Recycled feed liquid rectification and purification system containing NMP (N-Methyl Pyrrolidone)

A technology for recycling materials and rectification, which is applied in the field of rectification and purification systems for recycled materials and liquids, can solve the problems of difficulty in sewage treatment load, difficulty in secondary utilization, low purity and quality, etc., and achieve sustainable utilization, significant economic benefits and Environmental benefits, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

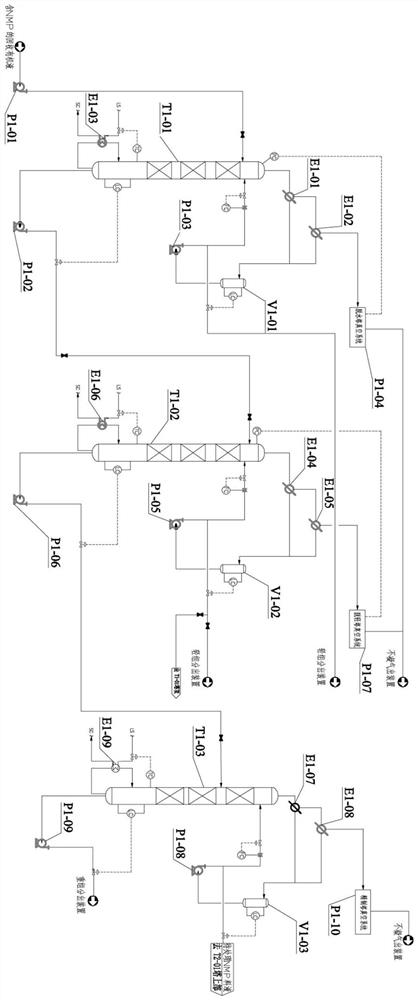

[0041] This embodiment is a rectification and purification system for recovered feed liquid containing NMP, which includes an industrial-grade NMP rectification unit and an electronic-grade NMP purification unit connected in sequence.

[0042] 1. Industrial grade NMP distillation unit section

[0043] Such as figure 1 As shown, the industrial-grade NMP rectification unit includes a first-stage negative pressure dehydration section, a first-stage negative pressure light removal section, and a first NMP refining section connected in sequence through pipelines.

[0044] Ⅰ: First-level negative pressure dehydration section

[0045] The primary negative pressure dehydration section includes primary negative pressure dehydration tower T1-01, primary negative pressure dehydration tower condenser E1-01, primary negative pressure dehydration tower recondenser E1-02, dehydration tower vacuum system P1-04, The first-stage negative pressure dehydration tower reflux tank V1-01.

[0046]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com