thermosensitivity of the microgel simultaneously during catalytic reduction of p-nitrophenol.

Owner:SHAANXI NORMAL UNIV

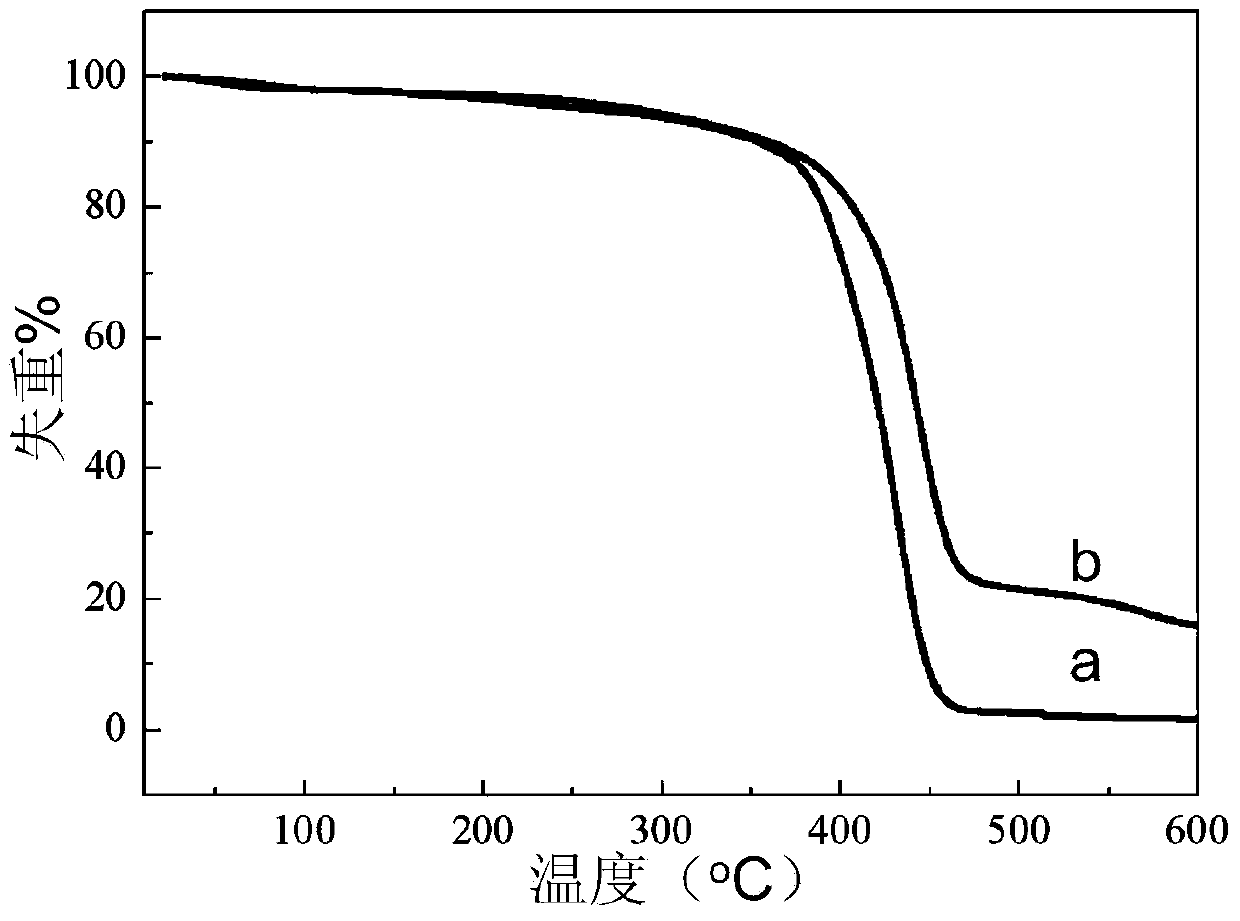

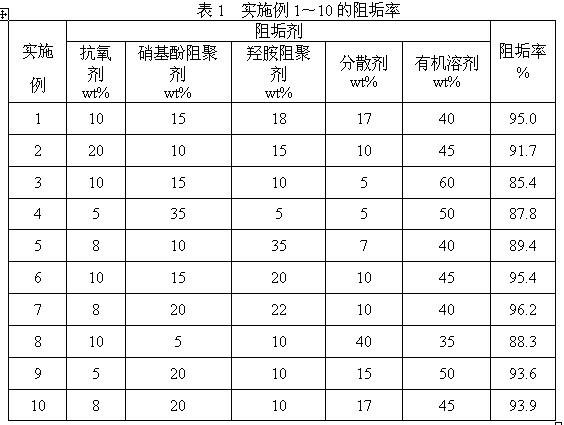

Scale inhibitor for styrene rectification system

InactiveCN102070394AInhibition of polymerizationSuppress generationDistillation purification/separationHydrocarbonsHydroxylamineOrganic solvent

The invention relates to a scale inhibitor for a styrene rectification system. The technical problem to be solved by the invention is to inhibit the generation of the scaling matter in the styrene rectification system and disperse the scaling matter adhered to the surface of the equipment so as to prolong the operation cycle of the styrene equipment. The scale inhibitor comprises the following components by weight percent: 5-20% of antioxidant, 5-35% of nitrophenol polymerization inhibitor, 5-35% of hydroxylamine polymerization inhibitor, 5-40% of dispersant and 35-60% of organic solvent.

Owner:浙江杭化科技股份有限公司

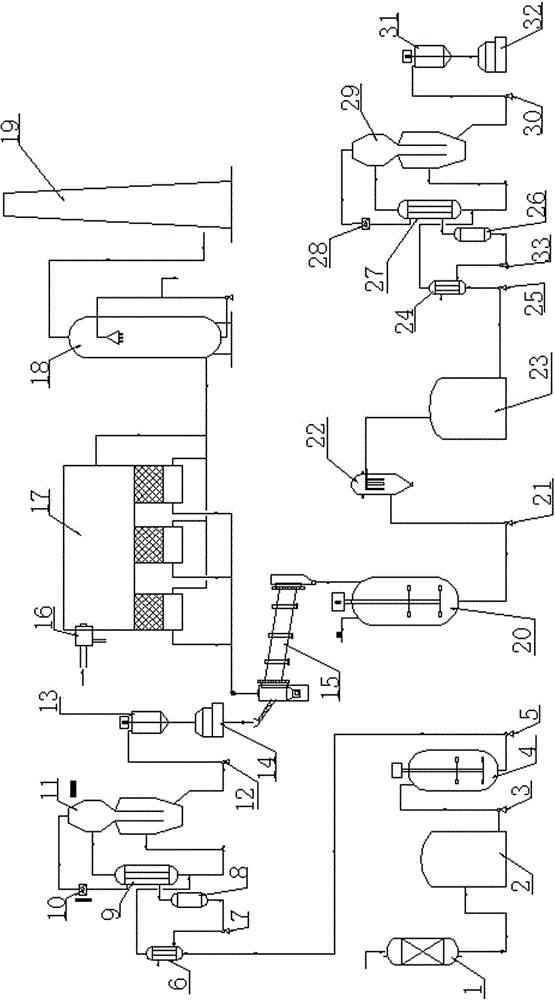

Catalyst used in the catalytic hydrogenation of p-nitrophenol and its preparation method

ActiveCN101007275AHigh activityReduce loadCatalyst carriersOrganic compound preparationFiltrationUltrasonic radiation

The invention involves a load palladium amorphous alloy catalyst used for nitrophenol hydrogenation and preparation method and belongs to catalyst technology field. Said catalyst uses NaY, MCM-41, molecular screen, Al2O3, TiO2, SiO2 or MgO as carrier, and is loaded with Pd-B amorphous alloy, the quality of Pd is 0.1-0.5% of toatl quality of catalyst. The preparation process includes ultrasonic dispersion, vacuum impregnation, KBH4 chemical reduction under vacuum conditions, filtration and washing of carriers; it is characterized by introducing vacuum and ultrasonic radiation conditions. The advantages of the invention lies in its high activity of catalyst, low preparation cost and simple preparation process, it could widely apply to the preparation of p-aminophenol through nitrophenol catalysis and hydrogenation.

Owner:NANJING UNIV OF TECH

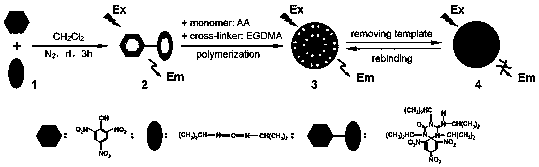

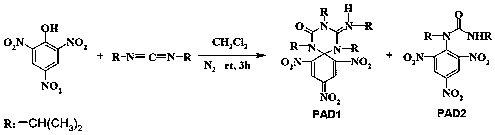

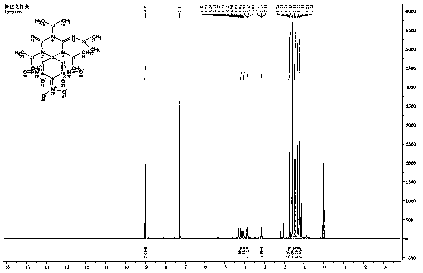

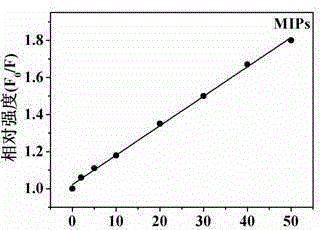

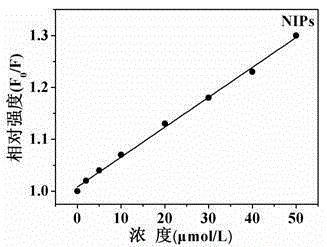

Preparation method of molecularly imprinted polymeric microspheres for 2,4,6-trinitrophenol detection

ActiveCN108246271ALarge specific surface areaMore effective recognition sitesOther chemical processesFluorescence/phosphorescenceTarget analysisMicrosphere

The invention discloses a preparation method of molecularly imprinted polymeric microspheres for 2,4,6-trinitrophenol detection. The preparation method is characterized in that polynitrophenol derivatives-imprinted molecules generated through reaction between 2,4,6-trinitrophenol and N,N'-diisopropyl carbodiimide have luminous yellow fluorescent light, the fluorescent light of the imprinted molecules has open and close characteristics under an acid-base condition, the imprinted molecules located in an imprinting layer of the molecularly imprinted polymeric microspheres can be eluted, a hole structure which is complementary with the structure, the size and the functional groups of the imprinted molecules is formed in the imprinting layer, polymeric microspheres of which the imprinted molecules are eluted have specific recognition sites on target analyte molecules, target molecules enter the specific recognition sites, selective recognition on the target analyte molecules is realized, sensitivity detection of the target analyte molecules can be realized through opening and closing of the fluorescent light of the target molecules, the specific surface area of the molecularly imprintedmicrospheres is large, and space in which the recognition sites are formed is stable in structure, has more effective sites, and is capable of carrying out high-selective recognition and high-sensitive detection on the target molecules.

Owner:霍尔姆斯(北京)生物科技有限公司

Preparing method of amino carbon quantum dot fluorescence silicon substrate imprint sensor

InactiveCN105385438AImprove quenching performanceNo pollution in the processFluorescence/phosphorescenceLuminescent compositionsCross linkerMolecularly imprinted polymer

The invention relates to a preparing method of an amino carbon quantum dot fluorescence silicon substrate imprint sensor and belongs to the technical field of preparation of an environment function material. The preparing method comprises the following steps: dissolving citric acid and a polymine solution to obtain a transparent solution, then transferring to a hydrothermal reaction kettle for reaction, and then cooling to room temperature to obtain dispersion liquid of amino carbon quantum dots; centrifuging the dispersion liquid to obtain an amino carbon quantum dot solution; then taking the amino carbon quantum dots as fluorescence carriers, p-nitrophenol as template molecules, (3-aminopropyl) triethoxy silane as a function monomer, and tetraethoxysilane as a cross-linking agent so as to obtain a fluorescence molecular imprinted polymer to be used for optical detection of p-nitrophenol. The amino carbon quantum dot fluorescence molecular imprinted polymer has very good optical and pH stabilities and has te capacity of selectively recognizing p-nitrophenol.

Owner:JIANGSU UNIV

Gold-MOFs-polymer composite membrane, and production method and application thereof

ActiveCN106397797AEfficient use ofSolving the Recycling ConundrumSemi-permeable membranesMembranesRoom temperatureContinuous flow

The invention discloses a gold-MOFs-polymer composite membrane, and a production method and an application thereof, and belongs to the technical field of polymeric functional membranes. An MOFs-polymer composite membrane obtained through self assembling of a covalent bond driven NMOFs material and mercapto group-containing functional polysiloxane is adopted to load gold nano-particles as a matrix in order to obtain the gold-MOFs-polymer composite membrane material. The gold-MOFs-polymer composite membrane has a high catalysis effect on Knoevenagel condensation of 4-nitrobenzaldehyde at room temperature and reduction of 4-nitrophenol as a continuous flow-through membrane reactor. The composite membrane has great application prospect in the field of membrane catalysis.

Owner:SHANDONG NORMAL UNIV

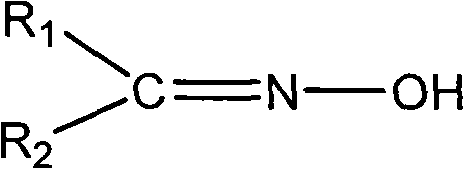

Polymerization inhibitor suitable for vinyl aromatic compound

ActiveCN101857519AHigh inhibition efficiencyLow costDistillation purification/separationHydrocarbonsSolubilityOrganic solvent

The invention discloses a polymerization inhibitor suitable for a vinyl aromatic compound, which can be applied in the processes of production, treatment, transportation and utilization of vinyl aromatic compounds. The compounded polymerization inhibitor is composed of an oxime compound, a nitrophenol compound and a nitroxide free radical compound and skilfully utilizes the respective advantages of a true polymerization inhibitor and a retarder; the synergy of components obviously improves inhibition effect, reduces use amount of highly toxic substances, lowers toxicity, improves solubility in the organic solvent and obtains good economic benefit.

Owner:ZHEJIANG UNIV

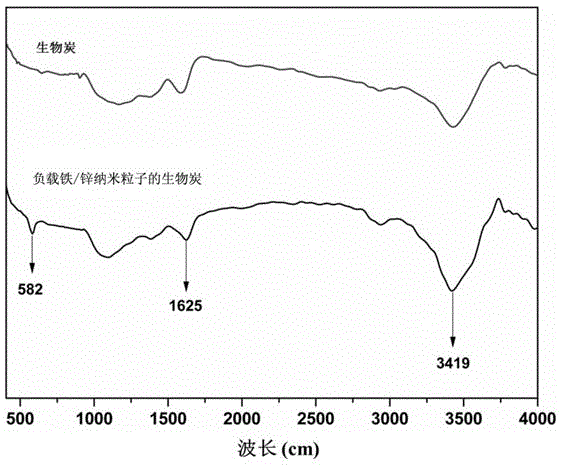

Biological charcoal loaded with iron/zinc nano-particles as well as preparation method and application thereof

ActiveCN106000311AIncrease the areaHigh pore volumeOther chemical processesWater contaminantsNitrophenolEnvironmental engineering

The invention discloses biological charcoal loaded with iron / zinc nano-particles as well as a preparation method and application thereof. The biological charcoal loaded with the iron / zinc nano-particles comprises biological charcoal, iron nano-particles and zinc nano-particles; the iron nano-particles and the zinc nano-particles are loaded in the surface and micro-pores of the biological charcoal. The preparation method takes the biological charcoal as a carrier and the iron nano-particles and the zinc nano-particles are loaded on the biological charcoal through a front immersion method; the prepared biological charcoal loaded with the iron / zinc nano-particles has relatively good magnetism, more functional groups and relatively large specific surface area and pore volume, can be used for rapidly and effectively removing p-nitrophenol in a water body and has the advantages of great adsorption amount, strong adsorption capability, high adsorption efficiency, simplicity in operation and the like.

Owner:HUNAN UNIV

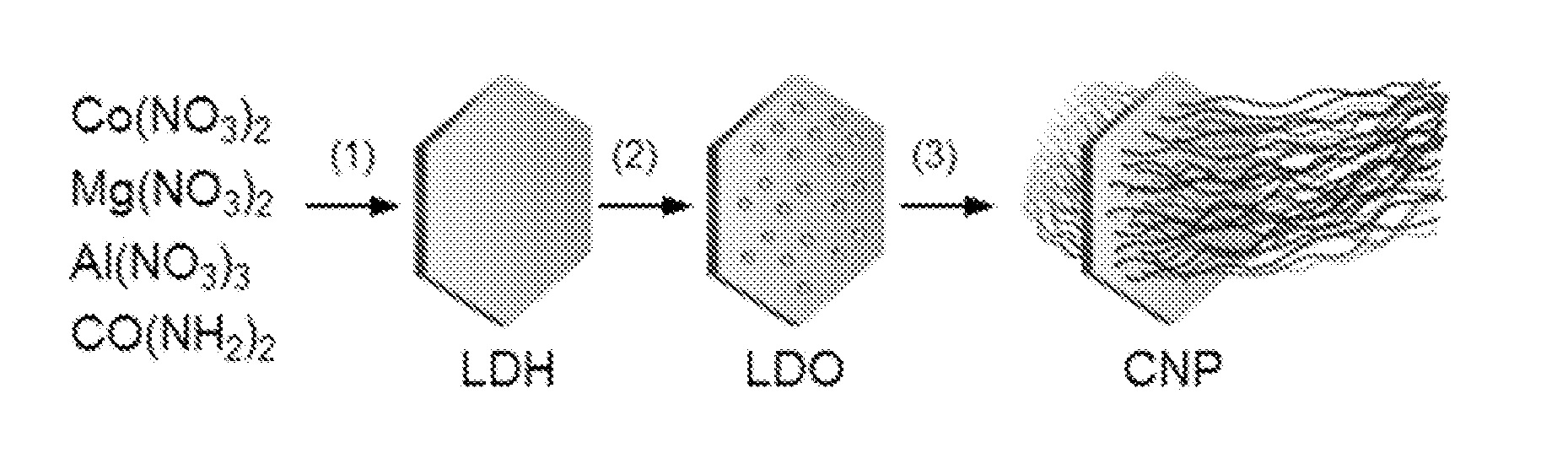

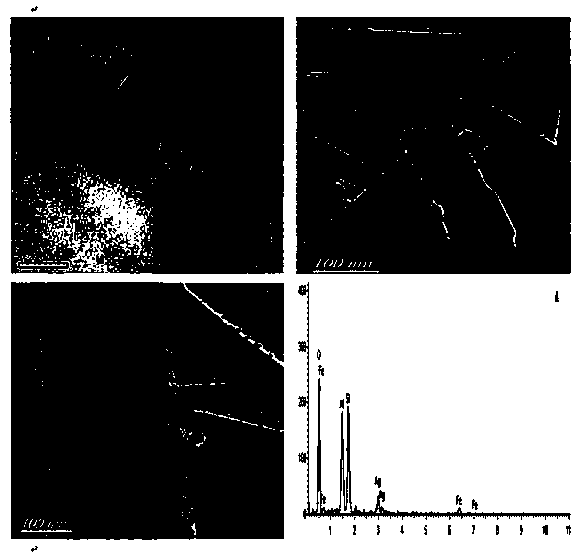

Carbon nanotube ponytails

InactiveUS20150321168A1Efficient separationImprove propertiesLiquid surface applicatorsIon-exchanger regenerationEscherichia coliNitrobenzene

Carbon nanotubes (CNTs) are promising nanomaterials that have the potential to revolutionize water and waste treatment practices in the future. The direct use of unbounded CNTs, however, poses health risks to humans and ecosystems because they are difficult to separate from treated water. Here, we report the design and synthesis of carbon nanotube ponytails (CNPs) by integrating CNTs into micrometer-sized particles, which greatly improves the effectiveness of post-treatment separation using gravitational sedimentation, magnetic attraction, and membrane filtration. We further demonstrate that CNPs can effectively perform major treatment tasks, including adsorption, disinfection, and catalysis. Using model contaminants, such as methylene blue, Escherichia coli, and p-nitrophenol, we show that all the surfaces of individual CNTs in CNPs are accessible during water treatment. Hierarchical structures containing CNPs can be employed in a multitude of nano-material engineering applications, such as water and waste treatment.

Owner:UNIV OF NOTRE DAME DU LAC

Mesopore carbon load nickel hydrogenation catalyst and preparation method thereof

InactiveCN101693201AOvercoming the problem of low activityHigh activityOrganic compound preparationCatalyst activation/preparationDispersityNickel salt

The invention provides a mesopore carbon load nickel hydrogenation catalyst and a preparation method thereof. For the load type catalyst, a carrier is mesopore carbon, an active component is metal nickel, and the mass of the nickel is 5-50 percent of that of the carrier. The preparation method comprises the following steps: soaking the mesopore carbon carrier in an organic soaking liquid containing nickel salt precursor under the action of ultrasonic, standing at room temperature, drying, and activating the precursor containing a metal component through the reducibility of the carrier, i.e. by a thermal reduction mode. The invention has the advantages of high dispersity of the active component, excellent performance of the catalyst, simple preparation process and low cost and can be used for preparing p-aminophenol by carrying out liquid-phase hydrogenation on p-nitrophenol.

Owner:NANJING UNIV OF TECH

Method for treating wastewater generated from fabricating nitrophenol as well as for reclaiming and using resources

InactiveCN1562790AAchieve recyclingCombustible gas purificationWater/sewage treatment by sorptionResource recoveryWastewater

The prodn. process are: pretreatment, adsorpting adsorpting para-nitrophenol in waste water, recovering and utilizing sodium chloride, deadsorpting obsorbed para-nitrophenol. The outstanding characteristic is that recovering ratio for nitrophenol is approach 100 percent, the recovered nitrophenol is reused by being send back to prodn process, large quantity of sodium chloride in waste water is used to produce caustic soda and hydrochloric which can be circulating used.

Owner:NANJING UNIV

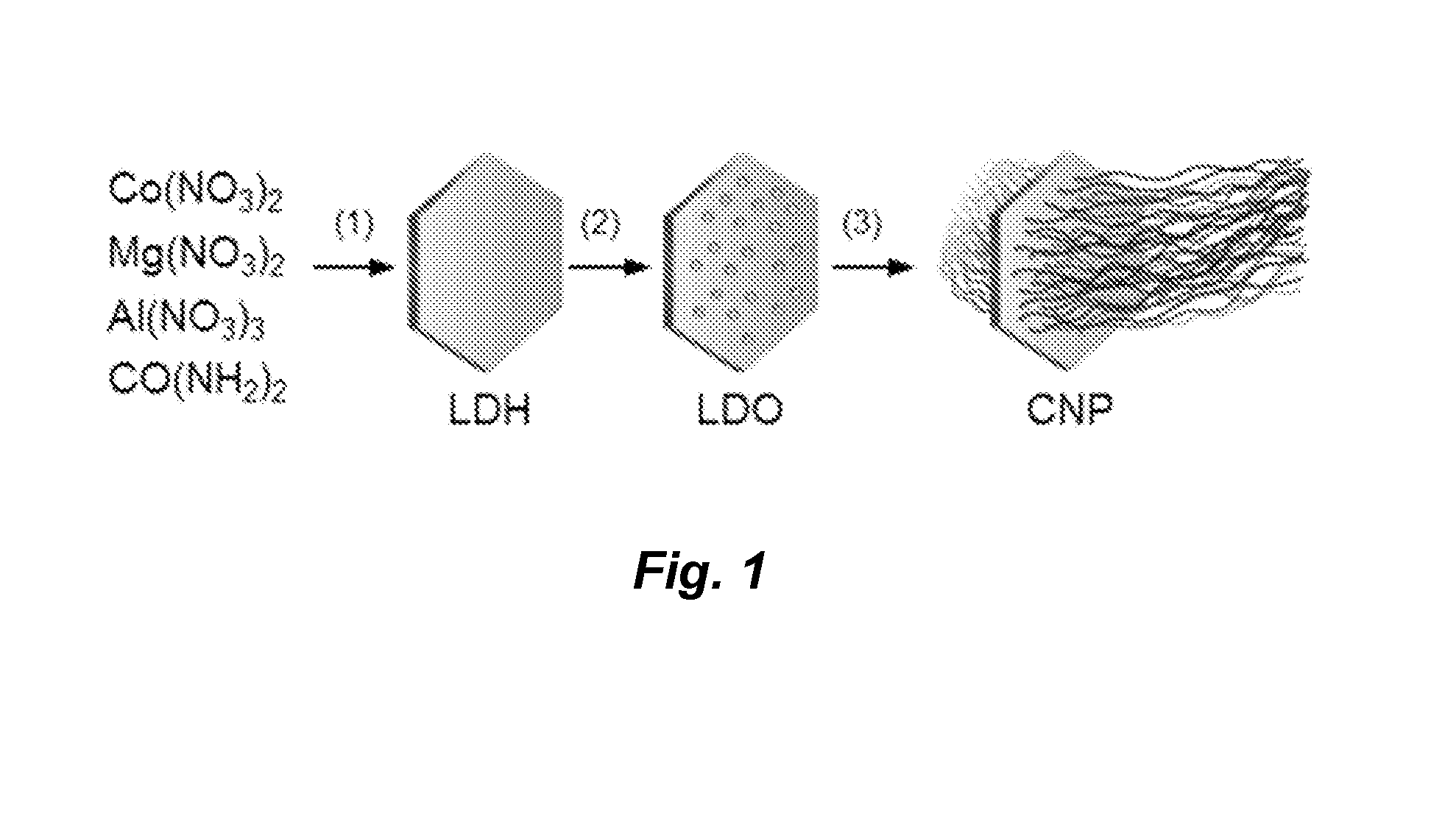

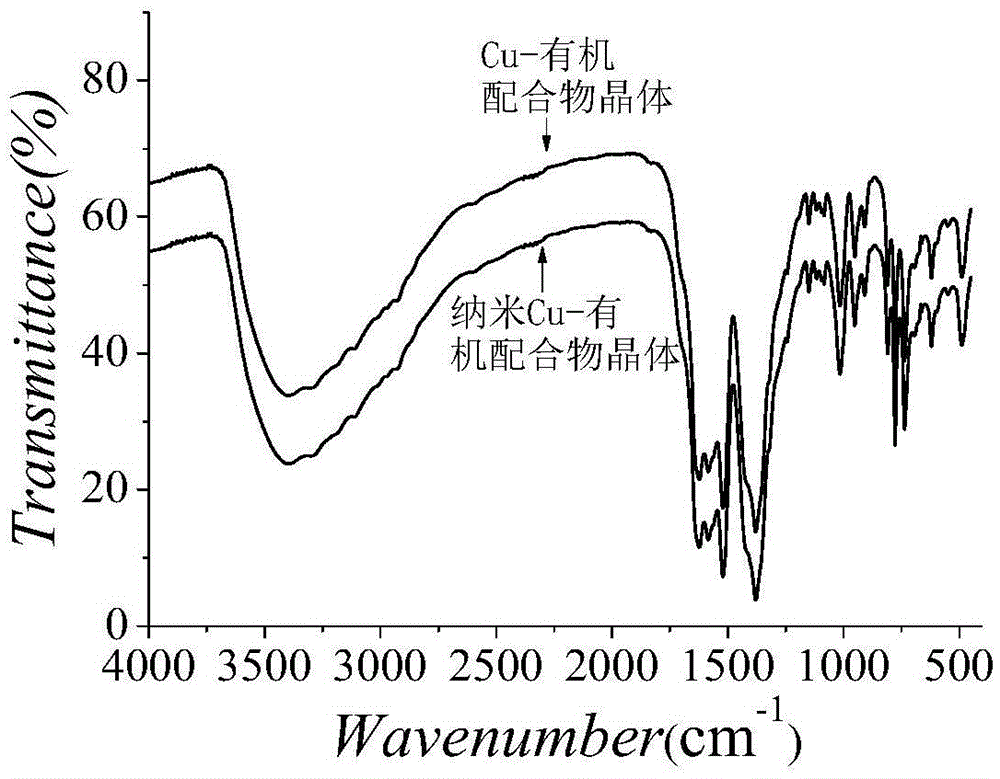

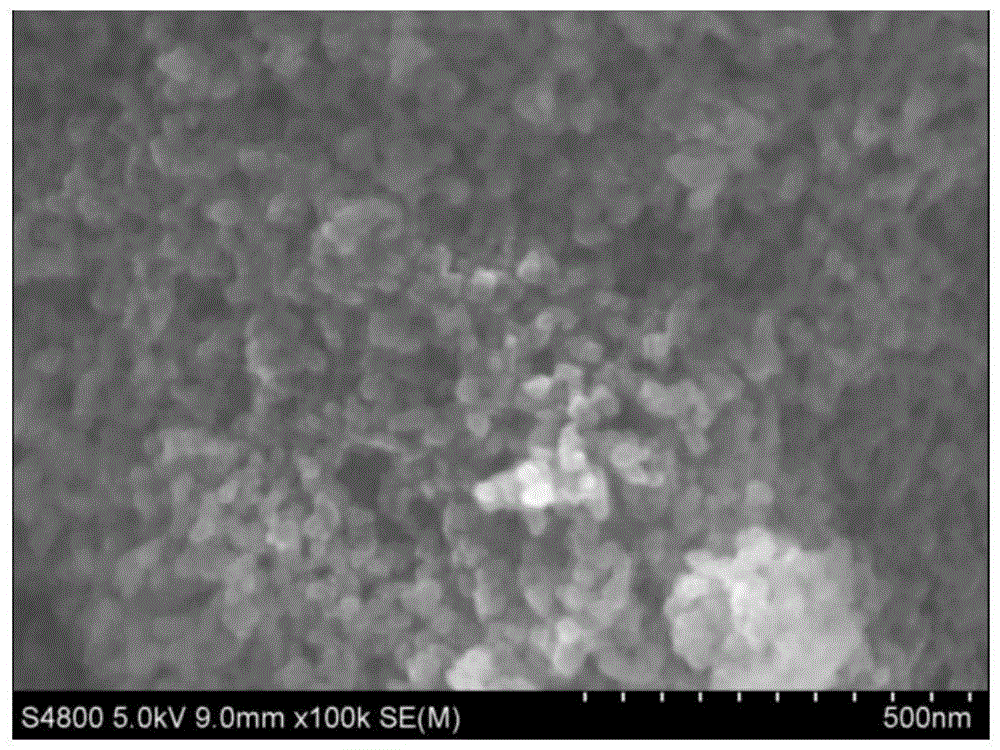

Preparation method and application of nanometer Cu-organic complex crystal

InactiveCN105524007ASimple methodSmall sizeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryM-aminophenol

The invention relates to a preparation method and application of a nanometer Cu-organic complex crystal, belonging to the technical fields of metal organic complexes, material science, nano-materials, chemical industry, catalysis and the like. According to the invention, cupric nitrate and 5-aminoisophthalic acid are used as main raw materials, and a metal organic complex gel method is employed to prepare the nanometer Cu-organic complex crystal. The preparation method has the advantages of low cost for raw materials, easy process and operation and low energy consumption. The nanometer Cu-organic complex crystal can realize high-efficiency catalytic reduction of 4-nitrophenol into 4-aminophenol and has good application prospect in heterogeneous catalytic reduction.

Owner:SHANDONG NORMAL UNIV

Preparation method of magnetic composite catalyst Ag/HNTs/Fe3O4

InactiveCN103638944AHigh catalytic activityGood magnetic response propertiesMetal/metal-oxides/metal-hydroxide catalystsNanotubeReducing agent

The invention relates to a preparation method of magnetic composite catalyst Ag / HNTs / Fe3O4, and belongs to the technical field of environmental function material preparation; a simple and effective chemical reduction method is used to prepare a Fe3O4 / Halloysite Nanotubes (HNTs / Fe3O4) magnetic composite material, then a silver nitrate solution and ammonia are mixed into a fresh silver ammonia solution as an oxidizing agent, glucose is used as a reducing agent, Ag nanoparticles are deposited on the magnetic composite material by a silver mirror reaction to prepare the magnetic composite catalyst Ag / HNTs / Fe3O4, and the magnetic composite catalyst Ag / HNTs / Fe3O4 is used for catalytic degradation of p-nitrophenol in a water solution.

Owner:JIANGSU UNIV

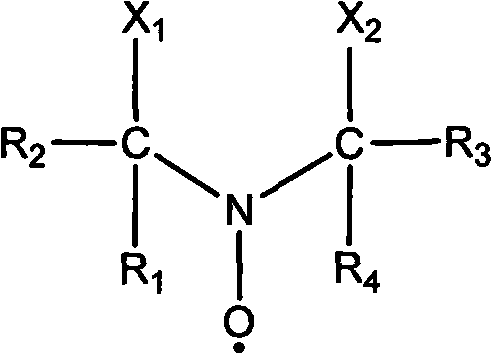

Aromatic sulfonic acids, amines, and nitrophenols in combination with nitroxyl radical-containing compounds or C-nitrosanilines as polymerization inhibitors

InactiveUS20060122341A1Highly efficient and inexpensiveSuperb true inhibitorOther chemical processesHydrocarbon purification/separationNitroxyl radicalsNitrophenol

Disclosed herein is a method for inhibiting and retarding the premature polymerization and the polymer growth of vinyl aromatic monomers wherein the method comprises adding to said monomers an effective amount of an inhibitor and retarder blend comprising: (A) at least one aromatic sulfonic acid; (B) at least one amine; (C) at least one nitrophenol; and (D) at least one member of the group consisting of nitroxy radical-containing compounds and nitrosoanilines.

Owner:ADDIVANT USA

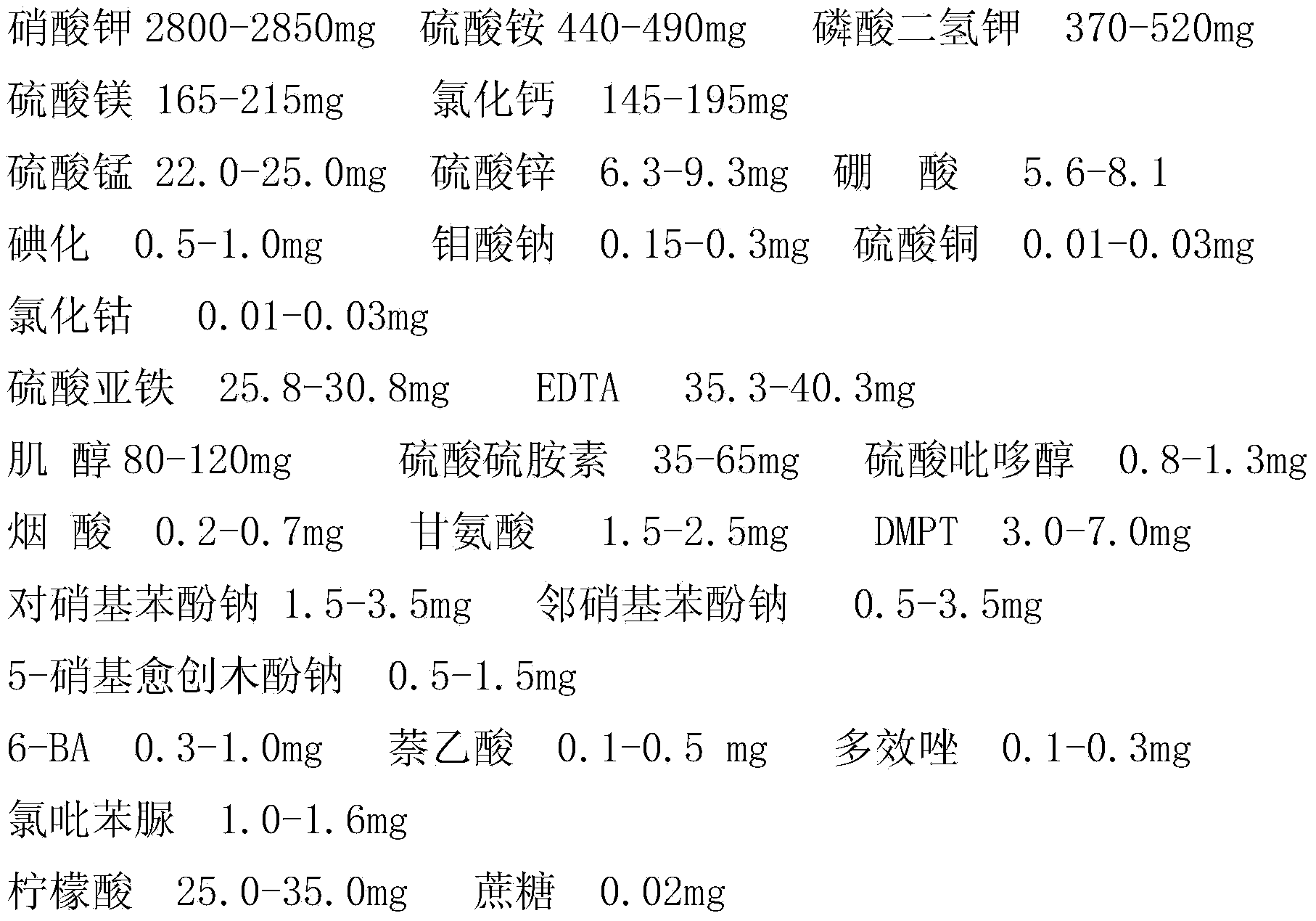

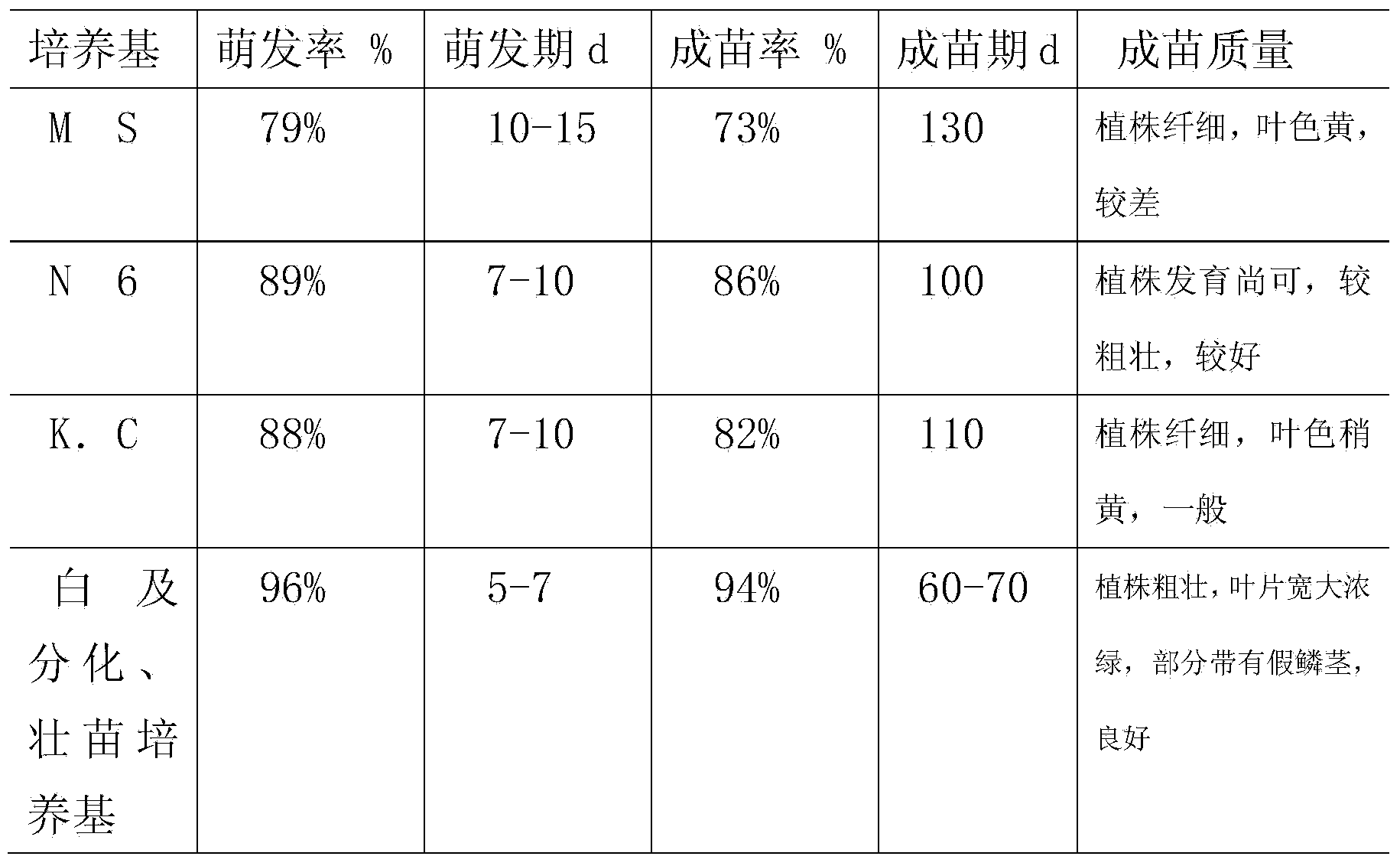

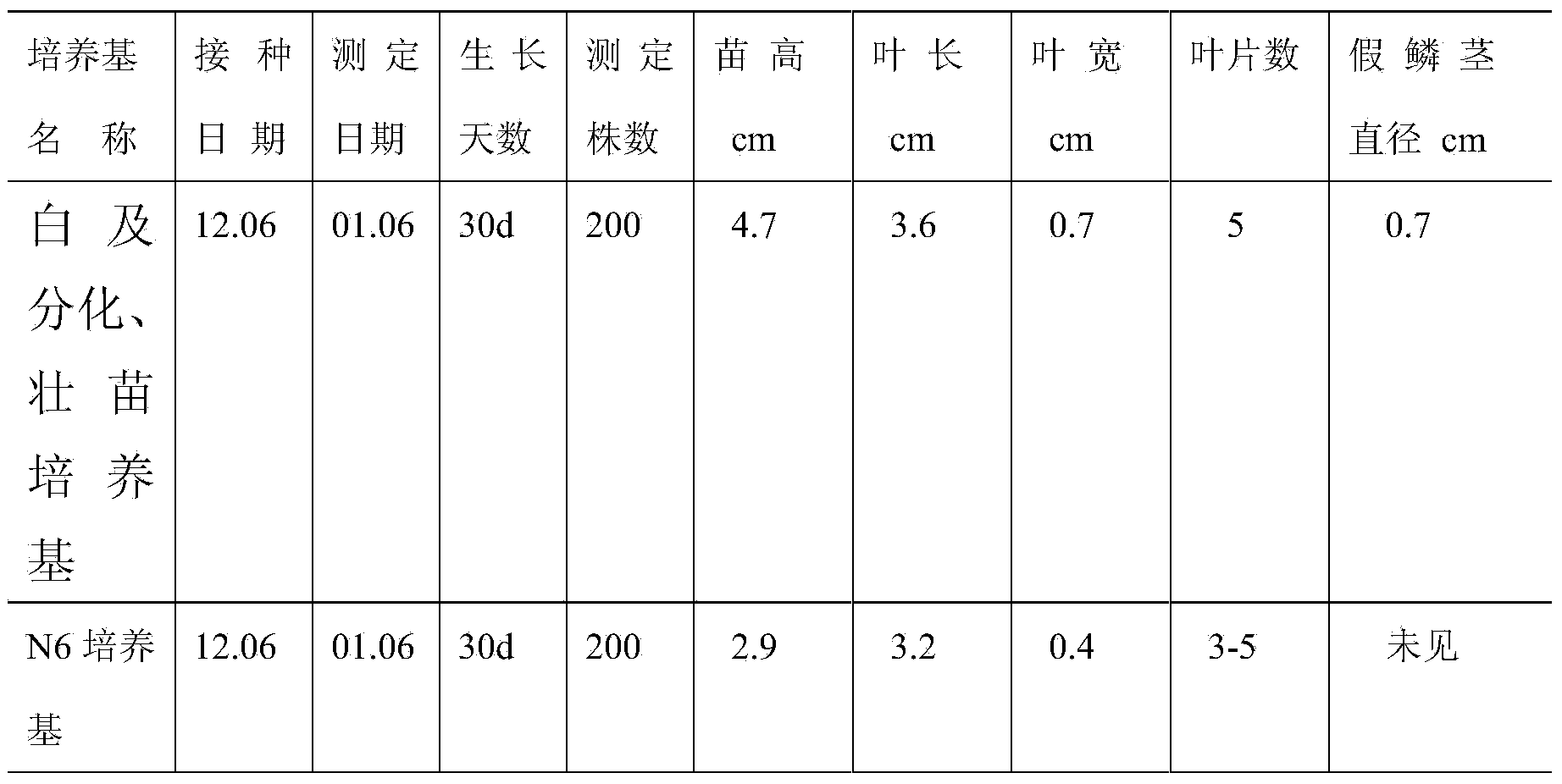

Bletilla striata differentiation and seedling strengthening medium

InactiveCN103651121AStrong differentiation abilityImprove germination ratePlant tissue cultureHorticulture methodsMonopotassium phosphatePotassium iodine

The invention a bletilla striata differentiation and seedling strengthening medium and relates to the technical field of bletilla striata planting and cultivation. The bletilla striata differentiation and seedling strengthening medium is prepared from the following raw materials including potassium nitrate, 440-490mg of ammonium sulfate, monopotassium phosphate, magnesium sulfate, calcium chloride, manganese sulfate, zinc sulfate, boric acid, potassium iodide, sodium molybdate, copper sulfate, cobalt chloride, ferrous sulfate, EDTA (Ethylene Diamine Tetraacetic Acid), phaseomannite, thiamine sulfate, pyridoxine sulfate, nicotinic acid, glycine, DMPT, sodium para-nitrophenolate, sodium ortho-nitrophenol, 5-nitroguaiacol sodium salt, 6-BA, NAA, PP-333, CPPU, citric acid, and cane sugar under a proper pH value condition. The bletilla striata differentiation and seedling strengthening medium can improve the differentiation effects of bletilla striata seeds, and promotes the growth of seedlings and the fast formation of pseudobulb, so that the germination rate of the seeds can be effectively increased, and the growth speed of an embryoid can be increased.

Owner:ANHUI ZHENYANG AGRI & FORESTRY ECOLOGY DEV

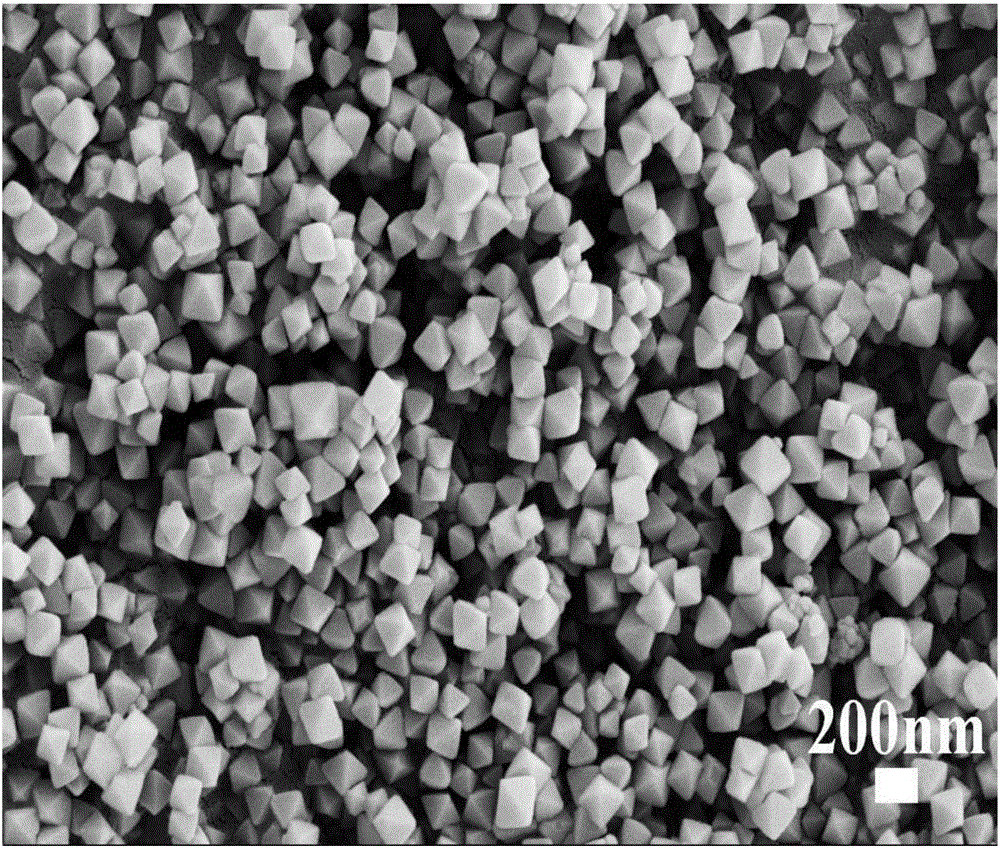

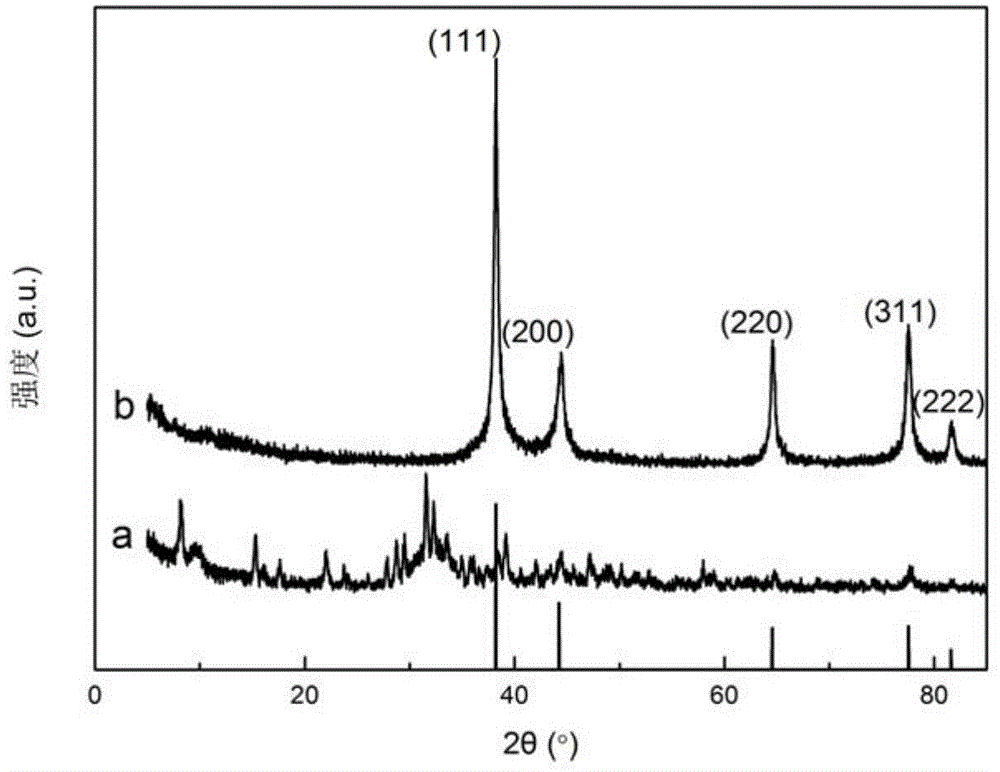

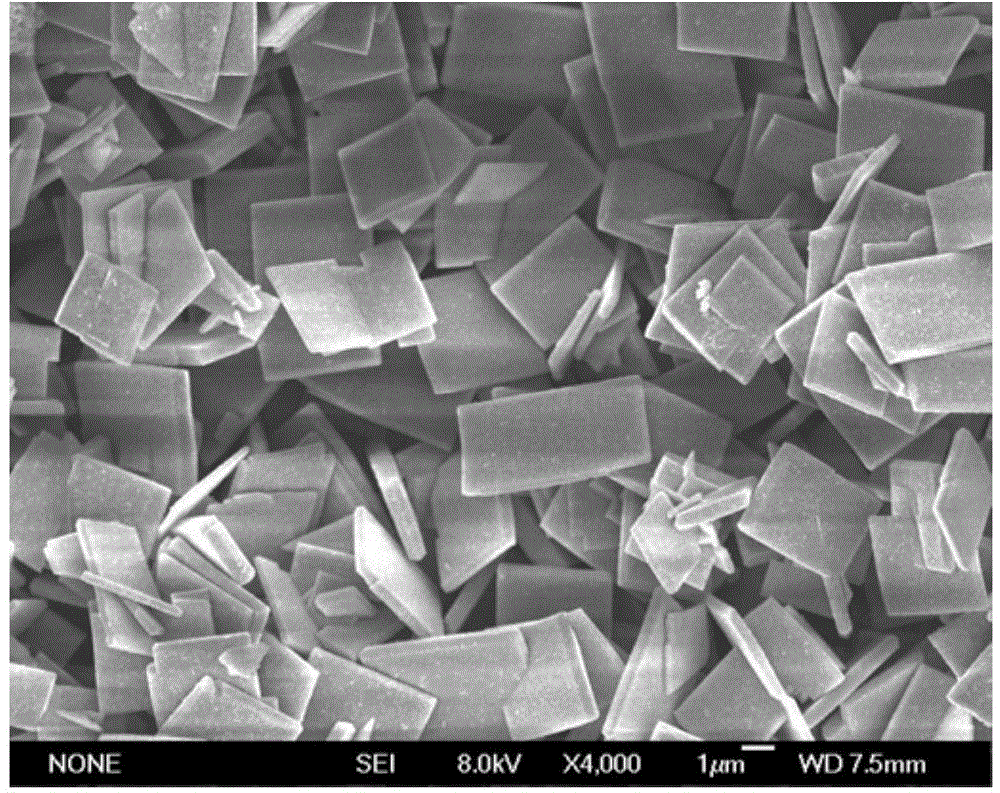

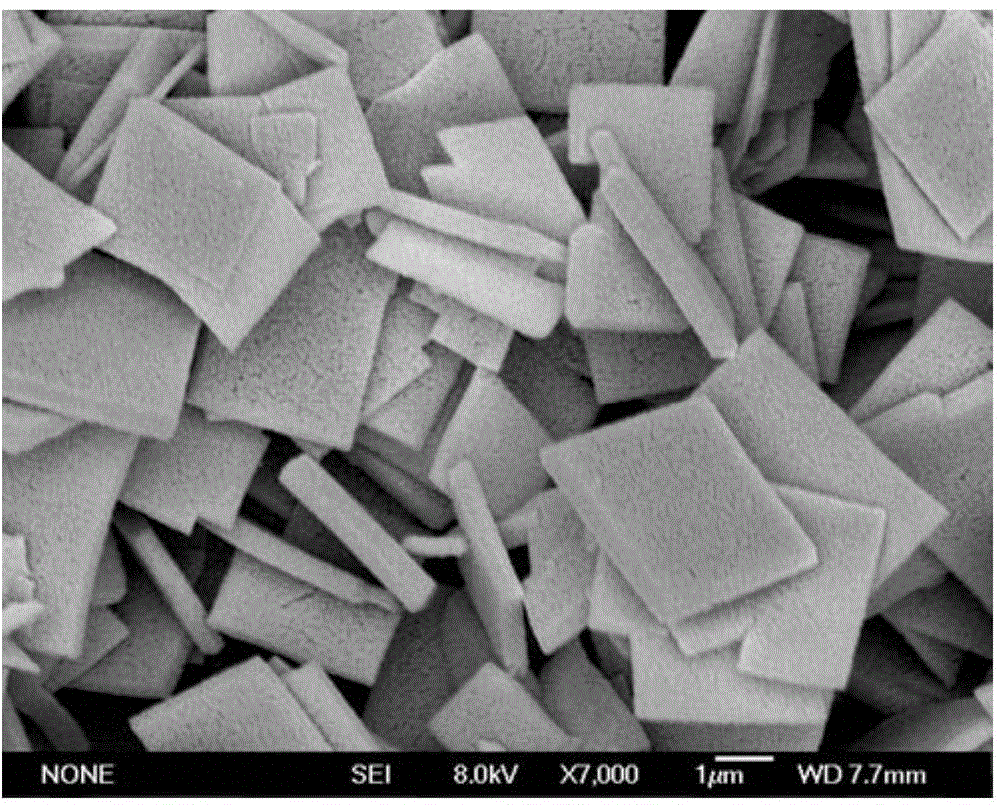

Porous silver micro-nano structure and shape and size controllable preparation method thereof

InactiveCN104525937ABreakthrough hazardReduce post processingMaterial nanotechnologyMicro nanoMaterials science

The invention provides a porous silver micro-nano structure and a shape and size controllable preparation method of the porous silver micro-nano structure, and belongs to the technical field of precious metal porous nano-crystalline structures. The overall appearance shape of the porous silver micro-nano structure is a hexagonal sandwich shape or a quadrilateral shape or a strip shape and is formed by stacking 30-50-nanometer silver basic composition units, and multiple pores are formed by stacking silver basic composition units. The preparation method includes the steps that sodium citrate, sodium carbonate and citric acid are dissolved in deionized water, a silver nitrate solution and a D-glucose solution are added in sequence, the mixture is stirred and sinks, and a precursor is obtained after centrifugal drying; the porous silver micro-nano structure is obtained after heat treatment is conducted on the precursor. The method is simple, environmentally friendly and controllable in shape and size; the prepared porous silver micro-nano structure is uniform in size distribution, large in specific surface area, good in permeability and higher in catalytic rate for p-nitrophenol, and has potential application in the precious metal catalytic aspect.

Owner:JILIN UNIV

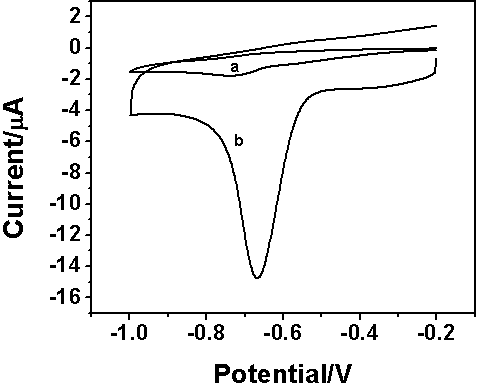

Method for detecting p-nitrophenol by using PDDA (Poly Diallyldimethylammonium) functionalized graphene modified glassy carbon electrode

InactiveCN103808779ALarge specific surface areaImprove catalytic performanceMaterial electrochemical variablesNitrobenzeneNitrophenol

The invention discloses a new method for detecting p-nitrophenol by using a PDDA functionalized graphene modified glassy carbon electrode. The method comprises the following steps: taking 50mL of 1mg*mL<-1> graphene oxide solution, and performing an ultrasonic treatment for 4 hours; adding 1mL of 20% PDDA solution into 50mL of secondary water, uniformly mixing, then adding the graphene oxide solution into the PDDA solution in a magnetic stirring manner, keeping on stirring for 30 minutes, adding 1.5mL of hydrazine hydrate (80%), uniformly stirring, putting into a hydrothermal synthesis reactor and reacting for 3 hours at 100 degrees centigrade, cooling, centrifuging and washing by using the secondary water, and performing vacuum drying at 60 degrees centigrade to obtain the PDDA functionalized graphene. Not only is the dispersibility of the PDDA functionalized graphene in the water increased, but also the graphene has positive electricity, a good matrix is provided for preparation of a graphene-based composite material, and the application of the graphene in electro-analytical chemistry is widened.

Owner:NORTHWEST NORMAL UNIVERSITY

Preparation method of molecular imprinting colloid array and application thereof

InactiveCN102350315AShort processOvercoming vulnerability to destructionOther chemical processesAlkali metal oxides/hydroxidesPhotonicsKetone

The invention relates to a preparation method of a molecular imprinting colloid array and an application thereof, and belongs to the technical field of applied chemistry and clinical analysis and test. By the combination of molecular imprinting and colloid array technologies, the preparation method comprises the following steps of: respectively using oestrone, beta-estradiol, p-nitrophenol and melamine as template molecules, preparing template molecular imprinting colloid microballoons, followed by direct self-assembly and alignment to obtain the corresponding molecular imprinting colloid array. The method provided by the invention overcomes defects that a preparation method of molecular imprinting photonic crystals is complex and the photonic crystal template is easy to destroy; and by the adoption of the method, the preparation technology is simplified and the preparation time is shortened. The prepared molecular imprinting colloid array has adsorption selectivity and obvious optical performance response for the template molecules, and can be used to provide a simple effective method for preparing optical sensor materials and provide the possibility for ''naked eye detection''.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for identifying genuine and fake honey

InactiveCN102252979AHigh sensitivityEasy to operatePreparing sample for investigationColor/spectral properties measurementsBiotechnologyAlglucerase

The invention provides a method for identifying genuine and fake honey. The genuine and fake honey is identified by determining whether the enzyme activity of beta-glucosidase in honey exists. The authenticity of honey is in proportion to the detected enzyme activity; a product contains more natural honey when absorbance is higher; and the product contains fewer natural honey when the absorbance is lower. The enzyme activity of beta-glucosidase in the honey is represented by an enzyme activity unit in each gram of honey; and one enzyme activity unit is represented by enzyme amount required by catalyzing one micromole of p-nitrophenol each minute. The method is suitable for identifying the raw materials of the honey or a product prepared from honey serving as raw materials and identifying whether a fake material is mixed in the product. The method is high in flexibility, easy to operate, low in cost and suitable for popularization, and the conventional instrument is used.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com