Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Realize resource regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical industrial waste salt refining process

ActiveCN104649495AImprove qualityRealize resource regenerationMultistage water/sewage treatmentAlkali metal chloridesTunnel kilnEvaporation

The invention relates to a chemical industrial waste salt refining process which comprises the following steps: pretreating high salt wastewater generated in the production process of aminobenzene ether and p-nitrophenol so as to adjust the pH value, adsorbing by using activated carbon, kieselguhr or macroporous resin, removing organisms and organic salts in the wastewater, reducing the COD of the wastewater, neutralizing the high salt wastewater, performing multi-effect evaporation or mechanical recompression so as to evaporate and crystallize, and centrifuging a solid salt; performing high-temperature calcination on the centrifuged solid salt in a rotary kiln or a tunnel kiln, thereby decomposing and oxidizing the organisms at a high temperature, further thoroughly combusting the tail gas generated through calcination in a heat accumulation type tail gas combustion furnace, preheating and recycling the tail gas, performing spraying absorption, dissolving the calcinated salt with water so as to prepare a saturated solution, filtering by using a precise filter, directly supplying the filtrate to ionic membrane caustic soda for use, or performing multi-effect evaporation or mechanical recompression on the filtered saturated salt water so as to evaporate, crystallize and purify, and performing centrifugation, thereby obtaining high-quality solid sodium chloride.

Owner:JIANGSU ZHONGDAN GROUP

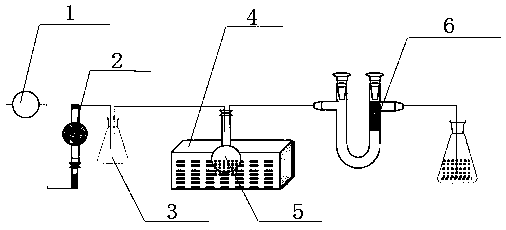

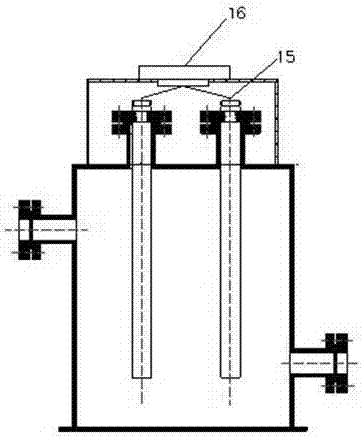

Technical method for electrorefining diamond

InactiveCN101049929AEliminate pollutionOperational securityPhotography auxillary processesUltra-high pressure processesElectricityElectrolysis

This invention relates to a method for purifying diamond by electrolysis. The method comprises: immersing diamond synthesized by powder method into the electrolyte in an electrolytic tank as the anode, electrolyzing, precipitating metals in the synthetic diamond onto the cathode plate under current action, and removing graphite by washing with water to obtain high-purity diamond. The method utilizes electricity power as a substitute for H2SO4 and HNO3 thus can effectively eliminate environmental pollution during the purification process, and the operation is safe and reliable. Metals in the synthetic diamond can be recovered, and the recovery rate is 80-90%.

Owner:ZHONGNAN DIAMOND CO LTD

Treatment for wastewater in para-nitraniline production and method for resource recovery and use

InactiveCN101244878AImprove adsorption capacityAchieve recyclingOrganic chemistryMultistage water/sewage treatmentAbsorption capacityPhosphate

The invention discloses a method for nitroaniline wastewater treatment and recycling, comprising a plurality of steps: cool p-nitroaniline mother liquor wastewater and crystals are allowed to be separated out; filter the wastewater after crystal precipitation and remove the free ammonia in the filtrate; filter the effluent ever treated at the procedure B and change PH value to acidity or weak alkalinity; use the viscose-based active carbon fiber made by phosphate-impregnated high-temperature steam activation to absorb the p-nitroaniline wherein; evaporate and concentrate the absorbed water; precipitate crystal and filter out ammonium chloride crystal. The active carbon fiber has large absorption capacity and fast absorption speed for p-nitroaniline and can be utilize repeatedly, which makes the recovery rate of p-nitroaniline near 100%. The method has the advantages that the method can fully recover p-nitroaniline and free ammonia in the p-nitroaniline wastewater and the byproduct of ammonium chloride, realizing the unification of wastewater treatment and resources recovery; the method is of great economic and practical value in the treatment of p-nitroaniline wastewater.

Owner:NANJING UNIV

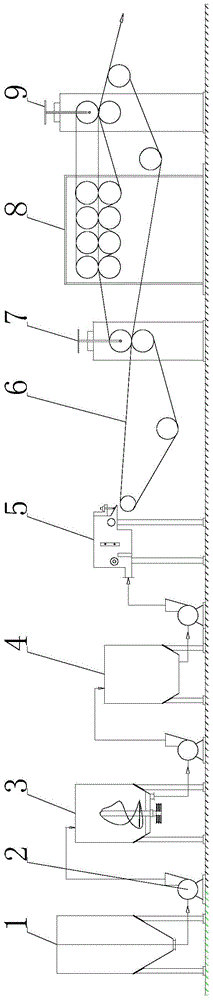

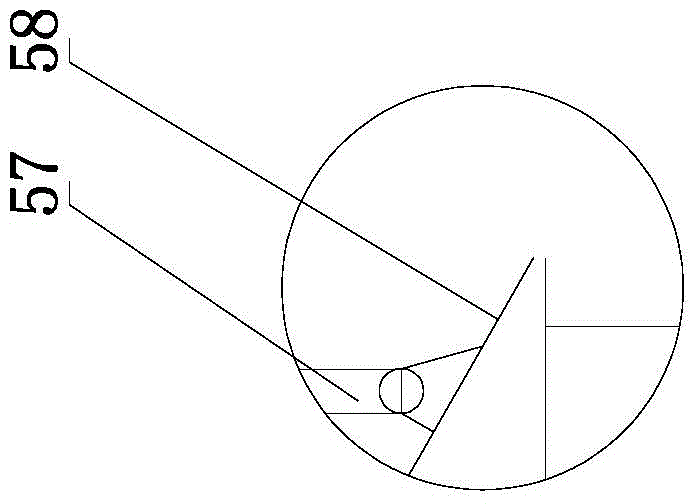

Waste salt refining device and process in chemical industry

ActiveCN104671576AImprove qualityRealize resource regenerationMultistage water/sewage treatmentNature of treatment waterChemical industryCooling tower

The invention relates to a waste salt refining device and a waste salt refining process in the chemical industry. The device is characterized by comprising an adsorber, evaporating crystallizers, a centrifugal machine, a rotary kiln, a dissolver, a filter, an incinerator, a cooling tower and an exhaust tower, wherein the adsorber is connected with the centrifugal machine by virtue of a first evaporating crystallizer; the discharge opening of the centrifugal machine is connected with the rotary kiln; the discharge opening of the rotary kiln is connected with a dissolving tank; the dissolving tank is connected with a second evaporating crystallizer by virtue of the filter; the second evaporating crystallizer is connected with the centrifugal machine; the air outlet of the rotary kiln is connected with the incinerator; and the incinerator is connected with the exhaust tower by virtue of the cooling tower.

Owner:JIANGSU ZHONGDAN GROUP

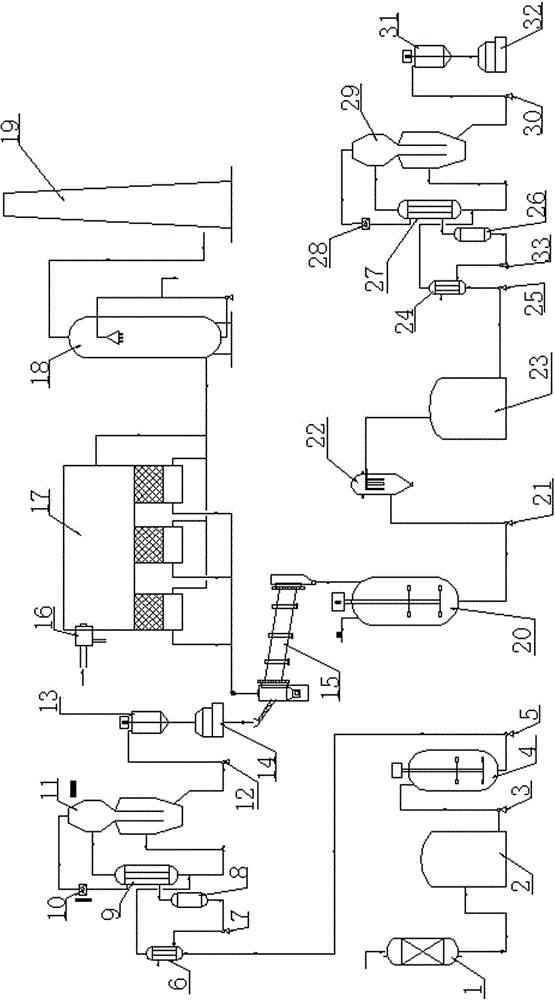

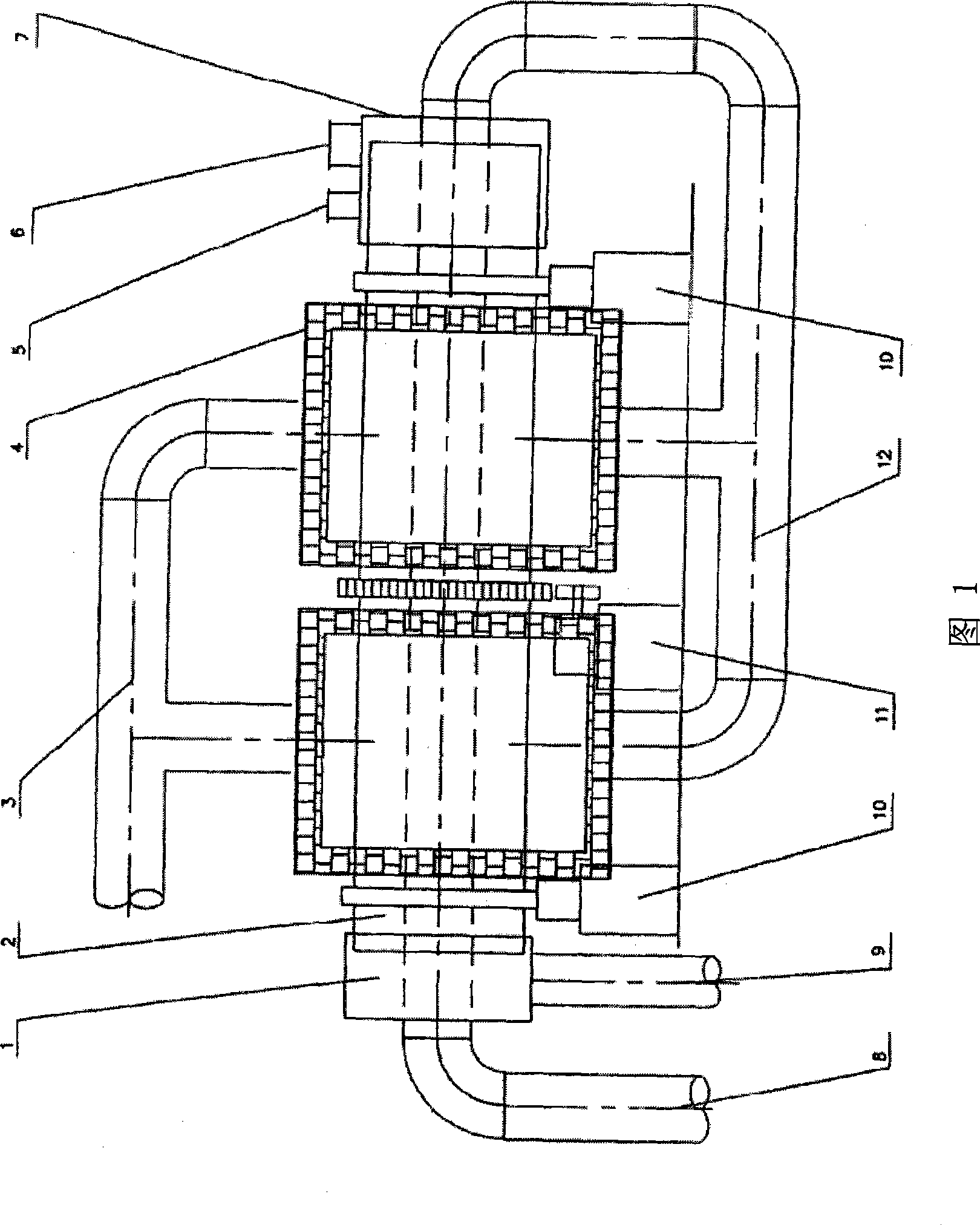

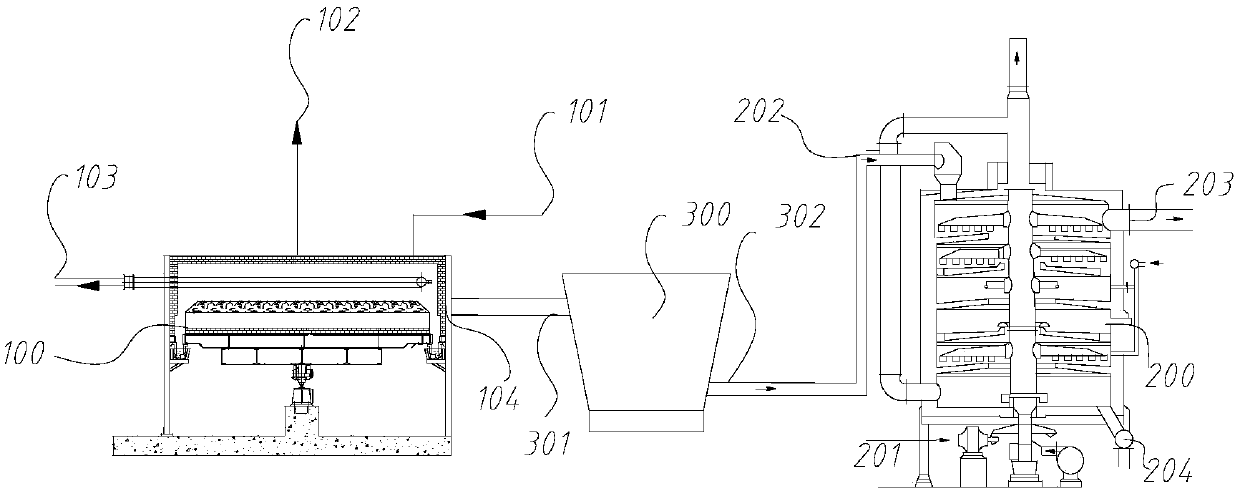

No-oxygen pyrolysis gasification processing device of urban domestic garbage and technique thereof

The present invention discloses a city domestic rubbish anaerobic schizolysis gasification processing apparatus and technical skill thereof, wherein the apparatus is composed by a rubbish storage hopper, a converting kiln, a compressor, an organic matter converting kiln and a sewage disposal system etc. The technical skill includes no exogenous source low energy consumption dispose and system secondary pollution control technique etc. Technical problems like system oxygen exhaust technology, domestic rubbish dehumidifying technology, flowing technology of solid material inside the system, heating technology during the process etc. are solved through the invention. Harmlessness and zero discharge, energy self-supply and basic energy source and substance recirculation in the process of production, social low cost input and facilitating operation of rubbish treatment, and every saving, exhaust reducing and material cycle in natural world can be realized.

Owner:SHANGHAI SHENGONG ENVIRONMENTAL PROTECTION CO LTD

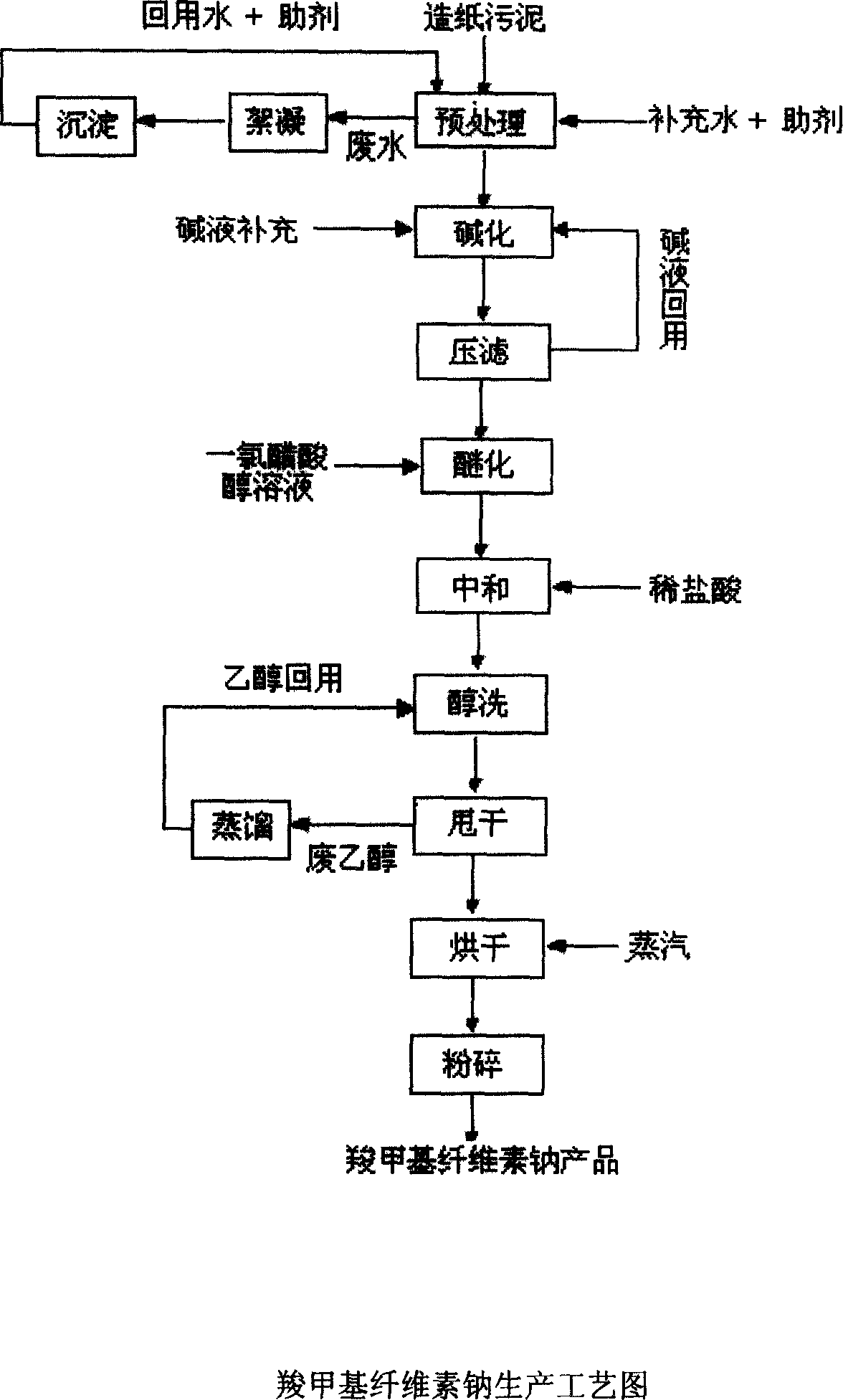

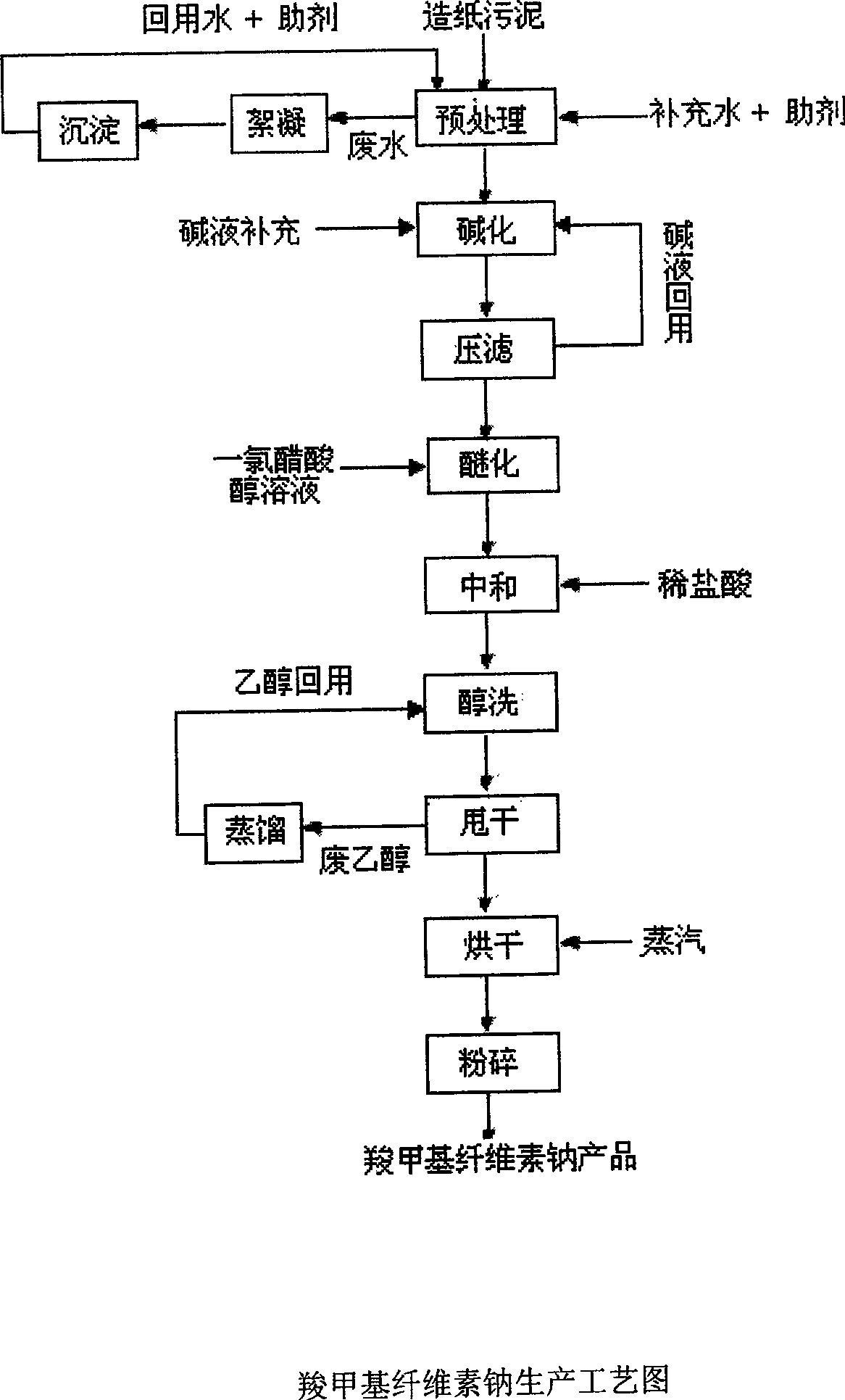

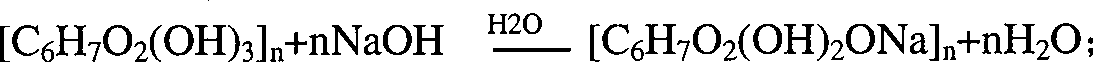

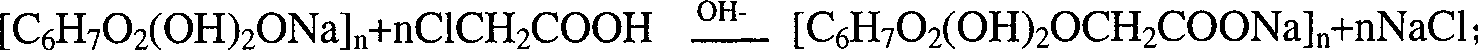

Process of producing sodium carboxymethyl cellulose with papermaking sludg as material

InactiveCN101020718ASolve a big problemIn line with the development modelCarboxymethyl celluloseCellulose

The process of producing sodium caboxymethyl cellulose with papermaking sludge with water content not higher than 80 wt% as material includes pre-treatment of the material, alkalizing, pressure filtering, etherizing, neutralizing, alcohol washing, spin drying, stoving and crushing. The present invention has facile material, waste utilization, low production cost, simple technological process, no secondary pollution and environment friendship.

Owner:北京盖雅技术中心有限公司

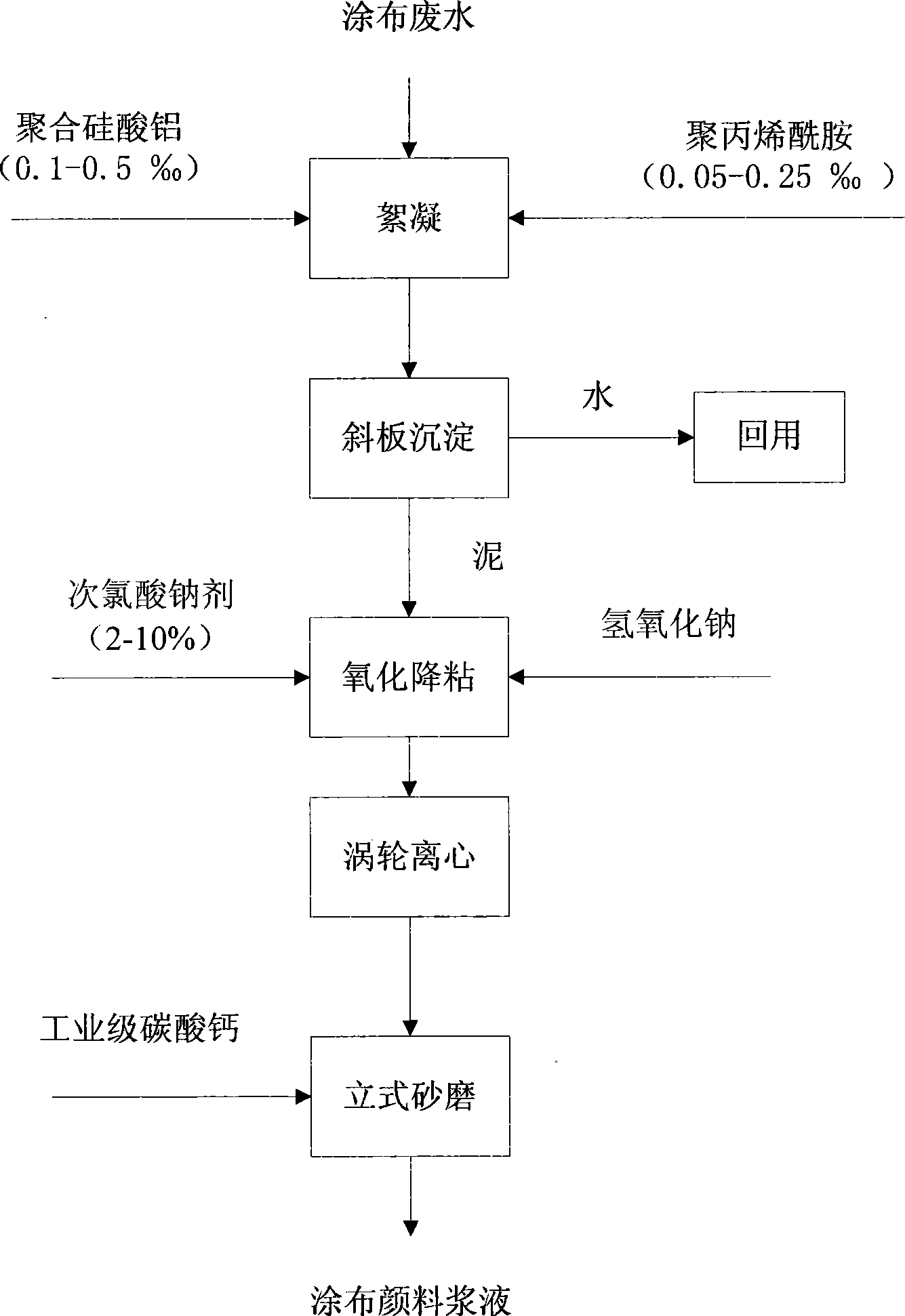

Reutilization process for painting and coating pigment pf paper mill

InactiveCN101367589AIn line with the development modelThe process steps are simpleSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSocial benefitsCentrifugation

The invention provides a process of recovering and treating the paper mill coating pigment and the secondary use as the coating pigment. The process comprises flocculating, inclined lamellar precipitation, oxidation and viscosity reduction, turbine centrifugation and vertical foundry mill. The treatment object is the paper mill coating wastewater. The step of the process is simple, and the process can not generate the secondary pollution. The quality of the products passes the coating tests and the paper reaches the related standards of the enterprise. The process is a novel technology with environmental benefit, economic benefit and social benefit.

Owner:北京盖雅技术中心有限公司

Eggshell high-calcium type organic fertilizer and preparing method thereof

InactiveCN105036828AGood fruit crackingImprove physical and chemical properties and microbial speciesBio-organic fraction processingOrganic fertiliser preparationChemistryMagnesium

The invention relates to eggshell high-calcium type organic fertilizer and a preparing method thereof, and belongs to the technical field of organic fertilizer production. According to the organic fertilizer, 150-200 parts of waste eggshells serve as the main material in match with 60-100 parts of peanut bran, 95-140 parts of poultry excrement, 100-145 parts of organic waste and 1-5 parts of microbial inoculants. The eggshell high-calcium type organic fertilizer is manufactured in the following steps that the eggshells are mixed with the peanut bran, the poultry excrement and the organic waste after being dried and ground to be stirred, the microbial inoculants are sprayed, and the high-calcium type organic fertilizer is manufactured through pool heap secondary fermentation. According to the eggshell high-calcium type organic fertilizer and the preparing method, the calcium element and magnesium element in waste eggshells serve as the main raw material, the safe, nuisanceless and multifunctional effective organic fertilizer capable of enhancing the water storage fertilizer maintenance capacity of soil is prepared, the limits that a traditional chemical acidic soil conditioner contains harmful substance and is singular in product effect are broken through, the problem that ordinary organic fertilizer is slow in fertilizer efficiency is solved while the problem of pollution, caused by the waste eggshells, to the environment is thoroughly solved.

Owner:广东恒丰生物科技有限公司

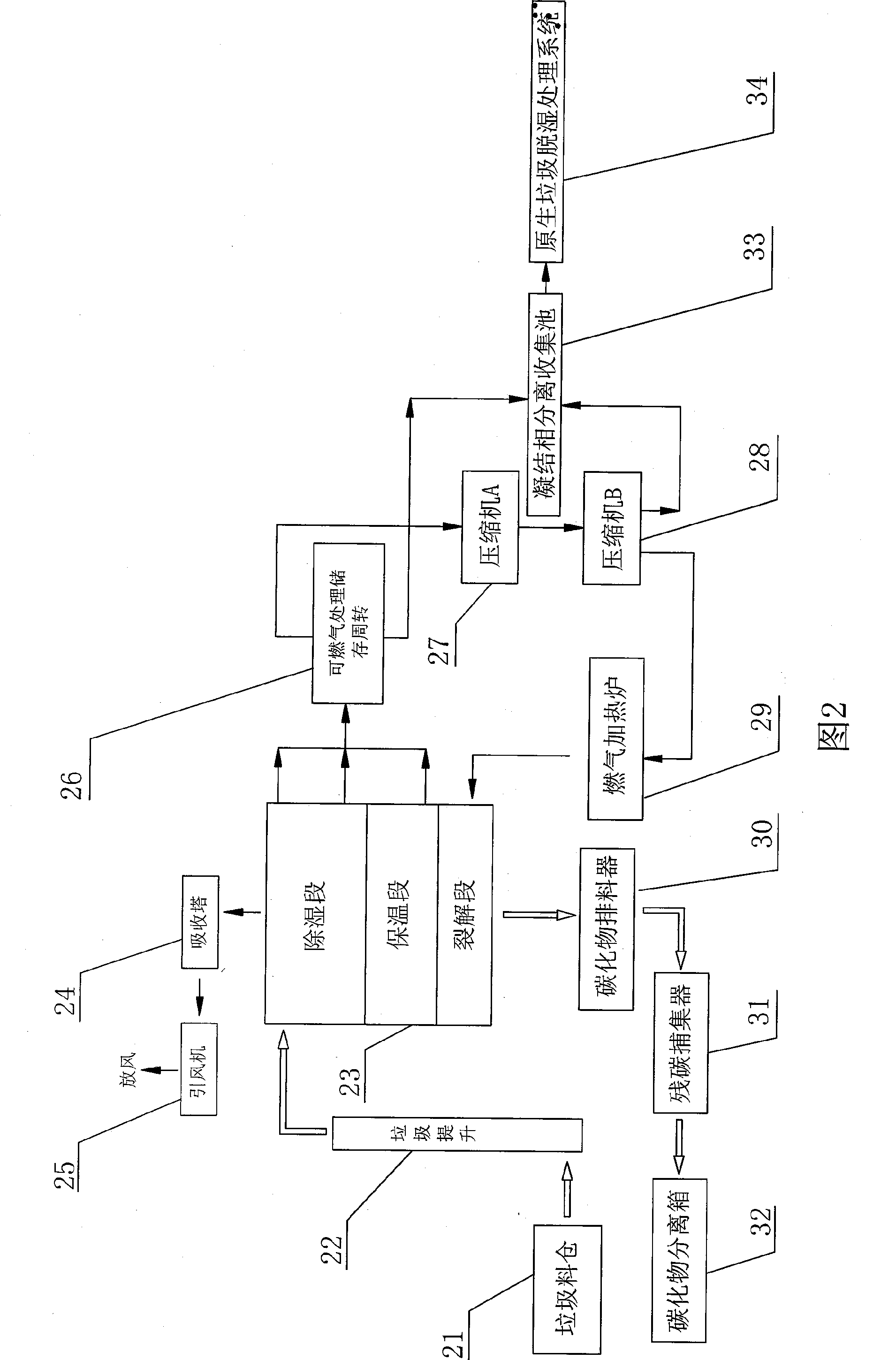

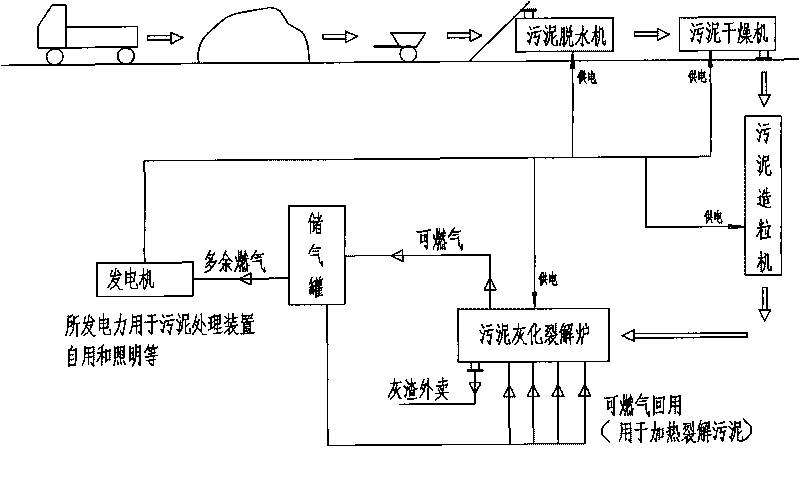

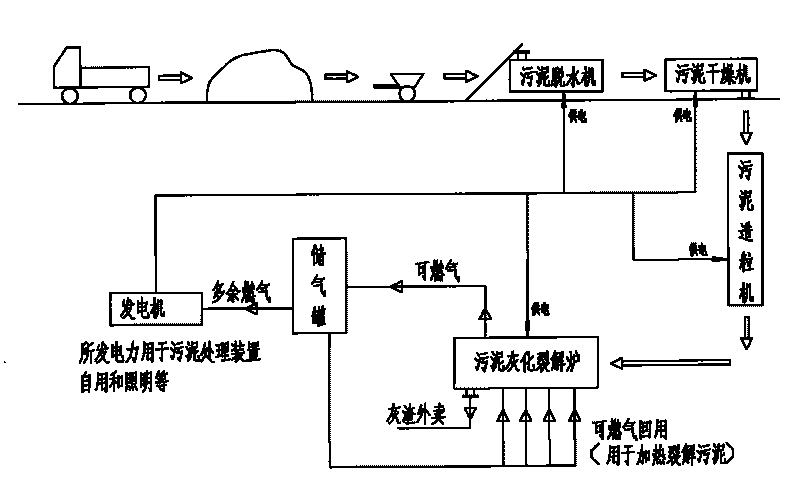

Harmless domestic sludge pyrolysis and carbonization treatment technique

InactiveCN101746939AHarmlessZero emissionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeCarbonization

The invention discloses a harmless domestic sludge pyrolysis and carbonization treatment technique. The technique includes pre-stage domestic sludge premixing and standing treatment, pre-dehydration, shaping, dehumidification, granulation, pre-reaction, pre-pyrolysis reaction, full carbonization reaction and other treatment processes, the completely reacted solid carbonized matter is discharged out of a system by a discharger, and is then collected and stored, the gas generated in sludge pyrolysis is separated by a gas condensation and separation system, the uncondensed flammable gas is guided into a gas holder and stored as heat source for the system, and the condensed gas is centrally treated by a reclaimed water system. The invention realizes purposes such as harmless and zero discharge in the process of production, energy self-sufficiency and low consumption in the process of production, resource and basic energy substance recycling, energy saving, discharge reduction and natural substance recycling, and has the advantages of easy operation, low investment cost, remarkable economic benefit, significant discharge reduction effect for the environment and the like.

Owner:SHANGHAI LOTUS ENVIRONMENTAL PROTECTION TECH

Novel wood-plastic composite floor board

The invention discloses a novel wood-plastic composite floor board which is prepared from the following raw materials in parts by weight: 10-30 parts of recycled plastic, 5-20 parts of chlorinated polyethylene, 5-20 parts of polyethylene, 50-70 parts of wood meal, 5-15 parts of complex fiber, 0.5-4 parts of a stabilizer, 1-4 parts of fire retardant, 3-12 parts of hollow glass beads, 2-10 parts of a plasticizer, 0.1-1.7 parts of zinc stearate, 1-2.5 parts of light calcium carbonate, 0.05-0.5 part of a UV absorber, 0.1-1 part of antioxidant, 0.5-1.5 parts of color masterbatch and 0-3 parts of an antimicrobial additive. In the novel wood-plastic composite floor board, recycled plastic is used for partially replacing polyvinyl chloride, and the complex fiber made of various crops is used as a base material; therefore, wastes can be recycled and reused, and the production cost of the wood-plastic composite floor board is saved. In addition, due to addition of the fire retardant, the UV absorber and the antimicrobial additive, the novel wood-plastic composite floor board has inflaming retarding, uvioresistant and antimicrobial properties. Paint applied to the surface of the floor board can be made into various colors, is capable of effectively protecting the floor board, also has faint scent, good gloss, good flexibility and levelling property, and is high in concentration, non-poisonous, pollution-free and harmless to a human body.

Owner:安徽浩峯塑业有限公司

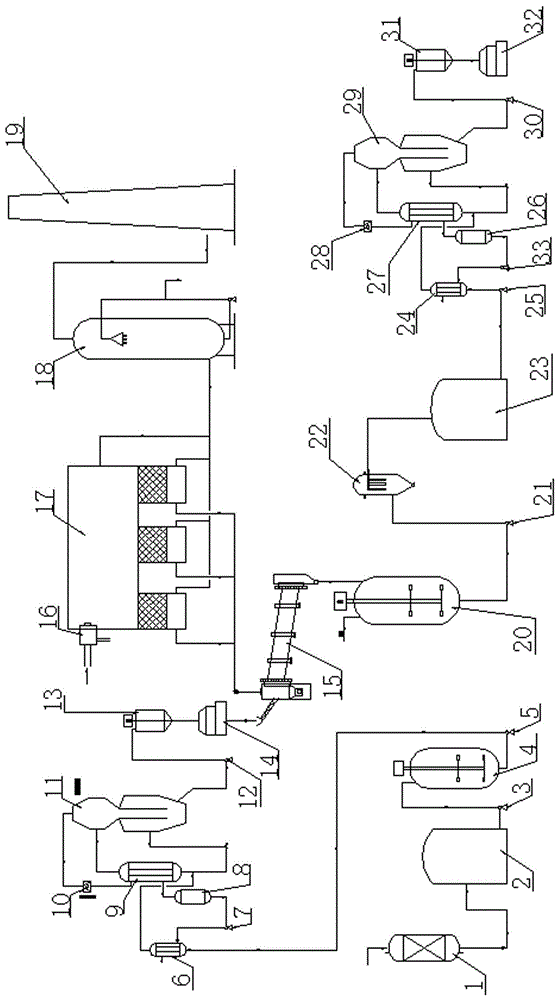

Chemical industrial waste salt refining device

ActiveCN104649496AImprove qualityRealize resource regenerationTreatment involving filtrationMultistage water/sewage treatmentCooling towerEvaporation

The invention relates to a chemical industrial waste salt refining device. The chemical industrial waste salt refining device is characterized by comprising an adsorber, evaporation crystallizers, a centrifugal machine, a rotary kiln, a dissolver, a filter, an incinerator, a cooling tower and a discharge tower, wherein the adsorber is connected with the centrifugal machine through a first evaporator crystallizer; a discharged material of the centrifugal machine is connected with the rotary kiln; the discharged material of the rotary kiln is connected with a dissolving tank; the dissolving tank is connected with the second evaporation crystallizer through the filter; the second evaporation crystallizer is connected with the centrifugal machine; a discharged gas of the rotary kiln is connected with the incinerator; and the incinerator is connected with the discharge tower through the cooling tower.

Owner:JIANGSU ZHONGDAN GROUP

Formaldehyde adsorption material and application thereof

ActiveCN108479721AImprove utilization efficiencyTurn waste into treasureGas treatmentOther chemical processesFiberOxalate

The invention discloses a formaldehyde adsorption material and application thereof. The material is prepared through a method including the steps of a, adding straw fiber panel leftover materials to an oxalic acid solution to be soaked and dried; b, mixing acid-pickled straw fiber panel powder, a modifier and a soybean protein adhesive to be granulated and soaked in a ZnCl2 solution, conducting suction filtration and product drying, and conducting carbonizing, cleaning and drying; c, preparing soybean protein hydrolysate from soybean derivatives; d, soaking the product in the step b in the soybean protein hydrolysate, and conducting suction filtration and drying to obtain the formaldehyde adsorption material. By means of the method, indoor and outdoor straw fiber artificial panel leftovermaterials and like are all resourcefully used, rich channels are formed in the materials after the materials are modified and activated, the contact time and contact area of gas and an adsorbent are effectively prolonged and increased, the adsorption resistance is reduced, the dispersing speed of adsorbate is greatly increased, the adsorption of adsorbate molecules is facilitated, and the effective adsorption of indoor formaldehyde is realized.

Owner:JIANGSU ACAD OF AGRI SCI

System and method for preparing activated carbon by energy cyclic utilization of waste tires

The invention relates to a system and method for preparing activated carbon by energy cyclic utilization of waste tires. The system comprises a waste tire pyrolysis furnace, a magnetic separator, a multi-section furnace, a carbon dioxide separator, and a heat accumulating type pipe type heating furnace; the waste tire pyrolysis furnace is internally provided with a reaction chamber and a burner; the magnetic separator is provided with a pyrolysis solid inlet and a pyrolytic carbon outlet, and the pyrolysis solid inlet is connected with a pyrolysis solid outlet of the waste tire pyrolysis furnace; the carbon dioxide separator is connected with a flue gas outlet of the burner in the waste tire pyrolysis furnace, an inlet of the accumulating type pipe type heating furnace is connected with a separated carbon dioxide outlet of the carbon dioxide separator, and a first inlet of the multi-section furnace is connected with the pyrolytic carbon outlet of the magnetic separator. According to the system and method, waste tire processing realizes production with energy saving, consumption reduction, pollution emission reduction, resource regeneration and high added value.

Owner:SHENWU TECH GRP CO LTD

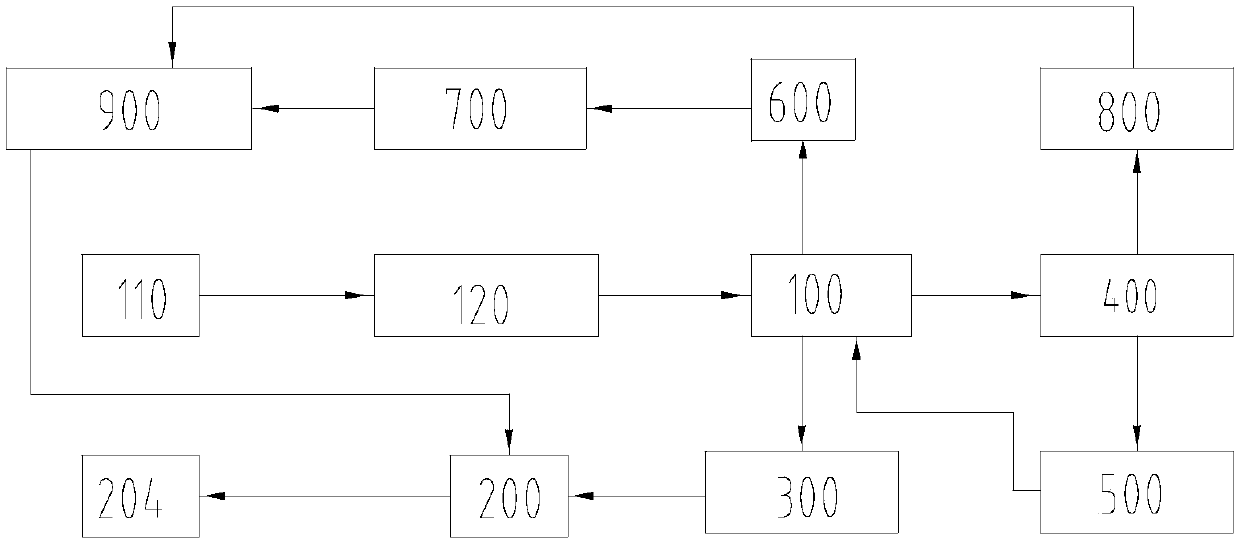

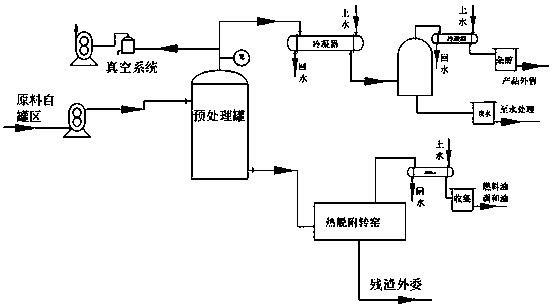

Method for disposing BDO (1,4-butanediol) waste liquid by recycling

ActiveCN108017109AReduce operating costsReduce in quantityNature of treatment waterWater/sewage treatment by heatingLiquid wasteOperational costs

The invention provides a method for disposing BDO (1,4-butanediol) waste liquid by recycling. The method comprises the steps of (1) putting the BDO waste liquid into a distillation column, conductingvacuum distillation, separating low-boiling-point substances and water, and bottom waste liquid; (2) putting the low-boiling-point substances and water separated in step (1) to the distillation columnto separate high-purity and low-boiling-point substances; (3) sending the bottom waste liquid obtained in step (1) to a thermal desorption rotary kiln, and after condensing gas phase components, andobtaining high calorific fuel oil blend oil and residue. The method for disposing the BDO waste liquid by recycling solves problems of high salt content of the BDO waste liquid and being unfavorable to distillation, and the method for disposing the BDO waste liquid by recycling has a simple process flow, strong operability, energy saving, ability to recover part of components, not only realizes resource regeneration, but also greatly reduces operating cost of hazardous waste incineration companies. The amount of waste slag produced after treatment is reduced, leachate precipitation during landfill and other treatment processes is reduced, a risk of secondary environmental pollution is avoided, and disposal of waste slag and subsequent disposal costs of an enterprise are reduced.

Owner:LUOYANG HAOHAI IND & TRADE

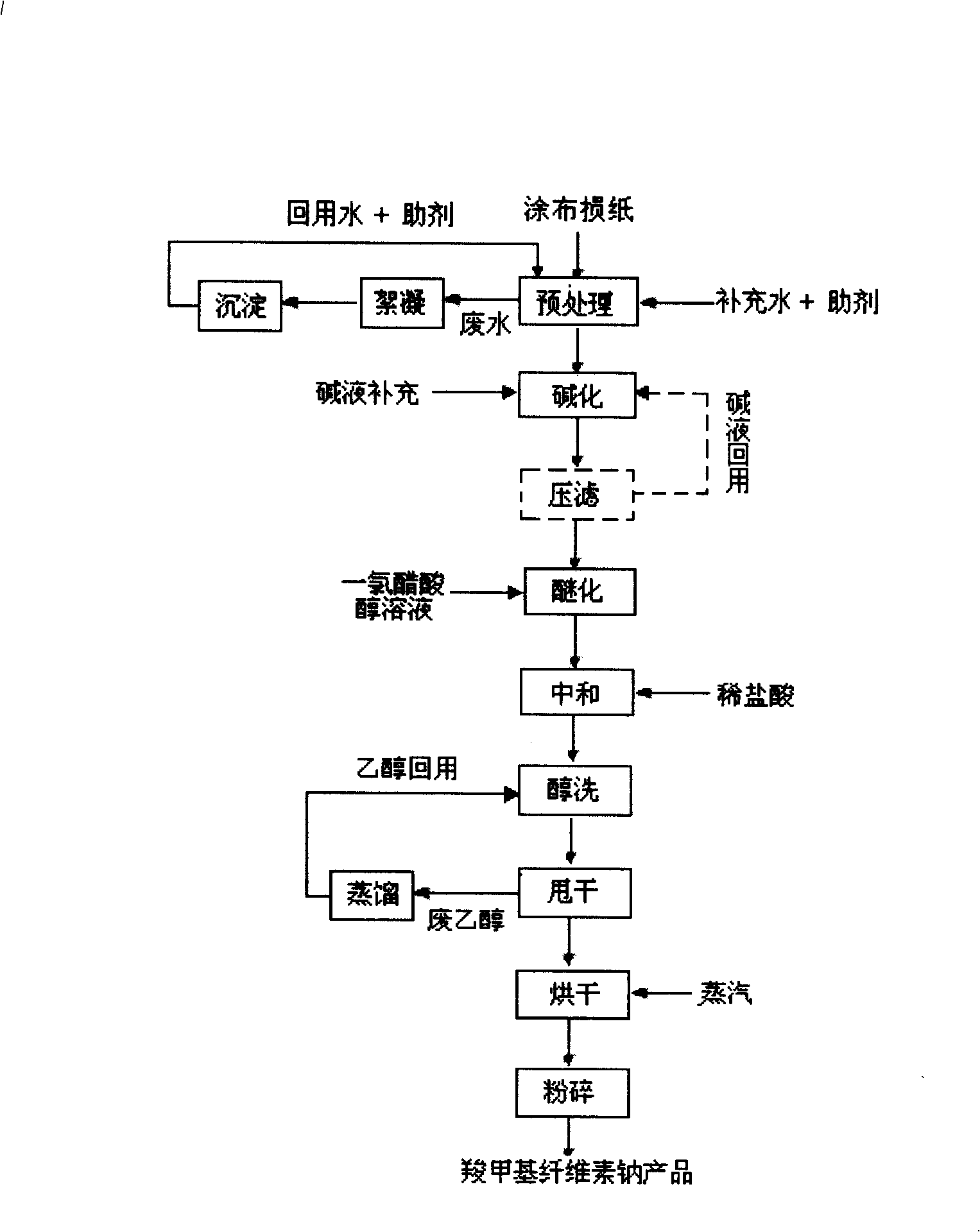

Method for producing sodium carboxymethylcellulose from waste coated paper

InactiveCN101324034AReduce manufacturing costRealize resource regenerationPaper recyclingWaste paper working-upChemistrySodium carboxymethylcellulose

The invention provides a method which is used for producing sodium carboxymethyl cellulose with raw materials of broken coating paper, comprises the steps of raw material preprocessing, alkalizing, (filter pressing), etherifying, neutralizing, alcohol washing, spin drying, parching and smashing, and a water ratio of used papermaking sludge is equal to or less than 80 percent and fiber content is equal to or more than 80 percent (mass fraction). The method has the raw materials from wastes in papermaking industries, concise techniques and steps, and low production cost, and does not generate secondary pollution. The method provided by the invention opens up new approaches for the reclamation of the broken coating paper. The invention further relates to recycled products that are obtained by the method which is used for producing the sodium carboxymethyl cellulose.

Owner:北京盖雅技术中心有限公司 +1

Resource recycling method of iron-containing waste sulfuric acid solution

InactiveCN108101121AIncrease profitEasy to storeSulfur-trioxide/sulfuric-acidIron sulfatesIron saltsDisinfectant

The invention discloses a resource recycling method of an iron-containing waste sulfuric acid solution. The method comprises steps as follows: the iron-containing waste sulfuric acid solution is addedto a pretreatment reaction kettle, iron powder and a heavy metal trapping agent are added to the pretreatment reaction kettle for a mixing and stirring reaction, filtration is performed and a reaction liquid is obtained; the reaction liquid is lifted to a crystalizing reaction kettle, industrial sulfuric acid is added to the crystalizing reaction kettle in a certain proportion during cooling, themixture is mixed and stirred, reactive crystallization and filtration are performed, and two products, namely, high-purity ferrous sulfate crystals (solids) and a diluted sulfuric acid solution, areobtained. The method has the benefits as follows: two products, namely, the high-purity ferrous sulfate crystals (solids) and the diluted sulfuric acid solution, are obtained from the iron-containingwaste sulfuric acid solution; the process operation is simple, production is safe and environmentally friendly, the sulfuric acid utilization rate is high, no waste liquids are discharged, and the economic benefits are good. Obtained ferrous sulfate is convenient to store and transport, has very low content of heavy metals, is high in additional value and is used for preparing iron salt, iron oxide pigments, mordants, water purifiers, preservatives, disinfectants and the like.

Owner:大拇指环保设备(天津)有限公司

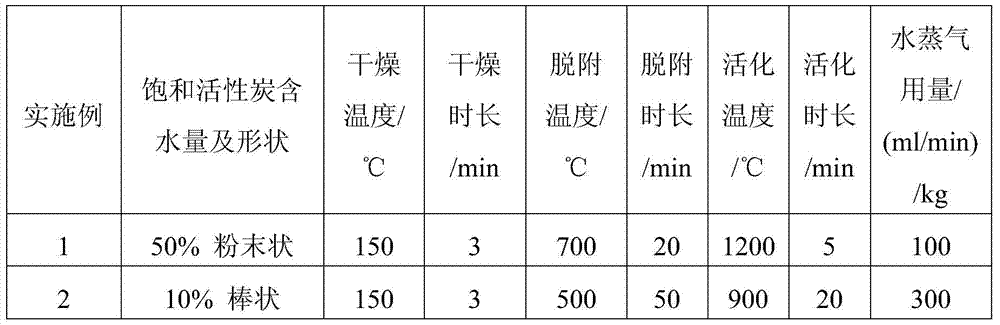

A kind of organic adsorption saturated activated carbon regeneration method

ActiveCN104741080BRealize resource regenerationEmission reductionOther chemical processesCombustible gas purificationThree stageWater vapor

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

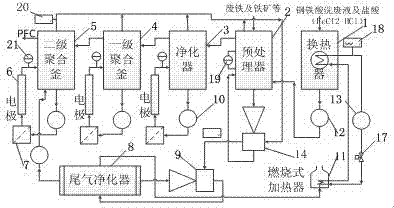

Environment-friendly steel pickling waste liquor treatment system and method for producing PFC (Polymerization Ferric Chloride) through electrochemical process

InactiveCN107487788AProduced noNo emissionsEnergy inputIron halidesElectrode potentialWaste treatment

The invention discloses an environment-friendly steel pickling waste liquor treatment system and a method for producing PFC (Polymerization Ferric Chloride) through an electrochemical process, and relate to the technical field of environment protection. The system comprises a heat exchanger, a pretreater, a purifier, a primary polymeric kettle, a secondary polymeric kettle and an exhaust purifier, and is matched with corresponding electrodes, a filter, a reaction circulating pump and a vacuum pump at the same time. On the basis of the electrochemical process, steel (hydrochloric acid) pickling waste liquor (ferrous chloride) is subjected to oxidation polymerization reaction through a different compound electrode potential difference under a certain direct voltage so as to produce a PFC flocculating agent. The exhaust purifier comprehensively treats and recycles waste gas produced by the method, recycled hydrogen gas is combusted to heat treating fluid, and recycled sodium chlorate and sodium hypochlorite carry out oxidation polymerization on the pickling waste liquor, so that the system is safe without adding hazardous chemical substances and producing secondary pollutants, truly realizes zero release, and is a best project with environment protection and recycling economy.

Owner:彭春来

Special container seedling growing substrate for leaf vegetables

InactiveCN106977321AWide variety of sourcesEasy to getExcrement fertilisersBioloigcal waste fertilisersPeatMushroom

The invention discloses a special container seedling growing substrate for leaf vegetables. The special container seedling growing substrate comprises, by volume, 20-40% of peat, 5-10% of expanded perlite, 15-20% of vermiculite, 5-10% of stove ash residues, 5-15% of sawdust, 22-40% of tea residues and earthworm casts, 0.5-2% of long-acting compound slow-release fertilizers, 0.5-2% of water retaining agents and 20-40% of waste mushroom bran. The special container seedling growing substrate has the advantages that raw materials for the special container seedling growing substrate can come from wide sources and are easily available, and accordingly the special container seedling growing substrate is low in production cost; the waste mushroom bran is organic agricultural waste, is high in quantity and can be used for producing soilless culture substrates, accordingly, environmental pollution can be reduced, waste can be turned into wealth, harm can be turned into benefits, and the special container seedling growing substrate can be widely used for growing seedlings of leaf vegetable crops such as brassica chinensis, purple brassica chinensis and different types of lettuces.

Owner:东至县云之慧农业开发有限公司

Process of producing sodium carboxymethyl cellulose with papermaking sludg as material

InactiveCN100519586CSolve a big problemIn line with the development modelSocial benefitsCarboxymethyl cellulose

Owner:北京盖雅技术中心有限公司

Method for recycling aluminum ash or aluminum slag by alkaline leaching method

InactiveCN112777620ARealize resource regenerationHigh purityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSocial benefitsAluminium hydroxide

The invention relates to the technical field of recycling of aluminum ash and aluminum slag, in particular to a method for recycling aluminum ash or aluminum slag through an alkaline leaching method. The method provided by the invention comprises the following steps: carrying out alkaline leaching on aluminum ash or aluminum slag in a strong alkaline solution to obtain a sodium metaaluminate crude product solution; carrying out desiliconization reaction on the sodium metaaluminate crude product solution to obtain a pure sodium metaaluminate solution; reacting the pure sodium metaaluminate solution with acid to obtain aluminum hydroxide; and roasting the aluminum hydroxide to obtain the aluminum oxide. The purity of aluminum hydroxide or aluminum oxide obtained through the method is high, resource regeneration of aluminum ash or aluminum slag can be well achieved, and good economic benefits and social benefits are achieved.

Owner:HARBIN INST OF TECH AT WEIHAI

A kind of resource disposal method of BDO waste liquid

ActiveCN108017109BReduce operating costsReduce in quantityNature of treatment waterWater/sewage treatment by heatingSlagFuel oil

The invention provides a method for disposing BDO (1,4-butanediol) waste liquid by recycling. The method comprises the steps of (1) putting the BDO waste liquid into a distillation column, conductingvacuum distillation, separating low-boiling-point substances and water, and bottom waste liquid; (2) putting the low-boiling-point substances and water separated in step (1) to the distillation columnto separate high-purity and low-boiling-point substances; (3) sending the bottom waste liquid obtained in step (1) to a thermal desorption rotary kiln, and after condensing gas phase components, andobtaining high calorific fuel oil blend oil and residue. The method for disposing the BDO waste liquid by recycling solves problems of high salt content of the BDO waste liquid and being unfavorable to distillation, and the method for disposing the BDO waste liquid by recycling has a simple process flow, strong operability, energy saving, ability to recover part of components, not only realizes resource regeneration, but also greatly reduces operating cost of hazardous waste incineration companies. The amount of waste slag produced after treatment is reduced, leachate precipitation during landfill and other treatment processes is reduced, a risk of secondary environmental pollution is avoided, and disposal of waste slag and subsequent disposal costs of an enterprise are reduced.

Owner:LUOYANG HAOHAI IND & TRADE

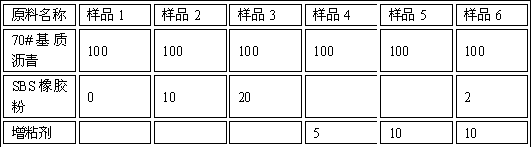

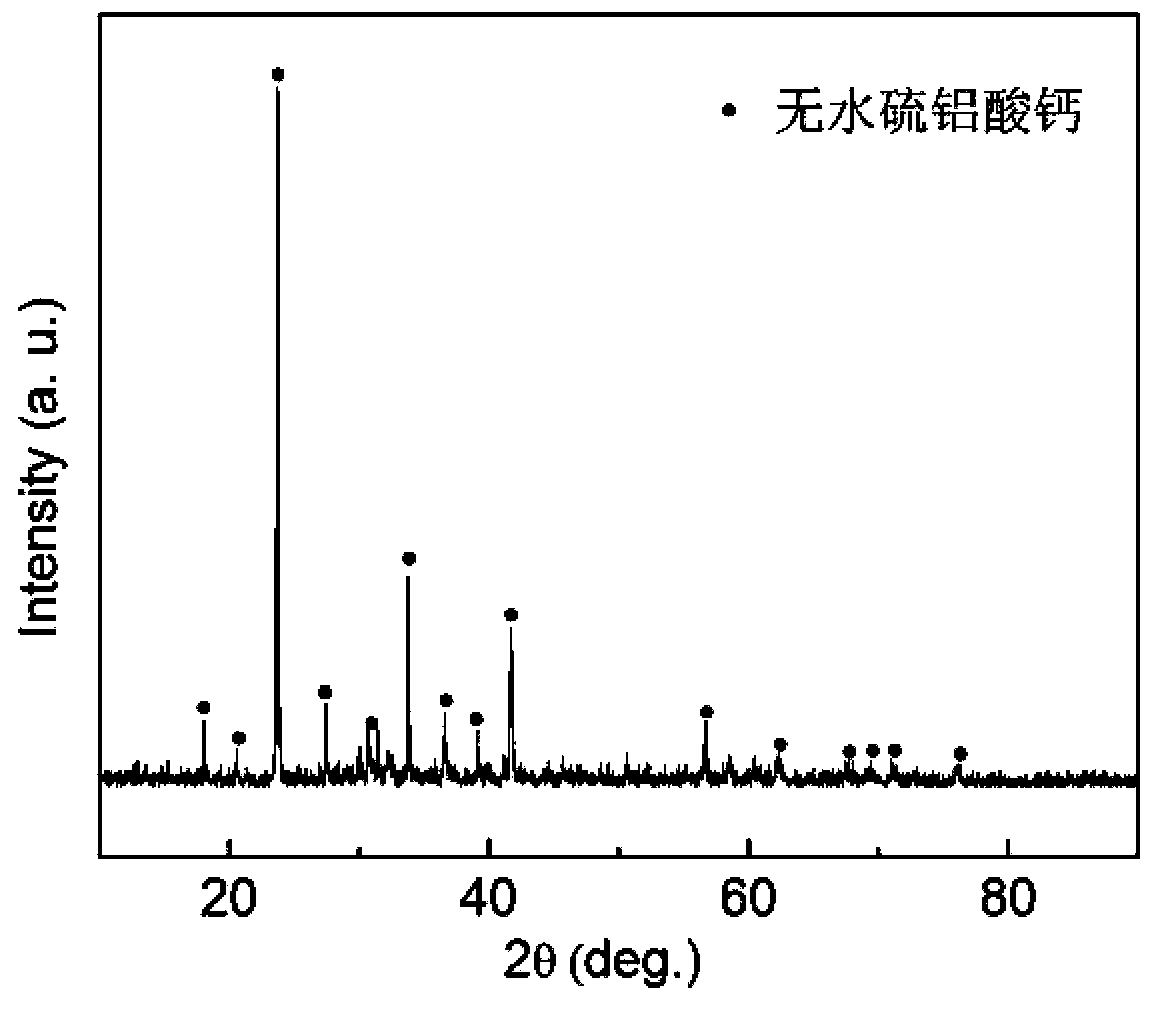

Preparation method using aluminum profile factory slag to synthesize anhydrous calcium sulphoaluminate expanding agent

ActiveCN106986569AEfficient use ofRealize resource regenerationSolid waste managementSlagAir atmosphere

The invention provides preparation method using aluminum profile factory slag to synthesize an anhydrous calcium sulphoaluminate expanding agent. The preparation method includes: weighing the aluminum profile factory slag, kaolin and limestone materials or limestone, and evenly mixing to obtain a raw material; grinding the raw material for 0.5-2 hours to obtain slurry, wherein the mass ratio of the raw material to spheres to water is 1:(1.4-1.6):(0.7-0.9); filtering and dewatering the slurry, drying, crushing, and sieving to obtain a powder material; mixing the powder material with binder, performing compression molding, and drying a formed base material; placing the dried base material into a kiln, calcining the dried base material under air atmosphere and the calcining temperature of 1310-1370 DEG C, performing heat preservation for 0.5-2 hours, and cooling to room temperature to obtain the anhydrous calcium sulphoaluminate expanding agent. The preparation method has the advantages that the aluminum profile factory slag can be utilized to the maximum extent under the premise that the high-purity anhydrous calcium sulphoaluminate can be obtained, the high-added-value recycling of the aluminum profile factory slag is achieved, and the production cost of the anhydrous calcium sulphoaluminate expanding agent is lowered evidently.

Owner:FUJIAN UNIV OF TECH

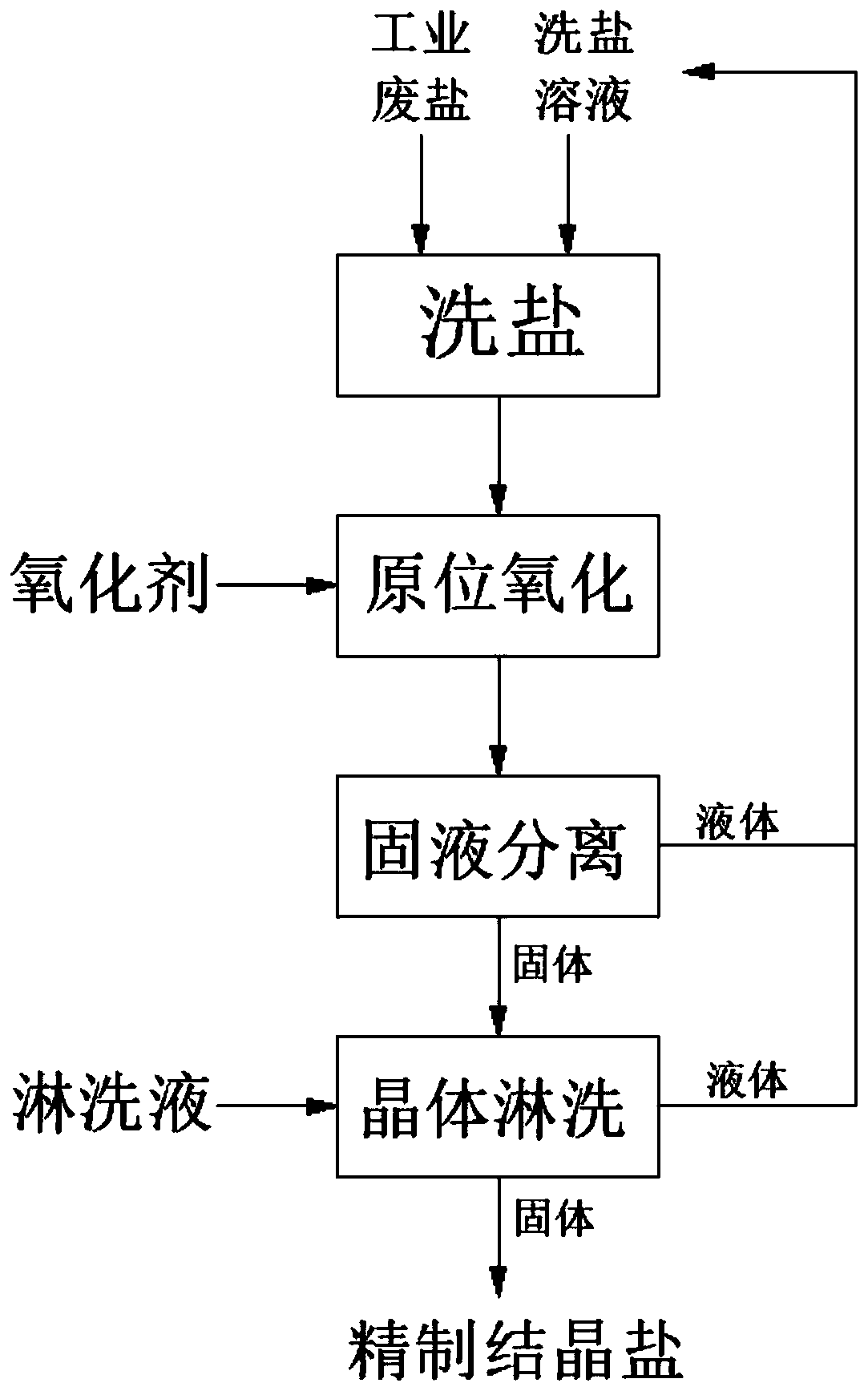

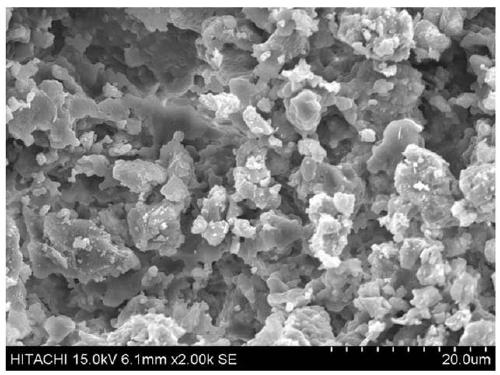

Salt leaching and in-situ oxidation combined method for refined treatment of industrial waste salt containing organic matters

InactiveCN110451531ARealize refining and purificationRealize resource regenerationAlkali metal sulfite/sulfate purificationAlkali metal chloridesHigh energyCombined method

The invention provides a salt leaching and in-situ oxidation combined method for refined treatment of industrial waste salt containing organic matters. The refined treatment method includes: mixing and rinsing an industrial waste salt and a salt leaching solution, then subjecting the obtained rinsing slurry to oxidation reaction with an oxidant, and conducting solid-liquid separation to obtain a refined crystalline salt. The method provided by the invention uses slurry rinsing to cooperate with in-situ oxidation, realizes refining and purification of the industrial waste salt, at the same timereduces the COD content of the industrial waste salt, avoids the high energy consumption and incineration tail gas pollution caused by incineration method and evaporative crystallization method, realizes resource regeneration of the waste salt, not only has a green and environment-friendly process, but also can realize effective removal of organic matters, and the obtained refined crystalline salt has high purity.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A process for refining waste salt in chemical industry

ActiveCN104649495BImprove qualityRealize resource regenerationMultistage water/sewage treatmentAlkali metal chloridesTunnel kilnChemical industry

The invention relates to a chemical industrial waste salt refining process which comprises the following steps: pretreating high salt wastewater generated in the production process of aminobenzene ether and p-nitrophenol so as to adjust the pH value, adsorbing by using activated carbon, kieselguhr or macroporous resin, removing organisms and organic salts in the wastewater, reducing the COD of the wastewater, neutralizing the high salt wastewater, performing multi-effect evaporation or mechanical recompression so as to evaporate and crystallize, and centrifuging a solid salt; performing high-temperature calcination on the centrifuged solid salt in a rotary kiln or a tunnel kiln, thereby decomposing and oxidizing the organisms at a high temperature, further thoroughly combusting the tail gas generated through calcination in a heat accumulation type tail gas combustion furnace, preheating and recycling the tail gas, performing spraying absorption, dissolving the calcinated salt with water so as to prepare a saturated solution, filtering by using a precise filter, directly supplying the filtrate to ionic membrane caustic soda for use, or performing multi-effect evaporation or mechanical recompression on the filtered saturated salt water so as to evaporate, crystallize and purify, and performing centrifugation, thereby obtaining high-quality solid sodium chloride.

Owner:JIANGSU ZHONGDAN GROUP

A kind of manufacturing device and method of ecological nutritional blanket base for breeding

InactiveCN104529681BRealize resource regenerationEmission reductionFertiliser formsFertilizer mixturesSludgeSlurry

The invention discloses a preparation device for a breeding eco-nutritional blanket medium. The preparation device comprises a deodorization and sterilization tank, a mixing agitator, a regulating tank, a slurry homogenizing box, a dewatering device, a simple presser, a drying device and a cutting device, wherein the deodorization and sterilization tank, the mixing agitator, the regulating tank and the slurry homogenizing box are connected through slurry delivery pumps and pipelines in sequence; the dewatering device is arranged at the discharge opening of the slurry homogenizing box; the simple presser is arranged at the discharge opening of the dewatering device; the drying device is arranged at the discharge opening of the simple presser; and the cutting device is arranged at the discharge opening of the drying device. The invention further provides a preparation method for the breeding eco-nutritional blanket medium. According to the invention, resource regeneration and efficient utilization of industrial sludge, domestic sludge and agricultural waste are realized, the produced breeding eco-nutritional blanket medium can avoid soil impoverishment, and a novel ecological breeding nutritional medium with a low production cost is provided.

Owner:SOUTH CHINA UNIV OF TECH

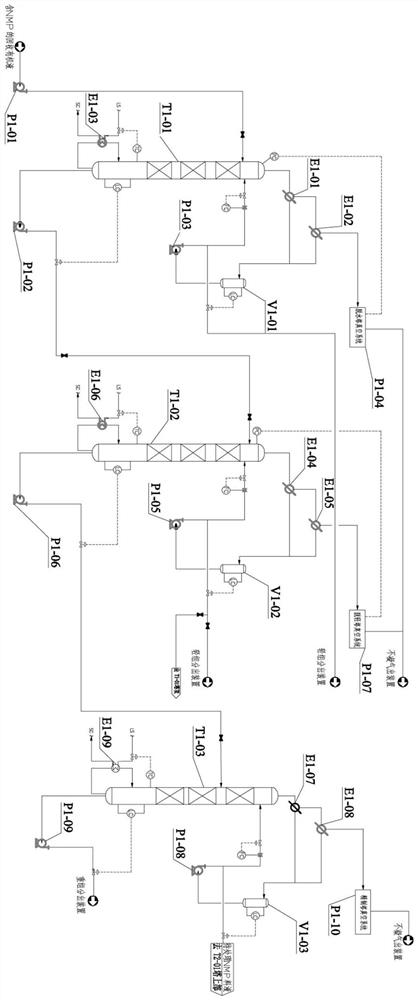

Recycled feed liquid rectification and purification system containing NMP (N-Methyl Pyrrolidone)

ActiveCN114452669AMeets the requirements of electronic grade NMPRealize resource regenerationOrganic chemistryFractional distillationProcess engineeringSewage treatment

The invention discloses an NMP-containing recovered feed liquid rectification and purification system, which comprises an industrial-grade NMP rectification unit and an electronic-grade NMP purification unit which are connected in sequence, and the industrial-grade NMP rectification unit comprises a first-grade negative pressure dehydration section, a first-grade negative pressure light removal section and a first NMP refining section which are connected in sequence through pipelines; and the electronic-grade NMP purification unit comprises a second-stage negative pressure light removal section, a second NMP refining section and a third NMP refining section which are sequentially connected through pipelines. The preparation process is easy to control, the impurity-containing NMP cleaning solution recycled in the lithium ion battery preparation process can be purified to reach the electronic-grade quality through the system, secondary utilization is achieved, meanwhile, the difficulty of rear-end sewage treatment is reduced, and the economic added value of the system is improved.

Owner:派尔森环保科技有限公司

Vegetable seedling culture medium

InactiveCN107125046ARealize resource regenerationProtect resourcesCultivating equipmentsFertilizerLong lasting

The invention discloses a vegetable seedling culture medium which is prepared from the following raw materials: 30-50% of turfy soil, 5-10% of puffed perlite, 15-30% of fermented field soil, 5-15% of sawdust, 10-15% of fulvic acid, 1-3% of medicines, 10-20% of carbonised rice husk and 0.5-2% of long-lasting composite slow-release fertilizer. The vegetable seedling culture medium is safe and environmental-friendly, free of pollution to plants, soil or underground water, wide in raw material source, easy to obtain and low in production cost.

Owner:东至县珊瑚生态农业发展有限公司

A kind of high-viscosity asphalt and preparation method thereof

ActiveCN105838097BHigh viscosityImprove thermal stabilityBuilding insulationsEnvironmental resistancePolymer science

The invention discloses high-viscosity asphalt and a preparation method thereof. The preparation method comprises the following steps: fusing and mixing asphalt raw materials, a tackifier and rubber powder so as to obtain the high-viscosity asphalt. The asphalt raw materials include matrix asphalt and an asphalt reclamation material; the rubber powder is one or more selected from reclaimed old tire rubber power, styrene-butadiene segmented copolymer rubber powder, styrene-acrylonitrile-butadiene grafted copolymer rubber powder; the tackifier is a polymerization product of aromatic vinyl copolymer and active monomers. The method is not only applicable to new raw materials, but also applicable to reclaimed materials, such as reclaimed asphalt and reclaimed tires, wastes are turned into things of value, environmental pollution is reduced, energy resources are saved, and the problem that the performances of products prepared by using reclaimed materials in the prior art are degraded is overcome. The prepared asphalt is high in viscosity, and good in thermal stability and ageing resistance, and is capable of realizing recycling, so that the method is environmentally friendly.

Owner:涂淑光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com