A kind of high-viscosity asphalt and preparation method thereof

A technology of high-viscosity asphalt and asphalt raw materials, applied in building components, building insulation materials, construction, etc., can solve the problems of difficult operation and high cost, achieve good aging resistance, low cost, ensure thermal stability and aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

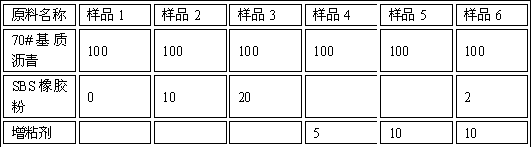

Embodiment 1

[0019] See Table 1. First, the asphalt material is heated and completely melted to a liquid state, and other components are added when the temperature is controlled at about 180 °C until the material is completely melted; the tackifier is obtained by polymerization of an aromatic vinyl copolymer and a reactive monomer (The amount of active monomer is 5%), such as polystyrene, styrene-acrylonitrile copolymer, styrene-acrylonitrile-butadiene copolymer, styrene-butadiene graft copolymer, styrene-butadiene One or more of ethylene block copolymers, hydrogenated styrene-butadiene block copolymers and one of glycidyl methacrylate, maleic anhydride, acrylic acid, and isocyanate as active monomers Or several kinds of aggregates can be obtained. After the material was cooled, the ductility, penetration and softening point were tested, and the results are shown in Table 2. The ductility, penetration and softening point parameters of the high-viscosity asphalt prepared by the method are ...

Embodiment 2

[0025] Refer to the composition of raw materials shown in Table 3. First, heat the asphalt material to completely dissolve it to a liquid state. When the temperature is controlled at about 180°C, add other components until the material is completely melted. The viscosity of the material was tested at 60°C after cooling, and the results are shown in Table 4. The high-viscosity asphalt prepared by this method has a viscosity greater than 2.0×10 at 60°C 4 Pa.s, in line with industry-related standards.

[0026] Table 3 Raw material composition (mass ratio)

[0027]

[0028] Table 4 Viscosity test results of samples at 60°C

[0029] sample

Embodiment 3

[0031] First, the asphalt material (30# base asphalt / recycled asphalt) is heated to completely melt to a liquid state, and when the temperature is controlled at about 180°C, 4% rubber powder and 6% SBS are added until the material is completely melted to obtain high-viscosity asphalt. Compared with existing Japanese products, the test results are shown in Table 5.

[0032] Table 5 Test results

[0033]

[0034] The method of the present invention enables the asphalt to form a moderately cross-linked network structure through the reaction of the active monomer of the tackifier and the asphalt, and prepares high-viscosity asphalt, which can improve the physical and chemical properties of the asphalt, and improve the penetration, softening point, and extension of the traditional asphalt. Degree and viscosity and other properties, the softening point is above 80°C, and the viscosity at 60°C is greater than 2.0×10 4 Pa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com