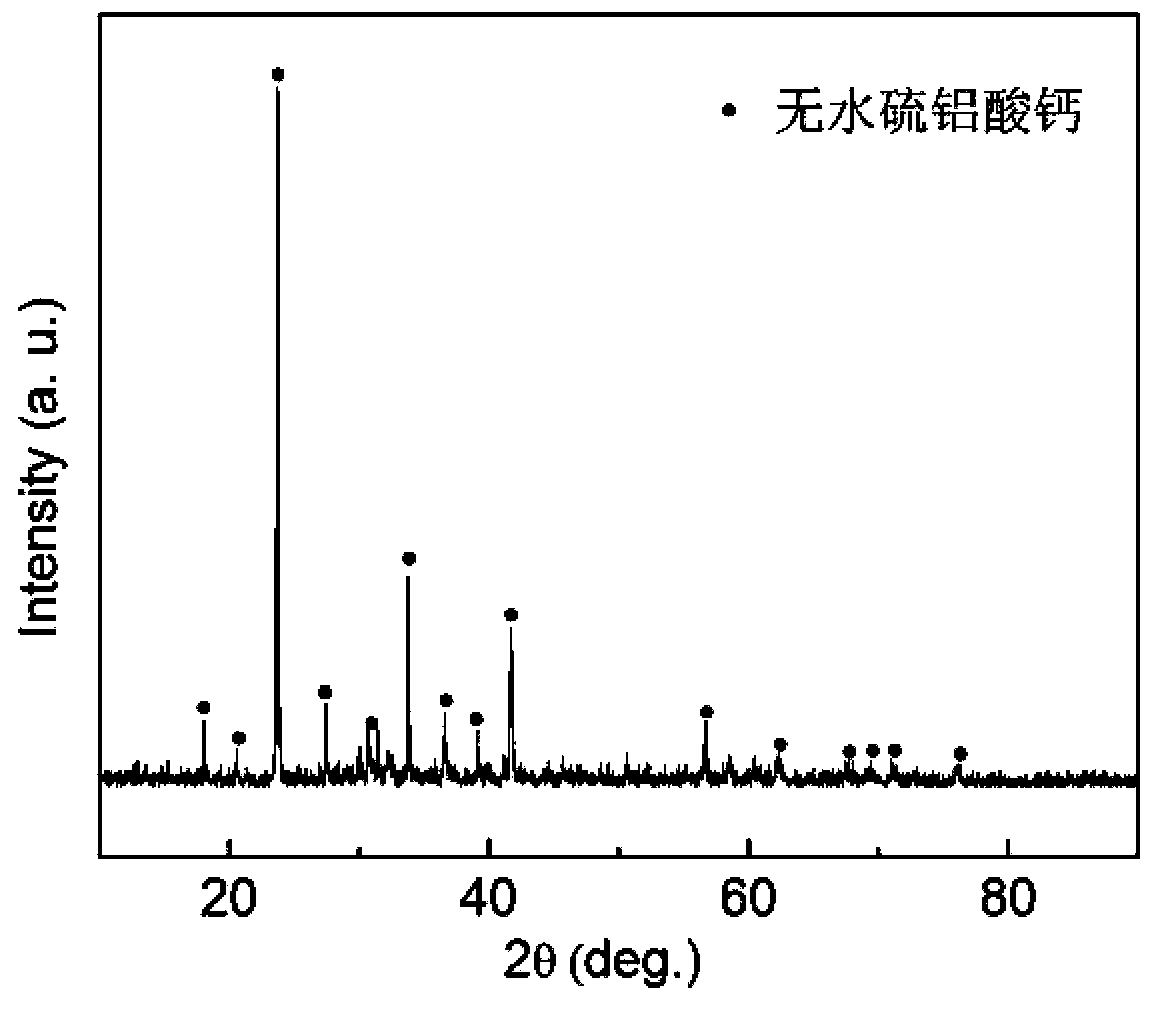

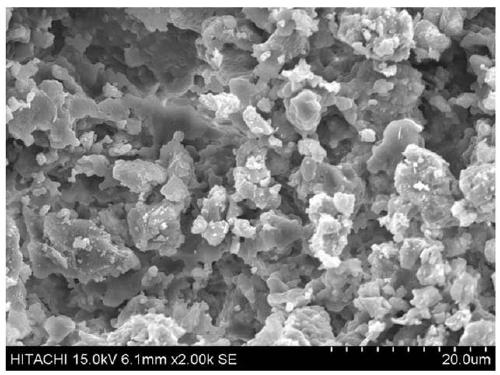

Preparation Method of Synthesizing Anhydrous Calcium Sulphoaluminate Expansion Agent Using Waste Slag from Aluminum Profile Factory

An anhydrous calcium sulfoaluminate and aluminum profile plant technology, applied in the field of cement concrete materials, can solve the problems of environmental pollution threat, sulfate escape, occupation of large land, etc., achieve simple composition of raw materials, avoid sulfur pollution, reduce preparation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention utilizes the waste slag of aluminum profile factory to synthesize the preparation method of anhydrous calcium sulfoaluminate expansion agent, and its specific operation steps are as follows:

[0028] (1) Weigh each component according to the following weight ratio: 51-70 parts of aluminum profile factory waste residue, 3-1.5 parts of kaolin, 28.5-46 parts of limestone material or limestone, and weigh each component Mix evenly to get raw materials, set aside;

[0029] (2) Put the obtained raw materials into the grinder, add water and ceramic balls, then start the grinder for grinding, and the mass ratio of raw materials: balls: water is 1:1.4~1.6:0.7~0.9, the grinding time 0.5 to 2 hours; slurry is obtained after grinding;

[0030] (3) Filter and dehydrate the slurry obtained by grinding, then dry at 100°C for 12 hours, then crush and pass through a 100-mesh sieve to obtain powder;

[0031] (4) Mix the obtained powder with the binder, and the mass...

Embodiment 1

[0036]Weigh 51.2 parts by weight of aluminum profile factory waste residue, 2.9 parts by weight of kaolin, and 46 parts by weight of limestone and mix them evenly to obtain the raw materials for later use; put the obtained raw materials into a grinder, add water and agate balls at the same time, and then start the grinder for grinding , and raw material: agate ball: water mass ratio is 1:1.5:0.8, and the grinding time is 0.5 hour; the slurry is obtained after grinding; the slurry obtained by grinding is filtered and dehydrated, and then dried at 100°C for 12 hours, then crushed and passed through a 100 mesh sieve to obtain a powder; the obtained powder is mixed with a polyvinyl alcohol aqueous solution with a mass concentration of 5%, and the mass ratio of the powder to a 5% polyvinyl alcohol aqueous solution is 100 : 2. Compress molding under the pressure of 20MPa to get the molding blank; put the molding blank at 100°C and dry for 12 hours to get the dry embryo; put the dry e...

Embodiment 2

[0039] Weigh 56.7 parts by weight of aluminum profile factory waste residue, 2.9 parts by weight of kaolin, and 40.4 parts by weight of calcium oxide and mix them evenly to obtain the raw materials for later use; put the obtained raw materials into a grinder, add water and agate balls at the same time, and then start the grinder for Grinding, and raw materials: agate ball: water mass ratio is 1:1.5:0.8, grinding time is 0.5 hours; slurry is obtained after grinding; the slurry obtained from grinding is filtered and dehydrated, and then dried at 100°C 12 hours, then crushed and crossed a 100 mesh sieve to obtain a powder; the gained powder was mixed with a 5% polyvinyl alcohol aqueous solution with a mass concentration, and the mass ratio of the powder to a 5% polyvinyl alcohol aqueous solution was 100:2, press molding under the pressure of 20MPa to get the molding blank; dry the molding blank at 100°C for 12 hours to get the dry embryo; place the dry embryo in the kiln and calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com