Method for increasing combustion efficiency of combustion engine

A combustion efficiency, internal combustion engine technology, applied in the direction of internal combustion piston engine, combustion engine, combustion air/combustion-air treatment, etc., can solve the problems of excessive fuel consumption, engine damage, high energy consumption, etc., to reduce the size of the device, improve Combustion efficiency, enhanced activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The present invention will be described in detail below in conjunction with the accompanying drawings.

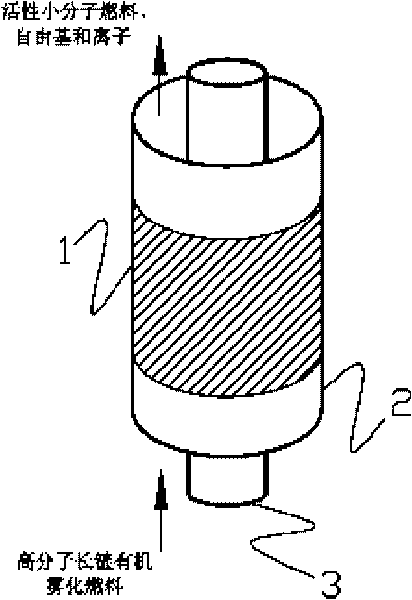

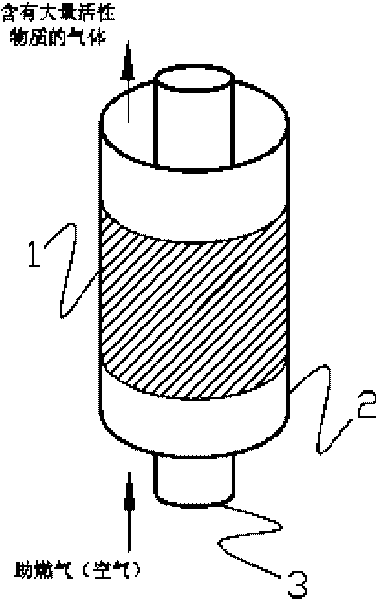

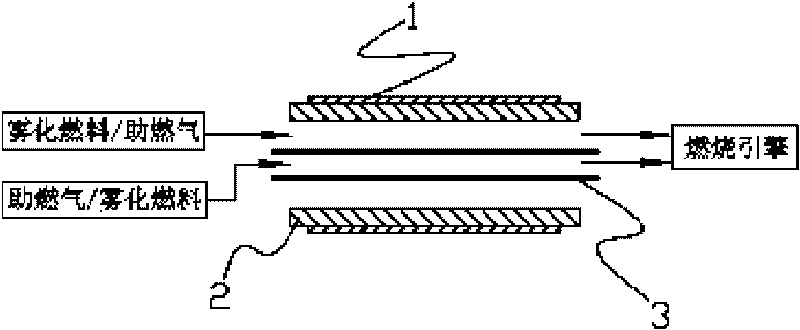

[0095] Such as Figure 1a , Figure 1b As shown, the main structure of the plasma generator (miniature plasma generator unit) proposed by the present invention is tube-tube type, and the tube-tube type structure can ensure smooth flow of air and obtain relatively uniform plasma; secondly, the adoption cost is low, Metal materials (stainless steel, copper, aluminum foil or platinum, etc.) that have little effect on the efficiency are used as the internal and external electrodes of the discharge; again, insulating materials with high withstand voltage and strong corrosion resistance (corundum, ceramics, mica, etc.) are selected as the tubular discharge medium . The tubular inner electrode 3 is located in the center of the tubular discharge medium 2, and its outer surface is a multi-turn convex platform or threaded structure. The outer electrode 1 (metal mesh or metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com