Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3614results about How to "Won't clog" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead-free silver conductive paste used for positive electrode of solar battery and preparation technique thereof

InactiveCN101609850AStrong adhesionLower resistanceFinal product manufactureConductive materialConductive pasteSilver electrode

The invention provides a lead-free silver conductive paste used for positive electrode of solar battery and a preparation technique thereof. The paste comprises the following materials by weight percentage: 65 to 85 percent of silver powder, 2 to 8 percent of lead-free glass powder, 10 to 25 percent of organic carrier and 0.1 to 3 percent of additive. The paste adopts the lead-free glass powder of Si-B-Bi-Al-Ti-Zn-O series to replace the traditional lead-bearing glass powder; and the series glass powder has lower softening point, can lead the silver electrode to have good adhesive force after sintering, and ensures the silver electrode to be well contacted with a silicon substrate. In addition, zinc resinate is used as the additive in the invention, not only can well improve the printing performance of the paste, but also can improve the electrical property of the electrode.

Owner:CENT SOUTH UNIV

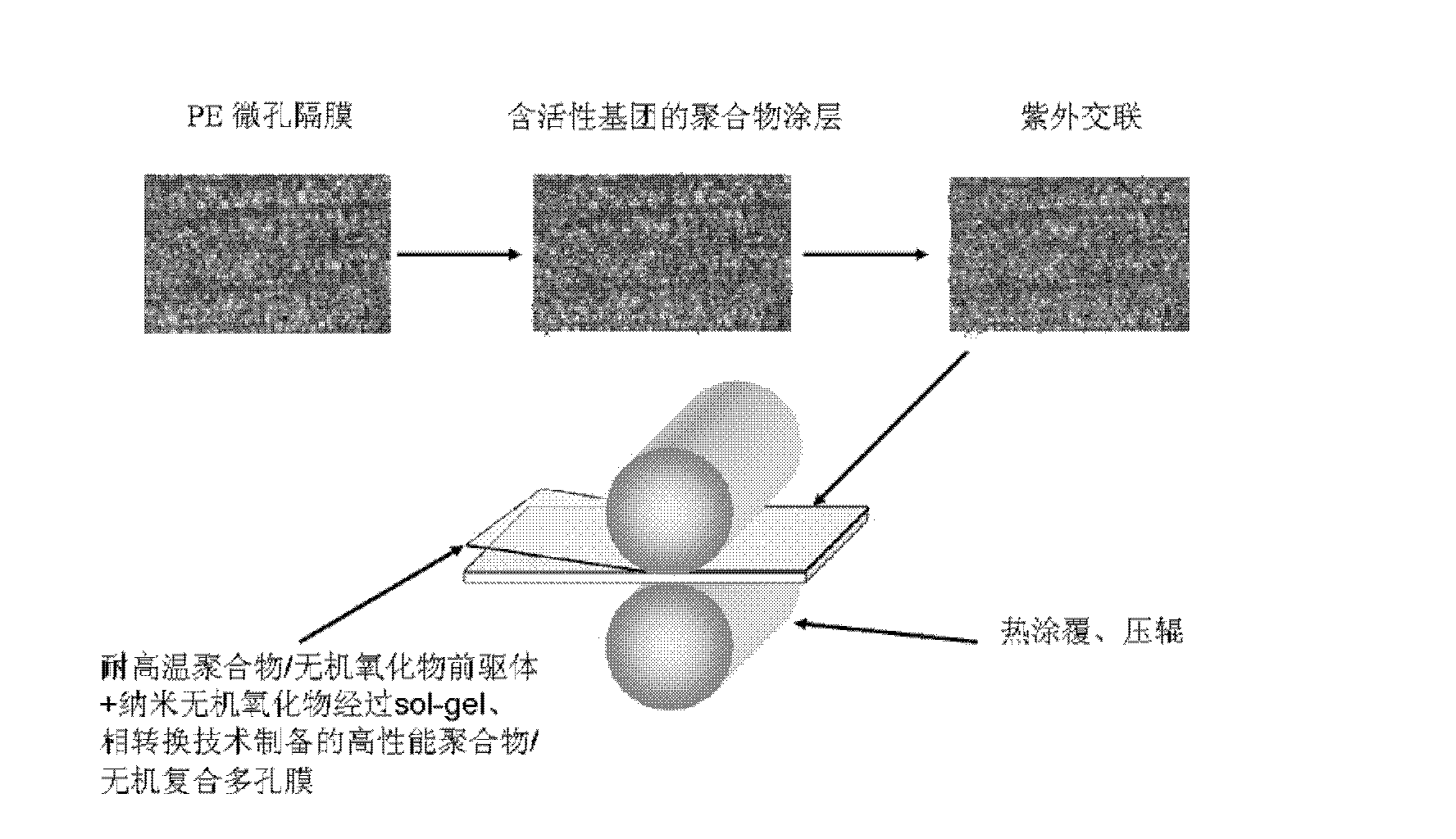

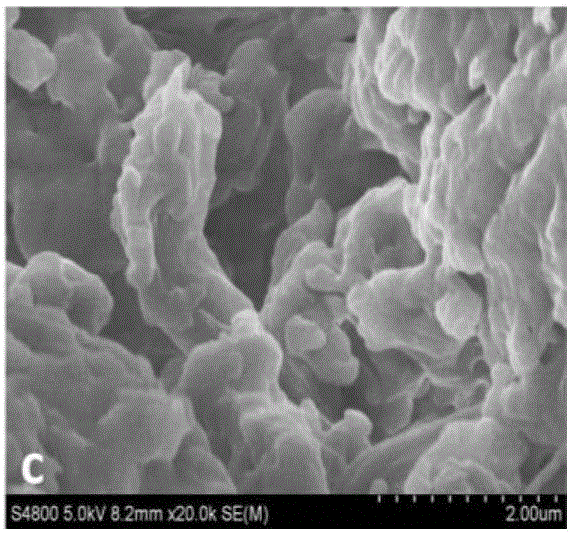

Composite microporous membrane used as lithium ion battery diaphragm as well as preparation method and application thereof

ActiveCN102122704AImprove bonding strengthEasy to prepareCell component detailsPolyolefinHigh performance polymer

The invention discloses a composite microporous membrane used as a lithium ion battery diaphragm as well as a preparation method and application thereof. The composite microporous membrane is prepared by the following steps of: steeping a polyolefin porous framework membrane in a modified liquid a and carrying out radiation crosslinking to obtain a modified framework membrane; preparing a modified liquid b, steeping the modified framework membrane in the modified liquid b and adding a sol-gel reaction catalytic agent to carry out a sol-gel condensation reaction; and immersing the modified membrane in a phase transforming agent solution, carrying out phase conversion to form a membrane and then drying to obtain a high-performance polymer / inorganic composite microporous membrane. In the invention, the preparation process is simple and the industrialization is easy to realize; the obtained composite microporous membrane has high air permeability, good electrolyte-favoring performance andhigh temperature resistance, a composite layer and the framework polyolefin membrane have good adhesion strength and cannot be separated when being placed in a lithium ion electrolyte solution with very good adhesion and without power-dropping and shedding. By means of the product of the invention, a series of defects in the prior art can be overcome.

Owner:河南惠强新能源材料科技股份有限公司

Self-compaction filling paste body and preparation process thereof

The invention discloses a self-compaction filling paste body and a preparation process thereof, relates to a filling material with self-compaction performance for coal mine cut and fill mining and a corresponding proportion stirring process, and belongs to the field of construction materials. The self-compaction filling paste body is characterized by being prepared by uniformly mixing coal gangue, coal ash, cements, high-efficiency water reducing agent and water according to proper proportion, wherein the slurry concentration of the paste body is 75-85 percent; and in terms of mass percentage, the proportion of the coal gangue to the coal ash to the cements to the water reducing agent to the water is 45-55 percent to 15-20 percent to 10-15 percent to 3-5 percent to 15-25 percent. The paste body is high in flowability, stability and filling performance, low in bleeding rate and uniform and consistent in quality, and fully fills every corner of a worked-out section; the bleeding and the segregation of the aggregates are avoided; the convenience in transportation and control is achieved; a pipeline is not blocked during transportation; and original mine wastes are adopted for the paste body for realizing the filling so as to protect the environment.

Owner:TAIYUAN UNIV OF TECH

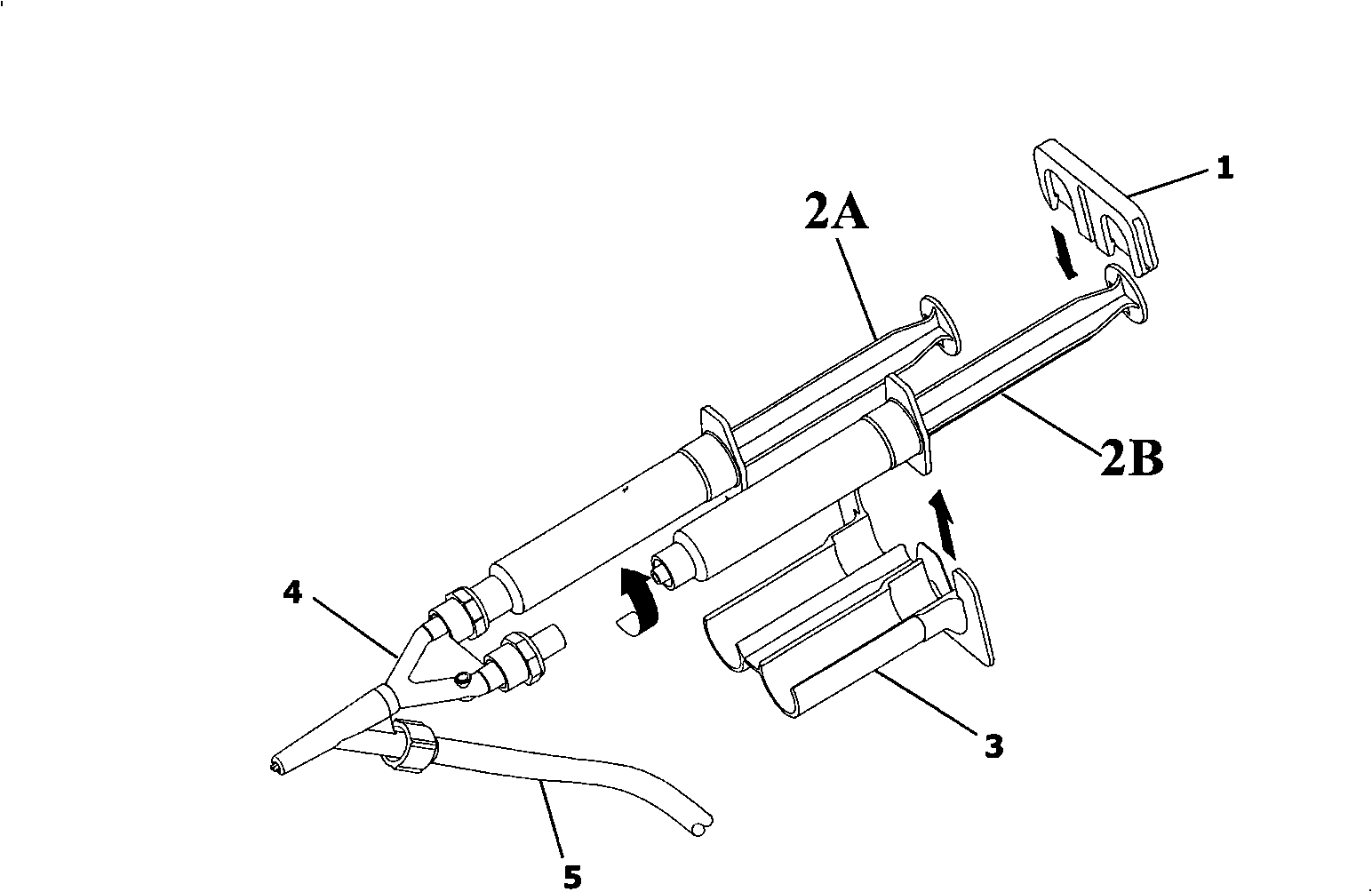

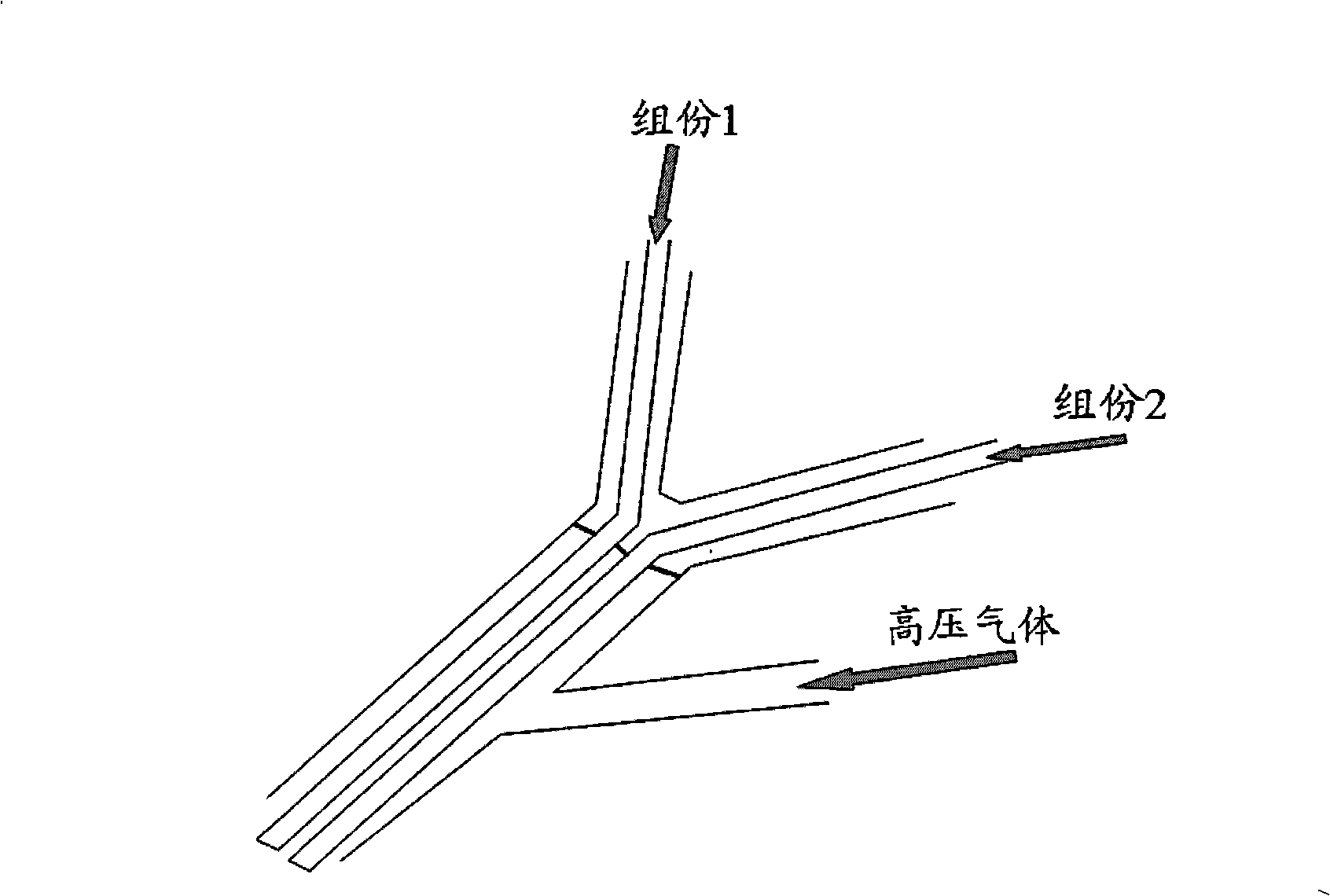

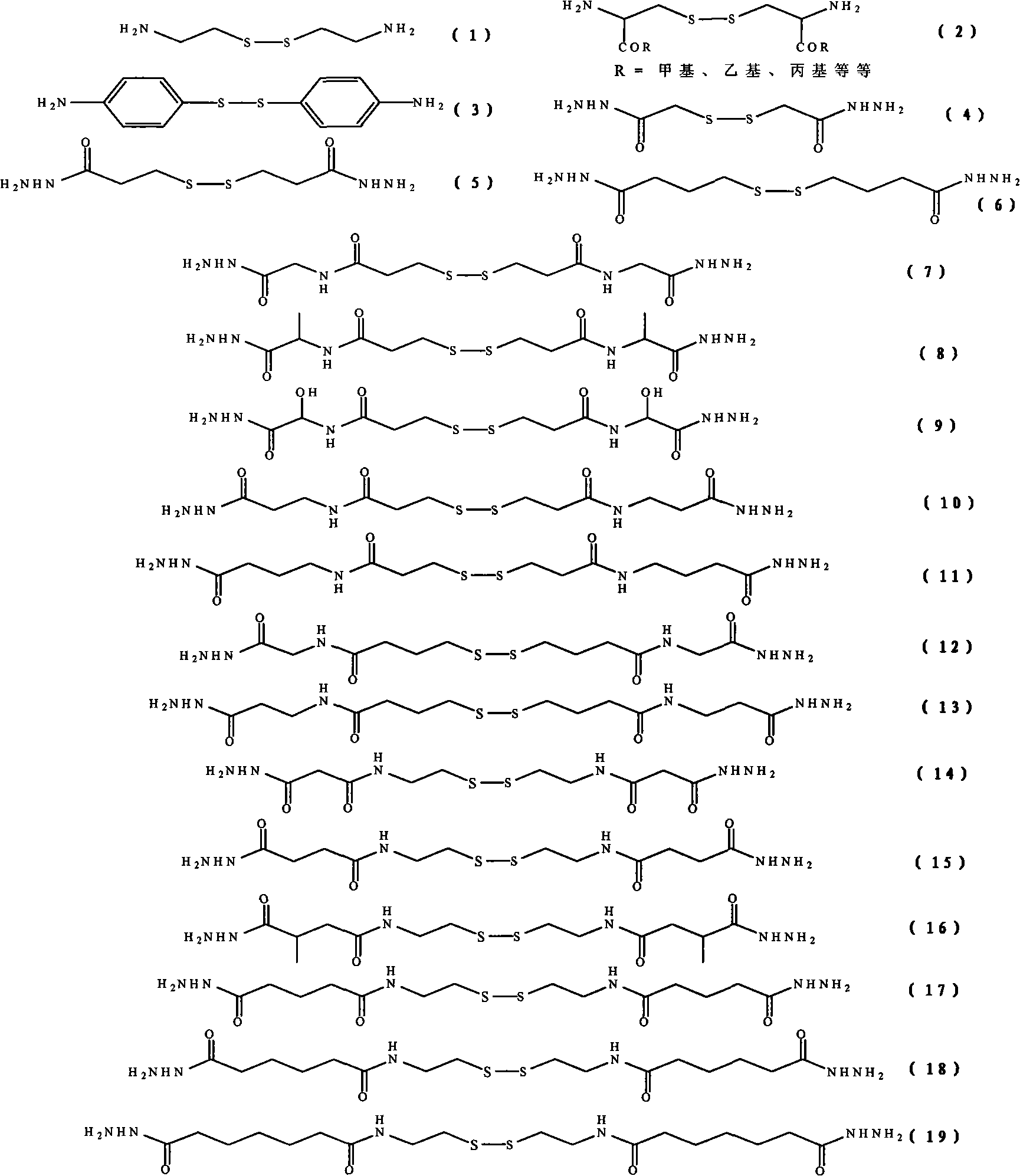

Biocompatible quick-gelatinizing hydrogels and method for preparing spray thereof

ActiveCN101338036AImprove stabilityReduce dosageOrganic active ingredientsPharmaceutical delivery mechanismCross-linkBiocompatibility Testing

The invention discloses a preparation method for biocompatible rapid gelating hydrogel. The hydrogel is formed by that a plurality of active compound components mix and undergo chemical cross linking reaction to rapidly chemically cross link under the specified conditions. The preparation method comprises the following steps: (1) a solution (component A) containing biocompatible macromolecular mercapto-derivatives and biocompatible mercapto reactive crosslinking agents (component B) mutually mix to form reactive mixture with specified cross linking conditions; (2) the reactive mixture forms the hydrogel. The invention also discloses a preparation method for novel rapid gelating hydrogel spray and an application in the medical field. The invention has the advantages of good biocompatibility, no by-products, good stability, convenient use, small amount of raw materials, many medical application, etc.

Owner:BIOREGEN BIOMEDICAL (CHANGZHOU) CO LTD

Lyophobic and oleophylic micro nano-coatings applied to of oil filtering dehydration and preparation method thereof

InactiveCN101601940AImprove hydrophobicityAvoid oleophobic effectDewatering/demulsification with mechanical meansFiltration separationMicro nanoFiltration

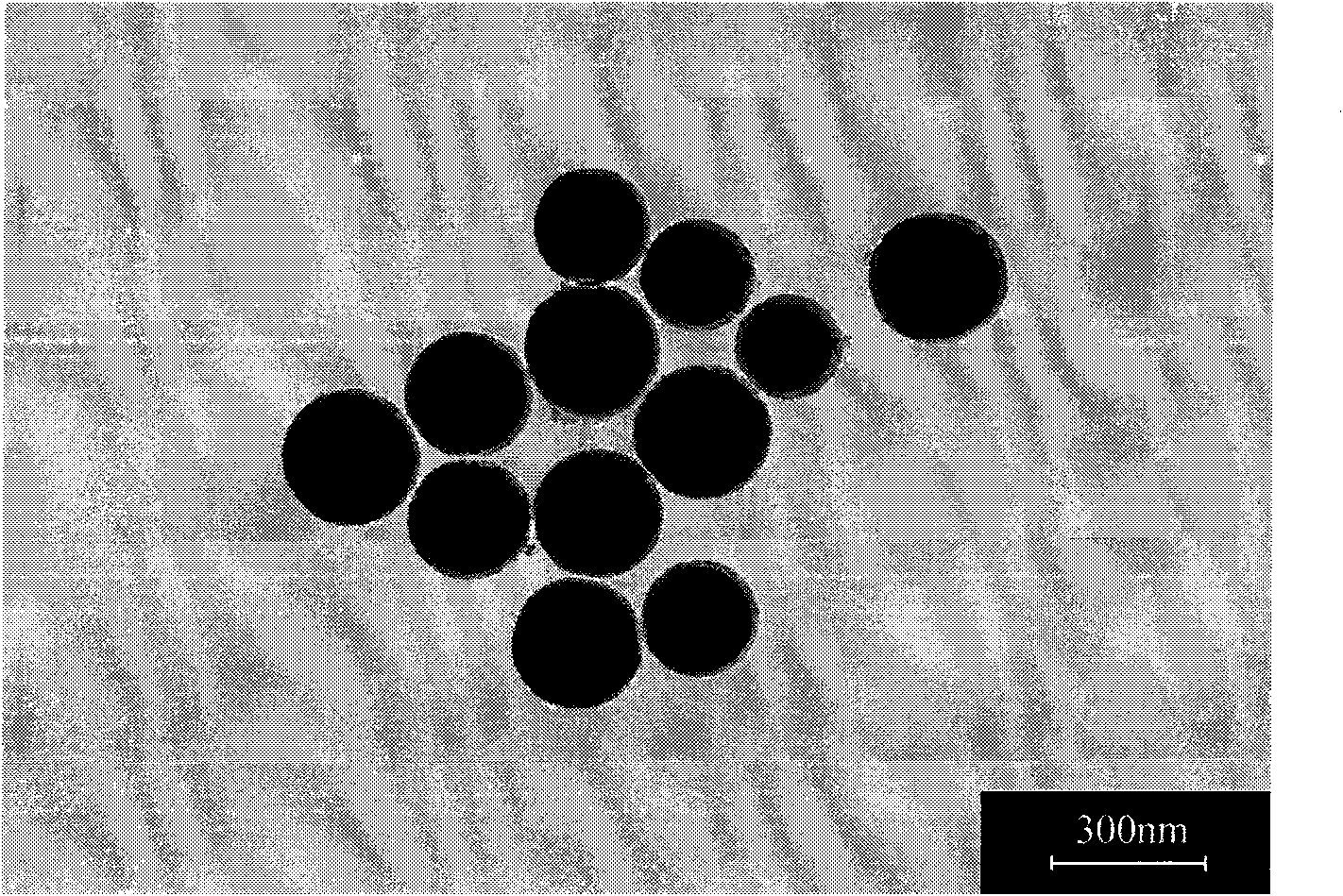

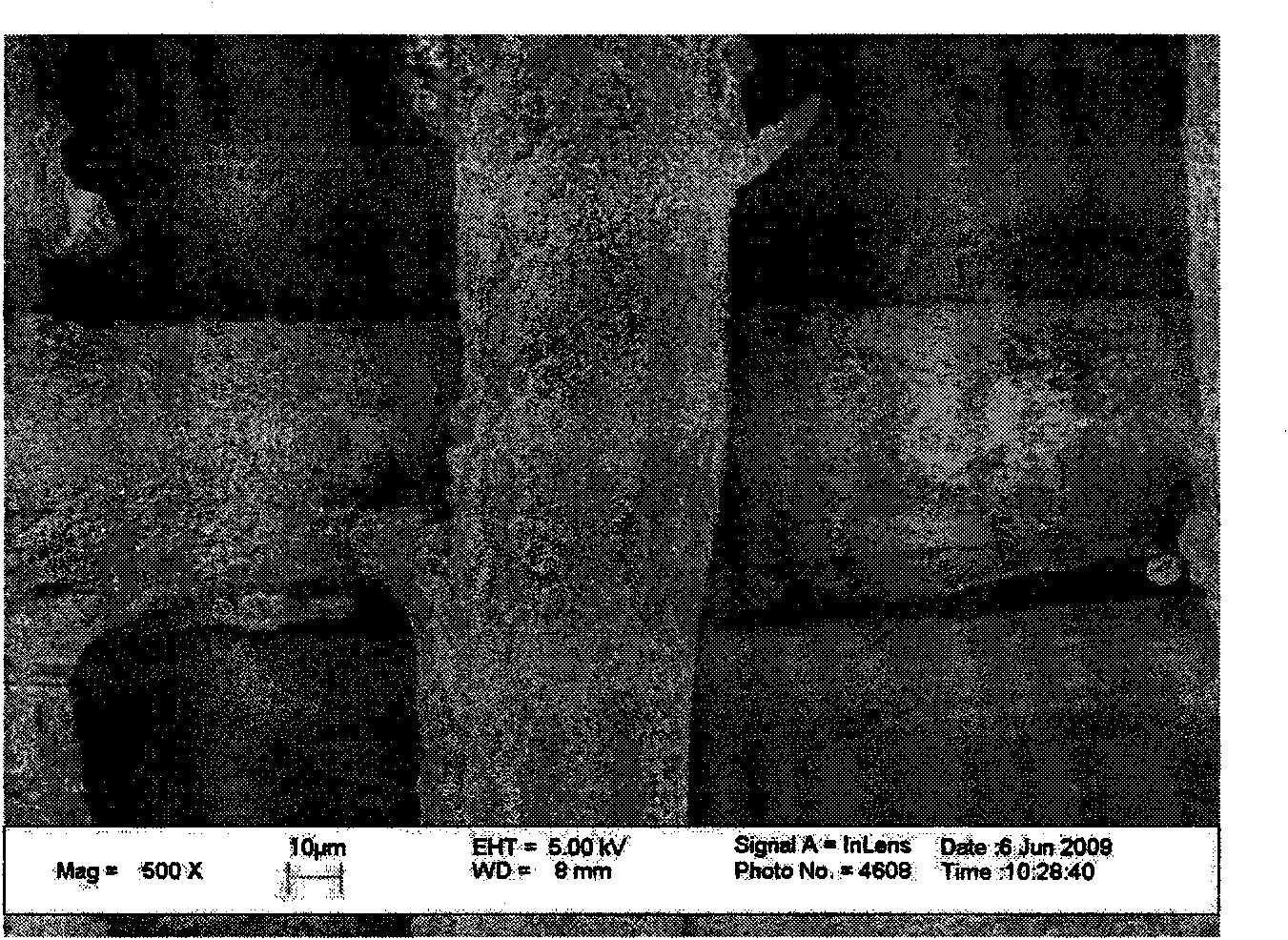

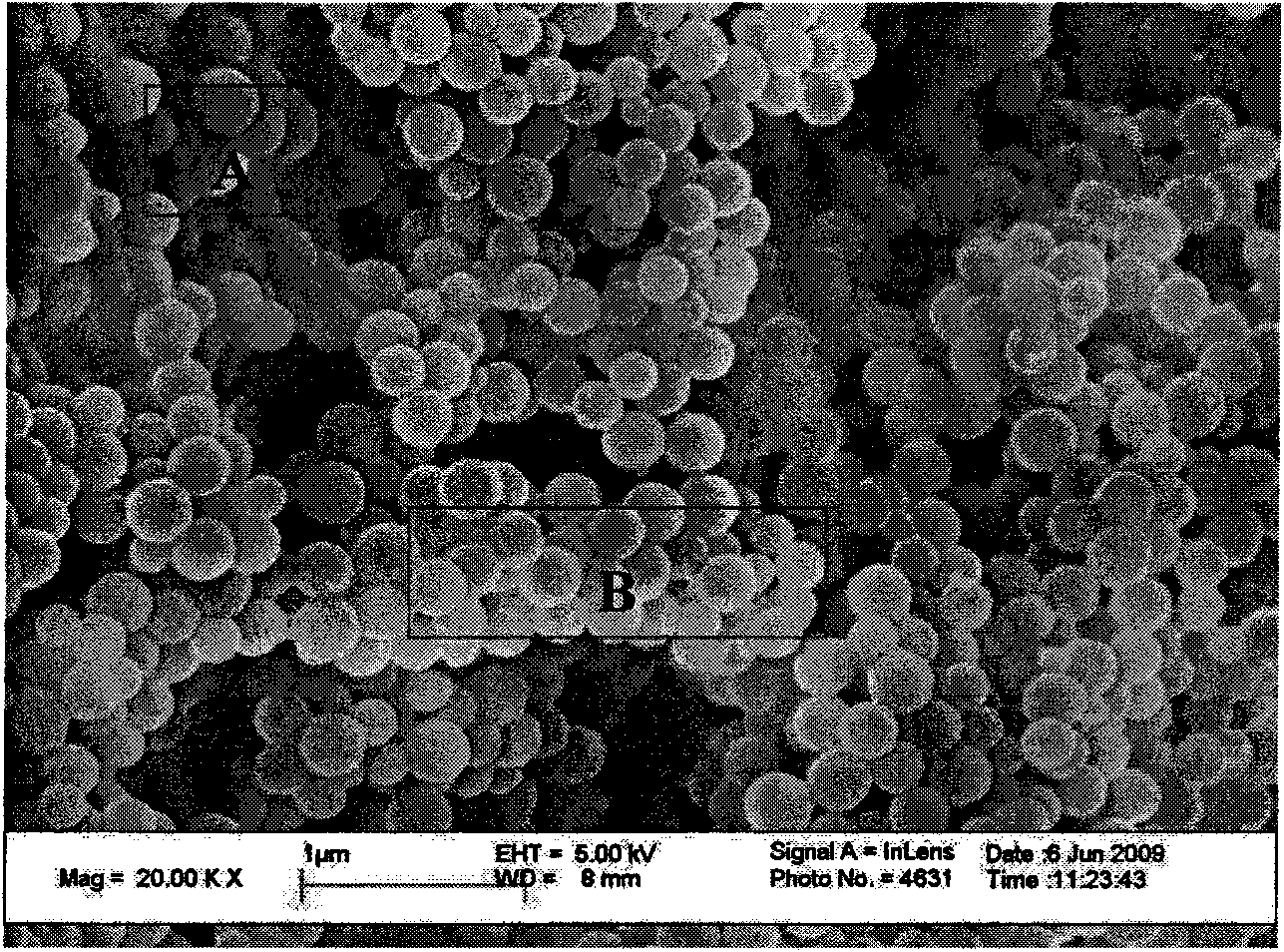

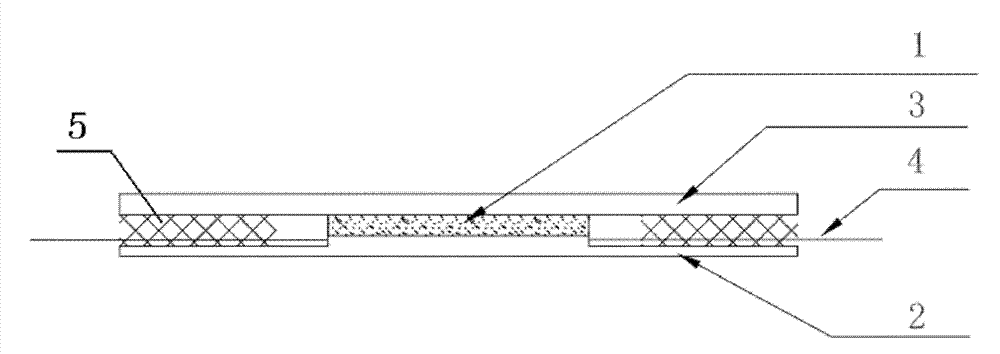

The invention discloses Lyophobic and oleophylic micro nano-coatings applied to oil filtering dehydration and a preparation method thereof. Base material of the coatings is metal mesh grid with 50-1800 meshes, the surface of the metal mesh grid is coated with a layer of dense micro nano-coating which is dense thin film composed of nano silica global particles with partical size ranging from 90nm to 500nm.In the method of the invention, the sol-gel method is adopted, tetraethyl ester serves as the precursor, ammonia water serves as the catalyst, ethanol serves as the solvent, alkyl oxosilane serves as lyophobic modifier, the method of hydrolytie polycondensation is adopted to obtain lyophobic nano silica sol, the process of impregnation or spraying is adopted to coat the gel on the metal mesh grid with 50-1800 meshes, after thermal treatment, oil-water separation net with lyophobic and oleophylic properties is obtained. The method of the invention features simple process, no harm to the environment, no need of fluorine material, wide application to coalescing separator as a separation filter element and the function of filtration and dehydration of oil.

Owner:SOUTH CHINA UNIV OF TECH

Microsphere type embolic agent and preparation technology thereof

The invention provides a microsphere embolic agent, which is an elastic microsphere formed by the crosslink polymer of the functionalized macromolecules with the biocompatibility, and the particle size of the microsphere ranges from 1 Mum to 1500 Mum. The preparing technology includes the steps as follows: in a covalent link, linking a crosslinkable micromolecules with an acrylic acid structure on the polyvinyl alcohol, polyethylene glycol or polysaccharide macromolecules, forming the functionalized macromolecules; after that, the functionalized macromolecules and the monomer of the 2- acrylamide-2-methyl propanesulfonic acid undertakes opposite suspension polymerization, obtaining the crosslink polymeric microsphere embolic agent. The embolic agent has comparatively large retractility and elasticity, whose particle size is controllable and has perfect dispersiveness; moreover, the raw material is non-toxic and at the same time has good biocompatibility and stability. The preparing technology is a real chemosynthesis technology, whose material and preparing process does not produce any virus pollution, according with various requirements of the international embolic agent, which can replace various import and domestic expensive embolic agent products and is extensively applicable to various surgeries in the interventional radiology field.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

Visualized microscopic model of real core and manufacturing method of visualized microscopic model of real core

ActiveCN102768812AMaintain physical and chemical propertiesAvoid breakingEducational modelsPorous mediumMicrosphere

The invention relates to a visualized microscopic model of a real core and a manufacturing method of the visualized microscopic model of the real core. The model comprises a real core sheet, an organic glass cover plate, an organic glass slide and a needle and is formed via the pressure at high temperatures; the real core sheet is milled to be visualized and is then clamped between two pieces of the organic glass; the needle is firstly fixed well, and the organic glass cover plate is then arranged; at a high temperature and at a high pressure, the organic glass is softened to be adhered more tightly with the core sheet; and the model is formed by cooling. According to the visualized microscopic model and the manufacturing method provided by the invention, the physico-chemical properties of the real core are kept, and the distribution and flowing condition of the multi-phase fluid in the porous medium pores are observed, so that the visualized microscopic model and the manufacturing method play an important role in studying the percolation mechanism and enhancing the yield of the polymer microspheres.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

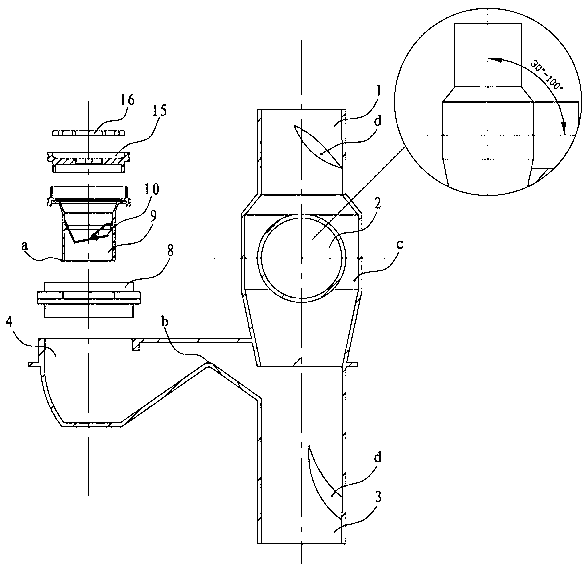

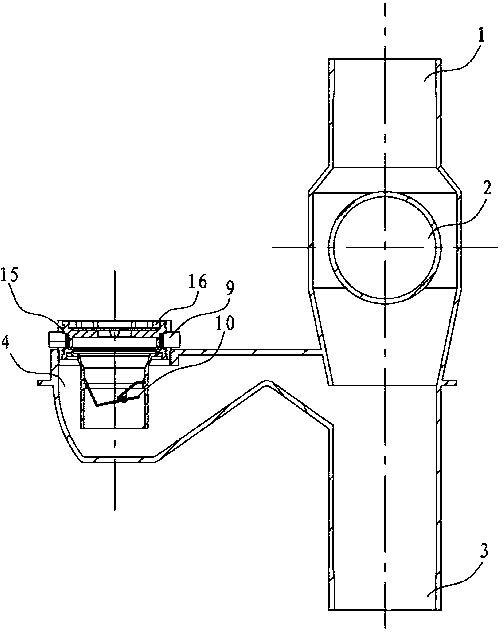

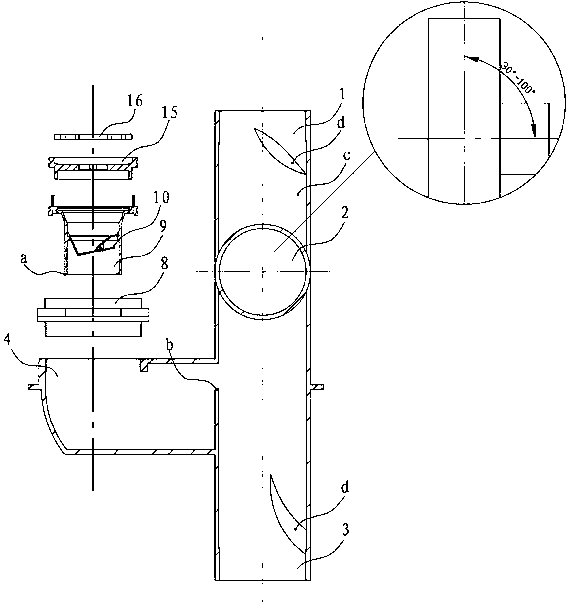

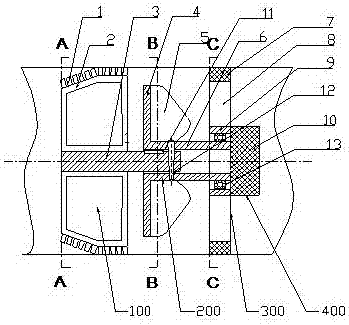

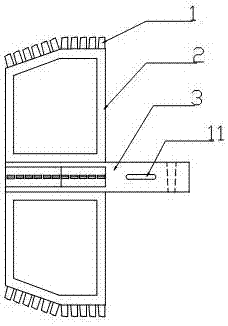

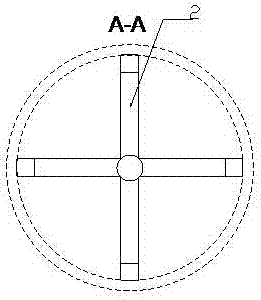

Same floor draining joint for building

InactiveCN102839724AIncrease drainage flowTo achieve the separation effectDomestic plumbingToiletCivil engineering

The invention relates to a same floor draining joint for a building, in particular to a same floor draining joint for a toilet, which consists of an upper vertical pipe draining port, a lower vertical pipe draining port and at least two transverse pipe draining ports; the upper vertical pipe draining port is communicated with the upper end and the lower end of the lower vertical pipe draining port; the at least two transverse pipe draining ports are staggered in position and are arranged between the upper vertical pipe draining port and the lower vertical pipe draining port; the orientation of the inlet of at least one of the transverse pipe draining ports is equal to or nearly equal to the orientation of the upper vertical pipe draining port, and the orientation of the inlet of at least one of the transverse pipe draining ports forms an included angle of 30-100 degrees with the orientation of the upper vertical pipe draining port. The same floor draining joint is rational and scientific in structure, and is capable of realizing the same floor draining and the same floor maintenance when the draining joint is adopted in the same floor draining of the non-falling plate or falling plate; the draining is more safe; the water is not easy to accumulate in the falling plate layer even the way of the falling plate is adopted, and the accumulated water is safely and completely discharged, so as to avoid the foreign smell in the room.

Owner:KUNMING QUNZHIYING TECH

Preparation method of nano-silver alginate fiber

ActiveCN103147167ASmall particle sizeUniform particle size distributionAlginate artificial filamentsWet spinning methodsFiberBiocompatibility Testing

The invention discloses a preparation method of a nano-silver alginate fiber. The preparation method comprises the following steps of: preparing an alginic acid silver complex which is a precursor of nano-silver by using algal polysaccharides and soluble silver salts, and then preparing a sodium alginate based nano-silver colloid system through a chemical reduction method; then adding fiber-grade sodium alginate into the sodium alginate based nano-silver colloid system to obtain a nano-silver algae spinning solution; and finally, obtaining a nano-silver algae primary fiber through wet spinning, and carrying out stretching, sizing, drying and oiling treatments to obtain the nano-silver alginate fiber. The prepared nano-silver alginate fiber integrates the excellent performances of the nano-silver and the alginate fiber, so that the novel fiber has excellent flame retardance, biocompatibility, moisture absorption permeability and the like, also has excellent antimicrobial performance, antistatic performance and irradiation resistance and can be widely used in medical treatment, the fire-fighting field, the military field, the aerospace field, the health textile field and the like.

Owner:QINGDAO UNIV

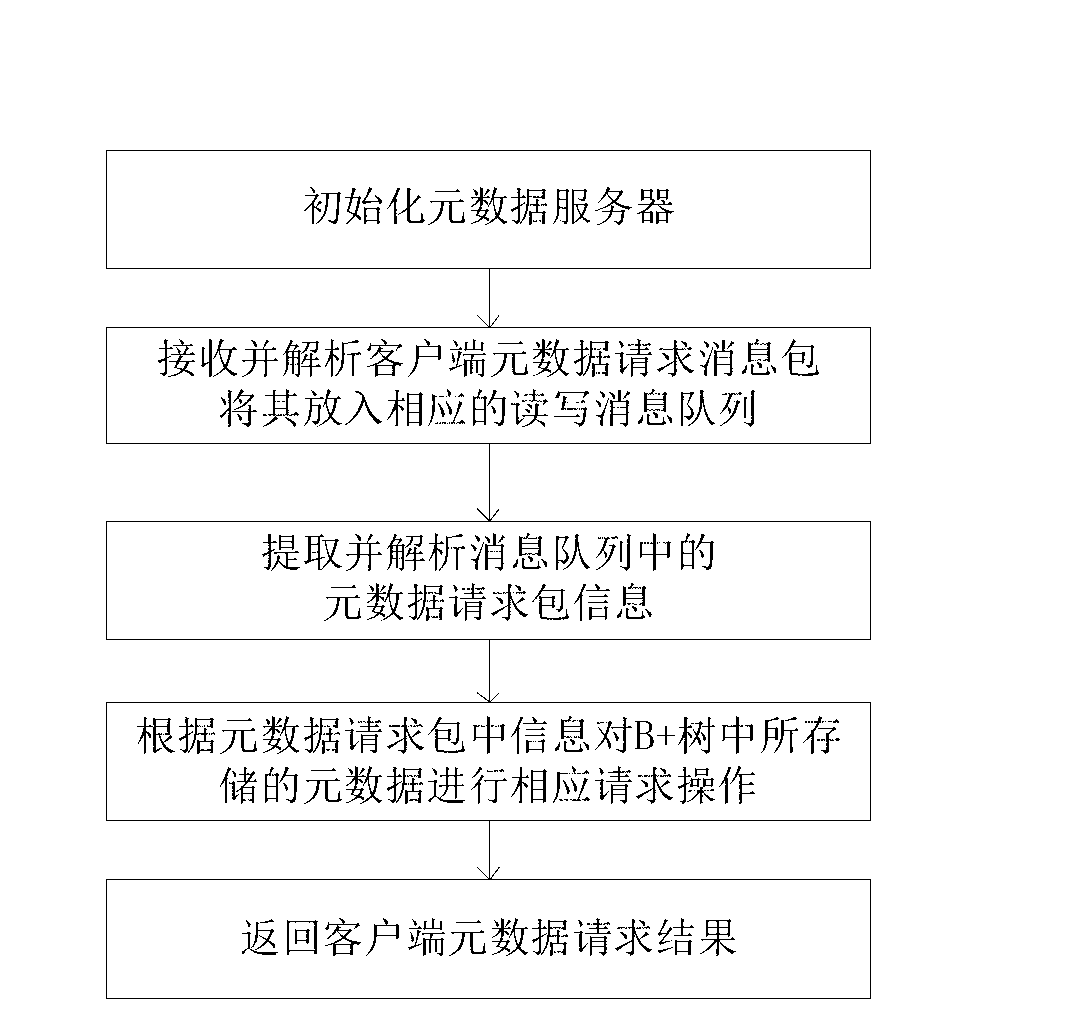

Metadata organization and management method and system of distributed file system

InactiveCN103294786AImprove efficiencyAvoid inefficienciesSpecial data processing applicationsClient-sideDistributed File System

The invention discloses a meta data organization and management method of a distributed file system. The method includes the steps: receiving meta data request message packets, parsing content of the meta data request message packets, putting the meta data request message packets into a corresponding message queue according to parsed types of the meta data request message packets, extracting meta data request message packets from message queues, parsing the meta data request message packets so as to obtain request types and request content of the meta data request message packets, acquiring meta data information stored in a tree B+ according to the meta data request message packets, performing corresponding read-write operation on the meta data information, putting results obtained after read-write operation in a meta data request response message packet, and returning the meta data request response message packet to a client side. The method can solve the problem of poor meta data processing performance of an MDS (meta data server) caused by existing meta data read-write high-concurrency operation, and processing capacity of the MDS is improved. .

Owner:HUAZHONG UNIV OF SCI & TECH

Biological ink material for 3D printing and preparation method and application thereof

ActiveCN105885436AEasy to sprayWon't clogAdditive manufacturing apparatusProsthesisBiological macromoleculeAntigenicity

The invention discloses biological ink material for 3D printing and a preparation method and application thereof. The biological ink material is prepared by, by mass concentration percentage, 5-18% of biological macromolecules, 76-93.5% of water or 76-93.5% of pre-crosslinking agent, and 1.5-6% of coagulant, wherein the sum of the mass concentration percentage of the above raw materials is 100%. The biological ink material is characterized in that water washing and crosslinking are performing for shaping after printing. The biological ink material has the advantages that the biological ink material can be easily squeezed out during printing, does not block printing needles and can be easily shaped after being squeezed out; the biological ink material is low in antigenicity in the bodies of organisms, low in caused rejection reaction, biodegradable, nontoxic to the organisms and high in safety.

Owner:THE FIRST AFFILIATED HOSPITAL OF SUN YAT SEN UNIV +1

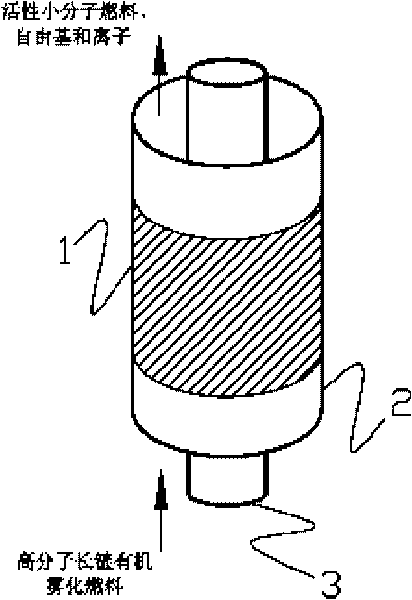

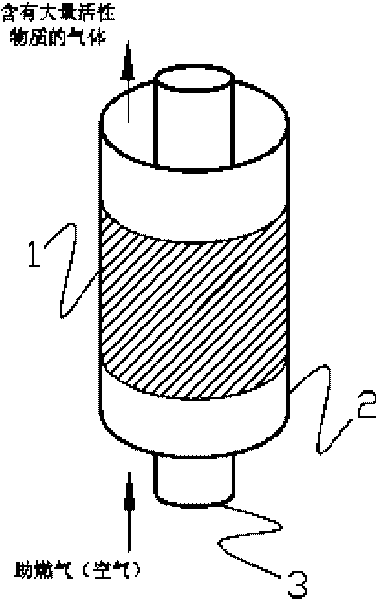

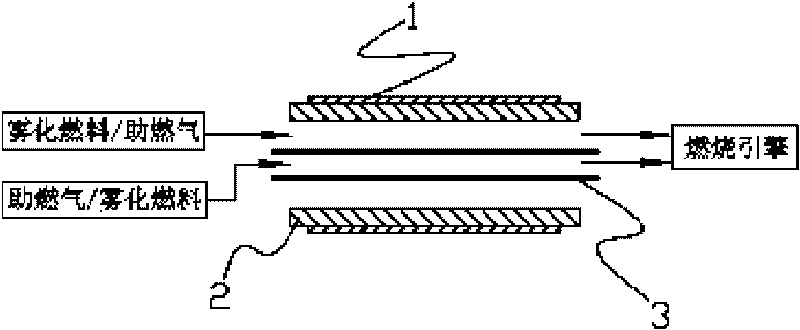

Method for increasing combustion efficiency of combustion engine

InactiveCN101701558ATake advantage ofIncrease the itineraryInternal combustion piston enginesCombustion-air/fuel-air treatmentJet aeroplanePlasma technology

The invention provides a new method for increasing combustion efficiency of a combustion engine; based on non equilibrium plasma technology, a non equilibrium plasma generator with low power is designed and applied, has small volume, can be widely applied to such as fuel power equipment such as automobiles, airplanes and the like and really realizes the combustion efficiency increase of the fuel equipment and exhaust emission reduction. The non equilibrium plasma generator provided by the invention is applied for carrying out controllable dielectric barrier discharge so as to activate fuel or combustion-supporting fuel, thus fundamentally improving combustion situation of the fuel, causing the fuel to fully and effectively burn and simultaneously achieving the effect of energy saving and emission reduction.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

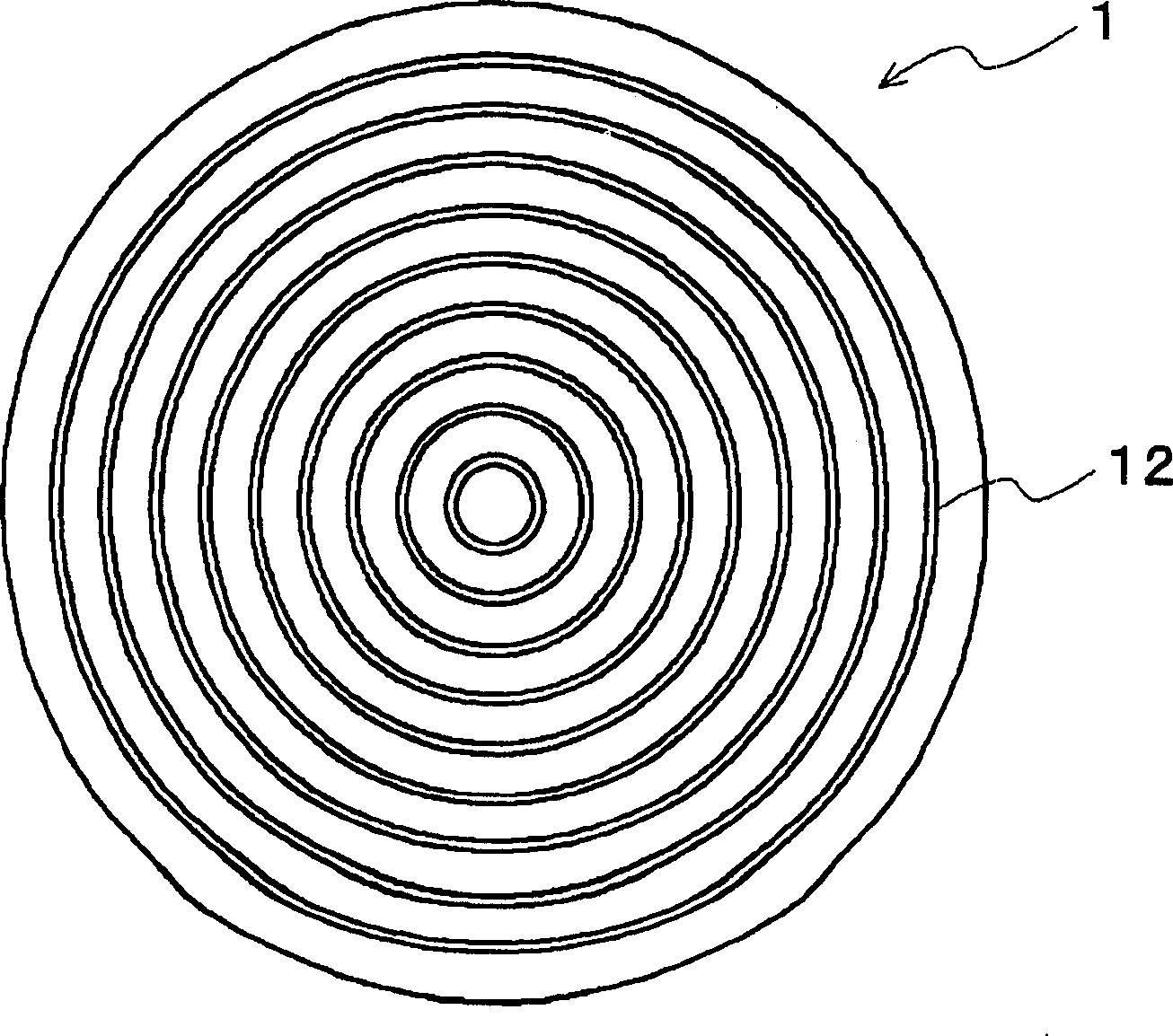

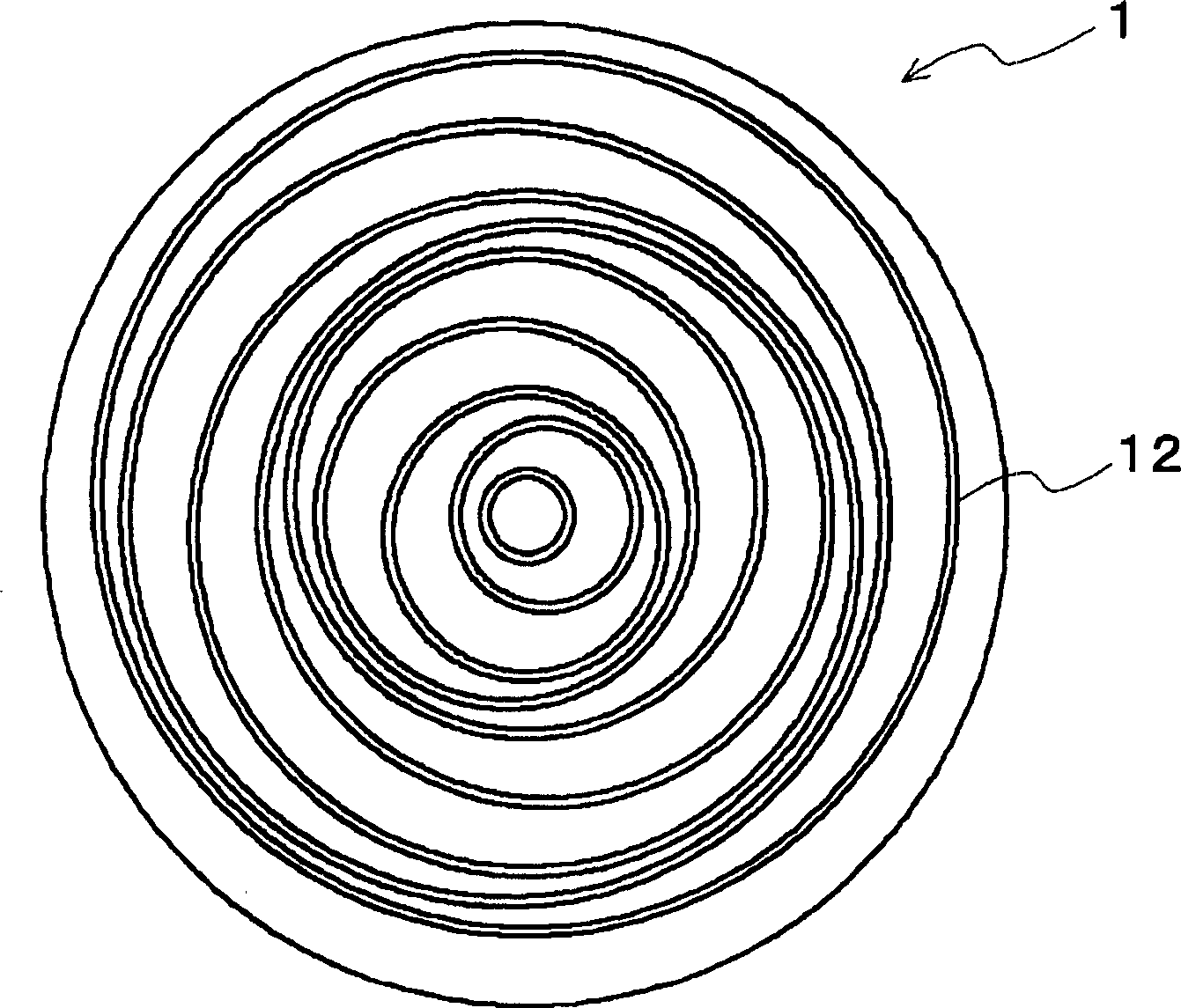

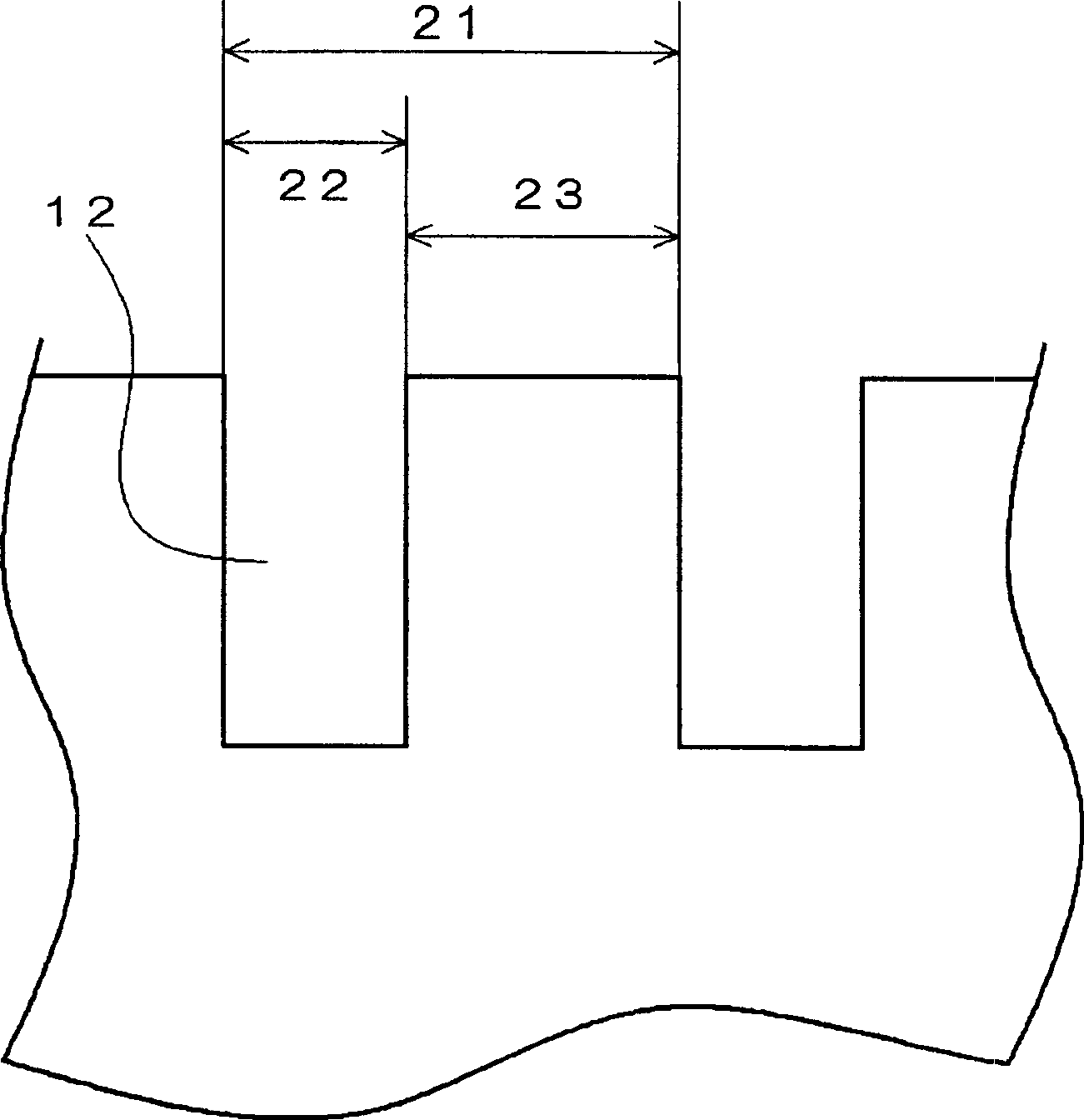

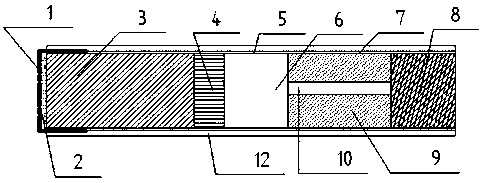

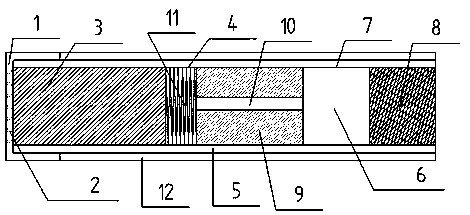

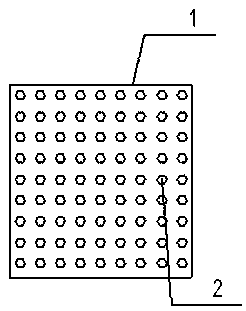

Polishing mattress and multilayer polishing mattress

InactiveCN1494983AInhibit chafingImprove flatnessSemiconductor/solid-state device manufacturingFlexible-parts wheelsSurface roughnessBiomedical engineering

The present invention intends to provide a polishing pad and a multi-layer polishing pad (1) that can particularly effectively suppress scratch from occurring. The polishing pad (1) of the invention comprises at least one part selected from a groove (a) having at least one kind of shape selected from annular, lattice-like and spiral form on a polishing surface side, a concave portion (b) and a through hole (c). In the above, surface roughness of an inner surface of the part is 20 mu m or less and the polishing pad (1) is used for chemical mechanical polishing.

Owner:JSR CORPORATIOON

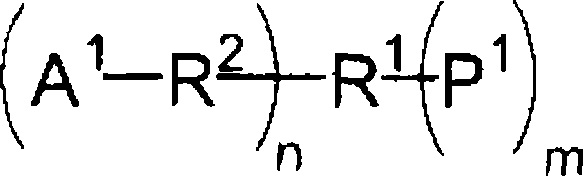

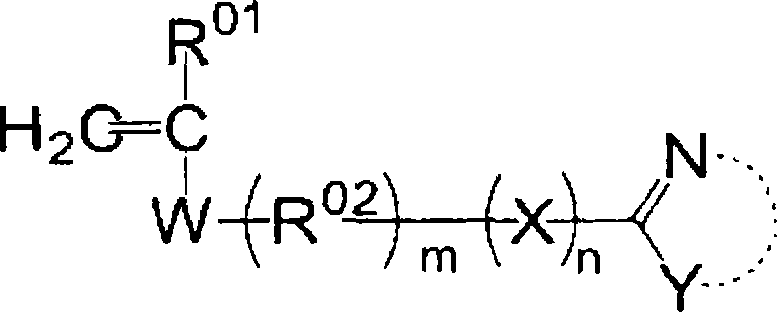

Curing colouration composition, color filtering device and liquid crystal display using the color filtering device

ActiveCN101154038AImprove dispersion stabilityConducive to preservationPhotosensitive materials for photomechanical apparatusNon-linear opticsSolventBoiling point

The invention provides a curing color composition, comprising: colouring agent, dispersion resin, polymerization initiator, polymerized compound and solvent, which is characterized in that the solvent comprises: (A) solvent whose boiling point is 180-280 DEG C under the atmospheric pressure and (B) solvent whose boiling point is 130-170 DEG C under the atmospheric pressure and the solubility parameter is 8.5-10.5. The dispersion resin contains the high molecule compound represented by the general formula (1).

Owner:FUJIFILM CORP

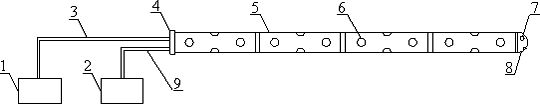

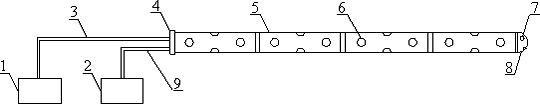

Feeding method and device for hole protecting pipe for soft coal seam gas extraction hole

The invention relates to a feeding method for a hole protecting pipe for a soft coal seam gas extraction hole. The feeding method is characterized in that an epoxy resin adhesive is used for filling sieve pores of the hole protecting pipe before the hole protecting pipe is fed into a drill hole, air with a certain pressure is pressed into the hole protecting pipe in the process of feeding the hole protecting pipe into the drill hole, the air flows into the drill hole through a vent hole arranged at the top end of the hole protecting pipe, and high-speed air currents discharge coal dusts from an orifice along the hole protecting pipe and a gap of the wall of the drill hole. After the hole protecting pipe is fed into the bottom of the hole, an epoxy resin adhesive dissolving agent is injected into inner holes of the hole protecting pipe for dissolving the expoxy resin adhesive in the sieve pores so as to extract the gas. The feeding method is convenient in operation, can overcome the problem that the hole protecting pipe is difficult to feed into the drill hole due to the residual coal dusts in the gas extraction hole and local hole collapse, and has the advantages of long feeding distance of the hole protecting pipe, thereby ensuring the higher concentration and high flow of the soft coal seam gas extraction. The feeding method is particularly suitable for soft coals and very soft coal seams in which hole collapse easily occurs.

Owner:CHINA UNIV OF MINING & TECH

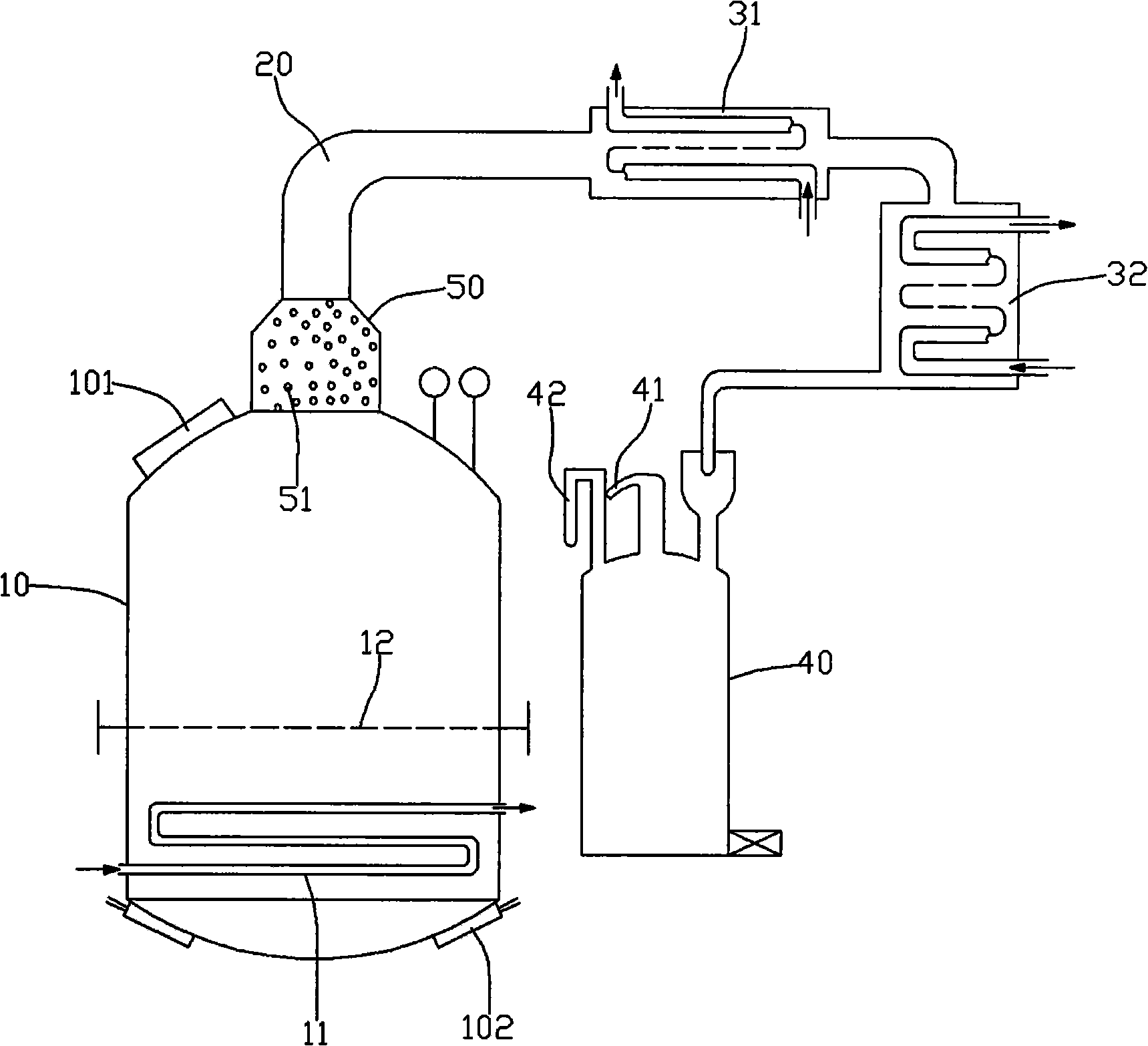

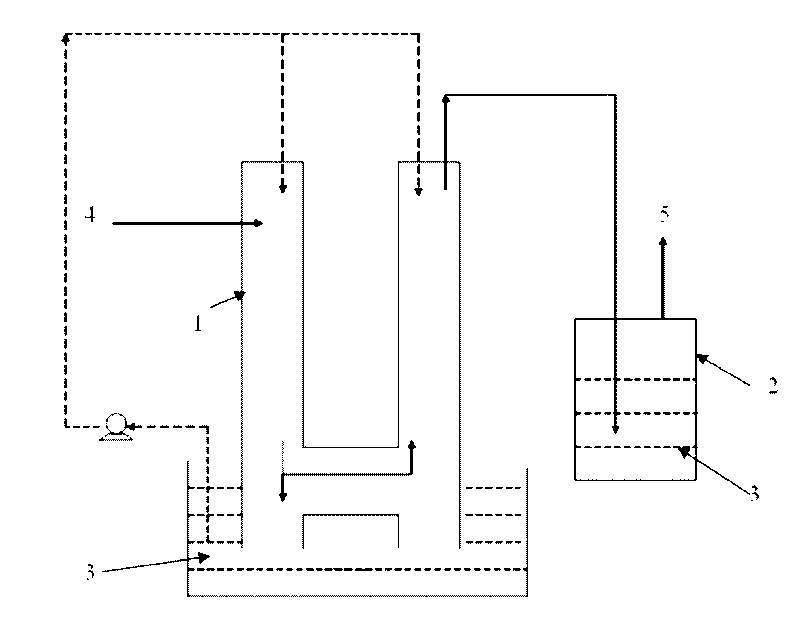

Rose essential oil and rose pure dew extraction equipment

InactiveCN101353611AAvoid direct accessInhibition of dissolutionEssential-oils/perfumesDistillationEngineering

The invention discloses extraction equipment for rose essential oil and rose hydrosol which mainly includes a distillation still, a steam conduit, a condenser and an oil-water separator, wherein, the distillation still is connected with the oil-water separator by the steam conduit and the condenser; the lower end of the interior of the distillation still is provided with a steam heating coil; and the upper part of the steam heating coil is provided with a transverse plate sieve which can be opened freely. An adsorption plant is arranged between the top of the distillation still and the steam conduit and internally filled with active ceramic rings serving as an absorbent. The extraction equipment of the invention has the advantages of simple operation, convenient use and high production efficiency, and can greatly enhance the quality of the rose essential oil and the rose hydrosol.

Owner:许向梅

Scented straw cat litter made by wheat straw and method thereof

ActiveCN104969866AWill not affect healthDoes not affect fishy tasteAnimal housingBiotechnologyCause blockage

The present invention discloses a scented straw cat litter made by wheat straws and a method thereof. The scented cat litter is manufactured by weight percentage by the following materials of 40-60 parts of wheat straws with a smashing mesh number being 40-70, 40-60 parts of wheat shorts, 1-3 parts of Sesbania gelatine powder, 0.5-2 parts of salt, 0.1-0.5 parts of a bio-enzyme preparation, and 10-25 parts of water. The method comprises mixing the bio-enzyme preparation, the salt and the water with stirring; mixing and stirring the wheat straw powder, the wheat shorts and the Sesbania gelatine powder to be uniform; comprehensively mixing the above raw materials with stirring; sending the mixed materials by a feed screw to a roller couple extrusion pelleting machine for roll extrusion to form pellets; transmitting the formed material pellets to a crushing and screening all-in-one machine for screening; and drying, cooling and packaging the screened pellets at normal temperature. The cat litter provided by the present invention has a strong water absorption capability and deodorization capability, can be flushed into the sewer without causing blockage, is convenient to clean, can be used as a fertilizer for grass and flowers, and is saving in using amount, high in cost performance, small in dust in a production process, and low in production cost. Products of different shapes can be produced by replacing pressing rollers of different patterns, thereby achieving multiple uses in one machine.

Owner:王洪恩

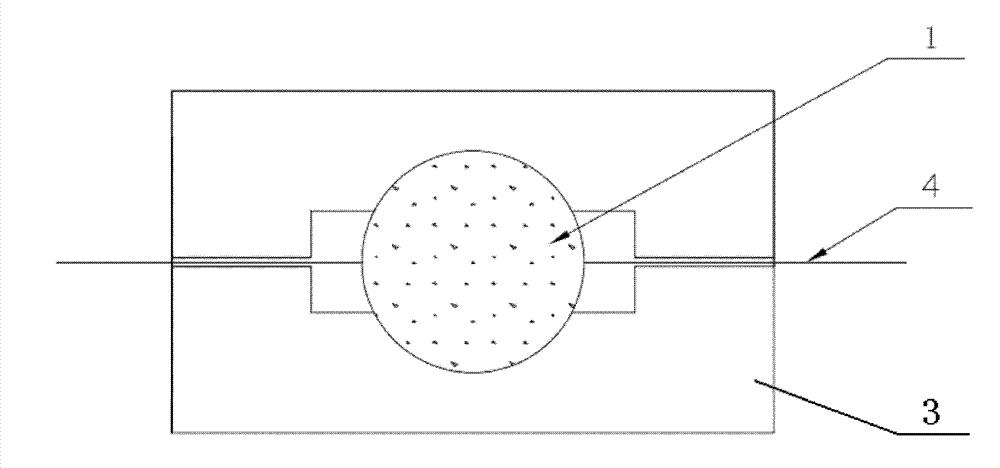

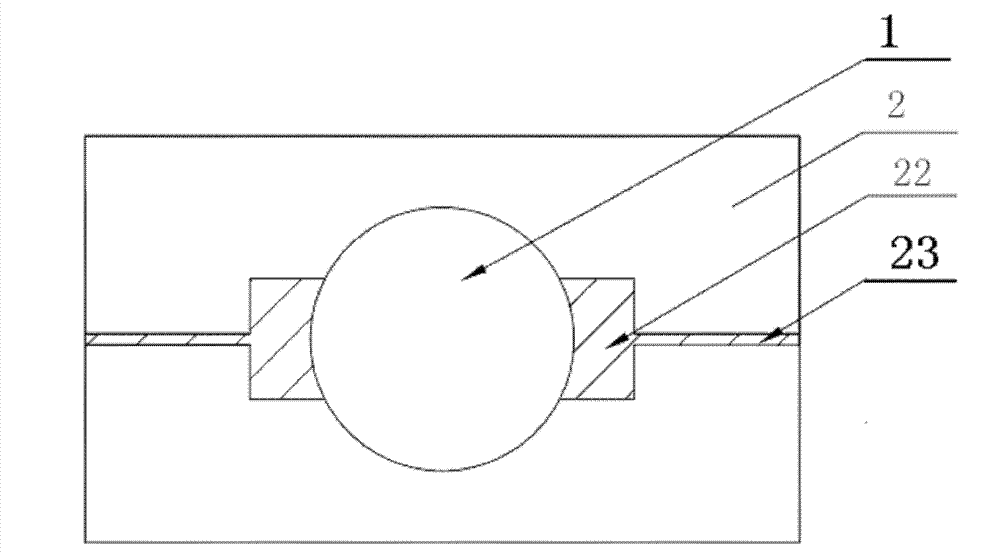

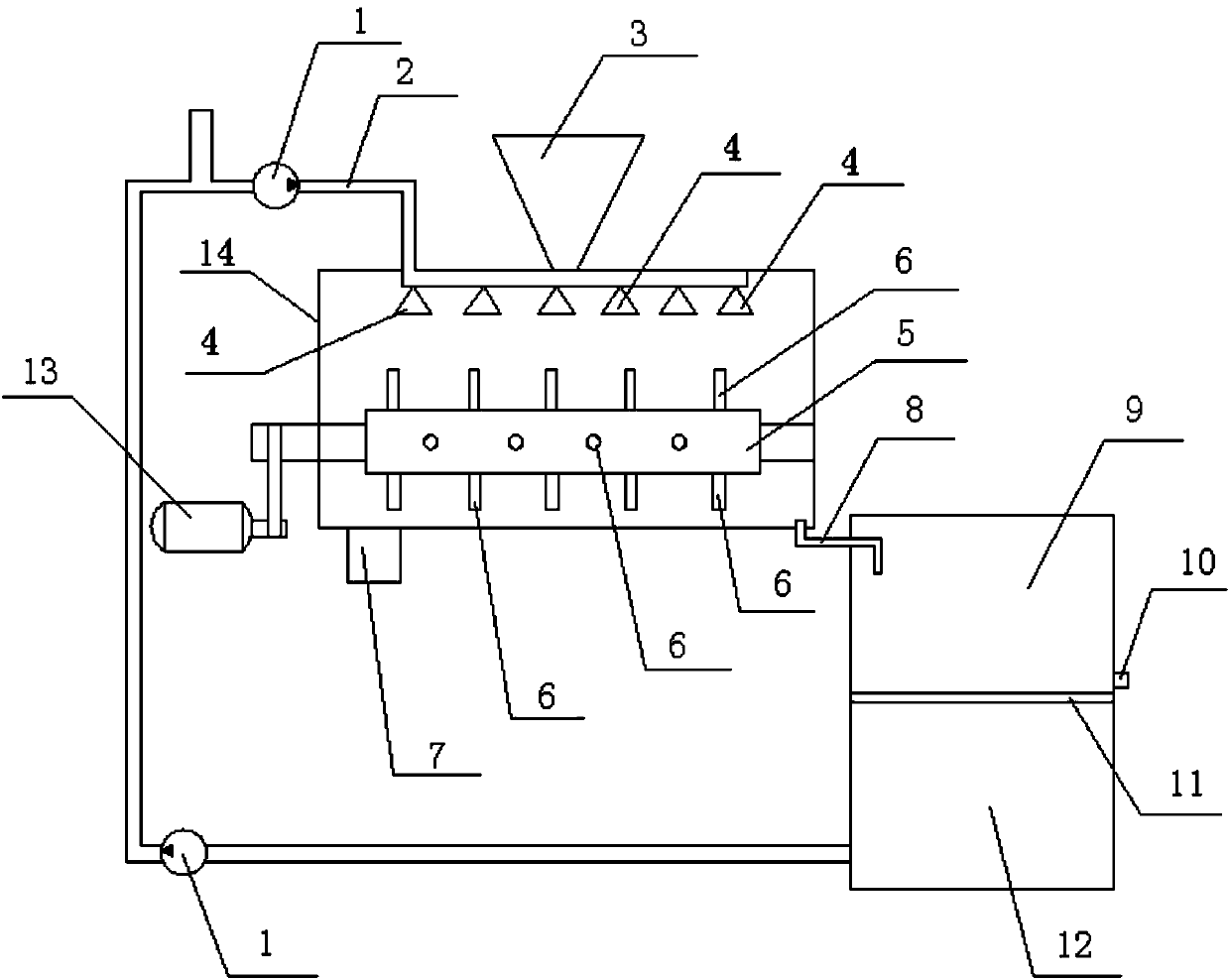

Ore washer

InactiveCN104084389AWash thoroughlyEmission reductionCleaning using liquidsWater/sewage treatment by sorptionEconomic benefitsEngineering

The invention relates to mine washing equipment, in particular to an ore washer. The ore washer comprises a motor, a washing box, a water inlet pipe, a plurality of spray heads, an agitating device, a water outlet pipe, a sewage treatment device and a feeding hopper, wherein the agitating device is mounted in the washing box; the motor is mounted outside the washing box and is connected with the agitating device through a lead; the feeding hopper is mounted above the washing box and is communicated with the washing box; the water inlet pipe transversely extends to the top in the washing box; the plurality of spray heads are uniformly mounted on the water inlet pipe at intervals; one end of the water outlet pipe is communicated with the bottom of the washing box, and the other end of the water outlet pipe is connected with the sewage treatment device; a discharge hole is also formed in the bottom of the washing box. The ore washer has the benefits that the structure is simple, the operation is convenient, the working efficiency is improved, ore is more completely washed at the same time, the sewage discharge is reduced, the resources are saved, and the economic benefit is improved.

Owner:GUANYANG CHENGONG ORE DRESSING MACHINERY MFG

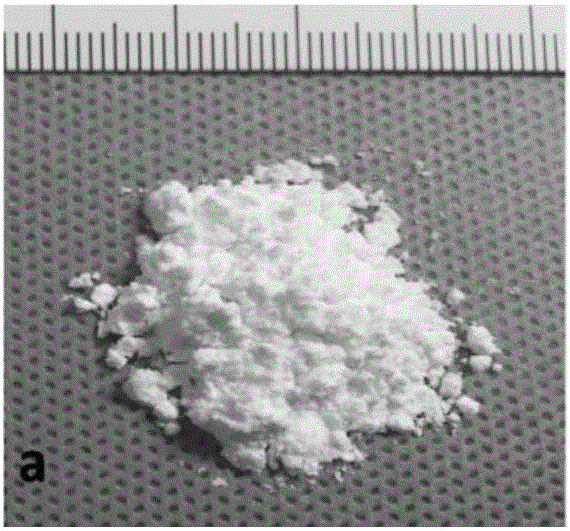

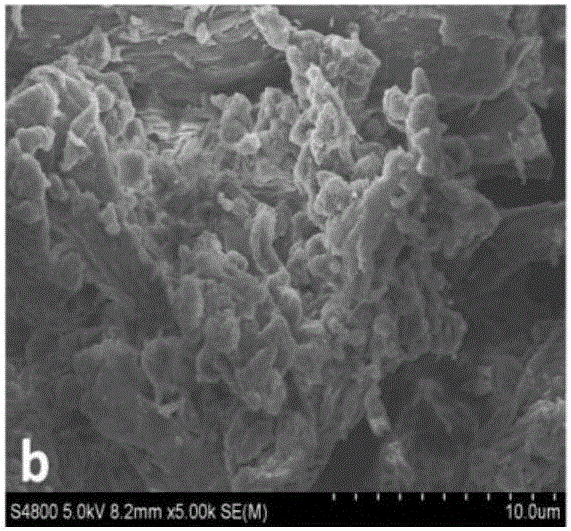

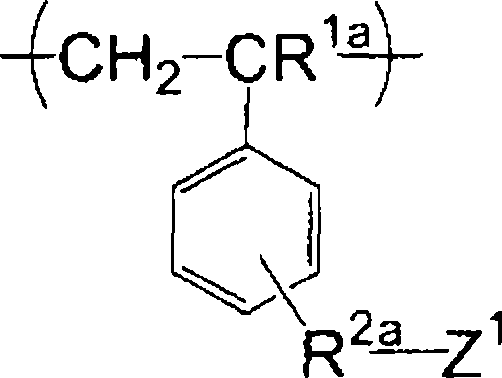

Preparation technology for microspheric embolization agent

ActiveCN101810587AUniform particle sizeGood dispersionPharmaceutical non-active ingredientsGranular deliveryChemical synthesisCross-link

The invention relates to a preparation technology for a microspheric embolization agent. The preparation technology is used for preparing elastic microspheres cross-linked and polymerized by functionalized macromolecules with biocompatibility, wherein the grain range of the microspheres is 1-1500mu m. The preparation technology comprises the following steps that: a cross-linkable micromolecule with a crylic acid structure is connected on a polyvinyl alcohol, polyethylene glycol or polyose macromolecule in form of a covalent bond to form a functionalized macromolecule; and reversed phase suspension polymerization is conducted to the functionalized macromolecule and a 2-acrylamide-2-methylpropanesulfonic acid monomer to prepare cross-linked and polymerized microspheric embolization agent. The embolization agent has the advantages that the flexibility and the elasticity are high, the grain is even and is controllable, the dispersity is good, the raw materials are nontoxic and the biocompatibility and the stability are good. The preparation technology is a pure chemical synthesis technology, no virus pollution is caused to the raw materials and the preparation process, the requirements on international embolization agents are satisfied, and the embolization agent can substitute for all kinds of imported or domestic expensive embolization agent products and can be widely used in surgeries in the field of interventional therapy.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

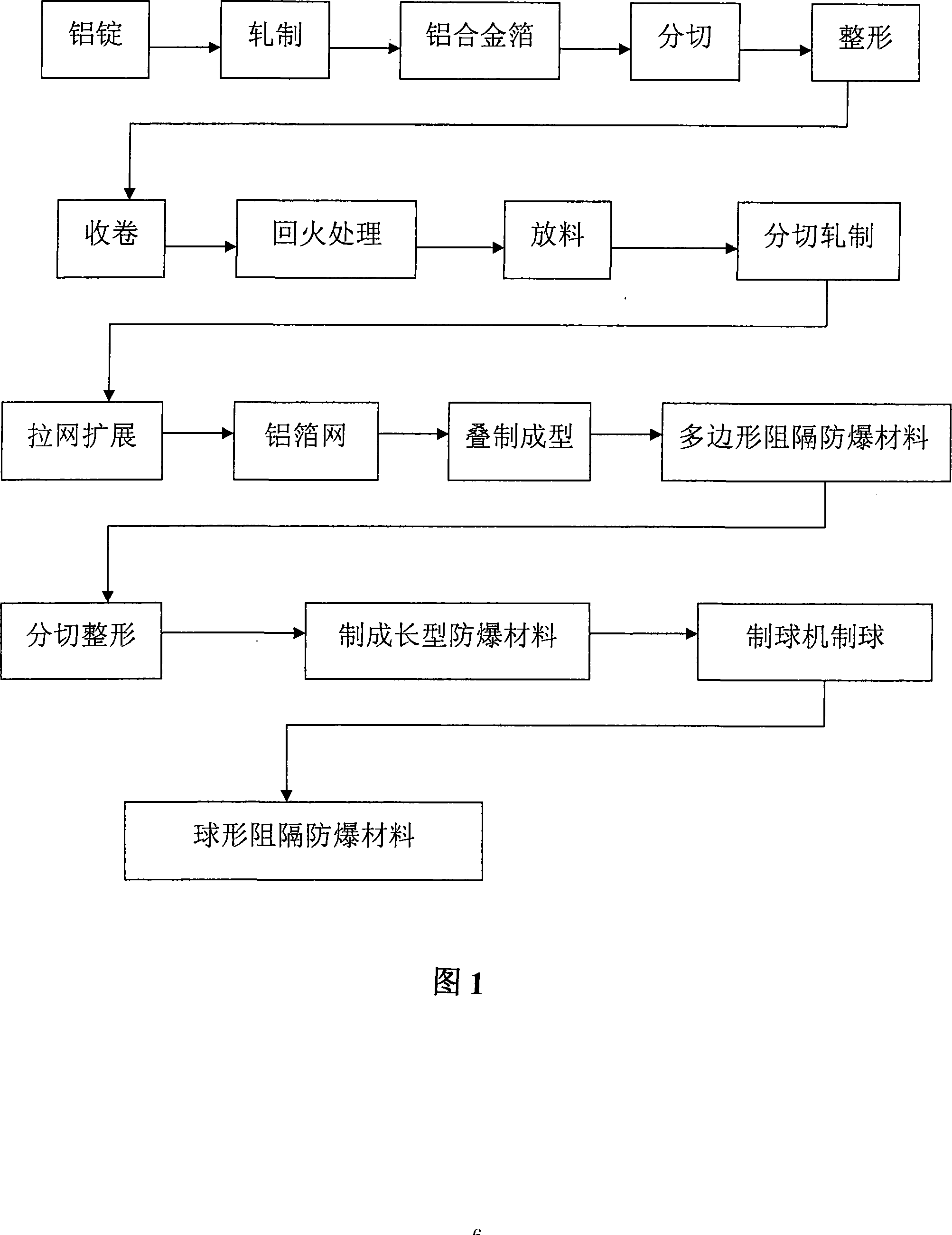

Obstruct explosion-proof material and manufacturing technique thereof

InactiveCN101144132AHigh tensile strengthGood explosion-proofContainer filling methodsContainer discharging methodsHoneycombTitanium

The present invention relates to an explosion-barrier material which is made of kerfed and expanded aluminum alloy foil grid, and has a honeycomb-shaped vesicular structure. The chemical components have weight percentages that silicon is 0.3-0.6 percent, iron is 0.3-0.7 percent, copper is 0.1-0.2 percent, manganese is 0.8-1.8 percent, zinc is 0.1 percent, titanium is 0.1-0.2 percent, and aluminum is residual. The present invention also relates to the manufacture process of the explosion-barrier material. The process has steps that the aluminum alloy ingot is rolled to be aluminum alloy foil, cut to be kerfed aluminum foil with a joint cutter, and shaped and wound, then tempering treatment is performed to the shaped and wound aluminum foil with the tempering temperature of 220-240 DEG C and the tempering time durance of 8-10 hours, the aluminum foil after the tempering is discharged, cut and rolled, and then pulled and expanded to be the aluminum foil grid, and the aluminum foil grid is folded and molded to be the grid shaped explosion-barrier material. The explosion-barrier material of the present invention has the advantages of good explosion-proof performance, good flexibility, high tensile strength, and high elongation ratio.

Owner:JIANGSU AMPUTE EXPLOSION PREVENTION TECH

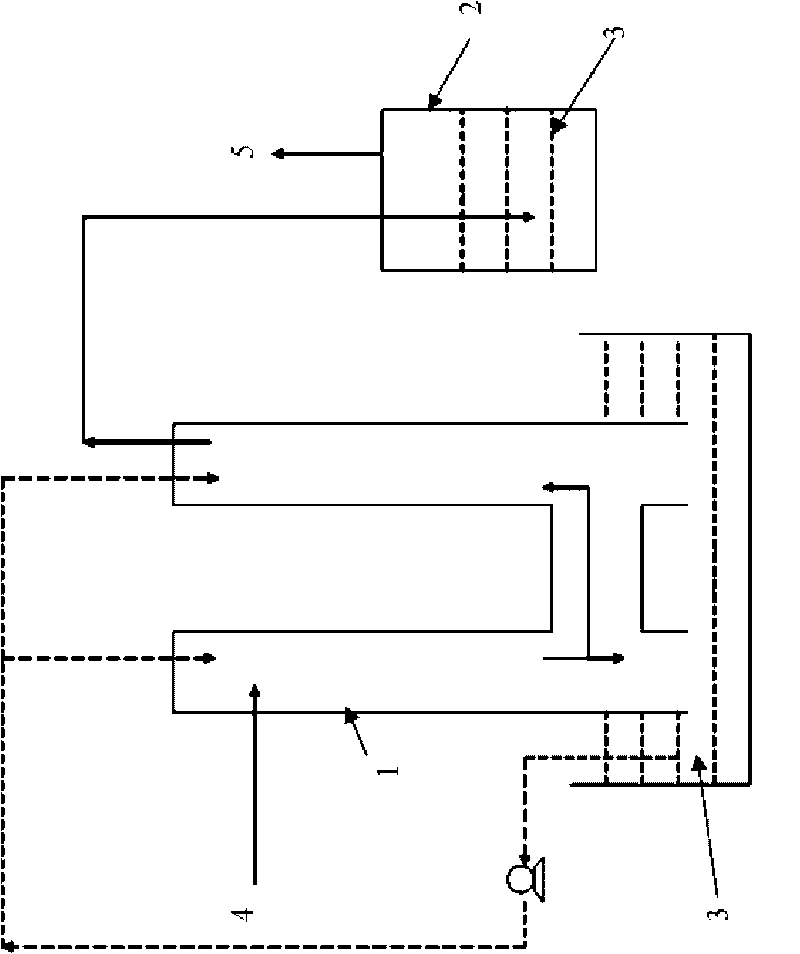

Process for treating residual liquid and tail gas in polysilicon production by improved Siemens method

InactiveCN101700466AReduce crystallizationCrystal looseDispersed particle separationSilicon compoundsProduct gasChloride

The invention relates to a process for treating a tail gas, in particular to a process for treating a residual liquid and a tail gas in polysilicon production by an improved Siemens method. The invention provides a process for treating the residual liquid and the tail gas in polysilicon production by the improved Siemens method, which is difficult to block a pipeline. The process comprises the following steps of: carrying out neutralization reaction on the high-boiling substance residual liquid, the chlorosilane tail gas and eluent; emptying the gas after the neutralization reaction; treating the liquid after the neutralization reaction to neutrality and then carrying out harmless treatment, wherein the eluent is lime milk with the volume percentage of 10-30 percent. When the lime milk eluent of the process is used, calcium chloride is slowly crystallized, and crystals are quite loose, are easy to clean and can not block the pipeline; compared with sodium hydroxide, 8-10 percent of eluent can be saved, and the production cost is saved.

Owner:LESHAN LEDIAN TIANWEI SILICON TECH CO LTD

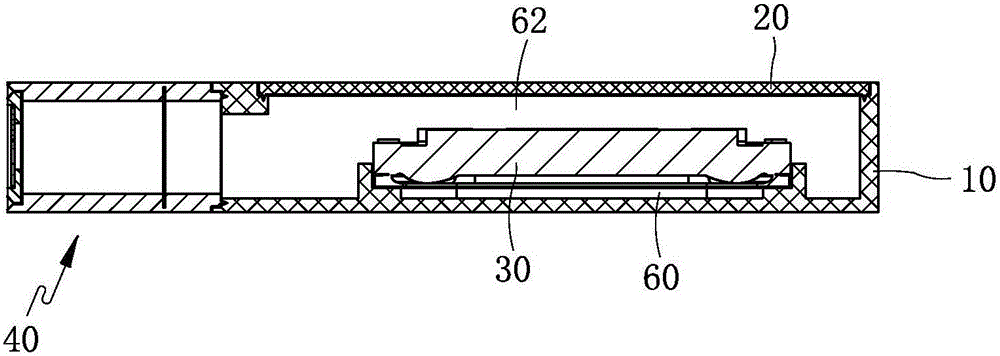

Heating non-combustible cigarette

The inVention belongs to the technical field of noVel cigarettes, and particularly relates to a cigarette structure of a heating non-combustible cigarette. The heating non-combustible cigarette is composed of a cylinder hollow coiling block, a cleaning spacer sleeVe arranged at the front end of the coiling block, and a smoking product section and a cooling filtering section which are sequentiallyarranged inside the coiling block. By arranging the cleaning spacer sleeVe, a user can insert a heating body into a cigarette, no cut tobacco can drop out, meanwhile, small parts in smoking products cannot fall into a heater in the heating process, and cleanness in the heater is ensured.

Owner:赵雪

Ceramic membrane support and preparation method thereof

The invention discloses a ceramic membrane support and a preparation method thereof. The support is prepared from the following materials by mass: 50 to 80% of alpha-alumina, 10 to 30% of a compound of silicon, 1 to 10% of a sintering aid and 3 to 15% of a binder and a pore forming agent. The preparation method provided in the invention mainly comprises the steps of formation of green bodies and sintering. According to the invention, alumina and a silicon-containing inorganic substance or organic matter are used as reaction components for manufacture of a mullite support, which enables a composition to have reduced volume and increased pore; the support prepared thereafter has high porosity and strength. According to the invention, cheaper alumina and lower sintering temperature can be employed for preparation of the support, which enables preparation cost for the support to be reduced.

Owner:SANDA FILM SCI & TECH XIAMEN

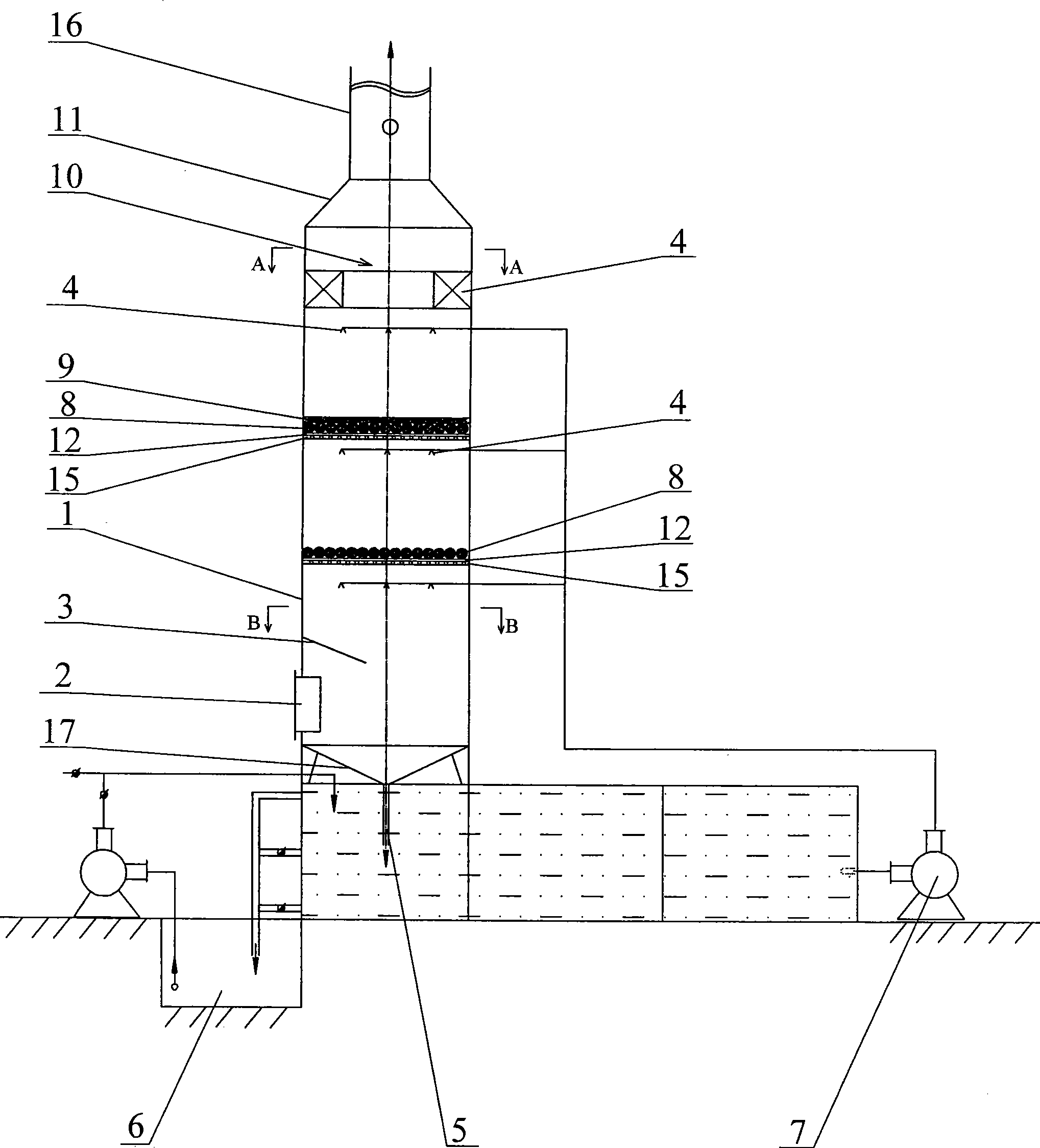

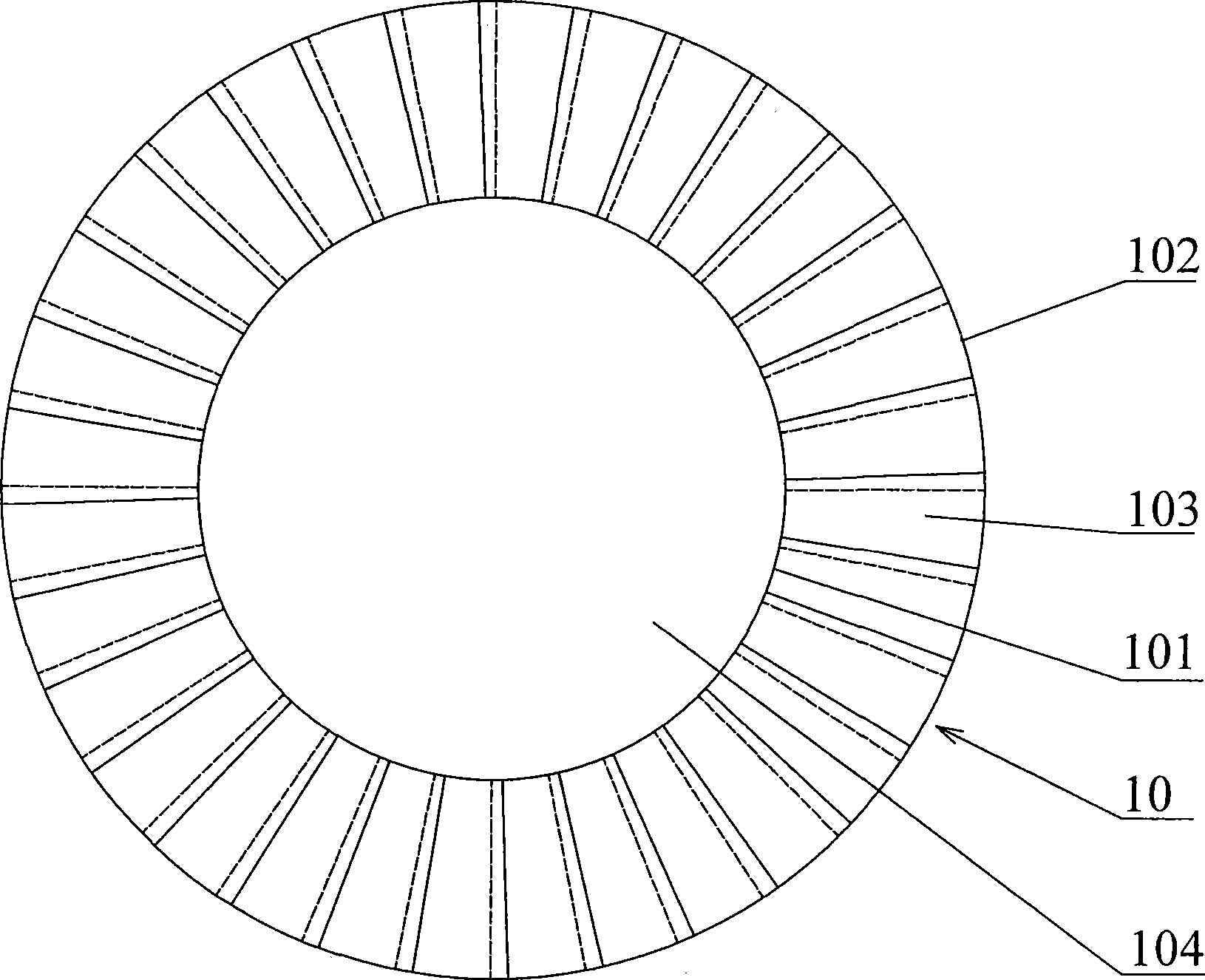

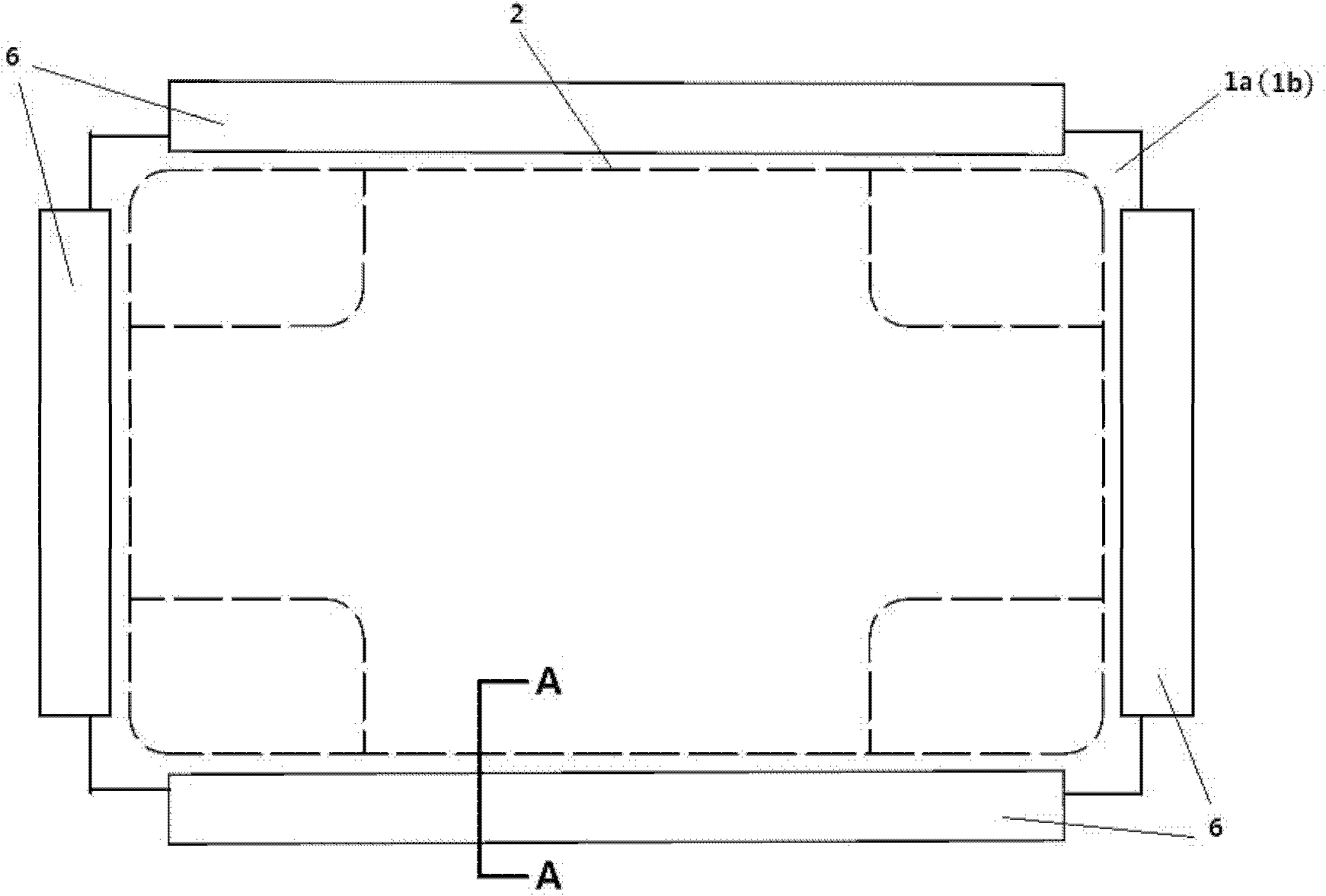

Spraying and dust-removing system

InactiveCN101502733AImprove dust removal effectWon't clogUsing liquid separation agentWater storage tankTower

The invention relates to a spray dedusting system, a dedusting tower is erected on a circulating deposition tank, an opening is opened at the top of the dedusting tower, the dedusting tower is connected with a smoke pipe, the inner wall of the dedusting tower corresponding to the upper part of the exit end of the smoke pipe is provided with a water baffle, the dedusting tower above the water baffle is internally provided with a plurality of spray heads, the bottom end of the dedusting tower corresponding to the lower of the exit end of the smoke pipe is provided with a water sealing device inserted in the circulating deposition tank, the spray heads are connected with the water outlets of a spray pump by pipelines, the water inlets of the spray pump are arranged in the circulating deposition tank, a quality regulating water storage tank is arranged beside the circulating deposition tank, a quality regulating mild base block layer is paved on the bottom of the quality regulating water storage tank, a non-water tight gland layer is paved on the quality regulating mild base block layer, a water supply device used for supplying water to the quality regulating water storage tank from the circulating deposition tank is arranged between the circulating deposition tank and the quality regulating water storage tank, and a water supplementing device for supplementing water to the circulating deposition tank from the quality regulating water storage tank is arranged between the circulating deposition tank and the quality regulating water storage tank.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

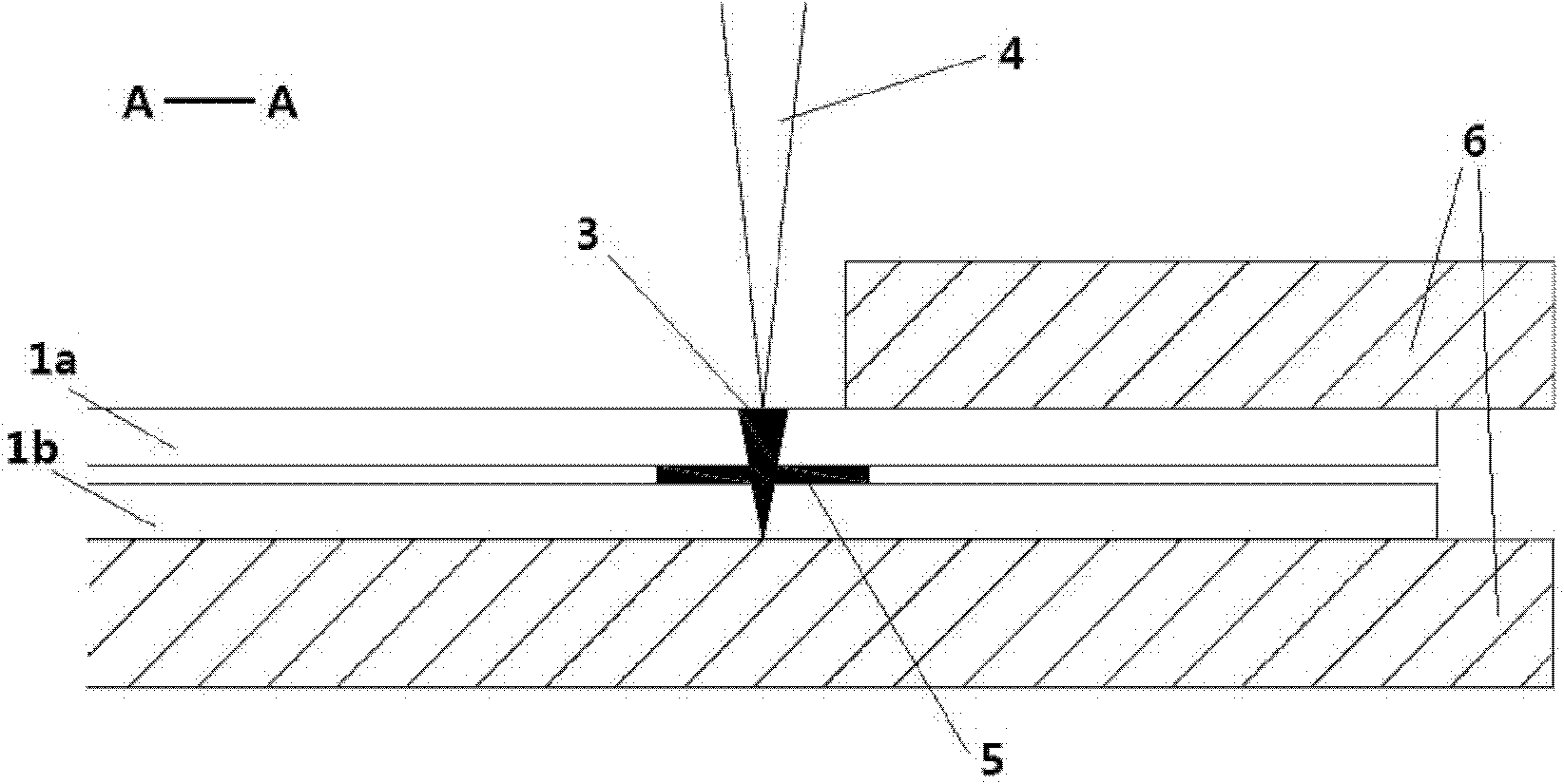

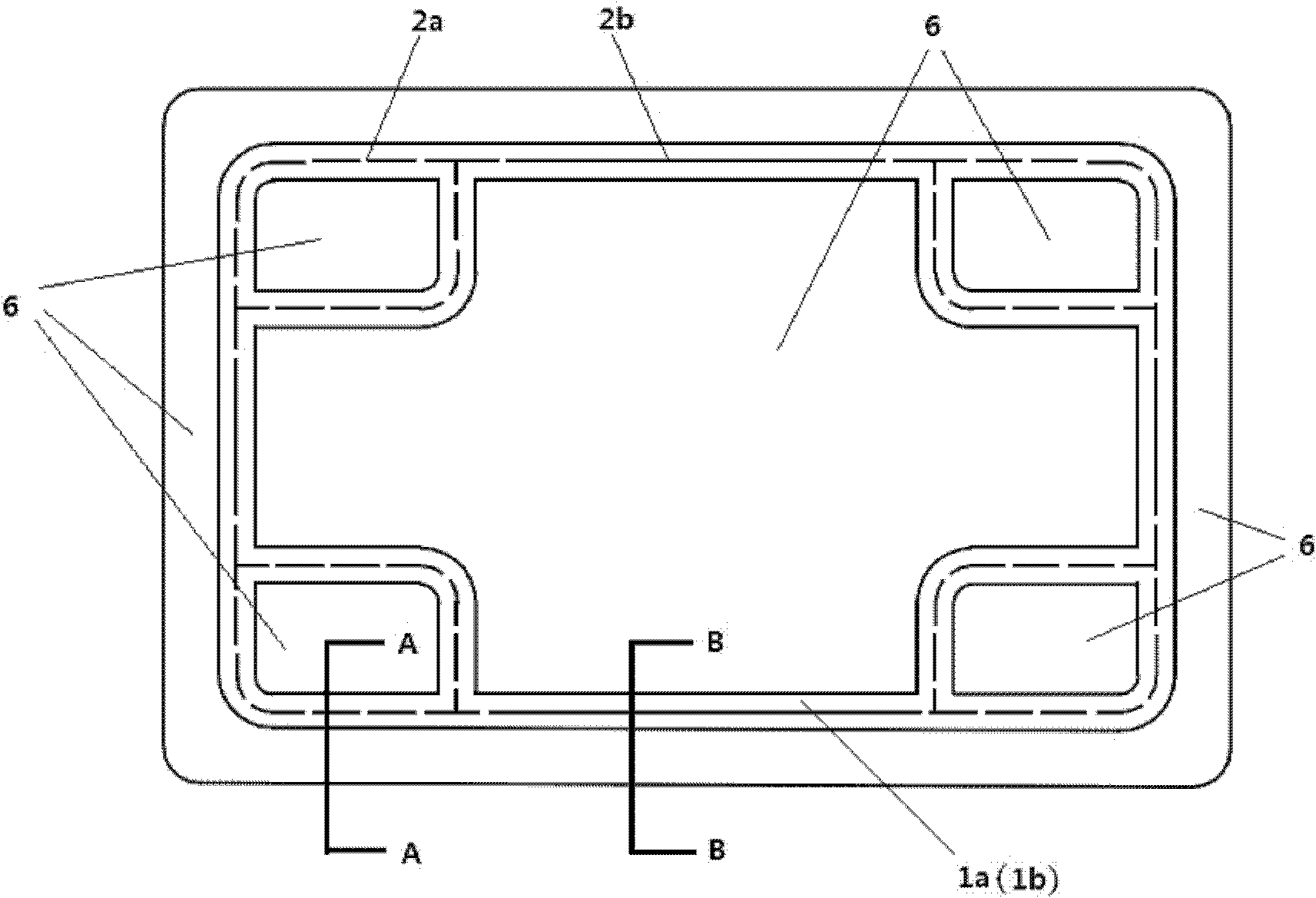

Laser weld-bonding method of bipolar plate of fuel cell

ActiveCN102581487AHigh mechanical strengthGood corrosion resistanceFinal product manufactureCell electrodesCorrosion resistantArc welding

The invention relates to a laser weld-bonding method of bipolar plates of a fuel cell. The method combines a bonding process and a laser welding process to connect the bipolar plates of the fuel cell, namely a normal-temperature curing adhesive is used to bond welding areas of the bipolar plates of the fuel cell, and then the laser welding is carried out to finish the connection of the bipolar plates of the fuel cell. Compared with the prior art, the laser weld-bonding method has the advantages that: because an adhesive bonding method is adopted to bond the bipolar plates of the fuel cell tightly, the phenomenas of sealing-off and welding seam breakage caused by assembling gaps in the laser welding are eliminated, the laser welding quality is improved, and the welding seam is high in mechanical strength and is corrosion resistant; a bond layer can evaporate rapidly under the high-heat input of a laser beam, the requirement of the bonding position is reduced; because the normal-temperature curing adhesive is adopted, the secondary heat input caused by high-temperature curing is avoided; and due to the introduction of the bonding process, the designs of a welding clamp, a welding path and welding parameters can be more flexible and simpler, so that the laser weld-bonding method is easy in large-scale production.

Owner:SHANGHAI JIAO TONG UNIV +3

Nano grade polymer micro-emulsion for ink-jet printing and method for preparing the same

InactiveCN1803913ANarrow particle size distributionNatural fabric colorDyeing processButyl acrylateEmulsion

The disclosed preparation method for nano-polymer microemulsion in ink-jet printing comprises: using soft monomer butyl acrylate as main polymonomer for well film-forming flexible; adding comonomer with cross-linkging group to form three-dimensional space network structure and fix the color particle hard on textile fabric to prevent film tacky and endow the fabric with well resistance ability; adding polymerisable surfactant to let the polymer microemulsion have super stability even with much soft monomer and average size less than 100nm hard to agglomeration. This invention can obtain the product with small size and narrow distribution.

Owner:ZHEJIANG UNIV

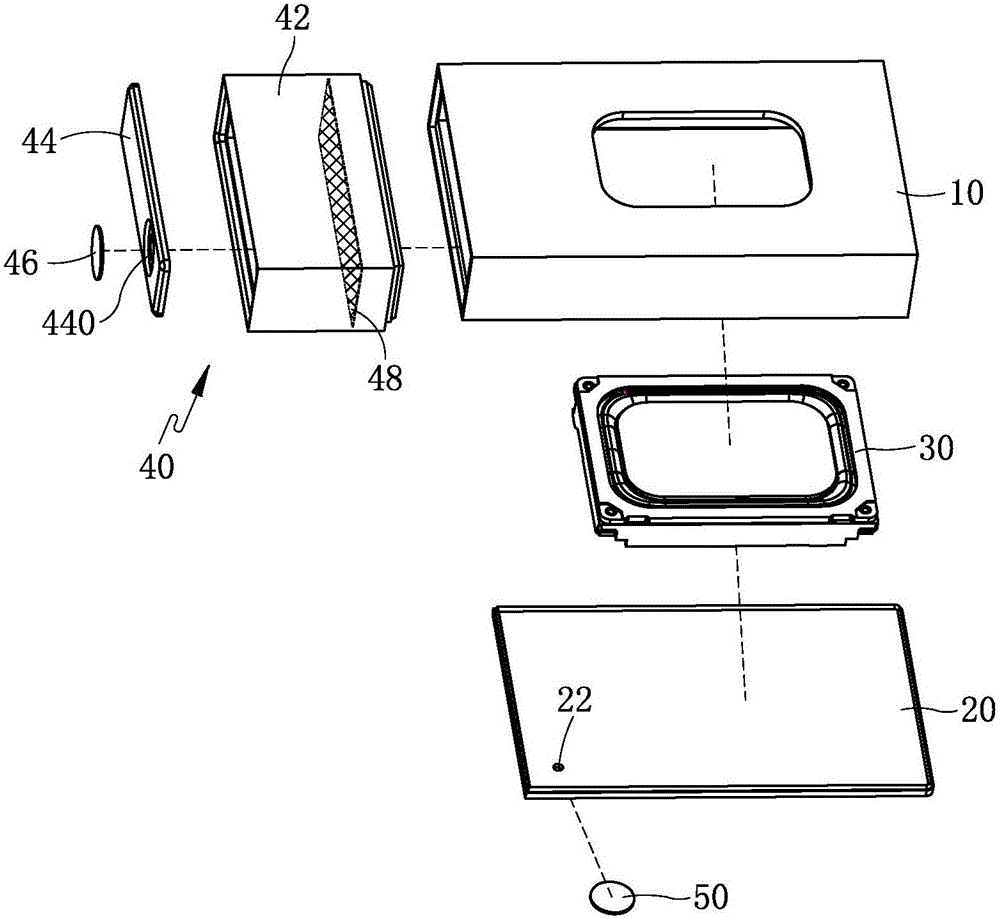

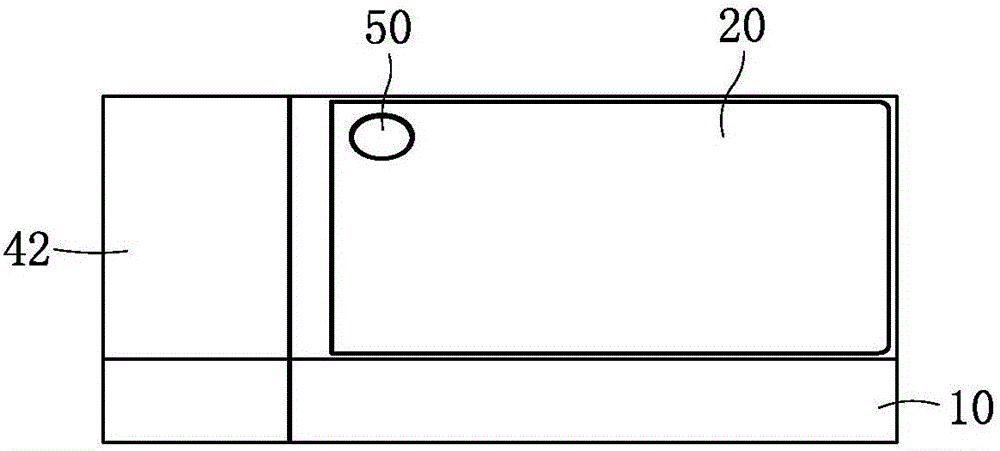

Loudspeaker module

ActiveCN105872917ALower F0Improve acoustic performanceElectrical transducersEngineeringSound quality

The invention discloses a loudspeaker module, and relates to the technical field of an electroacoustic product. The loudspeaker module comprises a module housing; a loudspeaker monomer is accommodated in the module housing; the loudspeaker monomer divides an integral module inner cavity into two cavities, i.e. a front sound cavity and a rear sound cavity; the rear sound cavity comprises an accommodating cavity and a sound adsorption cavity which are communicated; the loudspeaker monomer is positioned in the accommodating cavity; the sound adsorption cavity is filled with sound adsorption particles; the accommodating cavity is formed by the surrounding of the module housing; the sound adsorption cavity is formed by the surrounding of a sound adsorption cavity housing; the sound adsorption cavity housing is combined with the module housing; and a netted isolation part is arranged between the sound adsorption cavity and the accommodating cavity. The sound adsorption particles of the loudspeaker module disclosed by the invention cannot be influenced by a module production assembling process, and have a good sound adsorption effect; acoustic performance of the module is obviously improved; sound quality is higher; and meanwhile, the loudspeaker module is low in assembling difficulty and high in production efficiency.

Owner:GOERTEK INC

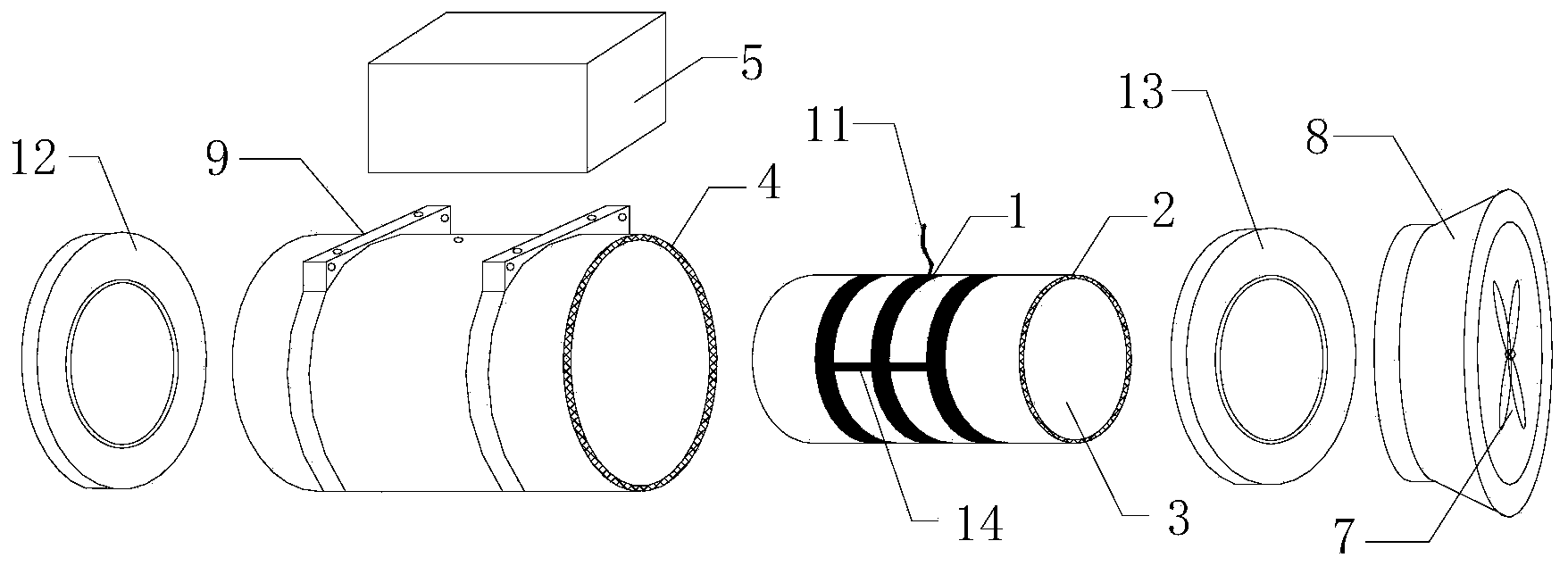

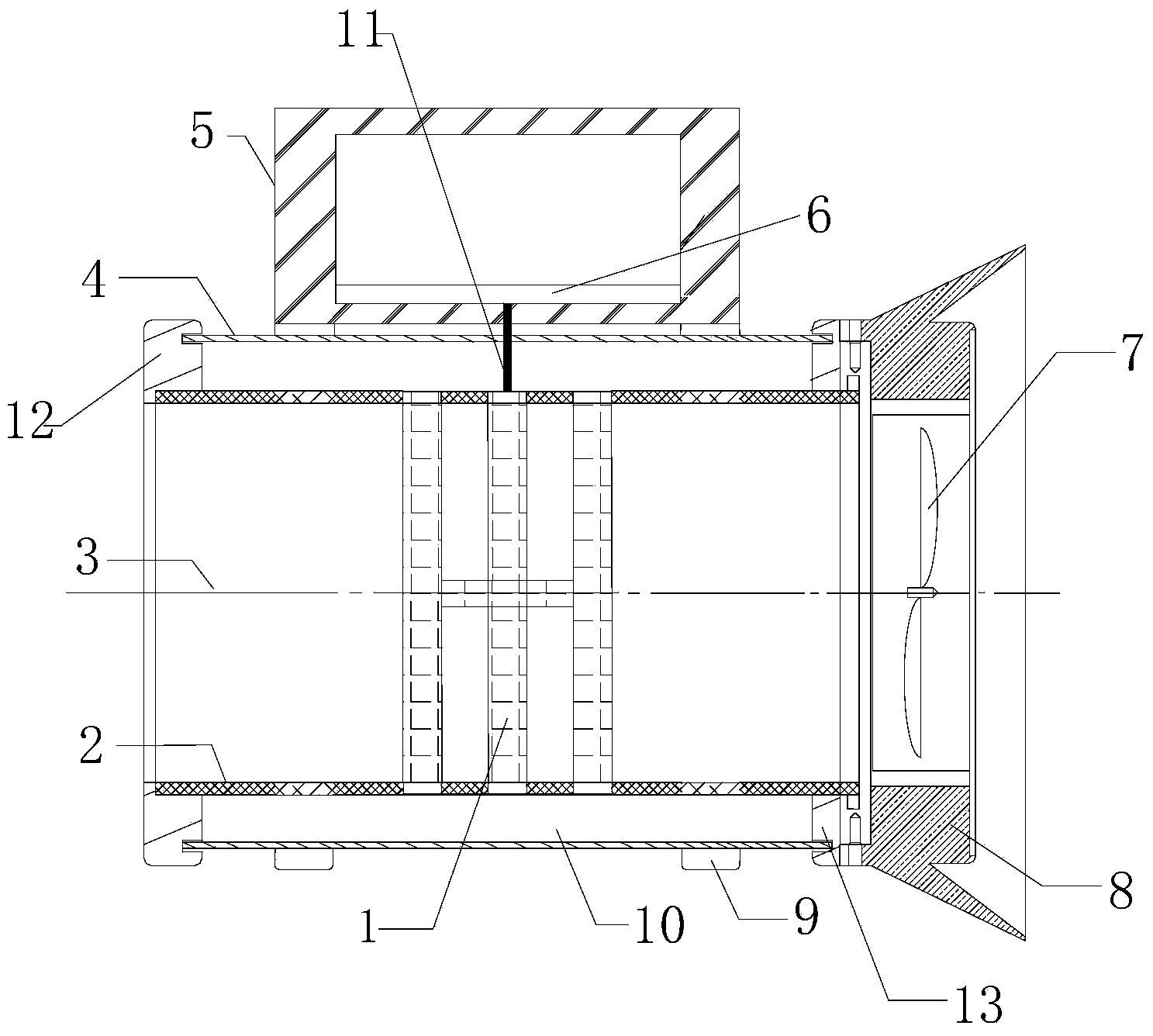

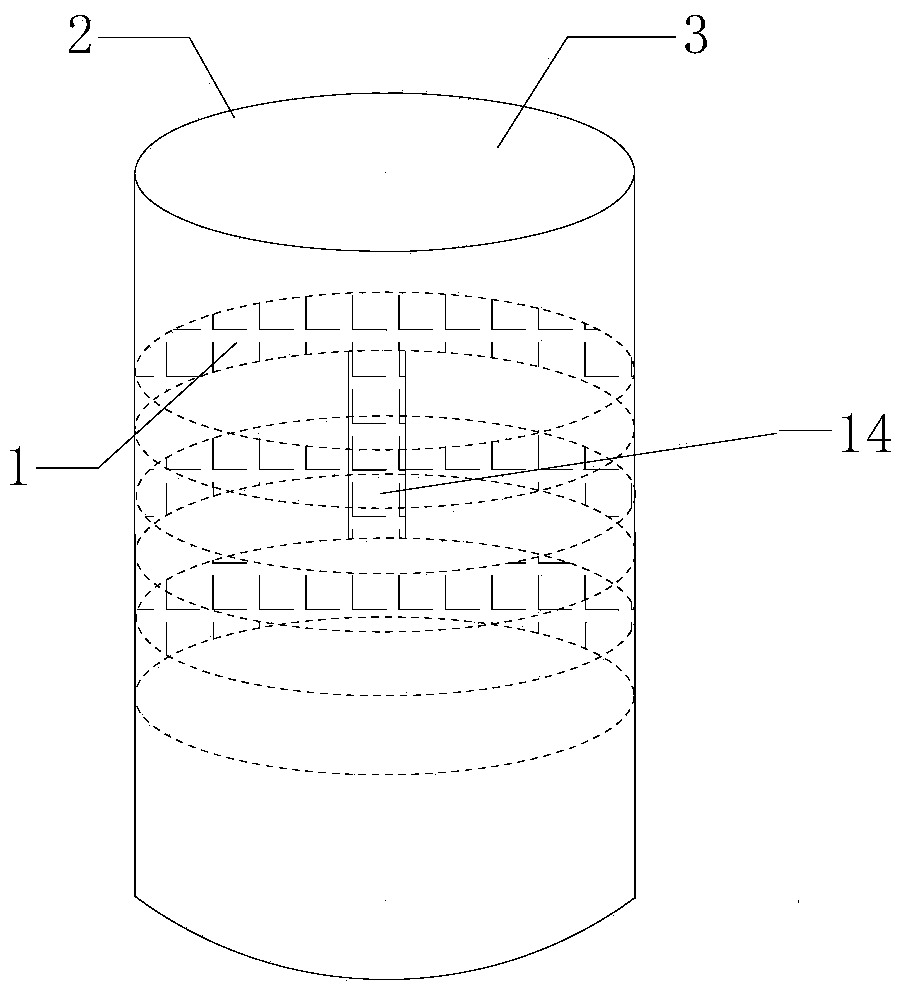

Intermittent cleaner

The invention discloses an intermittent cleaner for crude oil pipeline cleaning. The intermittent cleaner includes a scrapper, a turbine, an turbine, a power supply, and a power supply control module; the scrapper includes a scrapper core shaft and a plurality of hollow frames sleeving the scrapper core shaft; a plurality of scrapping blades are arranged on outer edges of the hollow frame; the turbine includes a rotor bottom plate and turbine vanes, the rotor bottom plate has a central opening, and a turbine rotor inner ring is inserted into the opening and is fixedly connected to the rotor bottom plate; the electromagnet includes a stator inner ring and an electromagnet outer ring, a tail end of the stator inner ring is fixedly connected to the power supply and the power supply control module; the scrapper core shaft and the turbine rotor are coaxial, and fixedly connected; and the turbine rotor inner ring is in matching connection with the stator inner ring through a bearing. The cleaner can use the impact force of fluid in a pipeline to regularly and automatically scrap wax in the pipeline, and can effectively prevent pipeline blockage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mine dust concentration sensor based on electrostatic induction

ActiveCN103454195AAddresses issues with reduced sensitivityHigh sensitivityParticle suspension analysisComputer moduleEngineering

The invention provides a mine dust concentration sensor based on electrostatic induction. The mine dust concentration sensor comprises a metal support, a metal shielding cover, an insulating tube, a left sealing ring, a right sealing ring, metal electrodes, a fan outer cover, a fan and a circuit box, wherein the metal shielding cover and the insulating tube are buckled through the left sealing ring and the right sealing ring, a sealed shielding space is formed between the insulating tube and the metal shielding cover, the insulating tube forms a straight-through type air channel, the fan outer cover is fixedly connected at the right end of the metal shielding cover, the fan is positioned in the fan outer cover, three metal electrodes are connected through metal connection plates and arranged in a groove formed in the inner wall of the insulating tube, the metal support is connected with the ground in a shielding mode, the circuit box above the metal shielding cover is provided with a control circuit module, and the induction signals of the metal electrodes can output dust concentration monitoring signals through the control circuit module. The mine dust concentration sensor effectively solves the problem that the flexibility of the sensor is reduced due to dust adhesion, dust accumulation and dust distribution change on the surface of a probe, can well overcome the defects of an optical sensor and is high in antijamming capacity, high in flexibility and simple in structure.

Owner:SHANDONG UNIV OF SCI & TECH

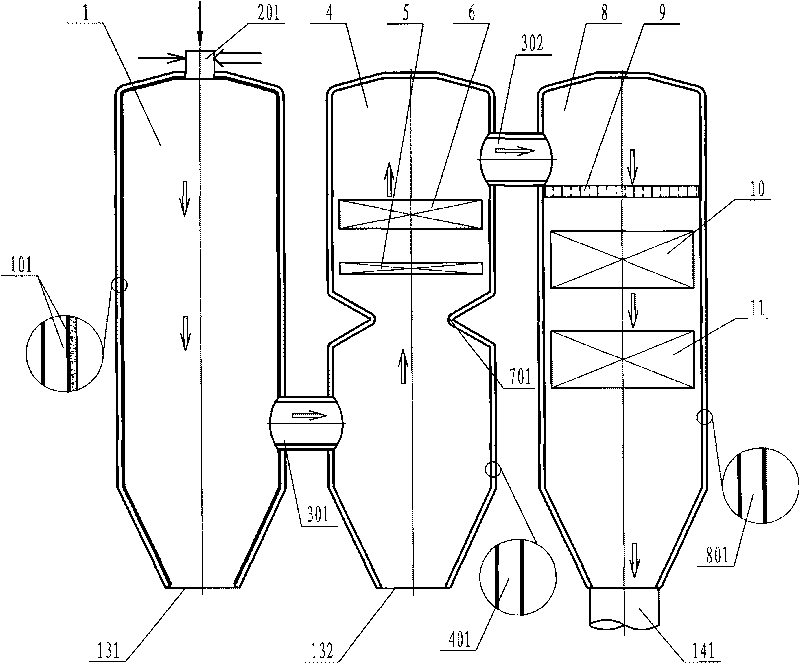

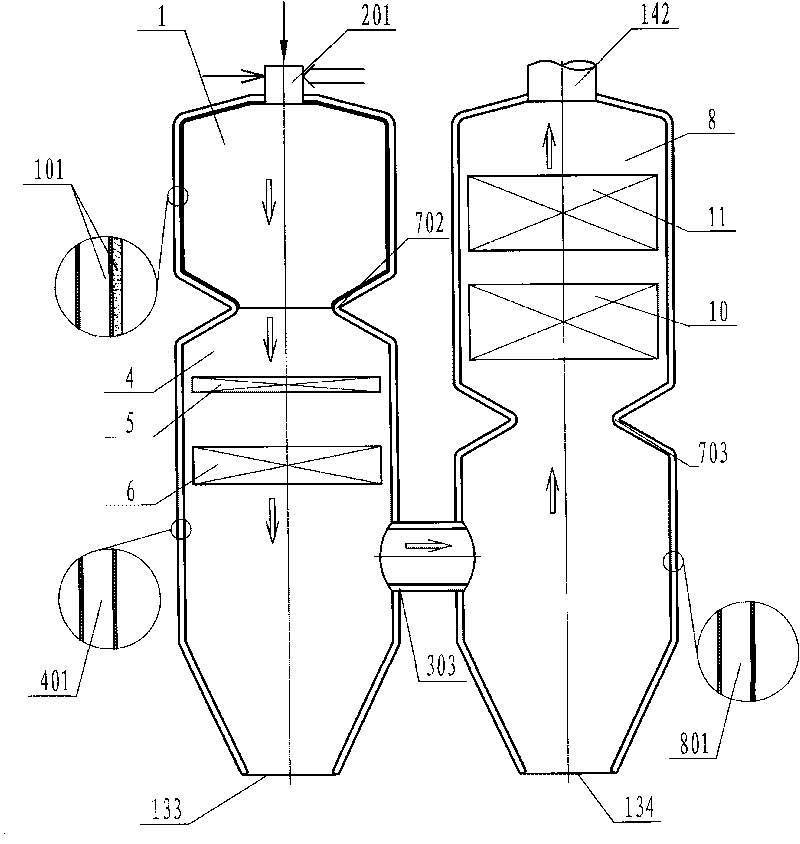

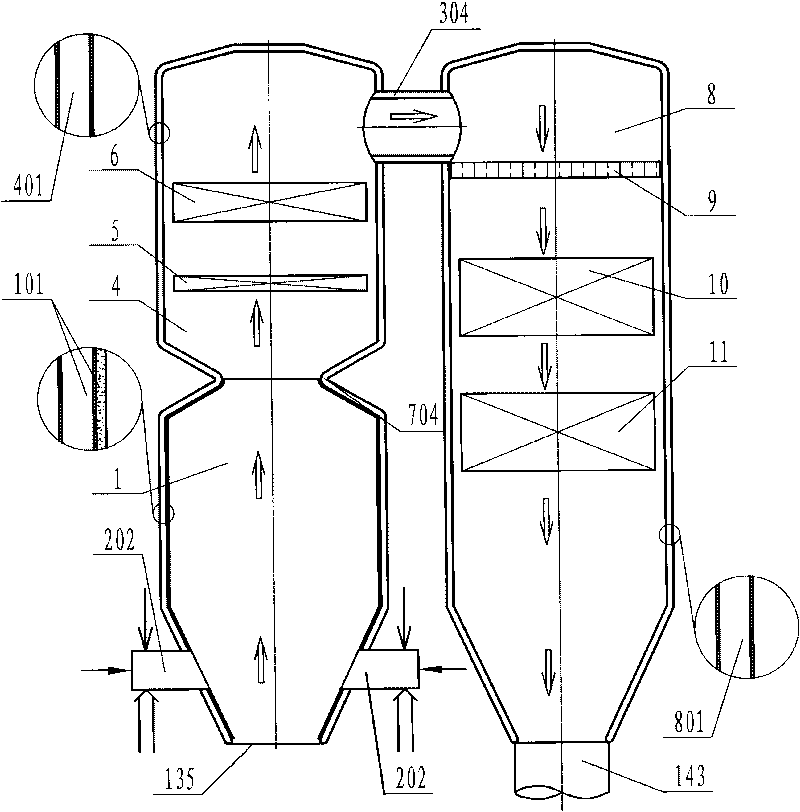

Biomass three-section type entrained flow bed gasification technology with function of waste heat utilization

InactiveCN101709228AAchieve energy efficiencyReduced carbon evolution reactionEnergy inputGasification processes detailsSuperheaterOxygen

The invention discloses a biomass three-section type entrained flow bed gasification technology with the function of waste heat utilization, which relates to the technical field of energy chemical technology. The gasification technology is realized in a way that: carbon powder, pyrolysis gas and oxygen, which are generated after the biomass is pyrolyzed, enter an entrained flow bed to obtain synthetic gas through gasification, and the energy of the gasification waste heat is transferred to water by a heat exchanger of a gasifier, thereby producing superheated steam. The gasifier of the entrained flow bed is divided into a high-temperature entrained flow bed section, a high-temperature heat exchanger section and a low-temperature heat exchanger section, wherein the high-temperature entrained flow bed section adopts a dry ash extraction entrained flow bed gasification technology, and the temperature of the synthetic gas at the outlet is 1280-1320 DEG C; at the high-temperature heat exchanger section, the temperature of the synthetic gas at the inlet is 1280-1320 DEG C, the temperature at the outlet is 580-600 DEG C, a shock chamber and a high-temperature superheater are arranged in the high-temperature heat exchanger section, and the synthetic gas enters the shock chamber at the temperature of 1000-1100 DEG C and leaves at the temperature of 700-800 DEG C; and at the low-temperature heat exchanger section, the temperature of the synthetic gas at the inlet is 580-600 DEG C, the temperature of the synthetic gas at the outlet is 220-230 DEG C, and a low-temperature superheater and a coal economizer are arranged in the low-temperature heat exchanger section. The invention is used for high-efficiency gasification of biomass.

Owner:ZHONGJIEHUAN BEIJING ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com