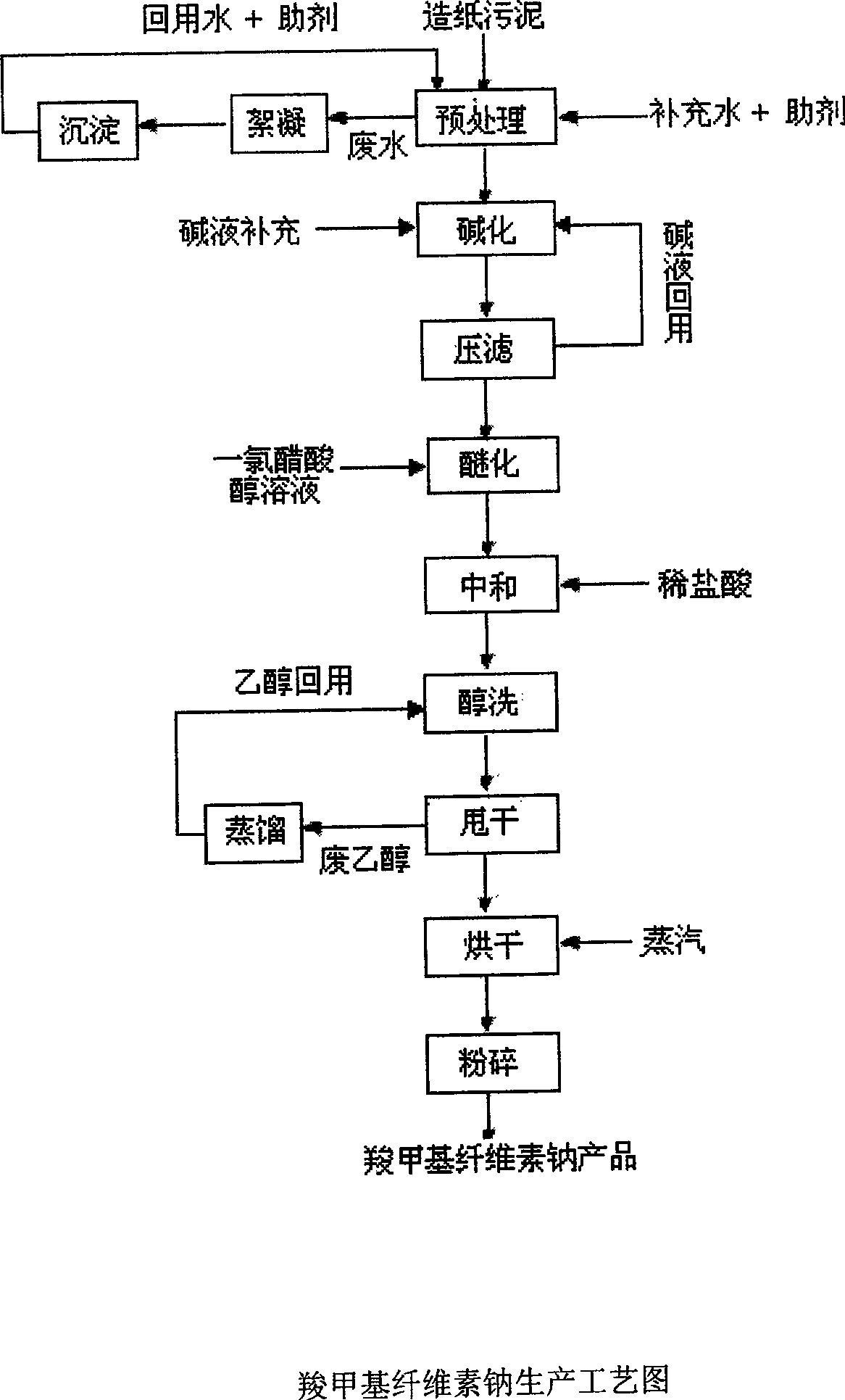

Process of producing sodium carboxymethyl cellulose with papermaking sludg as material

A technology of sodium carboxymethyl cellulose and papermaking sludge, applied in the field of sodium carboxymethyl cellulose, to achieve the effects of low production cost, protection of the ecological environment, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

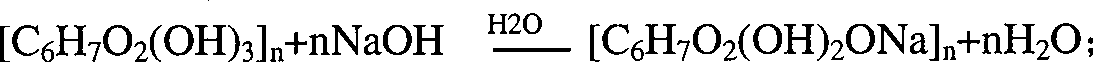

Method used

Image

Examples

Embodiment 1

[0024] Take 8.3 g of dry paper sludge pretreated with hydrochloric acid, add 100 mL of sodium hydroxide solution with a mass concentration of 18%, stir continuously at room temperature for 45 minutes, filter the alkali cellulose with a filter press, and reuse the filtered lye; Add alkali fiber to the reaction flask, add 120mL of 95% ethanol by mass and stir well, then add 8.9g of monochloroacetic acid and 30mL of 95% ethanol by mass, and react at 40℃ for 1 hour , Warm up to 75℃ and react for 3 hours; adjust the pH value to neutral with dilute hydrochloric acid; wash twice with ethanol with a mass concentration of 75% and wash once with ethanol with a mass concentration of 95%; spin dry the product, and distill the waste ethanol solution back Use; Finally, the product is dried and crushed.

Embodiment 2

[0026] Take 1Kg of dry paper sludge pretreated with sulfuric acid, add 12L of sodium hydroxide solution with a mass concentration of 20%, stir continuously at room temperature for 45 minutes, filter the alkali cellulose with a filter press, and reuse the filtered lye; The alkali fiber is added to the reactor, 15L of ethanol with a mass concentration of 95% is added and stirred, and then a solution of 14Kg of monochloroacetic acid and 4L of ethanol with a mass concentration of 95% is added, and reacted at 40°C for 1.5 hours. React for 3.5 hours at 75°C; adjust the pH value to neutral with dilute hydrochloric acid; wash twice with 75% ethanol by mass and once with 95% ethanol; spin dry the product, and reuse the waste ethanol solution by distillation; Finally, the product is dried and crushed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com